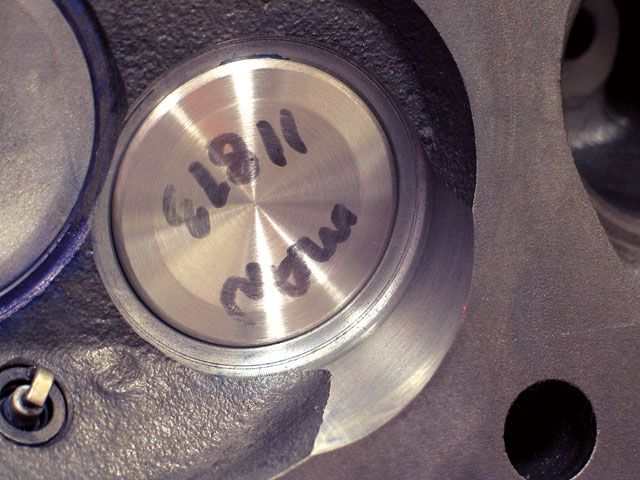

head gaskets are rarely completely round, nore are combustion chambers

you,ll want to place a head gasket you,ll use on the heads and mark the area inside the opening as the only areas you can change,

(notice the gasket fire ring is NOT a perfect circle like many people assume)

ideally you,ll want to un-shroud the valves while opening up the combustion chamber volume,

but not extend the combustion chamber past the front edge of the gasket fire ring,

as that usually causes gasket failure

http://garage.grumpysperformance.com/index.php?threads/ccing-my-heads.14187/

http://garage.grumpysperformance.com/index.php?threads/how-to-lap-valve-seats.1159/#post-2362

http://garage.grumpysperformance.com/index.php?threads/iron-vs-aluminum-heads.389/#post-31684

http://garage.grumpysperformance.co...r-piston-dome-or-port-volume.2077/#post-60554

you might be amazed at how much material can be removed ,

too noticeably increase air-flow and un-shroud the valves,

and how little it might effectively change,

the combustion chamber volume and compression.

laying a head gasket on the head and use machinist blue dye to show the areas inside the gasket fire-ring

http://www.skygeek.com/dymon-8000-s...MI8vPS24jm1gIVBolpCh2pnAoWEAQYAiABEgL2ZPD_BwE

thus the first logical step would be to carefully place a identical head gasket to what you'll use on the engine , properly lined up on the cylinder head and accurately scribe its inside dimensional limits on the cylinder head,

a metal scribe , a dremel tool and machinist blue would be helpful here

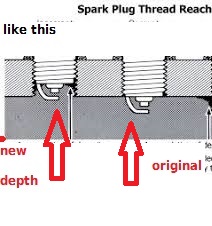

keep in mind its one of several factors working together, things like getting the quench correct, polishing and un-shrouding the combustion chamber, getting the ignition advance curve and fuel/air ratio correctly matched and taking the time to polish the piston, dome, removing sharp edges from valve clearance notches , and polishing and very slightly rounding sharp edges on the valves, use of the correct spark plug heat range, removing exposed threads in the combustion chamber after you test by inserting a correct spark plug, certainly helps reduce any potential hot spots.

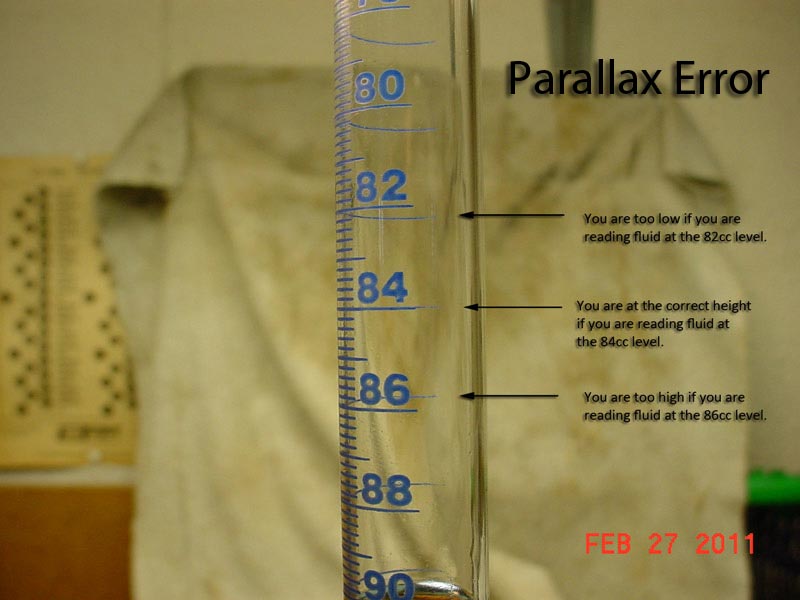

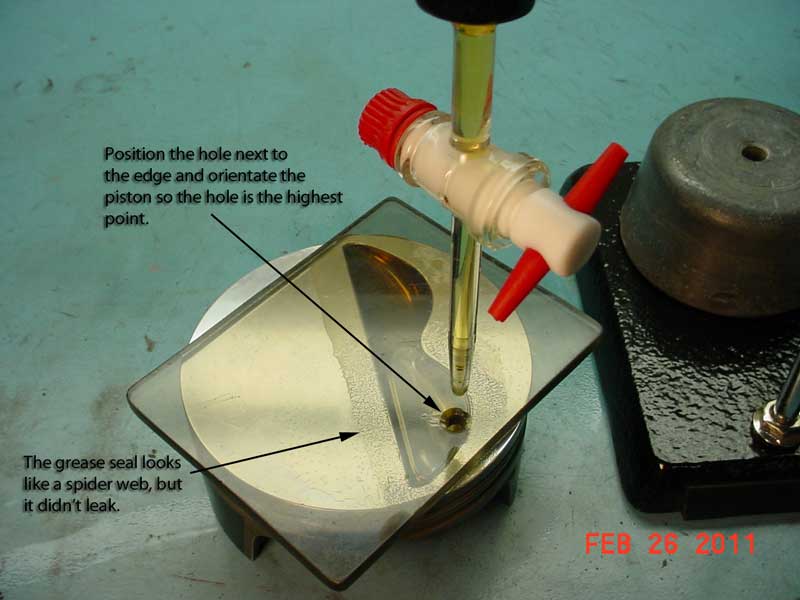

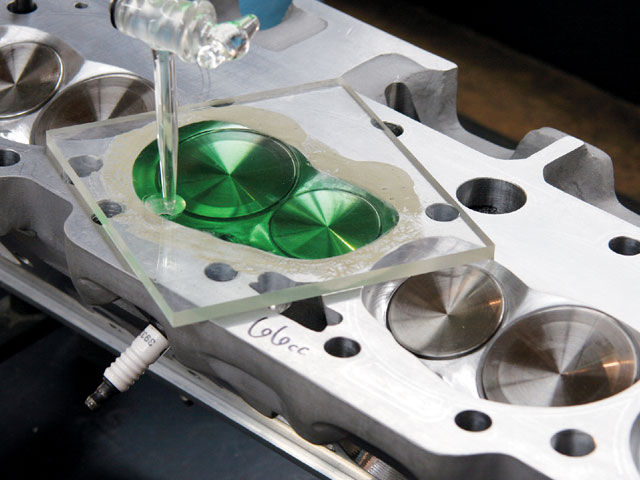

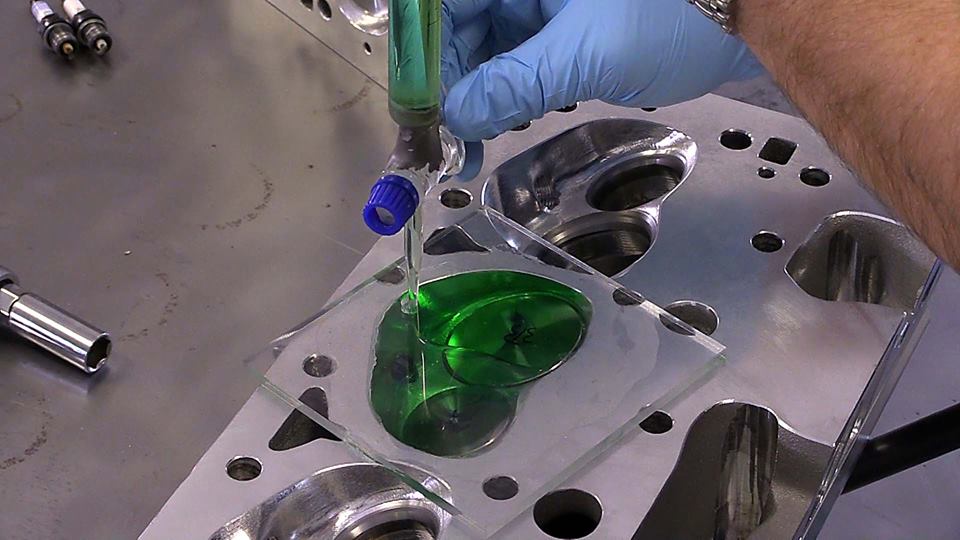

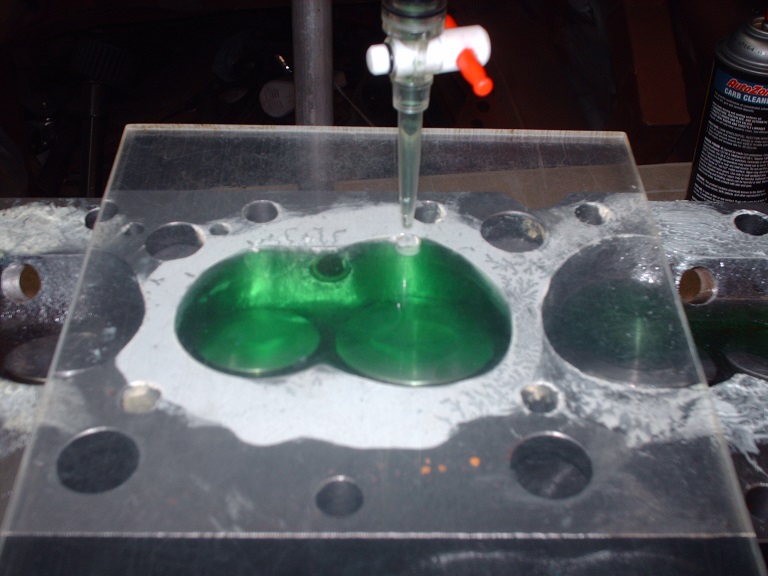

youll want too have a fluid with little or no surface tension ,

rubbing alcohol with food coloring will work.

most grocery stores sell food dye

and rubbing alcohol( but you might prefer water,

and a drop of dawn dish washing soap,

and food coloring )

(because alcohol dissolves some plastics (LIKE THAT BURRET AND COVER PLATE YOU JUST PAID BIG BUCKS FOR!!)

and its very flammable unlike water with food dye)

don,t work near flames or ignition sources alcohol like gas can ignite starting a fire and alcohol flames are difficult to see in bright light, but still very

dangerous

for checking valve seal integrity , and combustion chamber volume ,rubbing alcohol with food dye works just fine

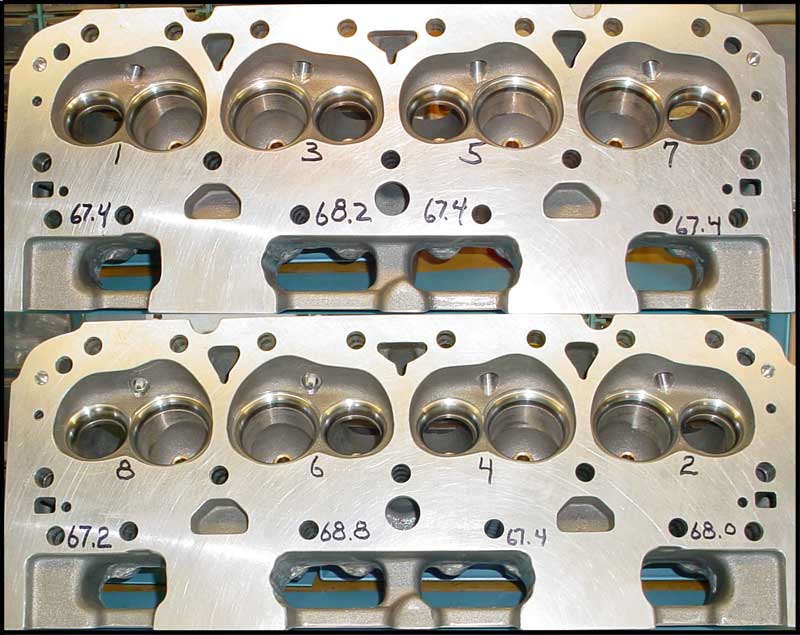

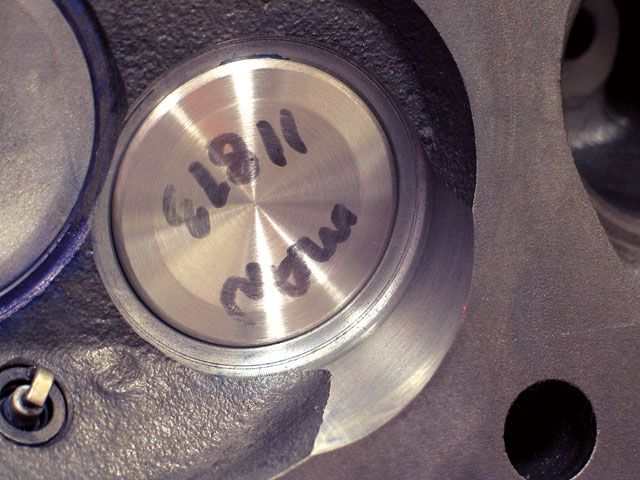

BlackoutSteve posted these pictures

What cylinder head?

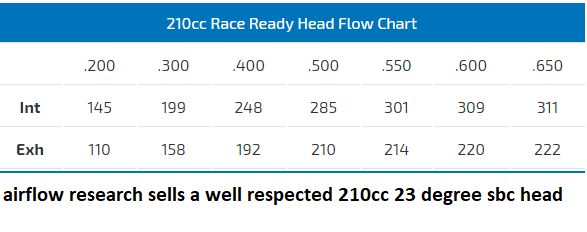

With my 4.280" bore and AFR head, I am forced to use a 4.540" bore gasket because the chambers are wide and would otherwise allow the gasket to "hang" in the chamber.

For example..

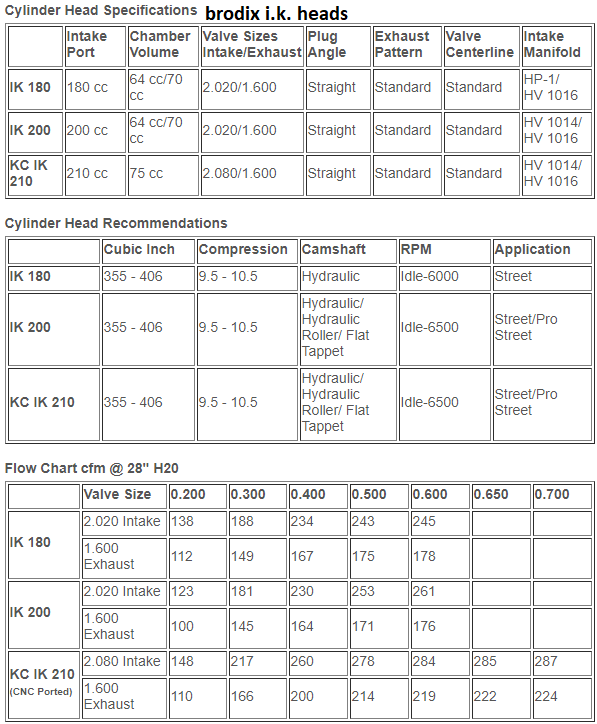

Ive suggested your average skilled mechanic or hot rod enthusiast,

spend time in doing research in, and then if they choose too,

cleaning up the bowl area under the valves , of casting flash,

and valve seat machining ridges,getting a multi angle valve job,

narrowing the valve guides port matching the heads/intake manifold,

and polishing and ccing the combustion chambers,

you should not be significantly altering or enlarging the ports or runners,

multi angle valve jobs should be left too the pros with the correct machinery,

and precise measuring equipment,

but a home shop can certainly lap valves and clean up the port and bowl area ,

and port match, and blend , polish and cc combustion chambers, etc.

reading links and sub-links generally helps

http://garage.grumpysperformance.co...ng-combustion-chambers.2630/page-3#post-77963

http://garage.grumpysperformance.com/index.php?threads/ccing-my-heads.14187/#post-71989

http://garage.grumpysperformance.co...needs-clean-up-equalization.12474/#post-62647

http://garage.grumpysperformance.co...r-piston-dome-or-port-volume.2077/#post-61068

http://garage.grumpysperformance.co...ing-tools-abrasives-sources.10683/#post-46209

http://garage.grumpysperformance.co...lve-seat-angles-and-air-flow.8460/#post-29682

http://garage.grumpysperformance.com/index.php?threads/multi-angle-valve-job-related.3143/#post-8387

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.com/index.php?threads/rocker-push-rod-wear-issues.9815/