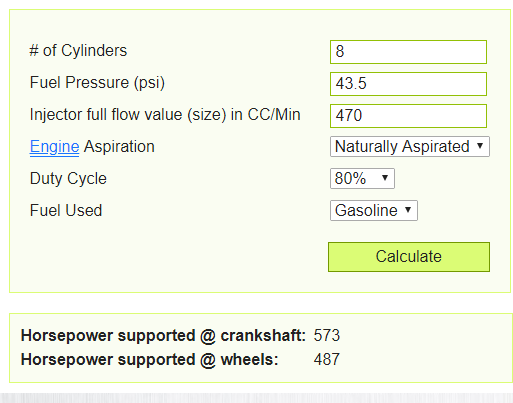

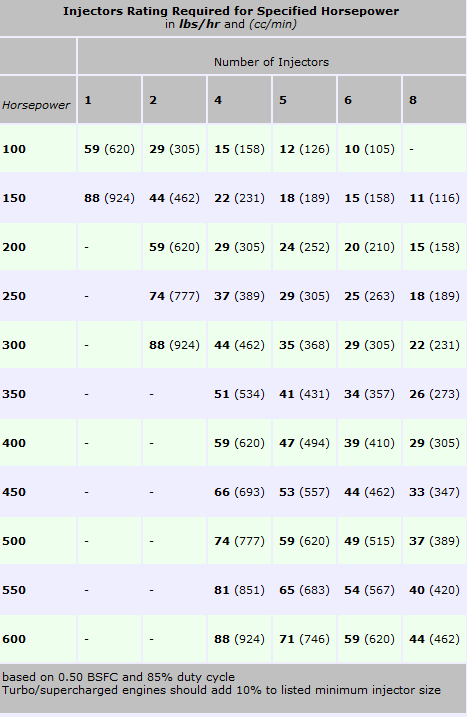

be sure you calculate the correct size injector and be sure you order the correct size injectors you need

be sure to accurately calculate the injector flow rate needed at the delivered fuel rail pressure

example on my corvette a 470cc in each runner port injector is approximately a 44 lb injector

https://fuelinjectorclinic.com/flow-calculator

Fuel Injector Calculator

FuelTech offers a Fuel Injector Calculator to assist racers and builders select the proper fuel injector sizing. Picking the proper fuel injector size is critical for performance and tuning control. All FuelTech engine management systems are capable of driving stock injectors to massive 850...

https://www.injectorrx.com/injector-size-calculator/

https://injector-rehab.com/shop/Injector-Flow-Conversion.html

https://fuelinjectorclinic.com/hp-calculator

https://www.witchhunter.com/injectorcalc1.php

http://www.wallaceracing.com/injector-sizing.php

http://www.raceworks.com.au/calculators/injector-hp-calculator/

http://www.rcfuelinjection.com/Technical

http://www.enginelabs.com/news/calculating-fuel-demands-and-injector-sizing-with-efi-university/

http://garage.grumpysperformance.com/index.php?threads/ideal-tpi-build.12203/#post-76070

related thread

Any ideas how fuel gets into oil?

I think somewhere in the past there was a known failure with the very popular, mass produced 3800 v6 motors found in millions of Chevys, Pontiacs, Buicks and Oldsmobles from the late 1980’s to the early 2000’s. My wife took the kid’s car that doesn’t get driven much at all to the pharmacy on...

garage.grumpysperformance.com

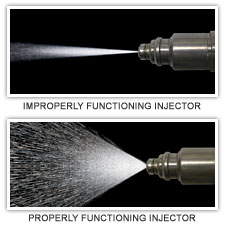

heres a bit of advice! so many times I get called over to help in some project, only to find the problems the guys hoping I can solve could have been avoided entirely ,

if the guy whos at this point is going partially insane, had only bothered to carefully read the details or installation instructions.

many times youll see the guy ordered the wrong part number, and theres a very similar component that exactly matches the concept ,

hes currently waist deep into, only to find the component he ordered is not compatible with the rest of the parts, hes working with.

Ive seen guys order high impedance injectors that are installed on a controller designed for low impedance injectors

http://fuelinjectorclinic.com/faqs

You can measure the resistance across the two electrical terminals of the injector. If the resistance is between 1.5 and 4.0 Ohm you have low impedance injectors. If the resistance is between 8 and 16 Ohm you have high impedance injectors.

https://www.hotrod.com/articles/hrdp-1211-low-impedance-vs-high-impedance-fuel-injectors/

Low impedance (peak and hold) injectors have a resistance of between 2 and 4 ohms. High impedance(saturated) injectors have a resistance of between 10 and 14 ohms. Low impedance and high impedance injectors cannot be used interchangeably without modification of the injector drivers.

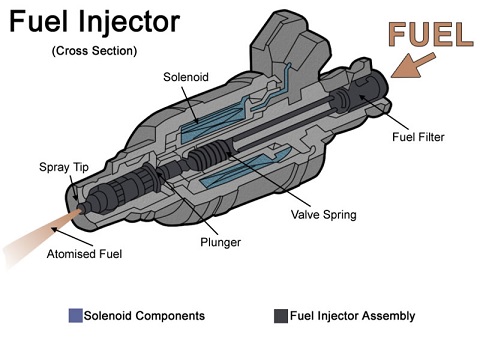

What are the differences between low impedance/peak & hold and high impedance/saturated injectors?

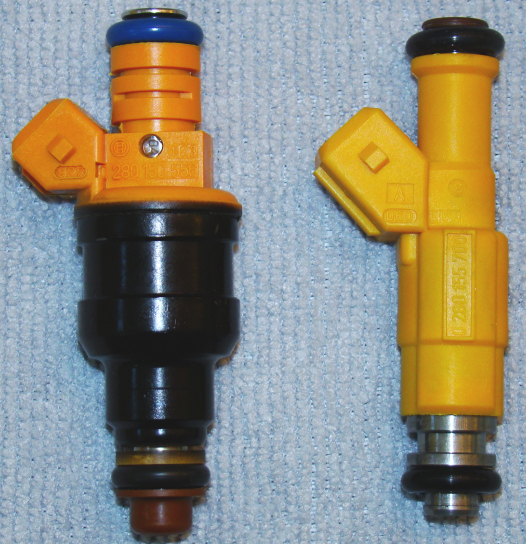

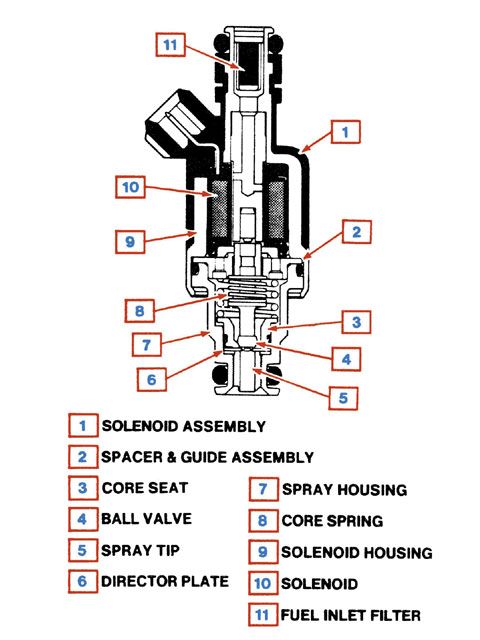

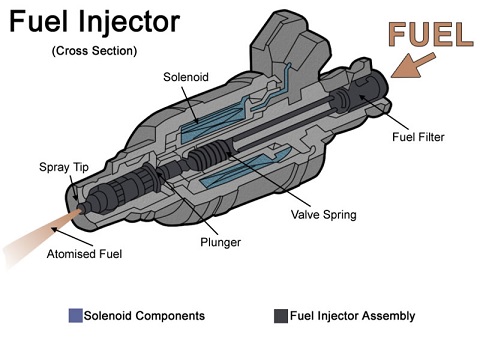

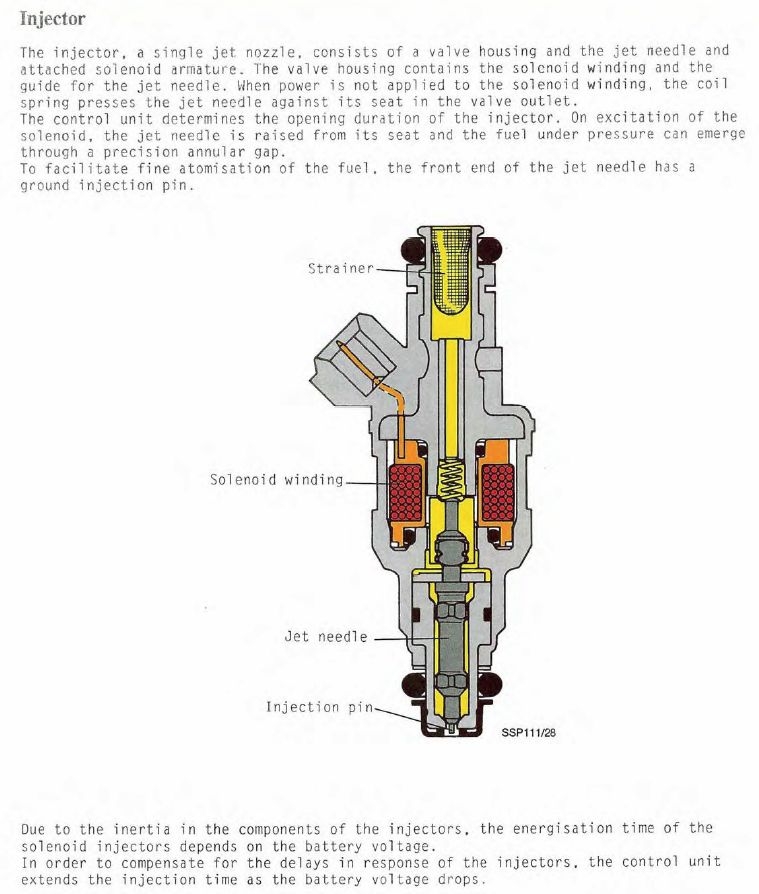

The older fat body style low impedance injectors (1.5 to 4.0 Ohm) used to have faster open and close times due to the type of electrical signal pattern emitted by an ECU equipped with proper P&H signal transmitters. This “Peak and Hold” injector signal typically uses a high (4 amp) initial current to open the injector, and which reduces to a lower (1 amp) current to keep the injector open until the pulse ends. Since this method put less total current into the coil, the coil heated up less and was therefore more reliable. Since the “hold” or lower current part of the signal has created a weaker magnetic field, the injector will also close more quickly.

High impedance injectors (10 to 16 Ohm) are triggered by a low (typically around 1.2 amps) constant current signal and kept open by the same constant (saturated) current for the entire cycle. Most OEM injectors today are high impedance injectors being driven by saturated injector signals from the ECU since car manufacturers are most interested in the simpler saturated signal which is more cost effective to produce when building ECU’s, especially where there is no apparent loss of drivability or performance.

https://www.summitracing.com/parts/...MIsMryyOf_3gIVjoTICh1o7wzhEAQYAiABEgKO9fD_BwE

https://www.summitracing.com/parts/...MInIGXief_3gIVy-DICh1rpgH3EAYYAiABEgJLafD_BwE

http://www.megamanual.com/v22manual/minj.htm

https://www.southbayfuelinjectors.com/fuel-injectors/high-performance

http://fuelinjectorclinic.com/hp-calculator

https://www.rceng.com/technical.aspx

READ THROUGH THIS CLOSELY RELATED THREAD

AND SUB LINKED INFO CAREFULLY

http://garage.grumpysperformance.com/index.php?threads/how-big-a-fuel-pump-do-you-need.1939/

http://www.fordracingparts.com/download ... FIComp.pdf

http://www.smartfireinjectors.com/fuelflowchart.html

http://www.smartfireinjectors.com/fuelflowchart.html

https://www.rceng.com/technical.aspx

https://www.holley.com/products/fuel_sy ... ts/522-831

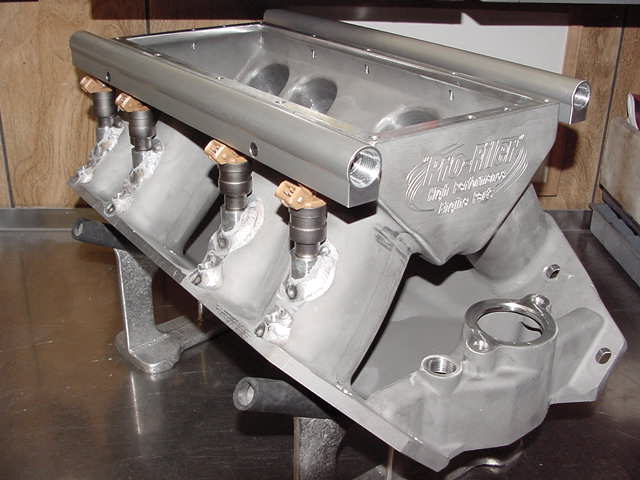

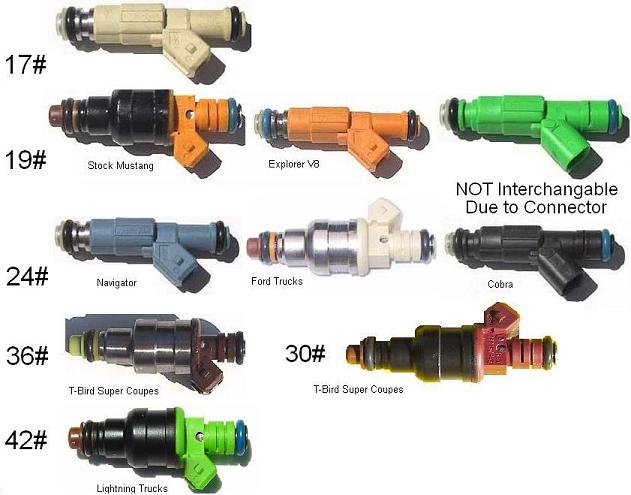

theres a good selection, of types, length, manufacturers, and mechanical types to select from, but obviously you need to calculate the correct size and know what fits your application.

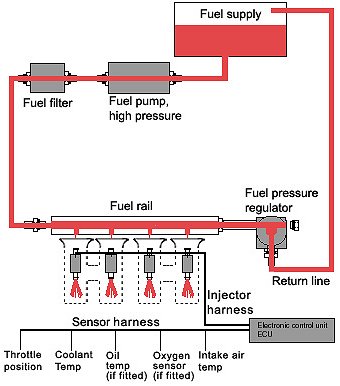

keep in mind sensor input to the controling computer from MAT,MAP,MAF,HEAT , OXYGEN and other SENSORS have a HUGE effect on the injector effective flow rates.

calculate it yourself.

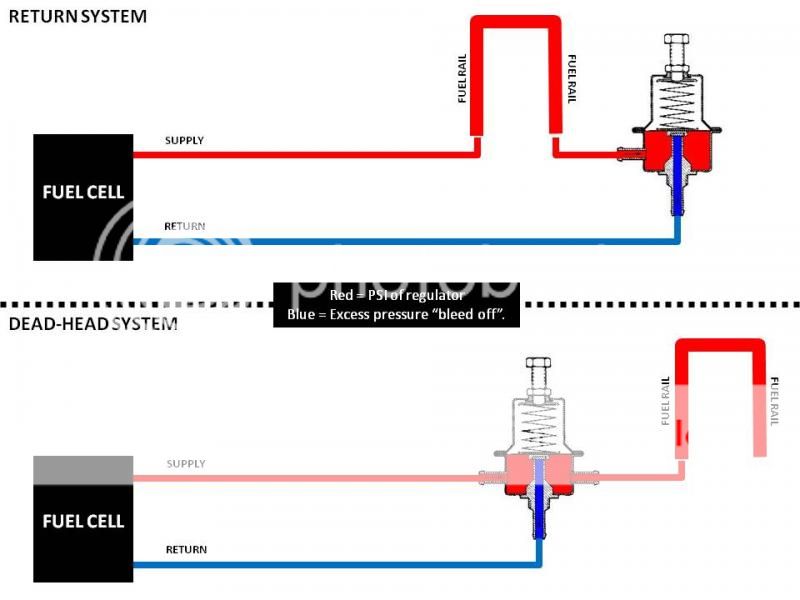

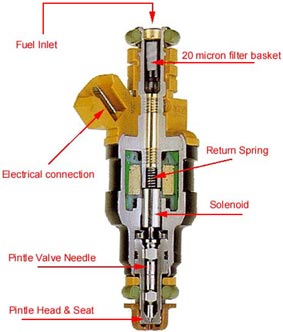

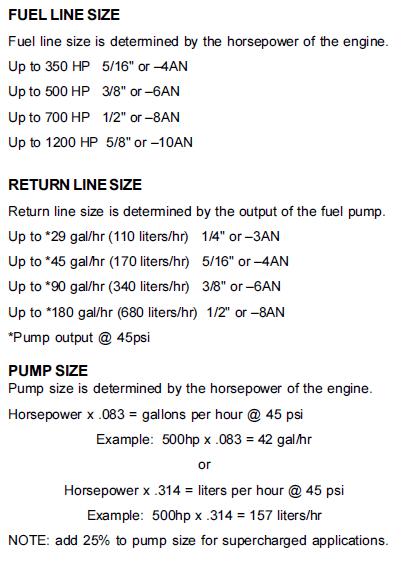

Max potential fuel flow is controlled by the injector size and design, and the pressure and voluum available in the fuel rails feeding the injectors

but

Effective FLOW

will rarely exceed 85% of the injectors RATED max and thats controlled in large extent by the pulse duration+sensor input values, the computer provides

http://garage.grumpysperformance.co...lay-switch-locations-and-info.728/#post-43477

http://garage.grumpysperformance.com/index.php?threads/what-kills-o2-sensors.3049/#post-51701

http://garage.grumpysperformance.com/index.php?threads/testing-1985-89-m-a-f-sensor.1475/#post-43635

watch these videos

http://www.youtube.com/watch?v=l2ne6AVn ... re=related

http://www.youtube.com/watch?v=aIUJbTXN ... re=related

links

http://garage.grumpysperformance.co...at-manifold-air-temp-sensor.10349/#post-42530

http://garage.grumpysperformance.com/index.php?threads/testing-1985-89-m-a-f-sensor.1475/#post-43635

http://garage.grumpysperformance.co...lay-switch-locations-and-info.728/#post-25471

http://www.witchhunter.com/injectorcalc1.php4

http://www.holley.com/TechService/Library.asp

http://www.scottsautorepair.net/viewtopic.php?f=10&t=33

http://www.injector.com/injectorselection.php

http://www.rceng.com/technical.aspx#Sel ... ctor_Size_

http://www.youtube.com/watch?v=7oTirEZN ... re=related

http://www.fuelinjectorconnection.com/s ... rcalc.html

http://www.youtube.com/watch?v=TMCrylOx ... re=related

http://www.witchhunter.com/injectorcalc1.php4

RELATED LINKS

http://www.rceng.com/technical.aspx

http://www.slowgt.com/Calc1.htm#FPHP

http://www.iroczone.com/calcs/injectorsize.htm

http://www.injectorsplus.com/

http://www.csgnetwork.com/fiflowcalc.html

http://www.bgsoflex.com/pwcomp.html

http://golenengineservice.com/calc/calcpchg.htm

http://www.ecs.fullerton.edu/~sowell/ja ... estRig.pdf

http://www.witchhunter.com/injectorcalc1.php4

http://users.erols.com/srweiss/calcpchg.htm

http://www.z31.com/software/injector.pl

http://www.solutions29.com/injcalc.htm

http://www.injectorrx.com/sizing.html

Holley Injector Tech Said:

HIGH IMPEDANCE INJECTORS — Most injectors can be divided into two major categories: high impedance 12 to 16 Ohms and low impedance 1.2 to 4.0 Ohms. The high impedance injectors are used with ECUs that are designed with saturation drivers. The advantage of using saturation drivers is that the currents running through the ECU circuits and the injectors are relatively low thus generating less heat. The disadvantage of saturation drivers is that the driver has a slower response time, which could affect the full utilization of such a system at very high engine RPM.

LOW IMPEDANCE INJECTORS — The low impedance injectors are designed to be run with an ECU that employs peak and hold drivers (also called current sensing or current limiting drivers). The current ratio (peak to hold) is generally 4:1 and the most common drivers available are 4 amp peak/1 amp hold or 2 amp peak/ 0.5 amp hold. The peak current is generated to overcome the inertia of the closed valve and once the valve is open the driver cuts down to 1/4 of the peak current to hold the injector open until the end of the metering event. Low impedance injector designs are mostly used in high flow applications.

http://www.racetronix.biz/itemdesc.asp? ... 6x&eq=&Tp=

http://www.racetronix.biz/itemdesc.asp? ... 91&eq=&Tp=

http://www.racetronix.biz/items.asp?Cc= ... =1&Tp=&Bc=

STOCK TPI,LTI,LSI ENGINES USE HIGH IMPEDANCE INJECTORS —

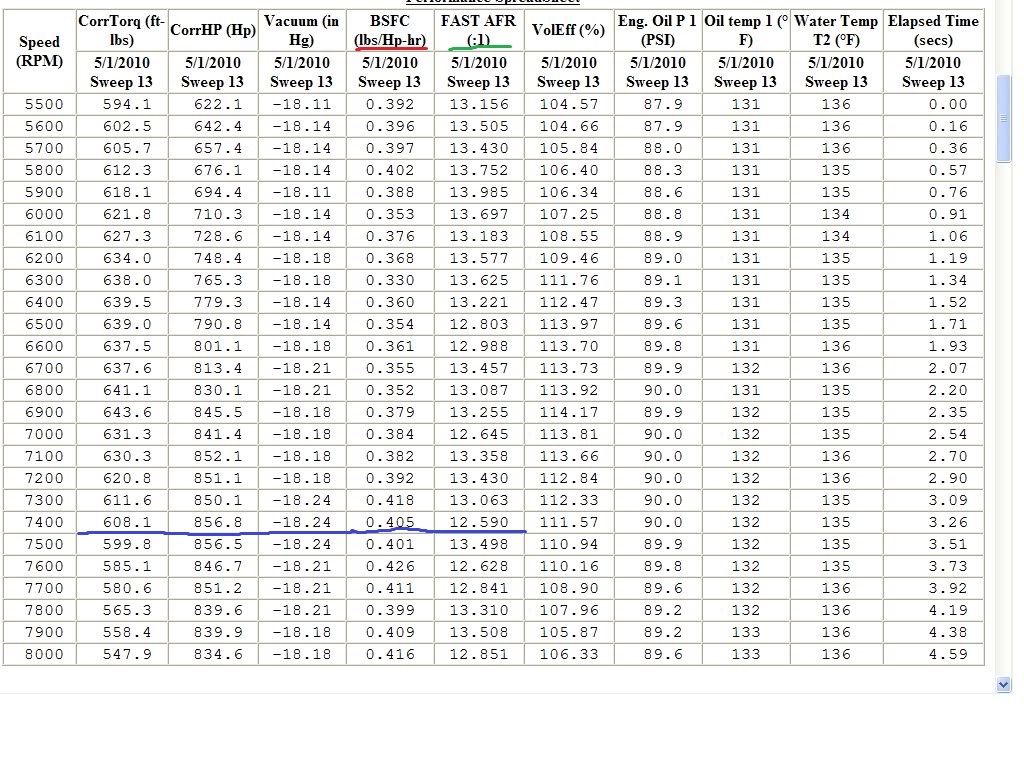

LETS LOOK AT A DYNO SHEET FOR A BIT OF INFO

http://www.land-and-sea.com/dyno-tech-t ... g_bsfc.htm

http://www.carcraft.com/techarticles/re ... yno_sheet/

http://hotrodenginetech.com/engine-dyno-testing/

NOTICE THE BSFC and fuel/air ratio on this dyno sheet from a LS race engine that makes almost 900hp

lets randomly select 7400 rpm

hes got 608 ft lbs of torque

/thats making about 857 horse power,

near the ideal 12.6:1 fuel air ratio,

.405 lbs of fuel per horse power per hour

a bit of math shows .405 lbs of fuel per hour x 857 hp=347 lbs of fuel per hour or 5.78 lbs per minute.

gas weights close to 6.1 lbs per gallon , so to make that 857 hp hes burning nearly a gallon per minute in fuel.

obviously he will need a fuel supply system that maintains that flow rate, plus a bit more at the injector fuel rail at 40 psi or higher

if we assume hes running at 75% of injector flow, so he has some safety margin built into the fuel delivery system, we see that 347 lbs of fuel per hour, delivered =347/75 x100=463 labs of fuel flow potential, divided by 8 injectors= a 58 lb minimum injector size, (60lb-64 lbs in an injector size selected,makes more sense)

read these links

http://fuelinjectorconnection.com/shop/ ... at&catId=2

viewtopic.php?f=55&t=2055&p=6026#p6026

Attachments

Last edited by a moderator: