heres an engine build I found that is obviously going to be a rather impressive street/strip engine,

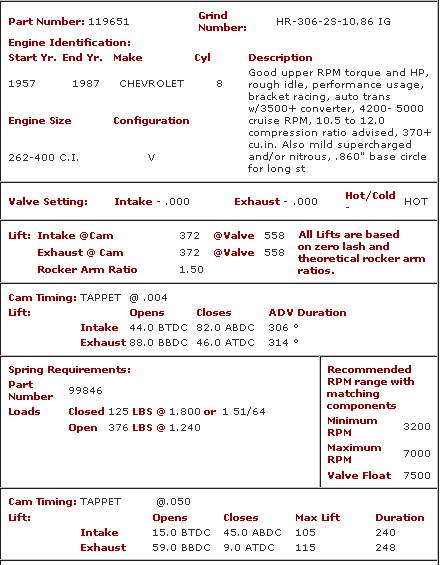

looking over the components use Id have made a few minor changes like a bit longer duration on the cam,

like the CROWER 00471 or CRANE 119651, ,

the reason would be to allow those heads to breath more effectively which I have little doubt would result in a small loss of low rpm torque but a noticeable gain in peak power.

they obviously designed the combo to maximize low and mid rpm torque and were willing to sacrifice some peak power to do that, but I'd point out that once your over about 450 ft lbs of torque at 3500rpm-4000rpm, adding additional torque is rather counter productive on street tires

look carefully at the listed valve lift

Intake Valve lift: 0.502

Exhaust Valve Lift: 0.51

vs

the port flow listed valve lift figures,

200cc Intake runners

Flow @ .700 Int: 270/ Exh: 195 cfm

Flow @ .600 Int: 263/ Exh: 190 cfm

it should be obvious that the cam they selected never gets close to maxing out the port flow due to limited valve lift even.

the duration selected is a little bit restrictive for the application,

Intake Duration @ .050: 224

Exhaust Duration @ .050: 230

yes I have to admit that when I personally swapped from a stock stall speed converter

,in my 383 sbc corvette and a 3200 rpm stall speed converter the difference in performance was amazingly better.

swap too a 3.73:1 rear gear and you've noticeably further enhanced that seat of the pants and slam in the back acceleration.

people tend to not fully appreciate the fact that the performance cars drive train gearing, power to weight ratio and the converter stall

(in the case of automatic transmission) must match the engine torque curve if the car is to perform to anything close to its best potential

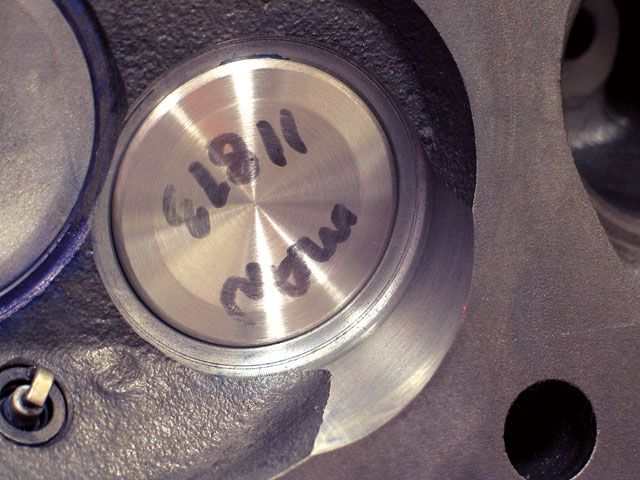

theres two, sizes ON the SBC O.E.M. REAR CAM PLUG

1.23/32-inch expansion plug or the 1.47/64ths (cam plug)

or

the dorman catalog showed both plugs for 62-68 327 & 67 up 350's also.

This looks like a darn bargain

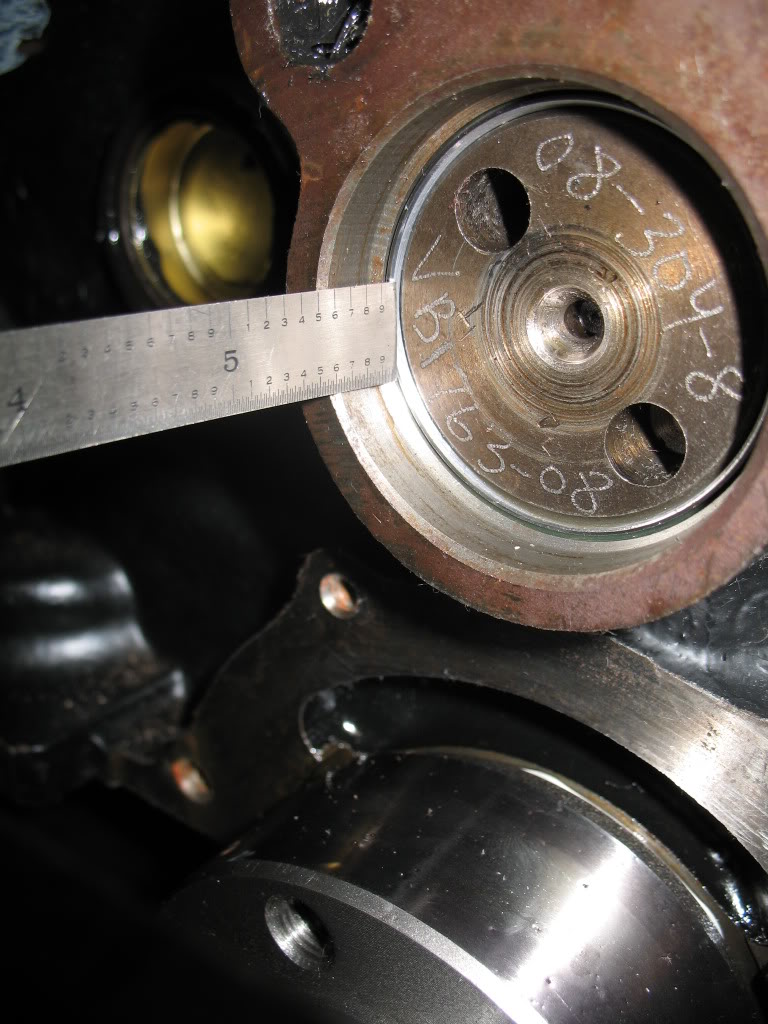

the double roller cloyes timing chains tend to last longer before they wear and have excess slack

and they can be used with the stock O.E.M timing chain cover

http://garage.grumpysperformance.com/index.php?threads/timing-tabs-and-indicators.1015/#post-49812

https://www.ebay.ca/itm/SB-Chevy-Ch...265086?hash=item2a6c66393e:g:jPgAAOSwRgJXiXxM

plugs are roughly 1 5/8" on a O.E.M block sbc

the small one is dorman # 555-049.

1.and 23/32 o.d.,

the large one is 555-080.

1. and 47/64 o.d.

just be sure an measure the one you knock out or the hole it fits and use an accurate caliper

yet with decent heads the results are still reasonably good, which again shows the importance of selected good cylinder heads

http://www.cranecams.com/product/cart.php?m=product_detail&p=24187

IF YOUR SIMPLY TRYING TO GET A STOCK TPI CORVETTE ENGINE BACK IN SERVICE AS CHEAPLY AS YOU CAN?

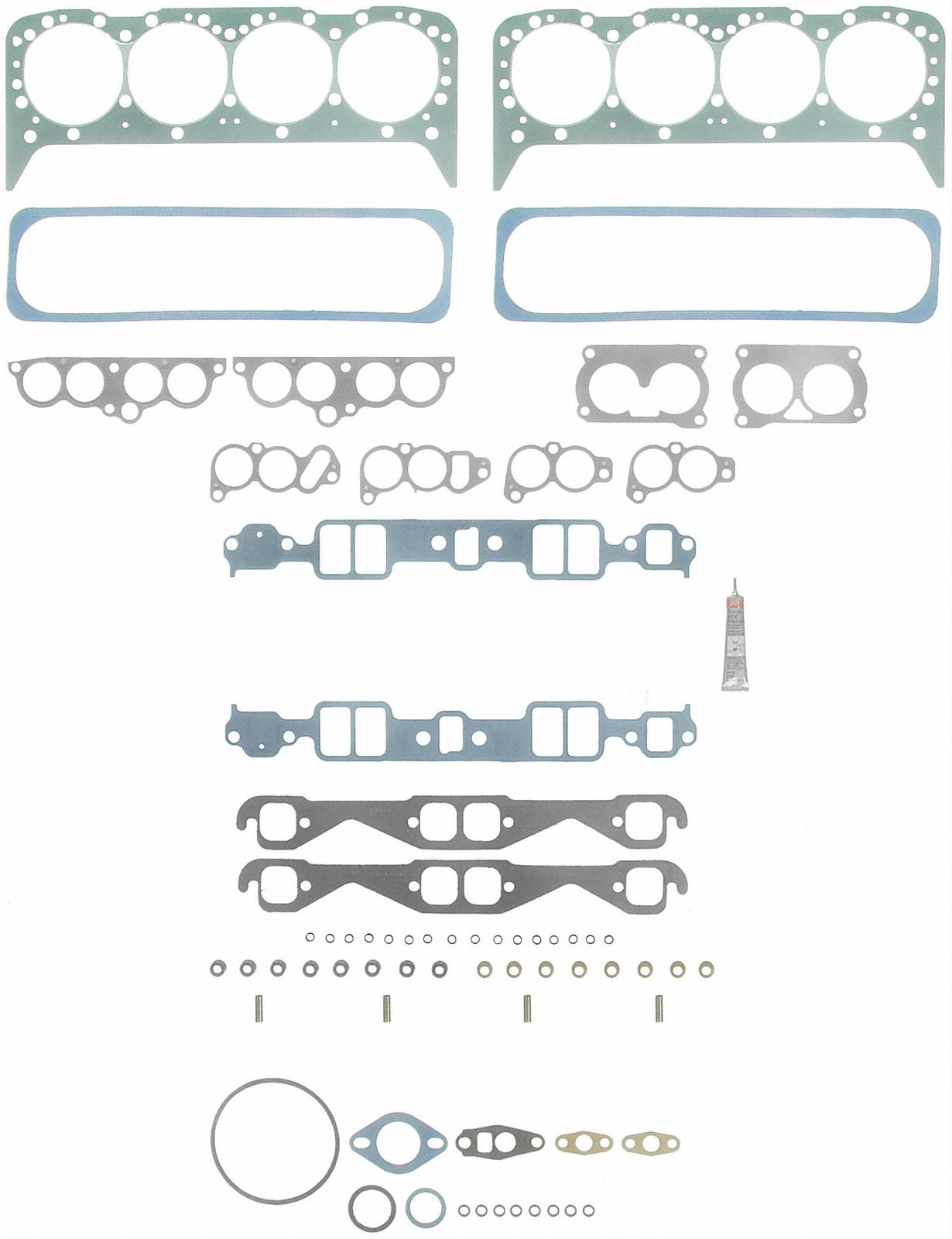

the heads and block surfaces must be very carefully examined for damage or warping issues and if found those issues must be corrected, before any new head gaskets installed, over time steam can and will cut grooves in even cast iron blocks and rather easily in softer aluminum. no head gasket will seal a badly machined or warped head or block

btw if youve managed to blow a head gasket on a 1986-91 TPI corvette with aluminum heads

the heads and block surfaces must be very carefully examined for damage or warping issues and if found those issues must be corrected, before any new head gaskets installed, over time steam can and will cut grooves in even cast iron blocks and rather easily in softer aluminum.

keep in mind coolant must have the anti-freeze ratio set at 50%water 50% antifreeze and be replaced at least every 4 years MAX to retain its anti corrosive additives

the stock 1986-91 tpi head gasket FELPRO HS7733pt9

http://garage.grumpysperformance.co...oving-gaskets-the-wrong-way.10464/#post-43962

http://garage.grumpysperformance.com/index.php?threads/head-gasket-related.1859/#post-50617

http://garage.grumpysperformance.com/index.php?threads/which-sealant-goes-where.700/#post-43768

http://garage.grumpysperformance.com/index.php?threads/sbc-head-gasket-choice.11070/#post-49297

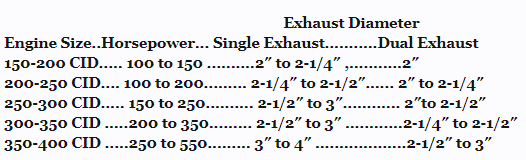

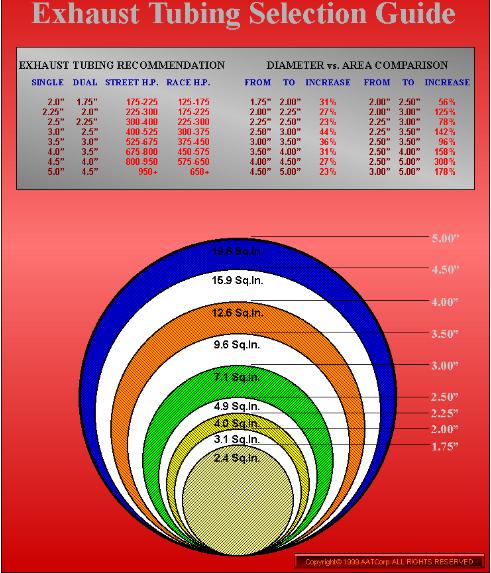

Here are some actual results from a back to back dyno run. 1 5/8" Hookers vs. 1 7/8" XS-Power

2.9 TQ and 12.9 HP yea for the 1 7/8"!!

Engine Specs

Chevy small block

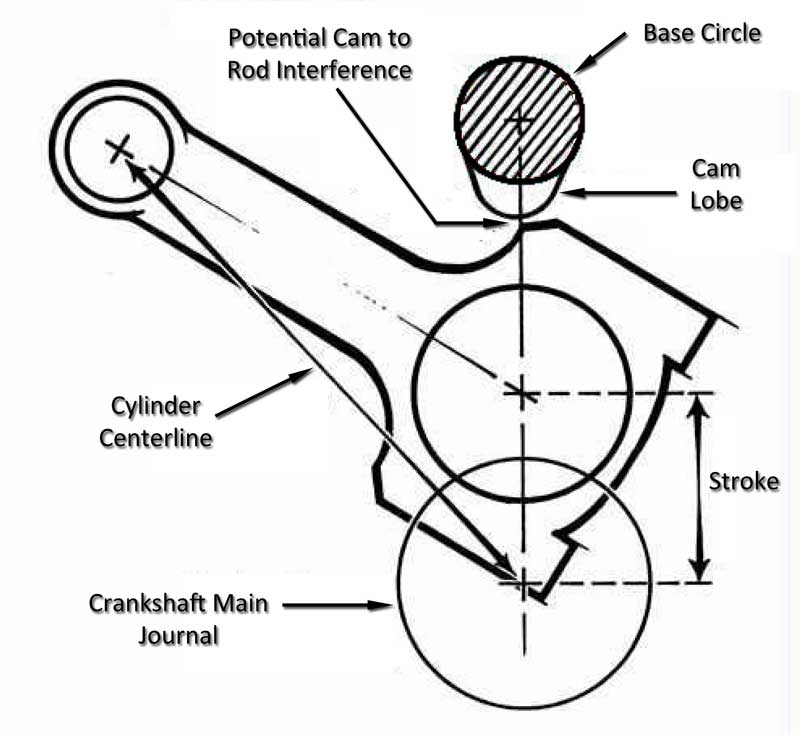

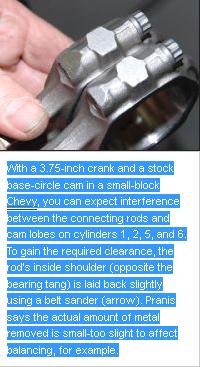

4.030” bore x 3.750” stroke

382.8 Cubic Inch Displacement

10.3:1 Compression Ratio

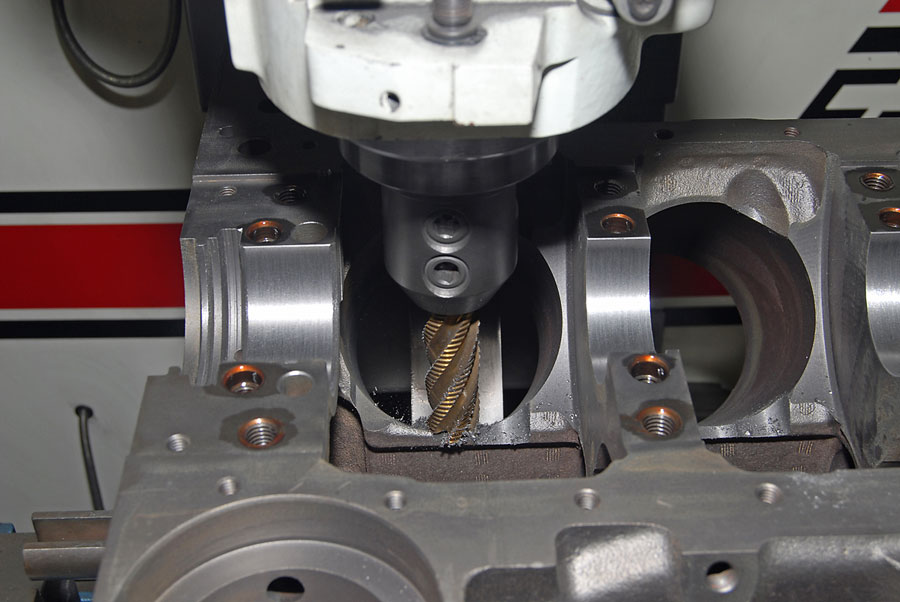

Block: GM 350 4-bolt .030” overbore

Engine Block Style: Stock

Engine Block Material: Cast iron

Main Bolt Style: 4-bolt ARP bolts

Main Caps:

Stock

Main Cap Material: Ductile iron

Align honed Yes

Crankshaft: Eagle 383 Cast Crank - p/n 103503750

Polished by Mile High Cranks

Rear Main Seal Style: 2-piece

Stroke (in): 3.75 in.

Engine Balance: External

Balanced Yes

Rated 500 hp

Main Bearings Clevite MS909HG

Rods: Eagle 6000BST2000

Length Center to Center: 6.000 in.

Rod Beam Style: H-beam

Rod Material: Forged 4340 steel

Rod Finish: Shot-peened

Wrist Pin Style: Floating

Cap Retention Style: Cap screw

Rod Bolt Brand: ARP

Rod Bolt Diameter: 7/16 in.

Rod Bolt Material: ARP

Fastener Yield Strength (psi): 200,000 psi

Rod Bolt Head Style: 12-point

Connecting Rod Weight (g): 645

Big End Bore Diameter (in): 2.100 in.

Pin End Bore Diameter (in): 0.927 in.

Horsepower Rating (hp): 1,200 hp

RPM Rating: 9,500 rpm

Rod Bearing Clevite CB663HN

Pistons: JE Racing 138093

Bore (in): 4.030 in.

Piston Style: Flat top, with two valve reliefs

Piston Material: Forged aluminum

Compression Distance (in): 1.125 in.

Piston Head Volume (cc): +5.00cc

Wrist Pin Style: Floating

Pin Diameter (in): 0.927 in.

Piston Ring Thickness: 1/16 in. x 1/16 in. x 3/16 in.

Weight: 416 grams

Rings: JE Pistons J100014155-5 File

Fit

.018” top, .020

2nd

Ring Set: J10008-41555

Spiral Locks: JE Pistons 927042CS

Camshaft: CompCams 12-423-8 [10,46]

Grind: XR276HR

XTREME Energy™ Retro-Fit Hydraulic Roller

Camshafts, RPM Range 1,900 – 5,600

513 HP / 496 ft/lb Torque

Intake Valve lift:

0.502

Exhaust Valve Lift:

0.51

Intake Duration @ .050: 224

Exhaust Duration @ .050: 230

Adv. Intake duration 276

Adv. Exhaust duration 282

Lobe separation: 110

Intake centerline 106

Lash Hyd

Cam Bolt Kit: ARP-234-1001

Timing Chain Cover: Milton 65555

Timing Chain: Comp Cams CS

Magnum

Roller Set 2100, Heavy-duty, heat-treated true double roller timing chain

Cam Thrust Button CompCams

Heads: Top ProLine - Cast Iron

Iron, 23 degree, 64cc chamber, angle plug head

200cc Intake runners

Flow @ .700 Int: 270/ Exh: 195 cfm

Flow @ .600 Int: 263/ Exh: 190 cfm

Springs: CompCams 986-16 Dual

Valve

Springs: 1.430" O.D. Outer, .697" I.D. Inner

Seat Load: 132 @ 1,750

Open Load: 293 @ 1,250

Coil Bind: 1.150

Rate (Lbs/in.) 322

Valves Precision

Engine Parts

Stainless Steel 21-4N

Intake Valves: P2470P 2.020

Exhaust Valves P2469P 1.600

Valve Seals Comp Cams

Retainers Comp Cams

Locks:

Spring Locators

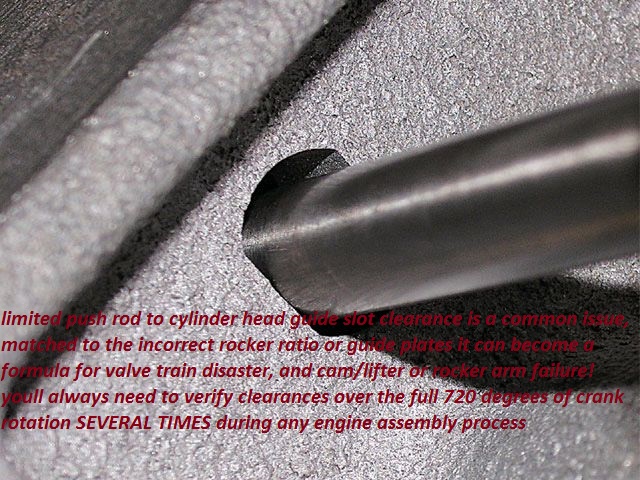

Guideplates Comp Cams

Pushrod Comp Cams 7809-16, High Energy Pushrods™: 5/16" Diameter, 7.266" Length

Hydraulic Roller Lifters:

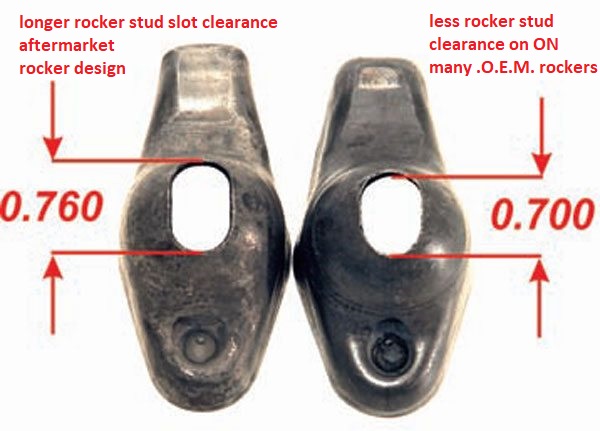

Rocker Arms: Hi-Tech™ Stainless Steel Rocker Arms:

Chevy; 7/16" Stud, 1.6 Ratio

Rocker Studs: 7/16”

Spark Plugs: AutoLite 23’s

Cylinder Head Bolts ARP 134-3701

Head Gaskets: Felpro Z1144061.061 thick version of Z1144

ear.

12/13

12/13

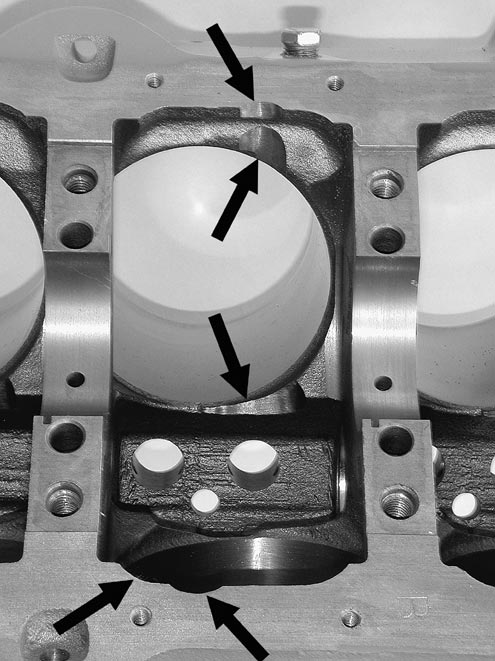

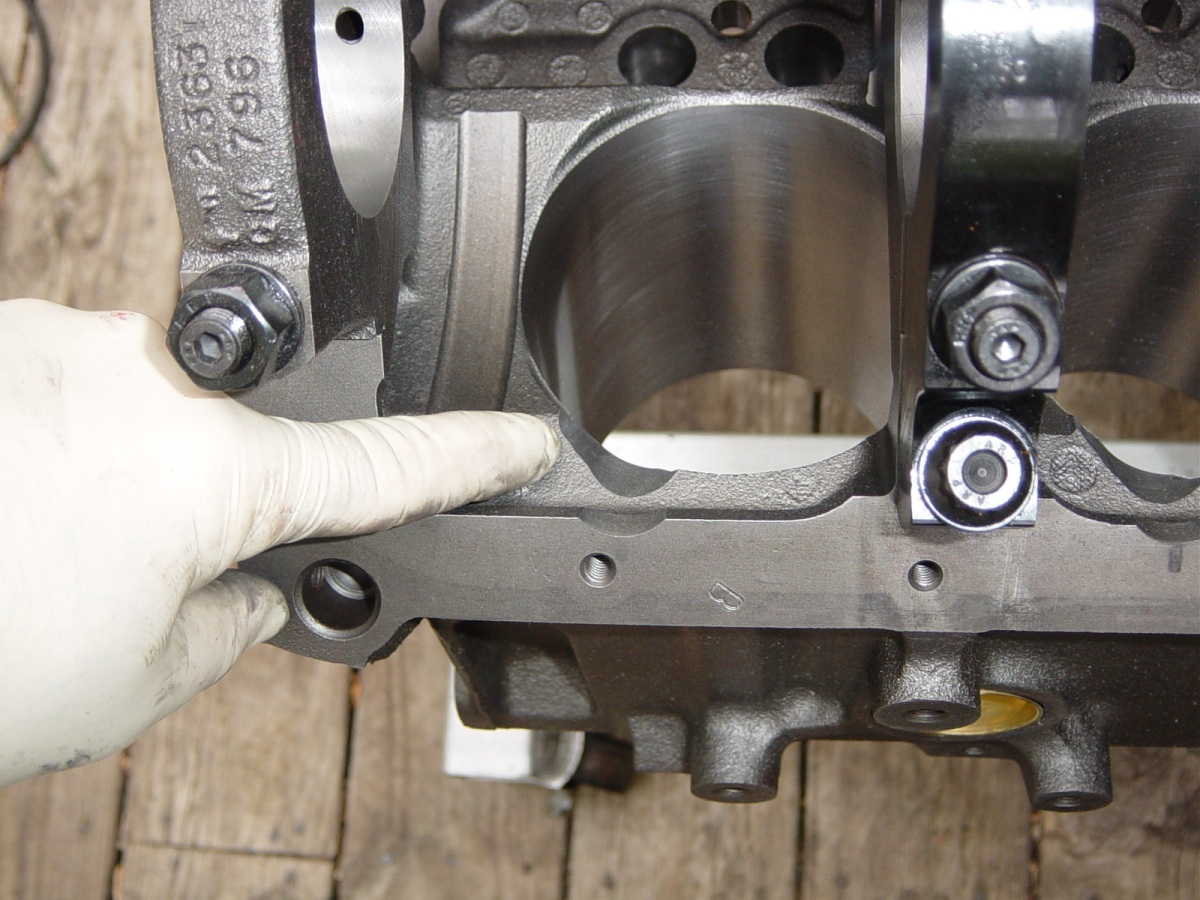

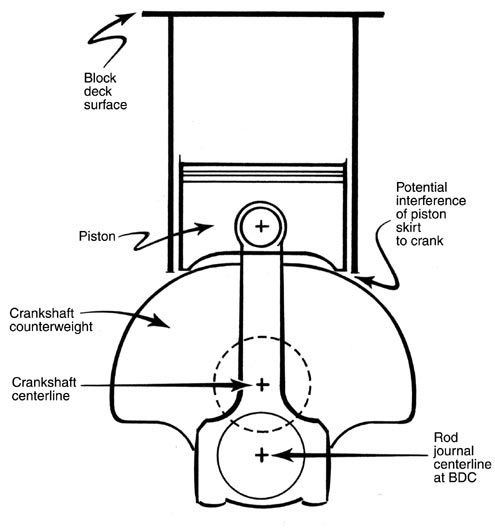

All ’87-and-later Chevy blocks come with a one-piece rear-main seal. This requires the use of a late-model one-piece rear-main seal crank. Starting with the ’88s, most passenger-car engines converted to hydraulic roller cams that required a spider. This is a truck block where the spider mounting bosses are not drilled and tapped, because the truck engine used a flat-tappet cam. These can be easily drilled and tapped to mount the spider for a hydraulic roller cam.

I am building an off idle 383. It will go into a street car. It will never be raced. It should never be necessary for it to exceed 5,500 RPM.

Now for the questions. I am considering using an Eagle, street performance rotator assembly kit. It is advertised as being balanced. The machine shop is telling me that I should pay them $240.00 to balance it because Eagle's balance will be off by as much as 2 grams.

I would like to know if anyone has had problems with the balance on Eagle assemblies and if 2 grams is going to cause an issue with a low RPM engine. Thank you, Tim

from what I've seen in the past EAGLES balanced assembly's are not as well balanced as they could be and yes, your machine shop is probably correct.

personally I've found the SCAT rotating assemblies to be a better value with closer tolerances

that being stated I don,t think you would have major issues if you carefully verify clearances , and installed it without additional,balance work.

(personally Id cough up the extra $240 as insurance the jobs done correctly, it beats pulling it down later

IF your machine shop is pushing Eagle vs SCAT,they probably don,t have nearly the same % mark up, thats most likely WHY

I've used over a dozen SCAT forged rotating assemblies with complete satisfaction.

both SBC and BBC

http://www.scatcrankshafts.com/rotating-assembies/rotating-assembly-product-search/

http://garage.grumpysperformance.co...a-scat-rotating-assembly-be.11495/#post-52962

http://garage.grumpysperformance.co...-displacement-street-engine.10961/#post-48185

http://garage.grumpysperformance.co...re-you-getting-for-your-cash.9986/#post-46530

http://garage.grumpysperformance.com/index.php?threads/scat-vs-eagle.5877/#post-17912

http://garage.grumpysperformance.co...pes-of-crankshaft-steel.204/page-2#post-46231

http://garage.grumpysperformance.com/index.php?threads/bits-of-383-info.38/#post-11766

http://garage.grumpysperformance.co...troker-tips-by-len-emanuelson.1249/#post-2674

http://garage.grumpysperformance.co...ing-rod-strength-h-vs-i-beam.1168/#post-41255

http://garage.grumpysperformance.com/index.php?threads/bearing-clearances.2726/#post-26199

http://garage.grumpysperformance.com/index.php?threads/block-choice.10472/

http://garage.grumpysperformance.com/index.php?threads/which-dart-shp-4-0-or-4-125.3219/

http://garage.grumpysperformance.com/index.php?threads/blocks-from-summitt-or-comp-products.10174/

http://garage.grumpysperformance.com/index.php?threads/engine-block-cylinder-wall-thickness.976/

http://garage.grumpysperformance.com/index.php?threads/sbc-cylinder-wall-thickness.7646/

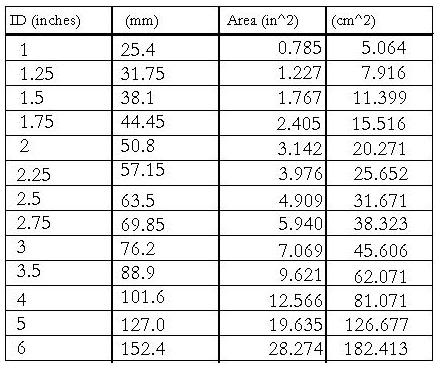

Chevy V8 bore & stroke chart

I saw this online and figured I would post it..I am going to add the popular lsx strokers soon

CID BORE STROKE

262 = 3.671" x 3.10" (Gen. I, 5.7" rod)

265 = 3.750" x 3.00" ('55-'57 Gen.I, 5.7" rod)

265 = 3.750" x 3.00" ('94-'96 Gen.II, 4.3 liter V-8 "L99", 5.94" rod)

267 = 3.500" x 3.48" (Gen.I, 5.7" rod)

283 = 3.875" x 3.00" (Gen.I, 5.7" rod)

293 = 3.779" x 3.27" ('99-later, Gen.III, "LR4" 4.8 Liter Vortec, 6.278" rod)

302 = 4.000" x 3.00" (Gen.I, 5.7" rod)

305 = 3.736" x 3.48" (Gen.I, 5.7" rod)

307 = 3.875" x 3.25" (Gen.I, 5.7" rod)

325 = 3.779" x 3.622" ('99-later, Gen.III, "LM7", "LS4 front wheel drive V-8" 5.3 Liter Vortec, 6.098" rod)

327 = 4.000" x 3.25" (Gen.I, 5.7" rod)

345 = 3.893" x 3.622" ('97-later, Gen.III, "LS1", 6.098" rod)

350 = 4.000" x 3.48" (Gen.I, 5.7" rod)

350 = 4.000" x 3.48" ('96-'01, Gen. I, Vortec, 5.7" rod)

350 = 3.900" x 3.66" ('89-'95, "LT5", in "ZR1" Corvette 32-valve DOHC, 5.74" rod)

364 = 4.000" x 3.622" ('99-later, Gen.III, "LS2", "LQ4" 6.0 Liter Vortec, 6.098" rod)

376 = 4.065" x 3.622" (2007-later, Gen. IV, "L92", Cadillac Escalade, GMC Yukon)

383 = 4.000" x 3.80" ('00, "HT 383", Gen.I truck crate motor, 5.7" rod)

400 = 4.125" x 3.75" (Gen.I, 5.565" rod)

427 = 4.125" x 4.00" (2006 Gen.IV, LS7 SBC, titanium rods)

Two common, non-factory smallblock combinations:

377 = 4.155" x 3.48" (5.7" or 6.00" rod)

400 block and a 350 crank with "spacer" main bearings

383 = 4.030" x 3.75" (5.565" or 5.7" or 6.0" rod)

350 block and a 400 crank, main bearing crank journals

cut to 350 size

--------------------------------------------------------------------------------

CHEVY BIG BLOCK V-8 BORE AND STROKE

366T = 3.935" x 3.76"

396 = 4.096" x 3.76"

402 = 4.125" x 3.76"

427 = 4.250" x 3.76"

427T = 4.250" x 3.76"

454 = 4.250" x 4.00"

496 = 4.250" x 4.37" (2001 Vortec 8100, 8.1 liter)

502 = 4.466" x 4.00"

572T = 4.560" x 4.375" (2003 "ZZ572" crate motors)

T = Tall Deck

ALL production big blocks used a 6.135" length rod.

READ THESE THREAD's

and don,t skip the sub linked info

http://garage.grumpysperformance.com/index.php?threads/engine-balancing.3900/

http://garage.grumpysperformance.com/index.php?threads/engine-balancing.3900/#post-57940

the longer exhaust duration and wide LSA is an advantage if the exhaust is restrictive.it provides more time for the mass of exhaust gases to exit the cylinders,keep in mind its that properly timed exhaust that drags in the following intake charge.

if your using open long tube headers with the proper length primary and collector design,to match your displacement ,compression ratio, and cam timing, longer exhaust duration rarely provides a useful advantage.

in the ideal exhaust system youll want to have less than .5

(thats 1/2 a PSI of back pressure) at the engines peak rpm

http://www.exhaustvideos.com/faq/how-to-calculate-muffler-size-pipe-diameter/

http://www.mk5cortinaestate.co.uk/calculator5.php

3" o.d = 2.87" diam. inside--approximately 6.5 sq inches of area

2.75 o.d = 2.62"diam. inside--approximately 5.4 sq inches of area

2.5 o.d = 2.37" diam. inside--approximately 4.4 sq inches of area

2.25 o.d = 2.12" diam. inside--approximately 3.5 sq inches of area

well worth reading

http://www.popularhotrodding.com/engine ... ndex1.html

http://garage.grumpysperformance.com/index.php?threads/exhaust-components.361/

http://garage.grumpysperformance.com/index.php?threads/calculating-required-exhaust-pipe-size.11552/

http://garage.grumpysperformance.co...-exhaust-pipe-diam-for-your-application.1730/

http://garage.grumpysperformance.com/index.php?threads/is-backpressure-hurting-your-combo.495/

http://garage.grumpysperformance.com/index.php?threads/building-an-exhaust-system-for-your-car.1166/

http://garage.grumpysperformance.co...-calculators-and-basic-math.10705/#post-72061

http://www.wallaceracing.com/Calculators.htm

read through these links, and sub links,

yes it may take a couple days,

but after understanding how and why things work,

the info is sure to save you a great deal of wasted time,

and a bunch of wasted money.

http://garage.grumpysperformance.com/index.php?threads/is-backpressure-hurting-your-combo.495/

http://garage.grumpysperformance.com/index.php?threads/exhaust-thinking-of-your-options.13115/

http://garage.grumpysperformance.co...a-cam-lobe-exhaust-duration.11080/#post-49325

http://garage.grumpysperformance.com/index.php?threads/calculating-ideal-port-size.624/

http://garage.grumpysperformance.com/index.php?threads/calculating-required-exhaust-pipe-size.11552/

http://garage.grumpysperformance.co...ful-exhaust-valve-size-and-header-info.11265/

http://garage.grumpysperformance.com/index.php?threads/semi-fool-proof-cam-sellection.82/

http://garage.grumpysperformance.com/index.php?threads/interesting-muffler-test-results.2916/

http://garage.grumpysperformance.co...lsa-effects-your-compression-torque-dcr.1070/

http://garage.grumpysperformance.co...rcise-in-camshaft-selection.12409/#post-61959

http://garage.grumpysperformance.co...gine-to-match-the-cam-specs.11764/#post-55651

http://garage.grumpysperformance.com/index.php?threads/semi-fool-proof-cam-sellection.82/

http://garage.grumpysperformance.co...gine-to-match-the-cam-specs.11764/#post-55651

http://garage.grumpysperformance.co...-calculators-and-basic-math.10705/#post-50173

there's a bit of discussion on cam selection in the thread links posted above and in this thread, notice the cam selected is far from the most radical that might fit the application,and there's discussion on the differential gearing intake selection and trans gearing and converter stall speed, and while the cam and heads selected were not (BY DESIGN) the components that would cost the least or produce the best peak power numbers they ARE well matched and can quite easily do two things, provide dependable and instantly available and impressive torque, and allow the car to drive without problems on the street, something, in the cars drive-able characteristics, that a much more aggressive cam, that makes a bit more peak power would most likely not provide.

this is a factor that a great many people don,t grasp or understand, and thats correctly matching the combos characteristics to the true intended application, it makes no sense to build a 600 hp sbc that produces peak power at 6700 rpm if your car has a transmission and gearing that restrict its operation to the 1500 rpm-6300 rpm range, yet I constantly see guys read the magazine articles in places like stock car magazine and decide to try and duplicate some 600 hp plus combo they read about on a street car engine build, then they proceed to really screw it up further because they decide that the expensive cylinder heads and block machine work can be ignored to save money, so they substitute much less expensive components and don,t match the drive train and gearing and act stunned and amazed when the combo of mis-matched components runs like crap, gets into detonation issues and surges and bucks at anything under 4500 rpm.

http://garage.grumpysperformance.com/index.php?threads/tbucket-engine-project-dart-shp.3814/

12/13

12/13