heres a bit of advice! so many times I get called over to help in some project, only to find the problems the guys hoping I can solve could have been avoided entirely ,Cool Rocking Daddy said:Good morning, Grumpy. I have come across your name and posts in various Vette forums when looking for tuned port injection information. Here's my story.....I have a 69 Camaro with a 355 (started as 10.25:1, 300 hp 350 out of '70 Nova. flat top pistons with 4 valve reliefs) 041 pocket ported heads. Comp Extreme Energy 262 cam (218-224 @ .050, .470 lift) . Edelbrock Performer, 650 Speed Demon carb. Usual headers. Extreme Automatics Stage II 200r4, 3.42 posi rear end.

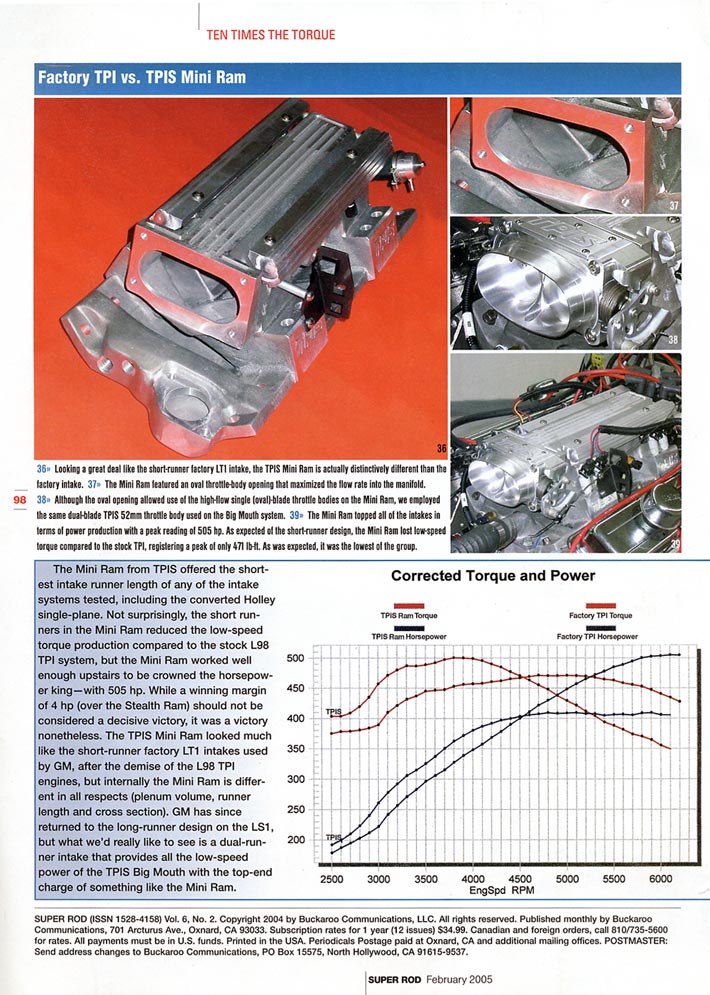

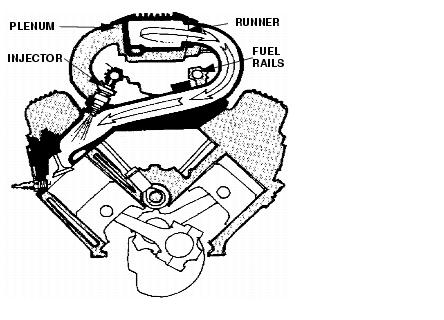

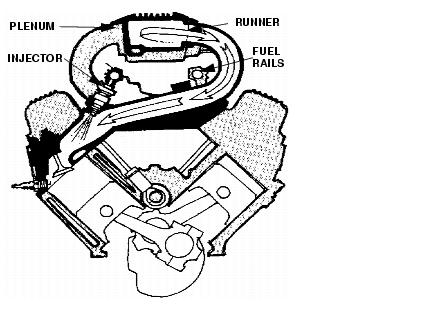

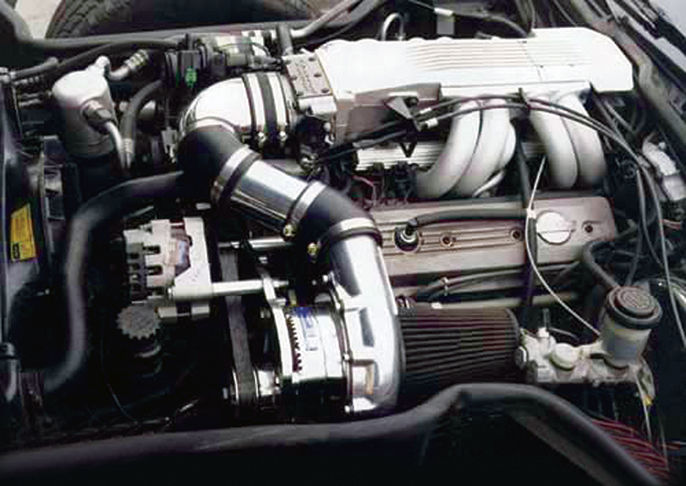

I love the look of a polished TPI. I picked up a complete unit off a '88 Vette less computer. Everything I have read says that if I want to reach my goals of having this engine pull to 5300-5500 rpms on this street-only car, I need to do some improving on the TPI parts. I have scored a set of large tube AS & M runners. I plan on having hi-flow -injection port the plenum and base. He says he can port the base to flow 265-270 cfm . I also plan on putting some Dart Iron Eagle or Pro 1 180 heads on the engine. I know that I will need to burn a chip to maximize the potential of the setup and I plan on switching to MAP computer and eliminate the ninth injector.

I get annoyed when I read threads on TPI because everybody talks about how they won't support 6500+ rpms and suck for racing. I don't want to race. I want a nice cruiser that will have the gobs of torque you want on the street. Do you feel that I can reach my goals. I am figuring I can get close to 420 flywheel HP with the proportionately bigger amount of torque that the TPI motors are famous for. The guy who runs the engine shop at TPiS seems to think I can do it. Just want a second on that before I completely jump into the water.

Thank you so much for your reply.

Chet

if the guy whos at this point is going partially insane, had only bothered to carefully read the details or installation instructions.

many times youll see the guy ordered the wrong part number, and theres a very similar component that exactly matches the concept ,

hes currently waist deep into, only to find the component he ordered is not compatible with the rest of the parts, hes working with.

Ive seen guys order high impedance injectors that are installed on a controller designed for low impedance injectors

http://fuelinjectorclinic.com/faqs

You can measure the resistance across the two electrical terminals of the injector. If the resistance is between 1.5 and 4.0 Ohm you have low impedance injectors. If the resistance is between 8 and 16 Ohm you have high impedance injectors.

https://www.hotrod.com/articles/hrdp-1211-low-impedance-vs-high-impedance-fuel-injectors/

Low impedance (peak and hold) injectors have a resistance of between 2 and 4 ohms. High impedance(saturated) injectors have a resistance of between 10 and 14 ohms. Low impedance and high impedance injectors cannot be used interchangeably without modification of the injector drivers.

What are the differences between low impedance/peak & hold and high impedance/saturated injectors?

The older fat body style low impedance injectors (1.5 to 4.0 Ohm) used to have faster open and close times due to the type of electrical signal pattern emitted by an ECU equipped with proper P&H signal transmitters. This “Peak and Hold” injector signal typically uses a high (4 amp) initial current to open the injector, and which reduces to a lower (1 amp) current to keep the injector open until the pulse ends. Since this method put less total current into the coil, the coil heated up less and was therefore more reliable. Since the “hold” or lower current part of the signal has created a weaker magnetic field, the injector will also close more quickly.

High impedance injectors (10 to 16 Ohm) are triggered by a low (typically around 1.2 amps) constant current signal and kept open by the same constant (saturated) current for the entire cycle. Most OEM injectors today are high impedance injectors being driven by saturated injector signals from the ECU since car manufacturers are most interested in the simpler saturated signal which is more cost effective to produce when building ECU’s, especially where there is no apparent loss of drivability or performance.

https://www.summitracing.com/parts/...MIsMryyOf_3gIVjoTICh1o7wzhEAQYAiABEgKO9fD_BwE

https://www.summitracing.com/parts/...MInIGXief_3gIVy-DICh1rpgH3EAYYAiABEgJLafD_BwE

TPI Torque Specifications

Below are the torque specifications as designated by GM for Tuned Port Injection intakes. Please note that some specifications are in lb. ft., and some are in lb. in.

Manifold to Runner Bolts 25 lb. ft. Runner to Manifold Bolts 25 lb. ft.

Fuel Rail Attaching Bolts 15 lb. ft.

Throttle Body Attaching Bolts 18 lb. ft.

Throttle Position Sensor 18 lb. in.

Idle Air Control Valve 13 lb. ft.

Throttle Body Coolant Plate 27 lb. in.

Throttle Body Cover Plate 30 lb. in.

Power Brake Vacuum Fitting 108 lb. in.

Fuel Line Nuts 20 lb. ft.

Fuel Tube Bracket Bolt 25 lb. ft.

Fuel Pressure Connection 115 lb. in.

Pressure Regulator Base to Rail 44 lb. in.

Pressure Regulator Bracket 44 lb. in.

Outlet Tube to R/H Rail Retainer 44 lb. in.

http://www.hobracing.com/tech/tpi_flow.asp

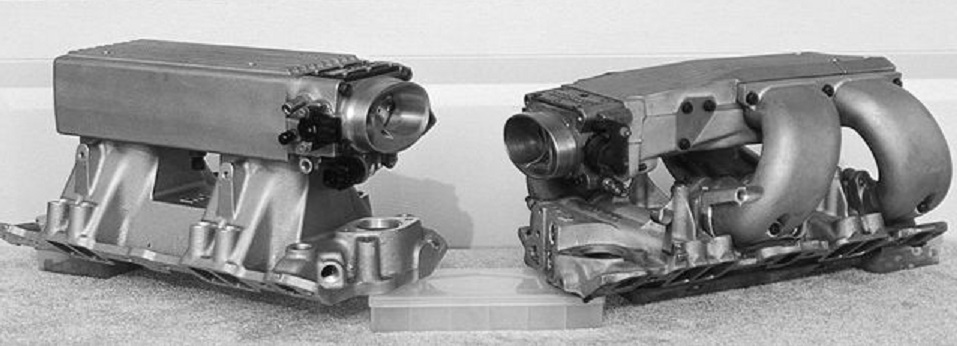

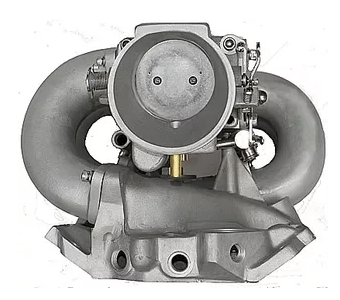

TPI Intakes and runners

The following airflow tests were performed on the University of Northwestern Ohio's SuperFlow SF600 Flow Bench. All CFM values are corrected for airflow at 28 inches of water. Injector flow rates are flowed at 43.5 PSI on an injector flow bench using test fluid with same density as gasoline.

AirFlow

Stock TPI/LT1 48mm Throttle Body w/o airfoil -- 783.0 cfm

Stock TPI/LT1 48mm Throttle Body w/ airfoil -- 821.9 cfm

TPI/LT1 52mm Throttle Body w/o airfoil -- 848.9 cfm

TPI/LT1 52mm Throttle Body w/ airfoil -- 898.8 cfm

Stock 98 Camaro 3800 II Throttle Body -- 554.3 cfm

Stock TPI Bosch MAF sensor w/ screens -- 517.8 cfm

Stock TPI Bosch MAF sensor w/o screens -- 658.4 cfm

Stock 87 GN 3.8L Turbo AC MAF sensor w/ screen -- 584.2 cfm

Stock 86 2.8L AC 5-wire MAF sensor w/ screen -- 576.2 cfm

Stock 96-up AC 3100 V6 MAF sensor w/ screen -- 616.4 cfm

Stock 96-up AC 3100 V6 MAF sensor w/o screen -- 670.7 cfm

Stock 94-up LT1 MAF Sensor w/o screen -- 719.0 cfm

Stock 85-87 Firebird TPI airbox mid piece -- 499.3 cfm

Stock 4.3/5.0/5.7 2bbl TBI complete -- 574.1 cfm (dry)

Stock 4.3/5.0/5.7 2bbl TBI w/o injectors -- 584.7 cfm

Stock 3800 vin L throttle body w/ screen -- 419.1 cfm

Stock 3800 vin L throttle body w/o screen -- 444.8 cfm

4bbl MPFI Holley Throttle Body -- 1287.6 cfm

Another source sent in these flow numbers

Flow and HP ratings for Throttle-bodies:

Flow (cfm) Max. NA HP

Stock 668 300

Stock w/airfoil 710 350

52MM w/airfoil 835 400

54MM (AS&M) 900 450

58MM 1050 500

TPI Intakes and runners flow rates

Stock intake manifold with runner

Stock....................198.72 cfm

ACCEL................213.52 cfm

Extrude/ACCEL....217.11 cfm

Super Ram............220.67 cfm

the stock TPI has a hard time flowing 230cfm even with minor port work, look here

most of this info is right off the accel,holley,edelbrock, and TPIS sites, add a little math and the results become much clearer!!!

Intake....... length ....... port in -- out

Stock GM Base--- 6.375"------ 1.47"- 1.96x1.2

TPiS base------ -6.125"------ 1.75"- 2.09x1.28

Accel base----- -6.125"------ 1.75"- 2.09x1.28

Holley base------- 6” runner 2.3”- 1.9”x 1.23 (2.337 sq inches)

Runners

Stock TPI----- -- 7.250"------1.470" round(1.70 sq inchs)

SLP ----------- - 6.625"------1.600" round (2.01 sq inchs)

Accel LTR------- 6.625"------1.615" round (2.05 sq inchs)

TPiS----------- 7.625"------1.660" round (2.168 sq inchs)

Mini ram -----3.5”

LT1 ----------3”

Runners (measured individually)

Stock....................203.17 cfm

ACCEL................242.02 cfm

Extrude/ACCEL...275.83 cfm

Super Ram............289.18 cfm

Intake manifold with 3/8 inch radiused intlet.............................222.45 cfm

Holley stealth ram ………..275cfm

Stock intake manifold with runner

Stock....................198.72 cfm

ACCEL................213.52 cfm

Extrude/ACCEL....217.11 cfm

Super Ram............220.67 cfm

Holley stealth ram …..275cfm

ACCEL Hi-Flow intake manifold with 3/8 inch radiused inlet.........251.51 cfm

ACCEL Hi-Flow intake manifold with runner

Stock....................215.83 cfm

ACCEL................232.53 cfm

Extrude/ACCEL....243.21 cfm

Super Ram............240.24 cfm

Extrude-Honed ACCEL Hi-Flow intake manifold with 3/8 inch radiused inlet ...............275.83 cfm

Extrude-Honed ACCEL Hi-Flow intake manifold with ACCEL runner ..............266.94 cfm

Edelbrock Performer RPM manifold (Stock)..........286.51 cfm

Edelbrock Victor Jr. ............275.24 cfm

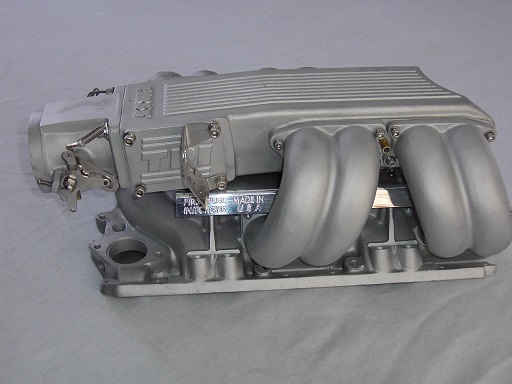

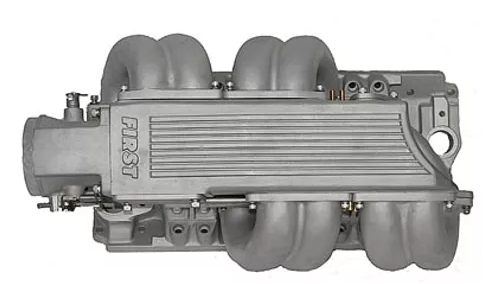

HOLLEY STEALTH RAM

the HOLLEY STEALTH RAM FLOWS at 275cfm out of the box, and has the potential when matched to the correct heads and cam to totally out flow most other intakes available,can easily reach 300cfm with minor port work and costs much less

Stock…………………………… 275cfm

Ported…………………………..300cfm

Runner lengths

Stock tpi manifold 8” runners 11.25”, cylinder head 6” total 25.25”

Accel super ram manifold 8” runners 7” cylinder head 6” total 21”

Holley stealth ram manifold 6.26” ” cylinder head 6” total 12.26”

Edelbrock performer RPM runners 6” ” cylinder head 6” total 12”

Edelbrock vic jr , runner length 5.5” ” ” cylinder head 6” total 11.5”

Also interesting TPI mods. Not so sure I agree with the one on bumping up the initial timing.

http://www.hobracing.com/tech/tpi_mods.asp

http://garage.grumpysperformance.com/index.php?threads/a-well-designed-c4-exhaust.786/#post-57392

Basic TPI modifications

Friday, May 23, 2014

READ THIS

increasing power is in large part the result of increasing the amount of air/fuel mix you can efficiently pack into and burn in the cylinders and the number of power strokes per second that the engine can produce in its effective power range.

intake comes with a new throttle body

Stealth TPI Induction - L98 Stroker Installation - Super Chevy Magazine

This Chevrolet L98 TPI engine has its displacement stroked to 383 cubic inches and has stealth mods installed including a new cam and an extrude honed tuned port injection system to make 458 HP - Super Chevy Magazine

Hello, 91 corvette building a 383

Im building a 383 for my 91 Corvette, looking for info on different combination that will make this a quick street car that may see some track time.

garage.grumpysperformance.com

RELATED INFO

A couple days of

reading the linked and sub-linked info

could save you a great deal of wasted time and money

and money spent on wrong or un-necessary parts

read the links and sub links below

a day or so spent doing reading and research,

(reading links and threads)

will frequently save you thousands of dollars and weeks of wasted work.

if you want a fast dependable car you will need to either do the research required to know exactly how and why things should work, or pay someone else to do the work that has taken that time and effort.

http://garage.grumpysperformance.co...reasonable-mild-but-dependable-upgrade.12130/

viewtopic.php?f=55&t=1052&hilit=pro+flo+edelbrock

viewtopic.php?f=32&t=546&p=685&hilit=tuned+port+restrictive#p685

viewtopic.php?f=32&t=546&p=685#p685

http://www.superchevy.com/how-to/en...ethal-weapon-project-top-gun/guide-plate.html

viewtopic.php?f=55&t=431

http://garage.grumpysperformance.com/index.php?threads/tbucket-engine-project-dart-shp.3814/

http://garage.grumpysperformance.co...-1985-corvettes-cold-start-9th-injector.2861/

viewtopic.php?f=52&t=10705&p=46582&hilit=there+with+tuned#p46582

with the mods listed you could rather easily reach or slightly exceed that 420 flywheel hp level.

the key is the better heads and porting the intakes component parts...

PROVIDED you supply the fuel/air ratio and low restriction exhaust to allow the heads to breath

a low restriction exhaust and headers would also be helpful

THESE HEADS,LINKED BELOW OR SIMILAR HEADS, but obviously verify the valve train clearances and geometry , and get the quench distance in the .038-.044 range

http://www.summitracing.com/parts/drt-127122

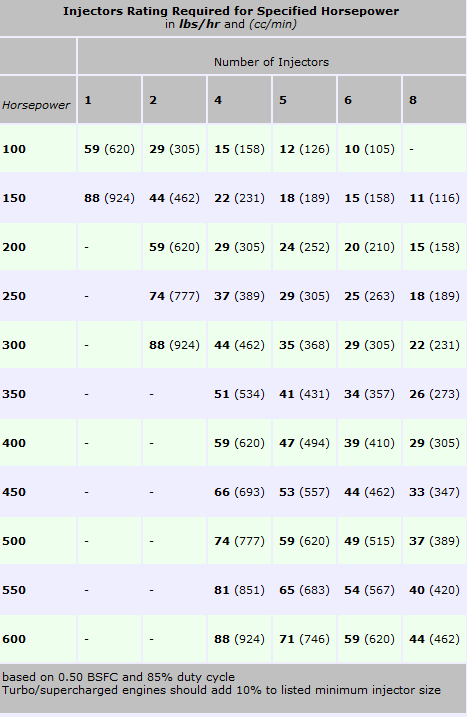

youll really need 36 lb injectors to support 420-440 hp.failure to upgrade injectors will cause lean burn durability issues at well under 420hp level with stock injectors

a swap to a roller cam and roller rockers along with those dart heads would make the goal far easier to reach, but like most of us your probably on a tight budget, while you may get to that power level with that flat tappet cam, a bit more duration in a similar cam like this should make it easier

http://www.cranecams.com/product/cart.p ... il&p=23976

in the future you might consider upgrading to a 3.75" stroker crank assembly and a mild over bore as the extra displacement gained converting a 350 to a 383 alone easily adds 40 ft lbs and 40 hp or more to the results from the extra displacement and crank leverage both allow the engine to operate at about 400rpm-500rpm lower and still make more power, as you look thru the links and sub links below keep in mind many are 383-406 displacement and many have larger cam duration numbers and better head flow numbers

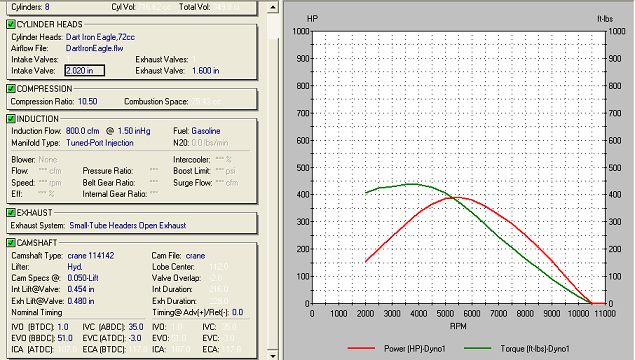

heres what DD2000 software predicts a similar build combo produce's with basically stock TPI flow rate components, and a cam similar too the one you listed and similar dart heads, with the port work the increased flow should easily get you to your goal, especially if you swapped to the upgrade crane cam, but that might also require a higher stall speed converter

of course theres options, and doing the mods listed an adding a supercharger could easily boost your results a further 30%-35%

http://www.jegs.com/webapp/wcs/stores/servlet/topcategory_10001_10002_-1

https://www.ebay.com/itm/Weiand-908...For-Use-With-144-174-Blower-Kits/400669303867

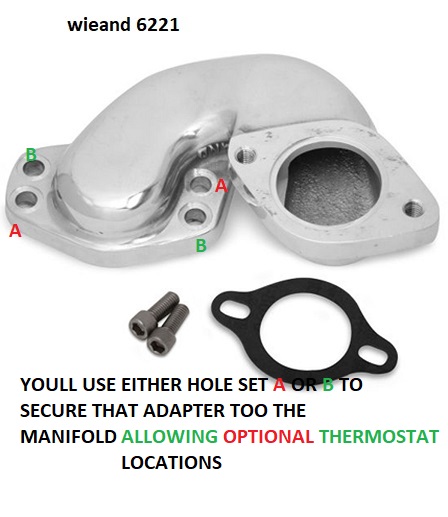

https://www.ebay.com/itm/Weiand-622...r-Small-Block-and-Big-Block-Chev/112273744933

Have one to sell? Sell now

Weiand 6221 Offset Thermostat Housing Adapter For Small Block and Big Block Chev

your problem is VERY COMMON, if the throttle body and thermostat housing has a clearance issue on some modified EFI intakes, heres the usual cure

a couple hours spent READING THRU THESE THREADS could give you more info

http://www.smartfireinjectors.com/fuelflowchart.html

if your on a very limited budget, simply, doing some port and runner porting on the stock intake, swapping to a fairly mild crane 114132 flat tappet hydraulic cam that works with the stock converter and brakes,

and a set of new lifters and some 1.6:1 roller rockers, on the intake and 1.5:1 on the exhaust would produce a rather cost effective extra 35-40 hp, in most 1985 TPI engines

https://www.summitracing.com/parts/scc-scp1027

a https://www.summitracing.com/parts/crn-114132

http://www.highperformancepontiac.com/t ... ck_engine/

Last edited by a moderator: