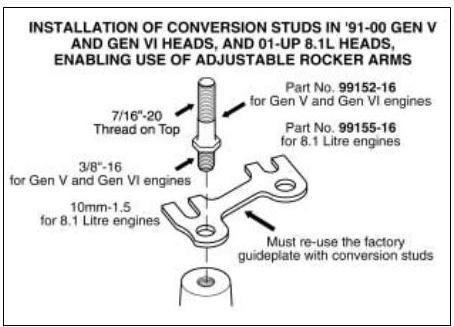

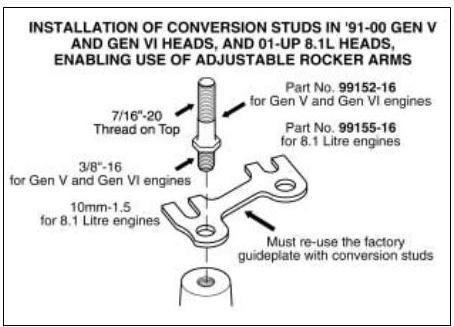

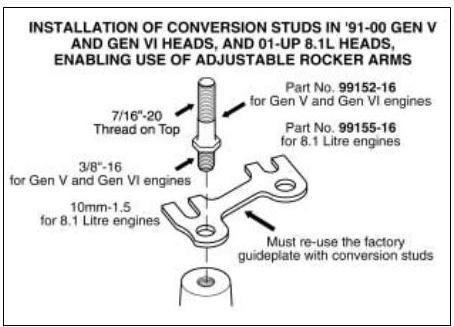

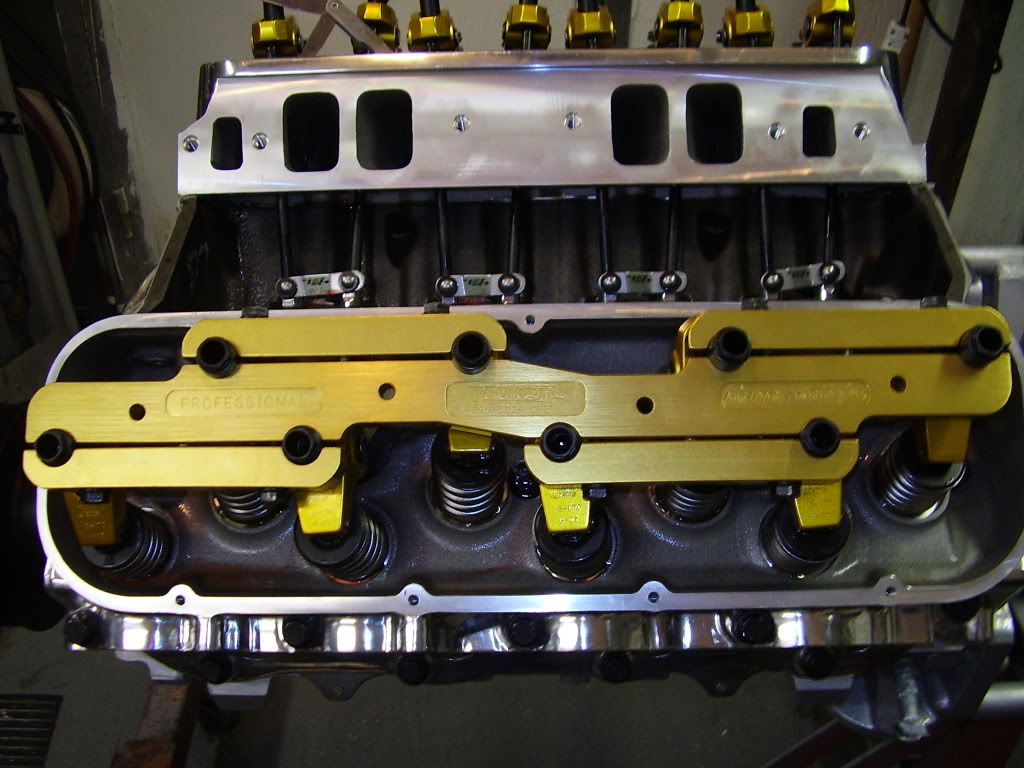

If you intend to use any other cam than the stock hydraulic cam that came in a MARK V or MARK VI (gen 5 or gen 6 BIG BLOCK CHEVY) you'll most likely want to install one with more lift or duration to increase performance, that means you'll most likely need to upgrade the valve train to an adjustable valve train,IN most cases the use of the conversion studs with the 3/8" 16 lower threads and 7/16" 20 thread uppers and the older mark IV rockers is the best way to convert the valve train on a limited budget, aftermarket stamped steel roller tip rockers, with grooved pivot balls for increased oil flow, don,t cost a great deal more than NEW standard stamped steel rockers so that may be an option on a budget

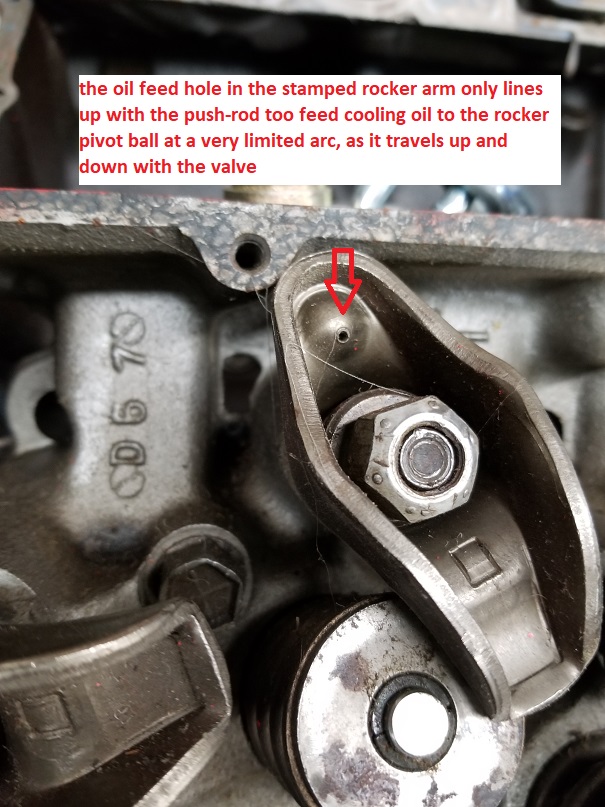

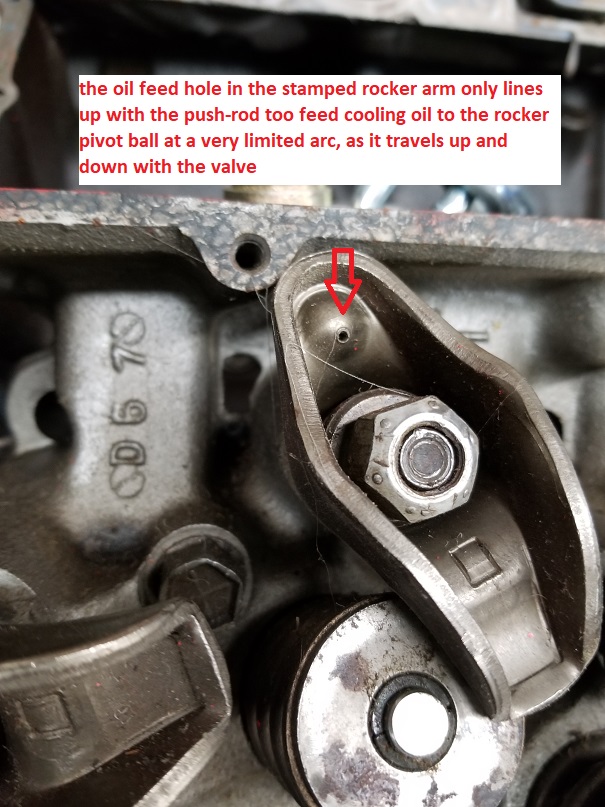

the grooved rocker pivot ball design was an effort by G.M. engineering to economically solve the issue of marginal oil flow causing rocker ball galling, and resulting noisy, or broken valve trains

http://garage.grumpysperformance.com/index.php?threads/busted-rocker-stud.689/

http://www.summitracing.com/parts/CCA-1411-16/

http://www.summitracing.com/parts/EDL-2162/

yes the theoretical ratios 1.7:1

I don,t know for sure if the OEM rocker balls and nuts work Ive always pitched them in the dumpster, the kit comes with a spacer

to allow the nut on the threads to hold the rock ball in place as without that spacer the nut runs out of thread before the rocker is properly adjusted

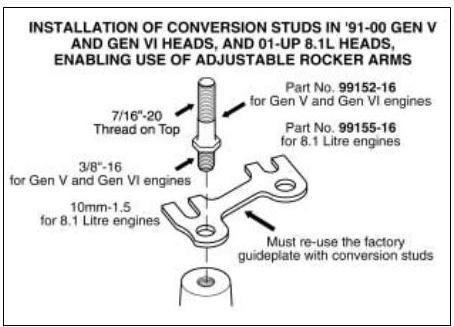

as many guys know COMP CAMS sells ADAPTER studs with the small 3/8/16 threads to fit the heads and larger 7/16" threads to fit the rocker adjusting nuts and as long as youll use a mild cam and near factory valve spring loads the conversion kit works ok.

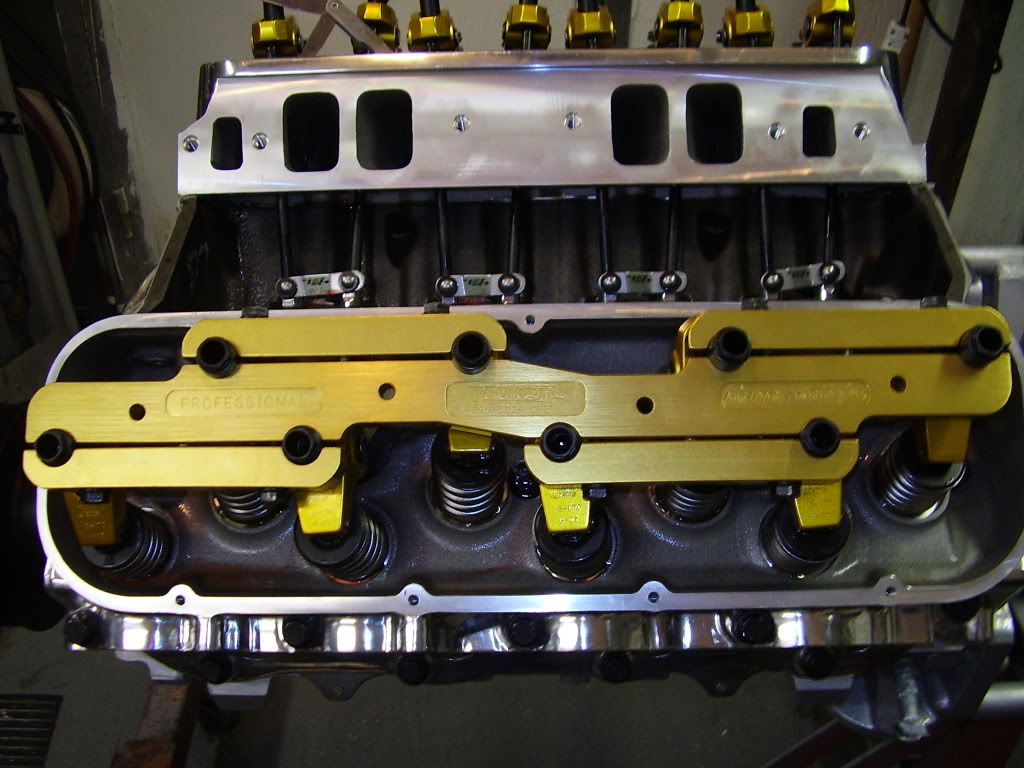

if your intent is a fairly aggressive cam with stiffer spring load rates your strongly advised to take the heads to a machine shop and get BOTH ARP studs with the longer and stronger 7/16" base threads and use a rocker stud girdle to spread and equalize stress

http://www.jegs.com/webapp/wcs/stores/servlet/KeywordSearchCmd?storeId=10001&catalogId=10002&langId=-1&Ntk=all&Jnar=0&itemPerPage=60&Ne=1+2+3+13+1147708&searchTerm=mark+v+rockers

http://www.jegs.com/i/COMP-Cams/249/4514-KIT/10002/-1?parentProductId=764287

https://www.centuryperformance.com/...ure.html?xid=lzE72fc7xSMfhyuSoWOoereKbqSCEK7w

as always youll NEED TO VERIFY CLEARANCES and ID sure be verifying that particular set of valve springs on the lobes that failed FIRST, the EDELBROCK cam is pushing the clearance limitations but it should work, of course its YOUR responsibility as the installer to verify clearances and that does NOT mean if it rotates without binding up its FINE!

I will point out that the PROPER conversion route is to take the heads to a local machine shop and have the heads re-drilled and threaded for the stronger 7/16' thread ARP rocker studs

stock stamped rockers $80

http://m.summitracing.com/parts/sum-g6803

ROLLER ROCKER $271

http://www.jegs.com/i/Scorpion+Racing+Products/347/SCP1014/10002/-1

obviously if a bit of extra performance is the goal and the extra cost is not a problem, true roller rockers are preferred,

http://www.summitracing.com/parts/BRO-BR1230/?rtype=10

http://www.compperformancegroupstores.c ... aProMagnum

comp cams sells these conversion rocker studs with the sleeves that allow re-use of the stock formally non-adjustable rocker that converts them to be adjustable, style rockers, but be aware that the smaller 3/8" diameter threads used on the conversion rocker studs are weaker than the standard 7/16" diameter rocker studs. (used on the MARK-IV rocker studs) so if you go the conversion route use of a rather expensive rocker stud girdle to make the valve train more rigid and stable.

yes your more than likely going to need to remove the cylinder heads and take them to a machine shop, but the much stronger 7/16" ARP studs are SUGGESTED

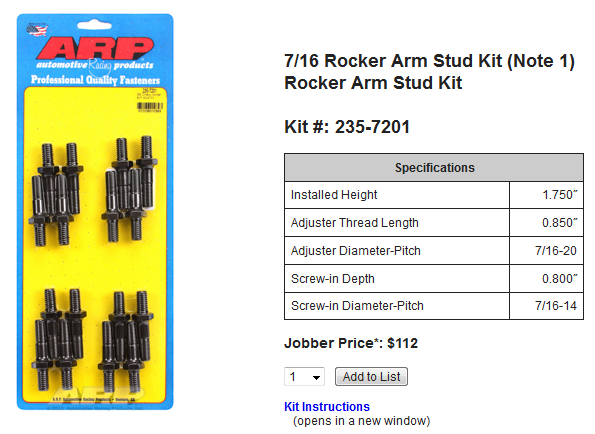

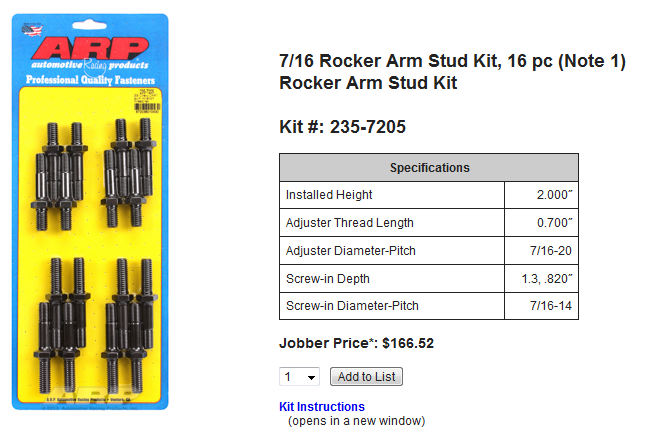

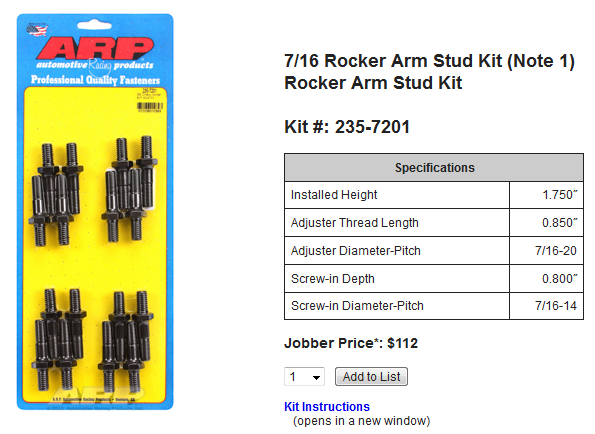

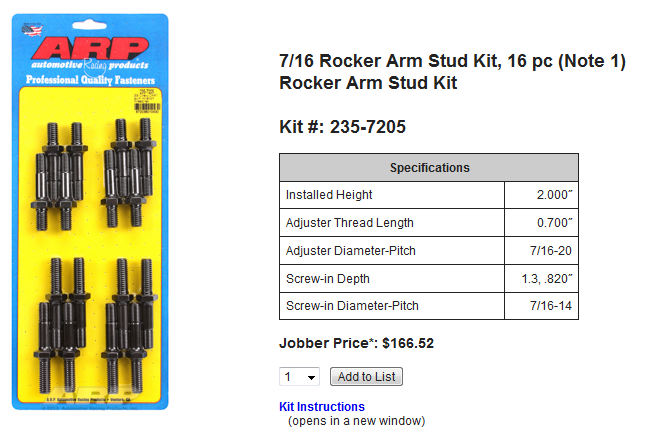

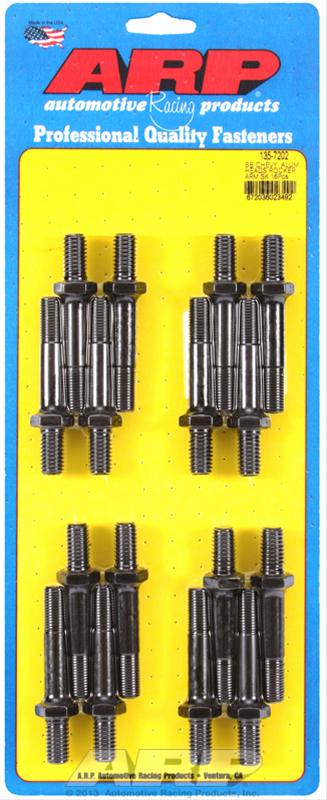

rocker studs come in several different lengths, longer versions are more versatile and used with stud girdles and jam nut style locking nuts

I don,t know a single person thats used those because most guys want to upgrade the valve train want to add significant strength and convert to some more common.cheaper and better MARK IV rockers than retain the stock MARK V-VI O.E.M stamped steel rocker versions

most guys either have the heads re-drilled and re-threaded to accept the MARK IV 7/16" MARK IV studs (16 of P/N 3921912 rocker studs)

http://www.summitracing.com/parts/ARP-135-7101/

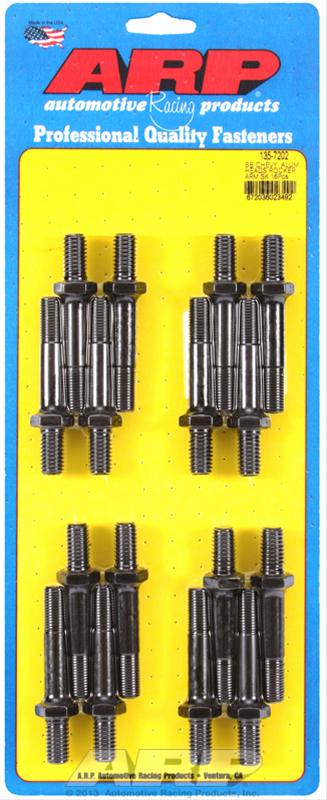

or INSTALL the ARP conversion studs that have the standard mark IV upper with the smaller 3/8" lower section

http://www.gmpartsdirect.com/performanc ... D=466.html

obviously youll need to do minimal research to make 100% sure any rocker stud girdle fits the cylinder heads and rocker stud spacing on YOUR ENGINE...not all cylinder heads have identical rocker spacing

http://www.jegs.com/i/Brodix/158/BR1230 ... tId=940090

http://www.competitionproducts.com/Joma ... o/JOM1114/

now if your using a fairly mild hydraulic roller cam in your gen V-VI big block and just need a bit of adjust-ability the use of the 3/8" base studs and 7/16" upper stud conversion studs makes sense, and if you elect to use he small base thread studs and if your using a rocker stud girdle the lower stud is under less stress, but the average huy that races wants the full 7/16" ARP mark IV studs installed and any decent machine shop can re-drill and re-thread the heads for a reasonable cost

it should be noted that if the rocker stud protrudes into the port it should be trimmed to the port roof as any threads sticking down into the runner disrupt flow and don,t supply extra support to the rocker stud,and stud threads should use loc-tite tread sealant

SMALL 3/8" thread base

http://www.summitracing.com/parts/CCA-4514-16/?rtype=10

STANDARD 7/16" BASE

http://www.summitracing.com/parts/CCA-4512-1/

YES THERES A GOOD DEAL MORE INFO IN THE LINKS BELOW

http://www.gmpartsdirect.com/performanc ... D=466.html

http://www.gmpartsdirect.com/performanc ... D=466.html

viewtopic.php?f=44&t=2839

http://www.454ss.com/Articles_new/GEN5.asp

http://www.chevyhiperformance.com/techa ... index.html

http://www.keitheickert.com/p-11694-big ... rsion.aspx

Ive used either one of these two products, applied on clean dry threads by dipping the stud threads just prior to assembly on those threads, waiting a minute for the stuff to start to get tacky,then screwing them in for decades

Ive never had a leak or loose stud, never had any issues removing them if required ,with the proper socket and breaker bar later either,

BTW, remember to visually verify the stud length and cut them a bit shorter if required you don,t want the lower end protruding into the intake port and any threads doing that do NOTHING to increase the stud rigidity but they sure can reduce port flow rates if left sticking down into the air flow path

threads/valve-train-clearances-and-problems.528/#post-57678

http://garage.grumpysperformance.com/index.php?

http://garage.grumpysperformance.co...gine-build-up-for-the-street.3153/#post-11626

http://garage.grumpysperformance.co...tting-up-the-valve-train.181/page-2#post-7684

http://www.cranecams.com/userfiles/PP0811A_SinglePages.pdf

http://garage.grumpysperformance.co...a-peanut-port-big-block-combo.2900/#post-7532

the grooved rocker pivot ball design was an effort by G.M. engineering to economically solve the issue of marginal oil flow causing rocker ball galling, and resulting noisy, or broken valve trains

http://garage.grumpysperformance.com/index.php?threads/busted-rocker-stud.689/

http://www.summitracing.com/parts/CCA-1411-16/

http://www.summitracing.com/parts/EDL-2162/

yes the theoretical ratios 1.7:1

I don,t know for sure if the OEM rocker balls and nuts work Ive always pitched them in the dumpster, the kit comes with a spacer

to allow the nut on the threads to hold the rock ball in place as without that spacer the nut runs out of thread before the rocker is properly adjusted

as many guys know COMP CAMS sells ADAPTER studs with the small 3/8/16 threads to fit the heads and larger 7/16" threads to fit the rocker adjusting nuts and as long as youll use a mild cam and near factory valve spring loads the conversion kit works ok.

if your intent is a fairly aggressive cam with stiffer spring load rates your strongly advised to take the heads to a machine shop and get BOTH ARP studs with the longer and stronger 7/16" base threads and use a rocker stud girdle to spread and equalize stress

http://www.jegs.com/webapp/wcs/stores/servlet/KeywordSearchCmd?storeId=10001&catalogId=10002&langId=-1&Ntk=all&Jnar=0&itemPerPage=60&Ne=1+2+3+13+1147708&searchTerm=mark+v+rockers

http://www.jegs.com/i/COMP-Cams/249/4514-KIT/10002/-1?parentProductId=764287

https://www.centuryperformance.com/...ure.html?xid=lzE72fc7xSMfhyuSoWOoereKbqSCEK7w

as always youll NEED TO VERIFY CLEARANCES and ID sure be verifying that particular set of valve springs on the lobes that failed FIRST, the EDELBROCK cam is pushing the clearance limitations but it should work, of course its YOUR responsibility as the installer to verify clearances and that does NOT mean if it rotates without binding up its FINE!

I will point out that the PROPER conversion route is to take the heads to a local machine shop and have the heads re-drilled and threaded for the stronger 7/16' thread ARP rocker studs

stock stamped rockers $80

http://m.summitracing.com/parts/sum-g6803

ROLLER ROCKER $271

http://www.jegs.com/i/Scorpion+Racing+Products/347/SCP1014/10002/-1

obviously if a bit of extra performance is the goal and the extra cost is not a problem, true roller rockers are preferred,

http://www.summitracing.com/parts/BRO-BR1230/?rtype=10

http://www.compperformancegroupstores.c ... aProMagnum

comp cams sells these conversion rocker studs with the sleeves that allow re-use of the stock formally non-adjustable rocker that converts them to be adjustable, style rockers, but be aware that the smaller 3/8" diameter threads used on the conversion rocker studs are weaker than the standard 7/16" diameter rocker studs. (used on the MARK-IV rocker studs) so if you go the conversion route use of a rather expensive rocker stud girdle to make the valve train more rigid and stable.

yes your more than likely going to need to remove the cylinder heads and take them to a machine shop, but the much stronger 7/16" ARP studs are SUGGESTED

rocker studs come in several different lengths, longer versions are more versatile and used with stud girdles and jam nut style locking nuts

I don,t know a single person thats used those because most guys want to upgrade the valve train want to add significant strength and convert to some more common.cheaper and better MARK IV rockers than retain the stock MARK V-VI O.E.M stamped steel rocker versions

most guys either have the heads re-drilled and re-threaded to accept the MARK IV 7/16" MARK IV studs (16 of P/N 3921912 rocker studs)

http://www.summitracing.com/parts/ARP-135-7101/

or INSTALL the ARP conversion studs that have the standard mark IV upper with the smaller 3/8" lower section

http://www.gmpartsdirect.com/performanc ... D=466.html

obviously youll need to do minimal research to make 100% sure any rocker stud girdle fits the cylinder heads and rocker stud spacing on YOUR ENGINE...not all cylinder heads have identical rocker spacing

http://www.jegs.com/i/Brodix/158/BR1230 ... tId=940090

http://www.competitionproducts.com/Joma ... o/JOM1114/

now if your using a fairly mild hydraulic roller cam in your gen V-VI big block and just need a bit of adjust-ability the use of the 3/8" base studs and 7/16" upper stud conversion studs makes sense, and if you elect to use he small base thread studs and if your using a rocker stud girdle the lower stud is under less stress, but the average huy that races wants the full 7/16" ARP mark IV studs installed and any decent machine shop can re-drill and re-thread the heads for a reasonable cost

it should be noted that if the rocker stud protrudes into the port it should be trimmed to the port roof as any threads sticking down into the runner disrupt flow and don,t supply extra support to the rocker stud,and stud threads should use loc-tite tread sealant

SMALL 3/8" thread base

http://www.summitracing.com/parts/CCA-4514-16/?rtype=10

STANDARD 7/16" BASE

http://www.summitracing.com/parts/CCA-4512-1/

YES THERES A GOOD DEAL MORE INFO IN THE LINKS BELOW

http://www.gmpartsdirect.com/performanc ... D=466.html

http://www.gmpartsdirect.com/performanc ... D=466.html

viewtopic.php?f=44&t=2839

http://www.454ss.com/Articles_new/GEN5.asp

http://www.chevyhiperformance.com/techa ... index.html

http://www.keitheickert.com/p-11694-big ... rsion.aspx

Ive used either one of these two products, applied on clean dry threads by dipping the stud threads just prior to assembly on those threads, waiting a minute for the stuff to start to get tacky,then screwing them in for decades

Ive never had a leak or loose stud, never had any issues removing them if required ,with the proper socket and breaker bar later either,

BTW, remember to visually verify the stud length and cut them a bit shorter if required you don,t want the lower end protruding into the intake port and any threads doing that do NOTHING to increase the stud rigidity but they sure can reduce port flow rates if left sticking down into the air flow path

threads/valve-train-clearances-and-problems.528/#post-57678

http://garage.grumpysperformance.com/index.php?

http://garage.grumpysperformance.co...gine-build-up-for-the-street.3153/#post-11626

http://garage.grumpysperformance.co...tting-up-the-valve-train.181/page-2#post-7684

http://www.cranecams.com/userfiles/PP0811A_SinglePages.pdf

http://garage.grumpysperformance.co...a-peanut-port-big-block-combo.2900/#post-7532

Last edited by a moderator: