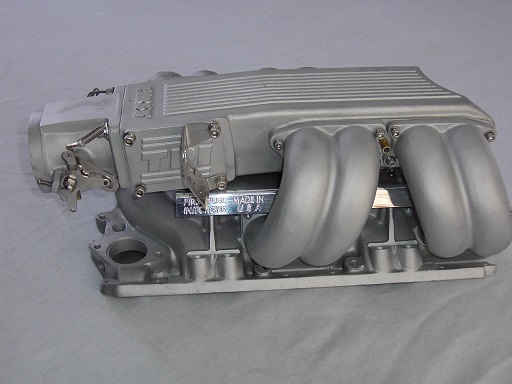

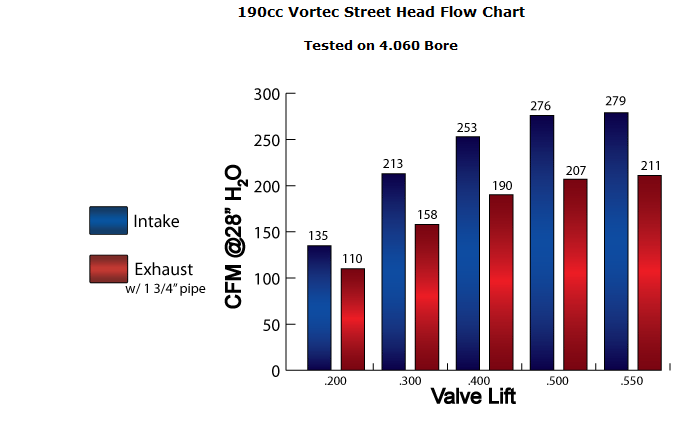

HERES TWO RELATED BITS OF INFO, BUT KEEP IN MIND THE LONGER EXHAUST DURATION CAM TIMING WAS DESIGNED IN MANY CASES,TO HELP OVERCOME A RESTRICTIVE EXHAUST FLOW THAT USING MUFFLERS AND SMALL EXHAUST PIPES ON A STREET CAR OFTEN FORCE THE ENGINE TO WORK WITH

ISKY Tech Tip - 2003

Longer Exhaust Duration: Is this really necessary?

Most stock camshafts from American production V8, V6 and 4 cylinder engines manufactured today are ground with the longer exhaust lobe duration. Or, another way of looking at this is that they are ground with shorter intake durations! The former embraces the viewpoint that either the Exhaust Ports or Exhaust Pipe system is somewhat restrictive, and is in need of an assist. The latter suggests that the intake system is rather efficient and cam timing can be trimmed back a bit with out much sacrifice in power, in order to maximize throttle response and cruising efficiency.

Take your pick here. There is no absolutely correct viewpoint - because both are probably true! In a stock engine running at conservative RPM levels, for the sake of overall efficiency, fuel economy and a quiet smooth running engine, this staggering of intake and exhaust duration is quite common and appropriate.

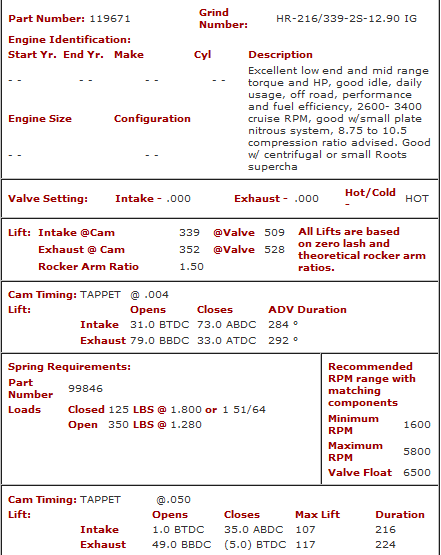

However, High Performance is another thing entirely. Change one factor, let's say in this case, the exhaust system (installing headers and larger pipes) and you have just negated in most cases, the need for that longer exhaust lobe. Now couple this change with a different intake system and camshaft and you have really scrambled the equation. But, wait just a moment. Why is it that so many people (racers & cam grinders alike) insist on running a cam with longer exhaust duration regardless of what equipment is employed? The answer is "habit". Most of them have been somewhat successful in doing it their way and will probably never change unless virtually forced by circumstances to do so.

Before we go any further however let's review what it actually is we are trying to do with an engine when we attempt to make more power. Our best result comes when we are cognizant of the fact that an engine is basically an air pump. We pump it in and out (although in a different form) and we have problems when one side or the other is restricted. Balance or the equilibrium or flow should be our objective, unless of course we are not trying to make more horsepower!

Example #1 (Oval track racing) Here, I have often observed that the most experienced drivers are those who are most likely to run a single pattern (equal on intake and exhaust duration) cam. Why? Because such cams always, I repeat always make more torque! These veterans have a more educated foot and greater experience in feathering the throttle in the corners. They can therefore, utilize the benefit of added torque, in the lower to mid RPM range, to their advantage.

Their counterparts, the younger drivers on the circuit, generally are not as experienced and may at times actually get "crossed up" in the corners especially with a lighter car or when they are learning the ropes. In their case, a longer exhaust duration is often the more appropriate choice. It will often help them to drive better, more "flat footed" if you will, without consequence. But please for the sake of accuracy, let us be truthful. The benefit comes from an actual bleeding off of low to mid range torque, which is always what happens when Exh. Duration is lengthened, not from any improvement. The improvement, (if any) would come because of an improvement in scavenging at the extreme upper end of the power curve and would usually be marginal at best. Yet the so-called "extra power" potential of a longer Exh. Duration cam is most often why they are touted - power most people are backing away from at the end of the strait away!

Example #2 (Drag Racing) At the drag strip it's a little different and I feel more honest. Here, racers have long enjoyed longer exhaust and longer durations across the board (If I may add specifically for the purpose of "killing" low-end torque) to keep the tires from too easily breaking lose. This has been successful and sometimes actually results in a slight increase in top end power - something you can actually use in drag racing since it is a full throttle endeavor through the lights. Keep in mind here though, it's quite possible that a longer duration cam overall would have done just as well or better. In other words if you needed that longer exhaust for top end, perhaps the intake could have benefited from such a lengthening as well.

One of my favorite expressions is how "The Drag Racing mentality has infiltrated the ranks of Oval Track". Many have crossed over and made the switch in the past 10-15 years and some have brought their preconceived notions about how to cam an engine with them. A few may actually read these concepts and if they do so will at least come away with a better understanding of what they are doing. On the other hand they also could find that this information might actually help their cars to run just a bit faster!

Note: Readers may find Camfather Ed Iskenderian's Top Tuners Tip #33 "Can an Exhaust System Over-Scavenge the Combustion Chambers" to be a relevant precursor.

back to top

Tech Tip - 2004

Intake Restriction and Over Scavenging: "Waste not...Want not!"

It is certainly an over simplification to make the statement "that which is not wasted, should be inducted". However, in the case of restricted intake systems and in particular 2-BBL carb rules, it is not far off the mark. Engines with such restrictions are "choked off" to the point where they will not run much past 6500 RPM (if even that high) without dropping off sharply in power. You might have trouble running very fast yourself if someone had your windpipe choked down to say 50 or 60% of it's normal capacity. Under such conditions, would you volunteer to give blood at the Red Cross? Of course not, but without knowing so, racers often do the equivalent with their engines by running a camshaft better suited for a 4-BBL class! How So?

If you'll recall in last months tech tip: "Longer Exhaust Duration: Is This Really Necessary?" I discussed how, through habit, many racers and cam grinders alike are predisposed to running camshafts with longer exhaust durations, whether they need to or not! Well, in the case of restricted intake applications, if there was ever a situation in which you'd want to avoid the longer exhaust "trap" it's here! Especially the 8, 10, 12 or even longer degree spreads, I often discover people employing.

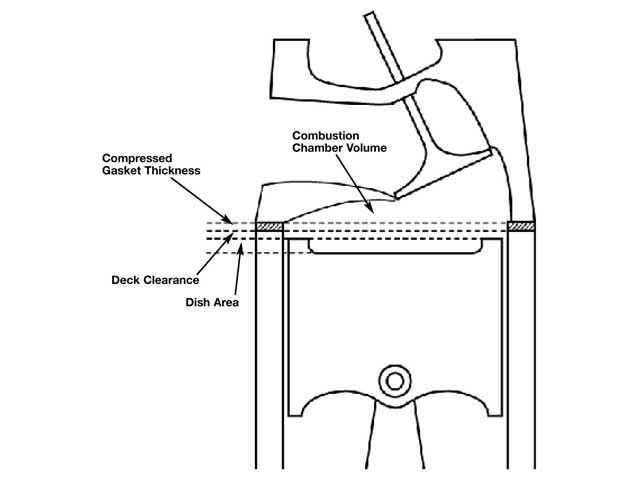

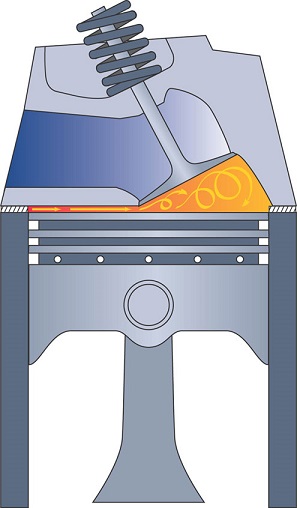

Use such a cam at you own risk - and don't be surprised to find that your exhaust temperatures are unusually high. Your headers in fact may even glow cherry red. There is a very good reason for this. Raw (unburned) fuel is burning "late" or in the pipe (header/manifold). You may have a good equilibrium of flow going here but there is just one problem. Much of what should be inducted into the cylinder is being scavenged out the exhaust! You see, although back pressure in an exhaust system can be restrictive, the only thing that could be even worse is a reduction of it to the point where you are now, in effect pulling a vacuum. In the case of an intake restriction, very slight back pressure is preferable to avoid "over scavenging".

Yes, Yes I know. You are probably thinking "what's wrong with a little scavenging?". Well, nothing if you can afford it. But with intake restrictions (either small 2-BBL carbs and/or restrictor plates) you must be very careful. You already have reduced intake potential and therefore simply cannot be cavalier about valve overlap and scavenging or you'll be way down on power and have those nice bright cherry red pipes to show for it! Case in Point: One racer who called me was in this exact situation and was running, not surprisingly, a 14 Degree longer exhaust duration. It was Friday afternoon and he needed a cam the next day for the last "points race" of the season and UPS had already picked up at Isky. "Too Bad" I said, "You don't have a set of those low ratio break-in rocker arms because they could really help in this case". " I do have some" he said "but they are only 1.2:1 ratio - is that okay?" I told him to use them (on his exhaust valves only of course) and he finished the race 2nd having come from the back of the pack. Later we made him the right cam so he could avoid this make shift approach.

Unfortunately, the symptoms are not always as obvious as in this case to allow for a speedy diagnosis. Also, it's not only longer exhaust duration that causes the problem. Although it is usually the primary offender, it is often coupled with too close a lobe separation angle of say 104 Degrees. A widening to 106 Degrees or preferably 108 Degrees (some go even wider) is usually prudent.

I am not absolutely dead set against a slightly longer exhaust duration in these cases as a 2-4 Degree longer exhaust lobe is permissible under some circumstances (if your running a completely stock exhaust system including mufflers for example). Each case is different, depending upon the equipment employed. I might even recommend shorter exhaust duration to some; if I feel they have "overdone" their exhaust ports and or exhaust system a bit. What matters is the end result and if you're out of balance on one side simply employ what I call the "Great Law of Compensation" to bring you back to that equilibrium of flow.

So, how can you tell if you may need to make some of these changes in your camshaft? Well, short of trying a lower exhaust rocker arm ratio, you can increase exhaust valve lash .004" - .008" temporarily to see if there is any improvement. You can also try and increase restriction (smaller headers or pipes, or in the case of open headers a longer collector) and simply observe the results. Remember, "One test is worth a thousand expert opinions". Keep this old axiom in your "tool box" and you'll be ahead of the game. How do you think Smokey's shop got to be "The best Damn Garage in Town" anyway? Yes, he had those country smarts, but his experiences in racing and his willingness to test are legendary!

back to top