First Id point out that nearly everyone occasionally confuses or at least makes the mistake of using the wrong abbreviation, (LSA, and LCA) these are terms,

that are almost, at least in many discussions

,incorrectly used interchangeably which they are not.

which they are not.

https://www.youtube.com/watch?v=9E3Is_ZsbfM

Quote Reply

Select for moderation Report Edit Delete IP

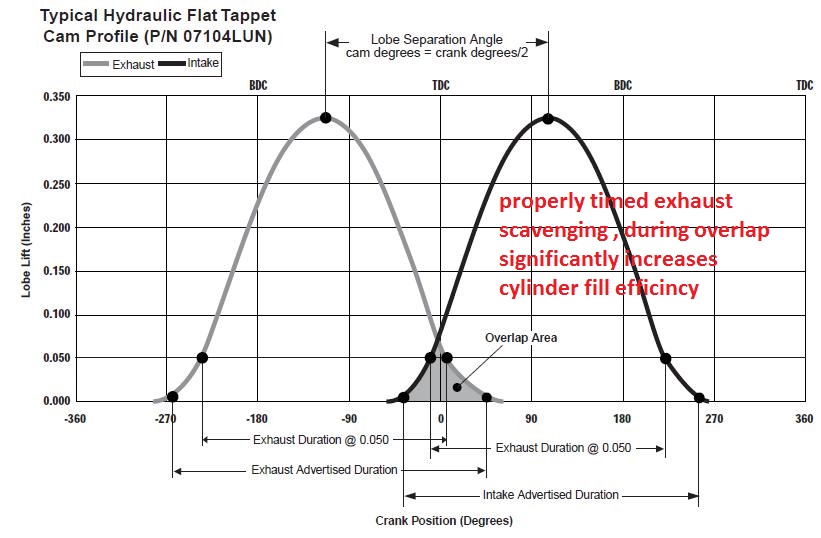

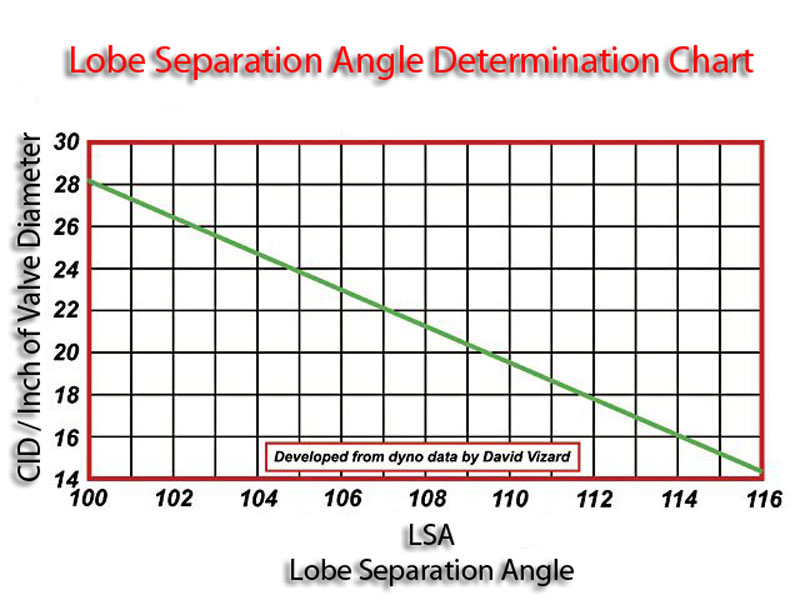

LSA =LOBE SEPARATION ANGLE ........ you can't select just a DURATION, LSA, or LIFT without making sure that clearances and the valve train geometry match, and the duration and lift will effect the cams operational power band, as will displacement, compression, head and intake flow rates and other factors like the cars drive train gearing,

LSA (LOBE SEPERATION ANGLE) alone is NOT the main factor that causes problems its the combination of duration, lift

,LSA and valve train acceleration

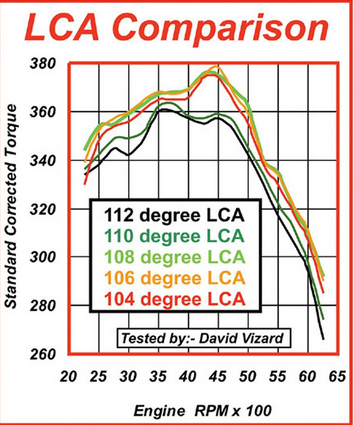

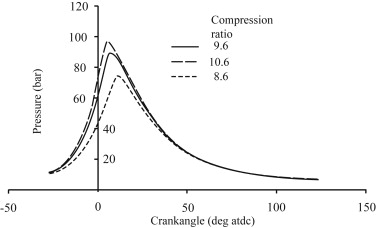

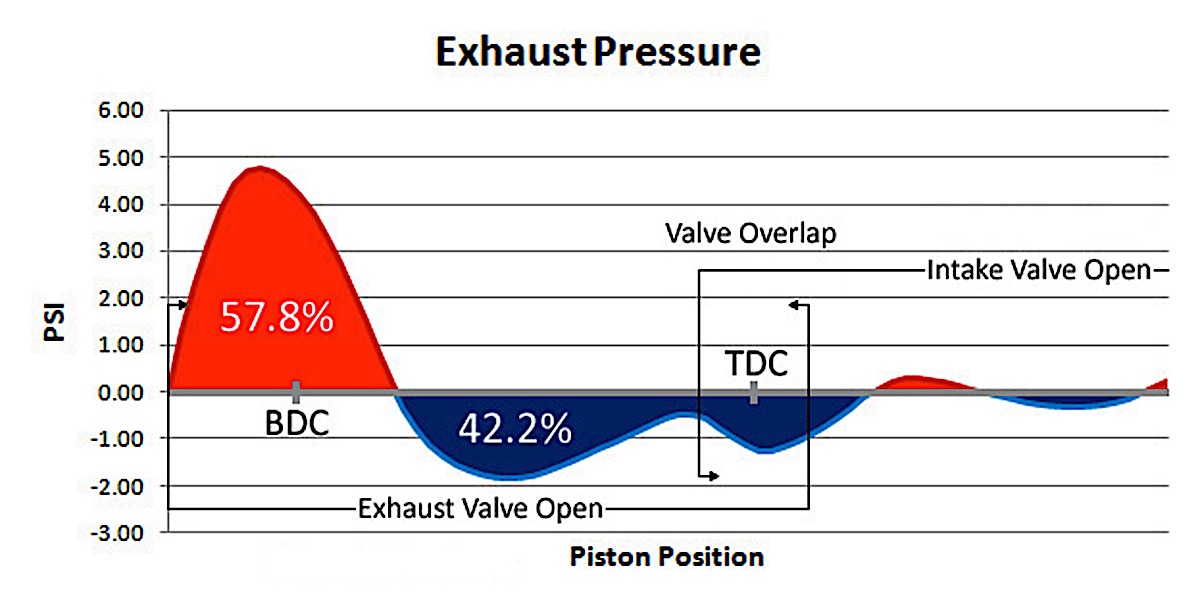

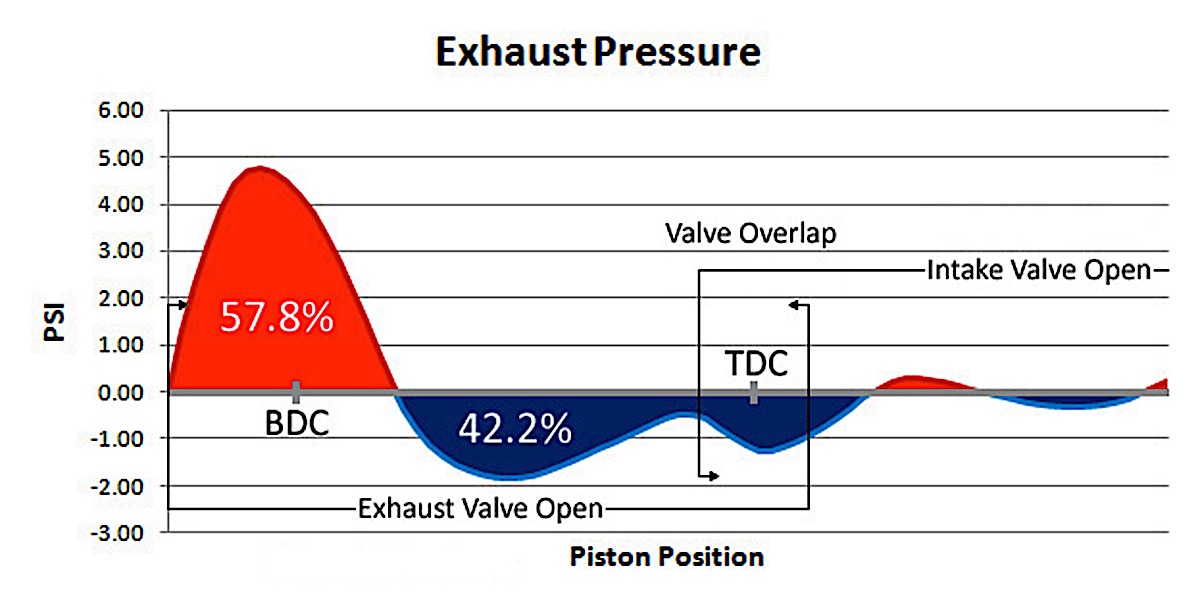

a good tuner can compensate for a great deal, and yes if your willing to make compensating changes in the sensors or the programing you can run the tighter LSA, but it WILL REQUIRE changes to run a tighter 110 LSA once the duration has increased to the point that it effects the sensor data feeding to the CPU, tighter LSA tends to increase OVERLAP and increase intake runner reversion pulse strength, but your compression ratio, displacement and exhaust scavenging efficiency also effect the sensor data

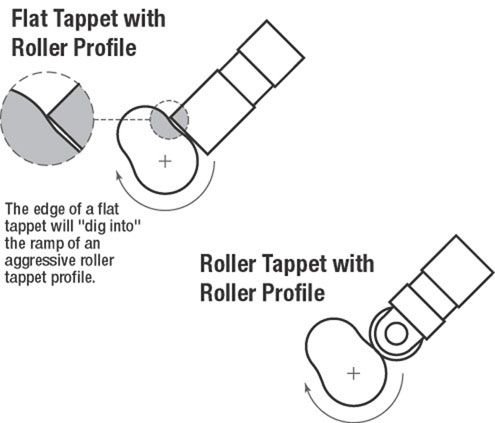

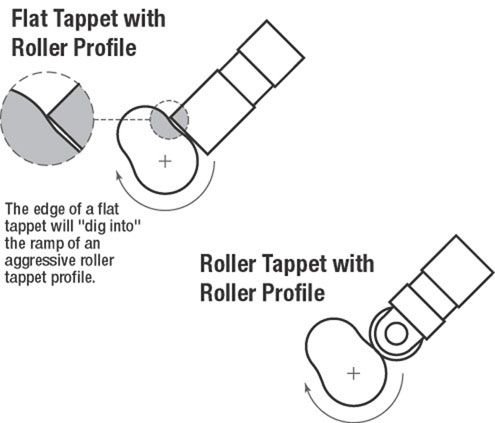

Isky claims that the Comp XE cams violate the 47.5% rule. The 47.5% rule applies to flat tappet cams for SBCs with 1.5 rockers but the concept is still the same for other configurations where the designs are "on the edge" or "over the edge" for lobe intensity. For 1.5 ratio SBCs, the duration at .050 must exceed 47.5% of the total valve lift or your asking valve train problems. For example, take a Comp Cams Magnum 280H, with 230 duration and, 480 lift...230/.480 = 47.9% which exceeds 47.5% therefore would not pose a threat to components. We do not regularly hear about the older, safer HE and Magnum designs rounding off lobes anywhere near as often as the XE cam designs. Unfortunately, some of the Comp Cams XE dual pattern lobes break this 47.5% rule on the intake side so they are likely to be problematic. The design has "steeper" ramps that are too quick for durability and reliability according to other cam manufacturers. They will wipe lobes in a heart beat especially if you have not followed the proper break-in procedure. Other designs are more forgiving during break-in and less likely to fail.

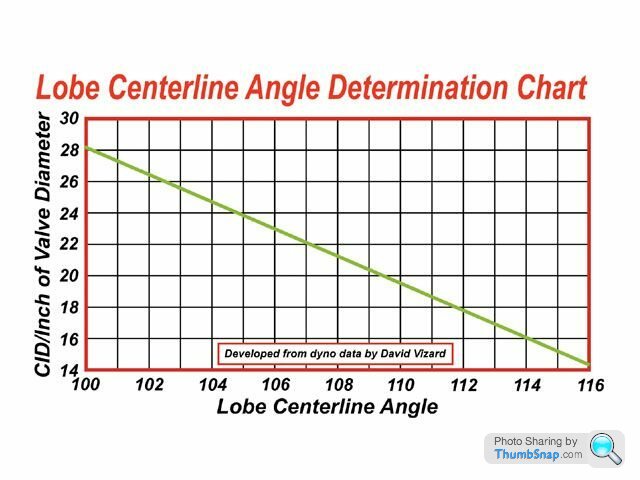

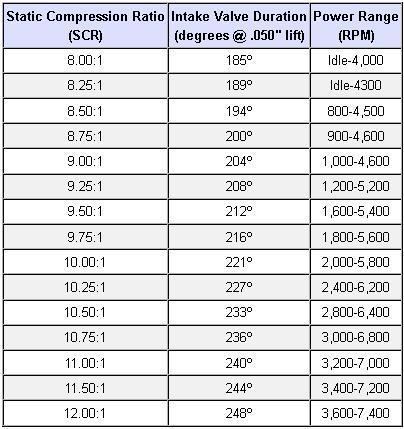

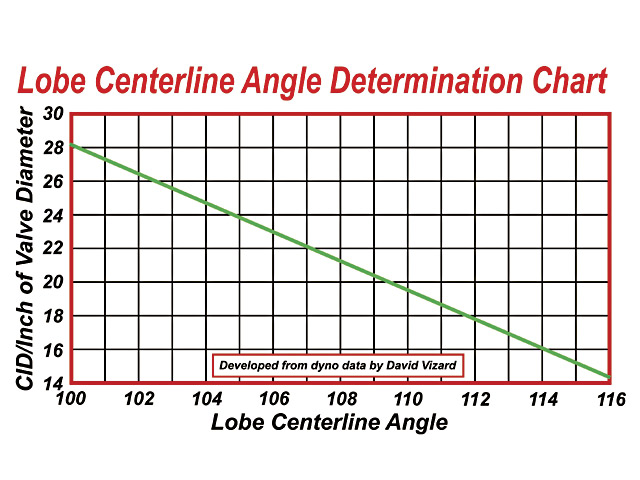

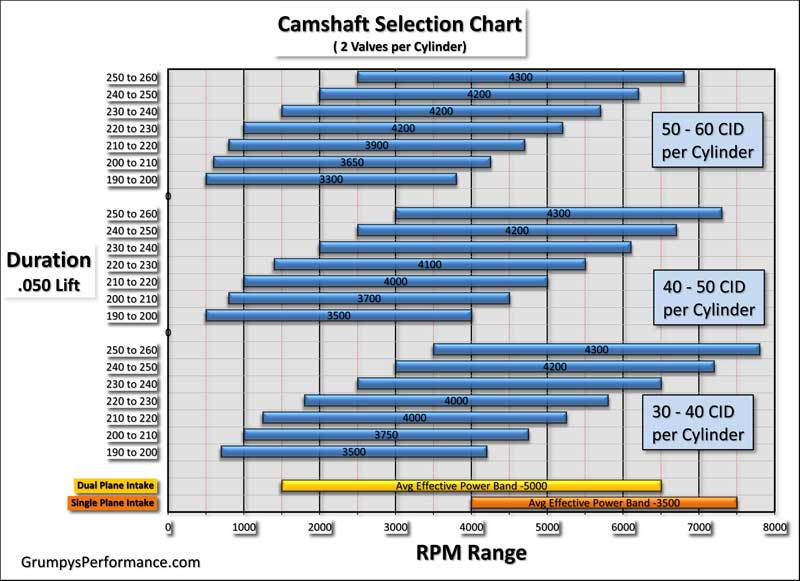

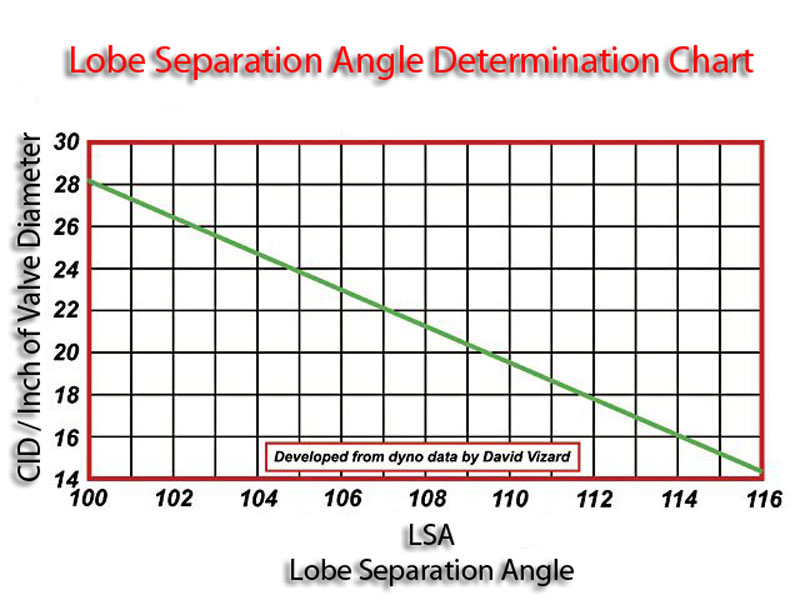

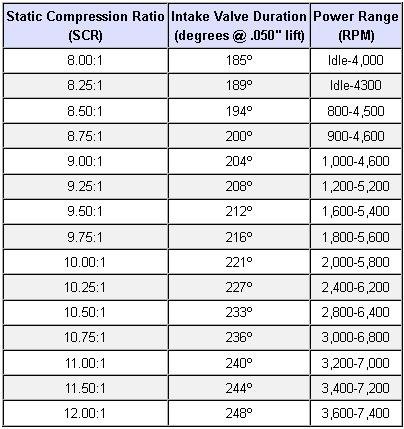

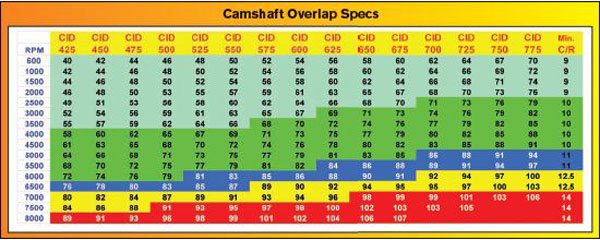

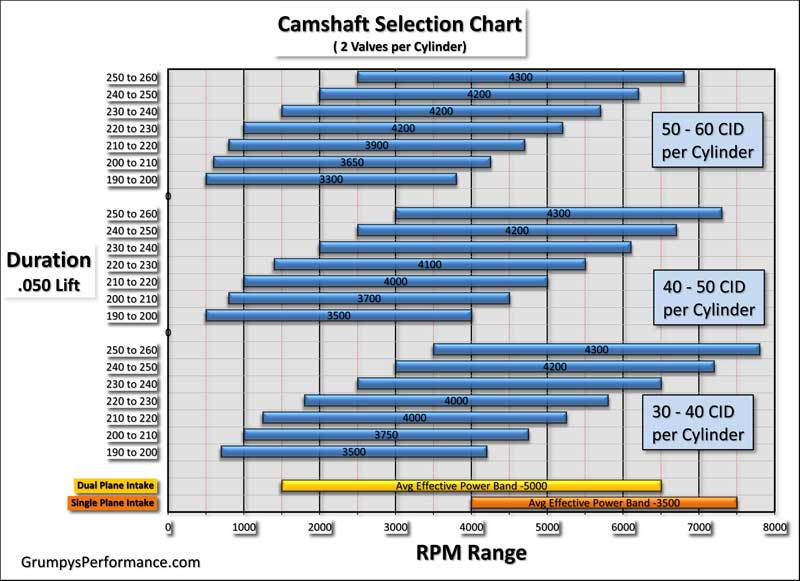

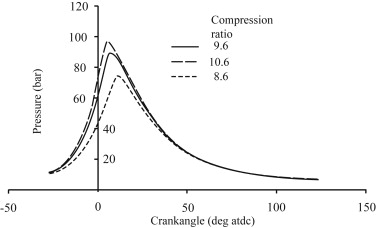

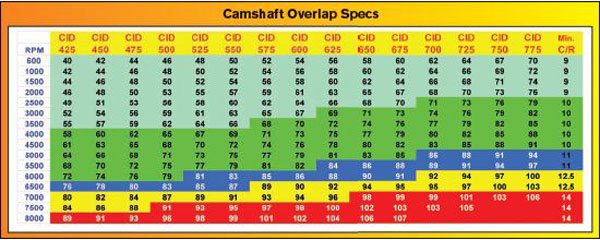

the chart above can be used as a rough guide to match cam duration at .050 lift and static compression in engines obviously other factors come into play so its only a rough guide

LSA is ground into the cam during manufactured, and can,t change,

LCA= LOBE CENTER ANGLE

LCA =(LOBE CENTER ANGLES)

remember lobe center angles can be changed thru indexing the cam when degreeing it in,

http://69.20.53.62/faq_valvetrain.php

READ THESE

www.motortrend.com

www.motortrend.com

www.enginelabs.com

www.enginelabs.com

http://www.stockcarracing.com/techartic ... index.html

http://www.hotrod.com/techarticles/engi ... index.html

http://www.chevyhiperformance.com/techa ... index.html

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/

http://victorylibrary.com/mopar/cam-tech-c.htm

FROM PAT KELLY

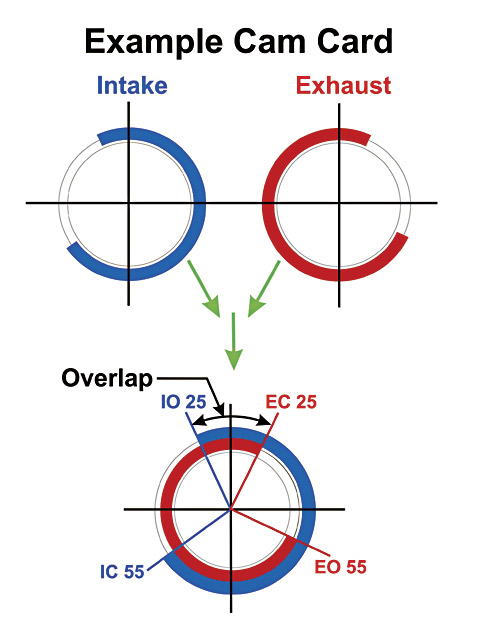

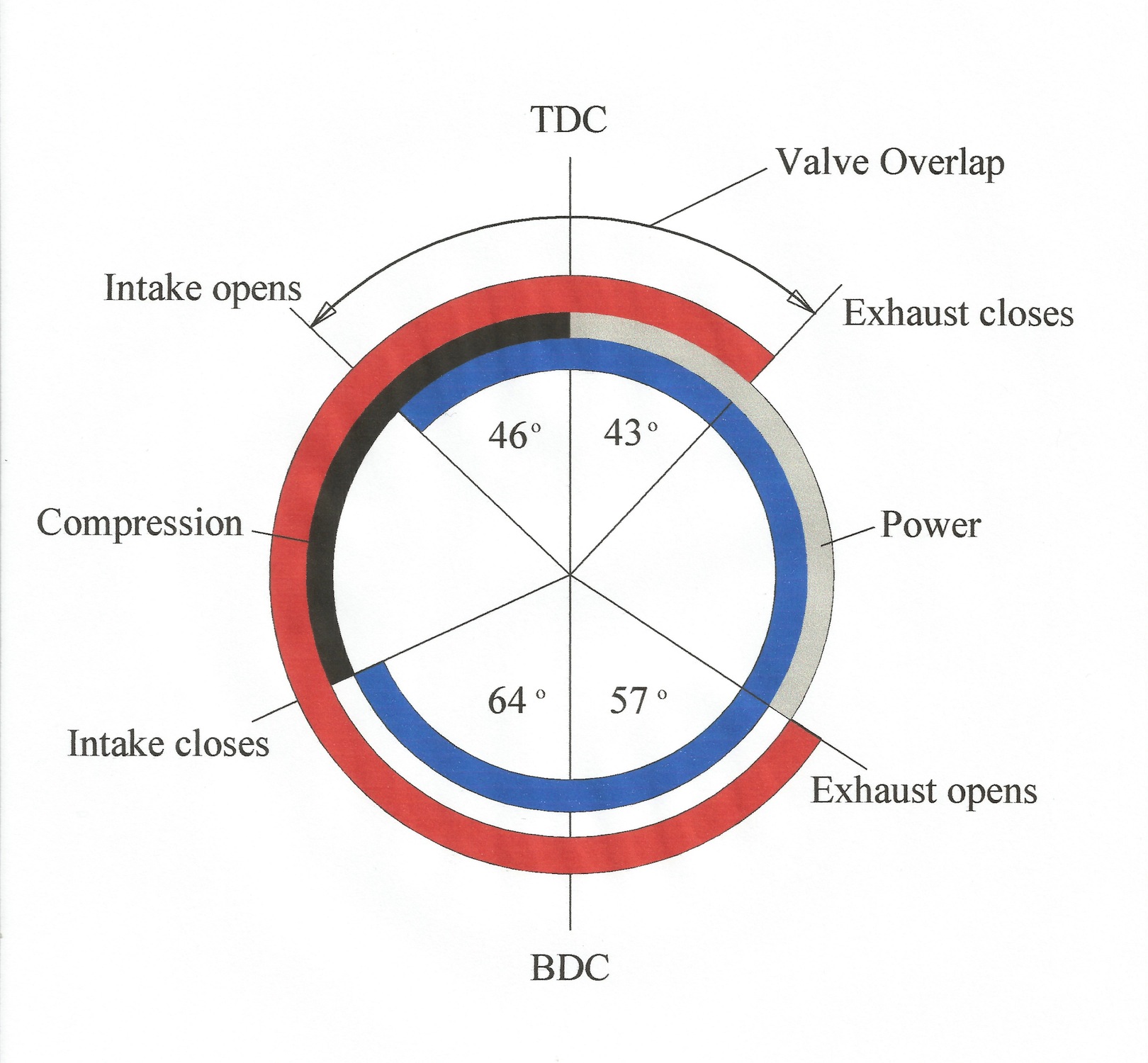

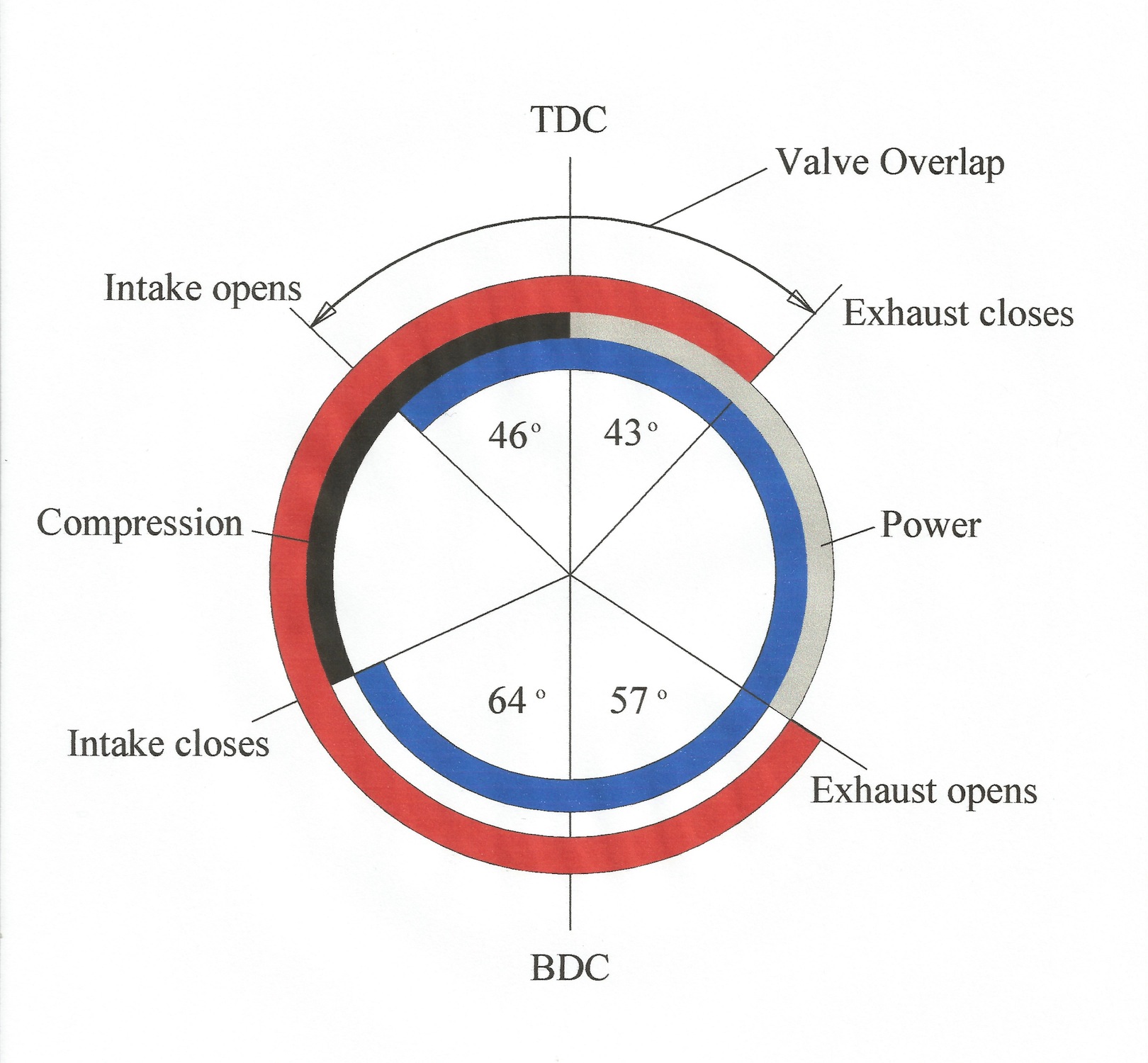

"There are a couple different ways to calculate the overlap of the cam.

1) The easiest way is to add the intake opening times to the exhaust closing time. Seat to seat times (advertised duration) must be used. .050" durations or timings will not give the correct overlap.

Example:

Comp Cams EX268H

Adv dur: int 268º, exh 280º

110 LSA, 106 ILC (4º advance)

Valve timing @ .006"

intake opens @ 28º BTDC

Intake closes @ 60º ABDC

Exhaust opens @ 76º BBDC

Exhaust closes @ 26º ATDC

In this example the overlap is 54º (28º+26º)

2) If the seat to seat opening and closing times are not known, the overlap can be calculated using the advertised duration and the Lobe Separation Angle (LSA). This formula works for both single and dual pattern cams.

Add the intake and exhaust adv durations

Divide the results by 4

Subtract the LSA

Multiply the results by 2

Using the example cam above:

268+280=548

548/4=137

137-110=27

27*2=54

The overlap is 54º

Here's another example:

Comp Cams XE294H

Adv Dur: int 294º, exh 306º

110 LSA, 106 ILC (4º advance)

Valve timing @ .006"

Int opens @ 41º BTDC

Int closes @ 73º ABDC

Exh opens @ 87º BBDC

Exh closes @ 39º ATDC

Adding the int open and exh close times (41+39) the overlap is 80º

Using the formula above:

294+306=600

600/4=150

150-110=40

40*2=80

The overlap is 80º

These are the valve timing overlap ranges that are most likely to work correctly (thanks to David Vizard for providing this):

trucks/good mileage towing 10-35 degs overlap

daily driven low rpm performance 30-55degs overlap

hot street performance 50-75 degs overlap

bracket/oval track racing 70-95degs overlap

dragster/comp eliminator engines 90-115 degs overlap "

yes reading thru the links, AND SUB LINKS IS WELL WORTH THE TROUBLE,IF YOU WANT TO LEARN,It gives you a great deal more info

https://www.hotrod.com/articles/roller-rocker-ratio-test/

https://www.onallcylinders.com/2018...rease-horsepower-engine-masters-gets-answers/

https://www.hotrod.com/articles/hrdp-1305-rocker-arm-comparo/

READ THRU THIS CAREFULLY

http://www.compcams.com/Community/Artic ... 2026144213

viewtopic.php?f=52&t=1070

http://members.uia.net/pkelley2/Overlap.html

http://victorylibrary.com/mopar/cam-tech-c.htm

http://www.popularhotrodding.com/tech/0 ... index.html

http://www.hotrod.com/techarticles/engi ... z2FeQk91VU

http://www.popularhotrodding.com/tech/0 ... ewall.html

http://www.chevyhiperformance.com/techa ... index.html

http://www.auto-ware.com/combust_bytes/camspecs.html

http://www.hotrod.com/techarticles/cam_ ... index.html

http://www.compcams.com/Technical/TimingTutorial/

http://www.compcams.com/technical/Catal ... 07/5-7.pdf

http://www.streetracersonline.com/articles/camshafts/

http://victorylibrary.com/mopar/cam-tech-c.htm

http://www.wighat.com/fcr3/confusion.htm

http://www.idavette.net/hib/camcon.htm

http://www.babcox.com/editorial/ar/ar119736.htm

http://tru-442.tripod.com/camselect.htm

http://www.projectlt10.com/content/modu ... .php?id=12

http://www.compcams.com/Technical/TimingTutorial/

this info posted By Mike Petralia may help

LSA and LC

Lobe Separation Angle (LSA) is NOT the same as Lobe Centerlines (LC), although the two are directly connected.

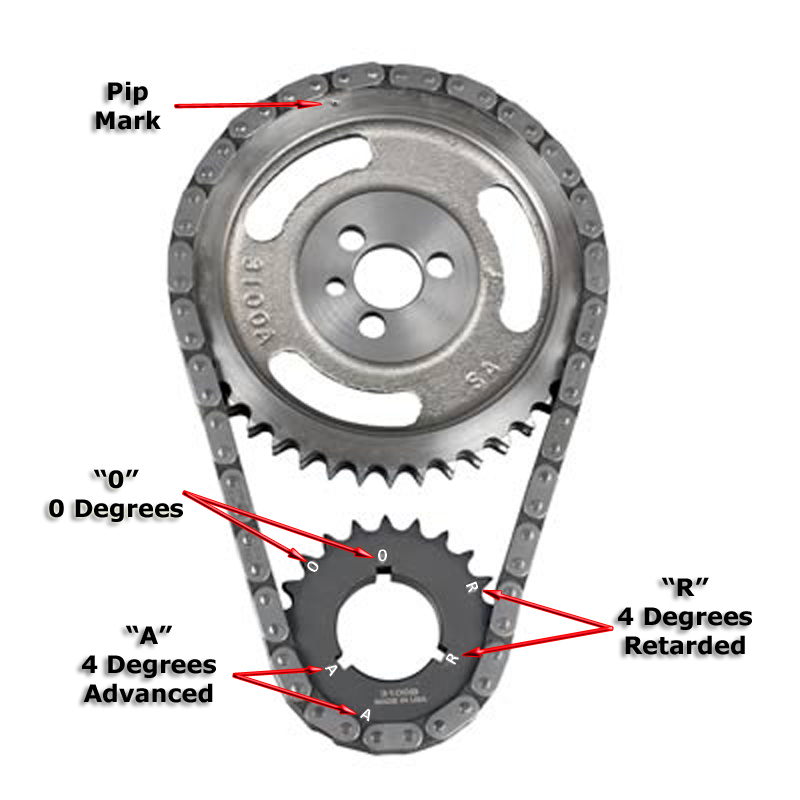

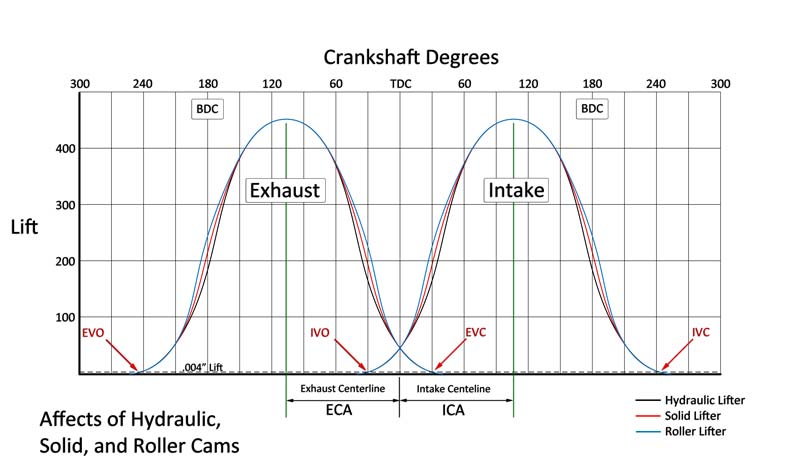

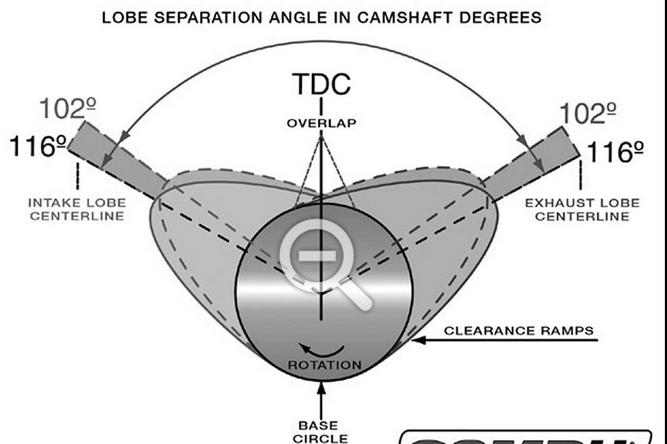

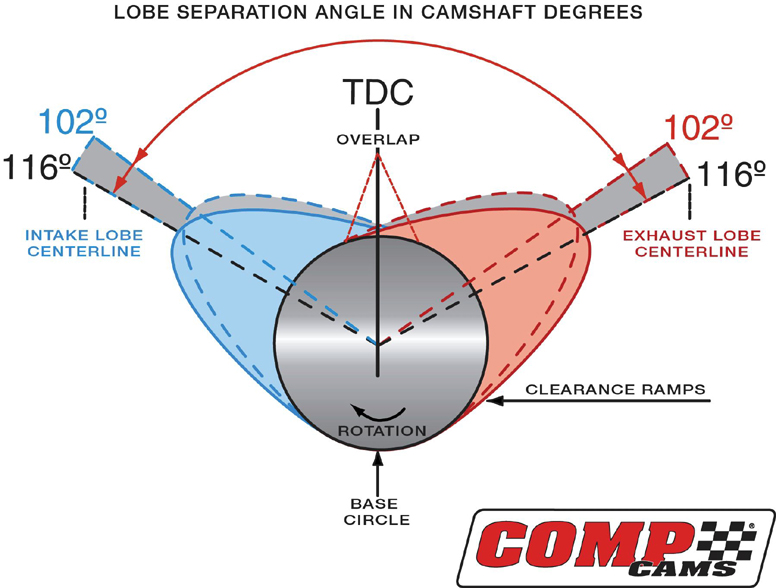

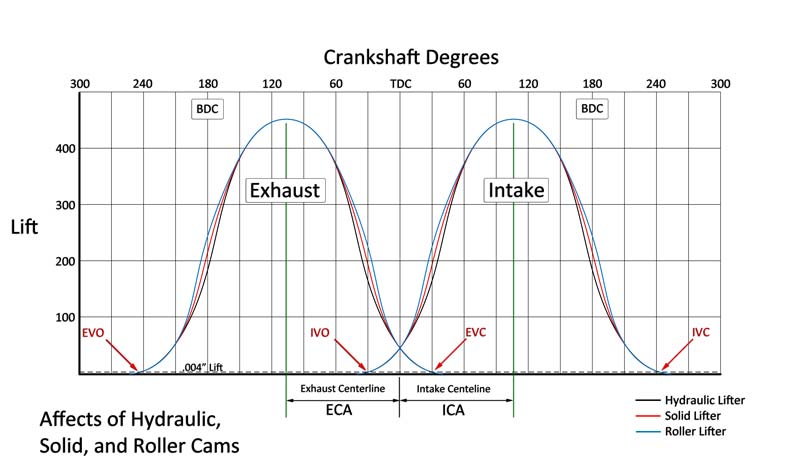

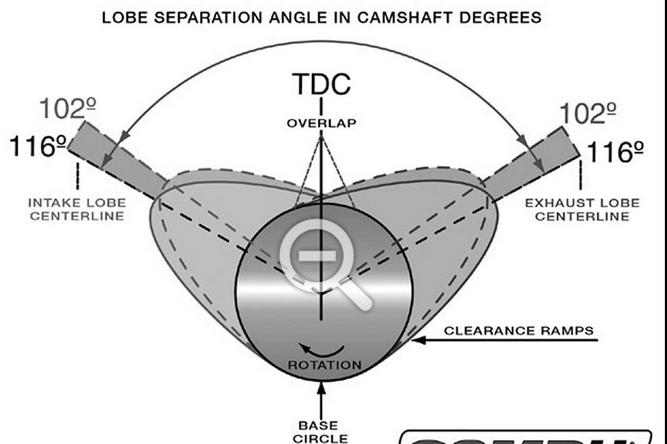

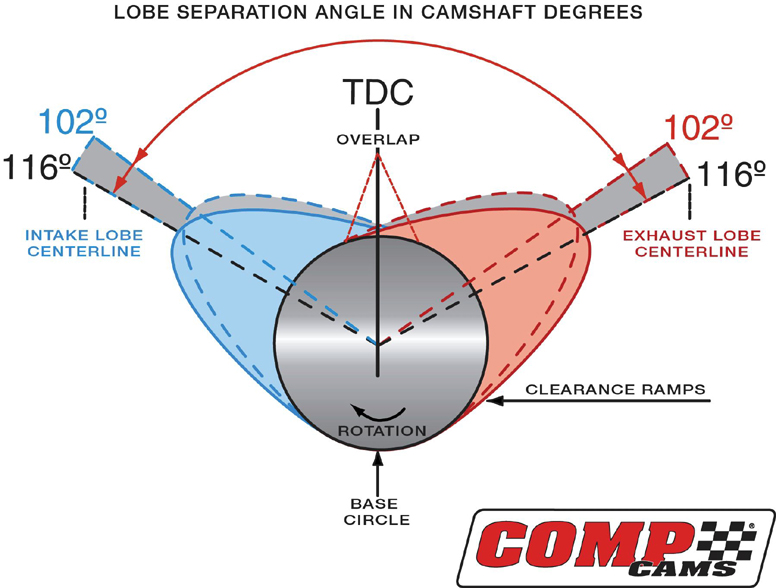

The Lobe Separation Angle is measured as the degrees that the crankshaft rotates BETWEEN the exhaust valve’s maximum lift point (aka: Exhaust Centerline) and the intake valve’s maximum lift point (aka: Intake Centerline). Check the lead illustration in this story from COMP Cams to show this effect. The highest lift points on the lobes are referred to as the cam “Lobe Centerlines†and are usually ground somewhere between 102 and 122 crankshaft degrees. Since Lobe Centerline is referenced in relation to crankshaft degrees as well, it can be moved around, depending on where you install the cam.

When you degree the cam, you’re usually checking to see if it’s installed at the cam manufacturer’s recommended Intake Centerline point. Let’s say your cam manufacturer recommends installing the cam at a 112-degree Intake Centerline. Using the degree wheel you check the intake’s highest lift point to be exactly at 112-degrees. That means you’ve now installed the cam “Straight Upâ€. If the degree wheel shows an intake max lift point of 110-degrees, the cam is now INSTALLED 2-degrees advanced from the manufacturer’s settings. If the degree wheel showed an installed position of 114-degrees, the cam is now INSTALLED 2-degrees retarded.

Lobe Separation Angle, on the other hand, is ground into the cam and it cannot be changed (see red arc in illustration). To check your LSA you calculate it by adding the intake and exhaust Lobe Centerline figures together and dividing their sum by two (Ex: 112 intake Centerline + 116 exhaust Centerline = 228 / 2 = 114-degree LOBE SEPARATION ANGLE).

There’s more. These are also the figures used to indicate how much the cam’s intake lobe was ground “advanced†or “retarded†from the factory. To find intake lobe advance/retard, simply subtract the Intake Lobe Centerline from the Lobe Separation Angle (i.e.: LSA 114 – IC 112 = 2-degree advance). This difference is how far advanced or retarded your cam was ground at the factory, 2-degrees in our example here. You cannot change Lobe Separation Angle because it is ground at the factory. But you can advance or retard the cam in relation to the crank when it’s degreed-in."

"EXAMPLE, OF A

very common mis- conception, is that a cam which is ground on a 108 degree lobe center. which has more overlap and will reduce your DCR due to greater overlap."

PROBABLY one of the MOST COMMON MYTHS

( is that overlap with a tight LSA bleeds off compression)

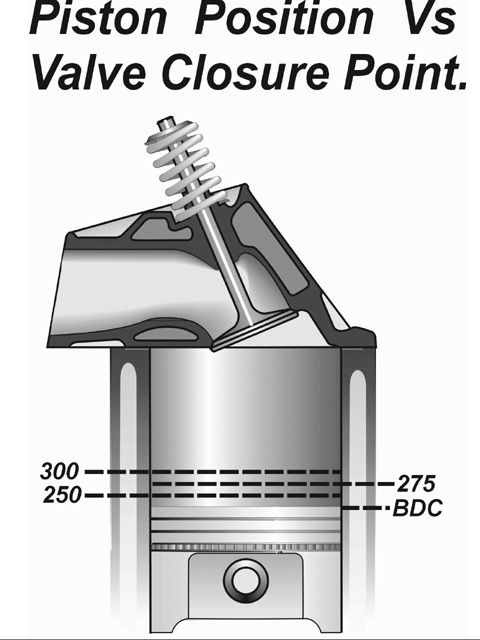

Overlap has nothing to due with DCR. A cam with 108 LSA will close the intake valve sooner on the compression stroke and create MORE cylinder pressure than a cam with 112 LSA. That assumes durations and cam lobe designs are the same of course "

this is correct

example

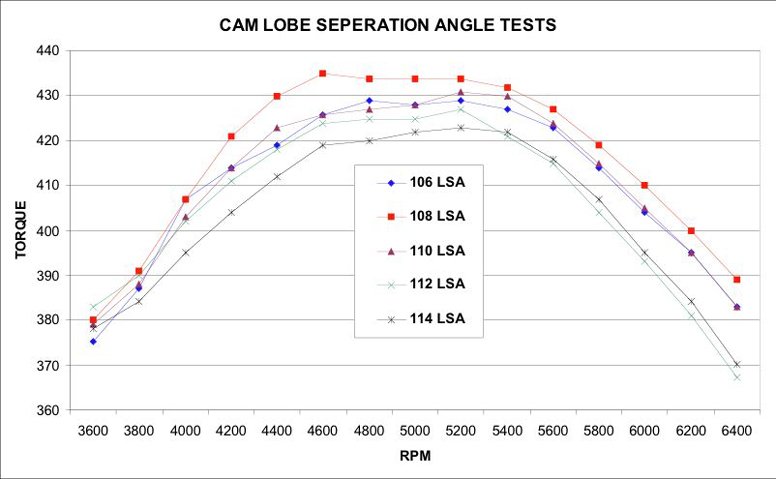

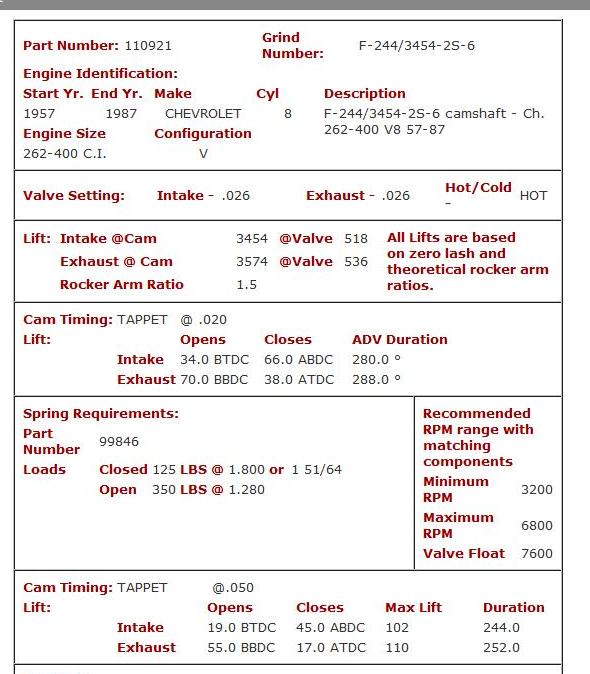

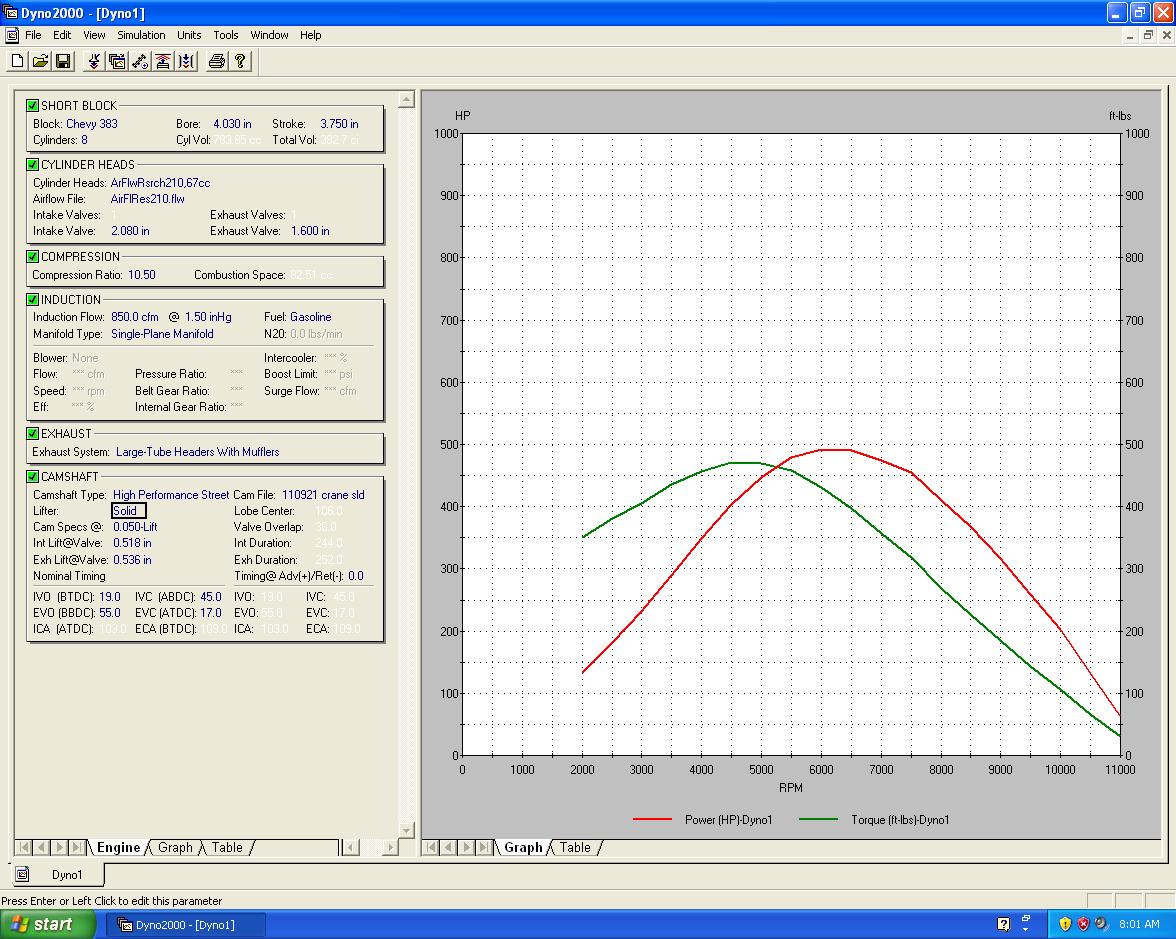

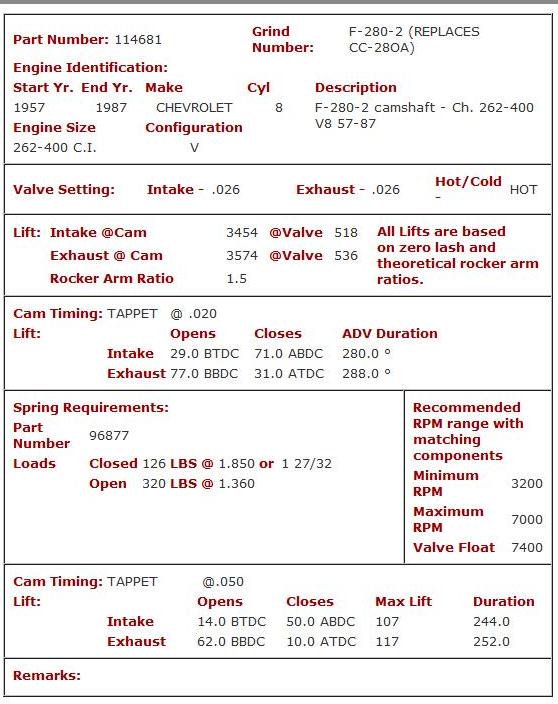

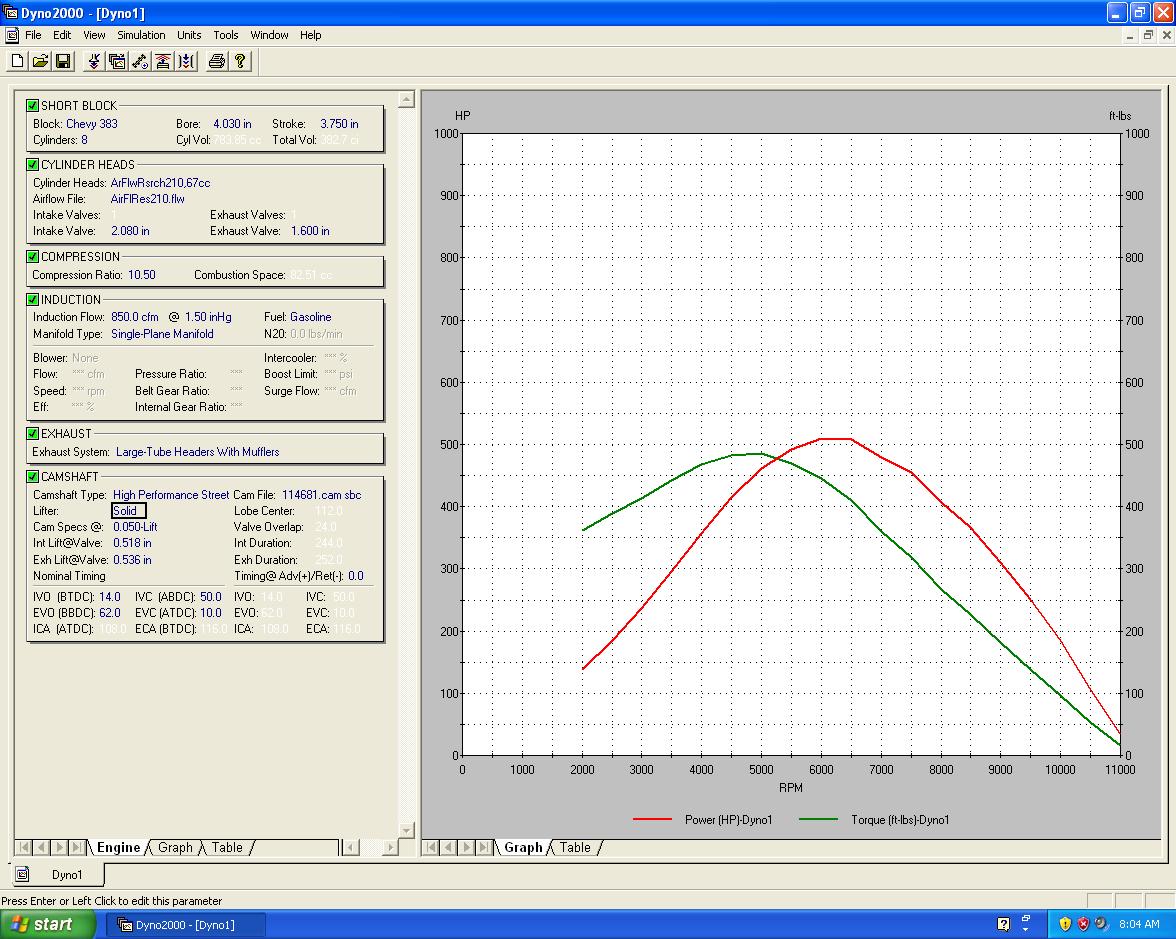

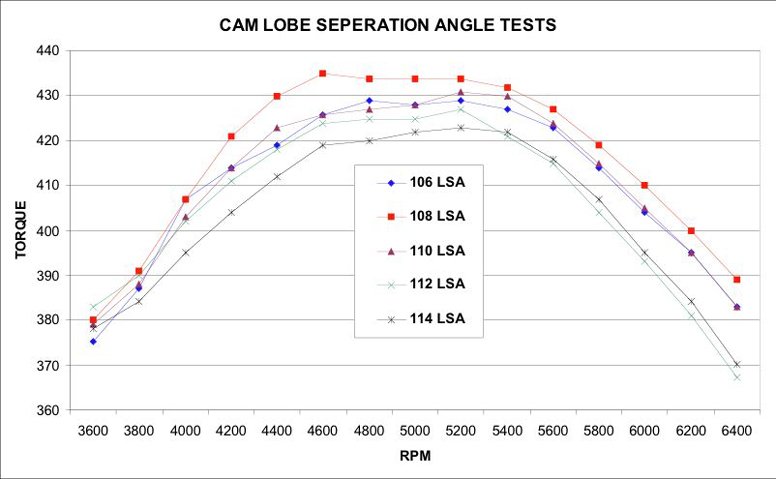

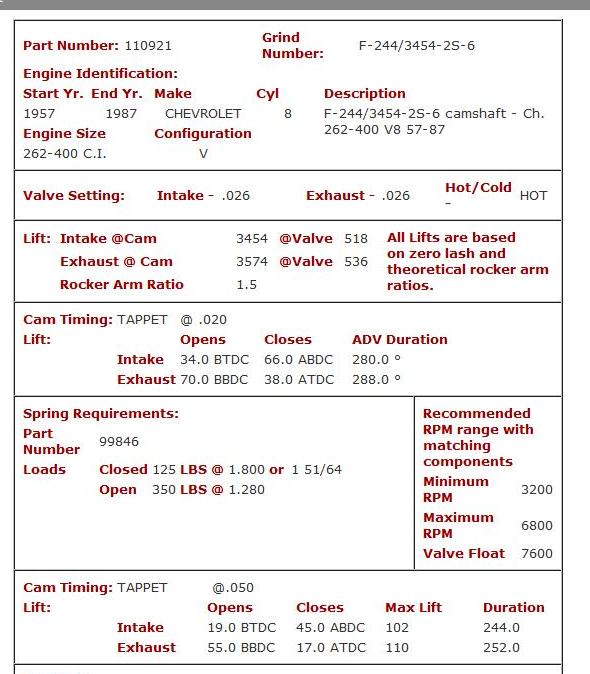

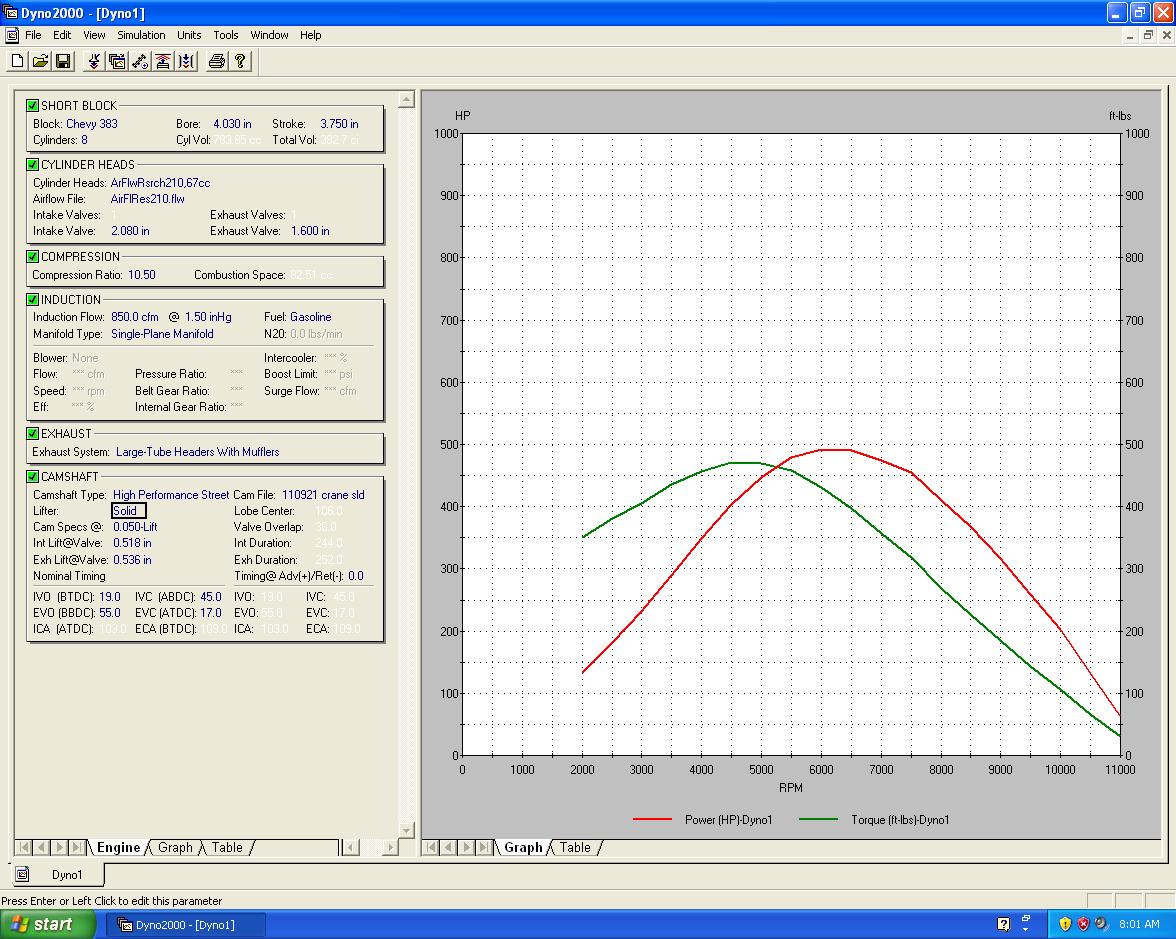

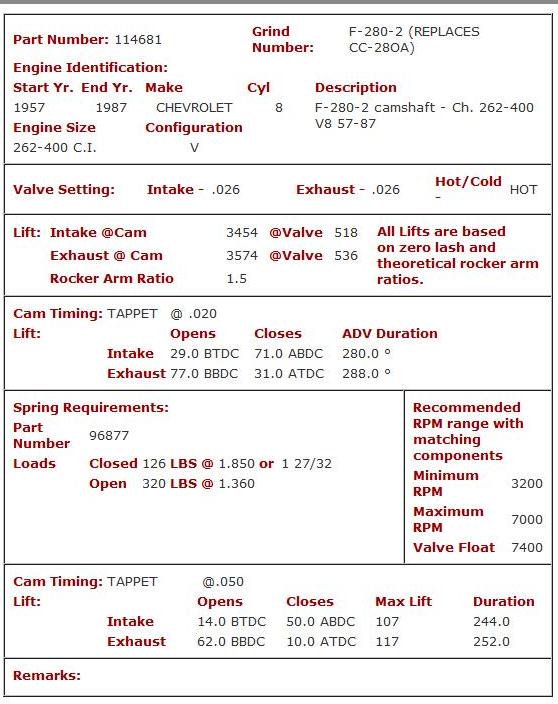

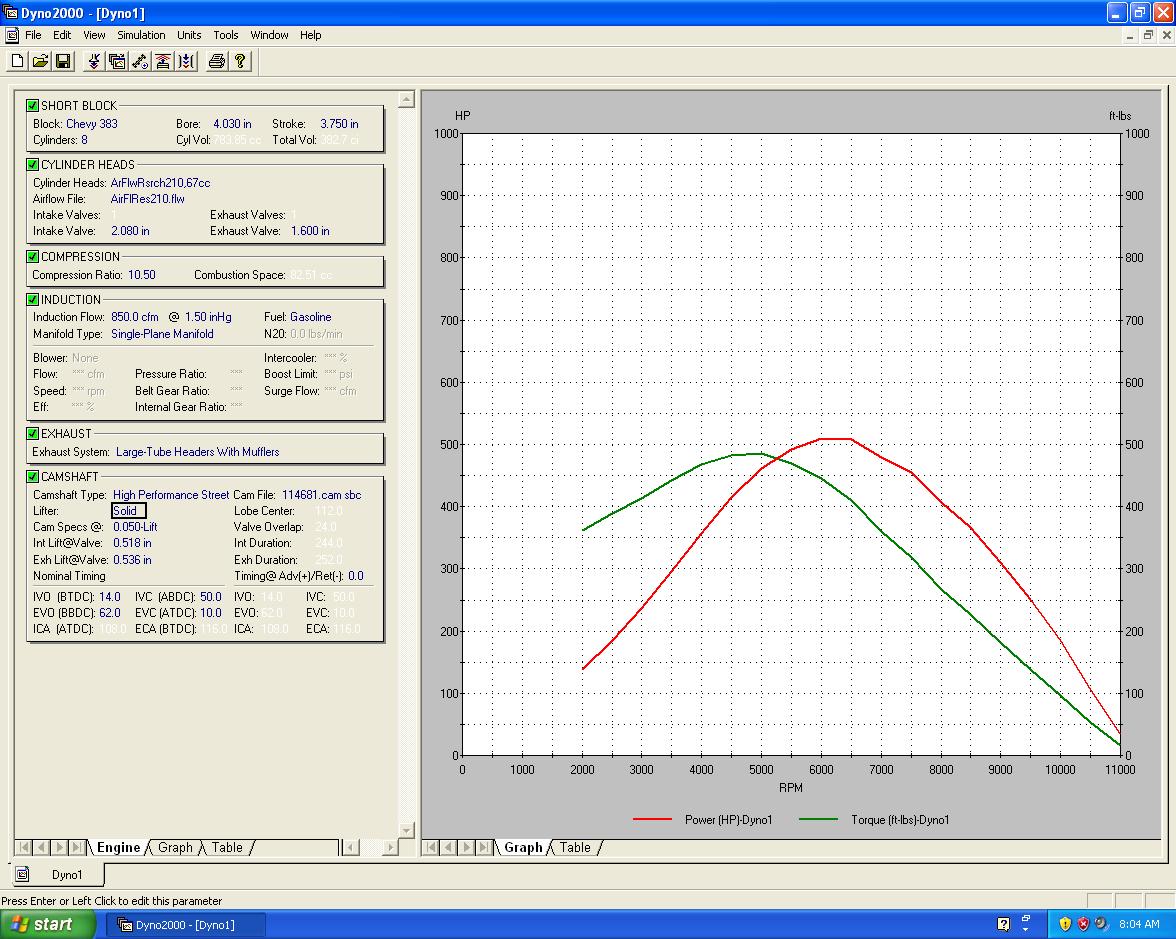

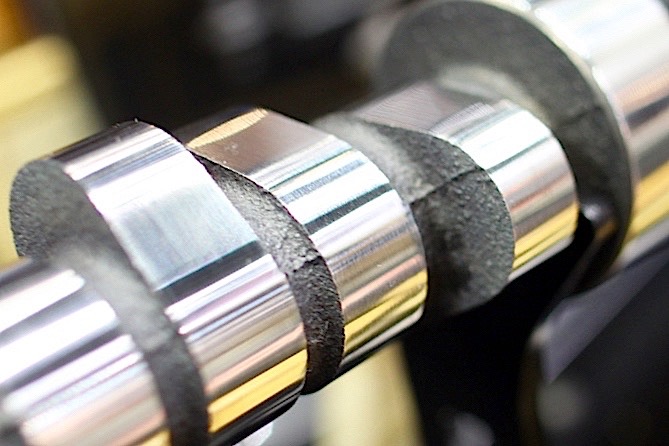

LOOK heres TWO cams IDENTICAL EXCEPT FOR THE LSA,(LOBE SEPARATION ANGLES) assuming both cams are installed with identical LCA (LOBE CENTER LINE ANGLE)remember lobe center angles can be changed thru indexing the cam when degreeing it in, LSA is ground into the cam during manufacture, the tighter LSA of the crane 110921 builds a bit more cylinder pressure and results in slightly more torque over a NARROWER rpm band so its better with a manual transmission, the crane 114681 with its wider LSA tends to work better with an auto trans with its wider torque band but very slightly lower peak torque, the crane 110921 has more overlap and better savaging in the mid rpm band, but it idles rougher at low rpms and that overlap doesn,t help if you use nitrous

COMPARE the TIMING

narrower LSA, more overlap & more effective compression, because the intake valve closes earlier

wider LSA, less overlap & less effective compression, because the intake valve closes later

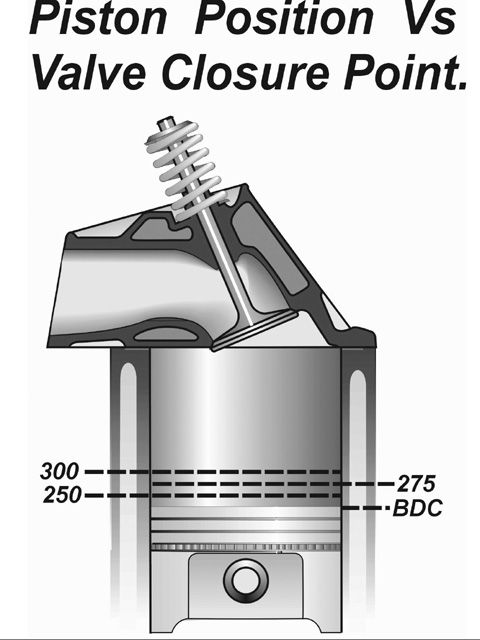

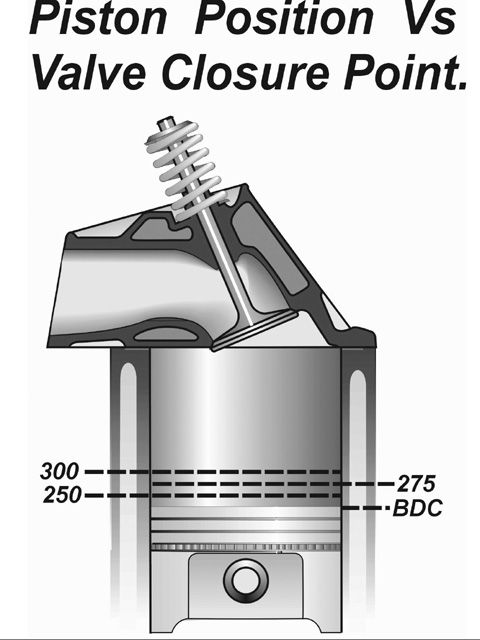

USING THE .050 LIFT figures, notice that the tighter LSA (LOBE SEPARATION ANGLE)cam CRANES 110921 has the intake close at 45 degrees ABDC while the wider lsa CRANES 114681closes the valves at 50.0 ABDC (the wider LSA results in the valve closing 5 degrees later on the pistons compression stroke, effectively reducing the effective compression ratio

(just enough links to make anyone insane, with calculating related factors)

reading piston burn patterns | Grumpys Performance Garage

http://www.wallaceracing.com/max-rpm2.php

http://www.wallaceracing.com/chokepoint-rpm.php

http://2.3liter.com/Calc2.htm#MinCross

http://www.wallaceracing.com/max-rpm.php

http://www.wallaceracing.com/header_length.php

http://www.dartheads.com/engine-calculators/

http://racingfeed.com/downloads/chevy_flow_data.pdf

http://www.swartzracingmanifolds.com/tech/index.htm

http://www.wallaceracing.com/ca-calc.php

www.enginelabs.com

www.enginelabs.com

http://www.wallaceracing.com/calcdchg.php

http://www.enginebuildermag.com/2016/02/theres-no-simple-formula-to-choosing-the-perfect-camshaft/

http://www.wallaceracing.com/area-under-curve.php

viewtopic.php?f=44&t=38

viewtopic.php?f=52&t=480

http://www.wallaceracing.com/curtain-area-calc.php

http://www.wallaceracing.com/calcafhp.php

http://www.wallaceracing.com/lpv.php

http://www.velocity-of-sound.com/veloci ... lator3.htm

viewtopic.php?f=44&t=3733

WATCH ALL THE VIDEOS

http://www.dartheadstv.com/featured_lan ... reset=true

that are almost, at least in many discussions

,incorrectly used interchangeably which they are not.

which they are not.

https://www.youtube.com/watch?v=9E3Is_ZsbfM

Quote Reply

Select for moderation Report Edit Delete IP

LSA =LOBE SEPARATION ANGLE ........ you can't select just a DURATION, LSA, or LIFT without making sure that clearances and the valve train geometry match, and the duration and lift will effect the cams operational power band, as will displacement, compression, head and intake flow rates and other factors like the cars drive train gearing,

LSA (LOBE SEPERATION ANGLE) alone is NOT the main factor that causes problems its the combination of duration, lift

,LSA and valve train acceleration

a good tuner can compensate for a great deal, and yes if your willing to make compensating changes in the sensors or the programing you can run the tighter LSA, but it WILL REQUIRE changes to run a tighter 110 LSA once the duration has increased to the point that it effects the sensor data feeding to the CPU, tighter LSA tends to increase OVERLAP and increase intake runner reversion pulse strength, but your compression ratio, displacement and exhaust scavenging efficiency also effect the sensor data

Isky claims that the Comp XE cams violate the 47.5% rule. The 47.5% rule applies to flat tappet cams for SBCs with 1.5 rockers but the concept is still the same for other configurations where the designs are "on the edge" or "over the edge" for lobe intensity. For 1.5 ratio SBCs, the duration at .050 must exceed 47.5% of the total valve lift or your asking valve train problems. For example, take a Comp Cams Magnum 280H, with 230 duration and, 480 lift...230/.480 = 47.9% which exceeds 47.5% therefore would not pose a threat to components. We do not regularly hear about the older, safer HE and Magnum designs rounding off lobes anywhere near as often as the XE cam designs. Unfortunately, some of the Comp Cams XE dual pattern lobes break this 47.5% rule on the intake side so they are likely to be problematic. The design has "steeper" ramps that are too quick for durability and reliability according to other cam manufacturers. They will wipe lobes in a heart beat especially if you have not followed the proper break-in procedure. Other designs are more forgiving during break-in and less likely to fail.

the chart above can be used as a rough guide to match cam duration at .050 lift and static compression in engines obviously other factors come into play so its only a rough guide

LSA is ground into the cam during manufactured, and can,t change,

LCA= LOBE CENTER ANGLE

LCA =(LOBE CENTER ANGLES)

remember lobe center angles can be changed thru indexing the cam when degreeing it in,

http://69.20.53.62/faq_valvetrain.php

READ THESE

Camshaft Shootout: Lobe-Separation Angle Tested and Explained

If the cylinder heads are the lungs of an engine, the camshaft is the brain. Lobe-Separation Angle Tested and Explained.

TECH QUICKIE: Camshaft Lobe Separation Angle And Power Relationship

Erson Cams, Doug Patton of Pro Line Race Engines, and Chuck Lawrence of Jon Kaase Racing Engines cover talking points on a camshaft's lobe separation angle.

LCA OR LSA

I'm looking at buying a GM crate vortec ( https://chevroletperforma nceparts.com/p/12530282-5... )which comes with a roller cam, and possibly upgrading the cam to this: https://chevroletperforma nceparts.com/p/hydraulic-...

garage.grumpysperformance.com

http://www.stockcarracing.com/techartic ... index.html

http://www.hotrod.com/techarticles/engi ... index.html

http://www.chevyhiperformance.com/techa ... index.html

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/

http://victorylibrary.com/mopar/cam-tech-c.htm

FROM PAT KELLY

"There are a couple different ways to calculate the overlap of the cam.

1) The easiest way is to add the intake opening times to the exhaust closing time. Seat to seat times (advertised duration) must be used. .050" durations or timings will not give the correct overlap.

Example:

Comp Cams EX268H

Adv dur: int 268º, exh 280º

110 LSA, 106 ILC (4º advance)

Valve timing @ .006"

intake opens @ 28º BTDC

Intake closes @ 60º ABDC

Exhaust opens @ 76º BBDC

Exhaust closes @ 26º ATDC

In this example the overlap is 54º (28º+26º)

2) If the seat to seat opening and closing times are not known, the overlap can be calculated using the advertised duration and the Lobe Separation Angle (LSA). This formula works for both single and dual pattern cams.

Add the intake and exhaust adv durations

Divide the results by 4

Subtract the LSA

Multiply the results by 2

Using the example cam above:

268+280=548

548/4=137

137-110=27

27*2=54

The overlap is 54º

Here's another example:

Comp Cams XE294H

Adv Dur: int 294º, exh 306º

110 LSA, 106 ILC (4º advance)

Valve timing @ .006"

Int opens @ 41º BTDC

Int closes @ 73º ABDC

Exh opens @ 87º BBDC

Exh closes @ 39º ATDC

Adding the int open and exh close times (41+39) the overlap is 80º

Using the formula above:

294+306=600

600/4=150

150-110=40

40*2=80

The overlap is 80º

These are the valve timing overlap ranges that are most likely to work correctly (thanks to David Vizard for providing this):

trucks/good mileage towing 10-35 degs overlap

daily driven low rpm performance 30-55degs overlap

hot street performance 50-75 degs overlap

bracket/oval track racing 70-95degs overlap

dragster/comp eliminator engines 90-115 degs overlap "

yes reading thru the links, AND SUB LINKS IS WELL WORTH THE TROUBLE,IF YOU WANT TO LEARN,It gives you a great deal more info

https://www.hotrod.com/articles/roller-rocker-ratio-test/

https://www.onallcylinders.com/2018...rease-horsepower-engine-masters-gets-answers/

https://www.hotrod.com/articles/hrdp-1305-rocker-arm-comparo/

READ THRU THIS CAREFULLY

http://www.compcams.com/Community/Artic ... 2026144213

viewtopic.php?f=52&t=1070

http://members.uia.net/pkelley2/Overlap.html

http://victorylibrary.com/mopar/cam-tech-c.htm

http://www.popularhotrodding.com/tech/0 ... index.html

http://www.hotrod.com/techarticles/engi ... z2FeQk91VU

http://www.popularhotrodding.com/tech/0 ... ewall.html

http://www.chevyhiperformance.com/techa ... index.html

http://www.auto-ware.com/combust_bytes/camspecs.html

http://www.hotrod.com/techarticles/cam_ ... index.html

http://www.compcams.com/Technical/TimingTutorial/

http://www.compcams.com/technical/Catal ... 07/5-7.pdf

http://www.streetracersonline.com/articles/camshafts/

http://victorylibrary.com/mopar/cam-tech-c.htm

http://www.wighat.com/fcr3/confusion.htm

http://www.idavette.net/hib/camcon.htm

http://www.babcox.com/editorial/ar/ar119736.htm

http://tru-442.tripod.com/camselect.htm

http://www.projectlt10.com/content/modu ... .php?id=12

http://www.compcams.com/Technical/TimingTutorial/

this info posted By Mike Petralia may help

LSA and LC

Lobe Separation Angle (LSA) is NOT the same as Lobe Centerlines (LC), although the two are directly connected.

The Lobe Separation Angle is measured as the degrees that the crankshaft rotates BETWEEN the exhaust valve’s maximum lift point (aka: Exhaust Centerline) and the intake valve’s maximum lift point (aka: Intake Centerline). Check the lead illustration in this story from COMP Cams to show this effect. The highest lift points on the lobes are referred to as the cam “Lobe Centerlines†and are usually ground somewhere between 102 and 122 crankshaft degrees. Since Lobe Centerline is referenced in relation to crankshaft degrees as well, it can be moved around, depending on where you install the cam.

When you degree the cam, you’re usually checking to see if it’s installed at the cam manufacturer’s recommended Intake Centerline point. Let’s say your cam manufacturer recommends installing the cam at a 112-degree Intake Centerline. Using the degree wheel you check the intake’s highest lift point to be exactly at 112-degrees. That means you’ve now installed the cam “Straight Upâ€. If the degree wheel shows an intake max lift point of 110-degrees, the cam is now INSTALLED 2-degrees advanced from the manufacturer’s settings. If the degree wheel showed an installed position of 114-degrees, the cam is now INSTALLED 2-degrees retarded.

Lobe Separation Angle, on the other hand, is ground into the cam and it cannot be changed (see red arc in illustration). To check your LSA you calculate it by adding the intake and exhaust Lobe Centerline figures together and dividing their sum by two (Ex: 112 intake Centerline + 116 exhaust Centerline = 228 / 2 = 114-degree LOBE SEPARATION ANGLE).

There’s more. These are also the figures used to indicate how much the cam’s intake lobe was ground “advanced†or “retarded†from the factory. To find intake lobe advance/retard, simply subtract the Intake Lobe Centerline from the Lobe Separation Angle (i.e.: LSA 114 – IC 112 = 2-degree advance). This difference is how far advanced or retarded your cam was ground at the factory, 2-degrees in our example here. You cannot change Lobe Separation Angle because it is ground at the factory. But you can advance or retard the cam in relation to the crank when it’s degreed-in."

"EXAMPLE, OF A

very common mis- conception, is that a cam which is ground on a 108 degree lobe center. which has more overlap and will reduce your DCR due to greater overlap."

PROBABLY one of the MOST COMMON MYTHS

( is that overlap with a tight LSA bleeds off compression)

Overlap has nothing to due with DCR. A cam with 108 LSA will close the intake valve sooner on the compression stroke and create MORE cylinder pressure than a cam with 112 LSA. That assumes durations and cam lobe designs are the same of course "

this is correct

example

LOOK heres TWO cams IDENTICAL EXCEPT FOR THE LSA,(LOBE SEPARATION ANGLES) assuming both cams are installed with identical LCA (LOBE CENTER LINE ANGLE)remember lobe center angles can be changed thru indexing the cam when degreeing it in, LSA is ground into the cam during manufacture, the tighter LSA of the crane 110921 builds a bit more cylinder pressure and results in slightly more torque over a NARROWER rpm band so its better with a manual transmission, the crane 114681 with its wider LSA tends to work better with an auto trans with its wider torque band but very slightly lower peak torque, the crane 110921 has more overlap and better savaging in the mid rpm band, but it idles rougher at low rpms and that overlap doesn,t help if you use nitrous

COMPARE the TIMING

narrower LSA, more overlap & more effective compression, because the intake valve closes earlier

wider LSA, less overlap & less effective compression, because the intake valve closes later

USING THE .050 LIFT figures, notice that the tighter LSA (LOBE SEPARATION ANGLE)cam CRANES 110921 has the intake close at 45 degrees ABDC while the wider lsa CRANES 114681closes the valves at 50.0 ABDC (the wider LSA results in the valve closing 5 degrees later on the pistons compression stroke, effectively reducing the effective compression ratio

(just enough links to make anyone insane, with calculating related factors)

reading piston burn patterns | Grumpys Performance Garage

http://www.wallaceracing.com/max-rpm2.php

http://www.wallaceracing.com/chokepoint-rpm.php

http://2.3liter.com/Calc2.htm#MinCross

http://www.wallaceracing.com/max-rpm.php

http://www.wallaceracing.com/header_length.php

http://www.dartheads.com/engine-calculators/

http://racingfeed.com/downloads/chevy_flow_data.pdf

http://www.swartzracingmanifolds.com/tech/index.htm

http://www.wallaceracing.com/ca-calc.php

TECH QUICKIE: Camshaft Lobe Separation Angle And Power Relationship

Erson Cams, Doug Patton of Pro Line Race Engines, and Chuck Lawrence of Jon Kaase Racing Engines cover talking points on a camshaft's lobe separation angle.

http://www.wallaceracing.com/calcdchg.php

http://www.enginebuildermag.com/2016/02/theres-no-simple-formula-to-choosing-the-perfect-camshaft/

http://www.wallaceracing.com/area-under-curve.php

viewtopic.php?f=44&t=38

viewtopic.php?f=52&t=480

http://www.wallaceracing.com/curtain-area-calc.php

http://www.wallaceracing.com/calcafhp.php

http://www.wallaceracing.com/lpv.php

http://www.velocity-of-sound.com/veloci ... lator3.htm

viewtopic.php?f=44&t=3733

WATCH ALL THE VIDEOS

http://www.dartheadstv.com/featured_lan ... reset=true

Last edited by a moderator: