below youll find a good deal of info on the 8100 vortec big block, the problem is that it was only in production for a rather limited time frame and performance parts available ar rather limited and fairly expensive, the good part is the engines can be occasionally found in salvage yards and don,t command a huge premium in cash like the performance 427-454-502 fourth gen bbc engines.

keep in mind you can generally build a standard fourth gen 496 displacement bbc engine buy installing a 4.25" stroke crank, in a 454 with a .060 over bore (the big block version of the 3.75' stroker crank in as 350 SBC with a .030 over bore, to build a 383)

496 VORTEC = 4.250" bore diam. x 4.37" stroke (2001 Vortec 8100, 8.1 liter)

http://www.raylarengineering.com/intake_manifold.html

https://www.youtube.com/watch?v=6qGrsEp_WxI

Part Numbers used for my swap: Keep in mind, my part numbers are for use with a manual transmission, mechanical throttle body and return type fuel system along with the G-van/Workhorse/Medium duty accessory brackets.

Part Number Description

52445253 A/C compressor

11516360 A/C compressor bolts

12581203 Belt tensioner

11516367 Belt tensioner bolt

12578330 Coolant Crossover

12571593 Coolant Crossover gasket

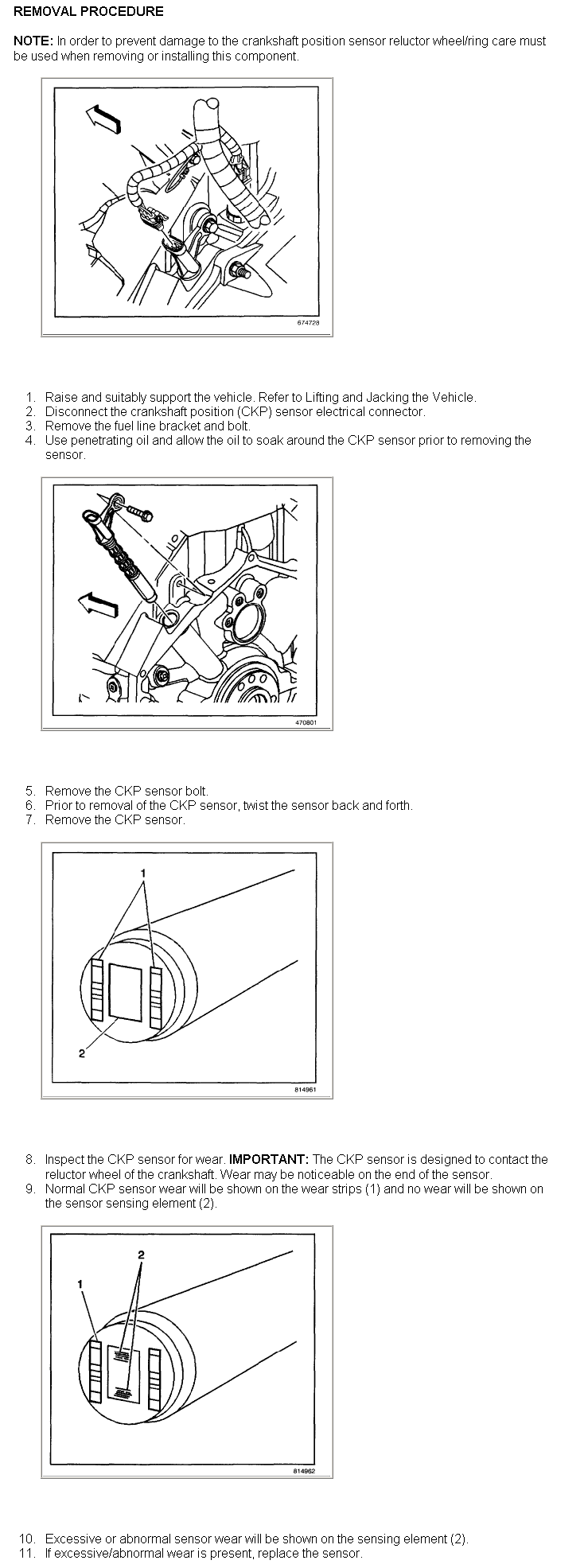

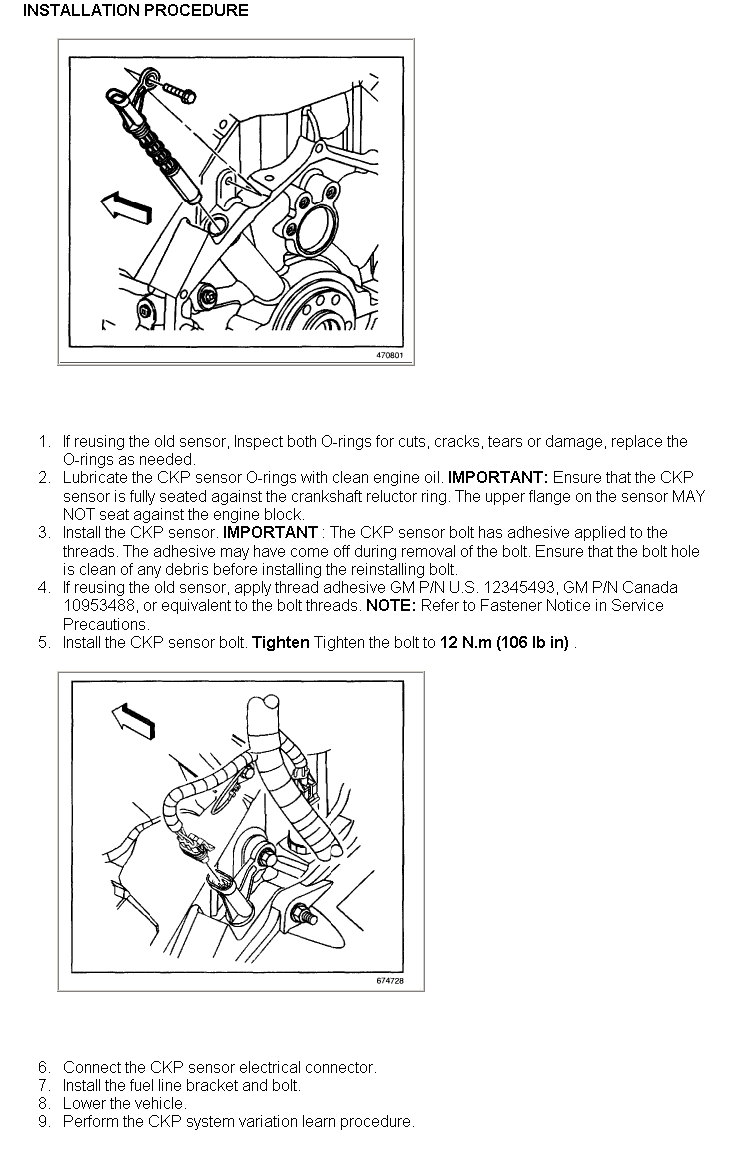

12575172 Crank Sensor

12575123 Dipstick

12570590 Dipstick tube

12559976 EGR Cover

12580673 EGR Cover gasket

12574560 Engine Cover

12567370 Engine Cover Ball Stud

12562957 Engine Cover Bracket

12562958 Engine Cover Bracket Stud

12582964 Flywheel

12563485 Flywheel bolts

EP381 Fuel pump

W0000393 HOUSING ASM - PCM

12580771 Idler on alternator bracket

213-298 Knock sensor - Drivers side

213-2829 Knock sensor - Passenger

12573337 Oil Cap

12573337 Oil Cap

12581140 Oil Fill Tube

11518950 Oil fill tube stud

12568356 Oil pump drive

12575055 RAIL KIT,M/PORT F/INJN FUEL

17096144 Throttle body (1998 L29 7.4L)

12570168 Throttle body gasket

1000LS1U Throttle cable

20416 Upper rad hose (Gates)

When swapping one of these engines in to a pre-GMT400 truck, the ORD HD engine crossmember works perfectly to address oil pan clearance. Taking a torch to the stock crossmember is just hacky…buy a nice ORD piece.

Swap info:

- The L18 8.1L has the same foot print as older BBC engines and will bolt in the same as any other older SBC and BBC. In fact, the L18 will accept any exhaust manifold or header from older BBC engines. The starter motor from any older SBC and BBC for use with a 168 tooth flywheel will also fit the L18. Any transmission from an old PowerGlide, TH350, TH400 to Allison, to NV4500, etc. will bolt on to it as well.

It is not required to run electronic throttle control on these engines. If you choose to keep it simple and reliable like I did, you can use a 1996-2000 L29 7.4L cable operated throttle body on the 8.1L. Cruise control could be adapted to mechanical TB buy using the cruise control controller from a L29 as well. An aftermarket TB spacer is required to be able to use the L29 TB in order to allow room for the arm to swing.

- These engines love higher than spec fuel pressure. Crank it up to about 67-68 psi and watch it come alive! (The adjustable fuel pressure regulator makes the early 2001-2003 fuel rails more desirable).

- There are 4 different accessory bracket designs used on these engines. In my experience, the G-van/Workhorse/GM Medium Duty accessory brackets are ideal for swapping into a vehicle with A/C as the A/C compressor is located up high on the driver’s side whereas the Silverado/Sierra brackets position the A/C compressor down low on the passenger’s side which causes a major frame clearance issue during swapping. To convert a pickup truck L18 to the the high mount compressor design the water pump, crank pulley/balancer must be replaced as well. Don’t be that guy to hack up a frame to make room for the A/C compressor! If not running A/C, the Silverado/Sierra brackets will work fine. More information on that below.

Wiring: Like any late model engine swap, there are many different avenues for wring these engines. I personally do not like going the route of reworked donor truck harnesses. There is just too much that needs to be removed from a donor harness to bring it down to a manageable/clean size and the margin of error while rewiring it is just too great. In my opinion the only way to go is start with a fresh stand- alone harness from Howell Engine Development or one of the many other good harness suppliers out there.

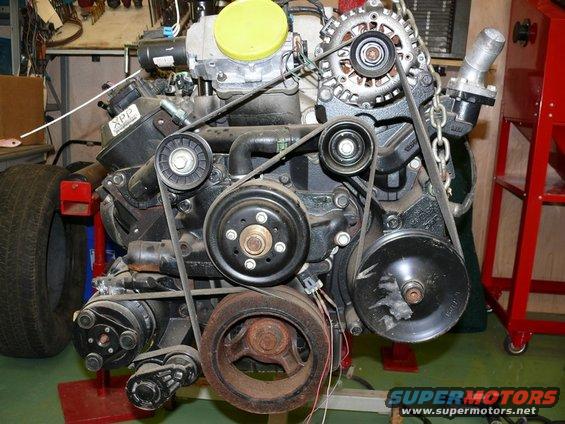

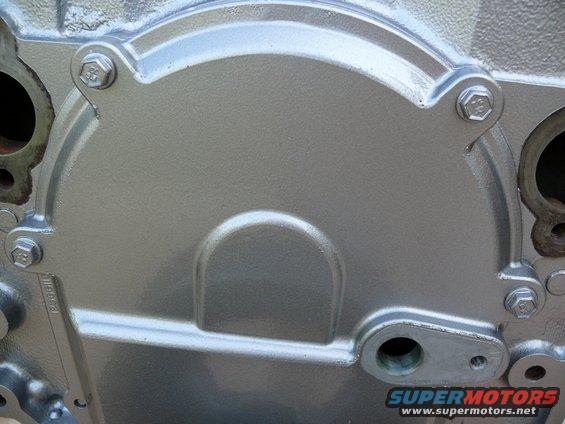

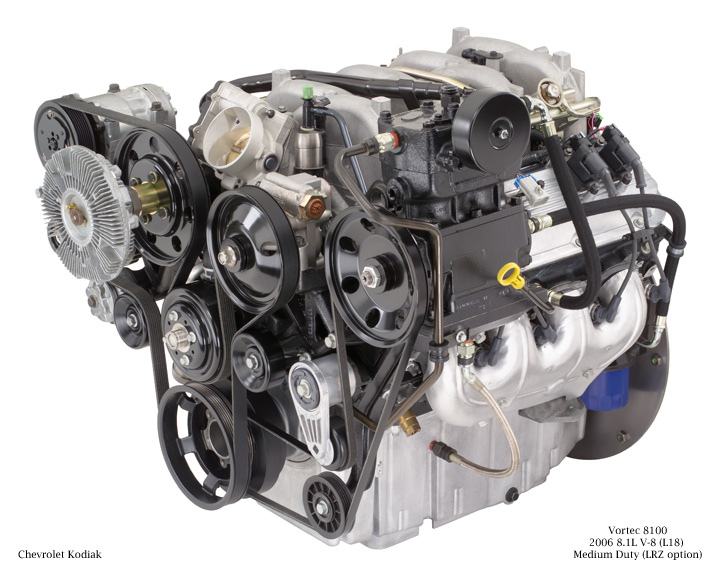

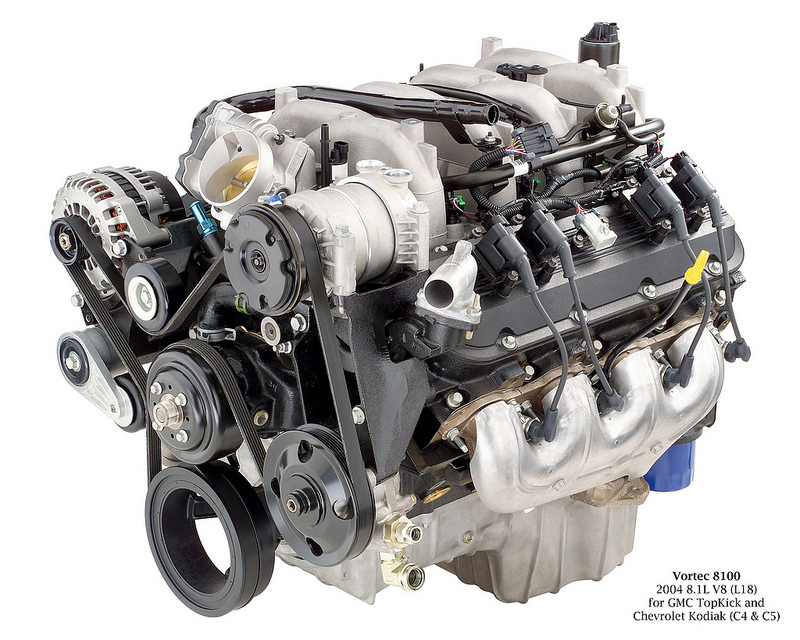

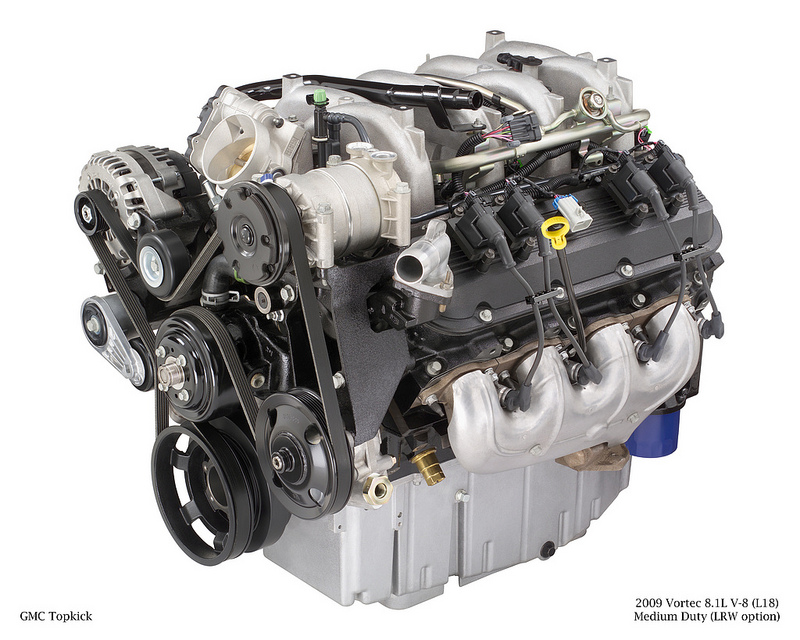

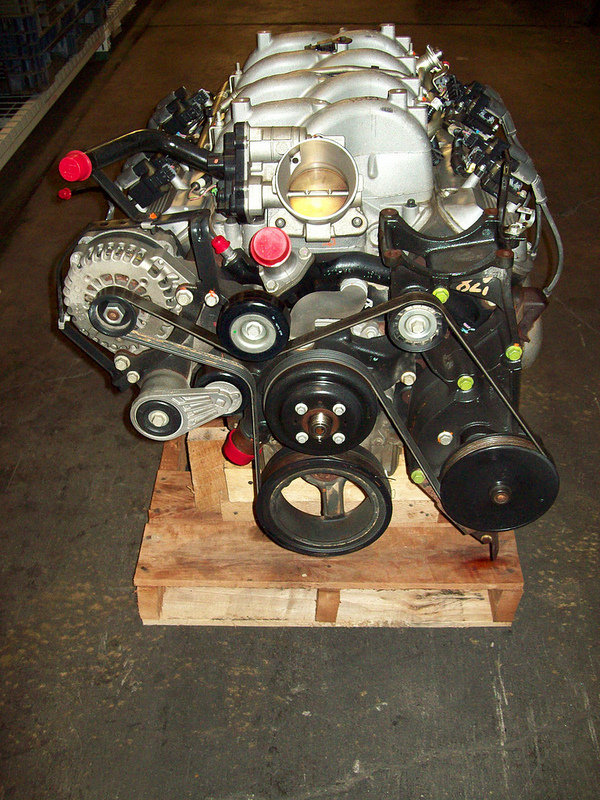

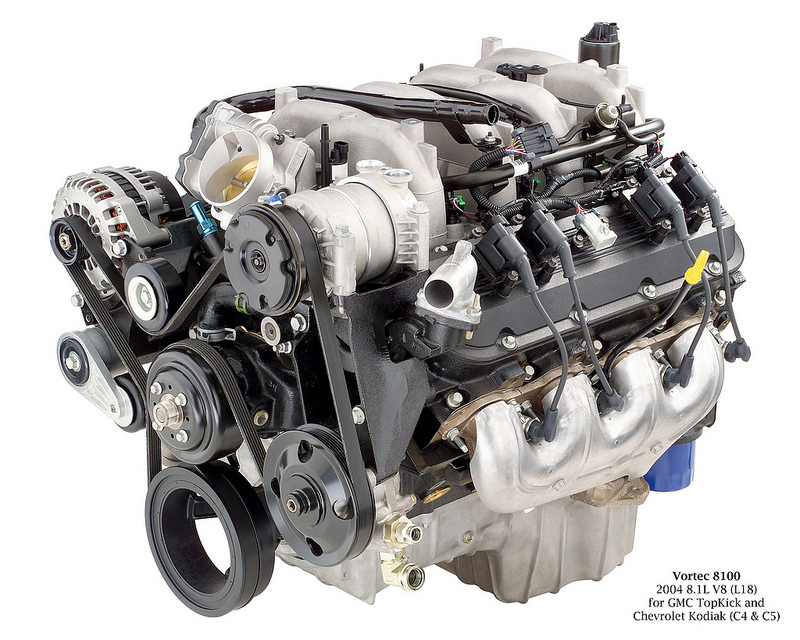

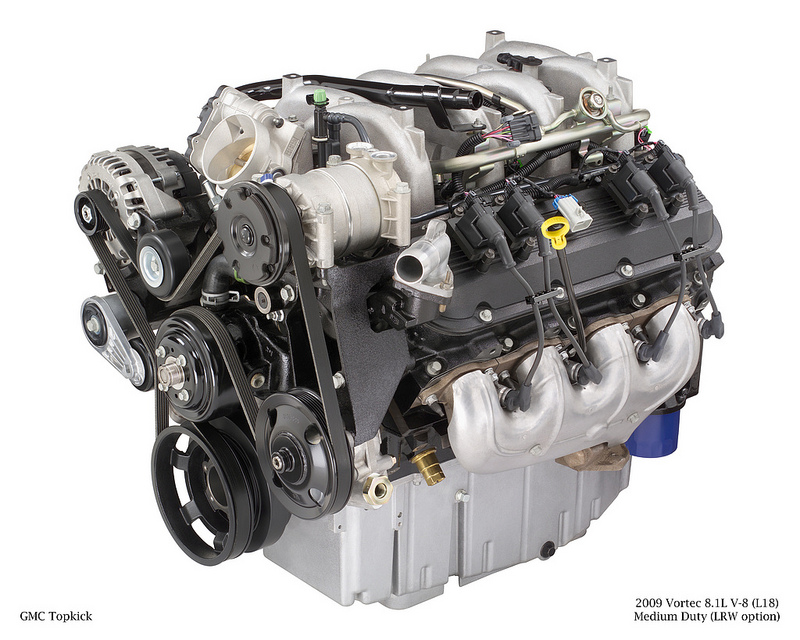

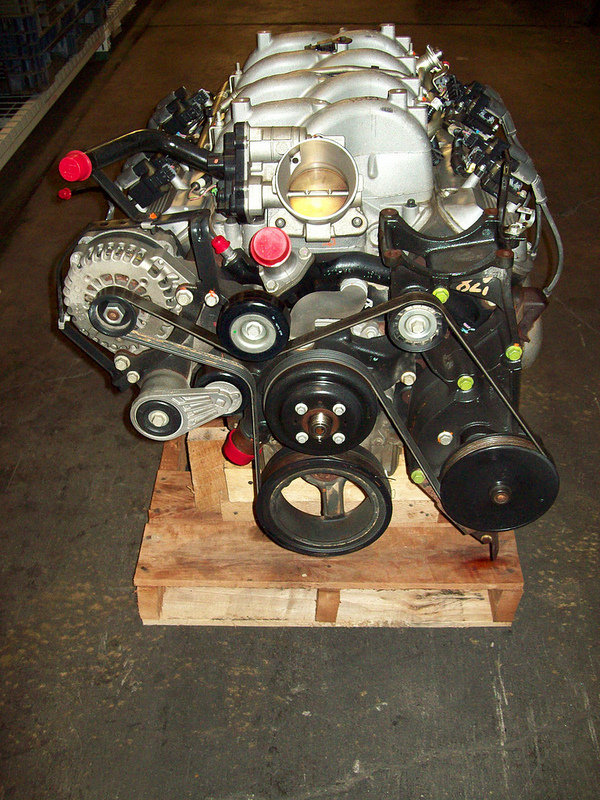

Identification Photo’s:

This is the most commonly found accessory bracket design, as it is the Silverado/Sierra setup. The location of the A/C compressor causes frame interference when swapping into an older truck. If installing into a non-A/C vehicle these brackets are great. Just remove this compressor and eliminate the belt.

http://www.lt1swap.com/vortec8100.htm

http://mcspeed.homestead.com/Killer-II.html

http://www.raylarengineering.com/vortec ... parts.html

http://www.digitalcorvettes.com/forums/ ... p?t=148376

http://www.dartheads.com/products/cylin ... -head.html

http://archives.media.gm.com/us/powertr ... 0Block.pdf

The 2001 truck line includes a new 8.1 liter 496 cubic inch "8100" big block. The bore will remain at 4.250", but the stroke will be increased to 4.370". The firing order is also new 1-8-7-2-6-5-4-3 and features individual ignition coils mounted near the spark plugs, similar to the LS1 Gen. III smallblocks. CR is 9.1-1 and it uses Sequential Fuel Injection (SFI). All 8.1 liter BBC production motors come with an internally balanced crank, four bolt main caps and redesigned heads with equal length port runners. The 2001 model 8.1 liter BBC uses a roller hydraulic cam and makes 340HP @ 4200 rpm and 455 ft./lbs. @ 3200 rpm. You'll be able to get either an Allison 1000 5-speed auto trannie or a new ZF S6-650 six speed manual gearbox with this new big block. Both trannies are built for a maximum of 520 ft./lbs. of torque.

The Marine versions of the 8.1 liter big block comes in two power levels, a 375hp/490 ft./lb. model or a 415hp/490 ft./lb model.

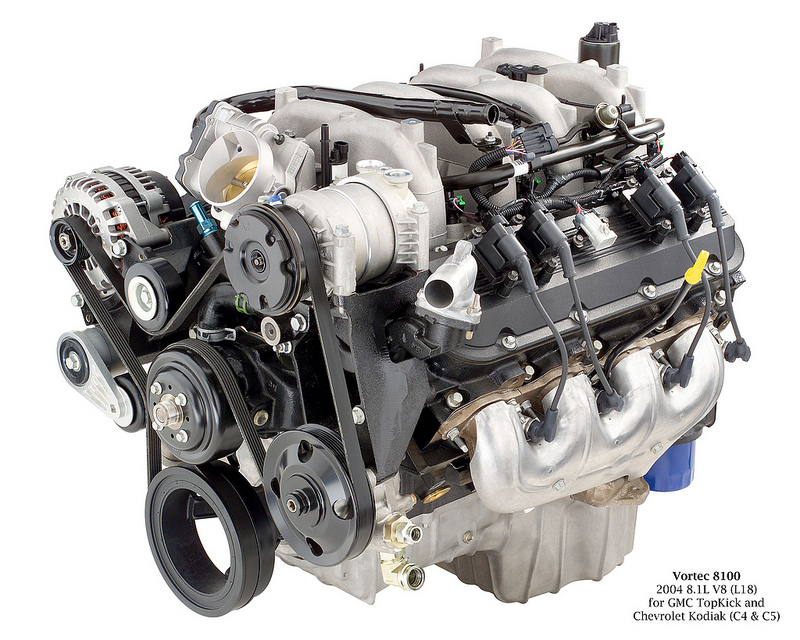

8100

The Vortec 8100 (RPO L18) is a V8 truck engine. It is a redesigned Chevrolet Big-Block engine and was introduced with the 2001 full-size pickup trucks. It retains the same bore centers as the old 7.4 L big-blocks, but stroke was upped by 9.4 mm to reach 8.1L (496cuin) for a total of 107.95 mm bore and 111 mm stroke. It is an all-iron engine (block and heads) with two valves per cylinder. Power output ranges from 225 hp (168 kW) to 340 horsepower (250 kW) and torque from 350 lb·ft (475 N·m) to 455 lb·ft (617 N·m). Vortec 8100s are built in Tonawanda, New York. The Vortec 8100 is the engine used in the largest Uhaul, their 26-foot (7.9 m) truck. GM stopped installing big block V-8's in the Silverado HD trucks, when the GMT-800 series was discontinued in 2007

http://www.sae.org/automag/techbriefs_05-00/11.htm

http://www.raylarengine.com/index.html

http://powerandmotoryacht.com/engines/0101vortec/

2005 Model Year Summary

· New for Chevrolet Kodiak and GMC TopKick with four-wheel drive

· Floating pin pistons

· Returnless fuel injection for marine applications

· Improved oil pan (for medium duty applications)

· Improved throttle actuator control module

· Rate-based diagnostics

· GF-4 engine oil

FULL DESCRIPTIONS OF NEW OR CHANGED FEATURES

NEW FOR CHEVROLET KODIAK AND GMC TOPKICK WITH FOUR-WHEEL DRIVE

For 2005, the Vortec 8100 will be available in Chevrolet Kodiak and GMC Topkick medium-duty trucks with four-wheel drive. Vortec 8100s built for this application require packaging adjustments to accommodate a front transaxle, including exhaust manifolds, heat shields and starter motor.

FLOATING PIN PISTONS

The Vortec 8100 is fitted with new floating-pin pistons. Introduced previously on GM Powertrain’s Vortec 6000 V-8, these pistons feature wrist pins that “float” inside the rod bushing and the pin bores in the piston barrel. Previously, the Vortec 8100 used a fixed-pin assembly, in which the connecting rod is fixed to the piston’s wrist pin, and the pin rotates in the pin bore. In the Vortec 8100, snap rings now retain the wrist pin in the piston, while the rod moves laterally on a bushing around the pin.

The Vortec 8100’s pistons, piston rings and connecting rods are identical to those used in 2004. The new floating-pin assembly allows tighter pin to pin-bore tolerances and reduces noise generated during engine operation.

RETURNLESS FUEL INJECTION FOR MARINE APPLICATIONS

All Vortec 8100s built for marine application are equipped with a new ``returnless’’ fuel injection system that eliminates fuel return lines between the engine and the gasoline tank. The new fuel system is also known as a demand system, and was introduced on Vortec 8100s built for the Chevrolet Silverado and GMC Sierra for model year 2004.

Before model year 2004, the sequential fuel injection (SFI) on all Vortec 8100s used a return line to manage fuel pressure by bleeding off excess fuel at the fuel rail and returning the excess to the tank. The new system eliminates the return lines and moves the fuel pressure regulator from the fuel rail on the engine to the fuel tank. The fuel line from the tank now includes pulse dampeners, or a series of baffles, that manage fuel pulsing and limit noise.

Because it delivers only the amount of fuel need by the injectors, and returns no fuel to the gas tank, the returnless system essentially eliminates heat transfer from the engine to tank. This reduces the amount of vapor generated in the tank and released as evaporation. The returnless system has been introduced on marine engines to give marine customers the same emissions standards and efficient operation as truck customers.

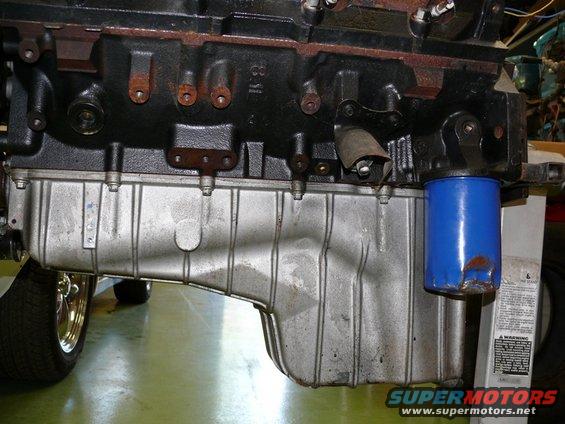

IMPROVED OIL PAN FOR MEDIUM DUTY AND MARINE APPLICATIONS

The oil pan on Vortec 8100s built for medium-duty (C4-C8 trucks) and marine use has been redesigned. This cast aluminum oil pan is essentially identical for both applications, with differences limited to final machining.

With the new pan, the interior baffle has been reconfigured to maximize oil flow, improve durability and stiffen the cast-aluminum pan’s structure, further reducing engine vibration. Moreover, sump capacity for medium-duty trucks increases 3.1 liters. The change was driven by the demands of the commercial fleet and rental markets. Rental truck customers may not be the most diligent operators when it comes to monitoring oil levels. The larger sump adds an extra measure of security for rental companies and fleet operators, even if customers use trucks for weeks without checking oil levels.

IMPROVED THROTTLE ACTUATOR CONTROL MODULE

All Vortec 8100’s are equipped with an improved throttle actuator control (TAC) module. Located on the throttle body, the TAC module is an integral component of the Vortec 8100’s electronic throttle control (ETC) system. The TAC takes command from the powertrain control module (PCM) and then operates the motor that opens and closes the throttle plate.

The TAC module has new read-only memory and control software. Like its predecessor, it allows multiple throttle progressions or algorithms, which operate the throttle at varying rates according to operating conditions and driver demands. It also has built-in default settings that protect the engine and ensure safe operation in the event of malfunction with the ETC or other engine subsystems.

RATE-BASED DIAGNOSTICS

The Vortec 8100’s powertrain control module (PCM) uses a new monitoring protocol known as rate-based diagnostics. Rate-based diagnostics improve the robustness of the Onboard Diagnostics System (OBD II) and ensure optimal performance of emissions control systems.

With rate-based diagnostics, the PCM applies a new formula to manage OBD II. Essentially, new software increases the frequency at which the PCM checks various engine systems, and particularly emissions-control systems such as the catalytic converter, oxygen sensors and exhaust gas recirculation (EGR). Rate-based diagnostics more reliably monitor real-word operation of these systems, and allow regulatory agencies to more easily measure and certify emissions compliance. The new protocol allows the Vortec 8100 to meet more stringent OBD II requirements two years ahead of a mandate by the California Air Resources Board.

GF-4 ENGINE OIL

All Vortec 8100s will be shipped to customers with a new engine oil that reduces engine deposits, extends oil change intervals, improves fuel economy and extends the life of emissions control systems. GM Powertrain has taken a leading role in developing and introducing the new oil, designated GF-4 (for “Gasoline Fueled, Standard 4’’) by the American Petroleum Institute.

GF-4 contains a new ash-free antioxidant ingredient and less phosphorous than the previous formulation (GF-3). The typical automotive engine now operates at a much higher temperature than an engine built 10 years ago. GF-4 is twice as resistant to oxidizing, which can present itself as foaming, at high operating temperatures. At the same time, GF-4 provides better low-temperature protection, reducing engine wear during the critical cold-start period. Lower phosphorus and sulfur content – chemicals that are harmful to catalytic converters – will extend anticipated catalyst life beyond 120,000 miles. Finally, GF-4 lowers friction overall and retains its optimal friction-reducing characteristics longer. The result is an anticipated improvement of 0.2 percent to 0.3 percent in an engine’s fuel economy, and longer oil change intervals.

Production of Vortec 8100s with GF-4 begin in fall 2004, ahead of an industry recommendation of April 30, 2005. This will allow vehicles with the Vortec 8100 to be tested for 2005 Corporate Average Fuel Economy (CAFE) standards with GF-4. GM’s industry-leading Oil Life System may be adjusted to account for the new oil. The owner’s manual in vehicles equipped with the Vortec 8100 will continue to recommend oil with the Starburst logo, which must be certified to GF-4 by May 2005.

OVERVIEW

Few words generate excitement for car and truck enthusiasts like ‘’Big Block.’’ The Vortec 8100 V-8 is the legendary GM Big Block for a new millennium, with a longer expected useful life and horsepower and torque that surpass the large displacement gasoline engines offered in competitors’ heavy-duty pickups. This heavy-duty engine also sets benchmarks for marine and industrial application worldwide.

Introduced in the 2001 Chevrolet Silverado and Suburban and GMC Sierra and Yukon XL, the Vortec 8100 was essentially a new engine. Nearly 90 percent of its parts have been completely redesigned. While it shares its valve centers, bore centers and bore diameter with the previous 7.4L Big Block, stroke was increased 9.4 mm (.37 inch) to increase displacement 700 cc. The latest math-based engineering tools were used to improve the flow and distribution of oil and coolant, to refine castings and to improve production quality and efficiency.

After extensive analysis of competitors' engines, the Vortec 8100 development team set a goal of 200,000 miles of useful life without major repairs – and then achieved it. Before it was ready for production, this big block had to pass the “Marine Dock'' test, in which it is run at full throttle for 300 consecutive hours without a failure, and a minimum of 1,000 hours at full-throttle operation for truck applications.

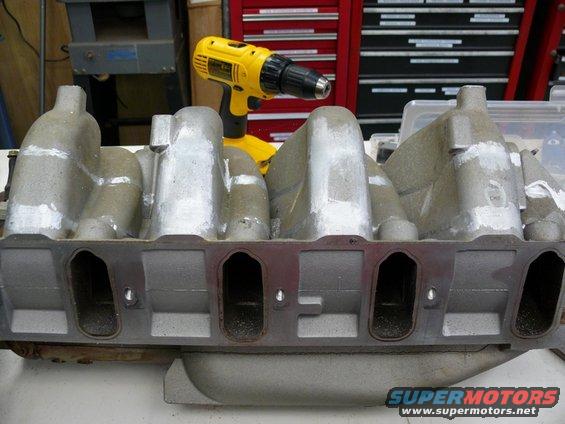

In the four years since its launch, virtually every aspect of the engine – from sealing to electronic management to noise, vibration and harshness control – has been re-examined and improved. For 2004, Vortec 8100s built for truck installation were equipped with a new returnless fuel injection system that eliminated fuel return lines between the engine and the gasoline tank and reduced evaporative emissions. Combined with new intake manifold and throttle body gaskets, manufactured of an advanced fluorocarbon material that is virtually impermeable to hydrocarbon molecules, the returnless fuel system allows the Vortec 8100 to meet near-zero evaporative emissions standards. Also in 2004, Vortec 8100s built for industrial applications were equipped with new valves, valve seat material and springs designed expressly for industrial operation at low, steady rpm.

GM's leadership in big-block V-8 technology dates to at least 1958, when the Vortec 8100's progenitor was launched with 348 cubic inches of displacement in the full-size 1958 Chevrolets. The 348 was followed by several variants, including a 409, 366 and 427. In 1970, the 454-cubic-inch big-block was introduced. It was retooled in 1991 as the Vortec 7400 – a truly powerful pickup engine that met stringent 1990s emission requirements. The Vortec 8100 bears little resemblance to those engines, but it maintains a tradition of outstanding durability and class-leading power.

__________________

keep in mind you can generally build a standard fourth gen 496 displacement bbc engine buy installing a 4.25" stroke crank, in a 454 with a .060 over bore (the big block version of the 3.75' stroker crank in as 350 SBC with a .030 over bore, to build a 383)

496 VORTEC = 4.250" bore diam. x 4.37" stroke (2001 Vortec 8100, 8.1 liter)

http://www.raylarengineering.com/intake_manifold.html

https://www.youtube.com/watch?v=6qGrsEp_WxI

Part Numbers used for my swap: Keep in mind, my part numbers are for use with a manual transmission, mechanical throttle body and return type fuel system along with the G-van/Workhorse/Medium duty accessory brackets.

Part Number Description

52445253 A/C compressor

11516360 A/C compressor bolts

12581203 Belt tensioner

11516367 Belt tensioner bolt

12578330 Coolant Crossover

12571593 Coolant Crossover gasket

12575172 Crank Sensor

12575123 Dipstick

12570590 Dipstick tube

12559976 EGR Cover

12580673 EGR Cover gasket

12574560 Engine Cover

12567370 Engine Cover Ball Stud

12562957 Engine Cover Bracket

12562958 Engine Cover Bracket Stud

12582964 Flywheel

12563485 Flywheel bolts

EP381 Fuel pump

W0000393 HOUSING ASM - PCM

12580771 Idler on alternator bracket

213-298 Knock sensor - Drivers side

213-2829 Knock sensor - Passenger

12573337 Oil Cap

12573337 Oil Cap

12581140 Oil Fill Tube

11518950 Oil fill tube stud

12568356 Oil pump drive

12575055 RAIL KIT,M/PORT F/INJN FUEL

17096144 Throttle body (1998 L29 7.4L)

12570168 Throttle body gasket

1000LS1U Throttle cable

20416 Upper rad hose (Gates)

When swapping one of these engines in to a pre-GMT400 truck, the ORD HD engine crossmember works perfectly to address oil pan clearance. Taking a torch to the stock crossmember is just hacky…buy a nice ORD piece.

Swap info:

- The L18 8.1L has the same foot print as older BBC engines and will bolt in the same as any other older SBC and BBC. In fact, the L18 will accept any exhaust manifold or header from older BBC engines. The starter motor from any older SBC and BBC for use with a 168 tooth flywheel will also fit the L18. Any transmission from an old PowerGlide, TH350, TH400 to Allison, to NV4500, etc. will bolt on to it as well.

It is not required to run electronic throttle control on these engines. If you choose to keep it simple and reliable like I did, you can use a 1996-2000 L29 7.4L cable operated throttle body on the 8.1L. Cruise control could be adapted to mechanical TB buy using the cruise control controller from a L29 as well. An aftermarket TB spacer is required to be able to use the L29 TB in order to allow room for the arm to swing.

- These engines love higher than spec fuel pressure. Crank it up to about 67-68 psi and watch it come alive! (The adjustable fuel pressure regulator makes the early 2001-2003 fuel rails more desirable).

- There are 4 different accessory bracket designs used on these engines. In my experience, the G-van/Workhorse/GM Medium Duty accessory brackets are ideal for swapping into a vehicle with A/C as the A/C compressor is located up high on the driver’s side whereas the Silverado/Sierra brackets position the A/C compressor down low on the passenger’s side which causes a major frame clearance issue during swapping. To convert a pickup truck L18 to the the high mount compressor design the water pump, crank pulley/balancer must be replaced as well. Don’t be that guy to hack up a frame to make room for the A/C compressor! If not running A/C, the Silverado/Sierra brackets will work fine. More information on that below.

Wiring: Like any late model engine swap, there are many different avenues for wring these engines. I personally do not like going the route of reworked donor truck harnesses. There is just too much that needs to be removed from a donor harness to bring it down to a manageable/clean size and the margin of error while rewiring it is just too great. In my opinion the only way to go is start with a fresh stand- alone harness from Howell Engine Development or one of the many other good harness suppliers out there.

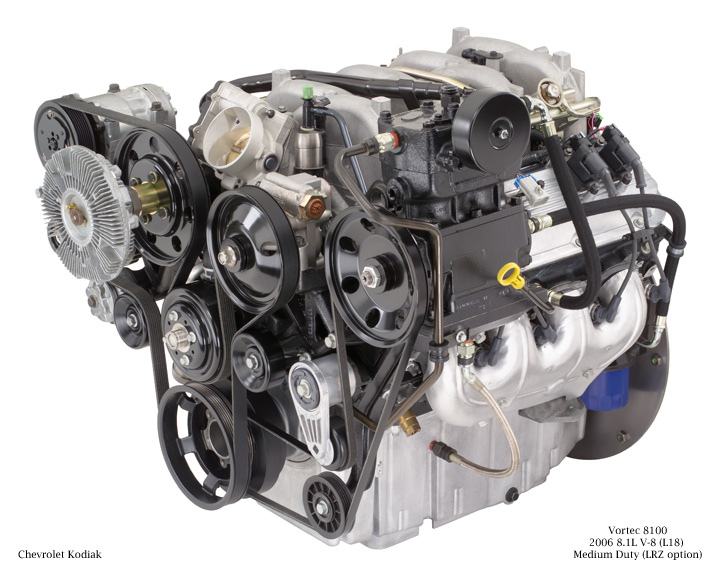

Identification Photo’s:

This is the most commonly found accessory bracket design, as it is the Silverado/Sierra setup. The location of the A/C compressor causes frame interference when swapping into an older truck. If installing into a non-A/C vehicle these brackets are great. Just remove this compressor and eliminate the belt.

http://www.lt1swap.com/vortec8100.htm

http://mcspeed.homestead.com/Killer-II.html

http://www.raylarengineering.com/vortec ... parts.html

http://www.digitalcorvettes.com/forums/ ... p?t=148376

http://www.dartheads.com/products/cylin ... -head.html

http://archives.media.gm.com/us/powertr ... 0Block.pdf

The 2001 truck line includes a new 8.1 liter 496 cubic inch "8100" big block. The bore will remain at 4.250", but the stroke will be increased to 4.370". The firing order is also new 1-8-7-2-6-5-4-3 and features individual ignition coils mounted near the spark plugs, similar to the LS1 Gen. III smallblocks. CR is 9.1-1 and it uses Sequential Fuel Injection (SFI). All 8.1 liter BBC production motors come with an internally balanced crank, four bolt main caps and redesigned heads with equal length port runners. The 2001 model 8.1 liter BBC uses a roller hydraulic cam and makes 340HP @ 4200 rpm and 455 ft./lbs. @ 3200 rpm. You'll be able to get either an Allison 1000 5-speed auto trannie or a new ZF S6-650 six speed manual gearbox with this new big block. Both trannies are built for a maximum of 520 ft./lbs. of torque.

The Marine versions of the 8.1 liter big block comes in two power levels, a 375hp/490 ft./lb. model or a 415hp/490 ft./lb model.

8100

The Vortec 8100 (RPO L18) is a V8 truck engine. It is a redesigned Chevrolet Big-Block engine and was introduced with the 2001 full-size pickup trucks. It retains the same bore centers as the old 7.4 L big-blocks, but stroke was upped by 9.4 mm to reach 8.1L (496cuin) for a total of 107.95 mm bore and 111 mm stroke. It is an all-iron engine (block and heads) with two valves per cylinder. Power output ranges from 225 hp (168 kW) to 340 horsepower (250 kW) and torque from 350 lb·ft (475 N·m) to 455 lb·ft (617 N·m). Vortec 8100s are built in Tonawanda, New York. The Vortec 8100 is the engine used in the largest Uhaul, their 26-foot (7.9 m) truck. GM stopped installing big block V-8's in the Silverado HD trucks, when the GMT-800 series was discontinued in 2007

http://www.sae.org/automag/techbriefs_05-00/11.htm

http://www.raylarengine.com/index.html

http://powerandmotoryacht.com/engines/0101vortec/

2005 Model Year Summary

· New for Chevrolet Kodiak and GMC TopKick with four-wheel drive

· Floating pin pistons

· Returnless fuel injection for marine applications

· Improved oil pan (for medium duty applications)

· Improved throttle actuator control module

· Rate-based diagnostics

· GF-4 engine oil

FULL DESCRIPTIONS OF NEW OR CHANGED FEATURES

NEW FOR CHEVROLET KODIAK AND GMC TOPKICK WITH FOUR-WHEEL DRIVE

For 2005, the Vortec 8100 will be available in Chevrolet Kodiak and GMC Topkick medium-duty trucks with four-wheel drive. Vortec 8100s built for this application require packaging adjustments to accommodate a front transaxle, including exhaust manifolds, heat shields and starter motor.

FLOATING PIN PISTONS

The Vortec 8100 is fitted with new floating-pin pistons. Introduced previously on GM Powertrain’s Vortec 6000 V-8, these pistons feature wrist pins that “float” inside the rod bushing and the pin bores in the piston barrel. Previously, the Vortec 8100 used a fixed-pin assembly, in which the connecting rod is fixed to the piston’s wrist pin, and the pin rotates in the pin bore. In the Vortec 8100, snap rings now retain the wrist pin in the piston, while the rod moves laterally on a bushing around the pin.

The Vortec 8100’s pistons, piston rings and connecting rods are identical to those used in 2004. The new floating-pin assembly allows tighter pin to pin-bore tolerances and reduces noise generated during engine operation.

RETURNLESS FUEL INJECTION FOR MARINE APPLICATIONS

All Vortec 8100s built for marine application are equipped with a new ``returnless’’ fuel injection system that eliminates fuel return lines between the engine and the gasoline tank. The new fuel system is also known as a demand system, and was introduced on Vortec 8100s built for the Chevrolet Silverado and GMC Sierra for model year 2004.

Before model year 2004, the sequential fuel injection (SFI) on all Vortec 8100s used a return line to manage fuel pressure by bleeding off excess fuel at the fuel rail and returning the excess to the tank. The new system eliminates the return lines and moves the fuel pressure regulator from the fuel rail on the engine to the fuel tank. The fuel line from the tank now includes pulse dampeners, or a series of baffles, that manage fuel pulsing and limit noise.

Because it delivers only the amount of fuel need by the injectors, and returns no fuel to the gas tank, the returnless system essentially eliminates heat transfer from the engine to tank. This reduces the amount of vapor generated in the tank and released as evaporation. The returnless system has been introduced on marine engines to give marine customers the same emissions standards and efficient operation as truck customers.

IMPROVED OIL PAN FOR MEDIUM DUTY AND MARINE APPLICATIONS

The oil pan on Vortec 8100s built for medium-duty (C4-C8 trucks) and marine use has been redesigned. This cast aluminum oil pan is essentially identical for both applications, with differences limited to final machining.

With the new pan, the interior baffle has been reconfigured to maximize oil flow, improve durability and stiffen the cast-aluminum pan’s structure, further reducing engine vibration. Moreover, sump capacity for medium-duty trucks increases 3.1 liters. The change was driven by the demands of the commercial fleet and rental markets. Rental truck customers may not be the most diligent operators when it comes to monitoring oil levels. The larger sump adds an extra measure of security for rental companies and fleet operators, even if customers use trucks for weeks without checking oil levels.

IMPROVED THROTTLE ACTUATOR CONTROL MODULE

All Vortec 8100’s are equipped with an improved throttle actuator control (TAC) module. Located on the throttle body, the TAC module is an integral component of the Vortec 8100’s electronic throttle control (ETC) system. The TAC takes command from the powertrain control module (PCM) and then operates the motor that opens and closes the throttle plate.

The TAC module has new read-only memory and control software. Like its predecessor, it allows multiple throttle progressions or algorithms, which operate the throttle at varying rates according to operating conditions and driver demands. It also has built-in default settings that protect the engine and ensure safe operation in the event of malfunction with the ETC or other engine subsystems.

RATE-BASED DIAGNOSTICS

The Vortec 8100’s powertrain control module (PCM) uses a new monitoring protocol known as rate-based diagnostics. Rate-based diagnostics improve the robustness of the Onboard Diagnostics System (OBD II) and ensure optimal performance of emissions control systems.

With rate-based diagnostics, the PCM applies a new formula to manage OBD II. Essentially, new software increases the frequency at which the PCM checks various engine systems, and particularly emissions-control systems such as the catalytic converter, oxygen sensors and exhaust gas recirculation (EGR). Rate-based diagnostics more reliably monitor real-word operation of these systems, and allow regulatory agencies to more easily measure and certify emissions compliance. The new protocol allows the Vortec 8100 to meet more stringent OBD II requirements two years ahead of a mandate by the California Air Resources Board.

GF-4 ENGINE OIL

All Vortec 8100s will be shipped to customers with a new engine oil that reduces engine deposits, extends oil change intervals, improves fuel economy and extends the life of emissions control systems. GM Powertrain has taken a leading role in developing and introducing the new oil, designated GF-4 (for “Gasoline Fueled, Standard 4’’) by the American Petroleum Institute.

GF-4 contains a new ash-free antioxidant ingredient and less phosphorous than the previous formulation (GF-3). The typical automotive engine now operates at a much higher temperature than an engine built 10 years ago. GF-4 is twice as resistant to oxidizing, which can present itself as foaming, at high operating temperatures. At the same time, GF-4 provides better low-temperature protection, reducing engine wear during the critical cold-start period. Lower phosphorus and sulfur content – chemicals that are harmful to catalytic converters – will extend anticipated catalyst life beyond 120,000 miles. Finally, GF-4 lowers friction overall and retains its optimal friction-reducing characteristics longer. The result is an anticipated improvement of 0.2 percent to 0.3 percent in an engine’s fuel economy, and longer oil change intervals.

Production of Vortec 8100s with GF-4 begin in fall 2004, ahead of an industry recommendation of April 30, 2005. This will allow vehicles with the Vortec 8100 to be tested for 2005 Corporate Average Fuel Economy (CAFE) standards with GF-4. GM’s industry-leading Oil Life System may be adjusted to account for the new oil. The owner’s manual in vehicles equipped with the Vortec 8100 will continue to recommend oil with the Starburst logo, which must be certified to GF-4 by May 2005.

OVERVIEW

Few words generate excitement for car and truck enthusiasts like ‘’Big Block.’’ The Vortec 8100 V-8 is the legendary GM Big Block for a new millennium, with a longer expected useful life and horsepower and torque that surpass the large displacement gasoline engines offered in competitors’ heavy-duty pickups. This heavy-duty engine also sets benchmarks for marine and industrial application worldwide.

Introduced in the 2001 Chevrolet Silverado and Suburban and GMC Sierra and Yukon XL, the Vortec 8100 was essentially a new engine. Nearly 90 percent of its parts have been completely redesigned. While it shares its valve centers, bore centers and bore diameter with the previous 7.4L Big Block, stroke was increased 9.4 mm (.37 inch) to increase displacement 700 cc. The latest math-based engineering tools were used to improve the flow and distribution of oil and coolant, to refine castings and to improve production quality and efficiency.

After extensive analysis of competitors' engines, the Vortec 8100 development team set a goal of 200,000 miles of useful life without major repairs – and then achieved it. Before it was ready for production, this big block had to pass the “Marine Dock'' test, in which it is run at full throttle for 300 consecutive hours without a failure, and a minimum of 1,000 hours at full-throttle operation for truck applications.

In the four years since its launch, virtually every aspect of the engine – from sealing to electronic management to noise, vibration and harshness control – has been re-examined and improved. For 2004, Vortec 8100s built for truck installation were equipped with a new returnless fuel injection system that eliminated fuel return lines between the engine and the gasoline tank and reduced evaporative emissions. Combined with new intake manifold and throttle body gaskets, manufactured of an advanced fluorocarbon material that is virtually impermeable to hydrocarbon molecules, the returnless fuel system allows the Vortec 8100 to meet near-zero evaporative emissions standards. Also in 2004, Vortec 8100s built for industrial applications were equipped with new valves, valve seat material and springs designed expressly for industrial operation at low, steady rpm.

GM's leadership in big-block V-8 technology dates to at least 1958, when the Vortec 8100's progenitor was launched with 348 cubic inches of displacement in the full-size 1958 Chevrolets. The 348 was followed by several variants, including a 409, 366 and 427. In 1970, the 454-cubic-inch big-block was introduced. It was retooled in 1991 as the Vortec 7400 – a truly powerful pickup engine that met stringent 1990s emission requirements. The Vortec 8100 bears little resemblance to those engines, but it maintains a tradition of outstanding durability and class-leading power.

__________________