Generation Gap: Big-Block Chevy OE And Aftermarket Block Variants

By GREG ACOSTA AUGUST 07, 2018

When it comes to big-block engines, there are quite a few variants across multiple manufacturers. However, when you hear the words “big block” with no other qualifier, there is one engine that comes to mind more than others, and that is the big-block Chevrolet.

The big-block Chevy – or BBC, as it’s colloquially known – is arguably the most popular big-block engine on the market. It has some serious legs, with a production lifespan totaling 51 years. If you include aftermarket applications which have continued on past the end of Chevrolet’s official production, the big-block Chevy engine is a spry 60-years-old and counting.

In those 51 years of production, there were a total of seven different variants of the engine’s design. Luckily, for the sake of simplicity, the first three of those variants were short lived, and rarely come up in the performance aftermarket discussion. For the sake of thoroughness, those three early variants were the aptly named “Mark I” (or W-engine), the Mark II (or “Mystery Motor”), and the aborted Mark III project.

When it comes to the bulk of the aftermarket, the big-block Chevy came into its own with the Mark IV variant, and that’s where this story starts, especially when talking about aftermarket engine blocks.

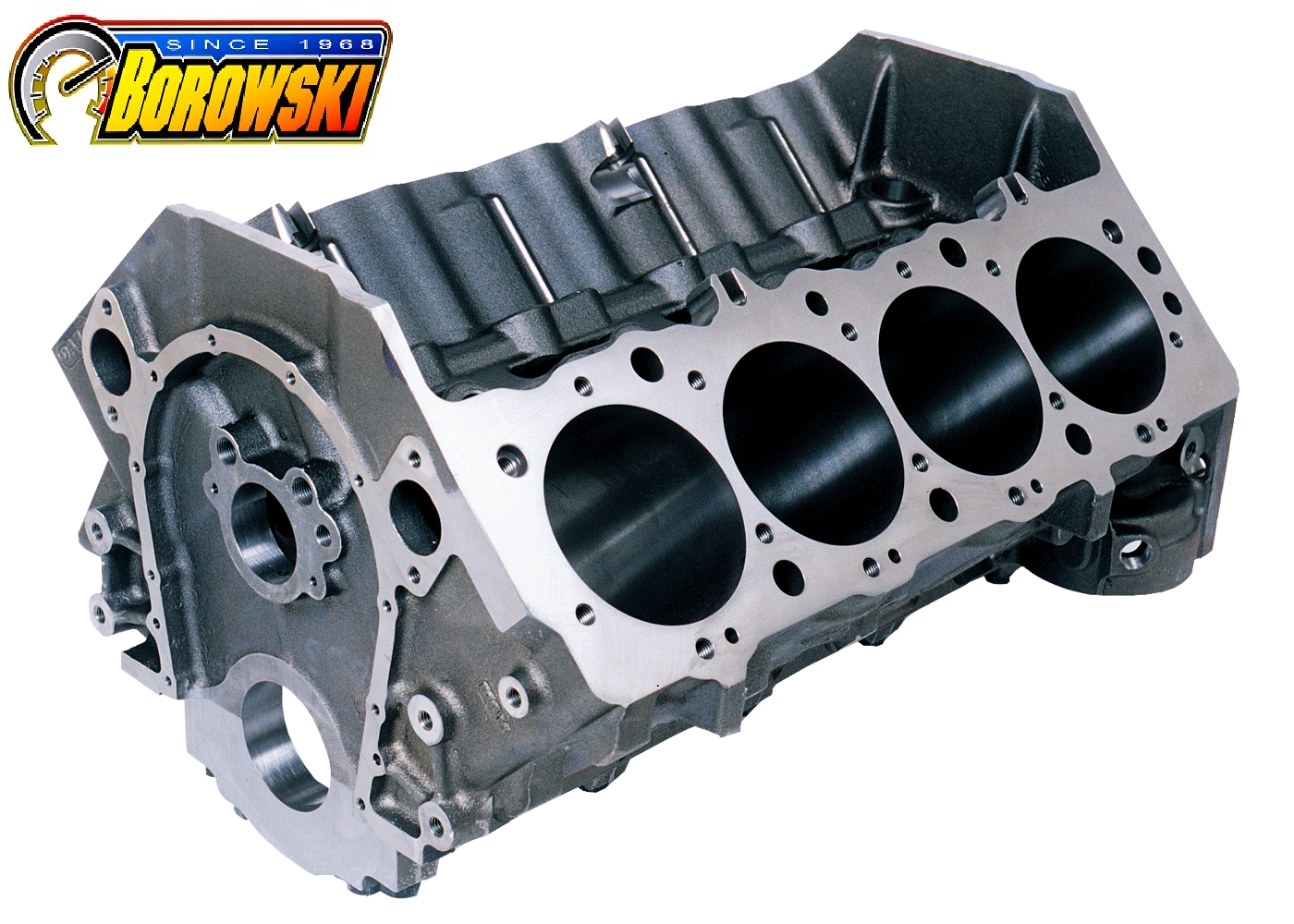

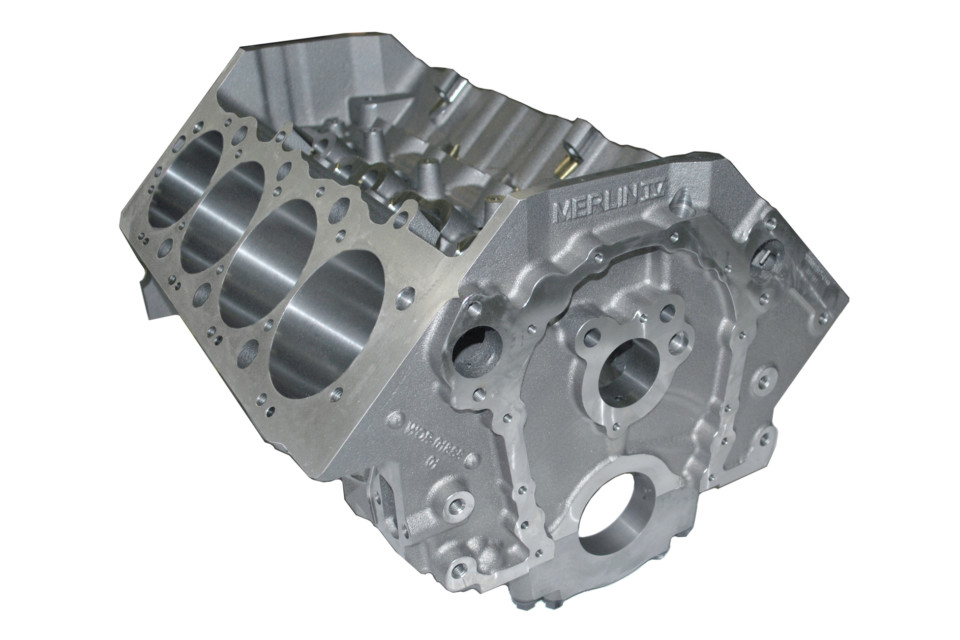

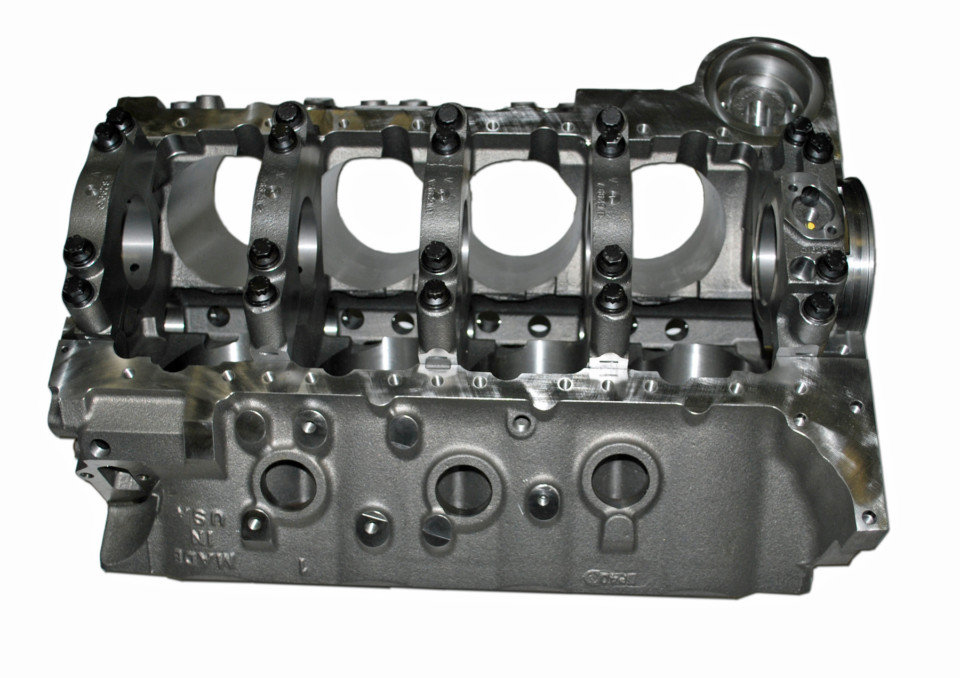

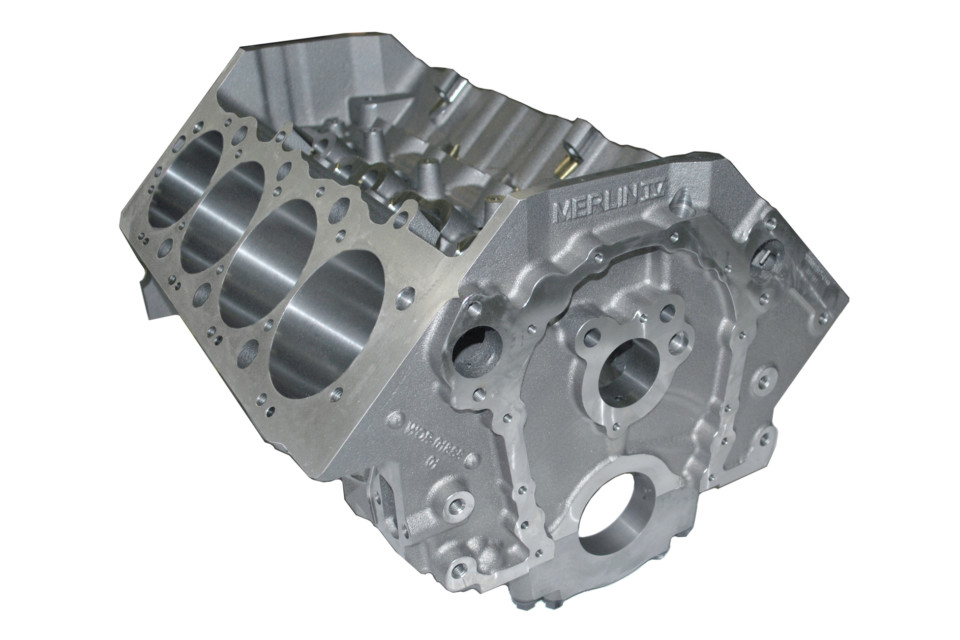

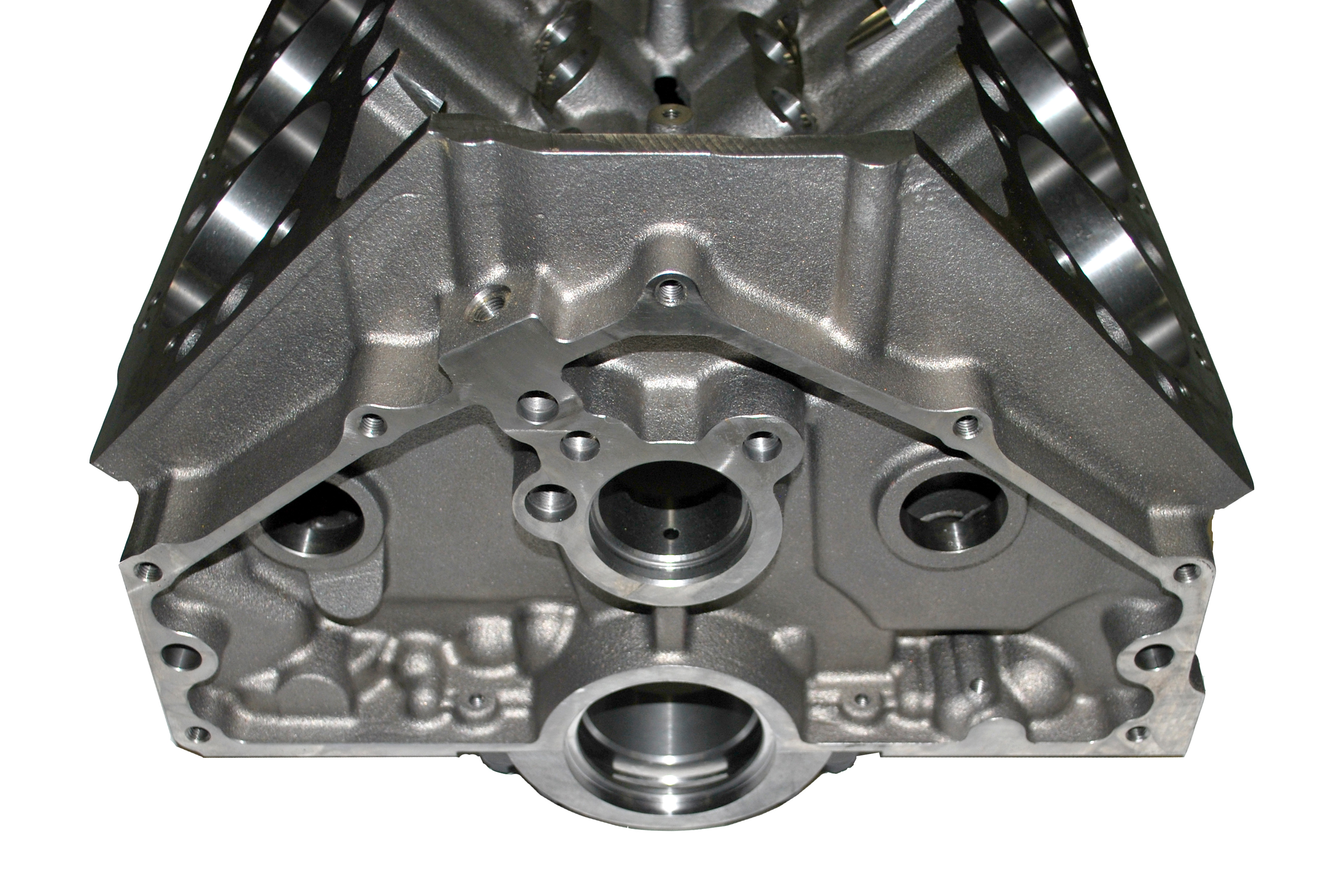

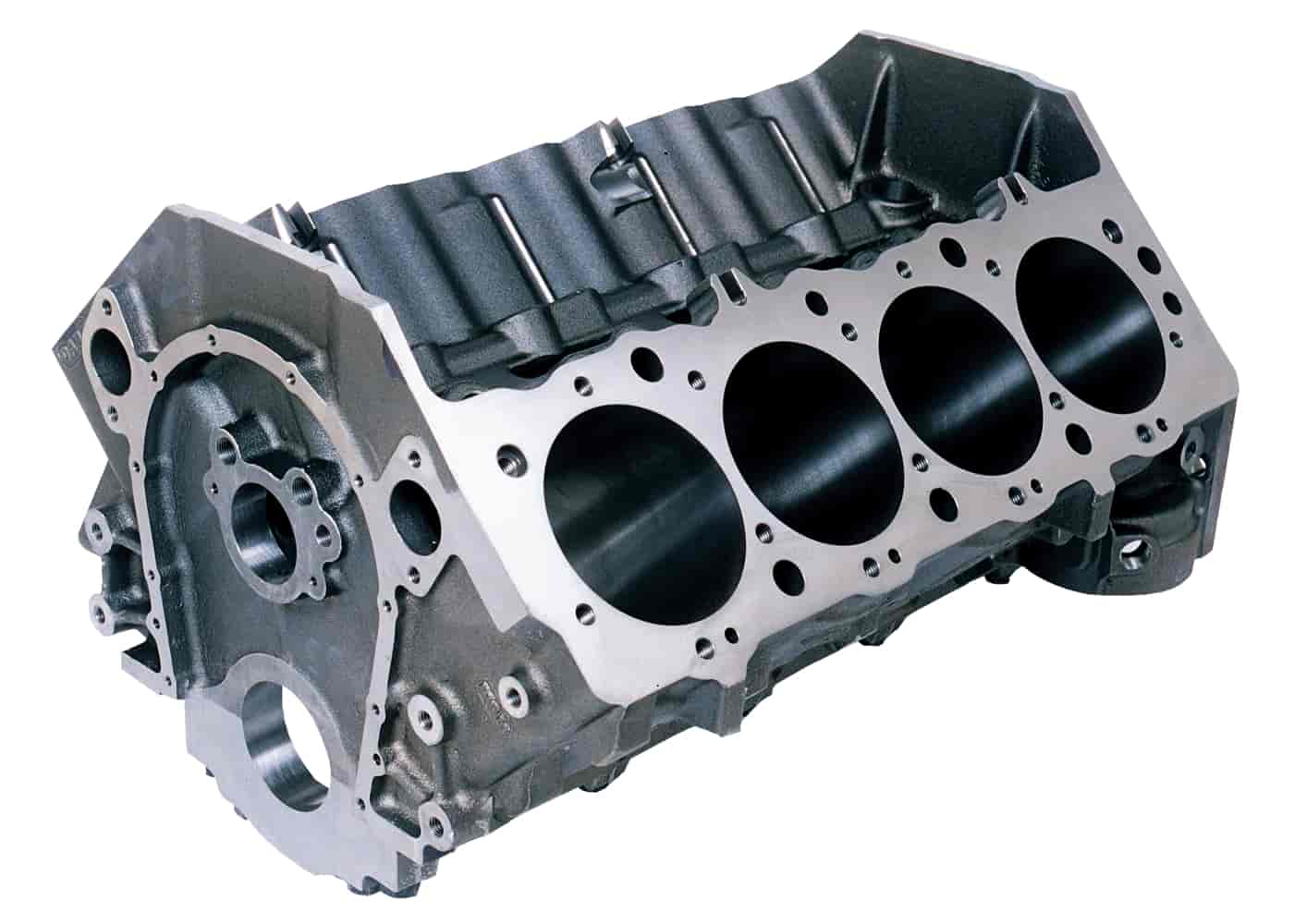

World Products’ Merlin IV engine block is the latest evolution of its aftermarket big-block Chevy block. With the current tooling setup, both Mark IV and Gen V/VI architecture blocks come from the same raw casting, with only machining processes being different.

Starting at Four

The Mark IV big-block Chevy began life in 1965 and was produced until 1990. In that time it was manufactured in a variety of displacements and capabilities, while powering some of the most iconic muscle cars of the era. In fact, it could be said that the big-block Chevy helped define the genre.

The Mark IV incorporated a more traditional wedge-style combustion chamber, and revised valve angles, which differed considerably from the original W-engine design. The Mark IV’s more traditional design led to a large increase in efficiency – and power – solidifying it as a performance engine in the history books. “The Mark IV is certainly the most versatile of the generations, because in OE form there were numerous performance variants made,” says Jack McInnis of World Products. “Parts are mostly interchangeable and tuning options for them are abundant.”

New Generation, New Name

The next generation of the big-block Chevy engine was known as the Generation V, keeping the numerical sequence alive, but transitioning from the “Mark” nomenclature to “Generation” or “Gen,” presumably due to the fact that Ford was manufacturing the Mark VII and Mark VIII under the Lincoln brand. A seemingly innocuous little fact, but it’s an important differentiation that comes up when discussing the big-block Chevy.

The Generation V big-block debuted in 1991 with considerable changes. A one-piece rear-main seal, revised oiling system passages, and the removal of a the mechanical fuel pump were the major revisions to the engine block, along with all factory-produced big-block engine blocks coming equipped with four-bolt main caps

Oftentimes, the Generation V and Generation VI will be lumped together when referring to engine blocks. That’s because the engine blocks of the Gen V/VI, as it’s often referred to, were the same, with the changes between those two generations occurring outside of the block.

“The Gen V/VI could theoretically be the equal of the Mark IV, but factory performance was not part of the plan,” McInnis explains of the factory offerings. “Parts interchangeability with the Mark IV [and the Gen V/VI blocks] has its limitations,” he says of why the Mark IV architecture still reigns supreme in the aftermarket.

On the left is a "traditional" Mark IV architecture big-block crate engine, and on the right is an 8.1L big-block. Notice externally, there aren't a whole lot of visual indicators. The stands on the valve covers for coil packs, and counting head bolts would both help identification.

It’s All Sevens and Eights

The Generation VII big-block is known by several other names as well – the “L18,” “8.1L” or “Vortec 8100,” mainly. Introduced in the 2001 model-year, there were a large number of significant changes in the Gen VII engine, including a new firing order, new head bolt pattern (along with a totally new cylinder head), and an electronic fuel injection system that closely mirrored that found on Gen III engines.

“The Vortec 8100 was built for trucks, motor homes, industrial use and boats, and in OE form is the least performance-oriented of the three main platforms,” shares McInnis. “There were no factory performance options and tuning required some fairly serious hacking skills.” The 8.1L big-block only lasted until 2009, and when the last L18 rolled off the production line, it marked the end of the factory-produced big-block Chevrolet.

Intergenerational Hand Me Downs

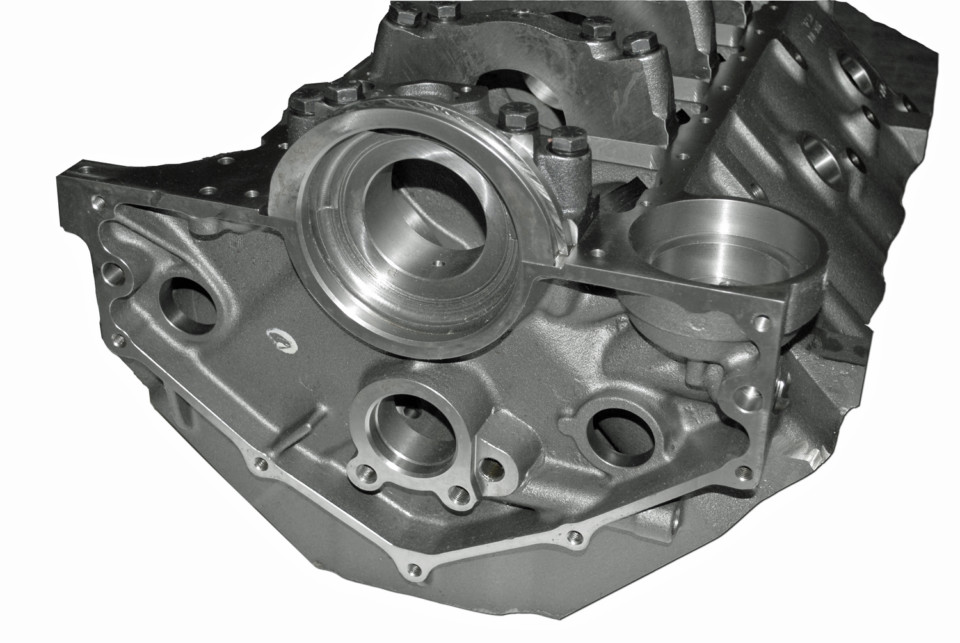

With all the different generations, parts interchangeability between them can be confusing. “The Mark IV and the Gen V/VI have a degree of parts interchangeability, but it is limited,” McInnis offers. “Probably the most significant difference is that the Gen V/VI is designed with a one-piece rear seal. This means that the main cap, oil pump, oil pan, crankshaft and flywheel are unique to that engine.”

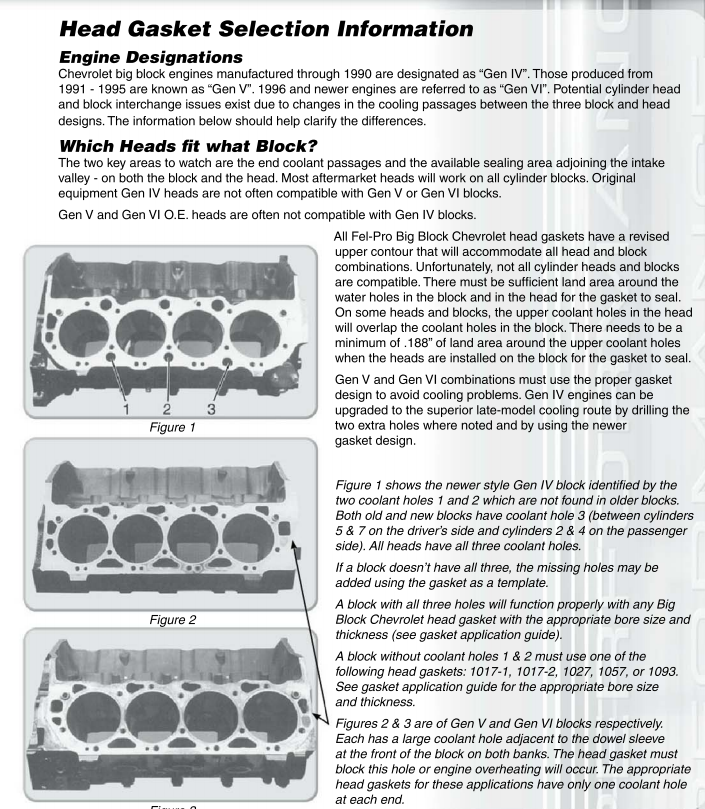

Moving to the top of the block, while the bolt pattern between the Mark IV and Gen V/VI cylinder heads are the same, swapping heads isn’t as simple a task as that might make it appear. “The cylinder heads are interchangeable, although cooling passages in the deck, particularly on early Gen V OE blocks, can cause sealing problems with Mark IV heads. The head gaskets are even different between the two,” says McInnis.

Notice the 8.1 is conspicuously absent from the interchangeability discussion. That’s not an oversight. “The 8.1 has almost no interchangeability with the other two,” McInnis says, flatly. “The 8.1 represents the last of the big blocks, and the factory changed a lot of things from the previous versions. If the 8.1 had been the first design back in 1965 and the aftermarket had developed a vast array of performance components for it, things might be different.” With the different head bolt pattern, different oil pan pattern, and a switch to largely metric thread throughout the engine, the Gen VII big-block Chevy is practically its own animal.

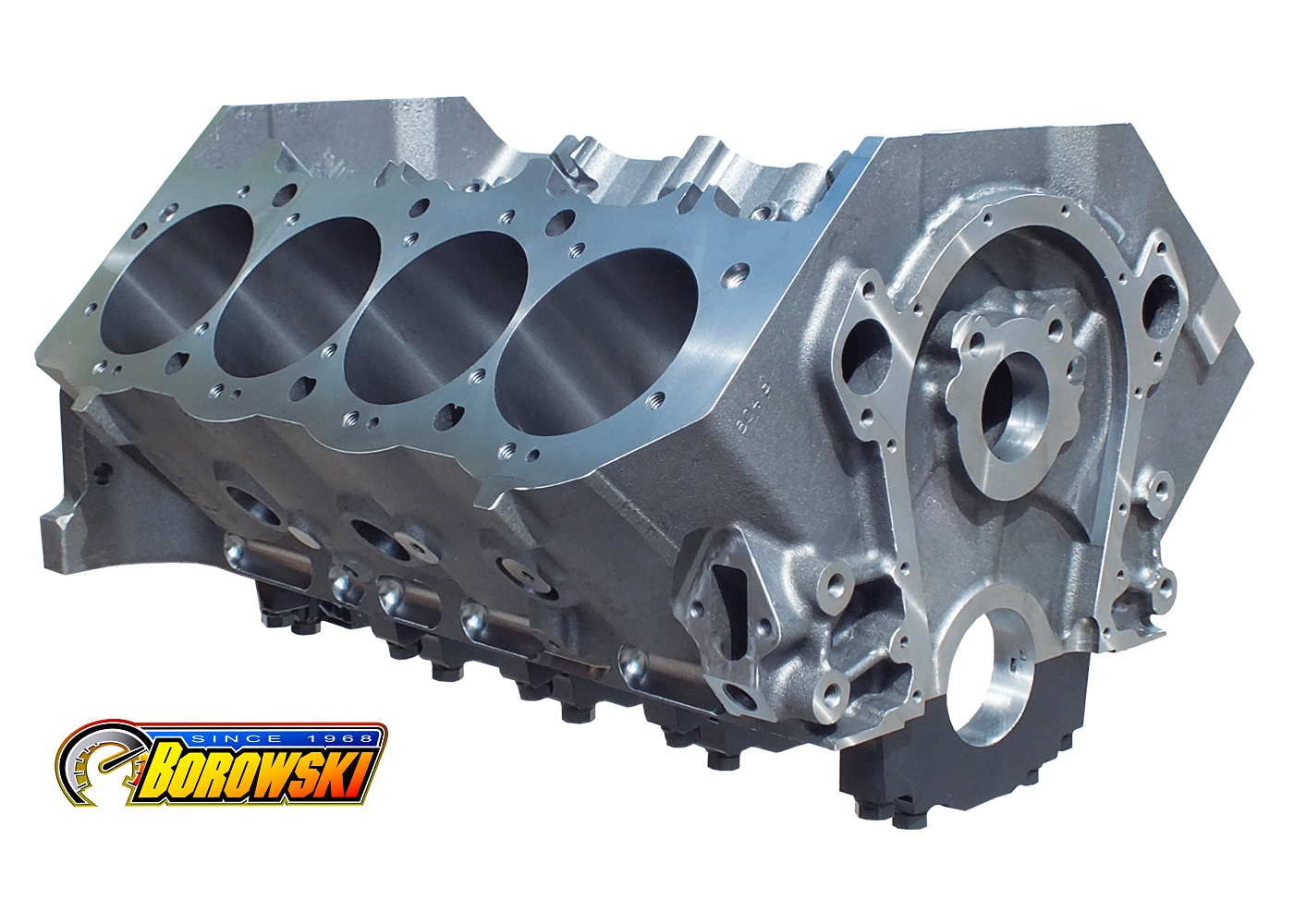

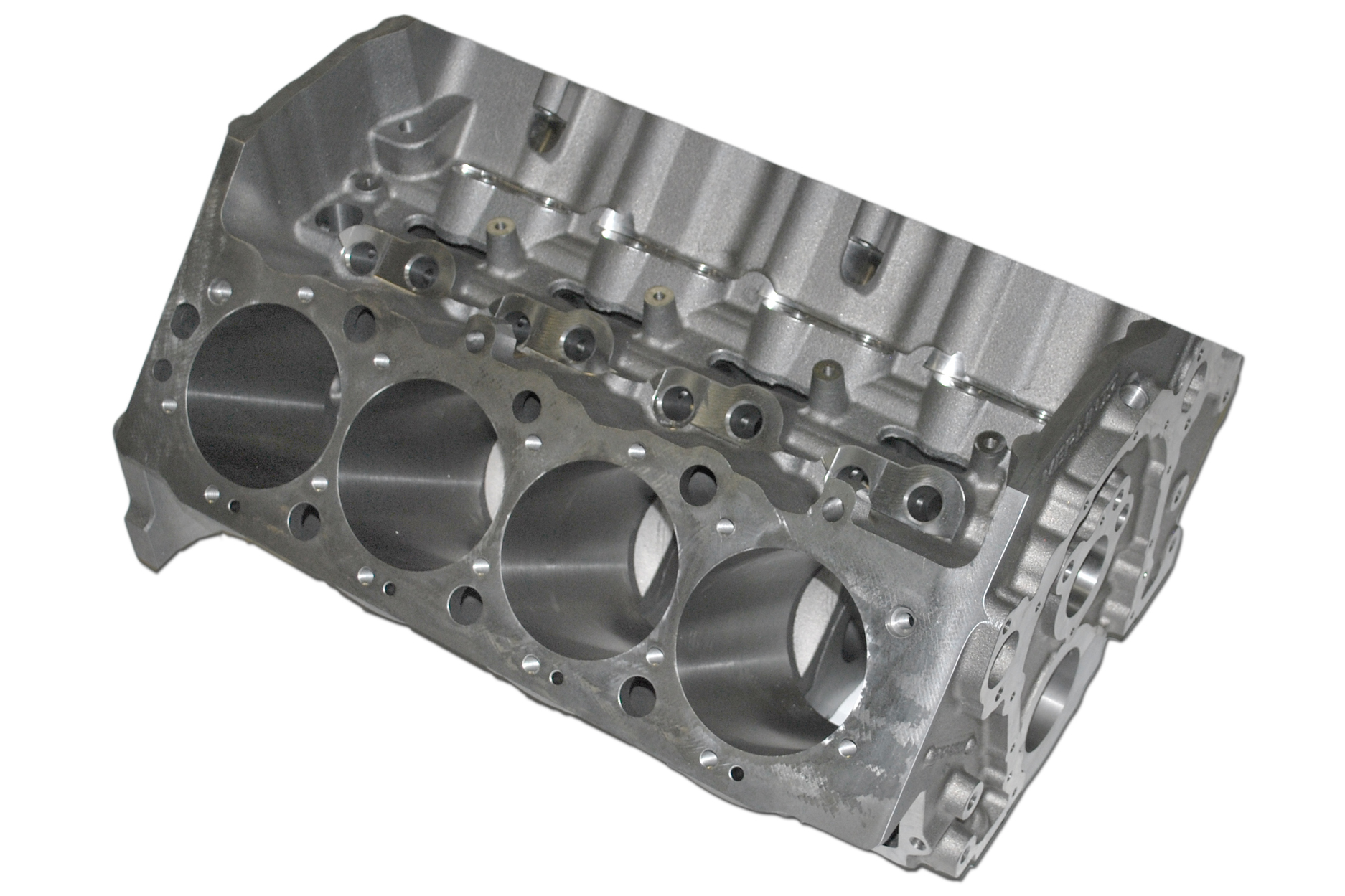

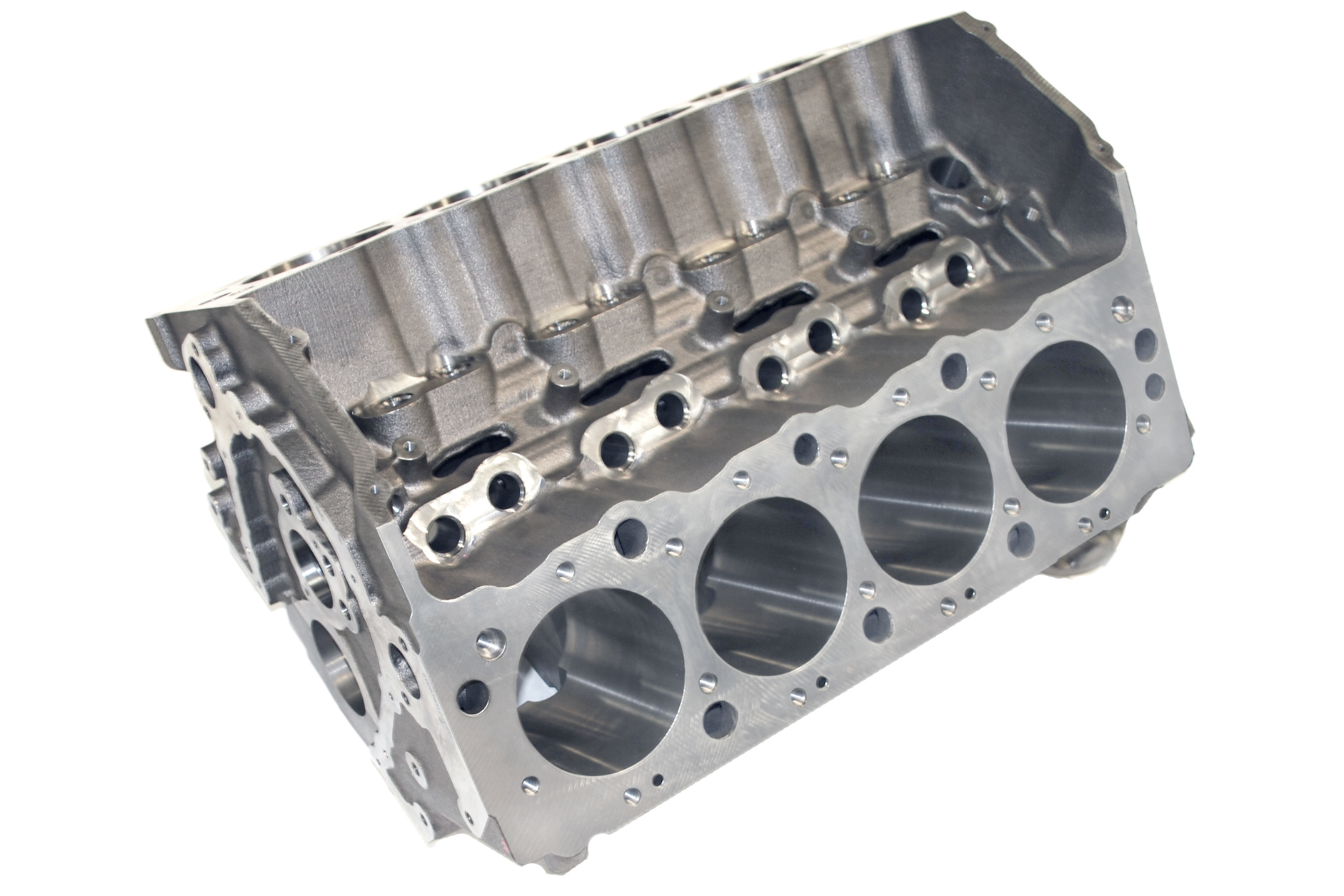

These two blocks are World's current big-block offerings. On the left is the Merlin IV, and on the right is the 8.1L replacement block. While you may notice additional head bolt holes on the Merlin, those are for various race heads on the market, and not for the L18's altered bolt pattern.

The Magic of Merlin

Now that we’ve discussed the three major generations of big-block Chevrolet blocks, we can effectively look at World Products’ aftermarket offerings, which cover Mark IV, Gen V/VI, and the 8.1L variants. “All three types, as produced by World, have significant upgrades over the OEM blocks,” says McInnis. “However, their capabilities are still skewed in the same order as the OEM blocks are, just at a higher level. That is, mostly dictated by the availability of (or lack thereof) performance parts for the respective engine types.”

World has been producing its line of aftermarket blocks for over 25 years, and is constantly improving the lineup, as noted by the fact that current production of the Merlin line of big-block Chevy engine blocks is dubbed the “Merlin IV.” “World has made continuous improvements to the Merlin big-block, with the newest iteration being the Merlin IV. When we made new foundry tooling for the new Merlin IV, we designed it so that all three types of block castings could be produced with the same tools,” McInnis explains.

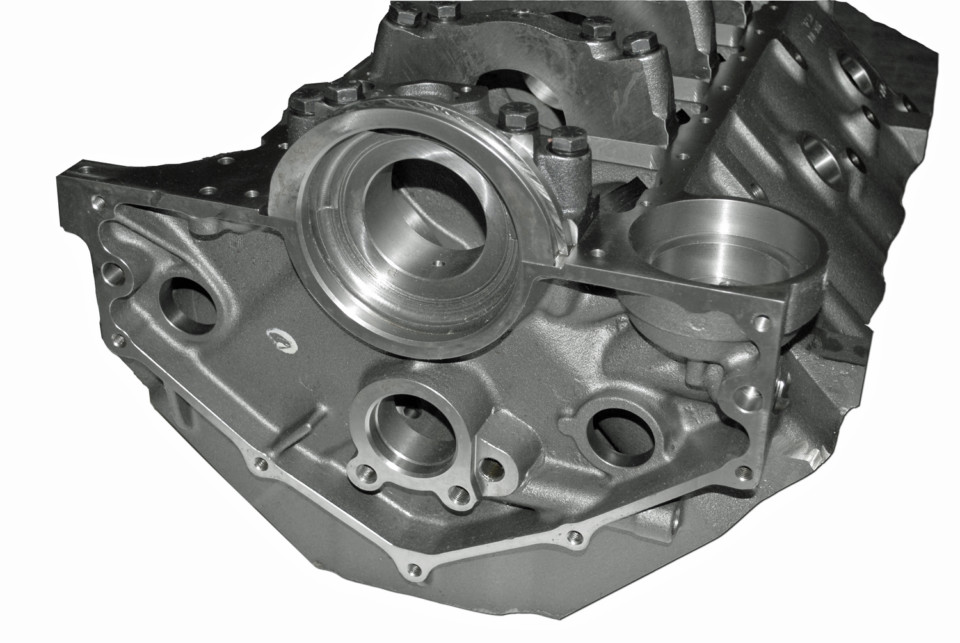

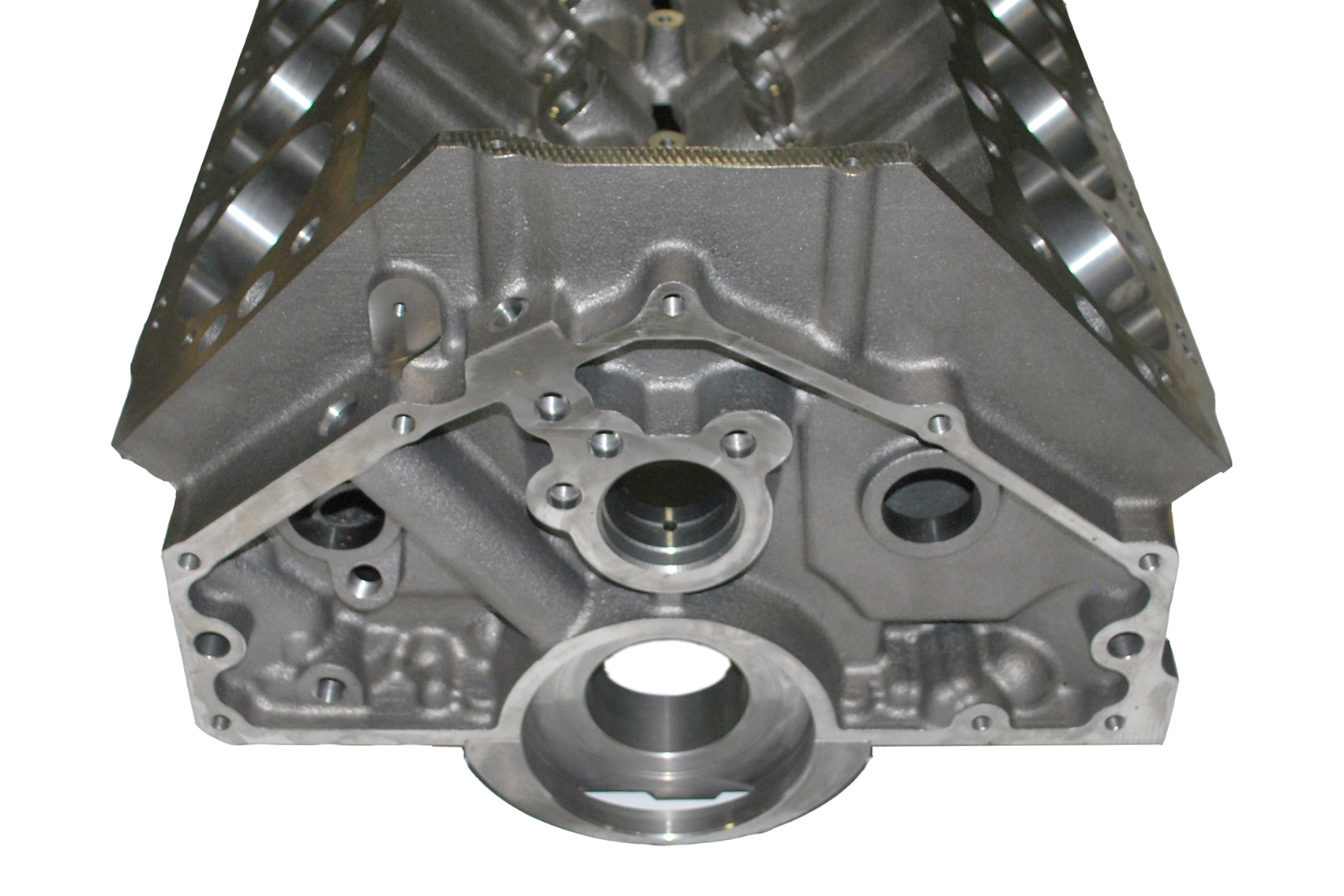

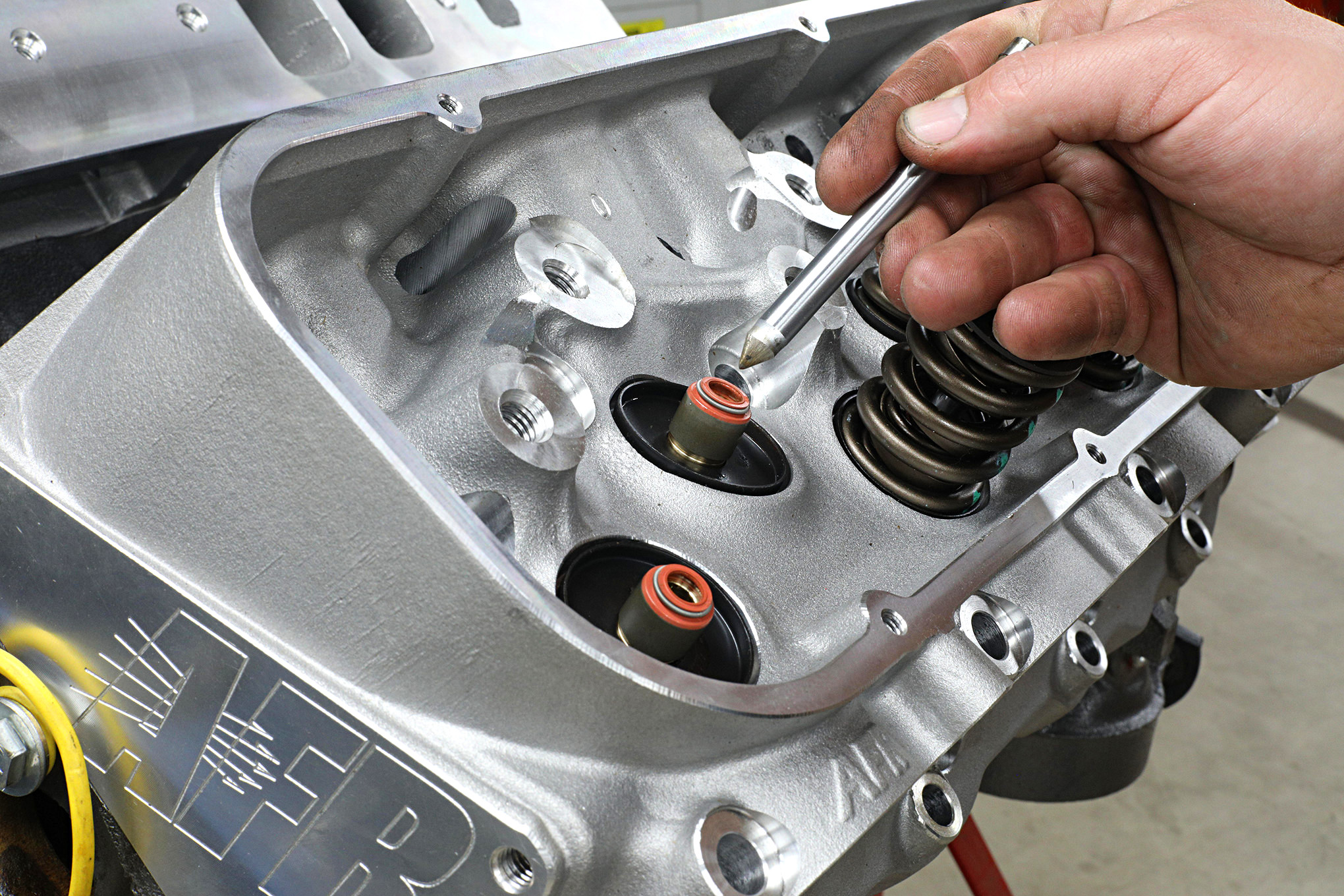

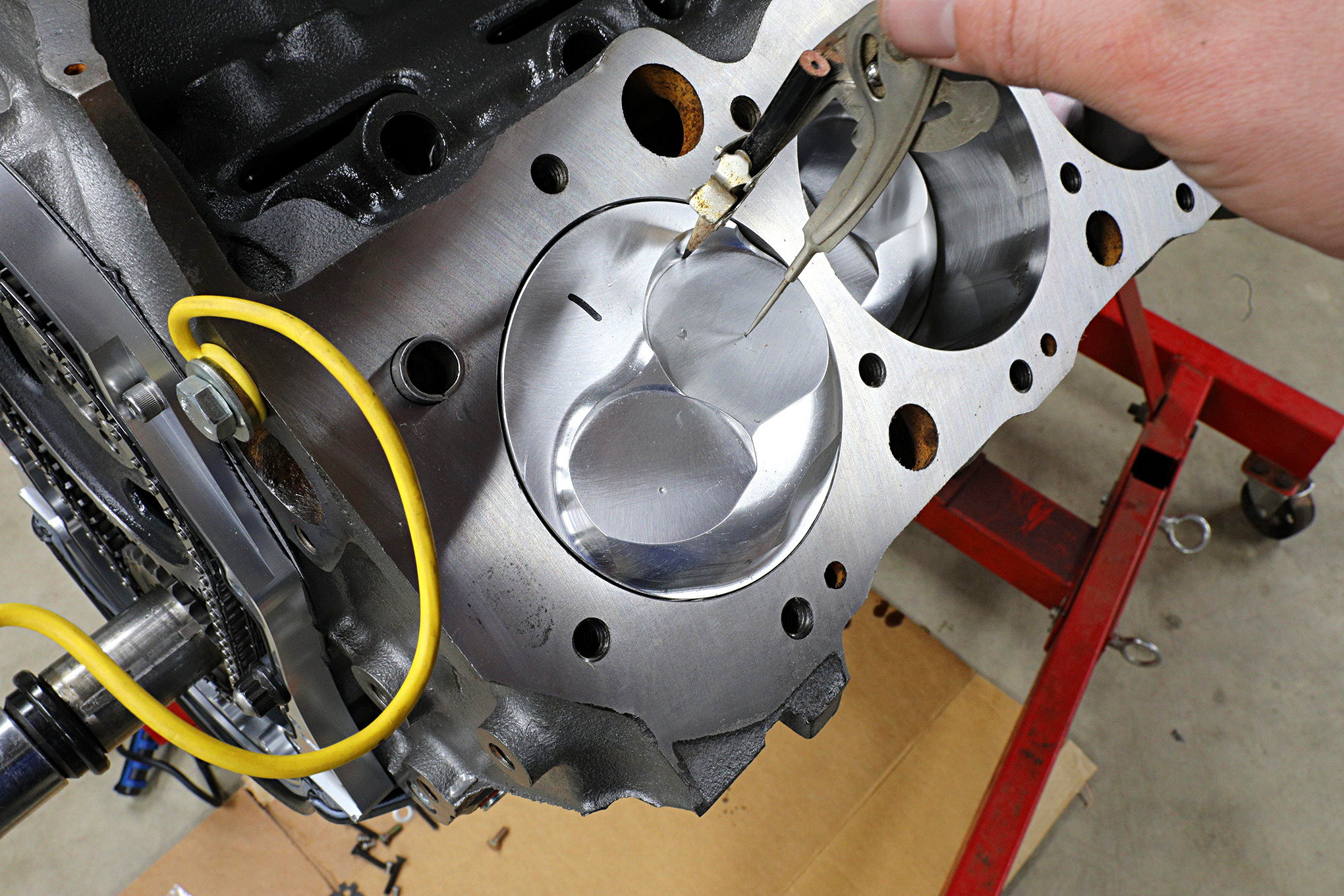

One of the largest differences between the Mark IV and Gen V/VI block is the one-piece and two-piece rear main seal.

While there are still three distinct versions of the block, World is able to use the same casting for the Mark IV and Gen V/VI blocks. “The Gen V/VI style block uses the same casting [as the Gen IV variant] with some changes in the machining. World’s Gen V/VI block is machined to accept the Gen VI-style one-piece rear seal, timing cover, and oil pan,” says McInnis. “It does have a Mark IV style oil filter pad and fuel pump boss, as well as Siamesed cylinders and splayed 4-bolt main caps.”

The Merlin IV block comes in 21 separate configurations, covering every OEM Mark IV and Gen V/VI applications, along with several configurations designed purely for aftermarket performance.

All of the Merlin blocks are made from high-density cast iron, and are designed to handle huge power. Available deck heights for the .600-inch thick deck range from 9.500-inch up to 10.250-inch, with a maximum bore size of 4.625 inches. At the maximum bore size, the cylinder wall thickness is approximately .290 inches thick (with additional thickness on the thrust side), making for a robust platform, even bored all the way out.

The Merlin IV has traditional-pattern 7/16-inch blind-tapped head bolt holes, along with an additional row of bosses in the valley area for several race heads that utilize the additional bolt holes. The blocks have two options when it comes to the main caps: standard four-bolt nodular-iron versions, or the more robust splayed-four-bolt billet steel caps. The Merlin IV comes with a 2.120-inch cam bore standard, with an option for a 55mm cam bore.

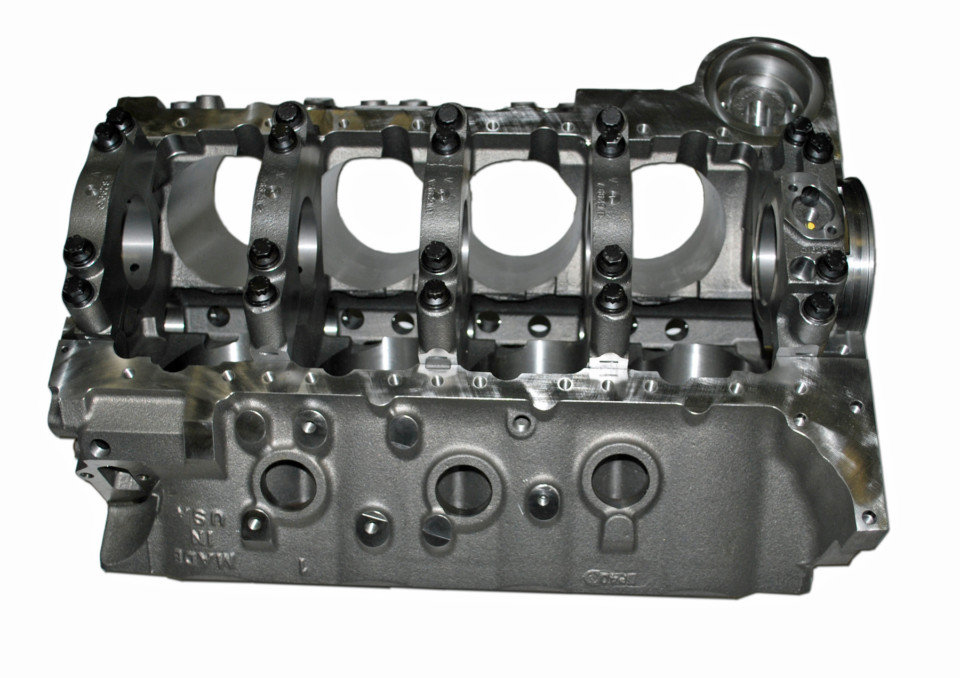

All of the Merlin-series engine blocks come with four-bolt mains standard. Here, you can see the standard nodular-iron main caps, while billet steel main caps, with splayed outer bolts are available as an upgrade and recommended for severe-duty applications, or anything making over 1,000 horsepower.

Internally, the water jackets have been expanded for enhanced cooling capability. The Merlin IV has a priority main oiling system with the block set up for a standard-style oil pump, but with provisions for a relatively-easy conversion to a dry-sump system, if that’s how you roll. The spin-on oil filter location has been revised to clear a kickout-style oilpan, and is dual-drilled to accept stock-style and aftermarket oil pans.

For the 8.1L big-block Chevy, World offers three part numbers for the cast-iron upgraded block, which doesn’t fall under the “Merlin” banner, but incorporates a number of the same upgrades, but in the late-model architecture. Available in three bore sizes — 4.245, 4.495, and 4.595 inches — the max bore size possible for the 8.1-family is 4.625 inches. When coupled with the supplied clearance for a 4.75-inch stroke, displacements of up to 638 cubic inches, are easily attained.

“We made the 8.1 block because GM no longer produced them. It is designed to be a stock replacement with the ability to upgrade performance beyond what the factory blocks were capable of,” says McInnis. “As an upgrade for your 8.1-equipped tow rig or boat it makes more sense, and for industrial applications, they are widely used.”

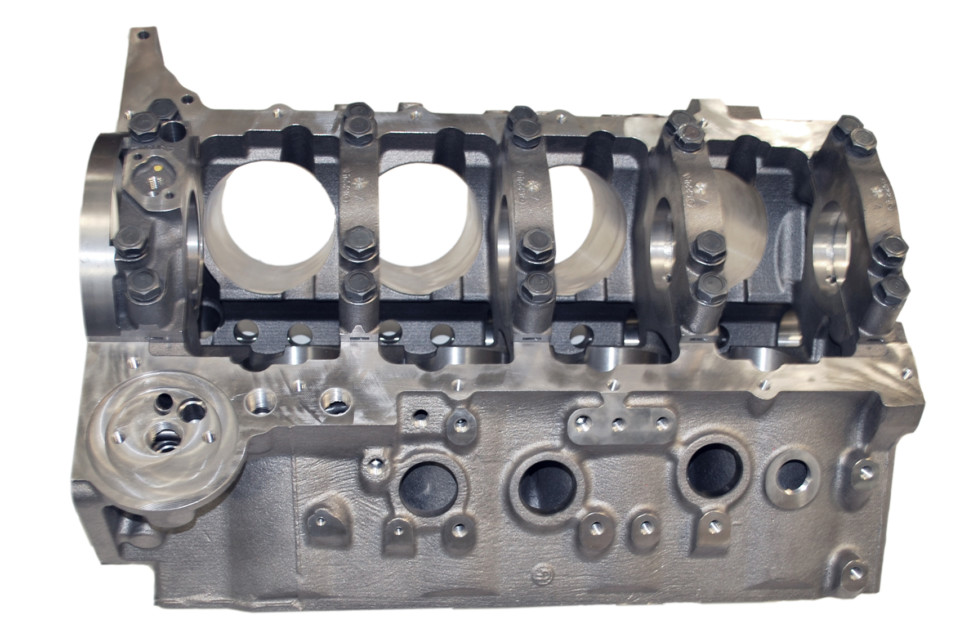

Again, Merlin IV on the left, World 8.1 on the right. From the rear, you'll notice the blocks are very similar at first glance, but the 8.1L block has passages and mounting provisions for modern electronics.

Which One Is Best?

With all the different variants, which one is best? That’s a very subjective term, but we tried to pin McInnis down on that one. “Inherently, there’s not much difference between them, but practically there is a huge difference,” he says. “The Mark IV style engine has the edge by far. There is an almost limitless range of aftermarket performance parts available from numerous manufacturers, enabling builders to create combinations for just about any type of use imaginable.”

Moving on to the Gen V/VI engines, as the blocks are the same castings as World’s Mark IV Merlin engines, there isn’t a power ceiling difference, at least not one that comes from the engine block. “The Gen V and VI can utilize many of the Mark IV components, but not all,” comments McInnis. There are a few performance parts available for the stuff that is specific to this engine.”

That leaves the Vortec 8100, which is definitely the red-headed step-child of the group. “While there are some aftermarket performance goodies available, it is a very limited selection,” McInnis says.

One of the subtle, but critically important differences of the 8.1L big-block, is the rampant use of metric hardware at the factory. That design shift further separated the Gen VII from the rest of its big-block brethren.

So when it comes to aftermarket performance, it appears the Mark IV pattern engine is the big dog, both in performance capability and variety of parts, which McInnis confirms: “For high performance builds, the Merlin IV (Mark IV style) would be the preferred choice by a large majority.”

However, McInnis was quick to qualify the statement. “It really depends on the application. In a marine application where an 8.1 was previously fitted it would make sense to build that type of engine because it avoids a lot of other changes which would be required to fit a different engine,” McInnis shares. “If all-out performance was the goal, then the Merlin IV would be the better choice, however.”

What’s right for you? We can’t answer that. That’s a discussion to be had between you and your engine builder, or between you and World’s tech department. Even though we’ve just barely scratched the surface of the 60-year legacy of the big-block Chevy, hopefully we’ve given you an understanding of the history, nomenclature, and differences between the factory generations, along with some of the aftermarket options available, which should keep the big-block Chevy as a viable option well into the twenty-first century.

http://garage.grumpysperformance.com/index.php?threads/big-block-chevy-info.710/

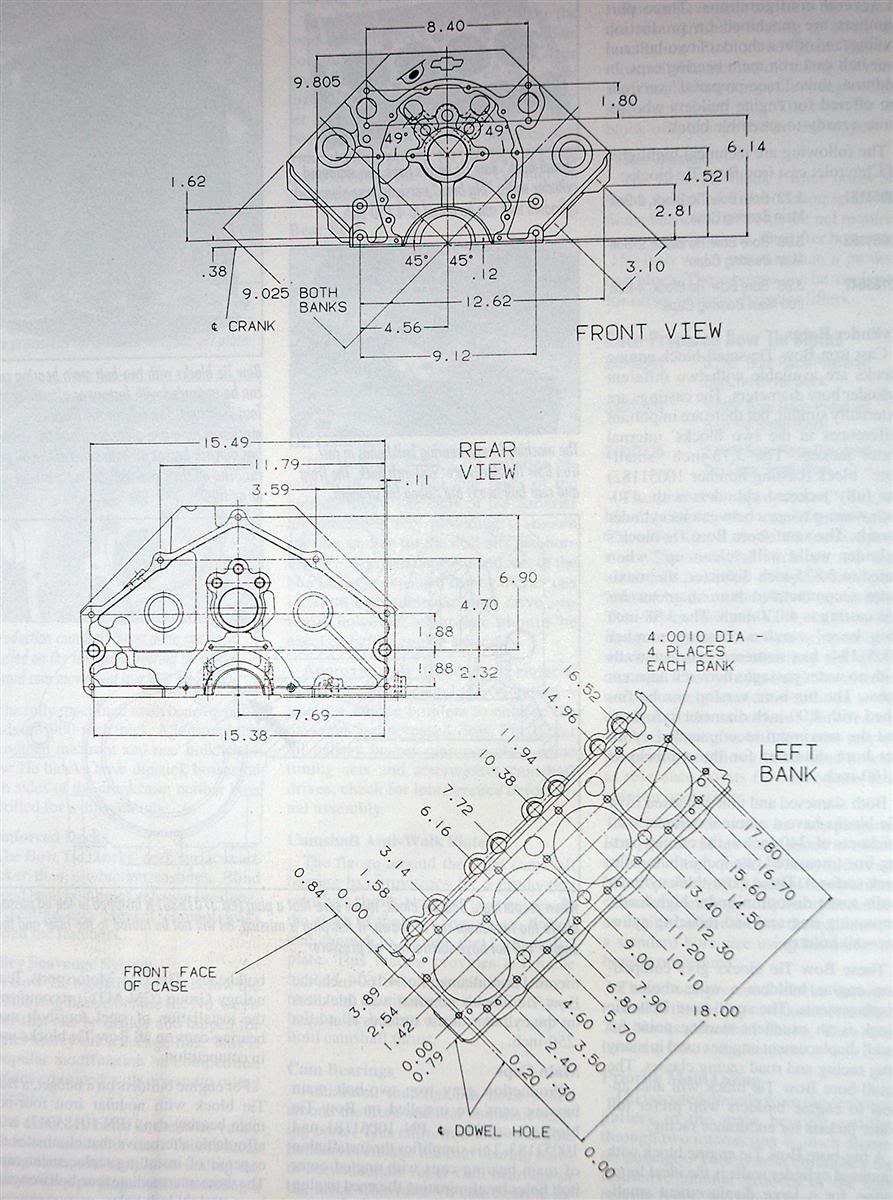

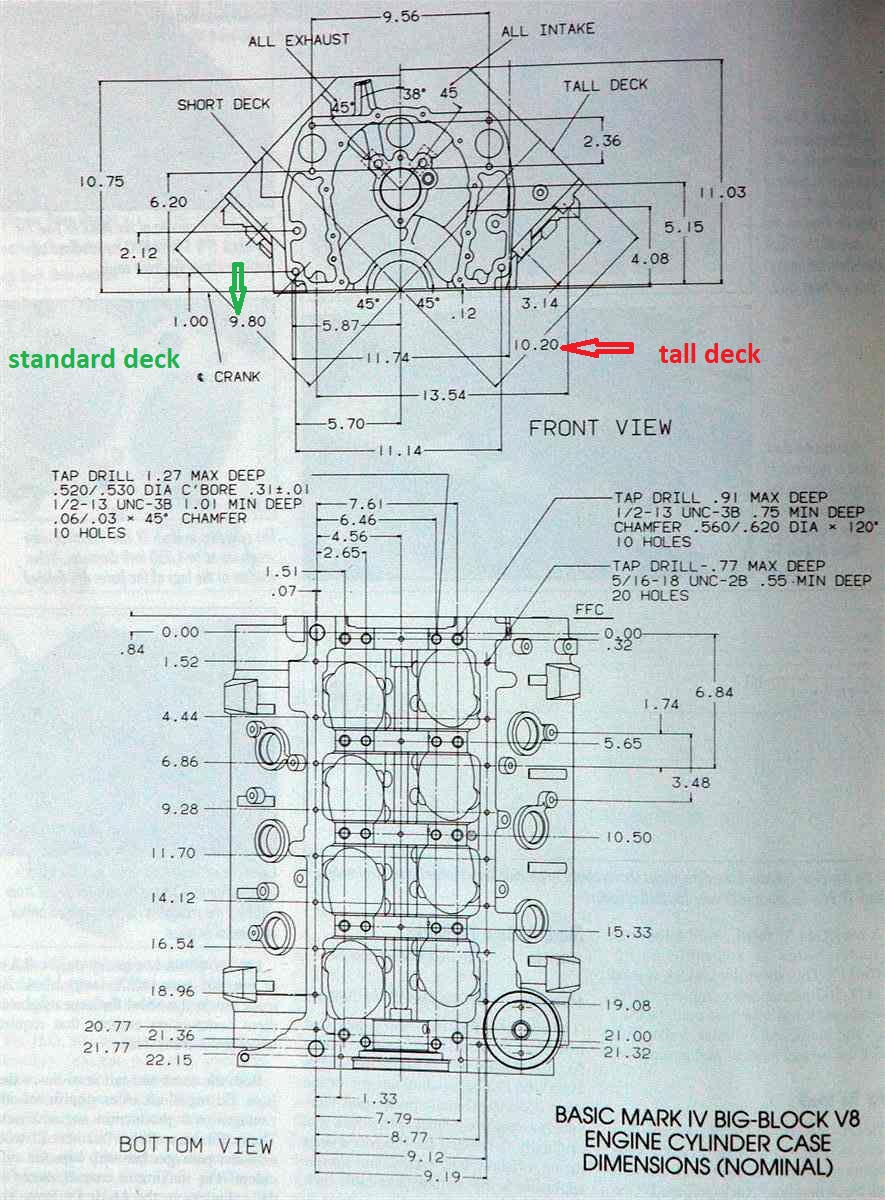

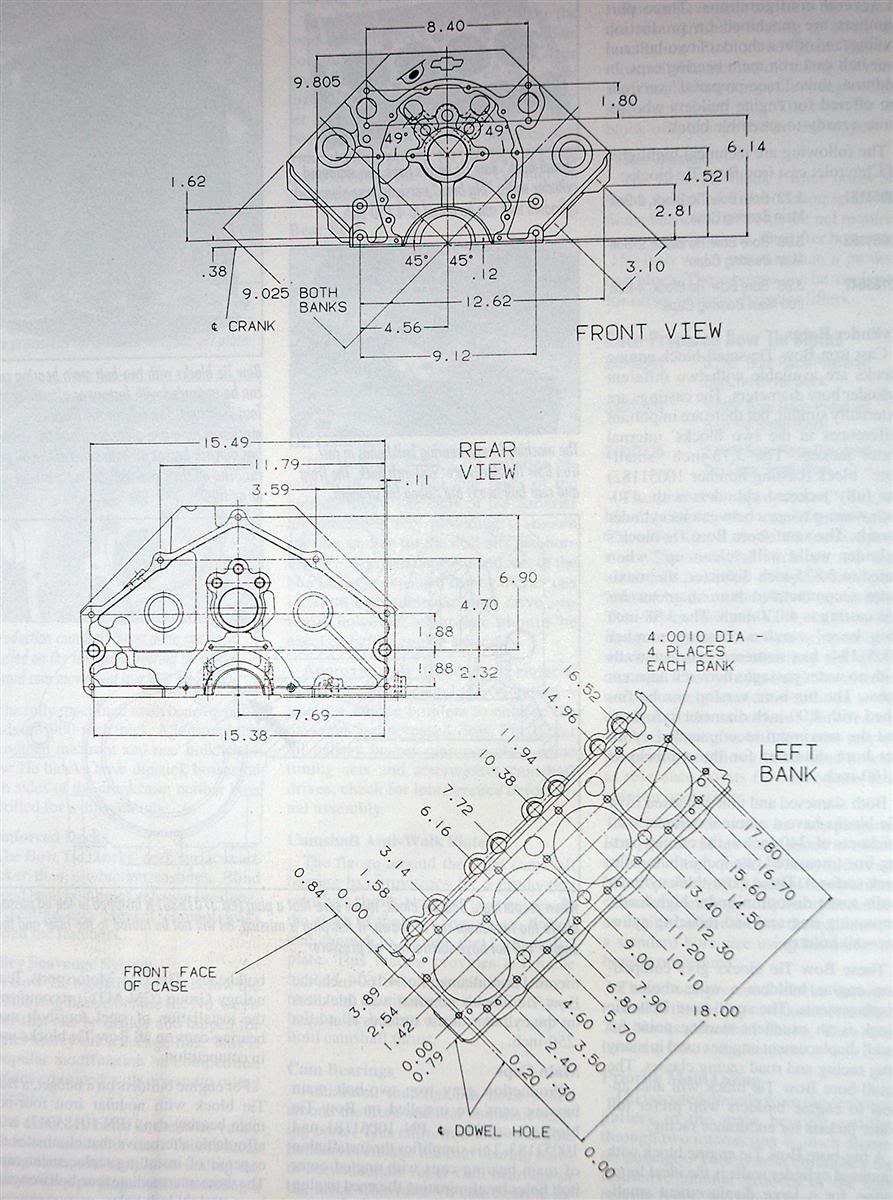

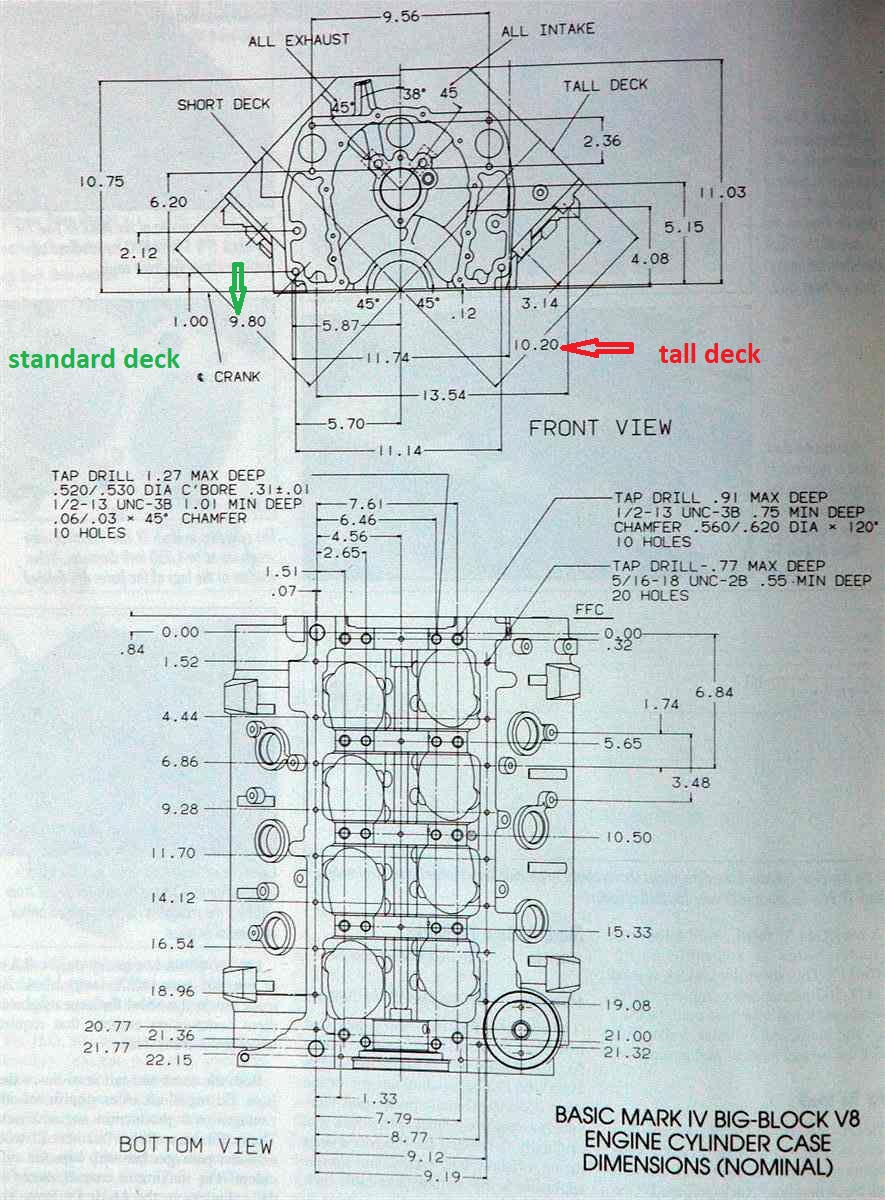

UN-machined SBC blocks have a nominal 9.0" deck height,

its very common to have the deck on a previously undecked block actually measure 9.022"-9.025"

UN-machined BBC blocks have a nominal 9.8" deck height,

its very common to have the deck on a previously undecked block actually measure 9.822-9.825

heres some calculators you might use

from a cost and parts availability vs the potential power levels you can generally expect there's

several BBC engine sizes that have consistently proven to perform rather well

the more common larger displacement combos ,these are

468 cid =454 .060 over bore stock 4"stroke crank

496 cid =454 .060 over bore + a 4.25" stroke crank

540 cid= 4.5" bore + a 4.25" stroke crank

572 cid=4.5" bore + a 4.5" stroke crank

632 cid=4.6" bore + a 4.75" stroke crank

hotrodworks.net

hotrodworks.net

users.erols.com

users.erols.com

users.erols.com

users.erols.com

gear spread sheet that comes in handy THANKS TO 1FATGMC

HERES OTHER INFO LINKS

users.erols.com

users.erols.com

users.erols.com

users.erols.com

users.erols.com

users.erols.com

auto.howstuffworks.com

auto.howstuffworks.com

a few resources to allow you to calculate the ideal results

http://www.tmossporting.com/tabid/1805/Default.aspx

here's some different calculators

http://www.kb-silvolite.com/calc.php?action=comp2

http://www.wallaceracing.com/dynamic-cr.php

http://www.smokemup.com/auto_math/compression_ratio.php

http://not2fast.wryday.com/turbo/com...pressure.shtml

average the results

By GREG ACOSTA AUGUST 07, 2018

some basic bbc math, to get you thinking about your potential dream bbc combos.

I recently had a discussion with one of the local guys concerning what heads and rotating assembly he should buy now that he recently purchased a tall deck (10.2") big block chevy block. he has a perfectly good 427 forged crank (3.76" stroke) but hes seriously thinking of buying a (4.25" stroke)...

garage.grumpysperformance.com

The big-block Chevy – or BBC, as it’s colloquially known – is arguably the most popular big-block engine on the market. It has some serious legs, with a production lifespan totaling 51 years. If you include aftermarket applications which have continued on past the end of Chevrolet’s official production, the big-block Chevy engine is a spry 60-years-old and counting.

In those 51 years of production, there were a total of seven different variants of the engine’s design. Luckily, for the sake of simplicity, the first three of those variants were short lived, and rarely come up in the performance aftermarket discussion. For the sake of thoroughness, those three early variants were the aptly named “Mark I” (or W-engine), the Mark II (or “Mystery Motor”), and the aborted Mark III project.

When it comes to the bulk of the aftermarket, the big-block Chevy came into its own with the Mark IV variant, and that’s where this story starts, especially when talking about aftermarket engine blocks.

World Products’ Merlin IV engine block is the latest evolution of its aftermarket big-block Chevy block. With the current tooling setup, both Mark IV and Gen V/VI architecture blocks come from the same raw casting, with only machining processes being different.

Starting at Four

The Mark IV big-block Chevy began life in 1965 and was produced until 1990. In that time it was manufactured in a variety of displacements and capabilities, while powering some of the most iconic muscle cars of the era. In fact, it could be said that the big-block Chevy helped define the genre.

The Mark IV incorporated a more traditional wedge-style combustion chamber, and revised valve angles, which differed considerably from the original W-engine design. The Mark IV’s more traditional design led to a large increase in efficiency – and power – solidifying it as a performance engine in the history books. “The Mark IV is certainly the most versatile of the generations, because in OE form there were numerous performance variants made,” says Jack McInnis of World Products. “Parts are mostly interchangeable and tuning options for them are abundant.”

New Generation, New Name

The next generation of the big-block Chevy engine was known as the Generation V, keeping the numerical sequence alive, but transitioning from the “Mark” nomenclature to “Generation” or “Gen,” presumably due to the fact that Ford was manufacturing the Mark VII and Mark VIII under the Lincoln brand. A seemingly innocuous little fact, but it’s an important differentiation that comes up when discussing the big-block Chevy.

The Generation V big-block debuted in 1991 with considerable changes. A one-piece rear-main seal, revised oiling system passages, and the removal of a the mechanical fuel pump were the major revisions to the engine block, along with all factory-produced big-block engine blocks coming equipped with four-bolt main caps

Oftentimes, the Generation V and Generation VI will be lumped together when referring to engine blocks. That’s because the engine blocks of the Gen V/VI, as it’s often referred to, were the same, with the changes between those two generations occurring outside of the block.

“The Gen V/VI could theoretically be the equal of the Mark IV, but factory performance was not part of the plan,” McInnis explains of the factory offerings. “Parts interchangeability with the Mark IV [and the Gen V/VI blocks] has its limitations,” he says of why the Mark IV architecture still reigns supreme in the aftermarket.

On the left is a "traditional" Mark IV architecture big-block crate engine, and on the right is an 8.1L big-block. Notice externally, there aren't a whole lot of visual indicators. The stands on the valve covers for coil packs, and counting head bolts would both help identification.

It’s All Sevens and Eights

The Generation VII big-block is known by several other names as well – the “L18,” “8.1L” or “Vortec 8100,” mainly. Introduced in the 2001 model-year, there were a large number of significant changes in the Gen VII engine, including a new firing order, new head bolt pattern (along with a totally new cylinder head), and an electronic fuel injection system that closely mirrored that found on Gen III engines.

“The Vortec 8100 was built for trucks, motor homes, industrial use and boats, and in OE form is the least performance-oriented of the three main platforms,” shares McInnis. “There were no factory performance options and tuning required some fairly serious hacking skills.” The 8.1L big-block only lasted until 2009, and when the last L18 rolled off the production line, it marked the end of the factory-produced big-block Chevrolet.

Intergenerational Hand Me Downs

With all the different generations, parts interchangeability between them can be confusing. “The Mark IV and the Gen V/VI have a degree of parts interchangeability, but it is limited,” McInnis offers. “Probably the most significant difference is that the Gen V/VI is designed with a one-piece rear seal. This means that the main cap, oil pump, oil pan, crankshaft and flywheel are unique to that engine.”

Moving to the top of the block, while the bolt pattern between the Mark IV and Gen V/VI cylinder heads are the same, swapping heads isn’t as simple a task as that might make it appear. “The cylinder heads are interchangeable, although cooling passages in the deck, particularly on early Gen V OE blocks, can cause sealing problems with Mark IV heads. The head gaskets are even different between the two,” says McInnis.

Notice the 8.1 is conspicuously absent from the interchangeability discussion. That’s not an oversight. “The 8.1 has almost no interchangeability with the other two,” McInnis says, flatly. “The 8.1 represents the last of the big blocks, and the factory changed a lot of things from the previous versions. If the 8.1 had been the first design back in 1965 and the aftermarket had developed a vast array of performance components for it, things might be different.” With the different head bolt pattern, different oil pan pattern, and a switch to largely metric thread throughout the engine, the Gen VII big-block Chevy is practically its own animal.

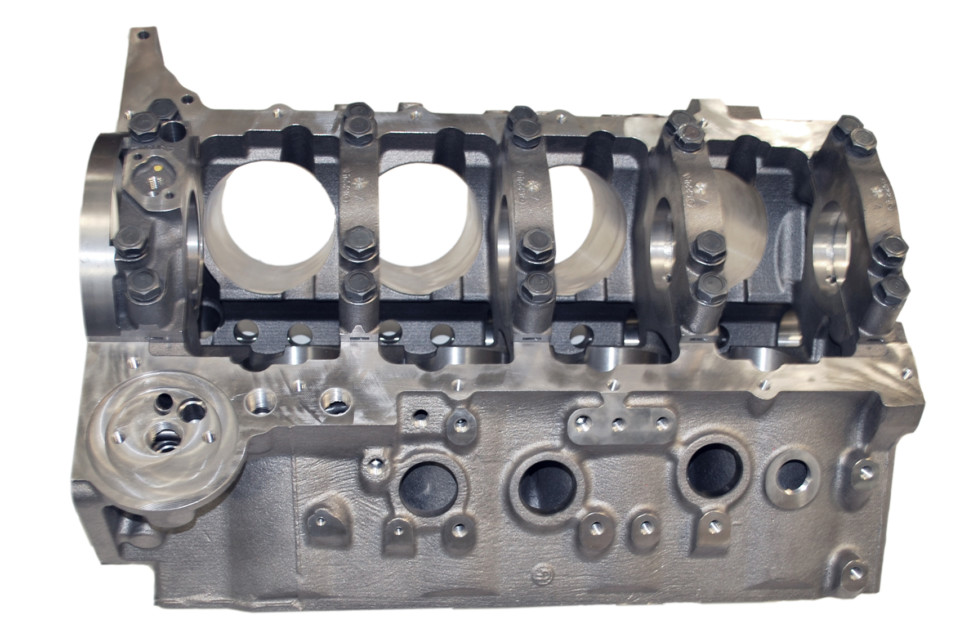

These two blocks are World's current big-block offerings. On the left is the Merlin IV, and on the right is the 8.1L replacement block. While you may notice additional head bolt holes on the Merlin, those are for various race heads on the market, and not for the L18's altered bolt pattern.

The Magic of Merlin

Now that we’ve discussed the three major generations of big-block Chevrolet blocks, we can effectively look at World Products’ aftermarket offerings, which cover Mark IV, Gen V/VI, and the 8.1L variants. “All three types, as produced by World, have significant upgrades over the OEM blocks,” says McInnis. “However, their capabilities are still skewed in the same order as the OEM blocks are, just at a higher level. That is, mostly dictated by the availability of (or lack thereof) performance parts for the respective engine types.”

World has been producing its line of aftermarket blocks for over 25 years, and is constantly improving the lineup, as noted by the fact that current production of the Merlin line of big-block Chevy engine blocks is dubbed the “Merlin IV.” “World has made continuous improvements to the Merlin big-block, with the newest iteration being the Merlin IV. When we made new foundry tooling for the new Merlin IV, we designed it so that all three types of block castings could be produced with the same tools,” McInnis explains.

One of the largest differences between the Mark IV and Gen V/VI block is the one-piece and two-piece rear main seal.

While there are still three distinct versions of the block, World is able to use the same casting for the Mark IV and Gen V/VI blocks. “The Gen V/VI style block uses the same casting [as the Gen IV variant] with some changes in the machining. World’s Gen V/VI block is machined to accept the Gen VI-style one-piece rear seal, timing cover, and oil pan,” says McInnis. “It does have a Mark IV style oil filter pad and fuel pump boss, as well as Siamesed cylinders and splayed 4-bolt main caps.”

The Merlin IV block comes in 21 separate configurations, covering every OEM Mark IV and Gen V/VI applications, along with several configurations designed purely for aftermarket performance.

All of the Merlin blocks are made from high-density cast iron, and are designed to handle huge power. Available deck heights for the .600-inch thick deck range from 9.500-inch up to 10.250-inch, with a maximum bore size of 4.625 inches. At the maximum bore size, the cylinder wall thickness is approximately .290 inches thick (with additional thickness on the thrust side), making for a robust platform, even bored all the way out.

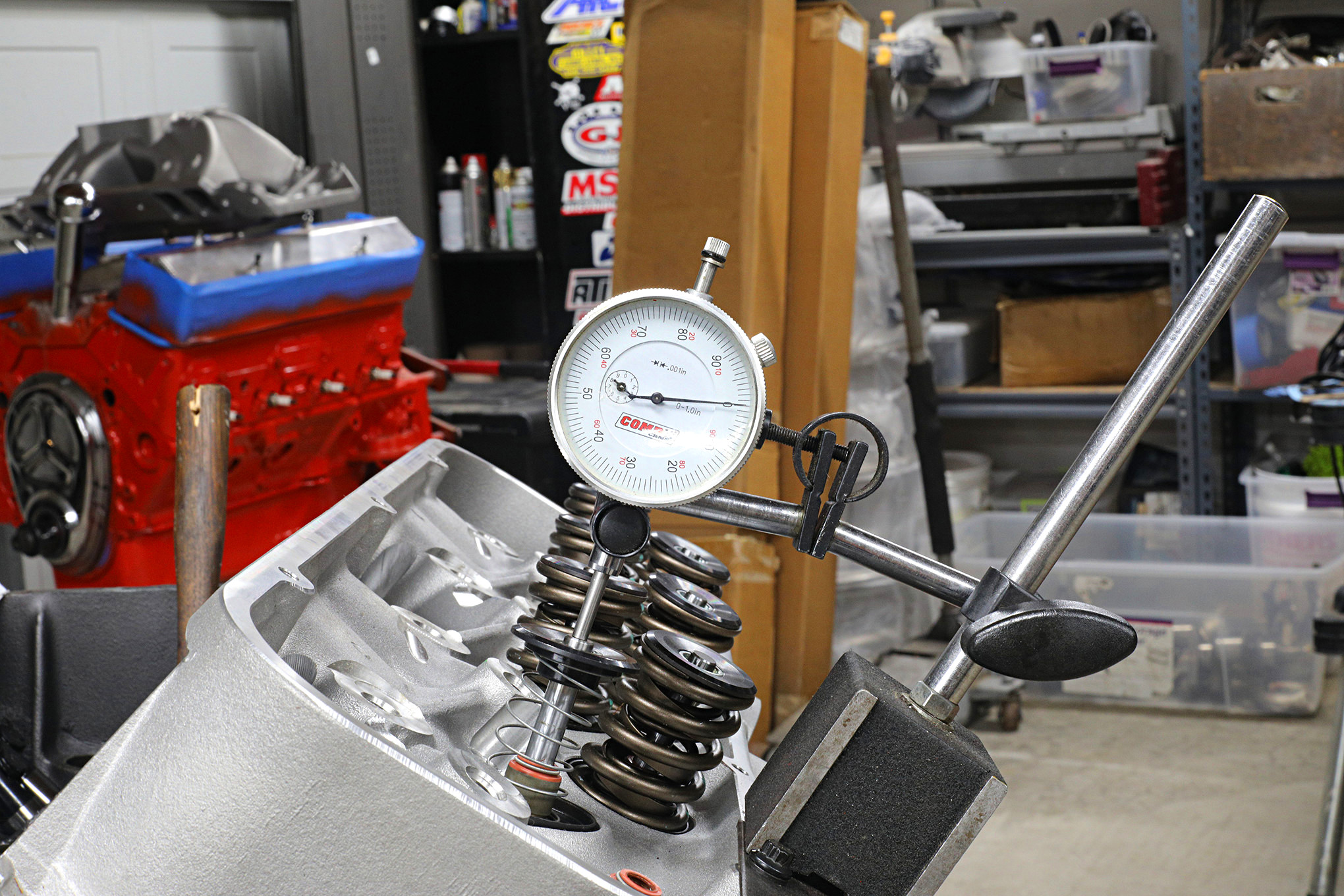

The Merlin IV has traditional-pattern 7/16-inch blind-tapped head bolt holes, along with an additional row of bosses in the valley area for several race heads that utilize the additional bolt holes. The blocks have two options when it comes to the main caps: standard four-bolt nodular-iron versions, or the more robust splayed-four-bolt billet steel caps. The Merlin IV comes with a 2.120-inch cam bore standard, with an option for a 55mm cam bore.

All of the Merlin-series engine blocks come with four-bolt mains standard. Here, you can see the standard nodular-iron main caps, while billet steel main caps, with splayed outer bolts are available as an upgrade and recommended for severe-duty applications, or anything making over 1,000 horsepower.

Internally, the water jackets have been expanded for enhanced cooling capability. The Merlin IV has a priority main oiling system with the block set up for a standard-style oil pump, but with provisions for a relatively-easy conversion to a dry-sump system, if that’s how you roll. The spin-on oil filter location has been revised to clear a kickout-style oilpan, and is dual-drilled to accept stock-style and aftermarket oil pans.

For the 8.1L big-block Chevy, World offers three part numbers for the cast-iron upgraded block, which doesn’t fall under the “Merlin” banner, but incorporates a number of the same upgrades, but in the late-model architecture. Available in three bore sizes — 4.245, 4.495, and 4.595 inches — the max bore size possible for the 8.1-family is 4.625 inches. When coupled with the supplied clearance for a 4.75-inch stroke, displacements of up to 638 cubic inches, are easily attained.

“We made the 8.1 block because GM no longer produced them. It is designed to be a stock replacement with the ability to upgrade performance beyond what the factory blocks were capable of,” says McInnis. “As an upgrade for your 8.1-equipped tow rig or boat it makes more sense, and for industrial applications, they are widely used.”

Again, Merlin IV on the left, World 8.1 on the right. From the rear, you'll notice the blocks are very similar at first glance, but the 8.1L block has passages and mounting provisions for modern electronics.

Which One Is Best?

With all the different variants, which one is best? That’s a very subjective term, but we tried to pin McInnis down on that one. “Inherently, there’s not much difference between them, but practically there is a huge difference,” he says. “The Mark IV style engine has the edge by far. There is an almost limitless range of aftermarket performance parts available from numerous manufacturers, enabling builders to create combinations for just about any type of use imaginable.”

Moving on to the Gen V/VI engines, as the blocks are the same castings as World’s Mark IV Merlin engines, there isn’t a power ceiling difference, at least not one that comes from the engine block. “The Gen V and VI can utilize many of the Mark IV components, but not all,” comments McInnis. There are a few performance parts available for the stuff that is specific to this engine.”

That leaves the Vortec 8100, which is definitely the red-headed step-child of the group. “While there are some aftermarket performance goodies available, it is a very limited selection,” McInnis says.

One of the subtle, but critically important differences of the 8.1L big-block, is the rampant use of metric hardware at the factory. That design shift further separated the Gen VII from the rest of its big-block brethren.

So when it comes to aftermarket performance, it appears the Mark IV pattern engine is the big dog, both in performance capability and variety of parts, which McInnis confirms: “For high performance builds, the Merlin IV (Mark IV style) would be the preferred choice by a large majority.”

However, McInnis was quick to qualify the statement. “It really depends on the application. In a marine application where an 8.1 was previously fitted it would make sense to build that type of engine because it avoids a lot of other changes which would be required to fit a different engine,” McInnis shares. “If all-out performance was the goal, then the Merlin IV would be the better choice, however.”

http://garage.grumpysperformance.com/index.php?threads/big-block-chevy-info.710/

UN-machined SBC blocks have a nominal 9.0" deck height,

its very common to have the deck on a previously undecked block actually measure 9.022"-9.025"

UN-machined BBC blocks have a nominal 9.8" deck height,

its very common to have the deck on a previously undecked block actually measure 9.822-9.825

heres some calculators you might use

from a cost and parts availability vs the potential power levels you can generally expect there's

several BBC engine sizes that have consistently proven to perform rather well

the more common larger displacement combos ,these are

468 cid =454 .060 over bore stock 4"stroke crank

496 cid =454 .060 over bore + a 4.25" stroke crank

540 cid= 4.5" bore + a 4.25" stroke crank

572 cid=4.5" bore + a 4.5" stroke crank

632 cid=4.6" bore + a 4.75" stroke crank

Tech Equations - ThirdGen.Org

The following equations and rules apply only to 4-cycle engines powered by pump gasoline. The equations have been simplified for ease of understanding. Answers will approximate, but generally close enough for use as a guideline. It is recommended that you round your result to the nearest...

www.thirdgen.org

Calculators - Ford-Trucks.com

Air Capacity » Air Capacity, Volumetric Efficiency, Street Carburator Size, Racing Carburetor Size Average MPH and MPG » Miles Per Gallon, Miles Per Hour Brake Horsepower » Horsepower, Torque, Brake Specific Fuel Consumption, Brake Horsepower Loss Center of Gravity » Location Behind Front...

www.ford-trucks.com

Hotrodworks.net - Ballistic Parts

Thanks for stopping by, Hope you enjoy the what you are about to checkout, ( just Basic Hot Rod Stuff for your viewing pleasure.) There are several reasons why it was developed. First, they dig Hot Rods (duh) and doing artwork. Second, The Demand and response from people online wanting my...

Stan Weiss' - Automotive Performance Software / Interactive JavaScript to Calculate Engine's Compression Ratio (CR)

JavaScript Calculators designed for the auto enthusiast. Which will do math for YOU. Interactive JavaScript to Calculate Engine's Compression Ratio (CR)

users.erols.com

users.erols.com

Automotive Performance Software / Interactive Calculators

Computer program designed for the motor sports enthusiast. Performance software that does the math for YOU, also Interactive JavaScript Calculators.

users.erols.com

users.erols.com

gear spread sheet that comes in handy THANKS TO 1FATGMC

Stan Weiss' - Automotive Performance Software / Interactive JavaScript to Calculate Speed(MPH) for given RPM, Rear Gear Ratio and Trans Gear Ratio

JavaScript Calculators designed for the auto enthusiast. Which will do math for YOU. Interactive JavaSript to Calculate Speed(MPH Km/H) for given RPM, Rear Gear Ratio and Trans Gear Ratio

users.erols.com

users.erols.com

Stan Weiss' - Automotive Performance Software / Interactive JavaScript to Calculate Speed(MPH) for given RPM, Rear Gear Ratio and Trans Gear Ratio

JavaScript Calculators designed for the auto enthusiast. Which will do math for YOU. Interactive JavaSript to Calculate RPM for given Speed(MPH), Rear Gear Ratio and Trans Gear Ratio

users.erols.com

users.erols.com

Stan Weiss' - Automotive Performance Software / Interactive JavaScript to Calculate Rear End Gear Ratio needed

JavaScript Calculators designed for the auto enthusiast. Which will do math for YOU. Interactive JavaScript to Calculate Rear End Gear Ratio needed

users.erols.com

users.erols.com

Primary Header Tube Length by JavaScript

Calculate Header Tube Length - by Wallace Racing Home of Pontiac Powered Firebirds,Trans Ams,Pontiac Powered Dragsters,Pontiac Power Rules!

www.pontiacracing.net

How Do Exhaust Headers on a Car Work?

If you're planning to make more power from your engine. Switching to hi-performance exhaust headers are a good idea. Find out how exhaust headers work to improve engine performance.

a few resources to allow you to calculate the ideal results

http://www.tmossporting.com/tabid/1805/Default.aspx

here's some different calculators

http://www.kb-silvolite.com/calc.php?action=comp2

http://www.wallaceracing.com/dynamic-cr.php

http://www.smokemup.com/auto_math/compression_ratio.php

http://not2fast.wryday.com/turbo/com...pressure.shtml

average the results

Last edited by a moderator:

![Click here for more information about JEGS M566DB - Heavy-Duty Die Grinder [1/8 in. & 1/4 in Collet] Click here for more information about JEGS M566DB - Heavy-Duty Die Grinder [1/8 in. & 1/4 in Collet]](/proxy.php?image=https%3A%2F%2Fwww.jegs.com%2Fimages%2Fmini%2F500%2F555%2F555-m566db.jpg&hash=6055cdfe863a756bd593f7d22e4737b8)