Im always rather amazed at the guys that don,t stop and think about the total process of making power and the failure of so many guys to think thru how each step can be improved.

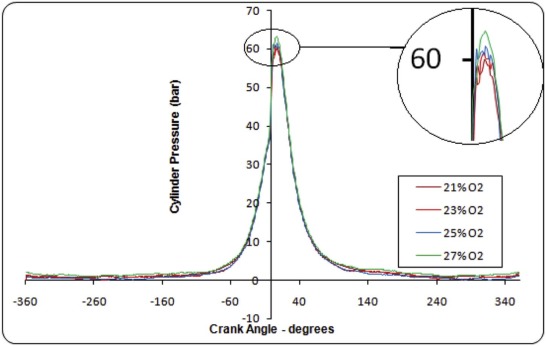

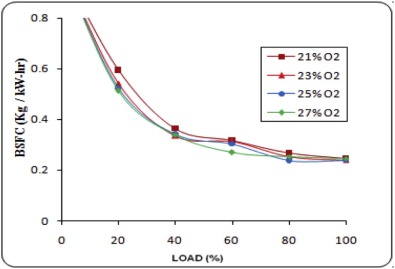

it really doesn,t matter if you have a single carb, dual quads or efi, cooler denser air will result in a more efficient engine , simply because cooler denser air contains more oxygen per cubic foot of air entering the engine, thus allowing more fuel to be burnt resulting in more power potentially produced, and isolating the engine air temp entering the engine your mixing with fuel, from the under hood temps goes a long way to help efficiency

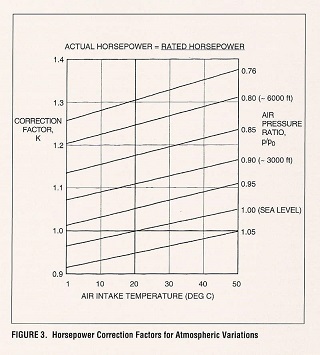

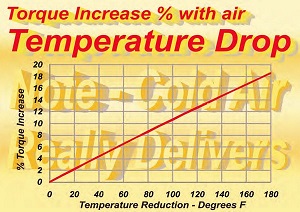

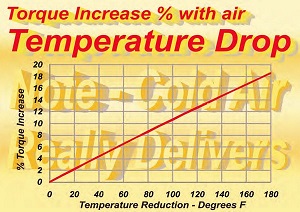

for about every 10 degrees C of increase or decrease in air temps, entering an engines carb, the horse power changes about 1% (hotter is less efficient, as cooler air is denser and contains more oxygen)

IF your not familiar with temps in C celsius that equates too about..

FOR EVERY 15 degrees change in F temp, the horse power changes about 1%

(hotter is less efficient, as cooler air is denser and contains more oxygen)

http://www.celsius.co.uk/converter/

think about that..under hood temps can easily be 100F-120F higher than outside air temps, thats a potential 7-8% decrease in effective horse power over cool air induction

yes it will in most cases take some time, fabrication skills , the ability to measure and think things thru, but the results from some individual creativity and custom fabrication can be amazing, and easily worth extra horse power, with some careful measuring and thought a cool ram air custom fabricated filter air filter housing and isolated air ducting from outside cool air could be designed and built for for most cars

like almost every other potential change you might make theres ways to duct cool outside airflow into the engine compartment to the carb or efi to limit the engine heat it absorbs in transit, cooler air is denser air and it contains a higher volume of oxygen, and its oxygen thats used to release the potential power in fuel, now you can get creative and add a super charger, turbo or add oxygen by using NITROUS, but all those routes will cost you money you might not be able to easily afford, but there are rather simple things you can do to route cooler outside air into your engine rather than allow the engine to suck up higher temp thinner and potentially far less usable air from under your hood.

you can start by getting a good air temp. gauge and measuring the air temps under your cars hood and then measuring the outside air temps. and don,t be surprised at a 80F-120F temp difference after your cars been running for awhile, between the two areas that can potentially be used as a source of air to mix with your fuel.

you might want to get creative and design a custom built hood scoop, vents or air ducts to route cooler outside air into your muscle car or corvettes engine!

http://www.vararam.com/sc1.html

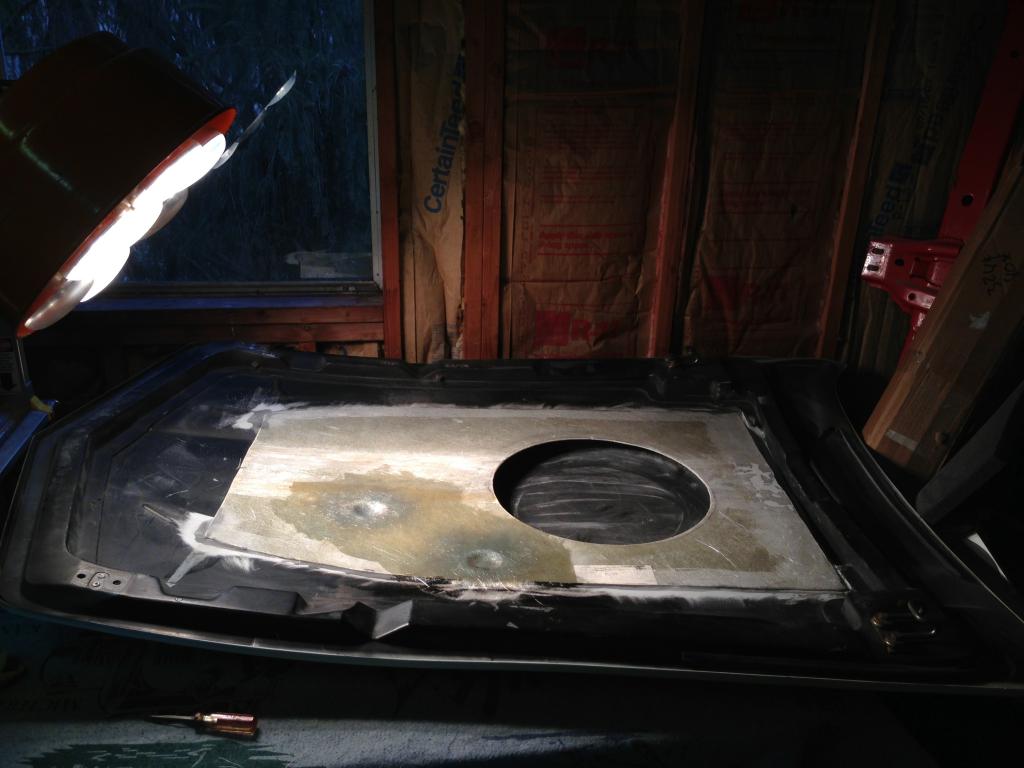

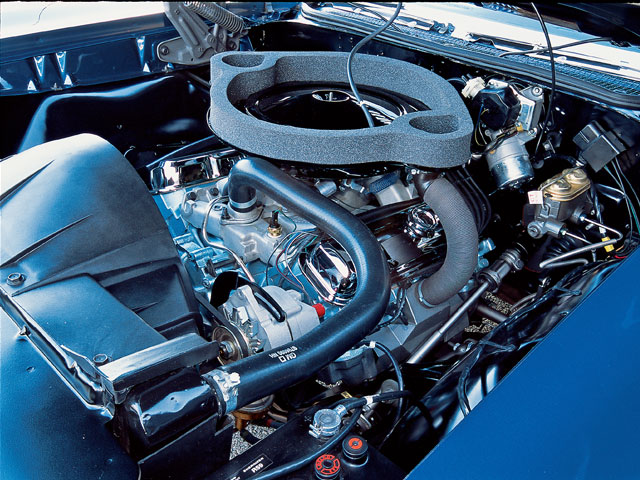

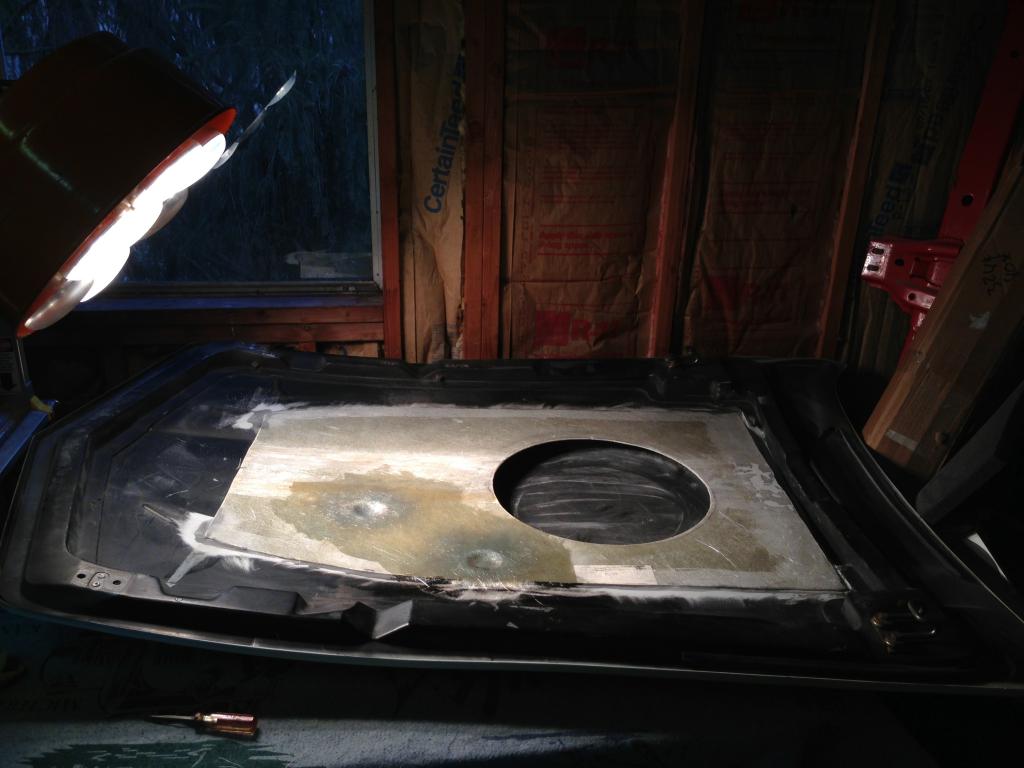

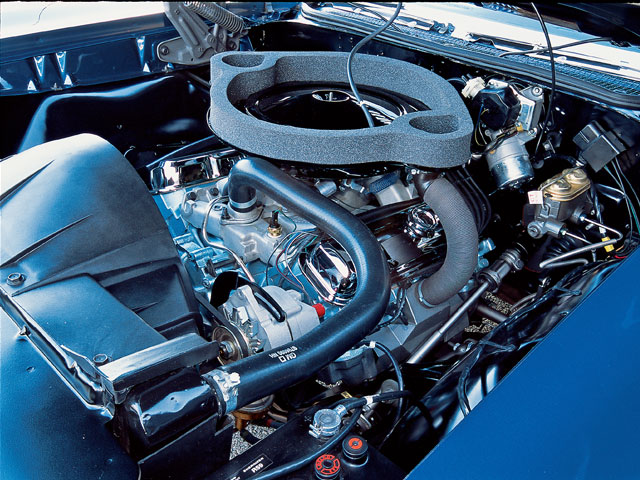

now heres a series of pictures a guy took when he designed a cold air routing duct and hood scoop to route cool air into his carb, from a scoop on the hood, he tested the results and had an 80F-120F difference in intake air temps due to the custom air ducting and insulation layer under the corvette hood, an 80F-100F temp difference will produce an easily measurable gain in power

READ THIS THREAD ALSO

viewtopic.php?f=35&t=5051&p=14478&hilit=clear+filter#p14478

http://garage.grumpysperformance.co...ferant-c-4-hoods-and-hoodscoops.353/#post-434

http://www.parts123.com/corvettecentral/dyndetail.pta?catalog=0000050f&ukey=22025

cool outside air duct entrance

card board separation duct test baffle pattern

rough the surface to get good adhesion on air duct floor surface

thin fiberglass air chamber duct lower surface wall

self adjusting foam baffle seal to isolate incoming air to air filter on carb.

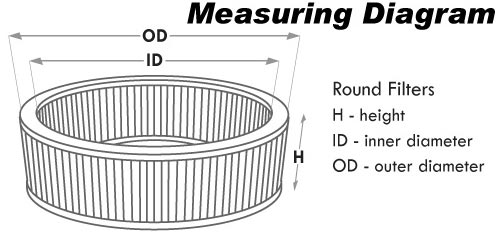

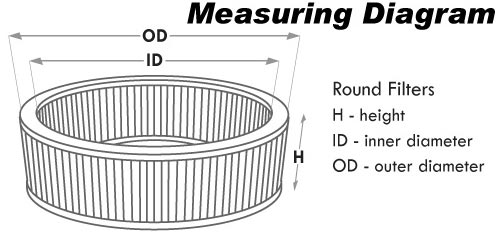

high efficiency ,low flow restriction air filter to prevent crud entering carb

carefully measuring where heat insulation foam baffle contacts duct floor then cutting matching air feed duct to carb

painting baffle or duct surface to match cars hood

insulating reflective surface film added to duct lower floor surface to reflect engine heat from incoming air to maintain max temp difference of air entering engine

https://www.autoaccessoriesgarage.com/Air-Filters/Top-10-Best-Car-Engine-Air-Filters

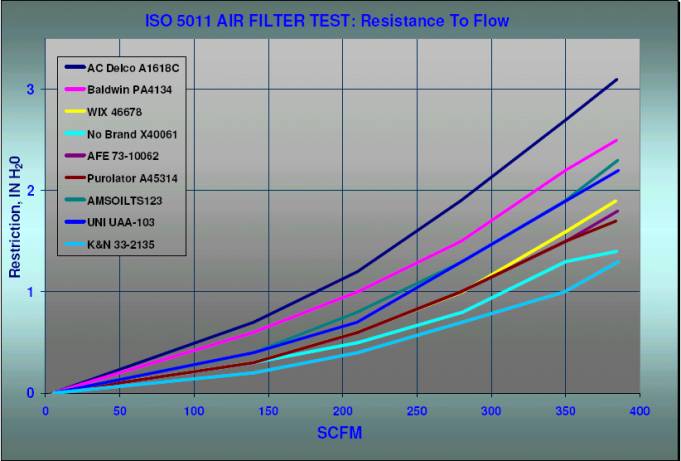

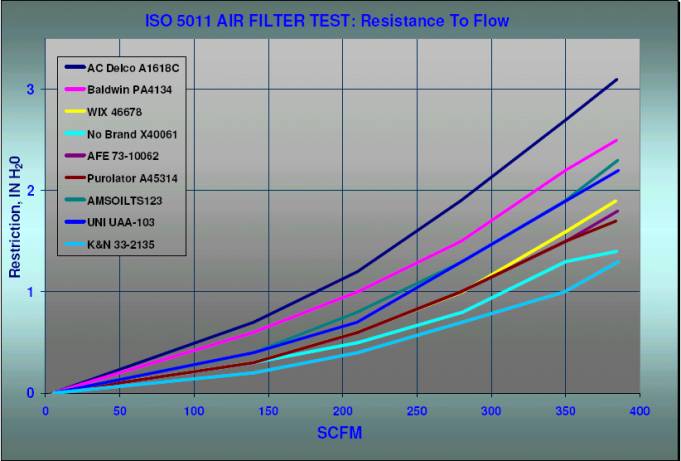

while its NOT 100% directly related, the resistance to air flow rates , is always a compromise between the air filter's efficiency at removing micro sized particles in the air that cause engine wear and restricting air flow that the engine requires to make power easily , increasing the surface area, number of pleats in the filter medium surface and height all tend to reduce air flow resistance, as the increased surface area reduces the resistance to flow

YOU CAN DO SIMILAR MODS TO A C4 CORVETTE, OR MOST CARS, IF YOU THINK IT THRU!

you can get creative and run duct work or use a custom hood design

read the links

http://garage.grumpysperformance.co...at-manifold-air-temp-sensor.10349/#post-42530

http://garage.grumpysperformance.co...elay-switch-locations-and-info.728/#post-9217

http://garage.grumpysperformance.co...om-air-cleaner-to-fit-your-cars-engine.16490/

http://www.ramairbox.com/

sells kits with the required components,

but with some basic fabrication skills and some ingenuity you would be amazed at what can be fabricated, from parts you can locate locally or from home depot or lowes hard ware, big box stores ,that will work remarkably well at ducting cool fresh airflow into the engine , look over the pictures in this thread, measure your hood clearance accurately, and let your imagination run a bit

BTW it generally helps too place some clay on your current air cleaner and shut the hood to compress the clay to get a better idea as to true hood to carb clearances, and a trip through several local salvage yards , and looking at other cars and trucks and remote mounted air filters and duct work.

may also give you some options

https://www.amazon.com/Claytoon-Set...d=1466872286&sr=8-17&keywords=plastilina+clay

https://www.amazon.com/Claytoon-Set...d=1466872286&sr=8-17&keywords=plastilina+clay

http://www.utrechtart.com/Plastalin...currency=USD&gclid=CN3G75zOw80CFQgaaQodKbgFjA

as always the more tools you have, the more options you look over, and the better your fabrication skills are the more options you,ll realistically have

owning a decent quality MIG or TIG welder and a drill press , and pop rivet guns, certainly helps and mocking up options with duct tape and card board helps give you more ideas

https://utahbiodieselsupply.com/customwork.php

commercial restaurant and beer brewing supply stores can be a gold mine for custom air filter fabrication components if you have a welder and some metal working skills and some imagination

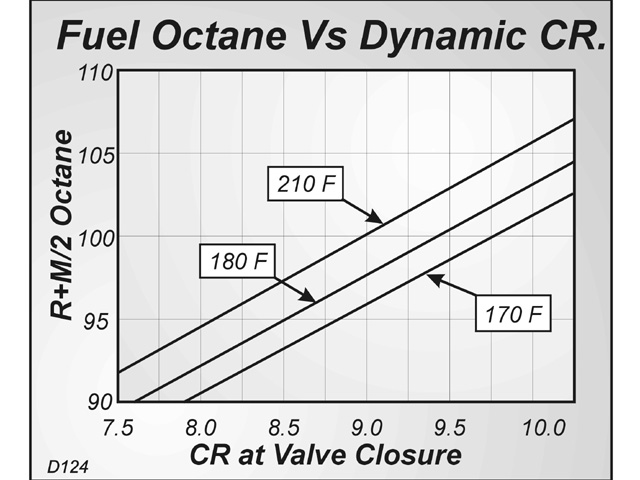

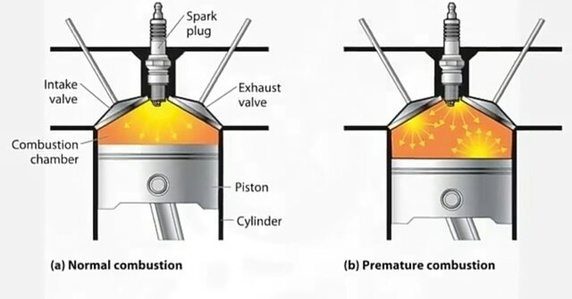

be aware that, the fuel octane, being used, alone is not the only factor here!

iron heads hold heat and transfer heat to coolant at a lower rate!

running a 180f -190f t-stat and use of a 7-8 quart oil pan, an oil cooler will tend too lower the effective operating temp.

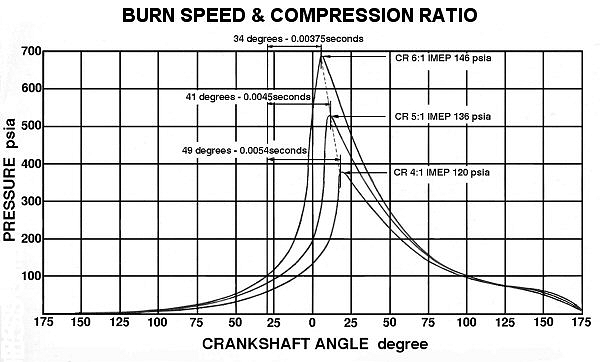

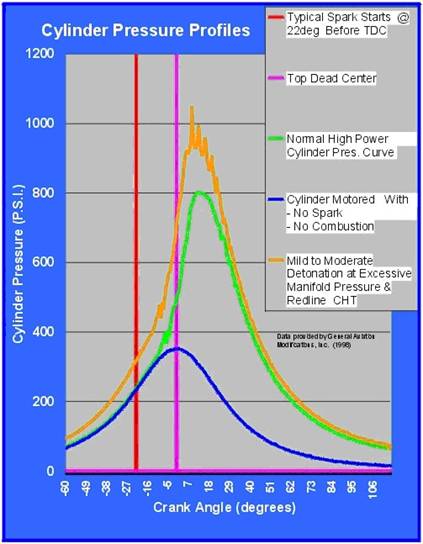

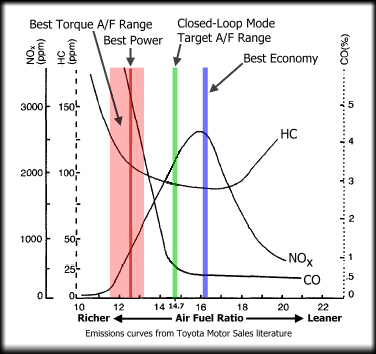

both the coolant and oil temps, and ignition advance curve, will effect the range where detonation will occur,richer fuel/air mixtures (12.5:1-13.5:1) tend to burn a bit cooler than lean mix ratios,(13.5:1-15.5:1)

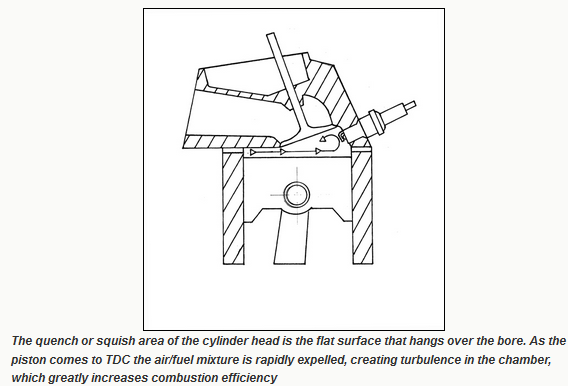

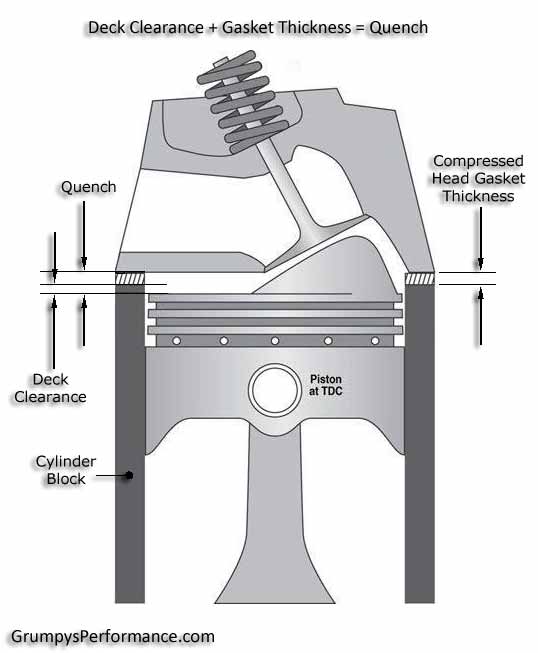

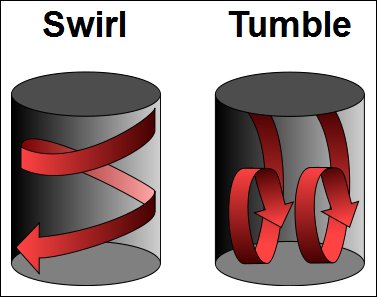

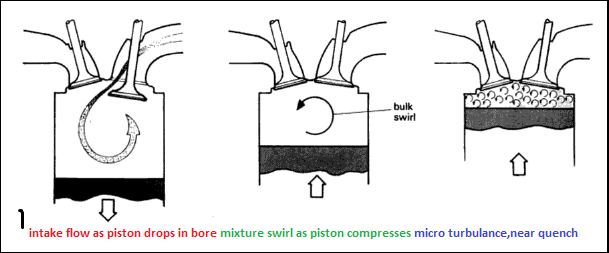

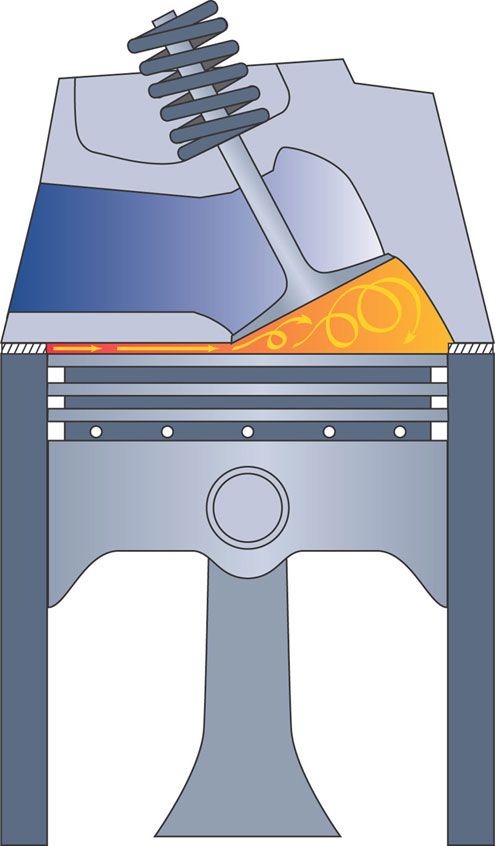

aluminum heads, transfer heat much faster, and benefit from, some, simple mods , like keeping the quench in the .040-.042 range, polishing the piston deck surface and combustion chamber and rounding the edges on the combustion chamber and piston valve notches, will reduce the tendency to get into detonation

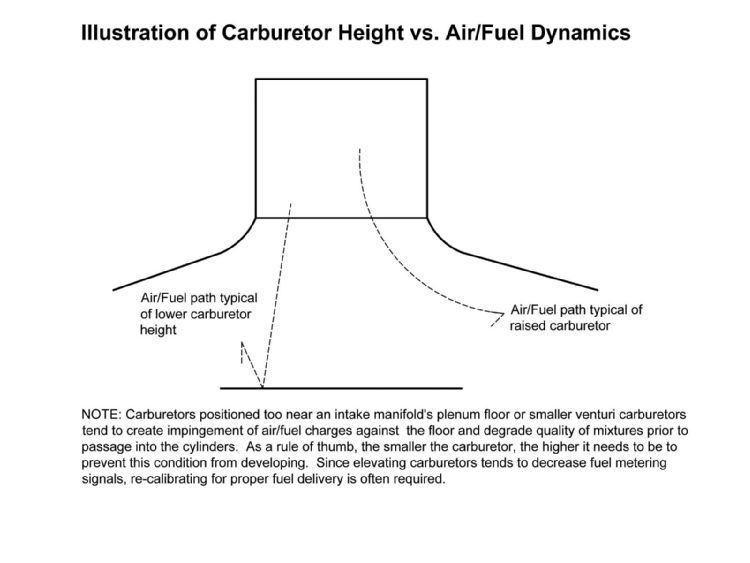

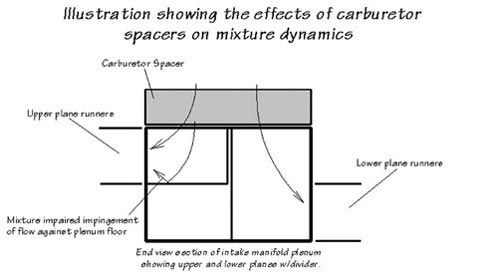

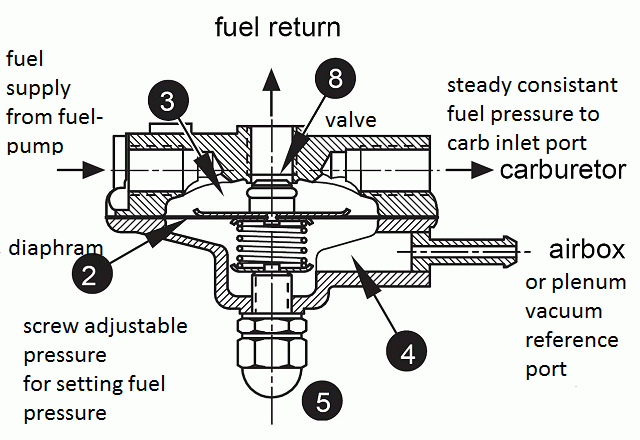

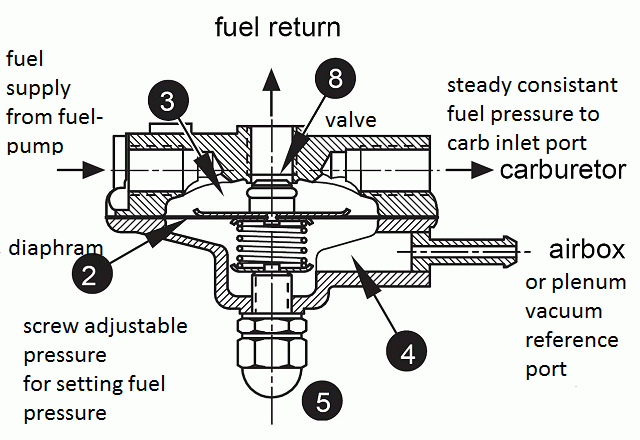

always keep in mind what the goal is here, its to keep the lowest temp fuel, and air possible, entering in the carb venturies and cool fuel bowls and lines that deliver the fuel too the carb, thus you want too limit potential heat absorption rates, , a phenolic spacer under the carb base limits heat from the intake manifold coming up through the base of the carb,

a fuel pressure regulator , with a return like bye-pass , that will have a significant volume of the fuel arriving fresh from the fuel tank at the correct pressure and having a significant percentage of the heat absorbed being routed back to the tank, through the return line limits the fuel line pressure and temperature at the carb inlet port.

if your still having vapor lock issues your fuel pump is either not supplying enough pressure and volume to cause a constant return flow or the regulator is not set correctly ,or the carb spacer is not blocking heat flow into the carb.

btw, it also helps to feed the carb with cooler ducted outside air , vs heated air from the engine compartment, as this helps avoid vapor lock and detonation issues

http://garage.grumpysperformance.com/index.php?thr...

THERE ARE A DOZEN WAYS TO ACCOMPLISH SIMILAR AIR ROUTING

http://www.ramairbox.com/

http://www.mjbperformance.com/

viewtopic.php?f=55&t=4113&p=29319#p29319

http://www.hotrod.com/articles/carburetor-dyno-testing-flowing-results/

http://members.shaw.ca/k2pilot/Homeade% ... ticle.html

http://garage.grumpysperformance.co...ferant-c-4-hoods-and-hoodscoops.353/#post-434

http://www.ramairbox.com/

http://www.parts123.com/corvettecentral/dyndetail.pta?catalog=0000050f&ukey=22025

http://www.autospeed.com/cms/A_1023/art ... larArticle

http://www.musclecarfilms.com/Pontiac_Ram_Air_3.html

http://www.knfilters.com/racing/custom.htm

viewtopic.php?f=35&t=353&p=5243&hilit=fiberglass+hood#p5243

http://www.vararam.com/sc1.html

viewtopic.php?f=32&t=3954&p=17008&hilit=hood+vents#p17008

it really doesn,t matter if you have a single carb, dual quads or efi, cooler denser air will result in a more efficient engine , simply because cooler denser air contains more oxygen per cubic foot of air entering the engine, thus allowing more fuel to be burnt resulting in more power potentially produced, and isolating the engine air temp entering the engine your mixing with fuel, from the under hood temps goes a long way to help efficiency

for about every 10 degrees C of increase or decrease in air temps, entering an engines carb, the horse power changes about 1% (hotter is less efficient, as cooler air is denser and contains more oxygen)

IF your not familiar with temps in C celsius that equates too about..

FOR EVERY 15 degrees change in F temp, the horse power changes about 1%

(hotter is less efficient, as cooler air is denser and contains more oxygen)

http://www.celsius.co.uk/converter/

think about that..under hood temps can easily be 100F-120F higher than outside air temps, thats a potential 7-8% decrease in effective horse power over cool air induction

yes it will in most cases take some time, fabrication skills , the ability to measure and think things thru, but the results from some individual creativity and custom fabrication can be amazing, and easily worth extra horse power, with some careful measuring and thought a cool ram air custom fabricated filter air filter housing and isolated air ducting from outside cool air could be designed and built for for most cars

like almost every other potential change you might make theres ways to duct cool outside airflow into the engine compartment to the carb or efi to limit the engine heat it absorbs in transit, cooler air is denser air and it contains a higher volume of oxygen, and its oxygen thats used to release the potential power in fuel, now you can get creative and add a super charger, turbo or add oxygen by using NITROUS, but all those routes will cost you money you might not be able to easily afford, but there are rather simple things you can do to route cooler outside air into your engine rather than allow the engine to suck up higher temp thinner and potentially far less usable air from under your hood.

you can start by getting a good air temp. gauge and measuring the air temps under your cars hood and then measuring the outside air temps. and don,t be surprised at a 80F-120F temp difference after your cars been running for awhile, between the two areas that can potentially be used as a source of air to mix with your fuel.

you might want to get creative and design a custom built hood scoop, vents or air ducts to route cooler outside air into your muscle car or corvettes engine!

http://www.vararam.com/sc1.html

now heres a series of pictures a guy took when he designed a cold air routing duct and hood scoop to route cool air into his carb, from a scoop on the hood, he tested the results and had an 80F-120F difference in intake air temps due to the custom air ducting and insulation layer under the corvette hood, an 80F-100F temp difference will produce an easily measurable gain in power

READ THIS THREAD ALSO

viewtopic.php?f=35&t=5051&p=14478&hilit=clear+filter#p14478

http://garage.grumpysperformance.co...ferant-c-4-hoods-and-hoodscoops.353/#post-434

http://www.parts123.com/corvettecentral/dyndetail.pta?catalog=0000050f&ukey=22025

cool outside air duct entrance

card board separation duct test baffle pattern

rough the surface to get good adhesion on air duct floor surface

thin fiberglass air chamber duct lower surface wall

self adjusting foam baffle seal to isolate incoming air to air filter on carb.

high efficiency ,low flow restriction air filter to prevent crud entering carb

carefully measuring where heat insulation foam baffle contacts duct floor then cutting matching air feed duct to carb

painting baffle or duct surface to match cars hood

insulating reflective surface film added to duct lower floor surface to reflect engine heat from incoming air to maintain max temp difference of air entering engine

https://www.autoaccessoriesgarage.com/Air-Filters/Top-10-Best-Car-Engine-Air-Filters

while its NOT 100% directly related, the resistance to air flow rates , is always a compromise between the air filter's efficiency at removing micro sized particles in the air that cause engine wear and restricting air flow that the engine requires to make power easily , increasing the surface area, number of pleats in the filter medium surface and height all tend to reduce air flow resistance, as the increased surface area reduces the resistance to flow

YOU CAN DO SIMILAR MODS TO A C4 CORVETTE, OR MOST CARS, IF YOU THINK IT THRU!

you can get creative and run duct work or use a custom hood design

read the links

http://garage.grumpysperformance.co...at-manifold-air-temp-sensor.10349/#post-42530

http://garage.grumpysperformance.co...elay-switch-locations-and-info.728/#post-9217

http://garage.grumpysperformance.co...om-air-cleaner-to-fit-your-cars-engine.16490/

http://www.ramairbox.com/

sells kits with the required components,

but with some basic fabrication skills and some ingenuity you would be amazed at what can be fabricated, from parts you can locate locally or from home depot or lowes hard ware, big box stores ,that will work remarkably well at ducting cool fresh airflow into the engine , look over the pictures in this thread, measure your hood clearance accurately, and let your imagination run a bit

BTW it generally helps too place some clay on your current air cleaner and shut the hood to compress the clay to get a better idea as to true hood to carb clearances, and a trip through several local salvage yards , and looking at other cars and trucks and remote mounted air filters and duct work.

may also give you some options

http://www.utrechtart.com/Plastalin...currency=USD&gclid=CN3G75zOw80CFQgaaQodKbgFjA

as always the more tools you have, the more options you look over, and the better your fabrication skills are the more options you,ll realistically have

owning a decent quality MIG or TIG welder and a drill press , and pop rivet guns, certainly helps and mocking up options with duct tape and card board helps give you more ideas

https://utahbiodieselsupply.com/customwork.php

commercial restaurant and beer brewing supply stores can be a gold mine for custom air filter fabrication components if you have a welder and some metal working skills and some imagination

be aware that, the fuel octane, being used, alone is not the only factor here!

iron heads hold heat and transfer heat to coolant at a lower rate!

running a 180f -190f t-stat and use of a 7-8 quart oil pan, an oil cooler will tend too lower the effective operating temp.

both the coolant and oil temps, and ignition advance curve, will effect the range where detonation will occur,richer fuel/air mixtures (12.5:1-13.5:1) tend to burn a bit cooler than lean mix ratios,(13.5:1-15.5:1)

aluminum heads, transfer heat much faster, and benefit from, some, simple mods , like keeping the quench in the .040-.042 range, polishing the piston deck surface and combustion chamber and rounding the edges on the combustion chamber and piston valve notches, will reduce the tendency to get into detonation

always keep in mind what the goal is here, its to keep the lowest temp fuel, and air possible, entering in the carb venturies and cool fuel bowls and lines that deliver the fuel too the carb, thus you want too limit potential heat absorption rates, , a phenolic spacer under the carb base limits heat from the intake manifold coming up through the base of the carb,

a fuel pressure regulator , with a return like bye-pass , that will have a significant volume of the fuel arriving fresh from the fuel tank at the correct pressure and having a significant percentage of the heat absorbed being routed back to the tank, through the return line limits the fuel line pressure and temperature at the carb inlet port.

if your still having vapor lock issues your fuel pump is either not supplying enough pressure and volume to cause a constant return flow or the regulator is not set correctly ,or the carb spacer is not blocking heat flow into the carb.

btw, it also helps to feed the carb with cooler ducted outside air , vs heated air from the engine compartment, as this helps avoid vapor lock and detonation issues

http://garage.grumpysperformance.com/index.php?thr...

THERE ARE A DOZEN WAYS TO ACCOMPLISH SIMILAR AIR ROUTING

http://www.ramairbox.com/

http://www.mjbperformance.com/

viewtopic.php?f=55&t=4113&p=29319#p29319

http://www.hotrod.com/articles/carburetor-dyno-testing-flowing-results/

http://members.shaw.ca/k2pilot/Homeade% ... ticle.html

http://garage.grumpysperformance.co...ferant-c-4-hoods-and-hoodscoops.353/#post-434

http://www.ramairbox.com/

http://www.parts123.com/corvettecentral/dyndetail.pta?catalog=0000050f&ukey=22025

http://www.autospeed.com/cms/A_1023/art ... larArticle

http://www.musclecarfilms.com/Pontiac_Ram_Air_3.html

http://www.knfilters.com/racing/custom.htm

viewtopic.php?f=35&t=353&p=5243&hilit=fiberglass+hood#p5243

http://www.vararam.com/sc1.html

viewtopic.php?f=32&t=3954&p=17008&hilit=hood+vents#p17008

Last edited by a moderator: