thats simply because, of experience!

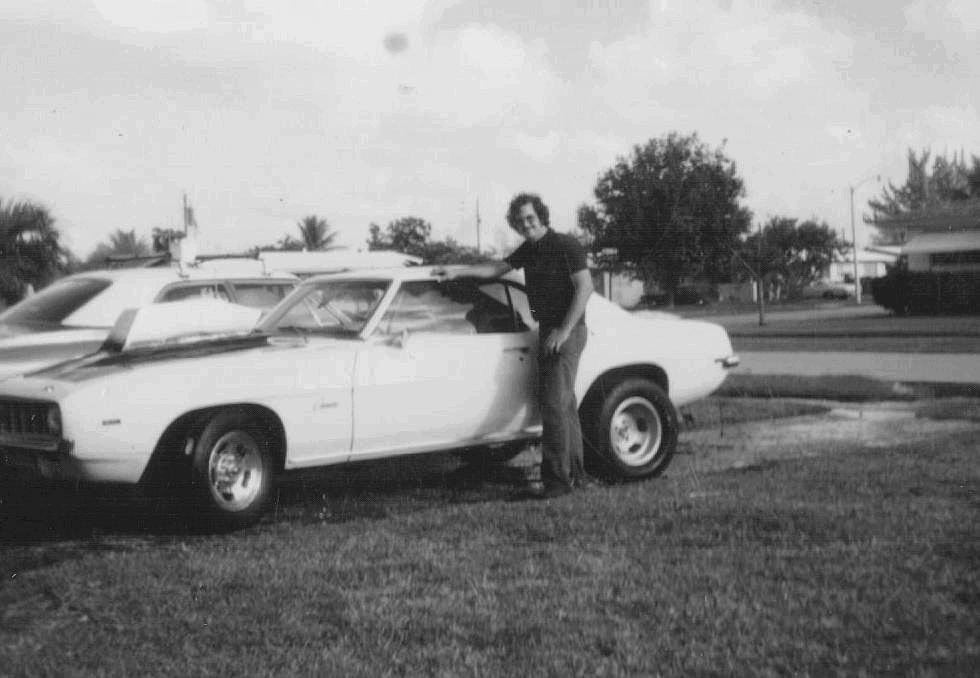

lets assume you have a 1969 camaro , that looks great like this

with several aluminum or fiberglass components and get the weight down near 3200 lbs with you in the car!

I learned decades ago that

you can have choices and choices have consequences,spin a small efficient , high compression (12.5:1) engine , like a 302 sbc with a carefully assembled solid lifter valve train to 7500-8000 rpm

and make lets say 1.5 hp per cubic inch (302 x 1.5-or 1.6:1 = about 450 hp- maybe even 480 hp) and use expensive race octane fuel, which gets constantly more expensive and limits what you can do and where you can go with the car,

or you can build a 496 BBC,

now lets say you build it to have 10.5:1 compression so you can run it on premium pump 95 octane(hard but not impossible to find, especially if you are willing to add some octane booster occasionally. )

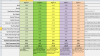

4200 fpm with a 302 and its 3" stroke = 8400 rpm

lets say you cam that 302 so your making

350 ft lbs at 7000-rpm. thats 466 hp

or you build the 496 and make lets say 1.3 hp per cubic inch, and 1.3 ft lbs per cubic inch of displacement and with its 4.25" stroke the same 4200 fpm, limits you to, about 6000 rpm.

the 496 BBC makes nearly 645 hp and 645 ft lbs, and while it weights about 100 lbs more and might cost an additional $1000-$2000 additional to build

(remember the small blocks going to require an expensive valve train and decent forged components just like the BBC if you want both engines to last long term)

lets say we go with a 4 speed muncie in the 302 and match it to a 12 bolt with 4.56:1 rear gears

on the BBC we install a 4L80E and a dana 60 so between the transmission, 3.55:1 rear differential and engine the BBC 496 car easily weights an additional 330 lbs

http://www.wallaceracing.com/et-hp-mph.php

http://users.erols.com/srweiss/calcehp.htm

your killer sbc in the 3200 lb camaro with its 466 flywheel hp is maybe at 400 rear wheel hp, that equates to about....Your

ET / MPH computed from your vehicle weight of 3200 pounds and HP of 400 is running near,

11.65 seconds and MPH of

116.01 MPH.

your much more street friendly 496 cubic inch pump gas BBC 3530 lb camaro has about 540 rear wheel hp

Your ET / MPH computed from your vehicle weight of 3530 pounds and HP of 540 is running 10.89 seconds and MPH of 124.09 MPH.

or close to a second faster, its much easier to drive and you can actually go on trips because if your careful pump gas can be used.

think about the difference here, one car sounds impressive like a chain saw running nitro methane, its damn impressive running mid 11 second times at near 116 mph in the 1/4 mile but you don,t get to drive it much on the street because race octane fuel cost over $4 a gallon, and it runs like crap under 3500rpm

on the other hand the BBC version runs pump high test (maybe a bit of octane booster) and costs you maybe an additional $3-$4 k to build but its damn near bullet proof and you can jump in and drive from Colorado to Miami if you wanted to with a more reasonable expectation of arriving without having had and issues.

(keep in mind with 28" rear tires the manual muncie sbc car spins roughly 3800 rpm at 70 mph.

the BBC version with the OD trans and the same tires is spinning about 2300 rpm on the same trip at 70 mph

http://users.erols.com/srweiss/calcmph.htm

here,s a picture of me in 1970 (46 years ago) with a 1969 camaro I installed a BBC-496 with a tunnel ram into, then later CROWER FUEL INJECTION

I agree with the SBC vs BBC comparison Grumpy. I was just looking at the piston speed alone.

It's good to know that if I do shift it at 8000, I'm not exceeding 4000 ft/min piston speed.

I chose that Crower oval track camshaft many years ago because it was the smallest solid FT

cam in existence at the time. I am not purposely trying to turn 8000 rpm, in fact my goal was

to try to make the hardly streetable 302 more street friendly - read more low end torque.

You have already yelled at me for this, but that is why I used the Rhoads #8178X VMAX RACE

Variable Duration lifters.

http://www.rhoadslifters.com/Pages/VFlatTappet.html

Rhoads says they can be used with a solid FT can and claim they are safe to 7500 rpm.

I'm using them with beehive springs (better valve control), and the retainer is smaller and lighter.

I am also using stud girdles and 7/16" ARP rocker studs. On the engine stand, with a 168 tooth

FLYWHEEL, the engine easily revs to 8000 rpm, and it wants to go more, but I stopped it there.

That camshaft has an rpm range of 2000-6000 in a 350/400, redline 7000, but will rev higher in

the 302 because of its shorter stroke. I ended up with a 10.25:1 SCR, and 8.55 DCR (93 octane - I hope).

With conventional SOLID FT lifters, this engine had only 5" vacuum at 1100 rpm idle. And it would

only hold idle with just the header glasspacks only - no added turbo mufflers. With the Rhoads lifters:

Results - with added turbos - 1000 rpm idle / 8½" vac, 1050 rpm idle / 9" vac, 1100 rpm idle / 9½" vac

with 2 turns out mixture screws and 36 degrees total timing (locked out), reads 33 degrees at idle.

Rhoads has a cam & lifter kit designed around these lifters:

http://www.rhoadslifters.com/Pages/CamKit.html

Currently available in small block Chevy only.

This unique Cam Kit together with Rhoads' new V-Max Lifter makes it possible to design a cam with extremely tight lobe centers (104 degrees). This greatly enhances low-end torque and throttle response for performance street or mild racing applications. This cam has .440" lift intake, and .460" lift exhaust. At idle the cam is reduced to .400" intake and .420" exhaust. This yields an incredible power curve with instantaneous throttle response and great upper-end power. The cam has 218 degrees intake duration at .050" lift and 227 degrees exhaust.

So with this engine, basically I am doing the same thing with the

narrow LSA, it's just that my cam is a little bigger, and a SOLID lifter camshaft.

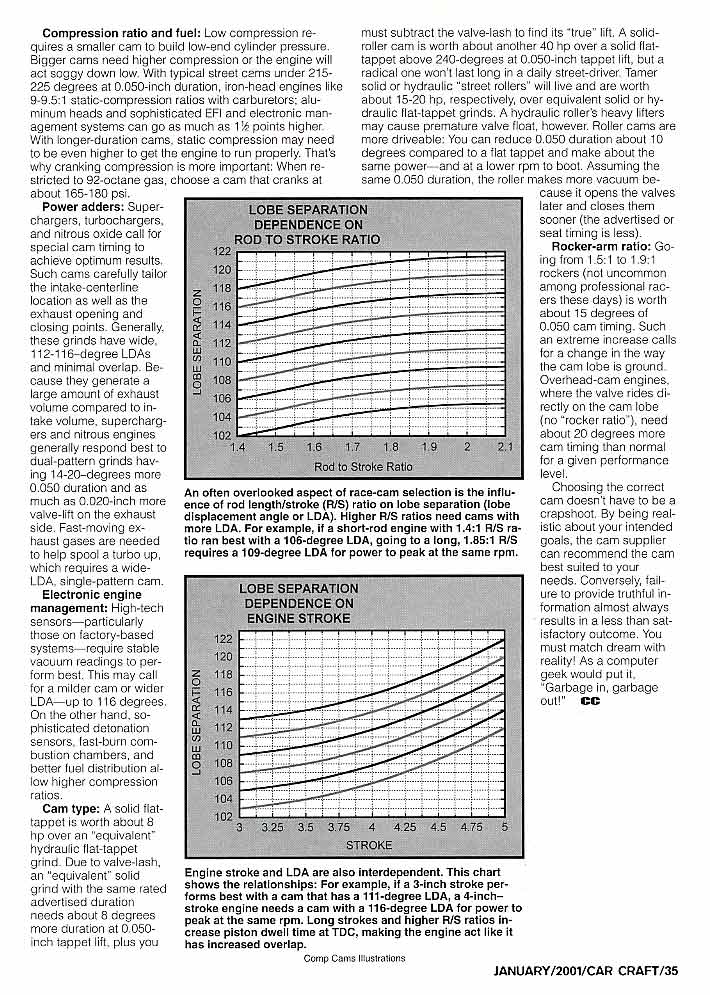

This engine has a 1.9 Rod to Stroke ratio and would normally like a cam ground with a 111 degree

lobe separation angle (305/8/2.02) = 18.874 .

The adjustment procedure for these lifters is DIFFERENT, you adjust the "clearance" with the plunger bottomed out in the lifter.

http://www.rhoadslifters.com/Pages/Installation.html "Adjustment is similar to solid lifters. Simply use a feeler gauge to adjust the exact amount of lift reduction you want, anywhere from .010" to .040", and that is exactly what you get at idle. Duration is reduced between 5 and 20 degrees at .050" lift depending on the adjustment."

This cam calls for .022/.024 lash. So you add that lash to the amount of desired lift reduction, and if setting COLD, use the proper lash correction. In my case, it's -.006 for aluminum heads. So, (.022 + .025 - .006) = .041 for INtake, .043 for EXhaust. On the base circle of the cam lobe for the valve you want to adjust, you place that feeler gauge between the valve stem tip and roller wheel of the rocker arm and tighten until the valve is just going to become unseated (with internal plunger of lifter bottomed out). Then lock this adjustment.

I still do not fully understand how this works, but I now have a better understanding of hydraulic lifter operation after solving the mystery

of why those JUNK IMPORT "100% Made in USA genuine Delphi / GM lifters" did not work. Jack Rhoads said that he would explain the VMAX operation to me - maybe it's time I gave him a call.

So this engine now just sits in the basement. Maybe someday I can put it in a light vehicle with a manual transmission.