DO YOU NEED STEAM HOLES DRILLED ? HERE'S HOW

http://www.gregsengine.com/converting-3 ... o-400.html

http://www.chevyhiperformance.com/techa ... index.html

YOU MAY WANT TO READ THRU THIS LINK ALSO

http://www.chevyhiperformance.com/techa ... ng_tricks/

http://garage.grumpysperformance.com/index.php?threads/water-wetter.2140/#post-5768

http://www.stewartcomponents.net/Mercha ... Code=Therm

any radiator needs a good large and effective multi blade fan shroud to match the fan and make air flow through that radiator much more efficient

buy and add a bottle, this stuff allows the micro surface contact of water inside the cylinder heads to allow a bit more efficient heat transfer rate, its no miracle, product , but its generally good for a 7-9 degree reduction in coolant heat.

tips on reducing the heat of your engine coolant,

you might also consider adding an oil cooler as oil does a great deal of the heat transfer inside any engine, thus reducing oil temperatures tends to reduce coolant temperatures.

Id also point out that,adding an auxiliary oil and/or trans mission fluid cooler with a powered fan, too the car, helps remove heat far more effectively and can remove a great deal of heat load from the radiator well before the coolant in the engine needs to deal with it

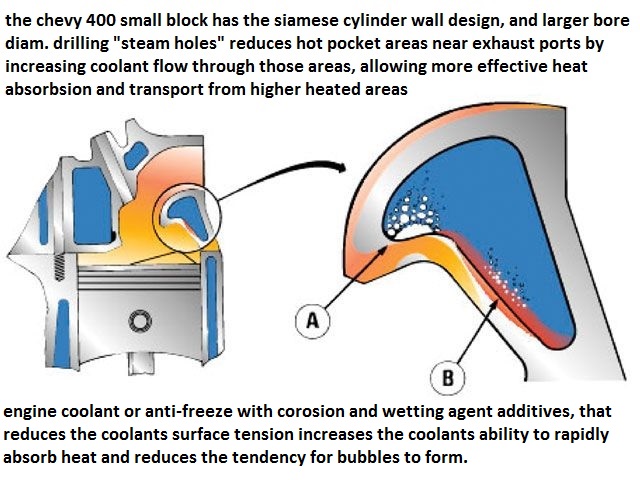

400 sbc engines have a reputation for running hotter than the average SBC thats only partially deserved

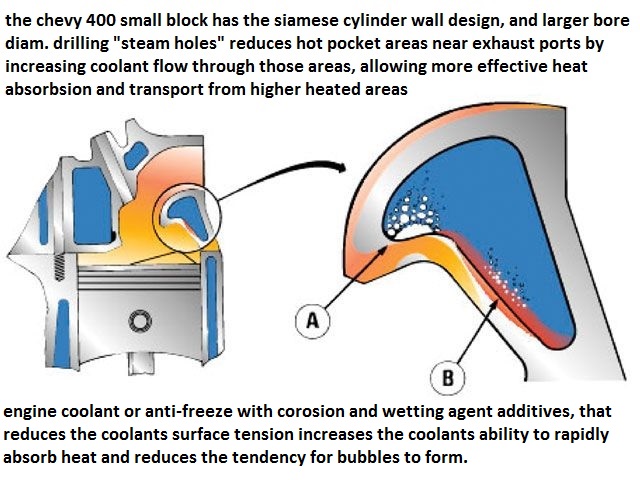

the 400 SBC used SIAMESE CYLINDER WALLS, and the average hot rodder , looking at the larger bore 400 block, only looked at the potential for increased displacement, and never put much thought into the engineering required to effectively use that increased bore diam. thus the fact the Siamese block design meant the coolant can't pass between the cylinders so heat does tend to have a very slightly lower surface area to allow coolant to absorb the heat generated from., for decades guys swapped the better flowing fuelie heads onto the larger displacement 400 based engines without adding the additional coolant steam holes, to help the Siamese cylinder wall block design, cool more effectively , and forget that if you increase compression, and produce significantly more horse power that power increase is the result of burning MORE FUEL BURNT FASTER, AT HIGHER AVERAGE RPMS, which, always results in producing higher average heat levels as a by product.

theres no free lunch , if you increase a 400 sbc power from a stock 185 hp two barrel engine that might have 9:1 compression that rarely saw 4500 rpm, into lets say a 406 SBC with better heads, 11:1 compression that, engine could easily, produce 470 hp , your going to reasonably expect nearly double the heat energy being produced.

a KNOWLEDGEABLE hot rodder, willing to think through the required modifications will have no trouble keeping a 400 SBC based engine cool

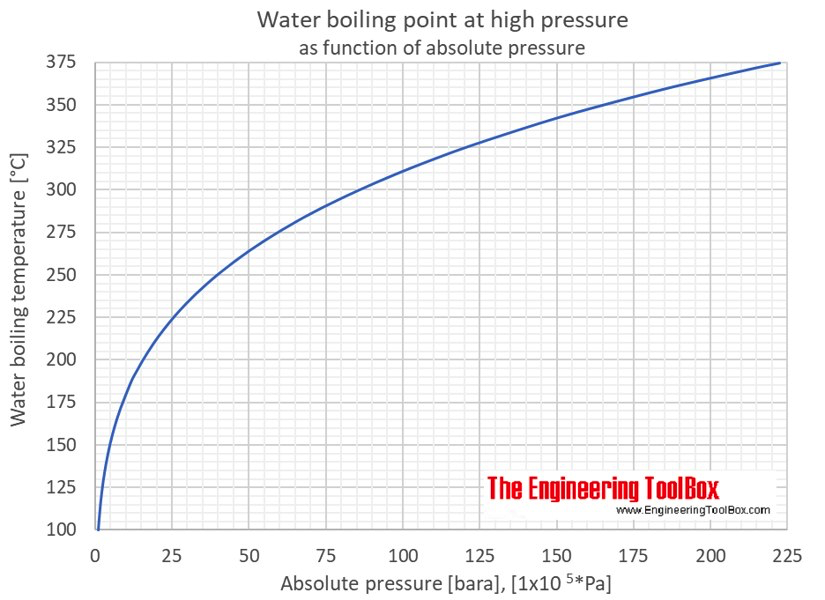

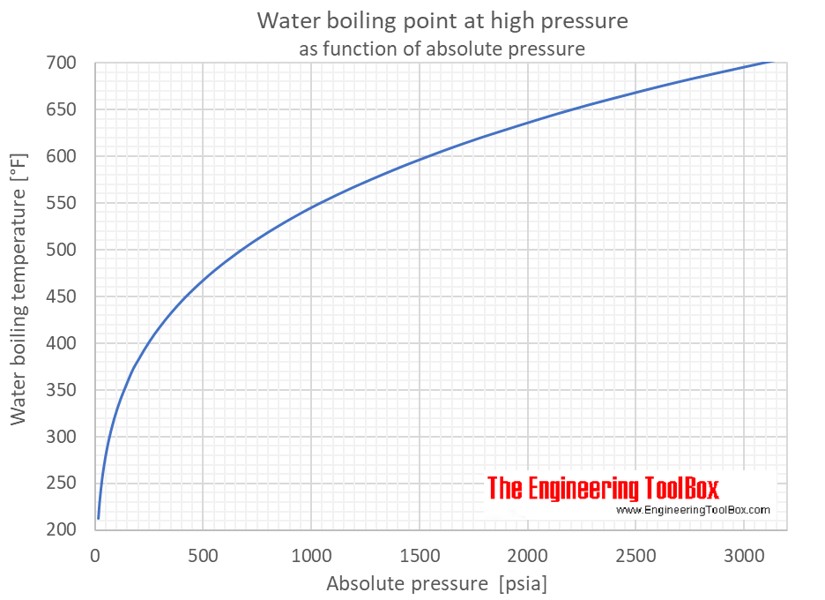

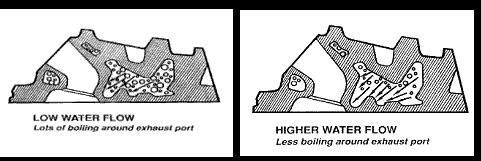

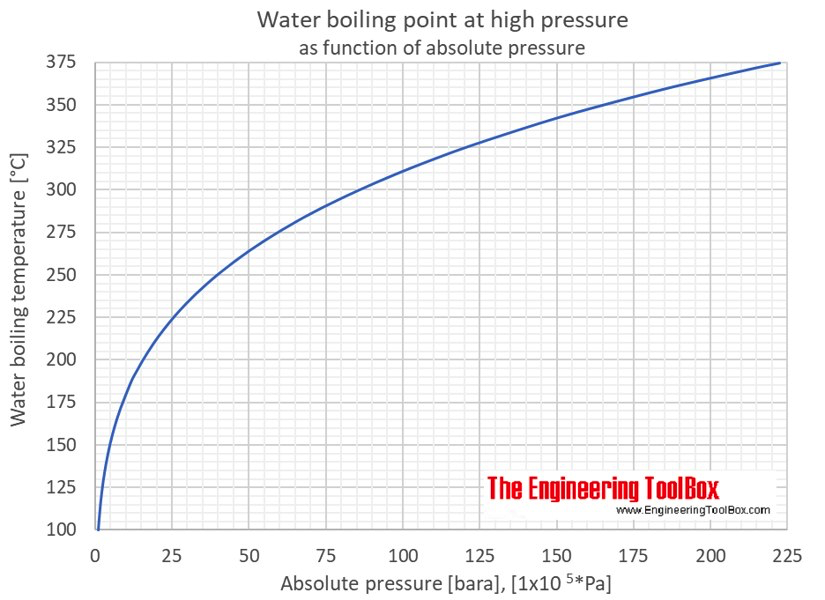

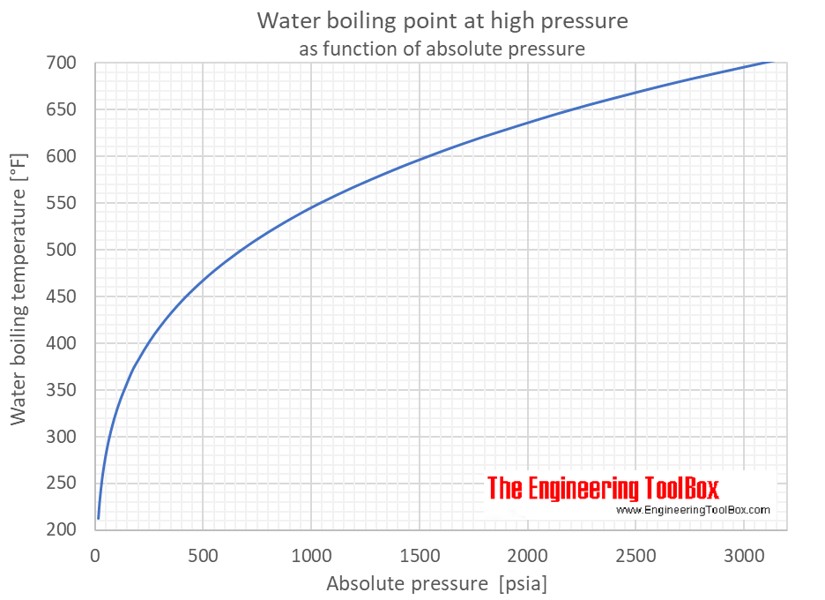

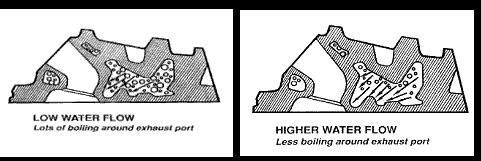

ONCE COOLANT BOILS it lost the full ability to absorb heat as partial direct contact with the metal surface is partially lost, one reason cooling systems are pressurized is to increase the boiling point threshold

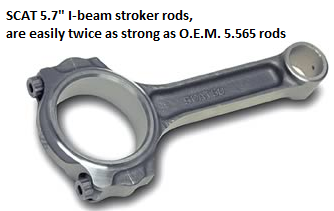

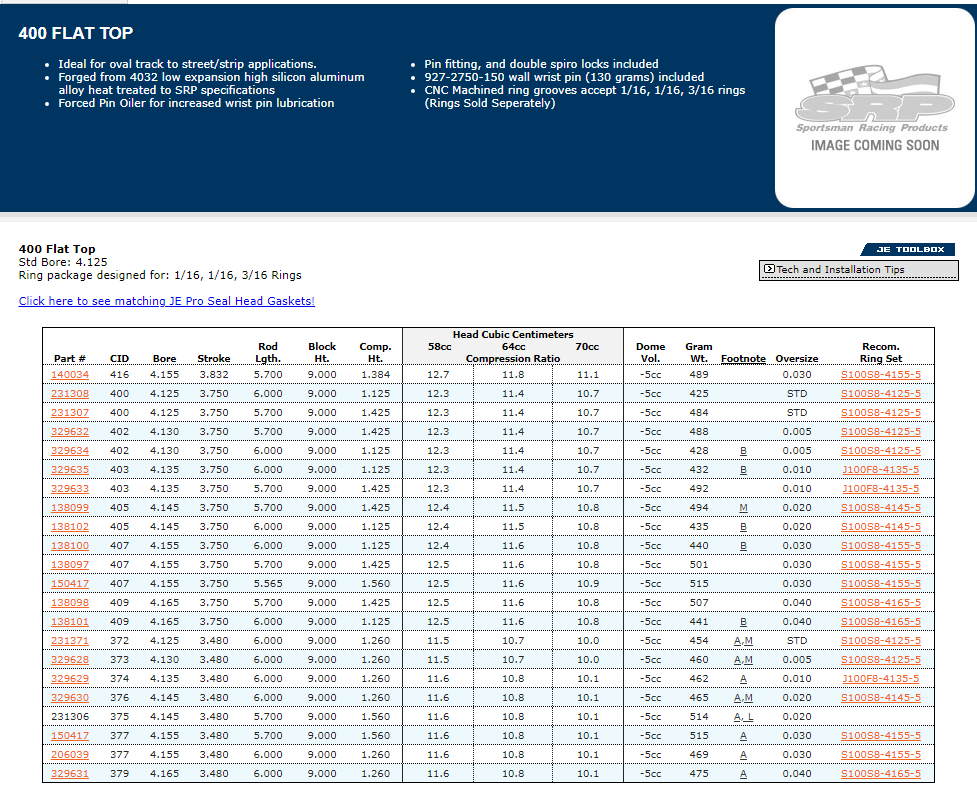

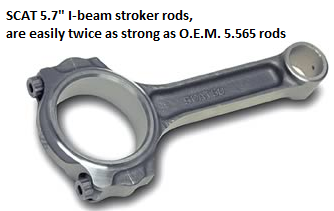

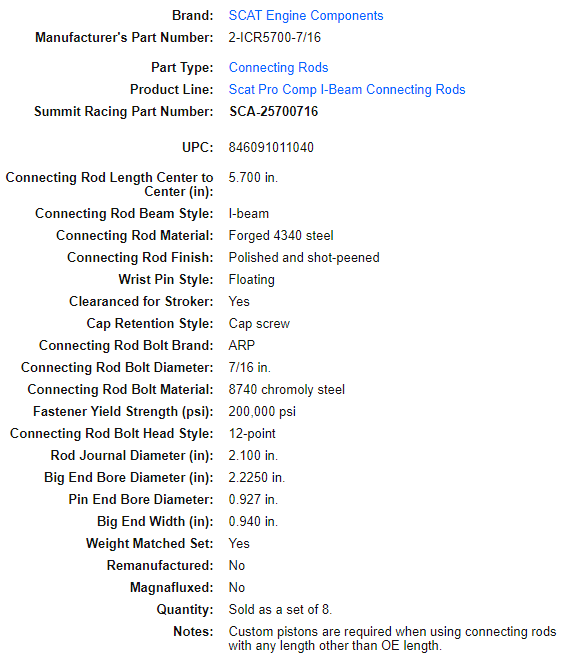

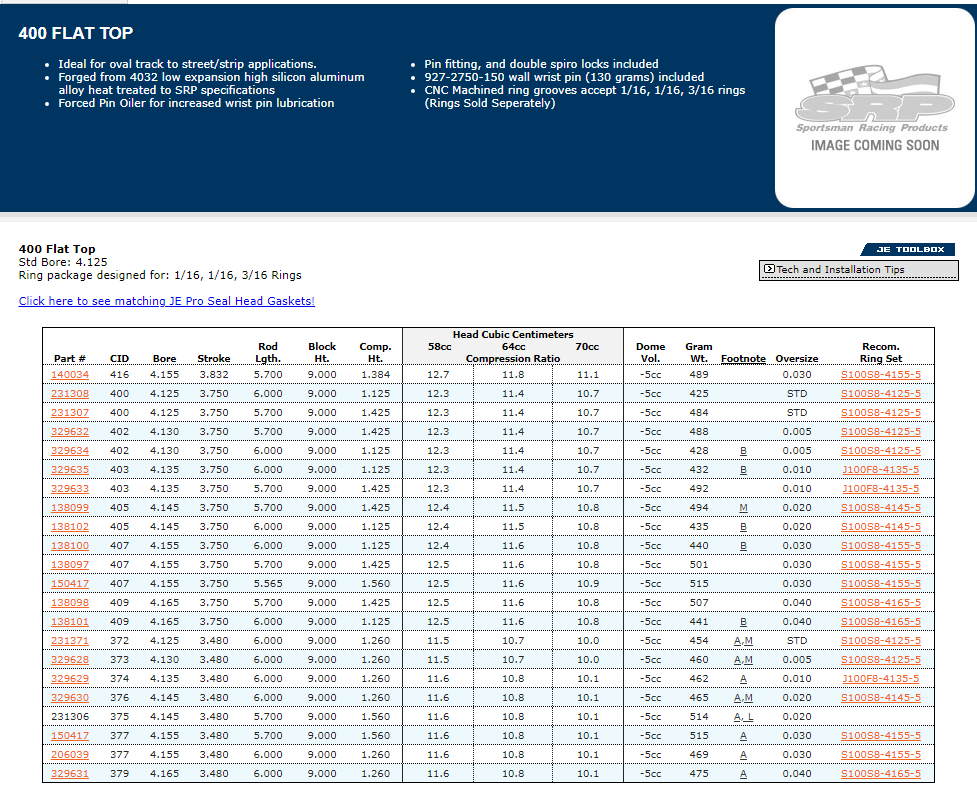

The 5.7" rods vs the stock 5.565 " rods are a slight improvement in rod angularity and 6" rods would be slightly better but even the shorter rods work reasonably well if correctly clearanced and the rotating assembly balance as long as the rpms keep the piston speeds reasonable for the components being used (GENERALLY under 6200rpm)

READ THE LINKS AND SUB LINKS CAREFULLY

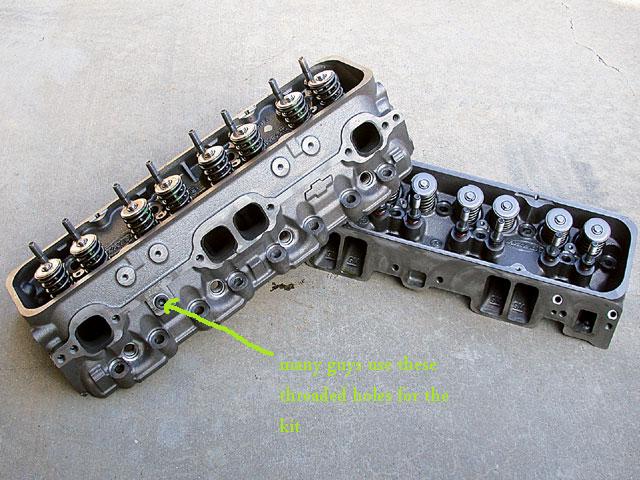

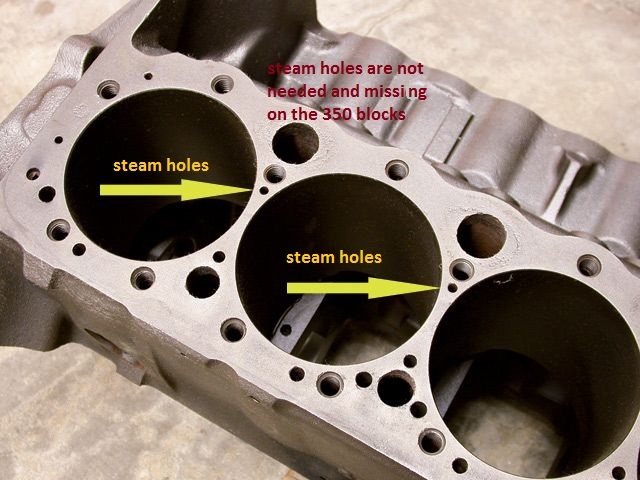

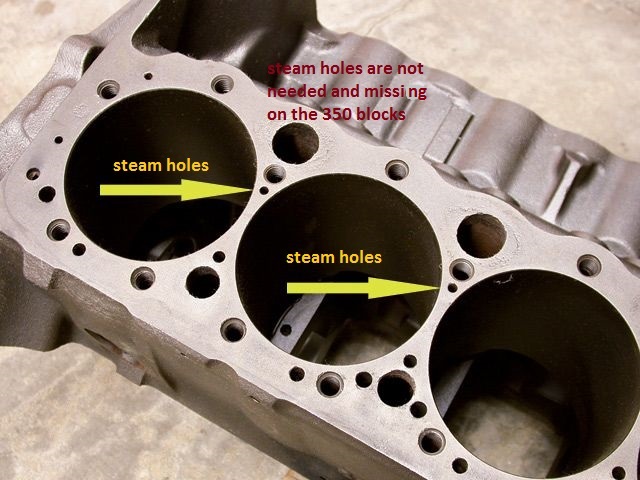

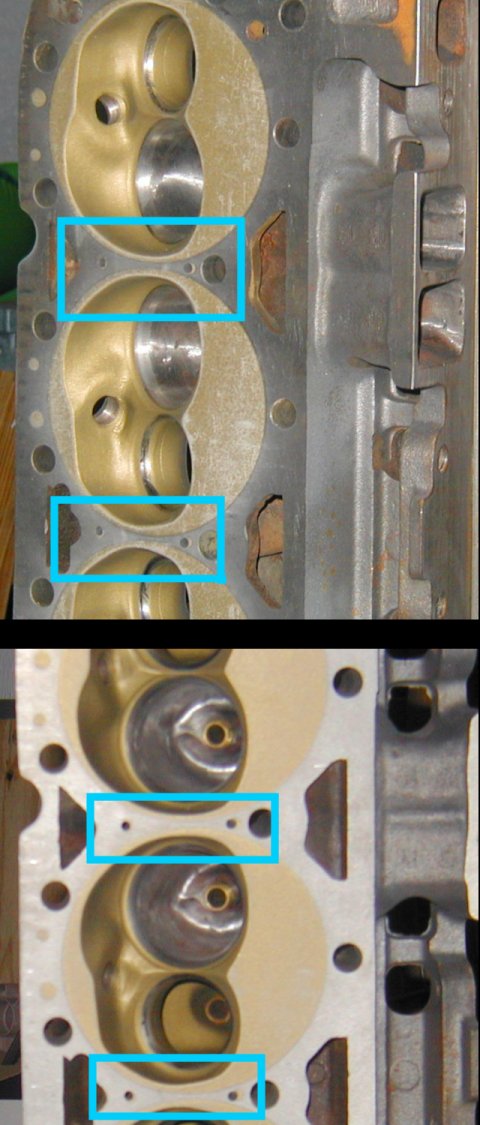

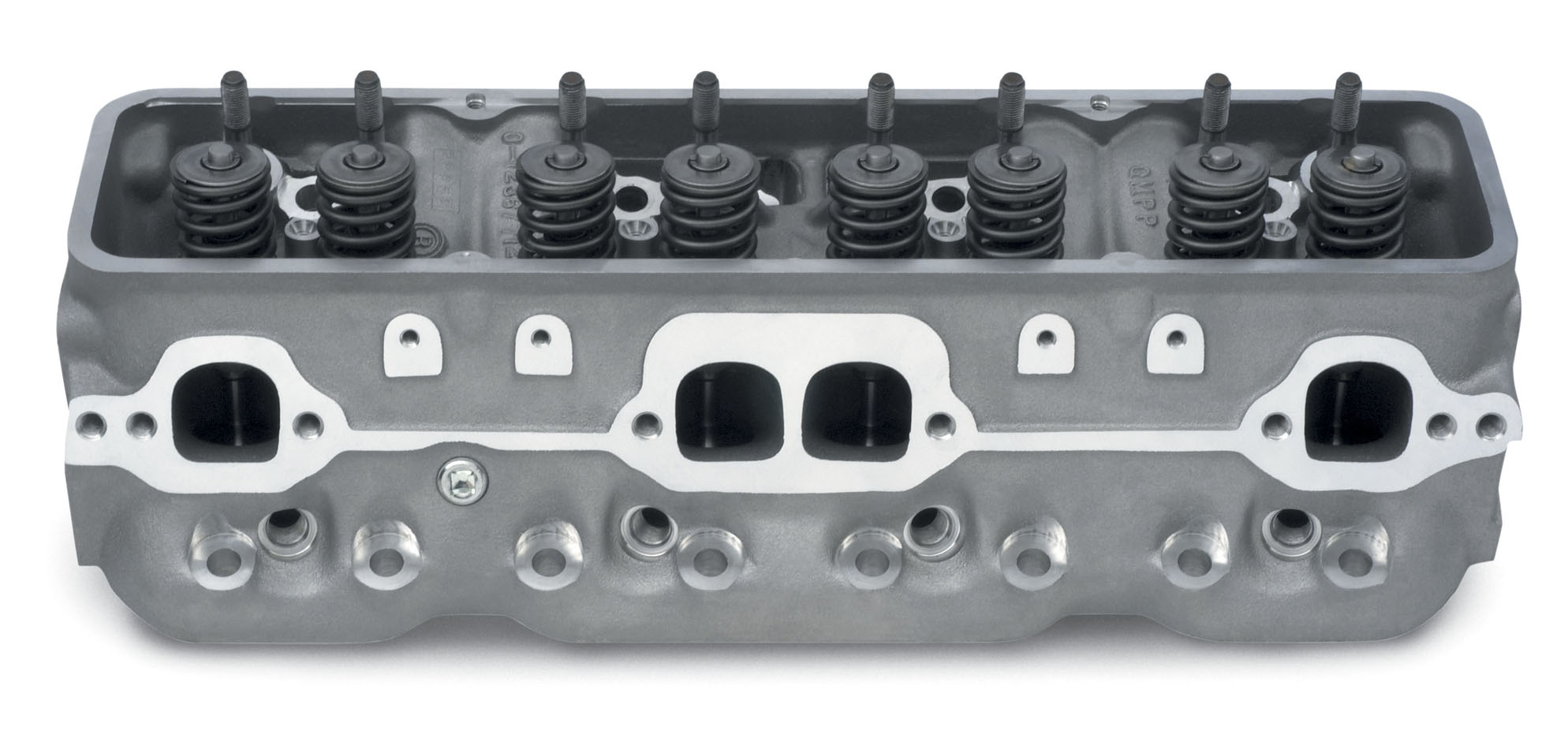

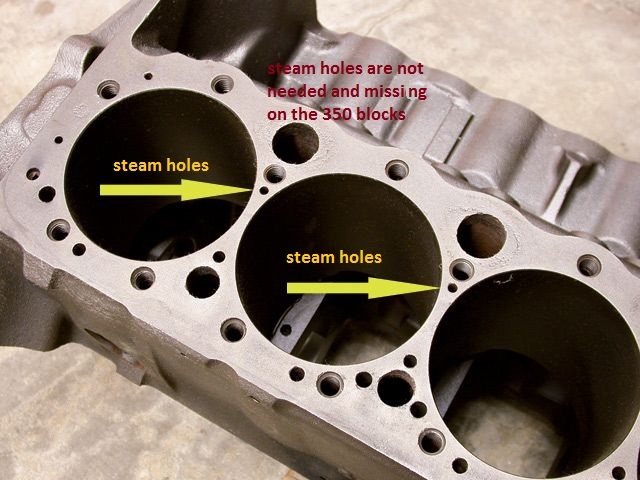

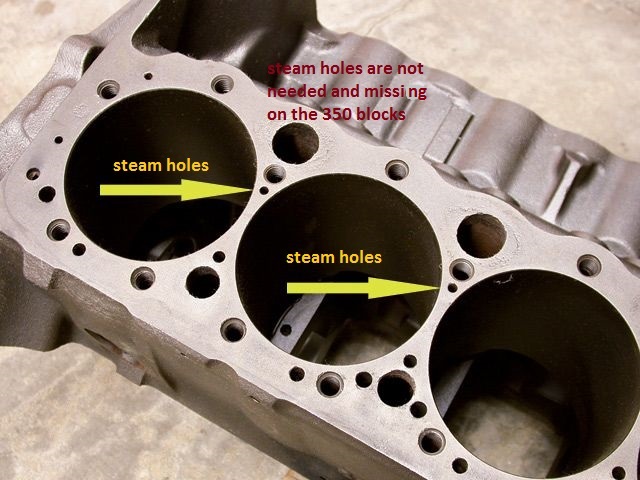

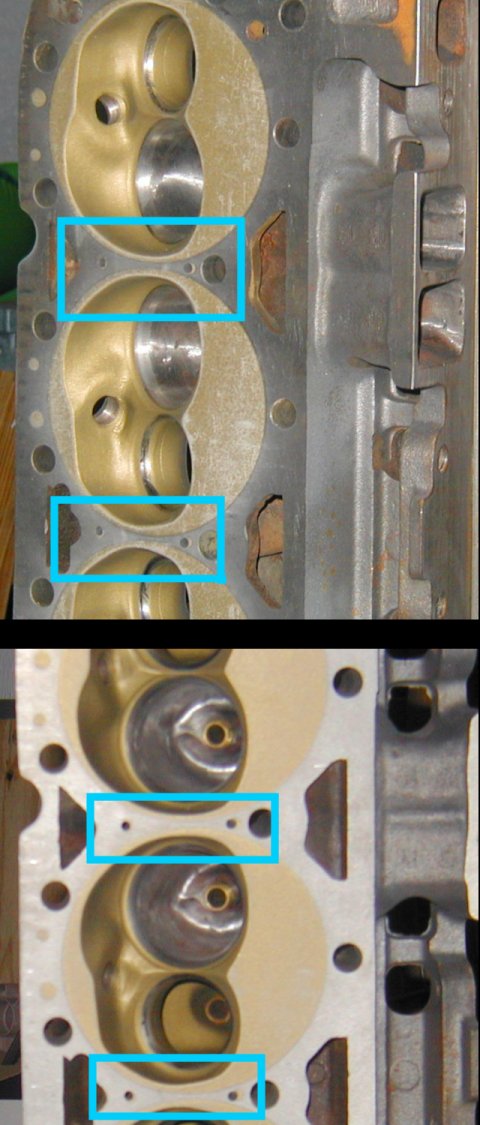

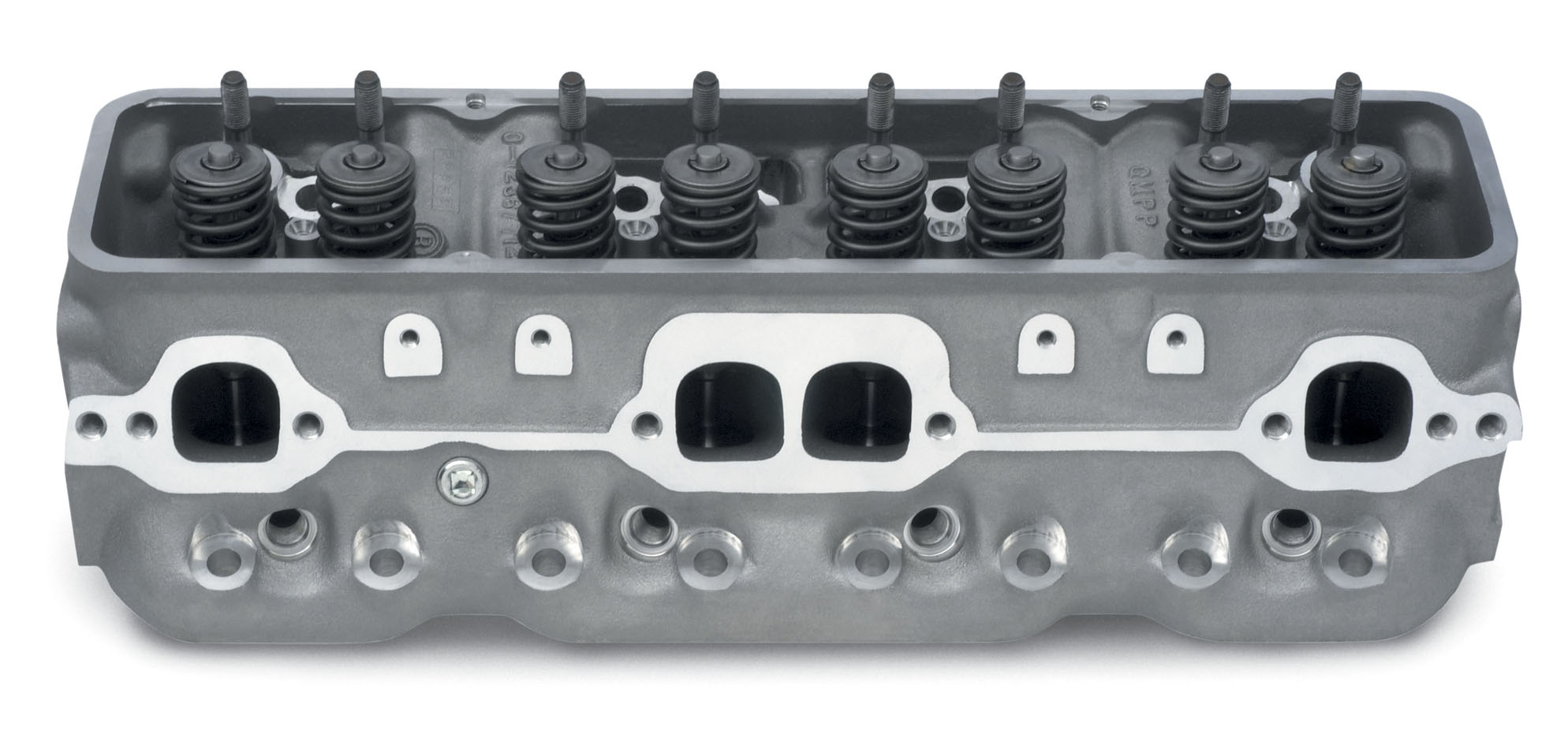

the cylinder heads, need to have extra "STEAM HOLES" drilled this allows coolant to more easily flow from the areas more prone to low coolant flow rates.

http://garage.grumpysperformance.com/index.php?threads/400-sbc-steam-holes-posted-by-dennyw.2991/

http://garage.grumpysperformance.com/index.php?threads/thoughts-on-cooling.149/

http://garage.grumpysperformance.com/index.php?threads/how-the-cooling-system-works-basics.853/

http://garage.grumpysperformance.co...ing-system-flow-rates-and-heat-transfer.9880/

http://garage.grumpysperformance.com/index.php?threads/water-wetter.2140/

use the correct sealants

http://garage.grumpysperformance.com/index.php?threads/sealants-and-threads.805/#post-1171

http://garage.grumpysperformance.co...venting-leaky-head-bolts-studs.50/#post-12528

using a surface tension destroying additive in the coolant like purple ice or water wetter can significantly reduce or prevent this, which is one of the reasons the 400 chevy has extra steam holes in the heads and gaskets

Solution

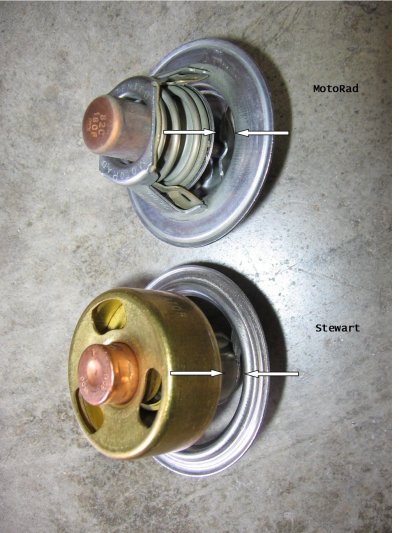

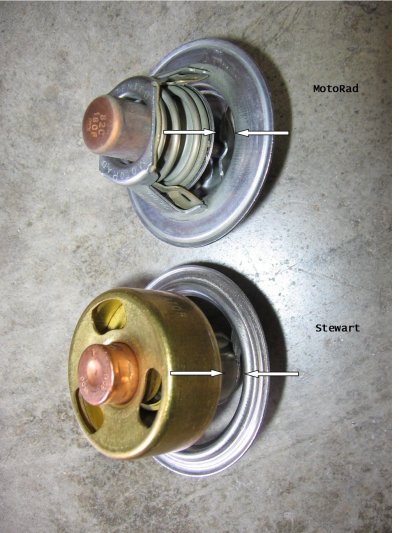

In an ideal world your coolant temp never exceeds 210F and spends most of its time around 180F-190F , oil MUST reach 215F occasionally during your cars operation, to burn off moisture and acids but should be at about 10 degrees hotter than the coolant, most good quality oil easily handles 240F for limited times, If I was you Id stick a 180F- or -190F T-stat in the car with several holes, ID custom drill in the flange, to allow some coolant flow at all times, this does slow the time required for the engine to reach operational temps but it alst tends to almost totally reduce the temperature swings as the t-stat opens and closes

buy a new 190F t-stat but before installing it drill 6 3/32" holes in the flange this mod usually prevents that problem and results in stable temps, stable temps are far less likely to result in a head gasket seal problem

http://www.newyorkrestomod.com/category_s/1820.htm

if you have the room mounting the coolant temp sensor in the radiator t-stat housing location with a custom spacer for the sensors, is a good option as it tends to read more consistently than sensors mounted in the cylinder head.

http://www.summitracing.com/parts/MEZ-WN0028U/?rtype=10

http://www.summitracing.com/parts/MEZ-WN0028U/?rtype=7

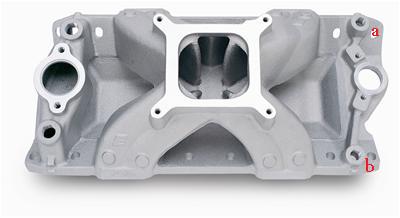

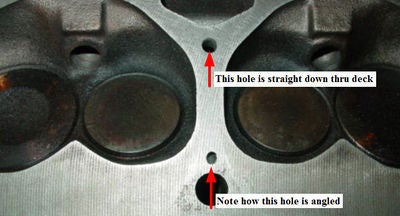

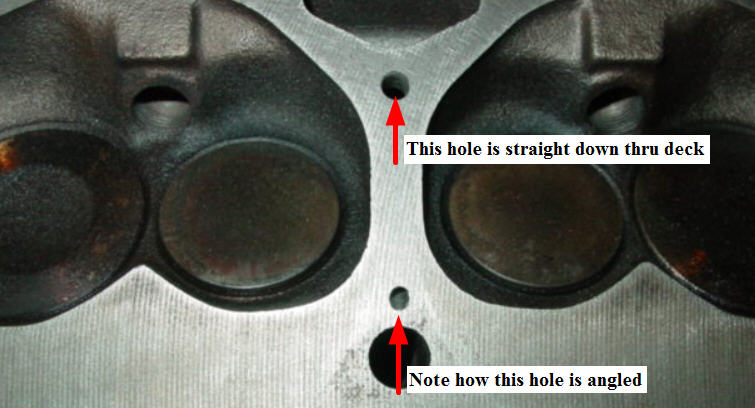

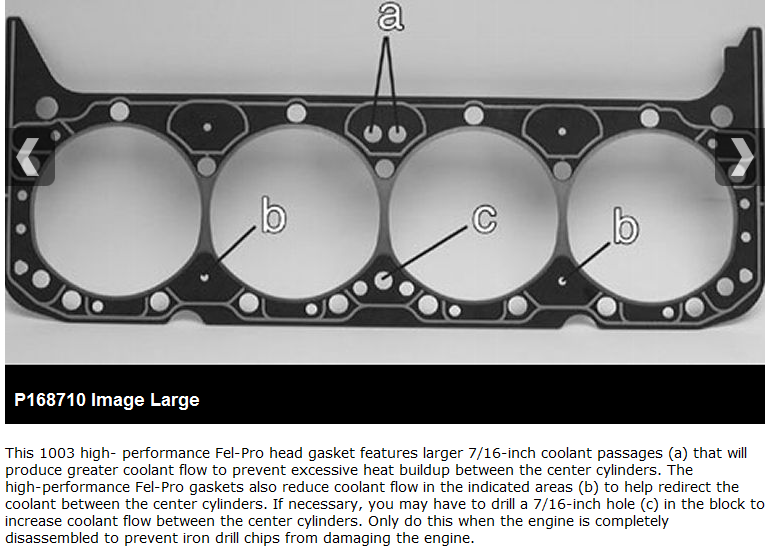

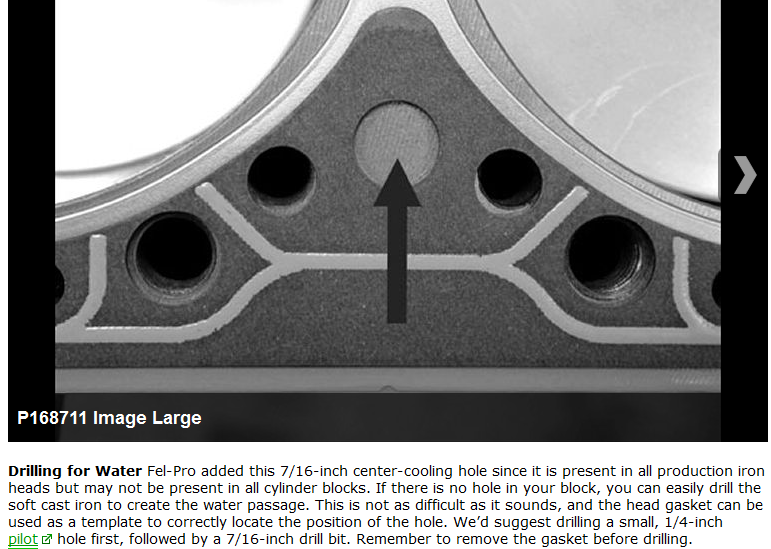

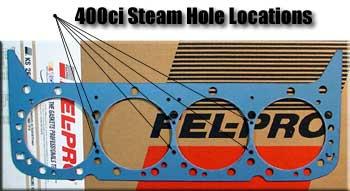

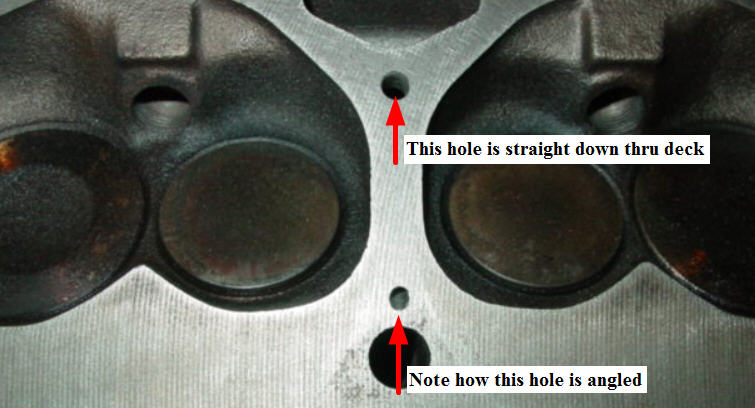

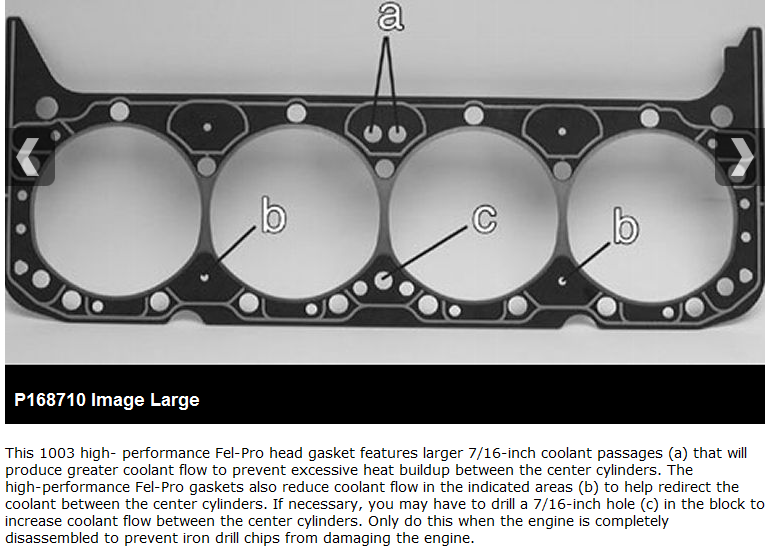

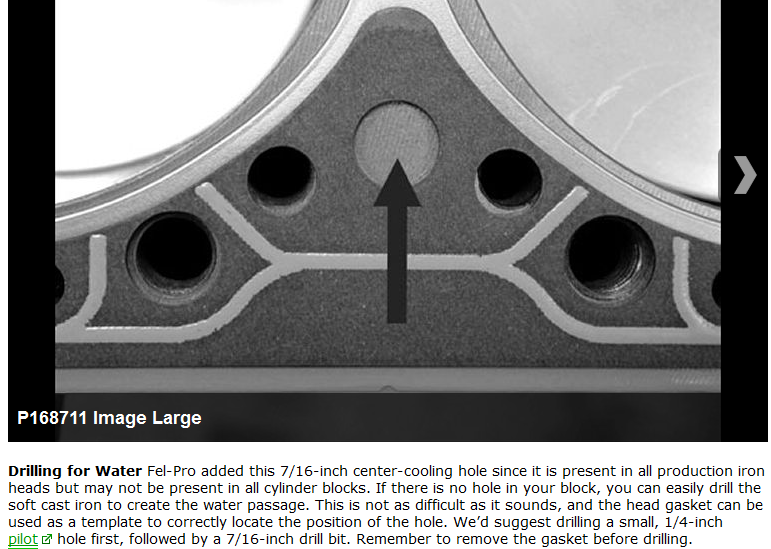

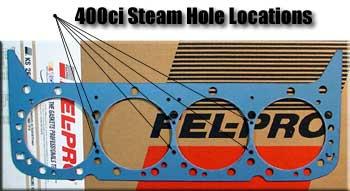

You should use a 400 head gasket as a template to mark the heads and Drill the 3 holes on the intake side using a 3/16 drill bit at a 10 degree angle towards the exhaust side of the head. Drill the 3 remaining holes using a 1/4 inch drill bit straight down towards the top of the head. 1- Start by marking the approximate steam hole locations with a marker or die. Next insert 2 dowel pins into the heads dowel pin holes and lay the 400 head gasket onto the head over the dowel pins. This will keep the gasket aligned precisely as you mark the holes. 2- Level the head with the deck side facing up and drill the 3 holes that run parallel to the exhaust side of the head using a 1/8 inch drill bit. The maximum size for these holes are .250 or 1/4 inch. 3- For the angled holes, level the head at 10 degrees so that you will be drilling from the intake side of the head down toward the exhaust side 4- To drill the remaining 3 holes in the head use a starter bit first then switch to a 1/8 inch drill bit. This will make it easier to get the holes started on angle without drill deflection. The maximum size for these holes are .187 or 3/16 inch. 5- clean off heads with brack clean or parts cleaner. use a new head gasket to make sure holes are correct.

I borrowed this info long ago, because all the pictures were there, and I hope it's ok to post here. This is a vital part on Head procedures. I always have done this when redoing heads. If the holes aren't there, they soon will be. Not that hard to do either.smile

The cylinder heads on the Small Block Chevy 400 were prone to crack and the cores for this engine are increasingly more difficult to find. Machining the 350ci cylinder heads to match the 400ci heads is an excellent way to keep your 400ci engine alive.

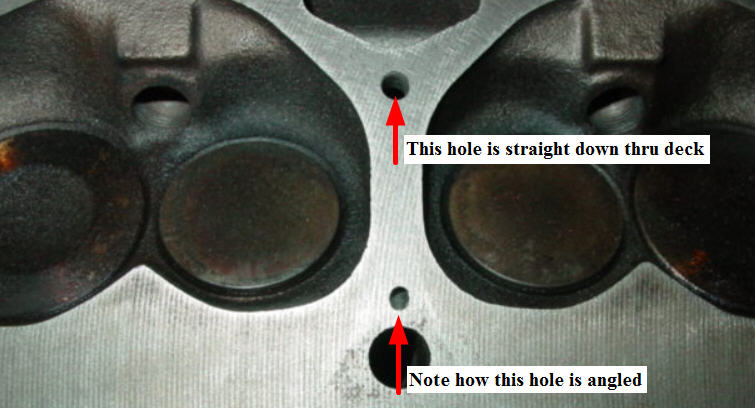

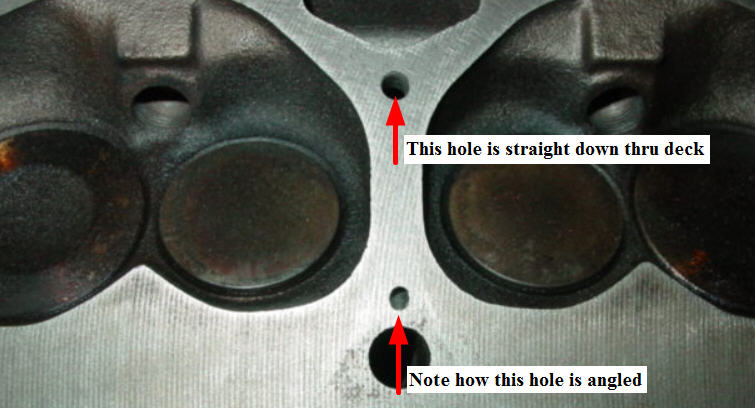

To use the Small Block Chevy 350 head on a 400 block, it will be necessary to drill six 1/8 inch holes in the cylinder heads. Use a 400 head gasket as a template to mark the heads and Drill the 3 holes on the intake side at a 40 degree angle towards the exhaust side of the head. Drill the 3 remaining holes straight down towards the top of the head.

PROCEDURE

1. Start by marking the approximate steam hole locations with a marker or die. Next insert 2 dowel pins into the heads dowel pin holes and lay the 400 head gasket onto the head over the dowel pins. This will keep the gasket aligned precisely as you mark the holes.

2. Level the head with the deck side facing up and drill the 3 holes that run parallel to the exhaust side of the head using a 1/8 inch drill bit. The maximum size for these holes are .250 or 1/4 inch.

3. For the angled holes, level the head at 40 degrees so that you will be drilling from the intake side of the head down toward the exhaust side as shown in the picture below.

4. To drill the remaining 3 holes in the head use a starter bit first then switch to a 1/8 inch drill bit. This will make it easier to get the holes started on angle without drill deflection. The maximum size for these holes are .156 or 5/32 inch.

The finished heads with the steam holes drilled and a 3 angle valve job.

Marine Use: The SBC 400 engine is not a good choice for use in marine applications unless you have a closed water system. The steam holes tend to get plugged up rather quickly followed by a blown head gasket. If you do choose the 400 engine for marine use then the maximum diameter steam holes may help. A better choice for use in a marine application would be the 350 engine or 383 stroker engine.

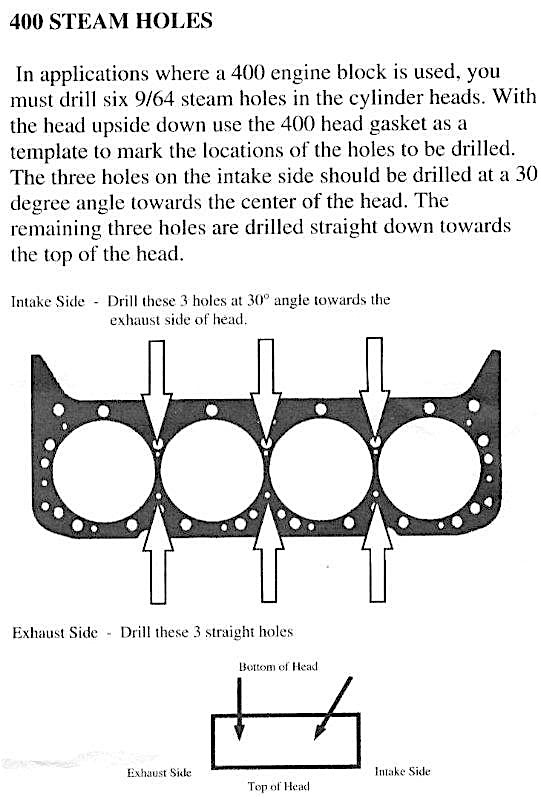

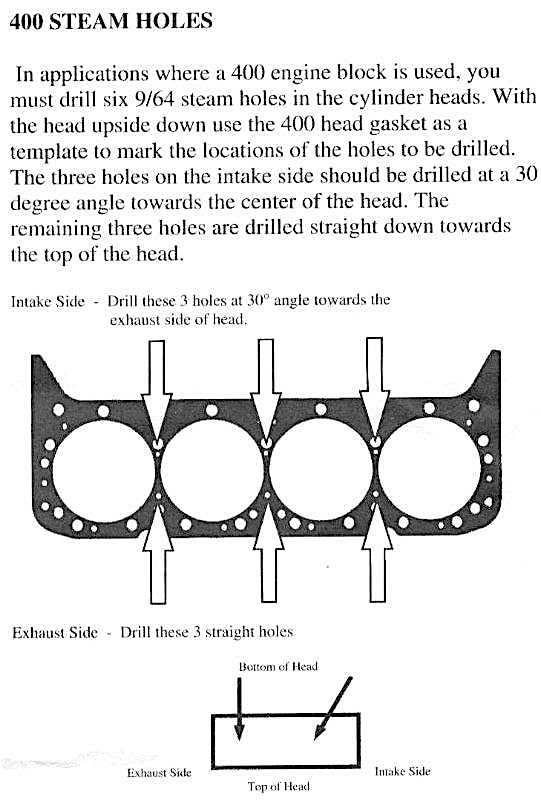

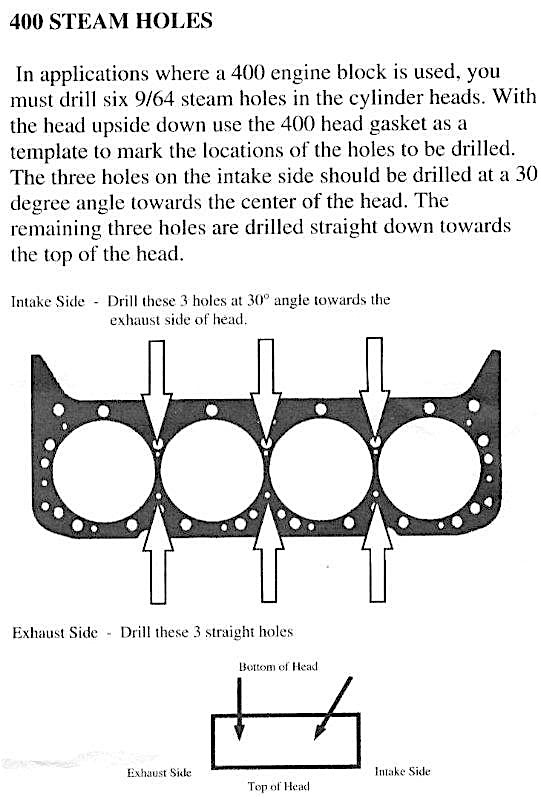

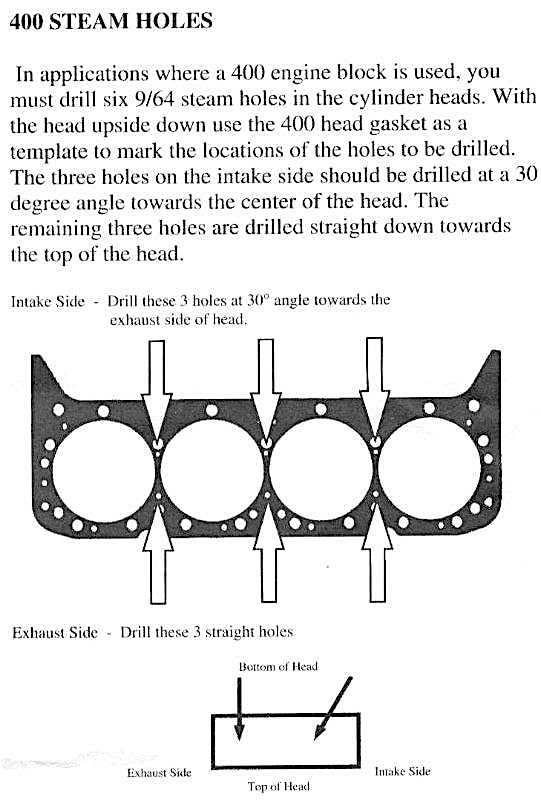

STEAM HOLES

In applications where a 400 engine block is used, you must drill six 9/64†steam holes in the

cylinder heads. With the head upside down use the 400 head gasket as a template to mark the

locations of the holes to be drilled. The three holes on the intake side should be drilled at a 30

degree angle towards the center of the head and may need to be over one inch deep. The

remaining three holes are drilled straight down towards the top of the head.

Intake Side - Drill these 3 holes at 30° angle towards the

exhaust side of head.

Exhaust Side - Drill these 3 straight holes

You should use a 400 head gasket as a template to mark the heads and Drill the 3 holes on the intake side using a 3/16 drill bit at a 10 degree angle towards the exhaust side of the head. Drill the 3 remaining holes using a 1/4 inch drill bit straight down towards the top of the head. 1- Start by marking the approximate steam hole locations with a marker or die. Next insert 2 dowel pins into the heads dowel pin holes and lay the 400 head gasket onto the head over the dowel pins. This will keep the gasket aligned precisely as you mark the holes. 2- Level the head with the deck side facing up and drill the 3 holes that run parallel to the exhaust side of the head using a 1/8 inch drill bit. The maximum size for these holes are .250 or 1/4 inch. 3- For the angled holes, level the head at 10 degrees so that you will be drilling from the intake side of the head down toward the exhaust side 4- To drill the remaining 3 holes in the head use a starter bit first then switch to a 1/8 inch drill bit. This will make it easier to get the holes started on angle without drill deflection. The maximum size for these holes are .187 or 3/16 inch. 5- clean off heads with brack clean or parts cleaner. use a new head gasket to make sure holes are correct.

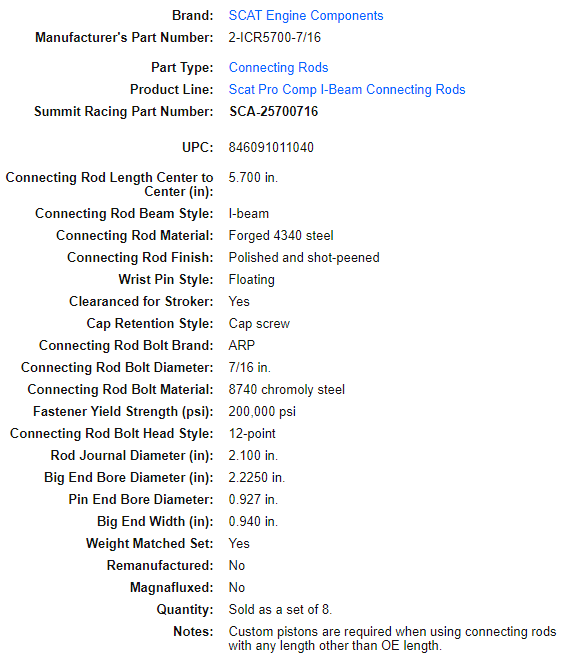

btw I would NEVER reuse the 400 sbc 5.565 rods, they are at least 40 years old,

have been through unknown millions of stress cycles,

and are well known to be a rather weak design,

that was originally designed for a lower to mid rpm torque engine,

intended mostly for pick-up trucks and luxury cars with automatic transmissions.

you can purchase 5.7" connecting rods that are

easily over twice as strong as the O.E.M. connecting rods used in a stock 400 sbc

for LESS,

than it would cost to rebuild ,resize and add ARP rod bolts to the original rods

below is only one of several dozen options if your building a performance SBC

https://www.summitracing.com/parts/sca-25700716

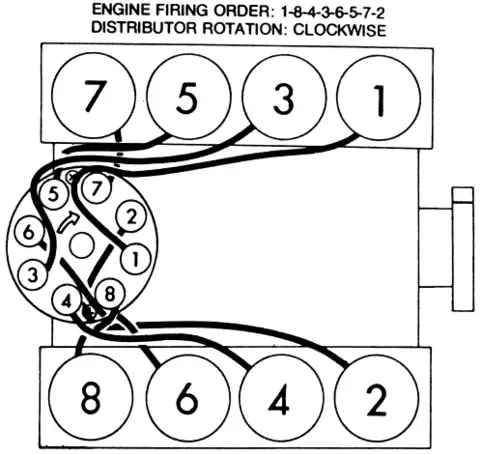

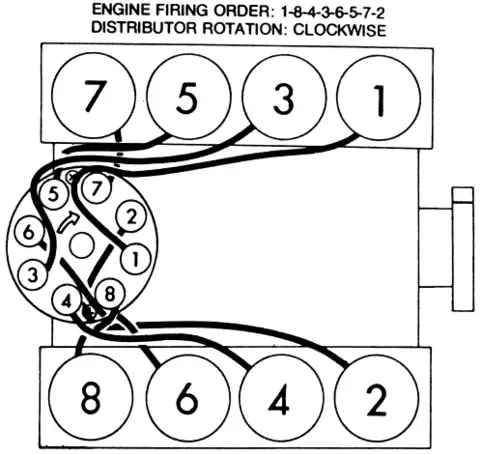

exhaust port numbers 3&5 and 4 &6 are next to each other, this tends to make that area of the sbc cylinder heads run hotter a more efficient water pump, forcing a bit more flow volume may help, as will a larger radiator and adding some

water wetter additives, and many guys find drilling steam holes on 400 sbc heads helps cooling issues, but keep in mind its oil flow rates that provide a significant percentage of the initial engine cooling.

many guys vastly under appreciate the cooling effect a 7-8 quart baffled oil pan and additional oil cooler,

have on the total heat transfer rates out of an engine compartment.

http://garage.grumpysperformance.com/index.php?threads/thoughts-on-cooling.149/

http://garage.grumpysperformance.com/index.php?threads/how-the-cooling-system-works-basics.853/

http://garage.grumpysperformance.com/index.php?threads/400-sbc-steam-holes-posted-by-dennyw.2991/

http://garage.grumpysperformance.co...pring-cooling-via-engine-oil.6491/#post-56753

http://garage.grumpysperformance.com/index.php?threads/choosing-an-engine-oil-cooler.15375/

http://garage.grumpysperformance.co...ing-system-flow-rates-and-heat-transfer.9880/

http://garage.grumpysperformance.co...g-fans-one-mostly-over-looked-component.2756/

http://garage.grumpysperformance.com/index.php?threads/do-i-need-the-fan-shroud.13847/

RELATED INFO

http://www.chevyhiperformance.com/techa ... index.html

http://www.gregsengine.com/converting-3 ... o-400.html

http://www.chevyhiperformance.com/techa ... index.html

YOU MAY WANT TO READ THRU THIS LINK ALSO

http://www.chevyhiperformance.com/techa ... ng_tricks/

http://garage.grumpysperformance.com/index.php?threads/water-wetter.2140/#post-5768

http://www.stewartcomponents.net/Mercha ... Code=Therm

how the cooling system works, basics

READ THE LINKS, POSTED IN THIS THREAD and their sub links ALSO Almost all engine combos run best, and have the least wear and emissions when your running a 180F-190F t-stat and the engine coolant temp stays in the 180F-210 f range, most of the time. keep in mind a t-stat does not limit the...

garage.grumpysperformance.com

any radiator needs a good large and effective multi blade fan shroud to match the fan and make air flow through that radiator much more efficient

buy and add a bottle, this stuff allows the micro surface contact of water inside the cylinder heads to allow a bit more efficient heat transfer rate, its no miracle, product , but its generally good for a 7-9 degree reduction in coolant heat.

tips on reducing the heat of your engine coolant,

you might also consider adding an oil cooler as oil does a great deal of the heat transfer inside any engine, thus reducing oil temperatures tends to reduce coolant temperatures.

Id also point out that,adding an auxiliary oil and/or trans mission fluid cooler with a powered fan, too the car, helps remove heat far more effectively and can remove a great deal of heat load from the radiator well before the coolant in the engine needs to deal with it

400 sbc engines have a reputation for running hotter than the average SBC thats only partially deserved

the 400 SBC used SIAMESE CYLINDER WALLS, and the average hot rodder , looking at the larger bore 400 block, only looked at the potential for increased displacement, and never put much thought into the engineering required to effectively use that increased bore diam. thus the fact the Siamese block design meant the coolant can't pass between the cylinders so heat does tend to have a very slightly lower surface area to allow coolant to absorb the heat generated from., for decades guys swapped the better flowing fuelie heads onto the larger displacement 400 based engines without adding the additional coolant steam holes, to help the Siamese cylinder wall block design, cool more effectively , and forget that if you increase compression, and produce significantly more horse power that power increase is the result of burning MORE FUEL BURNT FASTER, AT HIGHER AVERAGE RPMS, which, always results in producing higher average heat levels as a by product.

theres no free lunch , if you increase a 400 sbc power from a stock 185 hp two barrel engine that might have 9:1 compression that rarely saw 4500 rpm, into lets say a 406 SBC with better heads, 11:1 compression that, engine could easily, produce 470 hp , your going to reasonably expect nearly double the heat energy being produced.

a KNOWLEDGEABLE hot rodder, willing to think through the required modifications will have no trouble keeping a 400 SBC based engine cool

ONCE COOLANT BOILS it lost the full ability to absorb heat as partial direct contact with the metal surface is partially lost, one reason cooling systems are pressurized is to increase the boiling point threshold

The 5.7" rods vs the stock 5.565 " rods are a slight improvement in rod angularity and 6" rods would be slightly better but even the shorter rods work reasonably well if correctly clearanced and the rotating assembly balance as long as the rpms keep the piston speeds reasonable for the components being used (GENERALLY under 6200rpm)

READ THE LINKS AND SUB LINKS CAREFULLY

the cylinder heads, need to have extra "STEAM HOLES" drilled this allows coolant to more easily flow from the areas more prone to low coolant flow rates.

http://garage.grumpysperformance.com/index.php?threads/400-sbc-steam-holes-posted-by-dennyw.2991/

http://garage.grumpysperformance.com/index.php?threads/thoughts-on-cooling.149/

http://garage.grumpysperformance.com/index.php?threads/how-the-cooling-system-works-basics.853/

http://garage.grumpysperformance.co...ing-system-flow-rates-and-heat-transfer.9880/

http://garage.grumpysperformance.com/index.php?threads/water-wetter.2140/

use the correct sealants

http://garage.grumpysperformance.com/index.php?threads/sealants-and-threads.805/#post-1171

http://garage.grumpysperformance.co...venting-leaky-head-bolts-studs.50/#post-12528

using a surface tension destroying additive in the coolant like purple ice or water wetter can significantly reduce or prevent this, which is one of the reasons the 400 chevy has extra steam holes in the heads and gaskets

Solution

In an ideal world your coolant temp never exceeds 210F and spends most of its time around 180F-190F , oil MUST reach 215F occasionally during your cars operation, to burn off moisture and acids but should be at about 10 degrees hotter than the coolant, most good quality oil easily handles 240F for limited times, If I was you Id stick a 180F- or -190F T-stat in the car with several holes, ID custom drill in the flange, to allow some coolant flow at all times, this does slow the time required for the engine to reach operational temps but it alst tends to almost totally reduce the temperature swings as the t-stat opens and closes

buy a new 190F t-stat but before installing it drill 6 3/32" holes in the flange this mod usually prevents that problem and results in stable temps, stable temps are far less likely to result in a head gasket seal problem

a few 400-406 SBC related threads and tips

watch the videos, as they contain several tips you can use keep in mind that the 400 SBC , in O.E.M. form, has a larger , block bore diam. and larger crank bearing diam, and in factory form it uses shorter than the common 5.7" connecting rods, the larger bore allows the larger displacement for...

garage.grumpysperformance.com

http://www.newyorkrestomod.com/category_s/1820.htm

if you have the room mounting the coolant temp sensor in the radiator t-stat housing location with a custom spacer for the sensors, is a good option as it tends to read more consistently than sensors mounted in the cylinder head.

http://www.summitracing.com/parts/MEZ-WN0028U/?rtype=10

http://www.summitracing.com/parts/MEZ-WN0028U/?rtype=7

You should use a 400 head gasket as a template to mark the heads and Drill the 3 holes on the intake side using a 3/16 drill bit at a 10 degree angle towards the exhaust side of the head. Drill the 3 remaining holes using a 1/4 inch drill bit straight down towards the top of the head. 1- Start by marking the approximate steam hole locations with a marker or die. Next insert 2 dowel pins into the heads dowel pin holes and lay the 400 head gasket onto the head over the dowel pins. This will keep the gasket aligned precisely as you mark the holes. 2- Level the head with the deck side facing up and drill the 3 holes that run parallel to the exhaust side of the head using a 1/8 inch drill bit. The maximum size for these holes are .250 or 1/4 inch. 3- For the angled holes, level the head at 10 degrees so that you will be drilling from the intake side of the head down toward the exhaust side 4- To drill the remaining 3 holes in the head use a starter bit first then switch to a 1/8 inch drill bit. This will make it easier to get the holes started on angle without drill deflection. The maximum size for these holes are .187 or 3/16 inch. 5- clean off heads with brack clean or parts cleaner. use a new head gasket to make sure holes are correct.

I borrowed this info long ago, because all the pictures were there, and I hope it's ok to post here. This is a vital part on Head procedures. I always have done this when redoing heads. If the holes aren't there, they soon will be. Not that hard to do either.smile

The cylinder heads on the Small Block Chevy 400 were prone to crack and the cores for this engine are increasingly more difficult to find. Machining the 350ci cylinder heads to match the 400ci heads is an excellent way to keep your 400ci engine alive.

To use the Small Block Chevy 350 head on a 400 block, it will be necessary to drill six 1/8 inch holes in the cylinder heads. Use a 400 head gasket as a template to mark the heads and Drill the 3 holes on the intake side at a 40 degree angle towards the exhaust side of the head. Drill the 3 remaining holes straight down towards the top of the head.

PROCEDURE

1. Start by marking the approximate steam hole locations with a marker or die. Next insert 2 dowel pins into the heads dowel pin holes and lay the 400 head gasket onto the head over the dowel pins. This will keep the gasket aligned precisely as you mark the holes.

2. Level the head with the deck side facing up and drill the 3 holes that run parallel to the exhaust side of the head using a 1/8 inch drill bit. The maximum size for these holes are .250 or 1/4 inch.

3. For the angled holes, level the head at 40 degrees so that you will be drilling from the intake side of the head down toward the exhaust side as shown in the picture below.

4. To drill the remaining 3 holes in the head use a starter bit first then switch to a 1/8 inch drill bit. This will make it easier to get the holes started on angle without drill deflection. The maximum size for these holes are .156 or 5/32 inch.

The finished heads with the steam holes drilled and a 3 angle valve job.

Marine Use: The SBC 400 engine is not a good choice for use in marine applications unless you have a closed water system. The steam holes tend to get plugged up rather quickly followed by a blown head gasket. If you do choose the 400 engine for marine use then the maximum diameter steam holes may help. A better choice for use in a marine application would be the 350 engine or 383 stroker engine.

STEAM HOLES

In applications where a 400 engine block is used, you must drill six 9/64†steam holes in the

cylinder heads. With the head upside down use the 400 head gasket as a template to mark the

locations of the holes to be drilled. The three holes on the intake side should be drilled at a 30

degree angle towards the center of the head and may need to be over one inch deep. The

remaining three holes are drilled straight down towards the top of the head.

Intake Side - Drill these 3 holes at 30° angle towards the

exhaust side of head.

Exhaust Side - Drill these 3 straight holes

You should use a 400 head gasket as a template to mark the heads and Drill the 3 holes on the intake side using a 3/16 drill bit at a 10 degree angle towards the exhaust side of the head. Drill the 3 remaining holes using a 1/4 inch drill bit straight down towards the top of the head. 1- Start by marking the approximate steam hole locations with a marker or die. Next insert 2 dowel pins into the heads dowel pin holes and lay the 400 head gasket onto the head over the dowel pins. This will keep the gasket aligned precisely as you mark the holes. 2- Level the head with the deck side facing up and drill the 3 holes that run parallel to the exhaust side of the head using a 1/8 inch drill bit. The maximum size for these holes are .250 or 1/4 inch. 3- For the angled holes, level the head at 10 degrees so that you will be drilling from the intake side of the head down toward the exhaust side 4- To drill the remaining 3 holes in the head use a starter bit first then switch to a 1/8 inch drill bit. This will make it easier to get the holes started on angle without drill deflection. The maximum size for these holes are .187 or 3/16 inch. 5- clean off heads with brack clean or parts cleaner. use a new head gasket to make sure holes are correct.

btw I would NEVER reuse the 400 sbc 5.565 rods, they are at least 40 years old,

have been through unknown millions of stress cycles,

and are well known to be a rather weak design,

that was originally designed for a lower to mid rpm torque engine,

intended mostly for pick-up trucks and luxury cars with automatic transmissions.

you can purchase 5.7" connecting rods that are

easily over twice as strong as the O.E.M. connecting rods used in a stock 400 sbc

for LESS,

than it would cost to rebuild ,resize and add ARP rod bolts to the original rods

below is only one of several dozen options if your building a performance SBC

https://www.summitracing.com/parts/sca-25700716

exhaust port numbers 3&5 and 4 &6 are next to each other, this tends to make that area of the sbc cylinder heads run hotter a more efficient water pump, forcing a bit more flow volume may help, as will a larger radiator and adding some

water wetter additives, and many guys find drilling steam holes on 400 sbc heads helps cooling issues, but keep in mind its oil flow rates that provide a significant percentage of the initial engine cooling.

many guys vastly under appreciate the cooling effect a 7-8 quart baffled oil pan and additional oil cooler,

have on the total heat transfer rates out of an engine compartment.

http://garage.grumpysperformance.com/index.php?threads/thoughts-on-cooling.149/

http://garage.grumpysperformance.com/index.php?threads/how-the-cooling-system-works-basics.853/

http://garage.grumpysperformance.com/index.php?threads/400-sbc-steam-holes-posted-by-dennyw.2991/

http://garage.grumpysperformance.co...pring-cooling-via-engine-oil.6491/#post-56753

http://garage.grumpysperformance.com/index.php?threads/choosing-an-engine-oil-cooler.15375/

http://garage.grumpysperformance.co...ing-system-flow-rates-and-heat-transfer.9880/

http://garage.grumpysperformance.co...g-fans-one-mostly-over-looked-component.2756/

http://garage.grumpysperformance.com/index.php?threads/do-i-need-the-fan-shroud.13847/

RELATED INFO

http://www.chevyhiperformance.com/techa ... index.html

Last edited by a moderator: