http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.compcams.com/Community/Articles/Details.asp?ID=1737510521

http://users.erols.com/srweiss/tablehdc.htm

http://www.thecarburetorshop.com/Carburetorsizeselection.htm

http://www.wallaceracing.com/runnertorquecalc.php

http://www.wallaceracing.com/intake-runner-length.php

http://www.wallaceracing.com/lpv.php

http://www.wallaceracing.com/ca-calc.php

http://www.jsme.or.jp/esd/COMODIA-Procs ... 4_P535.pdf

http://www.malcams.com/legacy/misc/headflow.htm

http://victorylibrary.com/mopar/intake-tech-c.htm

http://www.4secondsflat.com/Carb_CFM_Calculator.html

heres a chart FROM THE BOOK,HOW TO BUILD BIG-INCH CHEVY SMALL BLOCKS with some common cross sectional port sizes

(measured at the smallest part of the ports)

...........................sq inches........port cc

edelbrock performer rpm ....1.43.............170

vortec......................1.66.............170

tfs195......................1.93.............195

afr 180.....................1.93.............180

afr 195.....................1.98.............195

afr 210.....................2.05.............210

dart pro 200................2.06.............200

dart pro 215................2.14.............215

brodix track 1 .............2.30.............221

dart pro 1 230..............2.40.............230

edelbrock 23 high port .....2.53.............238

edelbrock 18 deg............2.71.............266

tfs 18 deg..................2.80.............250

DYNO DON POSTED THIS BIT OF INFO

"AFR 195 Eliminators

actual cc's in the intake port.....184

cross section area...2.13 sq.in

Flow spec's.....281/221

AFR 195 comp Eliminators

actual cc's ....189

cross section...2.15 sq.in

Flow spec's...306/235

Trick Flow 195 K D

before porting actual cc's....185

after porting ...188

cross section....2.13 sq.in

Flow spec's....270/210

Edelbrock Etec 200's

actual cc's before porting N/A

after porting....197

cross section...2.13

Flow spec's...270/218

Potential HP based on Airflow (Hot Rod, Jun '99, p74):

Airflow at 28" of water x 0.257 x number of cylinders = potential HP

or required airflow based on HP:

HP / 0.257 / cylinders = required airflow

SO HOW MUCH WOULD YOU LIKELY GAIN FROM A HEAD SWAP THAT ALLOWED YOUR HEAD FLOW ON A SERIOUS BIG BLOCK TO JUMP FROM LETS SAY 370CFM to lets say 425CFM?

ITS A COMMON MISCONCEPTION,THAT YOU MEASURE PORT CROSS SECTION AT THE PORT ENTRANCE,BUT ITS NOT the port area at the entrance , you need to use in the calcs, ITS the MINIMAL port cross section at the SMALLEST point in the port, usually near the push rod area.

LIKE a funnel, its not the largest part of the opening but the smallest thats the restriction to flow

SO HOW do you MEASURE THEN??

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=5649

http://store.summitracing.com/partdetail.asp?autofilter=1&part=SUM-900014&N=700+115&autoview=sku

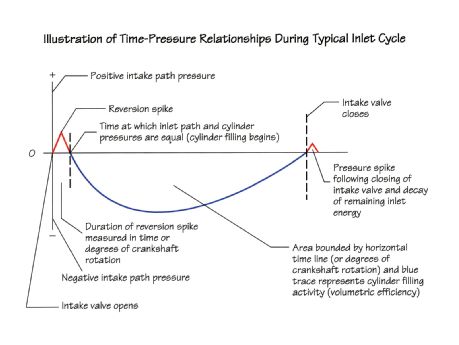

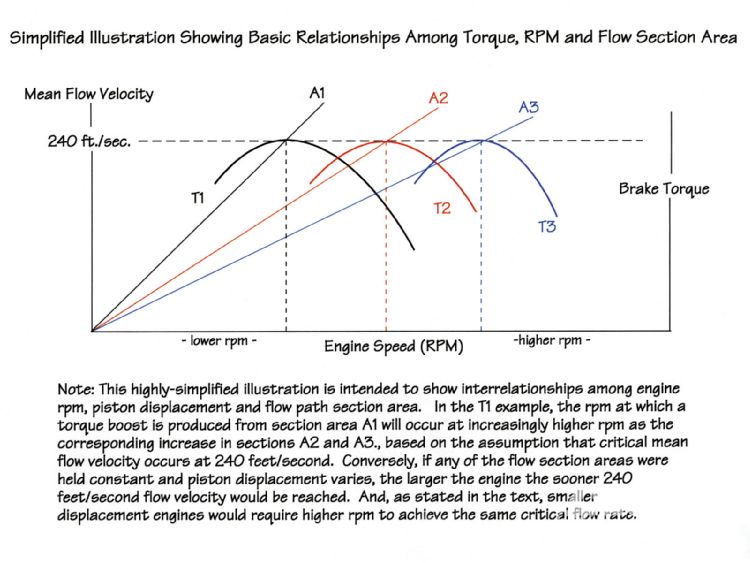

runner LENGTH and CROSS SECTION plus PLENUM VOLUME (if there is a plenum)effects the intake harmonics and how effectively you can ram tune the intake runner charge to fill the cylinders, and don,t forget exhaust scavaging , compression ratio and cam timing, and valve curtain area,and drive train gearing must match the intended combos effective operational power band

http://victorylibrary.com/mopar/intake-tech.htm

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.bgsoflex.com/intakeln.html

http://www.engr.colostate.edu/~allan/fluids/page7/PipeLength/pipe.html

http://www.compcams.com/Community/Articles/Details.asp?ID=1737510521

http://users.erols.com/srweiss/tablehdc.htm

http://www.thecarburetorshop.com/Carburetorsizeselection.htm

http://www.wallaceracing.com/runnertorquecalc.php

http://www.wallaceracing.com/intake-runner-length.php

http://www.wallaceracing.com/lpv.php

http://www.wallaceracing.com/ca-calc.php

http://www.jsme.or.jp/esd/COMODIA-Procs ... 4_P535.pdf

http://www.malcams.com/legacy/misc/headflow.htm

http://victorylibrary.com/mopar/intake-tech-c.htm

http://www.4secondsflat.com/Carb_CFM_Calculator.html

heres a chart FROM THE BOOK,HOW TO BUILD BIG-INCH CHEVY SMALL BLOCKS with some common cross sectional port sizes

(measured at the smallest part of the ports)

...........................sq inches........port cc

edelbrock performer rpm ....1.43.............170

vortec......................1.66.............170

tfs195......................1.93.............195

afr 180.....................1.93.............180

afr 195.....................1.98.............195

afr 210.....................2.05.............210

dart pro 200................2.06.............200

dart pro 215................2.14.............215

brodix track 1 .............2.30.............221

dart pro 1 230..............2.40.............230

edelbrock 23 high port .....2.53.............238

edelbrock 18 deg............2.71.............266

tfs 18 deg..................2.80.............250

DYNO DON POSTED THIS BIT OF INFO

"AFR 195 Eliminators

actual cc's in the intake port.....184

cross section area...2.13 sq.in

Flow spec's.....281/221

AFR 195 comp Eliminators

actual cc's ....189

cross section...2.15 sq.in

Flow spec's...306/235

Trick Flow 195 K D

before porting actual cc's....185

after porting ...188

cross section....2.13 sq.in

Flow spec's....270/210

Edelbrock Etec 200's

actual cc's before porting N/A

after porting....197

cross section...2.13

Flow spec's...270/218

Potential HP based on Airflow (Hot Rod, Jun '99, p74):

Airflow at 28" of water x 0.257 x number of cylinders = potential HP

or required airflow based on HP:

HP / 0.257 / cylinders = required airflow

SO HOW MUCH WOULD YOU LIKELY GAIN FROM A HEAD SWAP THAT ALLOWED YOUR HEAD FLOW ON A SERIOUS BIG BLOCK TO JUMP FROM LETS SAY 370CFM to lets say 425CFM?

A HARD number that has held pretty true for conventional BBC on gasoline , with compression ratios up ner optimum, near 12:1-13.5:1 to predict peak HP from head flow is .25-.27 x intake flow rate @ 28" x 8 (# of cyls). Like others have said, a lot of variables,like efficiency of exhaust scavenging,compression ratio and valve lift VS port potential flow, but it has been within 20 or 30 HP on several different BBC's I've seen being dynoed.

For example, I had an 357 AFR-headed 540, the heads flow 425cfm @ 28". So 425 x .27 x 8 = 918 HP. It made 940. Another motor calc'd at 1030, made 1040 on the dyno.

Using the same logic, 50 cfm x .27 x 8 = 108 hp. It's not that simple, it depends on combination, how optimized everything is etc. But if you are looking for round numbers, 50-75 hp is probably realistic, 100 hp possible

ITS A COMMON MISCONCEPTION,THAT YOU MEASURE PORT CROSS SECTION AT THE PORT ENTRANCE,BUT ITS NOT the port area at the entrance , you need to use in the calcs, ITS the MINIMAL port cross section at the SMALLEST point in the port, usually near the push rod area.

LIKE a funnel, its not the largest part of the opening but the smallest thats the restriction to flow

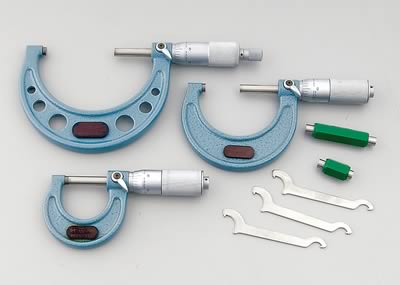

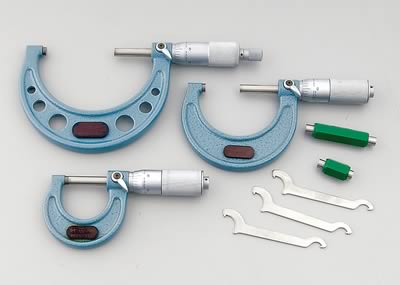

SO HOW do you MEASURE THEN??

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=5649

http://store.summitracing.com/partdetail.asp?autofilter=1&part=SUM-900014&N=700+115&autoview=sku

runner LENGTH and CROSS SECTION plus PLENUM VOLUME (if there is a plenum)effects the intake harmonics and how effectively you can ram tune the intake runner charge to fill the cylinders, and don,t forget exhaust scavaging , compression ratio and cam timing, and valve curtain area,and drive train gearing must match the intended combos effective operational power band

http://victorylibrary.com/mopar/intake-tech.htm

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.bgsoflex.com/intakeln.html

http://www.engr.colostate.edu/~allan/fluids/page7/PipeLength/pipe.html

Last edited by a moderator: