KEEP IN MIND, MANY PEOPLE THAT HAVE BROKEN ROCKER STUDS HAVE FAILED TO VERIFY THE PISTON TO VALVE, CLEARANCES, ROCKER STUD TO ROCKER SLOT CLEARANCES,AND SPRING BIND CLEARANCES, etc.

it takes hundreds of pounds of force to bust rocker studs and or bend push rods, if you have those issues STOP AND LOCATE the geometry or CLEARANCE ISSUES CAUSING THE PROBLEM

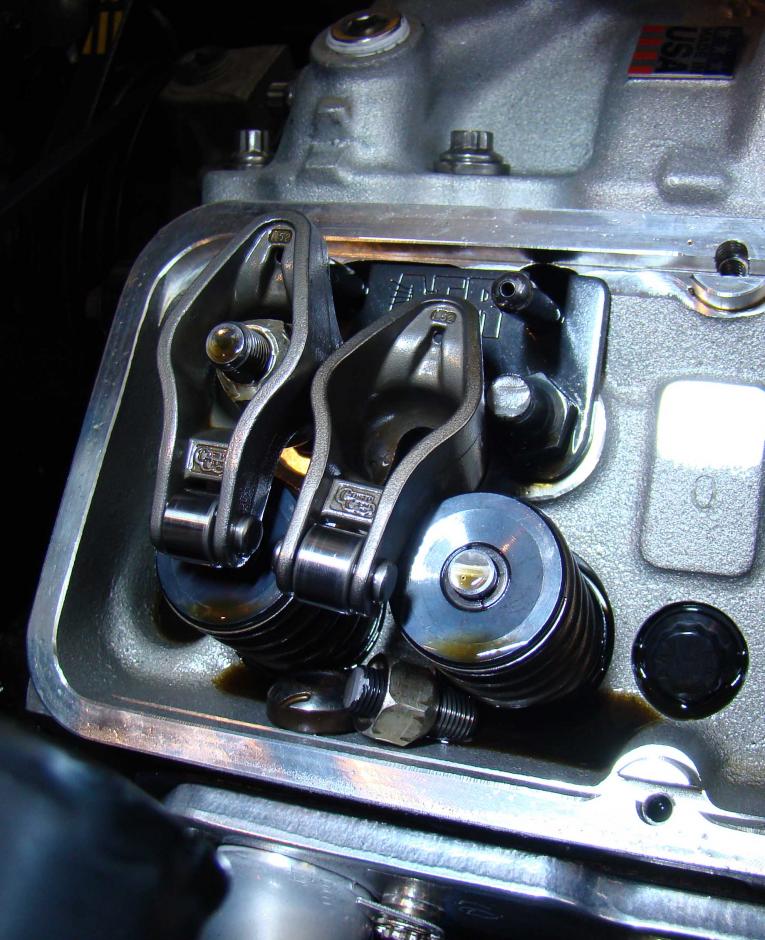

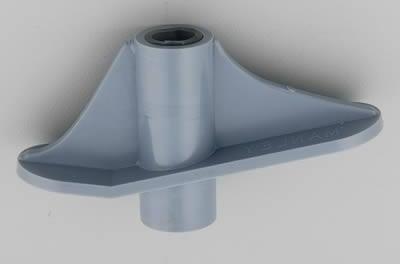

theres several manufacturers and models available , heres a basic 1.5:1 ratio SBC version.

http://www.summitracing.com/parts/lun-85025

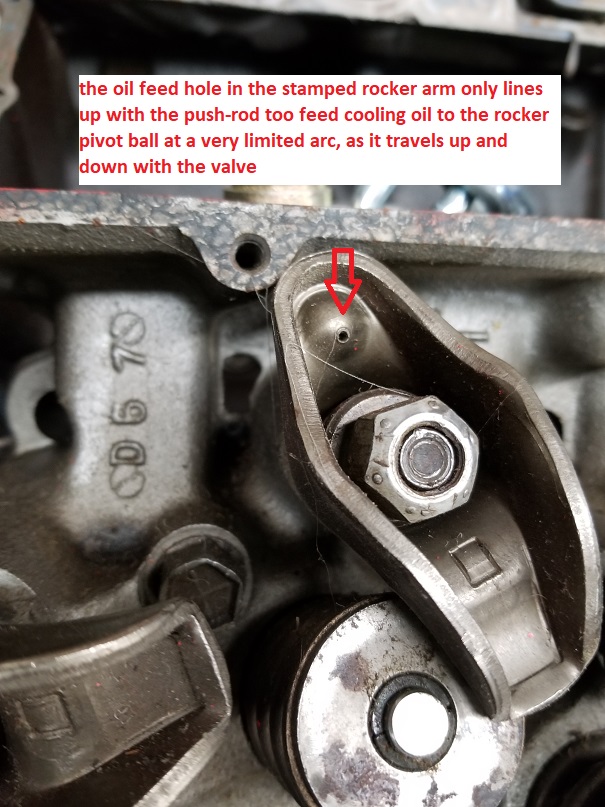

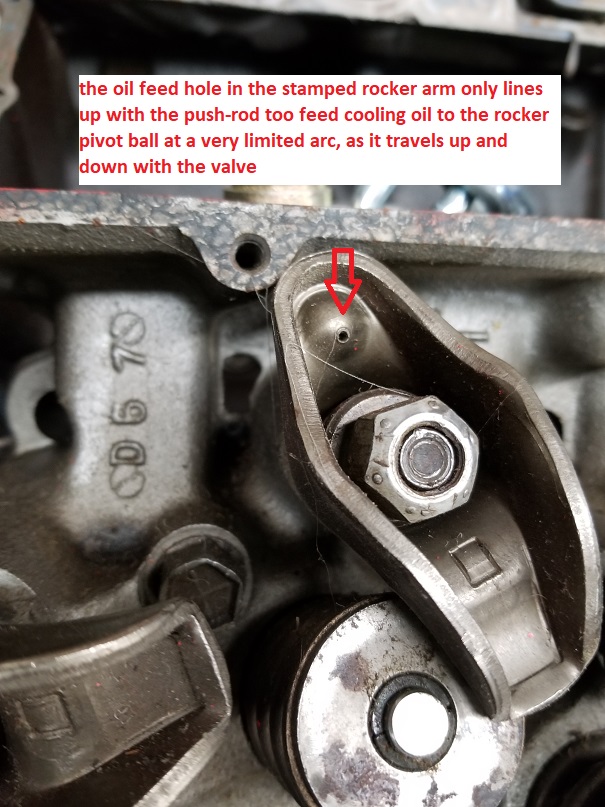

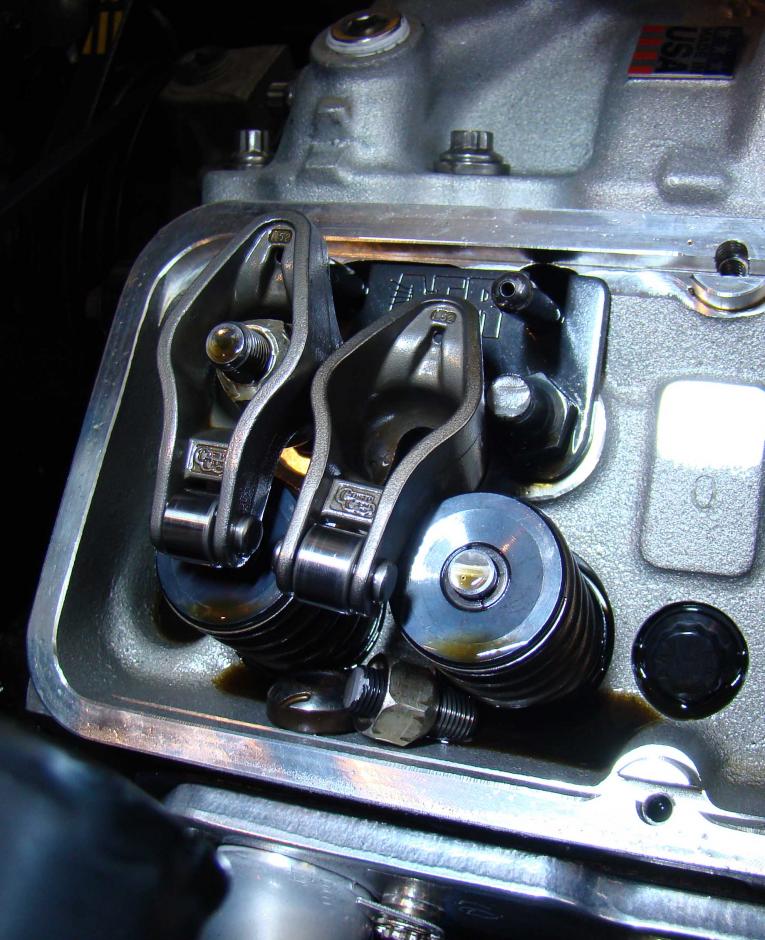

the grooved rocker pivot ball design was an effort by G.M. engineering to economically solve the issue of marginal oil flow causing rocker ball galling, and resulting noisy, or broken valve trains

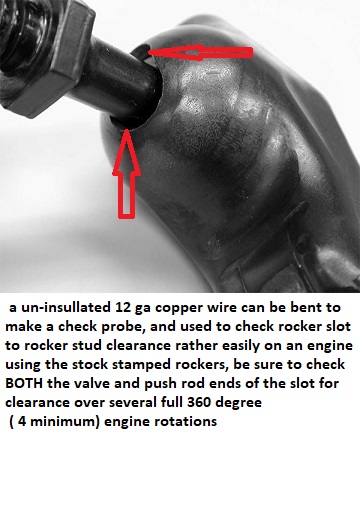

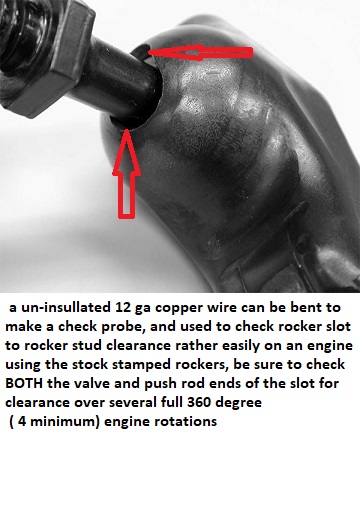

Upgrading to roller rockers or at least long slot stamped rockers will more than likely help, if you find your breaking rocker studs but checking your rocker geometry and valve train clearance is mandatory, and youll need to verify both clearances and geometry thru the full 720 degree engine rotation,and problems frequently only become obvious if you check,or if ignored until you develop problems (that way it gets expensive real fast)

if you install a cam with more lift the stock rockers and valve clearance is frequently not adequate.

read these, don,t skip the sub links and youll find it useful

viewtopic.php?f=52&t=181

[/size]

any change in the valve train components used requires verifying valve train clearances and geometry and potentially you might require new push rods, or rocker studs, springs or retainers ETC.

its been my experience that roller TIP rockers are a TOTAL WASTE of money in most cases, 90% of the friction is in the rocker ball area on the rockers or rocker stud roller bearing on roller rockers NOT AT THE TIPS that BARELY move .040- .050 across the valve tip in most cases, meaning the roller is rarely moving as much distance as a thin paper clip wire is wide

it should be noted that if the rocker stud protrudes into the port it should be trimmed to the port roof as any threads sticking down into the runner disrupt flow and don,t supply extra support to the rocker stud,and stud threads should use loc-tite tread sealant

the rocker stud failure could be the result of many things

but lack of oil flow, that allows the rocker ball to pressure weld to the rocker and snap off the stud is certainly a common one, it could certainly be a defective stud,and that appears to be the case here as theres no indication of extra heat and the break appears to be a stress crack, or its very unlikely but, too much spring pressure,could contribute to the failure.

in some cases the pushrod was clogged, the hole in the pushrod didn,t align with the hole in the rocker or the lifter was defective and was not pumping oil, but in some cases its not paying attention when the valves are adjusted, and getting the rocker adjustment nut, too tight, because that limits the oil flow rates , up the pushrod, and the lifter preload is pushed too far, or clearance issues are certainly suspect

from the ARP web site

Recognizing Common Failures

There are six types of metallurgical failures that affect fasteners. Each type has unique identifying physical characteristics. The following examples are designed to be used like a spark plug reading chart to help analyze fastener failures.

While few of us have access to sophisticated analysis equipment, a standard Bausch and Lomb three lens magnifying glass will generally show 98% of what we want to see. Several of the photos below have been taken utilizing a Scanning Electron Microscope (SEM) and are presented to simply illustrate typical grain configurations after failure.

. Cyclic fatigue failure originated by

hydrogen embrittlement.

Some of the high strength “quench and temper†steel alloys used in fastener manufacture are subject to “hydrogen embrittlement.†L-19, H-11, 300M, Aeromet 100 and other similar alloys popular in drag racing, are particularly susceptible and extreme care must be exercised in manufacture. The spot on the first photo is typical of the origin of this type of failure. The second is a SEM photo at 30X magnification.

more info

http://www.arp-bolts.com/Tech/TechWhy.html

https://www.crower.com/clearance.html?cat=1541

you might want to buy a few of these while they are on sale at a reduced price

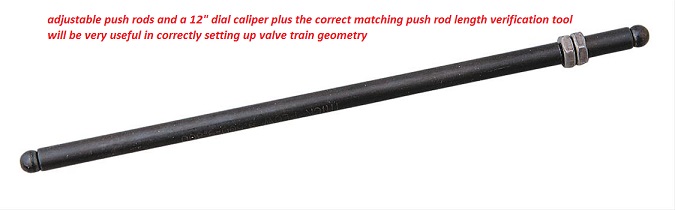

heres a bit of useful related push rod length info (POSTED HERE) youll want to select the correct set or SETS for your shop

Big Block Chevy, Standard Length Big Block Intake 3/8" / .080" 8.275"

295-7941-8 Big Block Chevy, Standard Length Big Block Exhaust 3/8" / .080" 9.250"

295-7969-8 Big Block Chevy, Standard Big Block +.100" Long Intake 3/8" / .080" 8.375"

295-7979-8 Big Block Chevy, Standard Big Block +.100" Long Exhaust 3/8" / .080" 9.350"

295-7951-8 Big Block Chevy, Standard Length Big Block Tall Deck Intake 3/8" / .080" 8.675"

295-7961-8 Big Block Chevy, Standard Length Big Block Tall Deck Exhaust 3/8" / .080" 9.650"

295-7800 V8 396-454 Retro Fit Pushrod Set, Intake & Exhaust, 1965-Present

3/8" / .080"

3/8" / .080" 7.725 Int.

8.675 Exh

295-7913-16 Small Block Chevy, Standard Length Small Block Chevy 3/8" / .080" 7.800"

295-7984-16 Small Block Chevy, +.100" Long 3/8" / .080" 7.900"

295-7934-16 Big Block Ford, Standard Length Ford `72-'78 429-460 3/8" / .080" 8.550"

295-7951-16 Big Block Ford, Standard Length Ford `69-'71 429-460 3/8" / .080" 8.675"

295-7582-16 Oldsmobile, Std Length 455 5/16" 9.550"

5. Cyclic fatigue cracks propagated

from a rust pit (stress corrosion)

Again, many of the high strength steel alloys are susceptible to stress corrosion. The photos illustrate such a failure. The first picture is a digital photo with an arrow pointing to the double origin of the fatigue cracks. The second photograph at 30X magnification shows a third arrow pointing to the juncture of the cracks propagating from the rust pits. L-19, H-11, 300M and Aeromet 100, are particularly susceptible to stress corrosion and must be kept well oiled and never exposed to moisture including sweat. Inconel 718, ARP 3.5 and Custom age 625+ are immune to both hydrogen embrittlement and stress corrosion.

IF Im changing just the cam and lifters do I need to recheck the pushrod length?

JUST WONDERING,IF YOU HAVE STOCK LENGTH PUSHRODS,YOU MILL THE HEADS,USE THIN METAL HEAD GASKETS,WOULDN'T THIS PUT THE ROCKER ARM CLOSER TO THE CAM?THEN WHY DO YOU NEED LONGER PUSHRODS WHEN YOU INSTALL A BIGGER CAM THAN STOCK?YOU WOULD THINK YOU WOULD NEED A SHORTER ONE SINCE THE LOBE IS TALLER THAN STOCK AN THE ROCKER ARM IS CLOSER TO THE CAM BECAUSE OF MILLING & THINNER HEADGASKETS.

while your correct! the answers not always that simple because the cam base circle dia. on the new cam is frequently a differant dia. than the stock cam and the lifter seat height varies also, it will require verifyiong the correct valve train geometry.

you want the rocker to exert it force as much as possiable on the valve centerline to reduce friction and valve guide wear

YOULL NEED TO CAREFULLY CHECK YOUR PARTICULAR ENGINE!

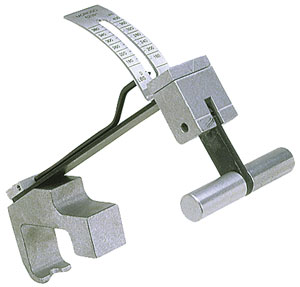

heres a simple way to get close to the correct length

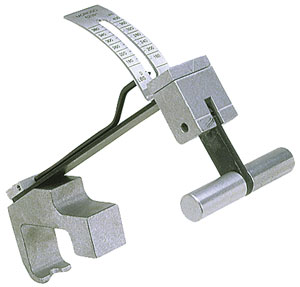

BUY ONE OF THESE

http://www.jegs.com/cgi-bin/ncommerce3/ProductDisplay?prrfnbr=3567&prmenbr=361

after making sure the valve springs are correctly installed you drop the checker in place on the rocker stud and install your adjustable pushrod

adjust the length to fit and measure the resulting length if its within twenty thousands of the stock length its fine for most applications, if its more than 30 thousands long or short get the closest length set available

<b>btw, if your one of the people that still does not own an adjustable push rod! you can easily make your own by cutting a stock pushrod in 1/2 (2 pieces), removeing 1 inch from the total length an then with about 2 " of a 4 inch section of 3/16 or 1/4" thread rod installed and (in one section epoxy it in place leaving about 2" sticking out thread two nuts onto the thread rod and slip on the other end of the cut pushrod,(no epoxy) use the two nuts to adjust to stock length and let the epoxy harded in the one section[/color] now you can easily measure and order custom push rods useing the pushrod checker and adjustable push rod as tools

AND YEAH IT ONLY WORKS WITH THE CYLINDER HEADS ON AND THE INTAKE REMOVED BECAUSE THE HOLE IN THE CYLINDER HEAD that GUIDEs THE PUSH ROD WON,T ALLOW THE NUTS ON THE ADJUSTABLE PUSHROD TO PASS THRU, UNLESS YOU PLACE THE CUT ABOUT 1" from the UPPER END OF THE ADJUSTABLE TEST PUSHROD BUT I prefer to place the adjusting nuts centered as I like to watch for all clearances with the intake manifold removed while manually checking as I turn the engine over by hand durring assembly, and at that point, while checking all the clearances, I use test springs which apply very little load on the push rod</b>

http://www.jegs.com/cgi-bin/ncommerce3/ProductDisplay?prrfnbr=3272&prmenbr=361

HERES OTHER TOOLS YOU MIGHT NEED

SOMETHING TO READ

http://www.compcams.com/information/Products/Pushrods/

CCA-7705 5.800 in. to 9.800 in. adjustment range, Master pushrod length checker 4 piece kit ... $78.69

here

http://www.circletrack.com/techarticles/ctrp_0611_rocker_arm_valvetrain_geometry/index.html

http://www.circletrack.com/techarti...m_valvetrain_geometry/roller_tip_rockers.html

http://www.compcams.com/Technical/FAQ/ValvetrainGeometry.asp

http://www.babcox.com/editorial/ar/eb50232.htm

viewtopic.php?f=52&t=181&hilit=rocker+studs

viewtopic.php?f=52&t=399

viewtopic.php?f=52&t=1376&p=3030&hilit=pushrod+length+checker#p3030

viewtopic.php?f=52&t=1005

viewtopic.php?f=52&t=4957

http://www.customspeedparts.de/content/en/technic/kipphebelgeometrie.php

http://www.hotrod.com/techarticles/camshaft_tips_definitions/index.html

http://www.eatonbalancing.com/blog/2007/12/10/rocker-arm-geometry/

http://www.fordmuscle.com/forums/engine ... tools.html

viewtopic.php?f=52&t=399

viewtopic.php?f=52&t=528

viewtopic.php?f=52&t=7716

viewtopic.php?f=52&t=5902

viewtopic.php?f=52&t=4957

viewtopic.php?f=52&t=2661

viewtopic.php?f=52&t=2746

it takes hundreds of pounds of force to bust rocker studs and or bend push rods, if you have those issues STOP AND LOCATE the geometry or CLEARANCE ISSUES CAUSING THE PROBLEM

theres several manufacturers and models available , heres a basic 1.5:1 ratio SBC version.

http://www.summitracing.com/parts/lun-85025

the grooved rocker pivot ball design was an effort by G.M. engineering to economically solve the issue of marginal oil flow causing rocker ball galling, and resulting noisy, or broken valve trains

Upgrading to roller rockers or at least long slot stamped rockers will more than likely help, if you find your breaking rocker studs but checking your rocker geometry and valve train clearance is mandatory, and youll need to verify both clearances and geometry thru the full 720 degree engine rotation,and problems frequently only become obvious if you check,or if ignored until you develop problems (that way it gets expensive real fast)

if you install a cam with more lift the stock rockers and valve clearance is frequently not adequate.

read these, don,t skip the sub links and youll find it useful

viewtopic.php?f=52&t=181

[/size]

any change in the valve train components used requires verifying valve train clearances and geometry and potentially you might require new push rods, or rocker studs, springs or retainers ETC.

its been my experience that roller TIP rockers are a TOTAL WASTE of money in most cases, 90% of the friction is in the rocker ball area on the rockers or rocker stud roller bearing on roller rockers NOT AT THE TIPS that BARELY move .040- .050 across the valve tip in most cases, meaning the roller is rarely moving as much distance as a thin paper clip wire is wide

it should be noted that if the rocker stud protrudes into the port it should be trimmed to the port roof as any threads sticking down into the runner disrupt flow and don,t supply extra support to the rocker stud,and stud threads should use loc-tite tread sealant

the rocker stud failure could be the result of many things

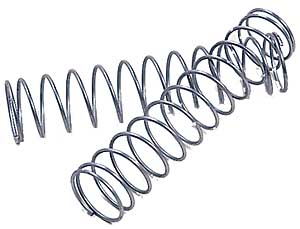

but lack of oil flow, that allows the rocker ball to pressure weld to the rocker and snap off the stud is certainly a common one, it could certainly be a defective stud,and that appears to be the case here as theres no indication of extra heat and the break appears to be a stress crack, or its very unlikely but, too much spring pressure,could contribute to the failure.

in some cases the pushrod was clogged, the hole in the pushrod didn,t align with the hole in the rocker or the lifter was defective and was not pumping oil, but in some cases its not paying attention when the valves are adjusted, and getting the rocker adjustment nut, too tight, because that limits the oil flow rates , up the pushrod, and the lifter preload is pushed too far, or clearance issues are certainly suspect

from the ARP web site

Recognizing Common Failures

There are six types of metallurgical failures that affect fasteners. Each type has unique identifying physical characteristics. The following examples are designed to be used like a spark plug reading chart to help analyze fastener failures.

While few of us have access to sophisticated analysis equipment, a standard Bausch and Lomb three lens magnifying glass will generally show 98% of what we want to see. Several of the photos below have been taken utilizing a Scanning Electron Microscope (SEM) and are presented to simply illustrate typical grain configurations after failure.

. Cyclic fatigue failure originated by

hydrogen embrittlement.

Some of the high strength “quench and temper†steel alloys used in fastener manufacture are subject to “hydrogen embrittlement.†L-19, H-11, 300M, Aeromet 100 and other similar alloys popular in drag racing, are particularly susceptible and extreme care must be exercised in manufacture. The spot on the first photo is typical of the origin of this type of failure. The second is a SEM photo at 30X magnification.

more info

http://www.arp-bolts.com/Tech/TechWhy.html

https://www.crower.com/clearance.html?cat=1541

you might want to buy a few of these while they are on sale at a reduced price

heres a bit of useful related push rod length info (POSTED HERE) youll want to select the correct set or SETS for your shop

Big Block Chevy, Standard Length Big Block Intake 3/8" / .080" 8.275"

295-7941-8 Big Block Chevy, Standard Length Big Block Exhaust 3/8" / .080" 9.250"

295-7969-8 Big Block Chevy, Standard Big Block +.100" Long Intake 3/8" / .080" 8.375"

295-7979-8 Big Block Chevy, Standard Big Block +.100" Long Exhaust 3/8" / .080" 9.350"

295-7951-8 Big Block Chevy, Standard Length Big Block Tall Deck Intake 3/8" / .080" 8.675"

295-7961-8 Big Block Chevy, Standard Length Big Block Tall Deck Exhaust 3/8" / .080" 9.650"

295-7800 V8 396-454 Retro Fit Pushrod Set, Intake & Exhaust, 1965-Present

3/8" / .080"

3/8" / .080" 7.725 Int.

8.675 Exh

295-7913-16 Small Block Chevy, Standard Length Small Block Chevy 3/8" / .080" 7.800"

295-7984-16 Small Block Chevy, +.100" Long 3/8" / .080" 7.900"

295-7934-16 Big Block Ford, Standard Length Ford `72-'78 429-460 3/8" / .080" 8.550"

295-7951-16 Big Block Ford, Standard Length Ford `69-'71 429-460 3/8" / .080" 8.675"

295-7582-16 Oldsmobile, Std Length 455 5/16" 9.550"

Reduced

Part Number: 70463-2

Checking Pushrods

Checking Pushrods 7.975 +-.250 (Pair)

Learn More

Regular Price: $28.13

Your Price: $13.99

Reduced

Part Number: 70461-2

Checking Pushrods

Checking Pushrods 7.150 +-.250 (Pair)

Learn More

Regular Price: $28.13

Your Price: $13.99

Reduced

Part Number: 70465T

Checking Pushrods

Checking Pushrod Kit (1) 8.150 +-.250 (1) 9.150 +-.250

Learn More

Regular Price: $28.13

Your Price: $13.99

Reduced

http://www.summitracing.com/search/...d-length-checkers?autoview=SKU&ibanner=SREPD5

Proform Pushrod Length Checkers 66789 SBC 3/8" rocker studs

Proform Pushrod Length Checkers 66790 SBC 7/16" rocker studs

Proform Pushrod Length Checkers 66806 BBC 7/16" rocker studs

5. Cyclic fatigue cracks propagated

from a rust pit (stress corrosion)

Again, many of the high strength steel alloys are susceptible to stress corrosion. The photos illustrate such a failure. The first picture is a digital photo with an arrow pointing to the double origin of the fatigue cracks. The second photograph at 30X magnification shows a third arrow pointing to the juncture of the cracks propagating from the rust pits. L-19, H-11, 300M and Aeromet 100, are particularly susceptible to stress corrosion and must be kept well oiled and never exposed to moisture including sweat. Inconel 718, ARP 3.5 and Custom age 625+ are immune to both hydrogen embrittlement and stress corrosion.

IF Im changing just the cam and lifters do I need to recheck the pushrod length?

JUST WONDERING,IF YOU HAVE STOCK LENGTH PUSHRODS,YOU MILL THE HEADS,USE THIN METAL HEAD GASKETS,WOULDN'T THIS PUT THE ROCKER ARM CLOSER TO THE CAM?THEN WHY DO YOU NEED LONGER PUSHRODS WHEN YOU INSTALL A BIGGER CAM THAN STOCK?YOU WOULD THINK YOU WOULD NEED A SHORTER ONE SINCE THE LOBE IS TALLER THAN STOCK AN THE ROCKER ARM IS CLOSER TO THE CAM BECAUSE OF MILLING & THINNER HEADGASKETS.

while your correct! the answers not always that simple because the cam base circle dia. on the new cam is frequently a differant dia. than the stock cam and the lifter seat height varies also, it will require verifyiong the correct valve train geometry.

you want the rocker to exert it force as much as possiable on the valve centerline to reduce friction and valve guide wear

YOULL NEED TO CAREFULLY CHECK YOUR PARTICULAR ENGINE!

heres a simple way to get close to the correct length

BUY ONE OF THESE

http://www.jegs.com/cgi-bin/ncommerce3/ProductDisplay?prrfnbr=3567&prmenbr=361

after making sure the valve springs are correctly installed you drop the checker in place on the rocker stud and install your adjustable pushrod

adjust the length to fit and measure the resulting length if its within twenty thousands of the stock length its fine for most applications, if its more than 30 thousands long or short get the closest length set available

<b>btw, if your one of the people that still does not own an adjustable push rod! you can easily make your own by cutting a stock pushrod in 1/2 (2 pieces), removeing 1 inch from the total length an then with about 2 " of a 4 inch section of 3/16 or 1/4" thread rod installed and (in one section epoxy it in place leaving about 2" sticking out thread two nuts onto the thread rod and slip on the other end of the cut pushrod,(no epoxy) use the two nuts to adjust to stock length and let the epoxy harded in the one section[/color] now you can easily measure and order custom push rods useing the pushrod checker and adjustable push rod as tools

AND YEAH IT ONLY WORKS WITH THE CYLINDER HEADS ON AND THE INTAKE REMOVED BECAUSE THE HOLE IN THE CYLINDER HEAD that GUIDEs THE PUSH ROD WON,T ALLOW THE NUTS ON THE ADJUSTABLE PUSHROD TO PASS THRU, UNLESS YOU PLACE THE CUT ABOUT 1" from the UPPER END OF THE ADJUSTABLE TEST PUSHROD BUT I prefer to place the adjusting nuts centered as I like to watch for all clearances with the intake manifold removed while manually checking as I turn the engine over by hand durring assembly, and at that point, while checking all the clearances, I use test springs which apply very little load on the push rod</b>

http://www.jegs.com/cgi-bin/ncommerce3/ProductDisplay?prrfnbr=3272&prmenbr=361

HERES OTHER TOOLS YOU MIGHT NEED

SOMETHING TO READ

http://www.compcams.com/information/Products/Pushrods/

CCA-7705 5.800 in. to 9.800 in. adjustment range, Master pushrod length checker 4 piece kit ... $78.69

here

http://www.circletrack.com/techarticles/ctrp_0611_rocker_arm_valvetrain_geometry/index.html

http://www.circletrack.com/techarti...m_valvetrain_geometry/roller_tip_rockers.html

http://www.compcams.com/Technical/FAQ/ValvetrainGeometry.asp

http://www.babcox.com/editorial/ar/eb50232.htm

viewtopic.php?f=52&t=181&hilit=rocker+studs

viewtopic.php?f=52&t=399

viewtopic.php?f=52&t=1376&p=3030&hilit=pushrod+length+checker#p3030

viewtopic.php?f=52&t=1005

viewtopic.php?f=52&t=4957

http://www.customspeedparts.de/content/en/technic/kipphebelgeometrie.php

http://www.hotrod.com/techarticles/camshaft_tips_definitions/index.html

http://www.eatonbalancing.com/blog/2007/12/10/rocker-arm-geometry/

http://www.fordmuscle.com/forums/engine ... tools.html

viewtopic.php?f=52&t=399

viewtopic.php?f=52&t=528

viewtopic.php?f=52&t=7716

viewtopic.php?f=52&t=5902

viewtopic.php?f=52&t=4957

viewtopic.php?f=52&t=2661

viewtopic.php?f=52&t=2746

Last edited by a moderator: