- Home

- Forums

- Technical Articles/muscle cars

- C1-C6 Corvettes

- Engine: Repairs and Modifications & generally corv

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

84 CFI 383 suggestions

- Thread starter Gibbles

- Start date

maybe rick can run a software dyno

that 3200 stall converter will allow this cam to really work rather well.

especially with that intake and the 1.6:1 rockers

between the displacement upgrade swapping to a longer stroke crank, going to a 383 vs 350, and that increased cam duration,

Id be amazed if after its correctly tuned, you did not see a very noticeable increase in the seat of the pants feel,in the cars acceleration,

as theres the potential for at least an additional 60-70 hp.

obviously have a long talk with crower and your machine shop, and check clearances carefully

and (ID degree the cam in at split over-lap/strait up)

retard the cam timing 4 degees from the dot-to-dot install to strait up and your dynamic compression drops off marginally,

and you gain about 150 rpm in the power curve and loose about 15 ft lbs of off idle torque,

(youll still smoke the tires easily if the throttles pushed to the floor)

but carry the peak torque about 150 rpm higher, all will help the car traction and acceleration

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.co...ng-cam-and-shifting-the-lca.10553/#post-44949

http://garage.grumpysperformance.co...lding-a-350-or-upgrading-too-a-383-sbc.11408/

http://garage.grumpysperformance.co...ectly-and-get-it-to-last-cam-install-info.90/

http://garage.grumpysperformance.co...ing-a-383-sbc-combo-planing.12168/#post-58778

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

http://garage.grumpysperformance.com/index.php?threads/a-383-build.10991/#post-48513

http://garage.grumpysperformance.co...ild-a-350-or-a-383-sbc-combo.8310/#post-28891

http://garage.grumpysperformance.com/index.php?threads/small-base-circle-cams.3810/

http://garage.grumpysperformance.com/index.php?threads/bits-of-383-info.38/

http://garage.grumpysperformance.co...cs-of-starting-a-383-sbc-combo-planing.12168/

http://garage.grumpysperformance.com/index.php?threads/tweaking-a-350-383.13087/

Last edited:

Gibbles

Clicker of buttons

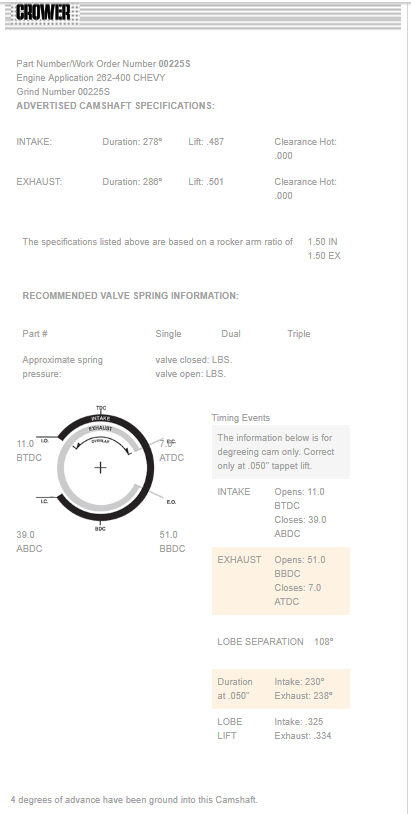

Looks like this baby: https://www.crower.com/camshafts/chevy-262-400-series-420-hyd-cam-small-base-circle-pro55.html

And we are getting much closer to the goal!

And we are getting much closer to the goal!

Will try to get to it tomorrow hopefully.maybe rick can run a software dyno

Will need type of heads and flow numbers.

Intake Manifold

Headers and Size

SCR

Gibbles

Clicker of buttons

Head info,

http://www.edelbrock.com/automotive/mc/cylinder-heads/chevy/e-street-sb.shtml

(Has flow numbers in the link)

Combustion chamber volume: 70cc

Intake runner volume: 185cc

Exhaust runner volume: 60cc

Intake valve diameter: 2.02"

Exhaust valve diameter: 1.60"

Valve stem diameter: 11/32"

Valve guides: Manganese bronze

Deck thickness: 9/16"

Valve spring diameter: 1.460"

Valve spring maximum lift: .550"

Rocker stud: 3/8" with guide plate

Guideplate: Hardended steel

Pushrod diameter: 5/16"

Valve angle: 23°

Intake; it's the renegade, but i don't see those details available...

Headers; melrose long tubes, 1 3/4 primaries

For scr, looking for what it is now, or what it will be?

(See above sheet, current is engine #3.

Possible future is engine #4)

http://www.edelbrock.com/automotive/mc/cylinder-heads/chevy/e-street-sb.shtml

(Has flow numbers in the link)

Combustion chamber volume: 70cc

Intake runner volume: 185cc

Exhaust runner volume: 60cc

Intake valve diameter: 2.02"

Exhaust valve diameter: 1.60"

Valve stem diameter: 11/32"

Valve guides: Manganese bronze

Deck thickness: 9/16"

Valve spring diameter: 1.460"

Valve spring maximum lift: .550"

Rocker stud: 3/8" with guide plate

Guideplate: Hardended steel

Pushrod diameter: 5/16"

Valve angle: 23°

Intake; it's the renegade, but i don't see those details available...

Headers; melrose long tubes, 1 3/4 primaries

For scr, looking for what it is now, or what it will be?

(See above sheet, current is engine #3.

Possible future is engine #4)

Loves302Chevy

"One test is worth a thousand expert opinions."

Per Edlebrock I would have to have the heads modified for different springs if I went roller, or over .550 lift.

Gibbles, the supplied springs in my Edelbrock Performer RPM heads were GARBAGE. The ends were not cut square and if you put them on a flat surface, every one was "leaning". I didn't use any of their valvetrain components. I suggest you buy bare heads and assemble them yourself with components you choose. You will be ahead in the long run.

I noticed you are using a .021" head gasket, which combined with your .025" piston down in the hole, gives a deck clearance of .046". Is this what you want?

Have you tried the combo of 64cc heads (more choices available than 70cc) with a .015 head gasket and a larger cc relief piston?

It is much easier to dial in your DCR with the camshaft rather than removing metal.

Some argue that you MUST increase your compression ratio when using aluminum heads, because the aluminum does a much better job of removing the heat from the combustion chamber as compared to cast iron. They say the engine will be a dog if you don't do this.

Let's see what Grumpy says.

Loves302Chevy

"One test is worth a thousand expert opinions."

this rpm range does look promising "Basic Operating RPM Range: 2,600-6,600 "

Look further down and notice that the rpm range gets shifted lower due to the longer stroke of the 383.

Attachments

Loves302Chevy

"One test is worth a thousand expert opinions."

These Keith Black HYPERs have a 12cc dish volume.

https://www.summitracing.com/parts/uem-kb197-030/overview/make/chevrolet

I used the .015 HG to give you .040 quench, 64cc heads, and that Crower cam with it's 63 degree IVC

with 4 degrees retard for a number of 67.

https://www.summitracing.com/parts/uem-kb197-030/overview/make/chevrolet

I used the .015 HG to give you .040 quench, 64cc heads, and that Crower cam with it's 63 degree IVC

with 4 degrees retard for a number of 67.

Attachments

Last edited by a moderator:

Loves302Chevy

"One test is worth a thousand expert opinions."

I read that you prefer FORGED pistons. Summit has these: https://www.summitracing.com/parts/dms-1403sx-4030/overview/make/chevrolet

13cc's but uses 6.00" rods. Price is only a little more than the KB hypers. ROSS are $700+/set.

13cc's but uses 6.00" rods. Price is only a little more than the KB hypers. ROSS are $700+/set.

Gibbles

Clicker of buttons

Rick: NP

302: During the 383 stroker upgrade, I'll likely have the block decked, however as it sit's the engine is pretty snappy.

however the smaller torque converter really made it noticeable when going from a 12in to the 9.5in.

I'm a little grey on some of the details, however I'll target closer to the .040 quench with this re-do.

I'm not wanting to buy new heads unless I really have to, I'll likely have these ones machined to add a cc or two.

And I am wanting to keep the SCR close to 10:1 as I can, if it's possible to get the engine to respond even better, I'm all for it!

I was reading that I might be ok having the DCR slightly over 8 (8.13) (as the upgraded camshaft would give me) with the aluminum heads?

If not then I'll see if I can't drop the SCR a little to get a closer to the safe DCR.

And I plan on replacing the valve springs, I just need to figure out what ones...

Edlebrock actually had an article noting the limitations of the valve springs included with their affordable heads... one note was to not exceed .500 lift with the included valve springs.

302: During the 383 stroker upgrade, I'll likely have the block decked, however as it sit's the engine is pretty snappy.

however the smaller torque converter really made it noticeable when going from a 12in to the 9.5in.

I'm a little grey on some of the details, however I'll target closer to the .040 quench with this re-do.

I'm not wanting to buy new heads unless I really have to, I'll likely have these ones machined to add a cc or two.

And I am wanting to keep the SCR close to 10:1 as I can, if it's possible to get the engine to respond even better, I'm all for it!

I was reading that I might be ok having the DCR slightly over 8 (8.13) (as the upgraded camshaft would give me) with the aluminum heads?

If not then I'll see if I can't drop the SCR a little to get a closer to the safe DCR.

And I plan on replacing the valve springs, I just need to figure out what ones...

Edlebrock actually had an article noting the limitations of the valve springs included with their affordable heads... one note was to not exceed .500 lift with the included valve springs.

Ok, this is what I have.

I would recommend that you not use these numbers as absolute, but to compare with future

results from future DynoSim5 runs. I can change between say 3 different intake manifolds

that will make 40 HP difference, but it's a guess to which one is closest to your situation. For

example, it's sometimes hard to know where a manifold fit DynoSim5 options. I included the

DynoSim5 parameter that I used (long vertical graphic), so you can check me on future Sims

or maybe you want to make a change now, but lets NOT change anything after that going

forward except those obvious changes like different heads/flow or camshaft.

Notice how the valve timing events have changed with the rocker ratio of 1.65:1

.

I would recommend that you not use these numbers as absolute, but to compare with future

results from future DynoSim5 runs. I can change between say 3 different intake manifolds

that will make 40 HP difference, but it's a guess to which one is closest to your situation. For

example, it's sometimes hard to know where a manifold fit DynoSim5 options. I included the

DynoSim5 parameter that I used (long vertical graphic), so you can check me on future Sims

or maybe you want to make a change now, but lets NOT change anything after that going

forward except those obvious changes like different heads/flow or camshaft.

Notice how the valve timing events have changed with the rocker ratio of 1.65:1

.