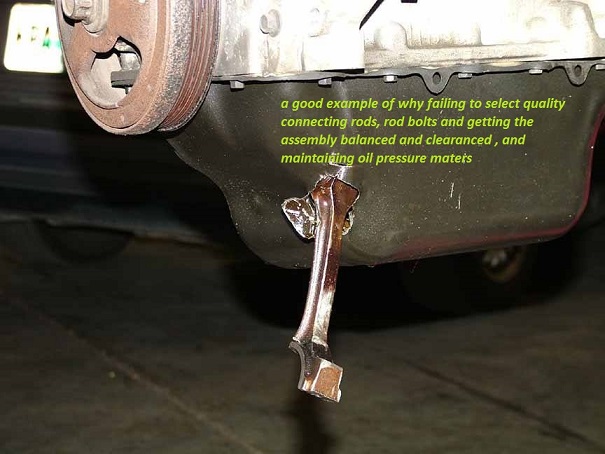

I saw this procedure in the book below, but don't assume it will work in all cases !!!

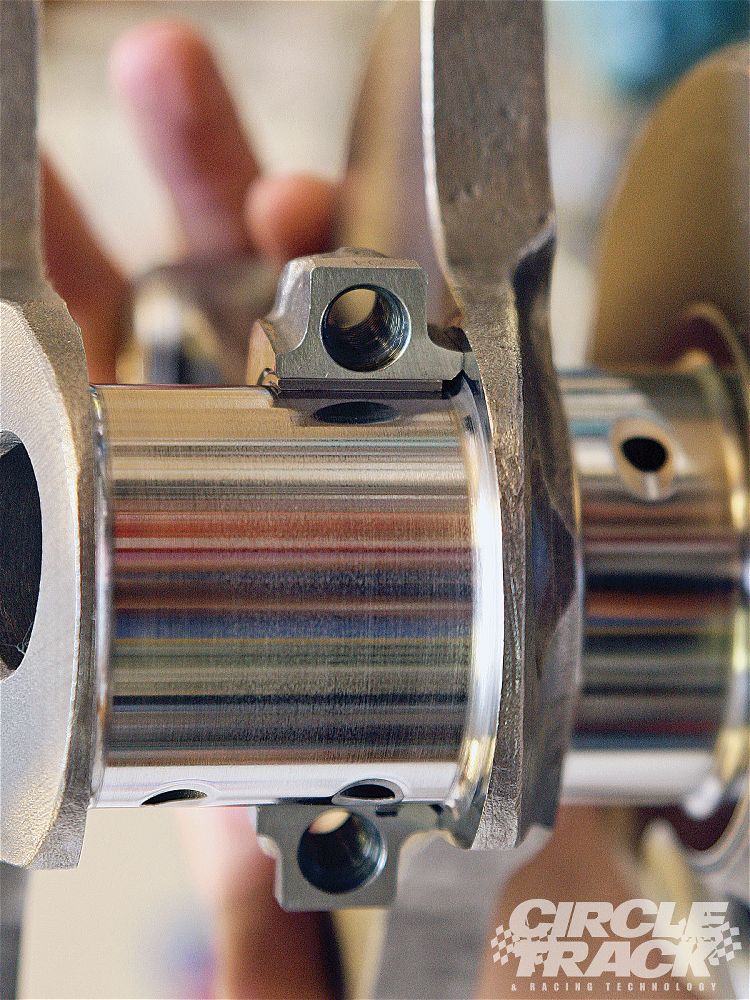

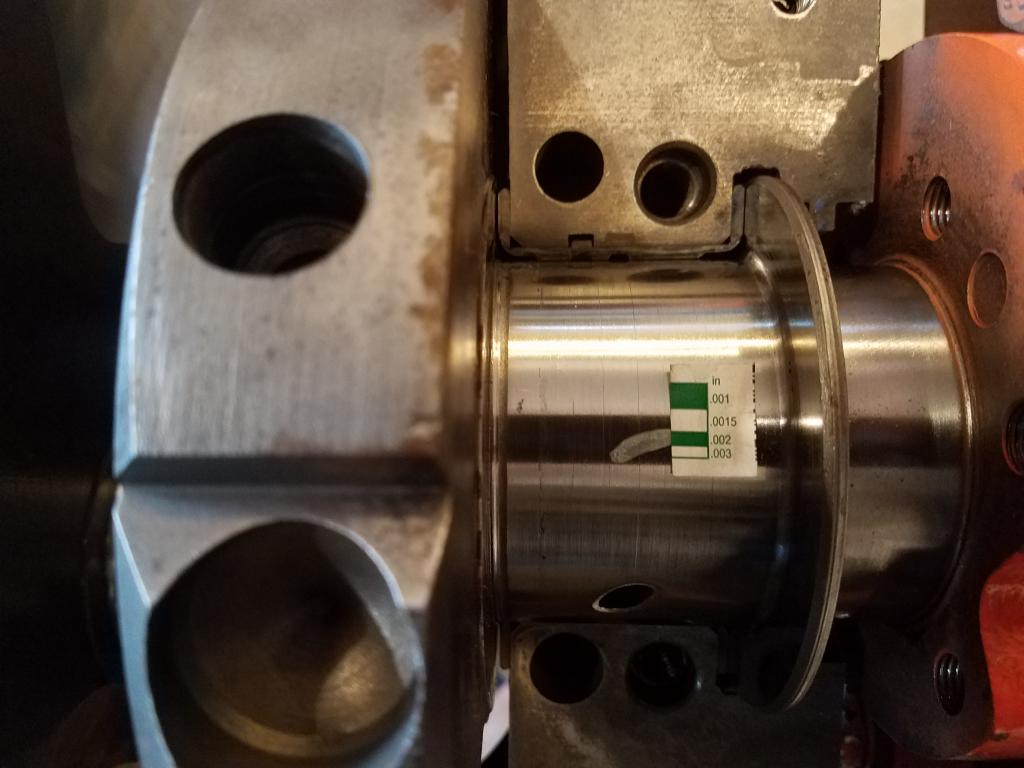

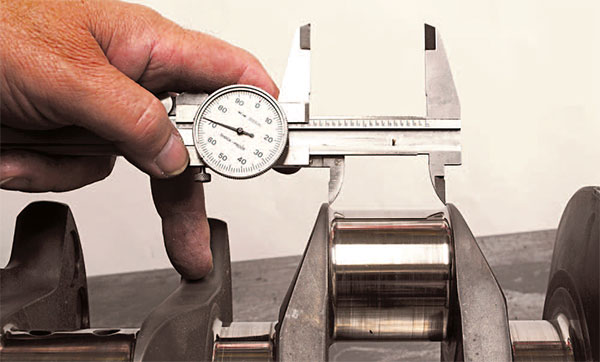

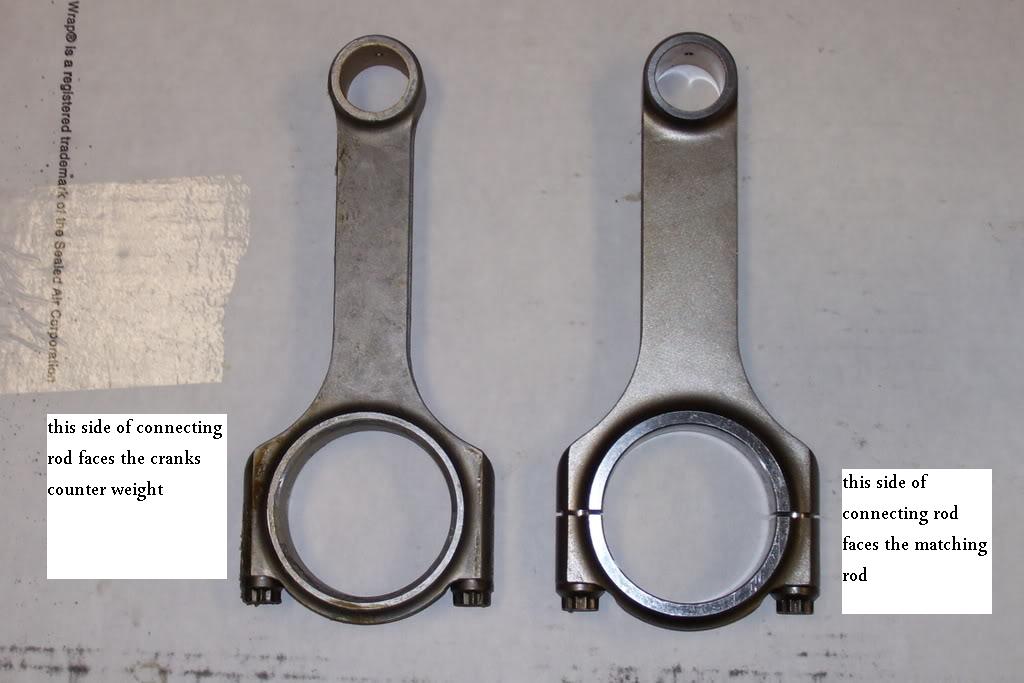

When checkingrod side clearance you can place two rods together and measure their width. Below is

exactly how they had them lined up. I'm using the clamps so I can take the picture.

You can see the light coming thru because the small end of the rod is wider than the big

end causing the gap. When I measured this way, I got a measurement that was 0.018" wider. Maybe this

works for stock rods.

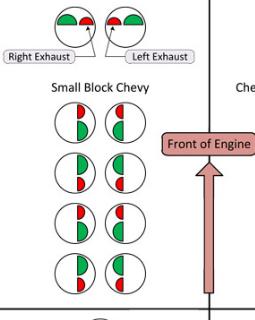

one factor to keep in mind is that rods typically have a side that rides against its matched companion and a side thats BEVELED for clearance on the crank journals radias EXAMPLE

notice the top rods non-beveled side that faces the matching rod is up, but on the lower rod the the beveled side that faces the crank counter weight is up on the lower rod

BTW, I did make sure the sides with the biggest bevel were facing to the outside.

Scat Forged Rods

Part Number: 2-ICR6000-7/16 -- Bushed, ARP 8740 7/16†x 1.400 cap screws for stroker clearance