Derek from Hamburg

Member

Dear All,

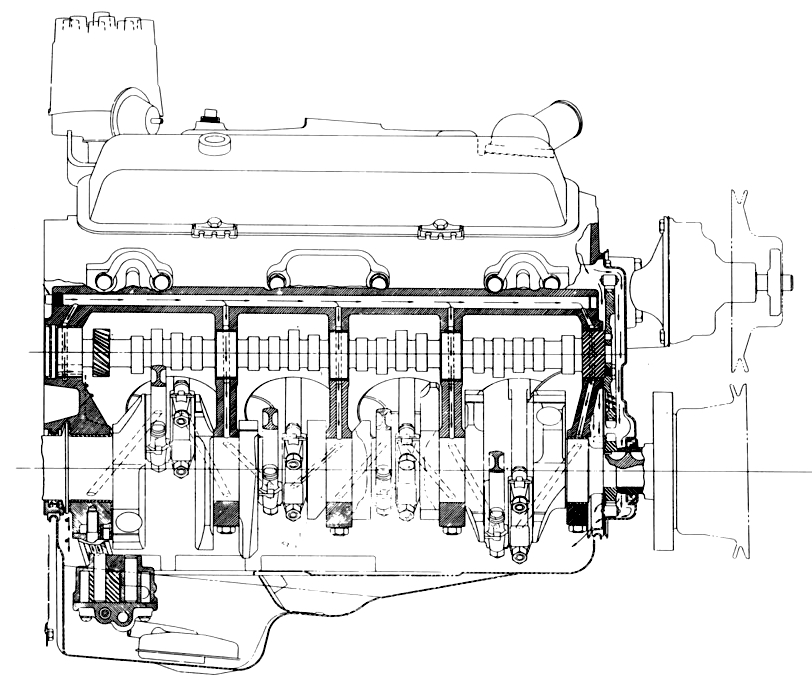

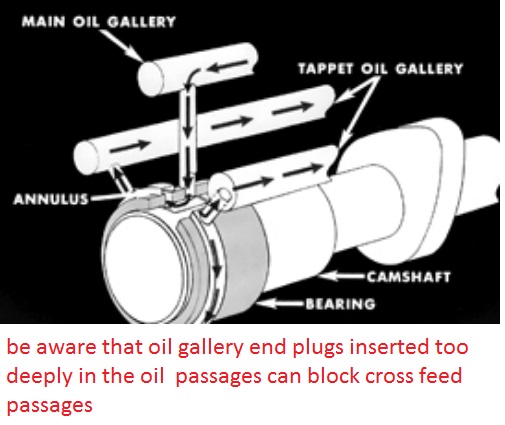

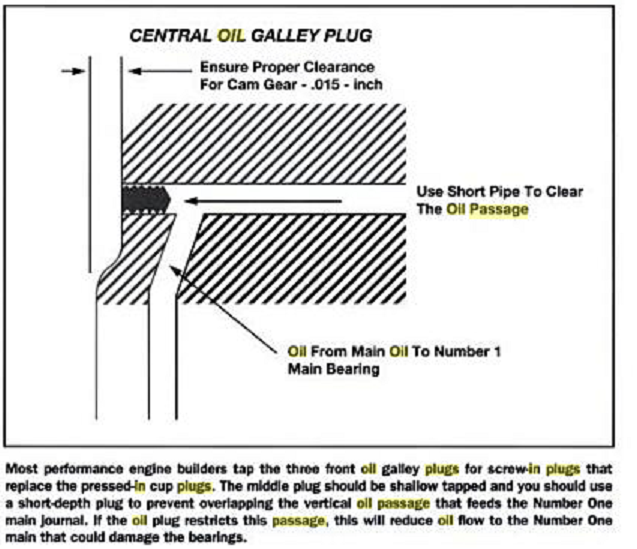

I have a Chevy Small block from 1978. I have changed the oil pump to a high volume type and changed camshaft, hydraulic lifters and pushrods. Now after breaking in the camshaft I realized that the oil supply on cylinder No.2 on the exhaust rocker system is the last one where the oil supply through the pushrod is coming. Until I can see the oil coming (I have some valves covers cut out at the top for inspection and valve adjustment) the engine is already running for some minutes in idle and has nearly reached its normal running water temperatur.

I am very sensible at the moment, as especially this rocker arrangement failed in the past, and that was the reason to change all the components mentioned above.

I have no experience how it will look like on this cylinder, (as it is the one most far away from the oil pump)

when everything is normal. So your experience would be very helpful for me.

Best Regards

Derek

I have a Chevy Small block from 1978. I have changed the oil pump to a high volume type and changed camshaft, hydraulic lifters and pushrods. Now after breaking in the camshaft I realized that the oil supply on cylinder No.2 on the exhaust rocker system is the last one where the oil supply through the pushrod is coming. Until I can see the oil coming (I have some valves covers cut out at the top for inspection and valve adjustment) the engine is already running for some minutes in idle and has nearly reached its normal running water temperatur.

I am very sensible at the moment, as especially this rocker arrangement failed in the past, and that was the reason to change all the components mentioned above.

I have no experience how it will look like on this cylinder, (as it is the one most far away from the oil pump)

when everything is normal. So your experience would be very helpful for me.

Best Regards

Derek