your stock corvette

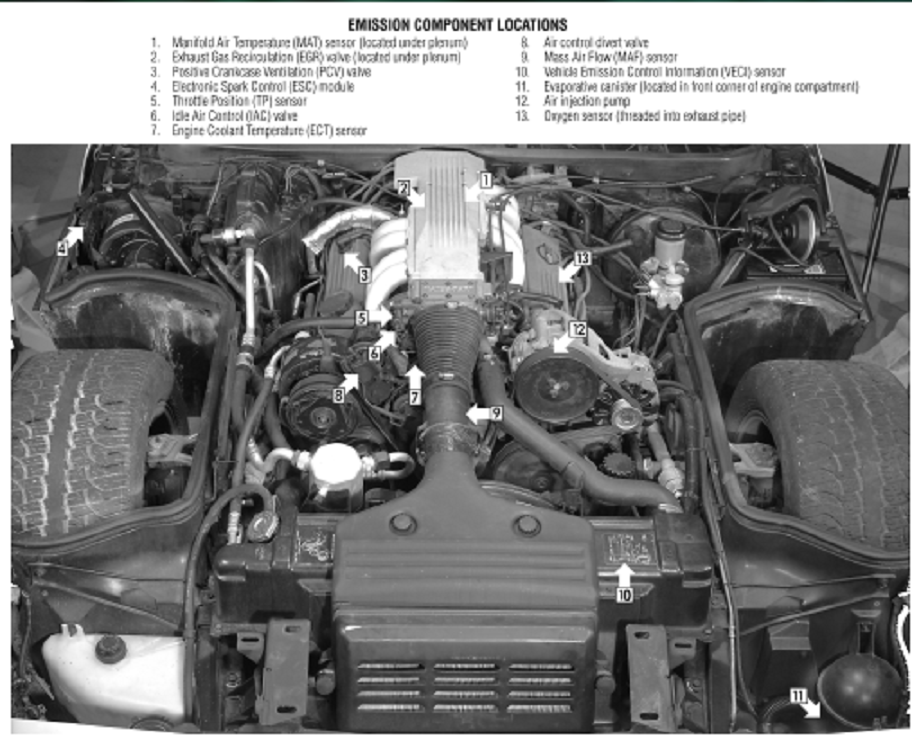

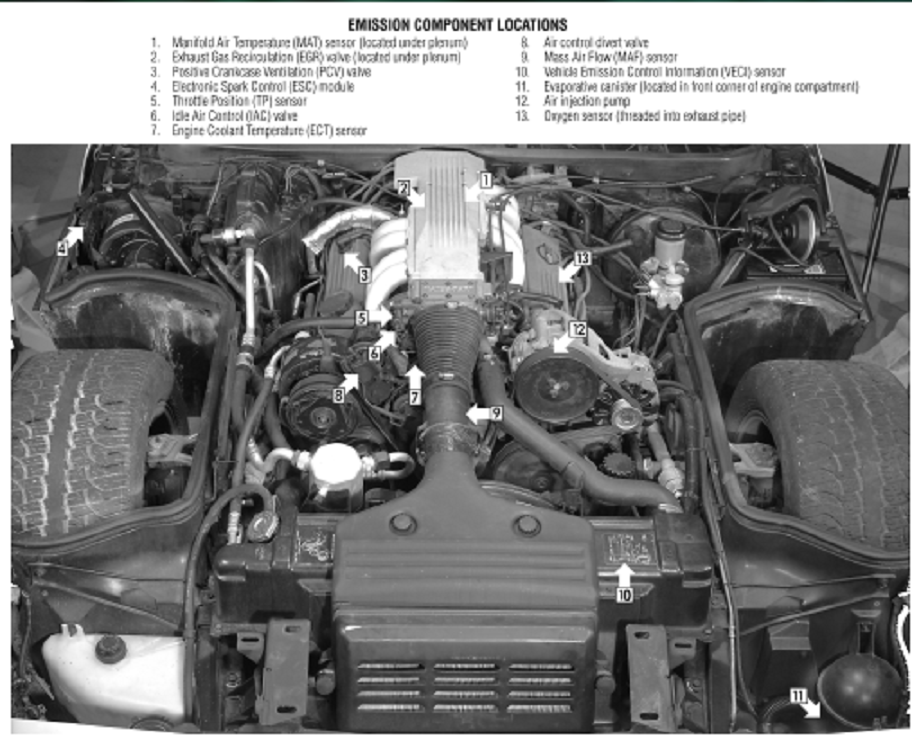

has a rather marginal cooling system if your engines been modified for significantly higher hp levels, that cooling system can be significantly improved upon.I run into this frequently, and theres several sources or causes for an engine to run hotter than you might want it to,and cures, obviously you'll need to check fluid levels and your ignition timing.

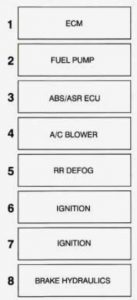

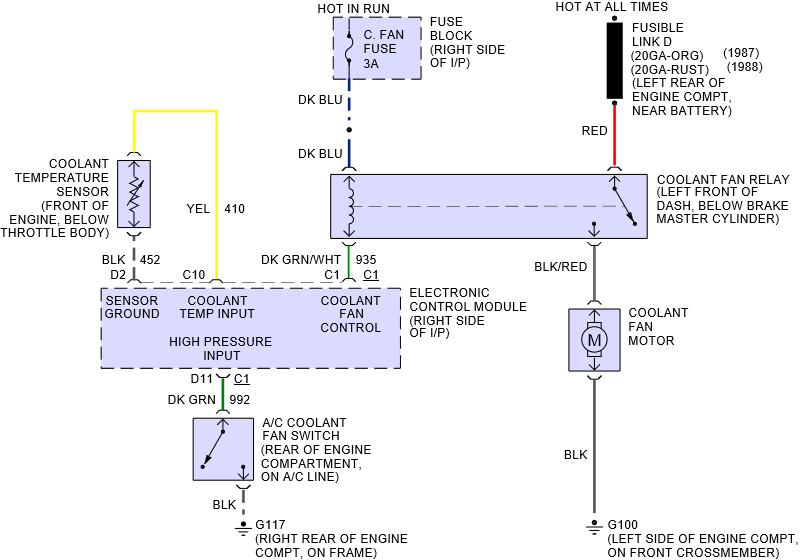

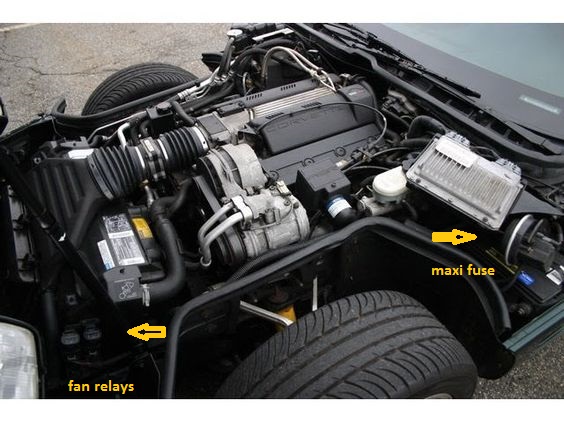

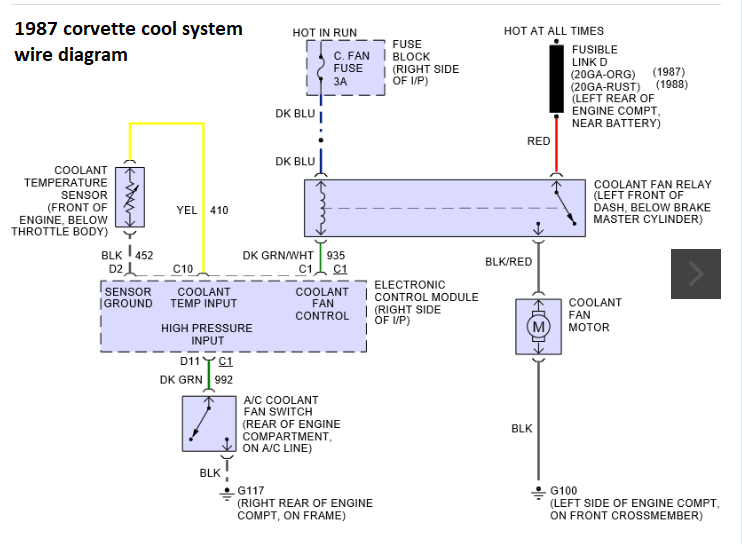

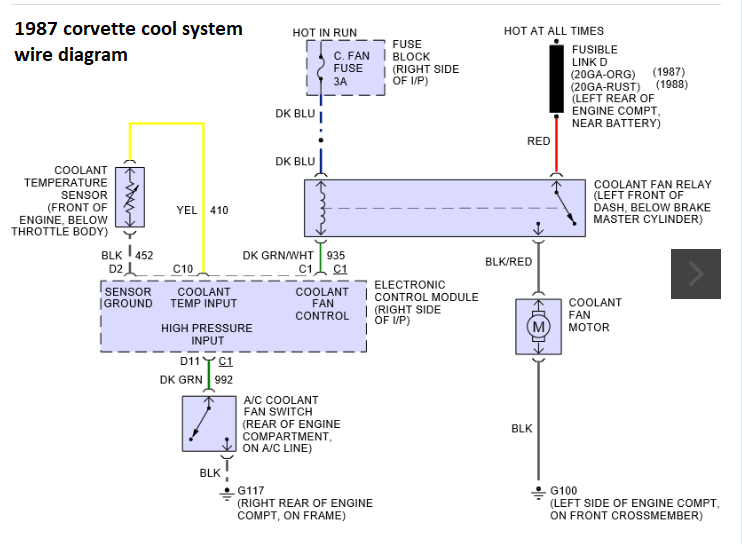

Your Corvette’s main cooling fan is controlled by the PCM. The PCM sends a ground signal to the fan relay when it sees the desired temperature from a sensor to run the fan has been met. You need to check the sensors and fan relays and make sure you are getting your battery 12V and ignition 12V when the key is on. get a shop manual, and a bulti meter youll need them, now with the key on, jump the ground wire in the relay. If the fan turns on, you have an issue in the PCM and it may be time for a rebuild. If it does not turn on, then your problem lies in the fan circuit between the relay and the fans.

keep in mind a corvette draws air from under the car so its prone to pick up a good deal of street trash like leaves and plastic bags , so inspect and clean off any trash in the radiator fins before you assume the systems defective

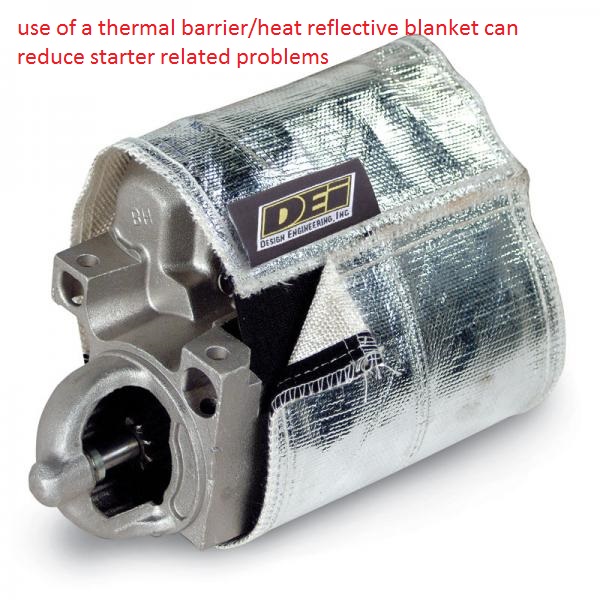

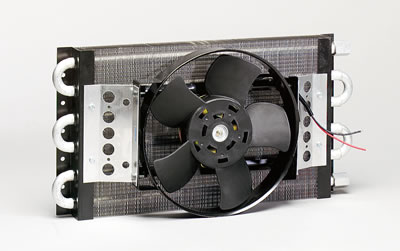

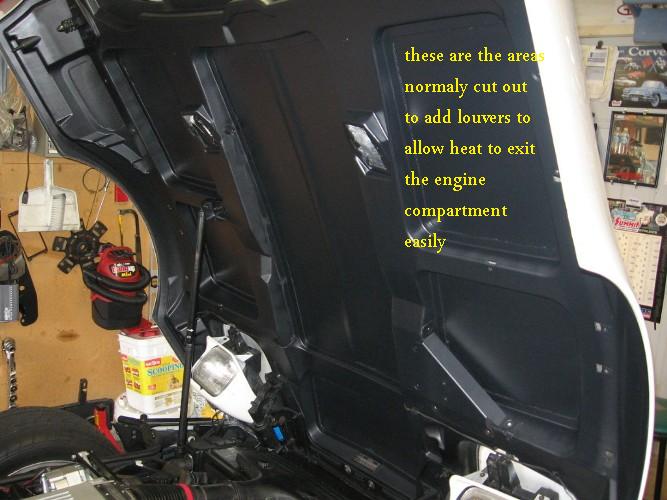

also be aware that you can attack the heat control issues you might have from two directions, you can concentrate on removing heat from the engine more effectively with a larger more efficient radiator, bigger fans,, adding an alternator that allows more AMPS to spin those fans , adding more effective duct work, adding oil coolers, transmission coolers or a larger capacity baffled oil pan, adding heat exhaust vents to the hood,adding additives to the coolant that reduce the tendency to boil, like WATER WETTER, etc. or you can concentrate on reducing the heat generated thru control of your fuel/air mix ratio, ignition advance curve, timing and exhaust restriction.Id also point out that chevy water pumps can be purchased that are designed to spin in either clock wise or counter clock wire rotation and installing the wrong part number will cause big problems

obviously the first step in testing an over heating issue would be to verify the coolant and oil levels and verify the fans turn on and the water pumps pushing fluid thru the engine, and your not dealing with a defective t-stat or clogged radiator.

if those are correct it may be a sensor or tuning issue so verify sensor outputs with a good multi meter.

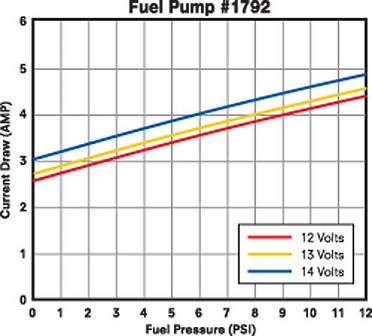

just a point many guys seem to over look, the fans run on electricity and a higher amp capacity alternator provides a good deal more current to spin those cooling fans, Ive seen several cars with marginal cooling that had that cooling issue disappear once a 160-200 amp alternator replaced the stock alternator, the increased current allowed the cooling fans to spin a good deal faster at low engine speeds and the result was more efficient cooling.

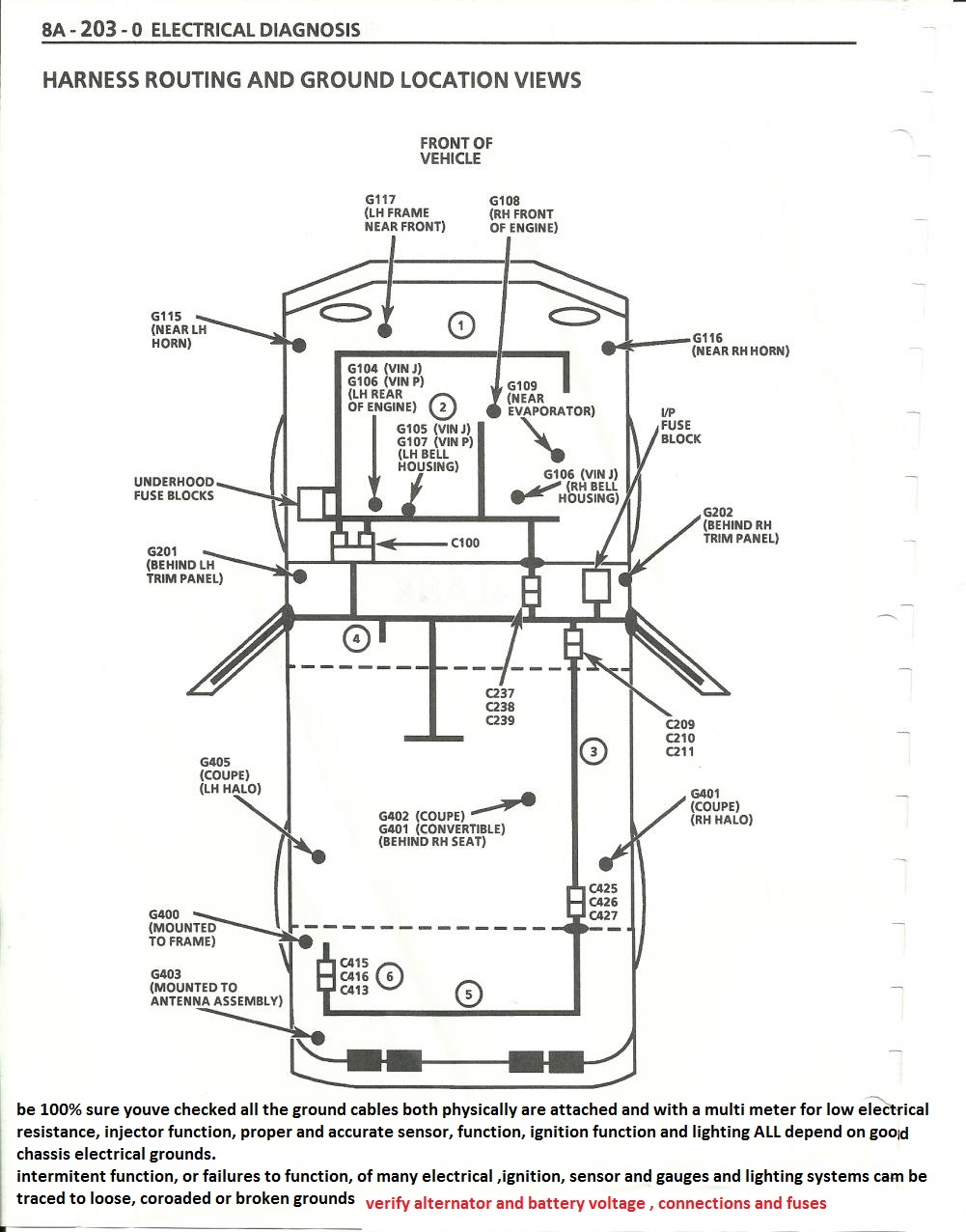

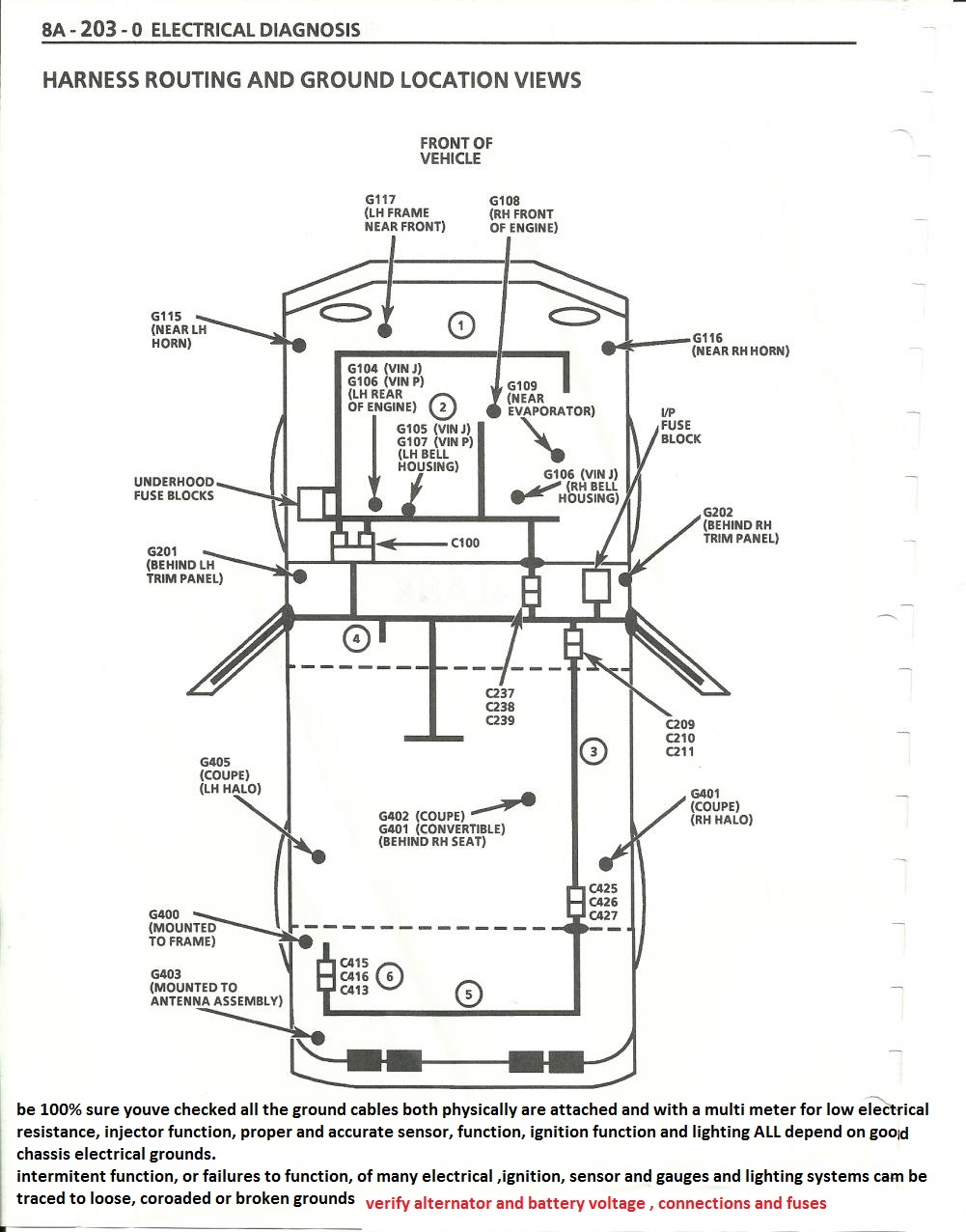

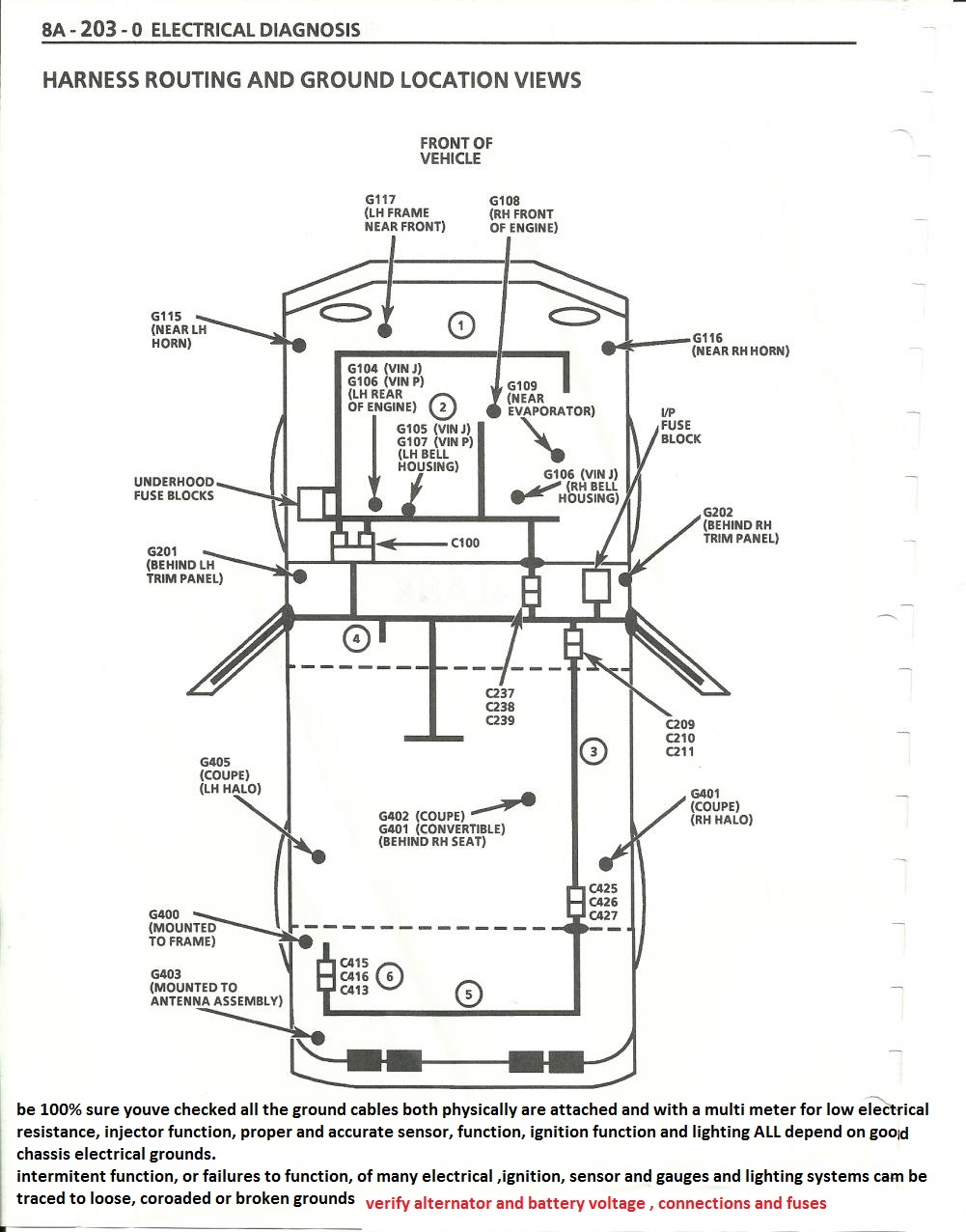

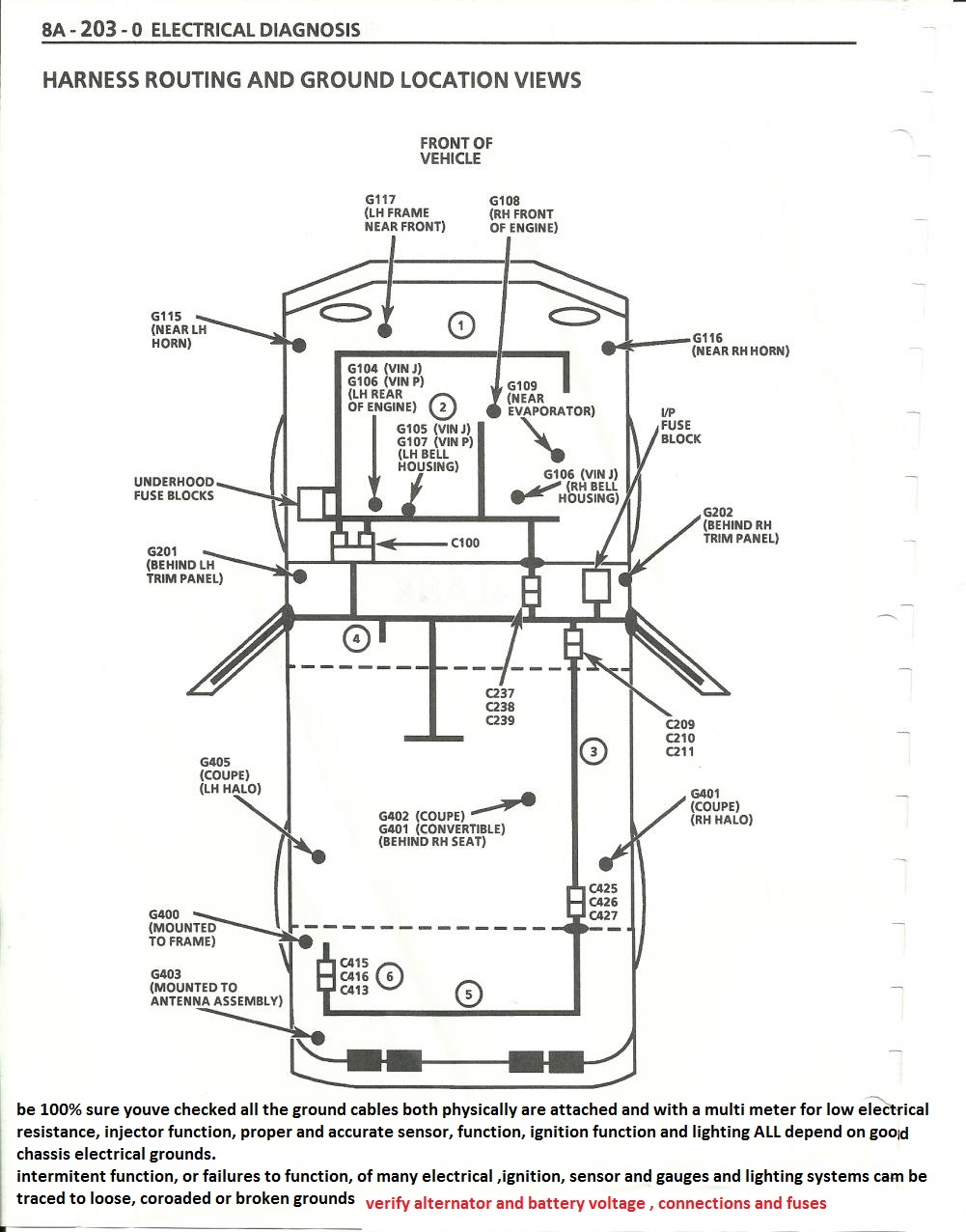

The key to C4 electrical is the checking for good solid low ohm resistance GROUNDS. They control almost everything, as sensors complete grounds or sense resistance. Voltage takes a backseat to good low ohm resistance grounds on these cars.

Locate the ground bundle of 5 wires on a bolt near the oil filter. (G104-107) Clean and repair. Also clean and repair the hot wires to the jumper post behind the battery.

Check the connections on the various temp sensors/switches. There is a different sensor for the gauge than the ecm or fan control. Some cars have as many as 4 or 5 temp sensors. What you see on the dash is not always what the ECM is seeing.

buy a CHEVY SHOP MANUAL FOR YOUR YEAR CORVETTE!

a logical step by step approach will lead you to the problem, youll be amazed at what youll learn reading links. use of a shop manual and multi meter can be very helpful,the cooling system tests are listed in shop manual book 2 of 2 in section engine controls 6-640 thru 6-645

http://www.professionalequipment.com/ex ... ermometer/

Wide temperature range from -58 to 1832°F (-50 to 1000°C)

any time that your dealing with a potential temperature issue or a trouble issue where , knowing the exact temperature vs what a gauge might say, it helps to have a handy and accurate infrared temp gun handy to locate and confirm heat, levels.

http://www.harborfreight.com/5-in-1-dig ... 98674.html

learn to use the factory shop manual, and a multi meter

https://www.youtube.com/watch?v=CQylm1IvmYk

read this related linked info post carefully

http://garage.grumpysperformance.co...es-got-me-scratching-my-head.7499/#post-25434

http://www.summitracing.com/parts/tff-8173nep/applications/year/1996

speedcooling.com

speedcooling.com

http://garage.grumpysperformance.com/index.php?threads/lots-of-wiring-info-diagrams.317/#post-83877

READ THRU THIS THREAD AND SUB LINKS

viewtopic.php?f=80&t=728&p=1025&hilit=sensors+camaro#p1025

http://garage.grumpysperformance.com/index.php?threads/head-scratcher-cooling-issue.3010/#post-84329

http://garage.grumpysperformance.co...996-corvettes-got-me-scratching-my-head.7499/

http://garage.grumpysperformance.co...-air-conditioner-on-cooling.12232/#post-59597

the coolant temp sensor is located on the Pass side head between # 6 and 8 plugs.

Fan control varies by year.

As I recall.

'84 has temp switch for fan only ,no ECM control;

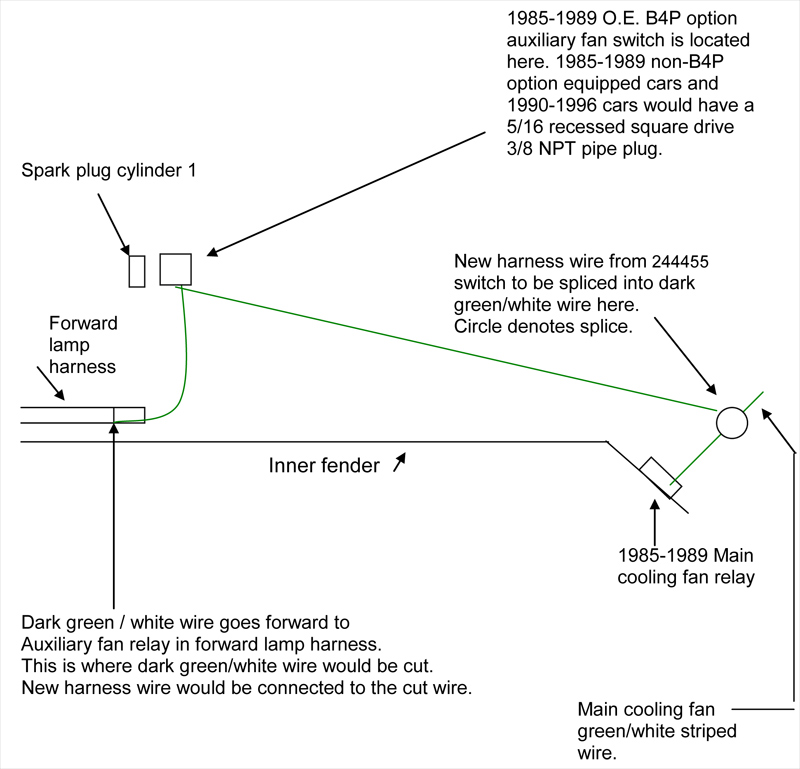

'85 has ECM control but temp switch acts as over ride backup direct to fan

'86- '89 as stated above

'90 onward ; both fans on ECM ; no temp switch.

And all have provision to turn the fans on with A/c on.

ve had good results with a 200F T-stat with the holes drilled (READ THE LINK) but many guys select a 180F t-stat

most t-stats work by by having a thermo reactive wax that starts to expand at a set temperature , then over about 10F-20F it continues to expand,and allow heated coolant to flow to the radiator, thus the t-stat will remain closed until its rated temperature range is reached and it will open wider up to its fully open position over about a 2-5 minute time frame

most t-stats work by by having a thermo reactive wax that starts to expand at a set temperature , then over about 10F-20F it continues to expand,and allow heated coolant to flow to the radiator, thus the t-stat will remain closed until its rated temperature range is reached and it will open wider up to its fully open position over about a 2-5 minute time frame

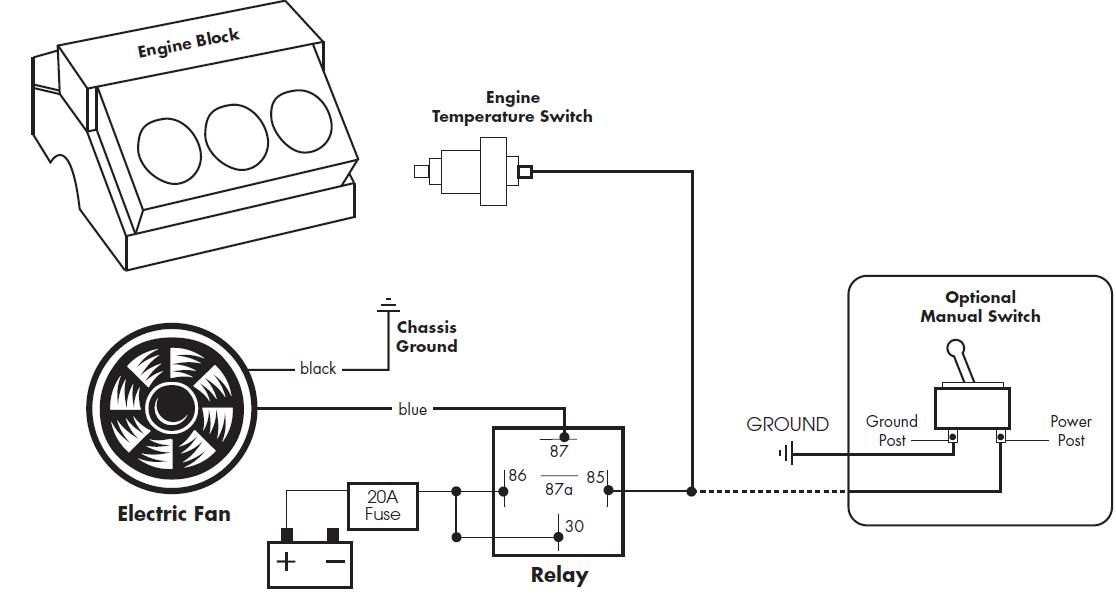

Loves302Chevy posted these diagrams that will be helpful

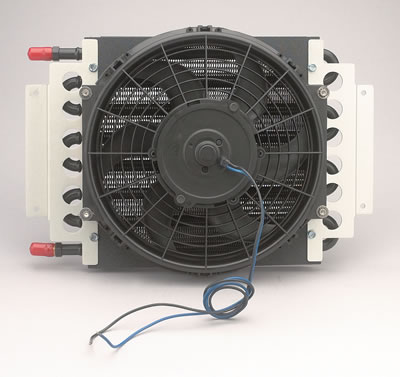

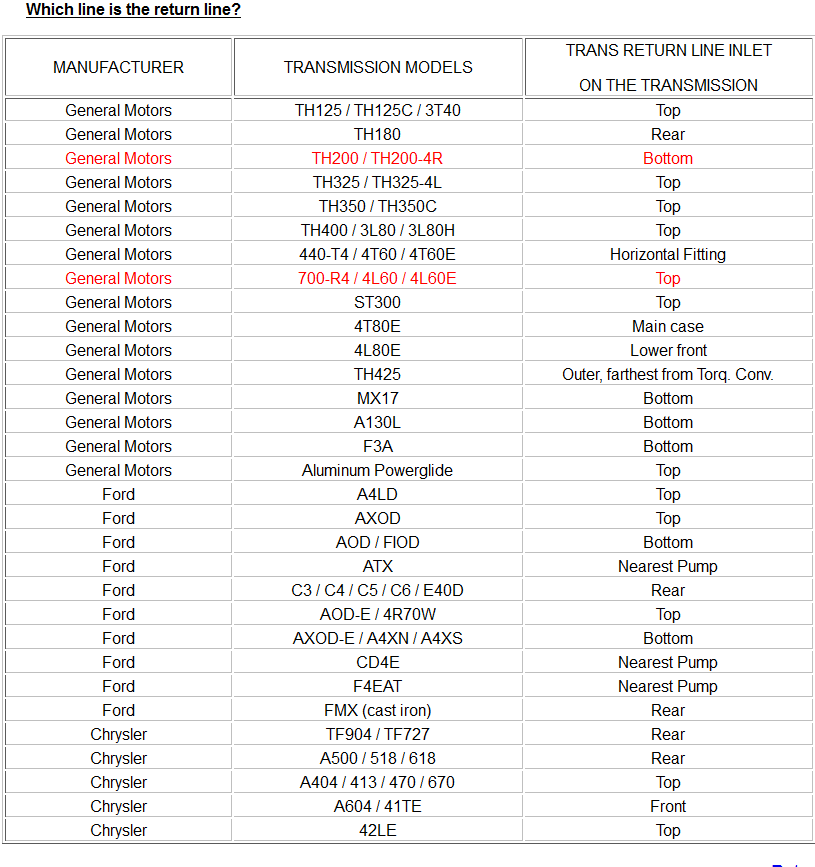

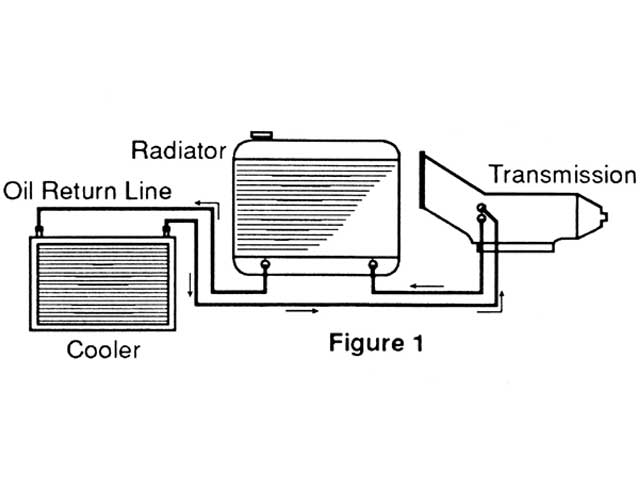

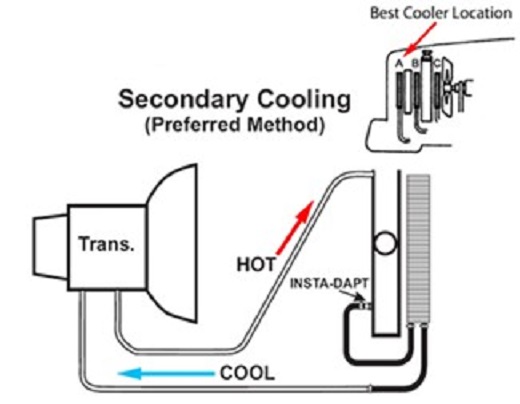

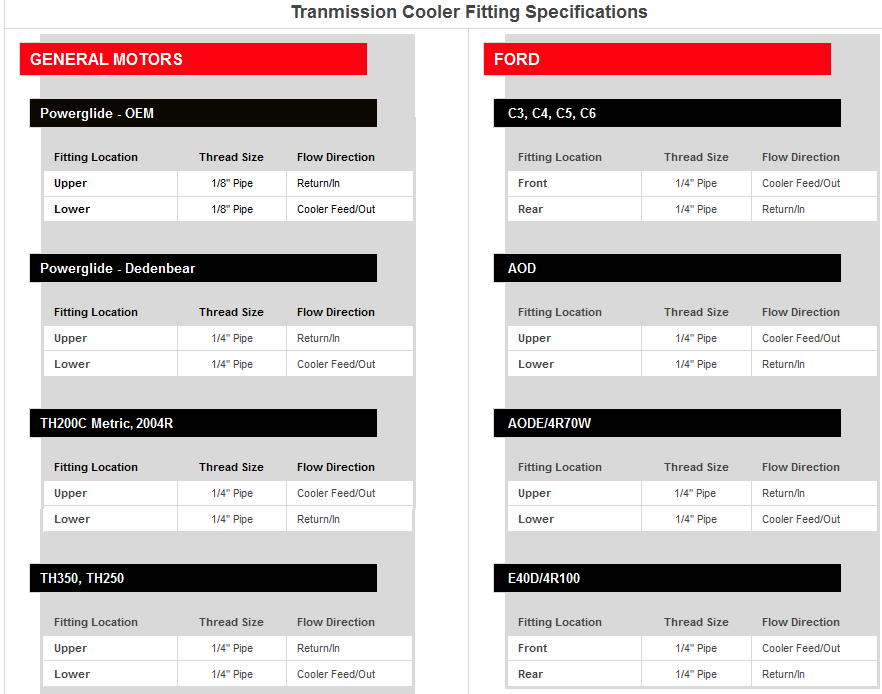

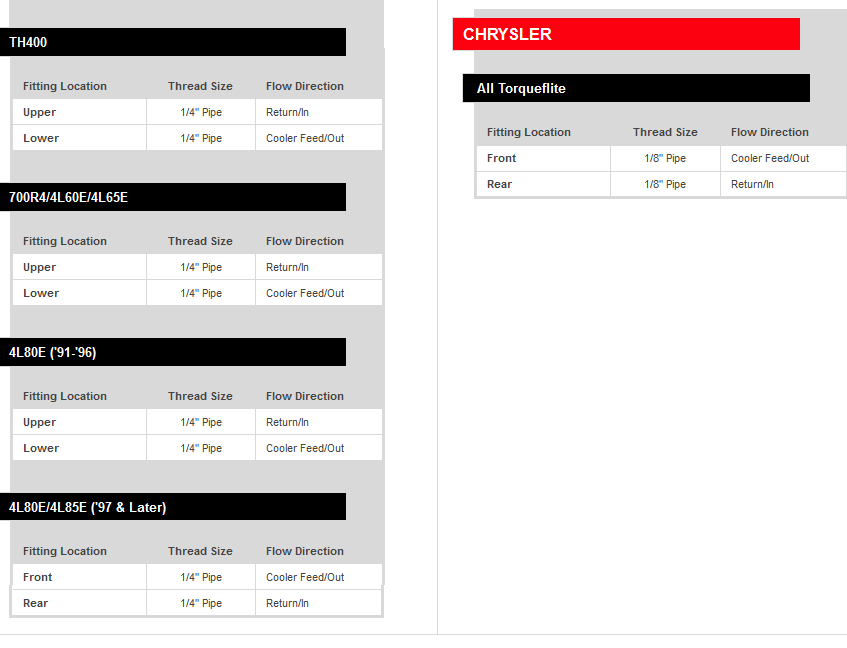

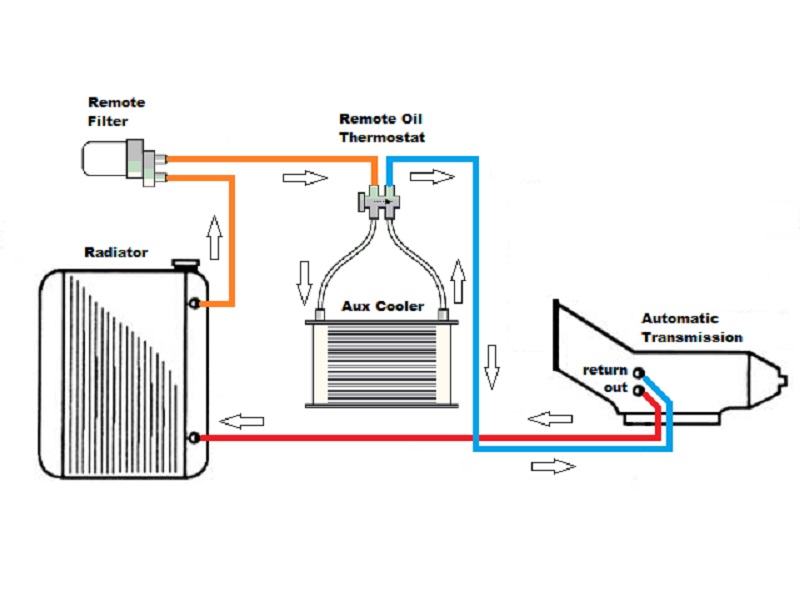

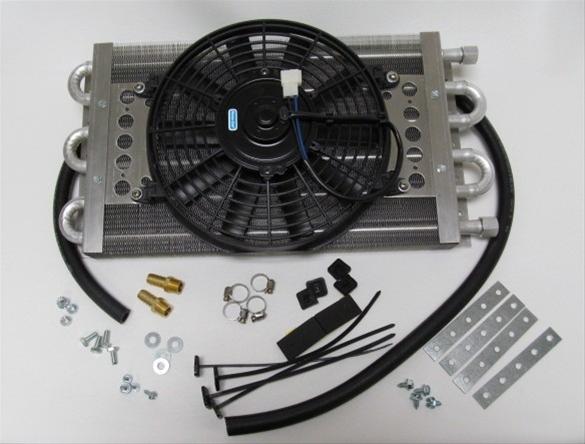

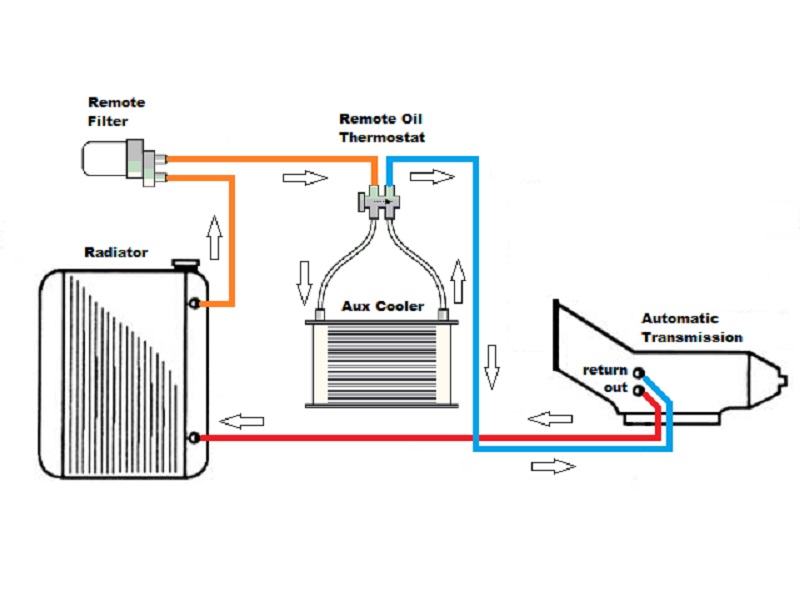

I don,t remember, where I purchased most of the oil/trans fluid coolers Ive used ,

but I've purchased and installed several oil and trans fluid coolers

over the decades, almost all were used 1/2" or an#8 connections and were purchased from summit or jegs

as always read carefully,

and measure accurately, remembering you must be leaving room for the hot oil or trans fluid hose and connections

and access to get the cooler in and mounted and connections made too it!

you would certainly not be the first or last guy to buy a cooler that will not fit in the space you though it would,

due to the connections and hoses required or forgetting about the thickness or lack of easy access.

https://www.summitracing.com/parts/der-15820

https://www.summitracing.com/search?PageSize=100&SortBy=BestKeywordMatch&SortOrder=Ascending&keyword=oil cooler with fan

https://www.jegs.com/i/Derale/259/15850/10002/-1

https://www.jegs.com/webapp/wcs/sto...&submodel=&engine=&Nrpp=&No=&persistYmm=false

one factor thats frequently over looked is the oil feed and return line internal size and line heat rating,THINK IT THRU, now it should be obvious that fittings tend to have smaller more restrictive holes thru them than the hose internal dimensions of the fittings used with that hose, a fitting designed for 3/8" hose wont allow full 3/8"hose or component oil flow rates, AN-6 is normally considered about equal to 3/8" but thats doesn,t tend to be true, AN-8 size fittings are usually used to get decent flow in a 3/8" oil cooler , if your oil cooler has 3/8" internal passages youll want an AN#8 line size too insure the MINIMUM 3/8" internal passage size is maintained , and you really NEED a full 1/2" or AN#10 size fittings and internal fluid transmission cooler lines to a fan cooled trans fluid cooler rated at at least a 24000 lb vehicle weight for race /performance use, and not restricted by use of the internal passage size of AN#6 fittings which are at best minimal and only delay the heat build-up related problems.

http://www.summitracing.com/parts/prm-13182

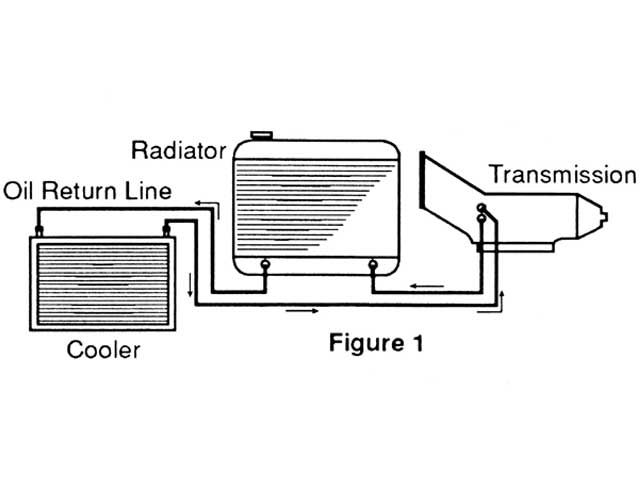

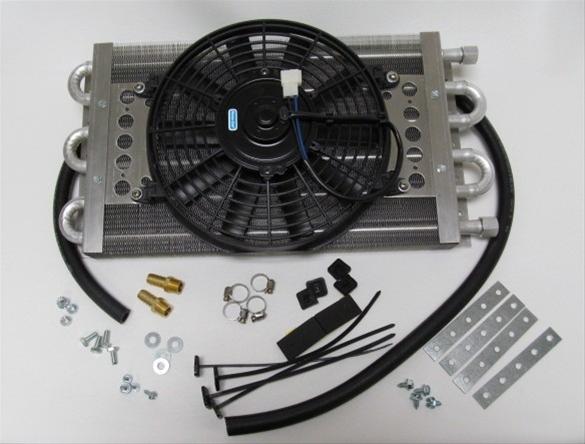

If I did it again Id select this trans cooler (pictured below) as the larger line size would help reduce flow restriction, its smaller width would make it easier to install,

THATS IMPORTANT!, MEASURE VERY CAREFULLY BEFORE ORDERING

I know several people that ordered trans coolers and found they would not fit into the originally intended location because they failed to correctly measure the intended location space, in ALL three dimensions,and over the whole space, before ordering , I know I failed to measure carefully so I was forced to place it where the spare tires normally mounted

http://www.summitracing.com/parts/FLD-DB30901/?rtype=10

Fluidyne High Performance DB30901 - Fluidyne Oil Cooler with Fan Kits

speedcooling.com

speedcooling.com

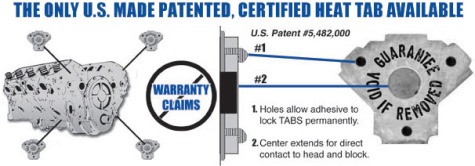

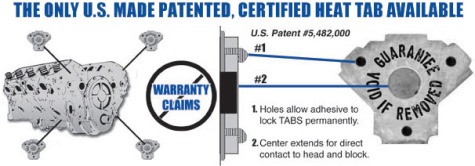

BTW you may find freeze plugs that look like this on blocks and cylinder heads, especially from engine rebuilder machine shops, the "exterior outside BUTTONs are made from a very special low melt metal like bismuth thats specifically designed too melt and distort if the blocks coolant temp reaches about 250-260F indicating and proving beyond question that you over heated the engine and voided your warranty

http://www.silver-seal.com/category/shop.1_cylinder_head_rebuilding.2_heat_tabs/

http://www.engineheattabs.com/products

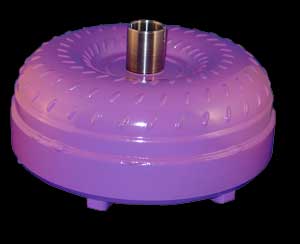

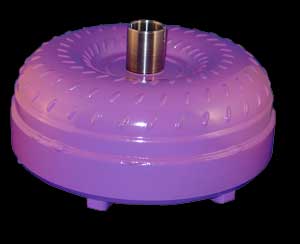

btw torque converters are frequently painted with a very special paint that changes color at a specific temperature for the exact same reason, proof you voided the warranty and failed to run the transmission fluid thats supposed to act as a lubricant and coolant within the designed temperature range, they did not select the pink or purple because they like the color, its done to reduce warranty cost issues , if you over heat the converter its waranty is void

https://www.paintwithpearl.com/shop-custom-paint/temperature-changing-paint/

https://www.paintwithpearl.com/shop-custom-paint/temperature-changing-paint/

http://garage.grumpysperformance.co...sion-and-oil-cooler-increases-durability.176/

http://garage.grumpysperformance.co...n-cooler-info-and-derale-trans-cool-pans.662/

http://garage.grumpysperformance.co...ans-cooler-on-a-c4-corvette.10514/#post-44478

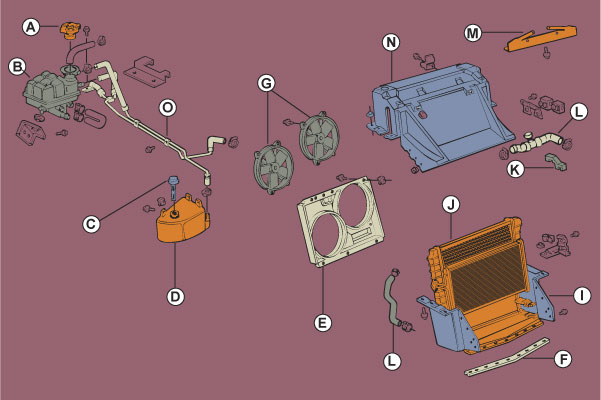

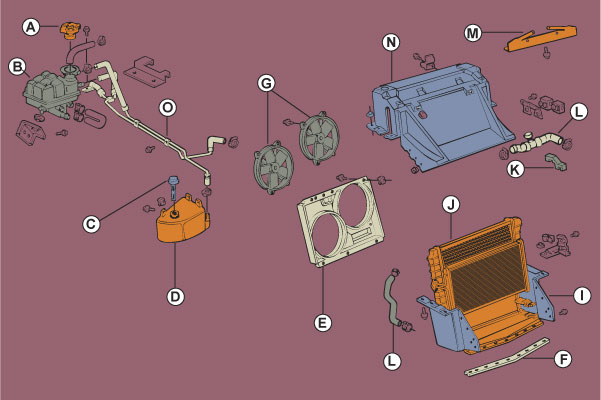

the lower white over flow tank under the hood near the pass side head light (#638 below) is not directly involved in cooling, its simply the overflow puke tank that the radiator will siphon coolant from as the radiator cools and the coolant contracts while it sits.

yes the radiator will pull coolant from that tank if the radiator level gets low , the coolant will only be warm or hot if the radiator over heats to the level where it forces coolant out, which it normally won,t doe every time the cars driven, normally its just sucking coolant in far more than trapping excess over heated coolant, if your seeing coolant in this tank every time you drive somethings wrong, and Id be looking for a problem like a defective t-stat, leaking hose or leaking head gasket.

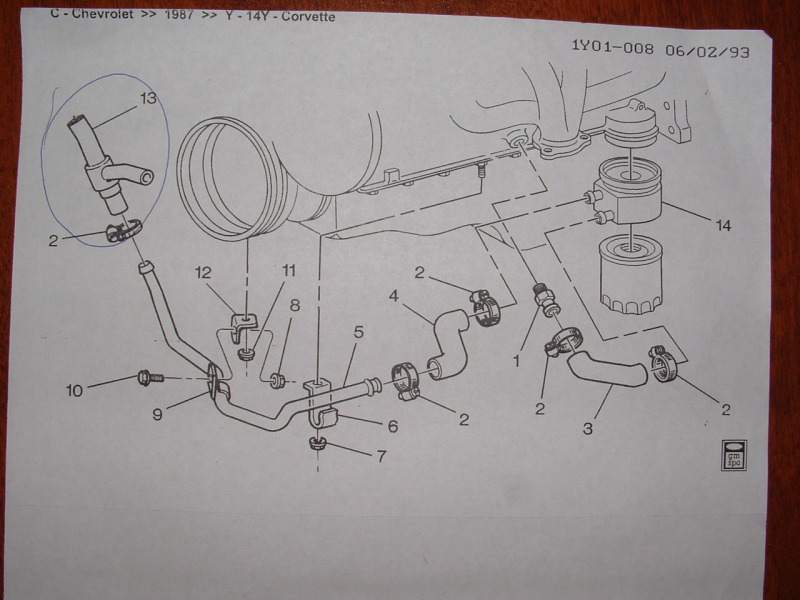

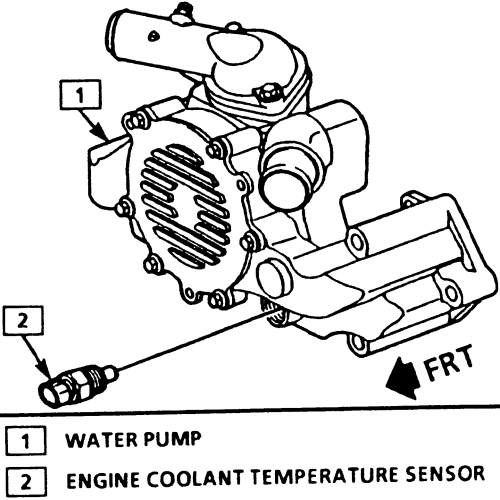

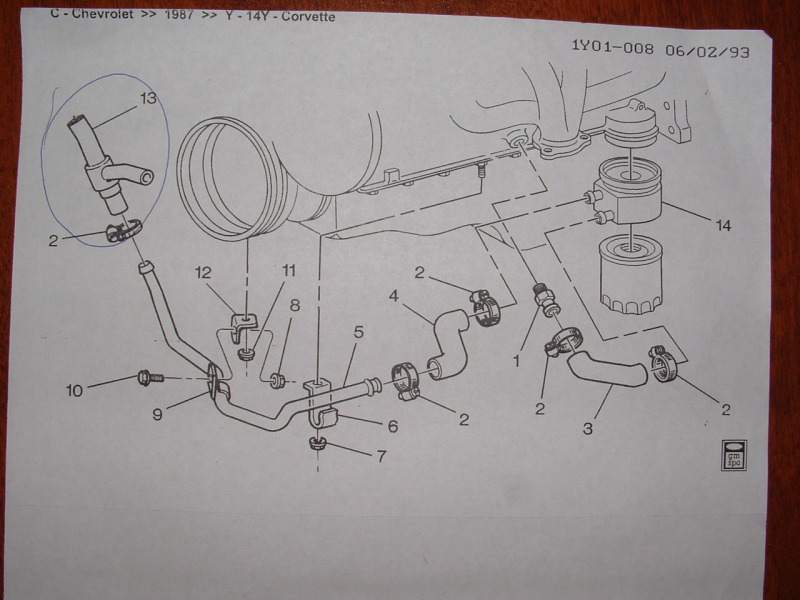

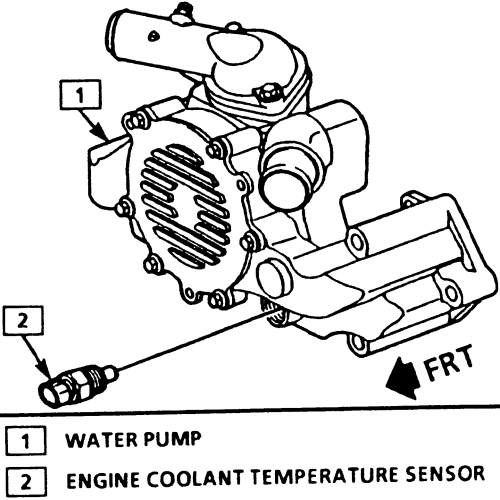

the coolant temp sensor for the PCM is on the water pump a black and a yellow wire.

speedcooling.com

speedcooling.com

http://www.griffinrad.com/load_details3.php?PartID=441&year=1987&make=Chevrolet&model=Corvette

swapping to a 200 amp alternator will frequently improve the operation of both the cars ignition and electric cooling fans

https://www.summitracing.com/parts/tff-8173nep/applications/year/1996

http://tech.corvettecentral.com/2011/02 ... fications/

http://www.dbelectrical.com/casearch.as ... ageSize=60

http://members.shaw.ca/corvette86/Cooli ... ontrol.pdf

http://www.dbelectrical.com/p-9594-alte ... -1993.aspx

http://forums.superchevy.com/corvette-f ... mediately/

http://www.dbelectrical.com/p-3478-ford ... t-101.aspx

http://www.hotrodlane.cc/NewTPI%20links ... ml#tpitech

viewtopic.php?f=32&t=2697&p=7100#p7100

http://www.justanswer.com/uploads/carfi ... vette1.pdf

http://www.justanswer.com/uploads/carfi ... vette2.pdf

http://www.racerpartswholesale.com/prod ... cessories2

http://tech.corvettecentral.com/2011/02 ... fications/

http://www.racerpartswholesale.com/prod ... cessories2

http://garage.grumpysperformance.co...sh-out-of-the-radiator-fins.11712/#post-54986

http://tech.corvettecentral.com/2011/02/1984-1996-corvette-cooling-fan-control-modifications/

http://www.summitracing.com/parts/prf-30111/overview/

http://www.stewartcomponents.net/Mercha ... Code=Therm

http://www.racerpartswholesale.com/prod ... cessories2

http://www.chevythunder.com/cts_diagnostics.htm

http://www.chevythunder.com/cts_diagnostic_pg2.htm

http://tech.corvettecentral.com/2011/02 ... fications/

http://members.shaw.ca/corvette86/Cooli ... ontrol.pdf

https://www.youtube.com/watch?v=YEaWeEtOeJ8

viewtopic.php?f=80&t=728&p=9217&hilit=sensor+mass#p9217

http://aspwholesale.com/index.php?act=v ... uctId=5159

viewtopic.php?f=57&t=149

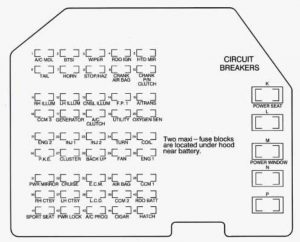

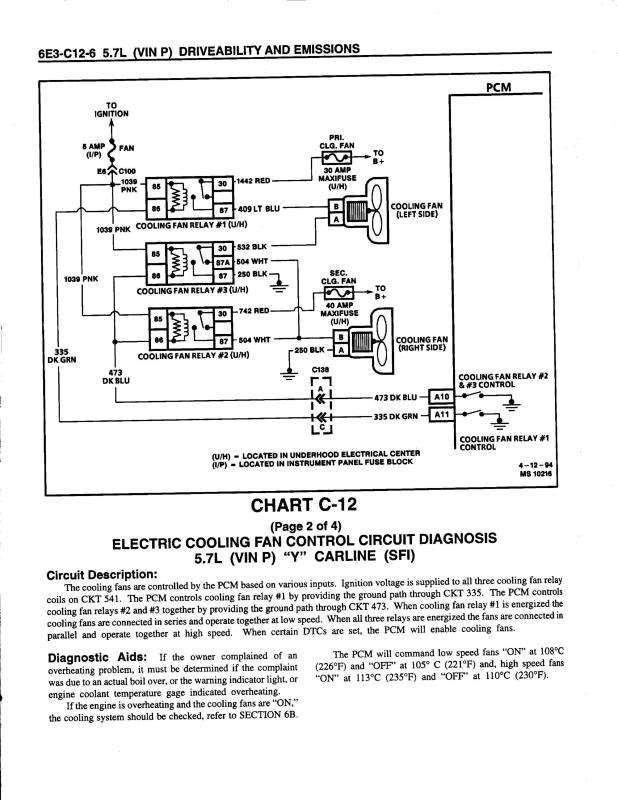

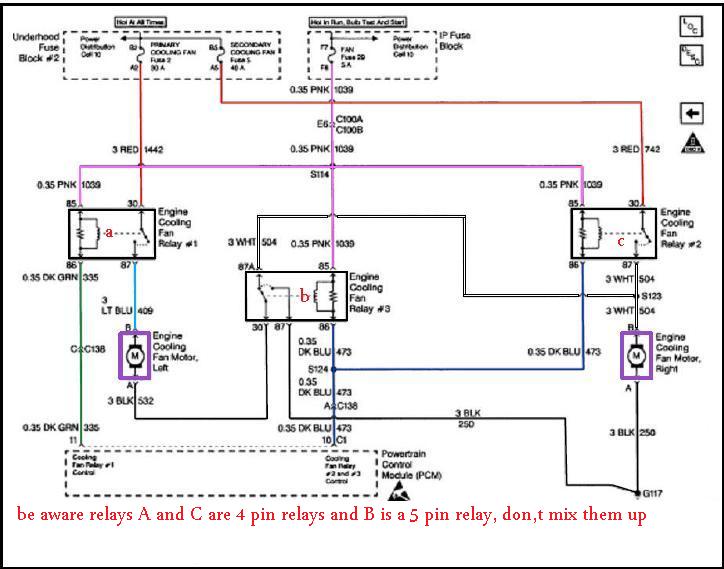

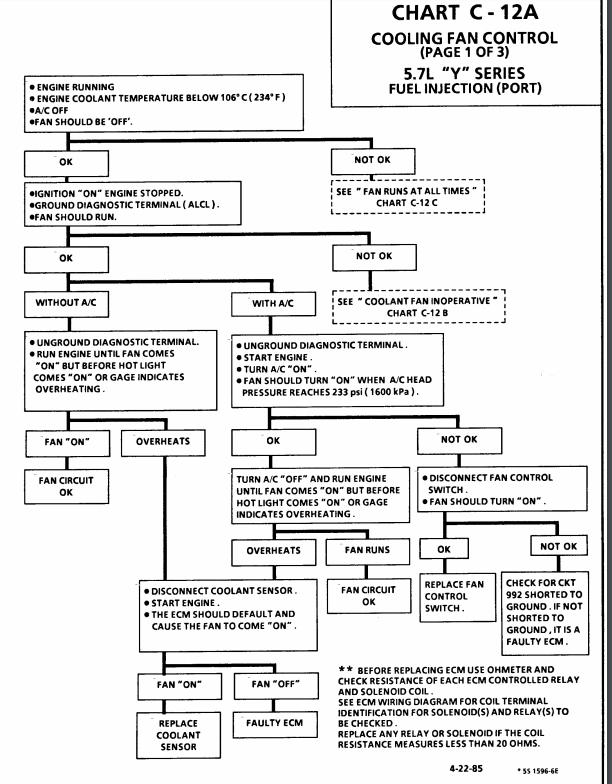

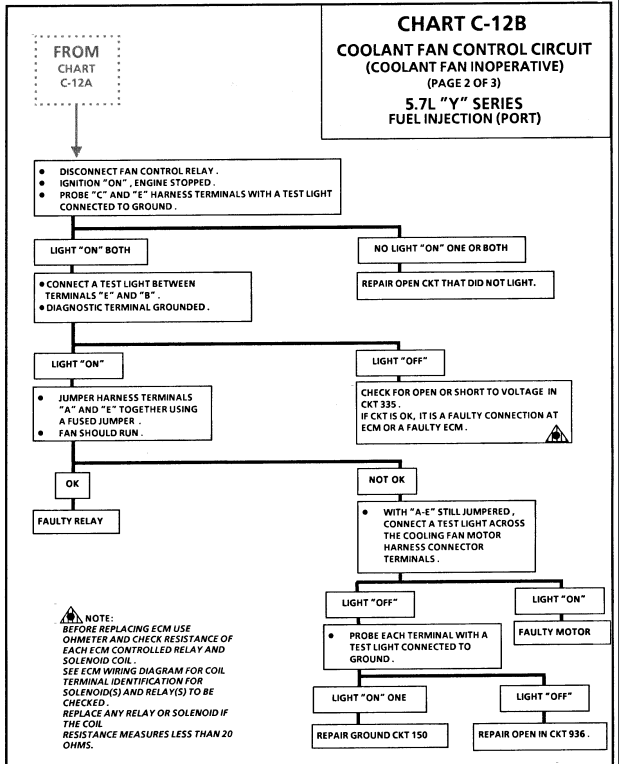

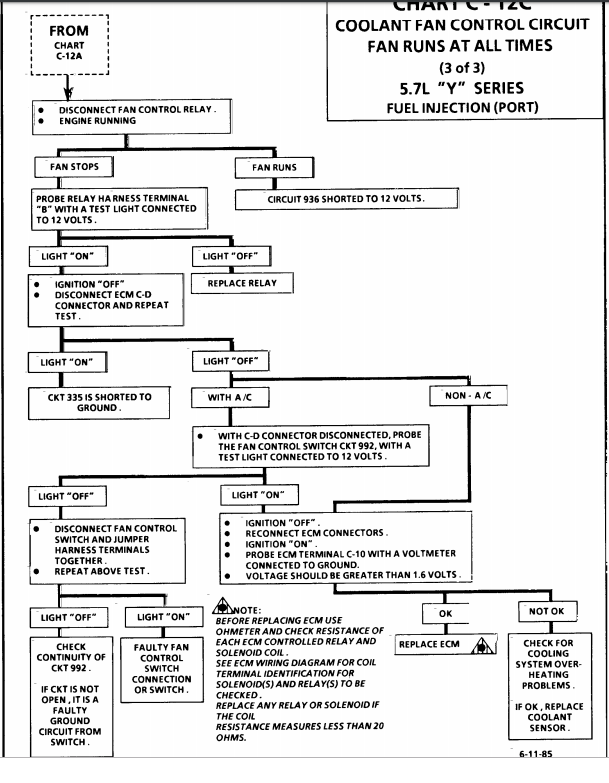

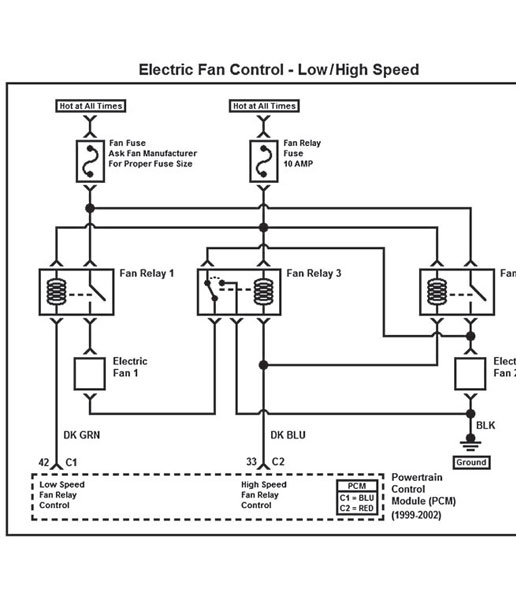

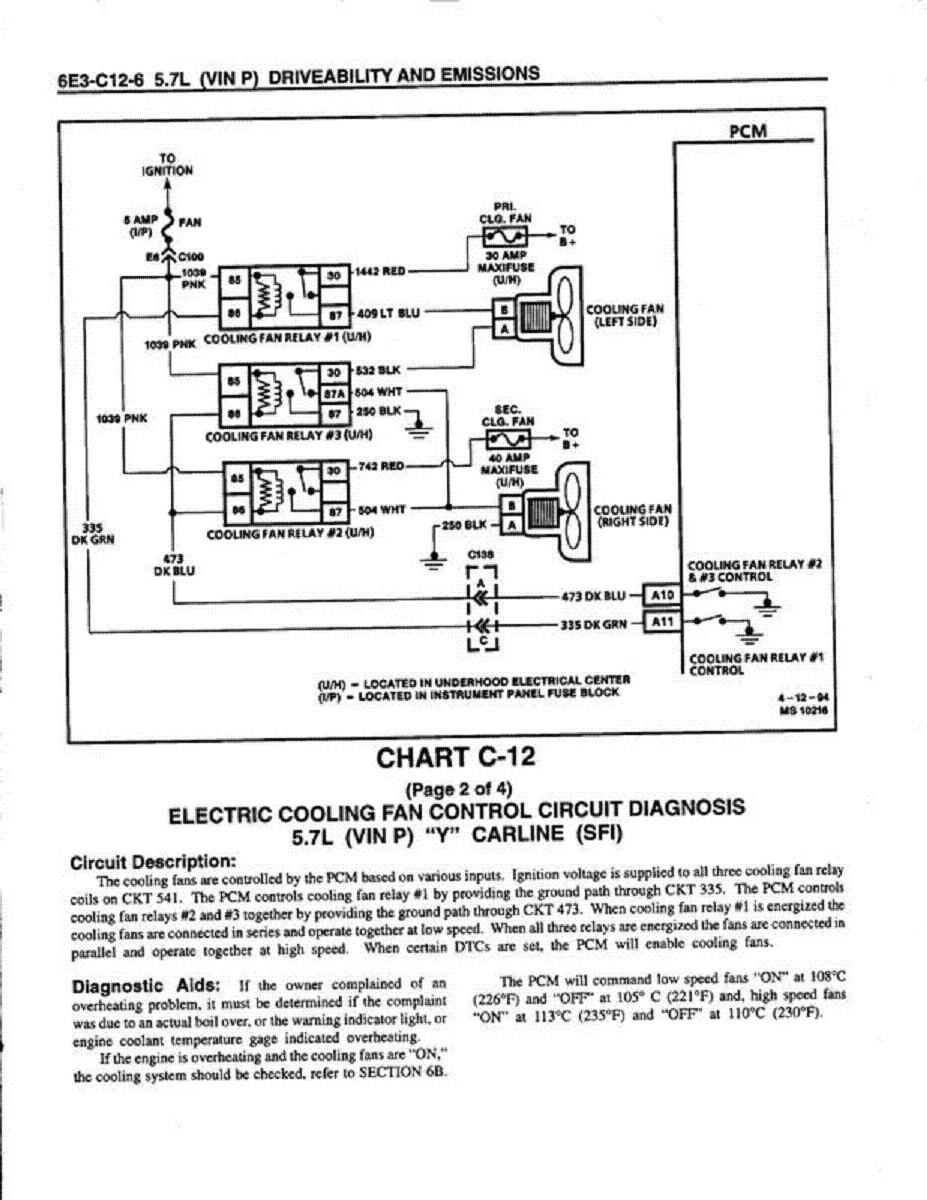

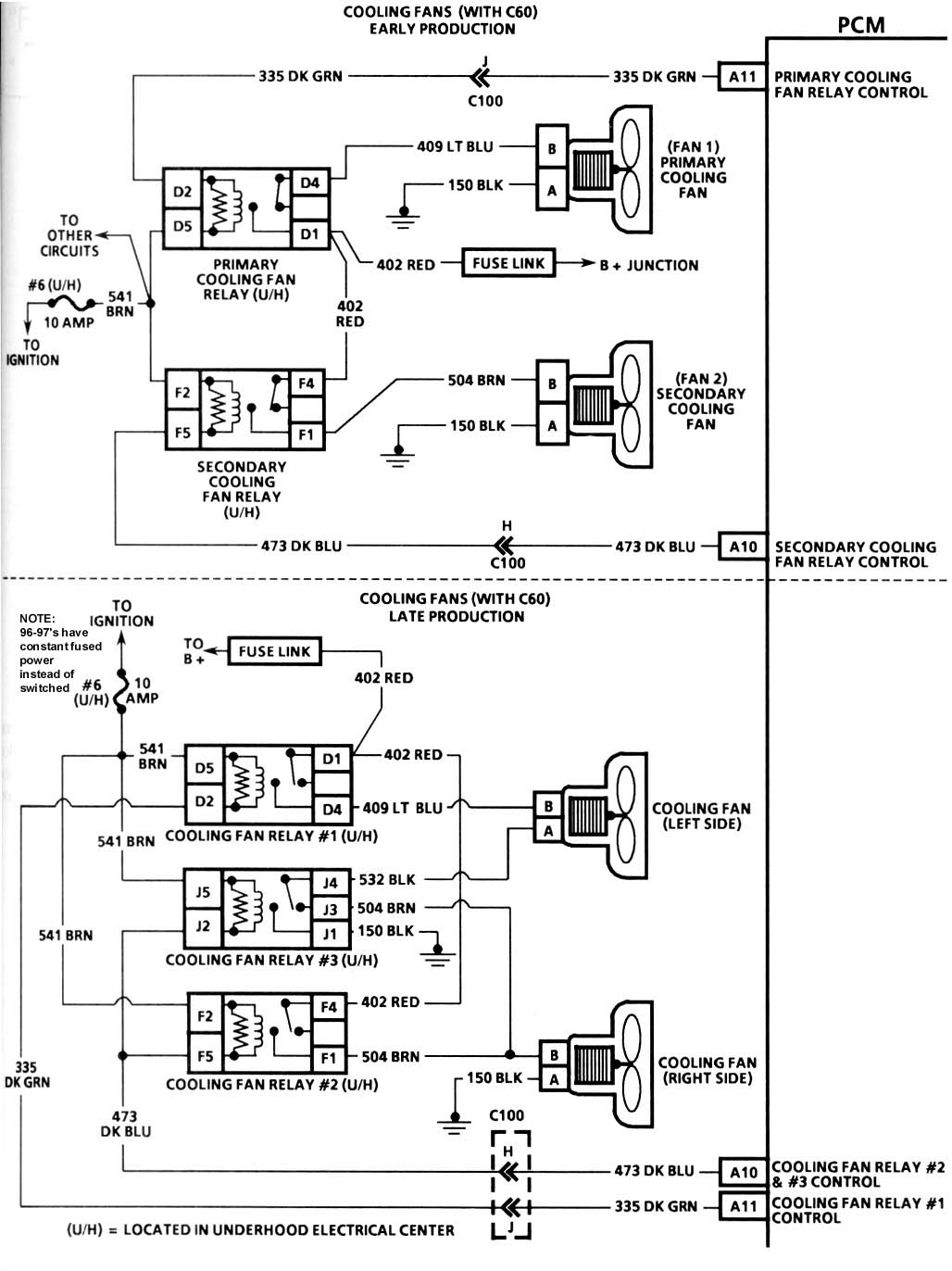

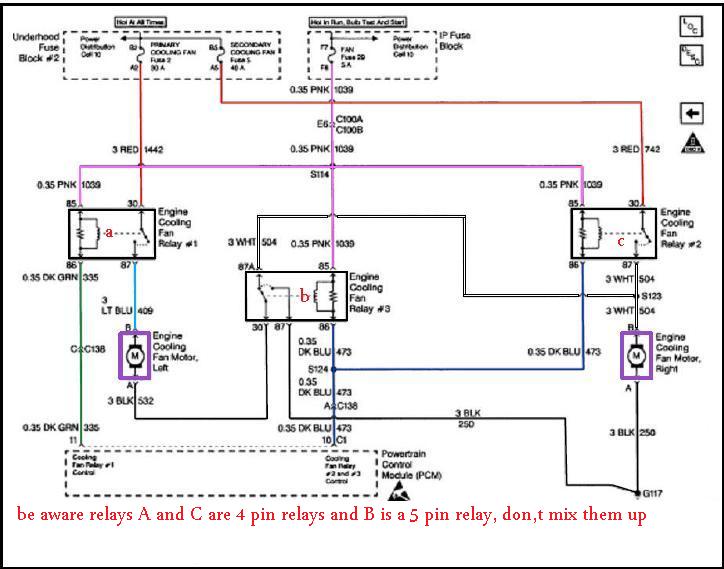

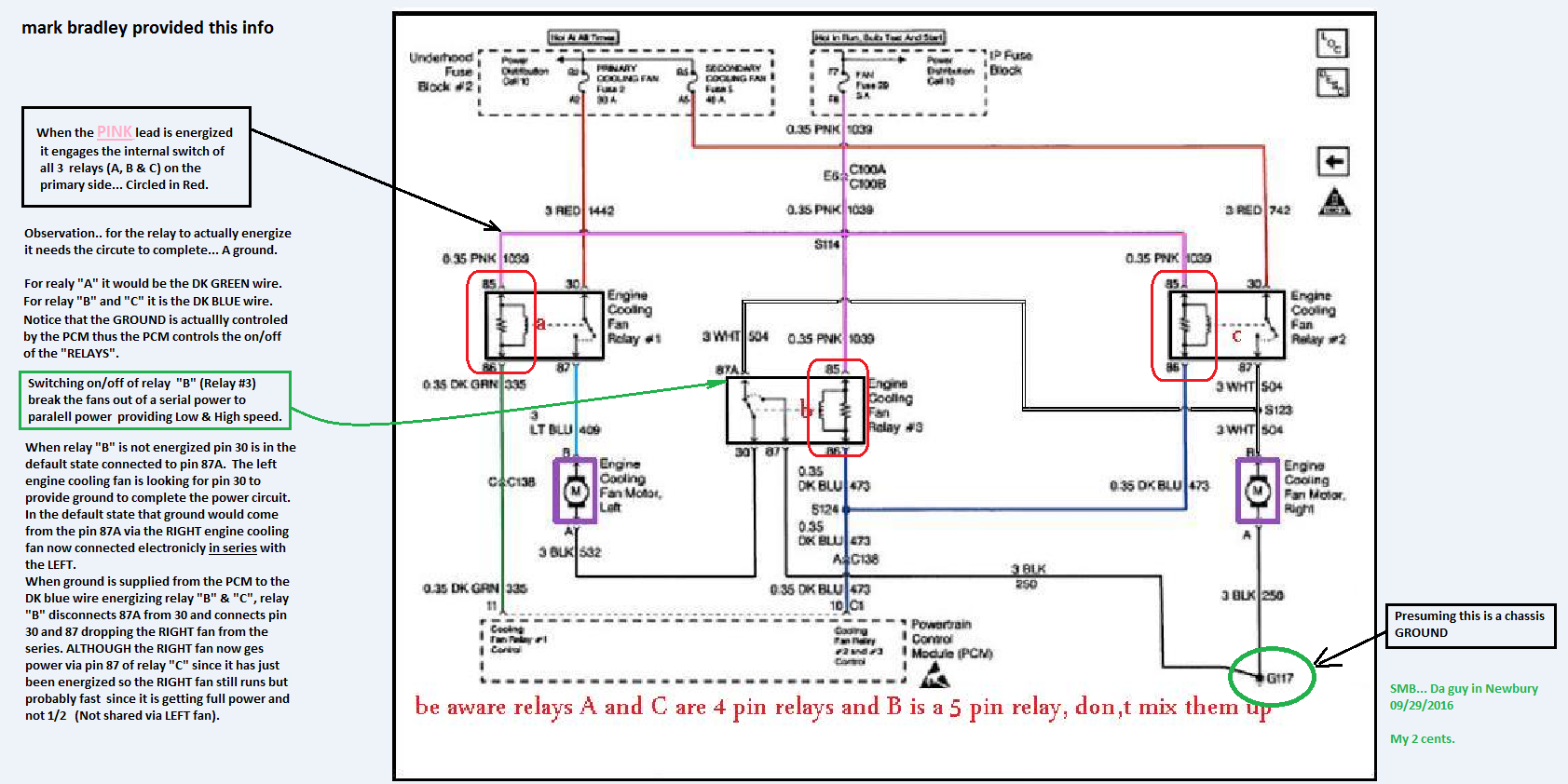

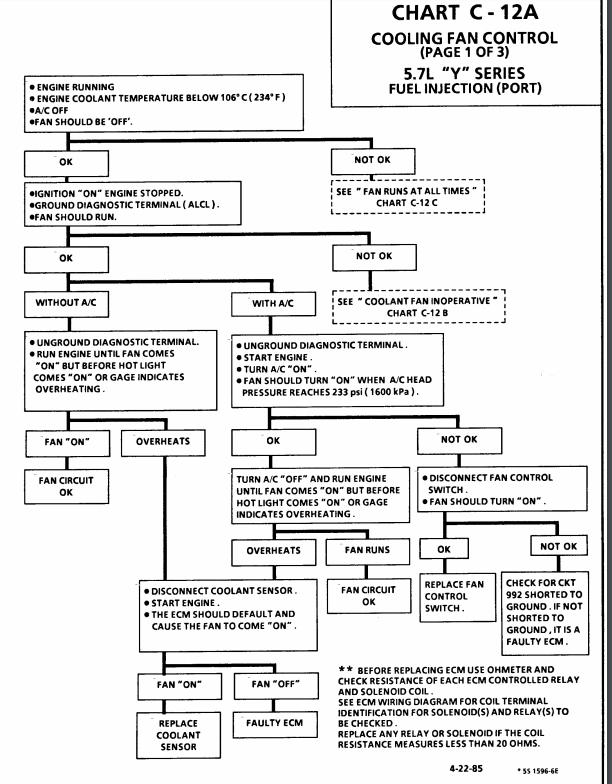

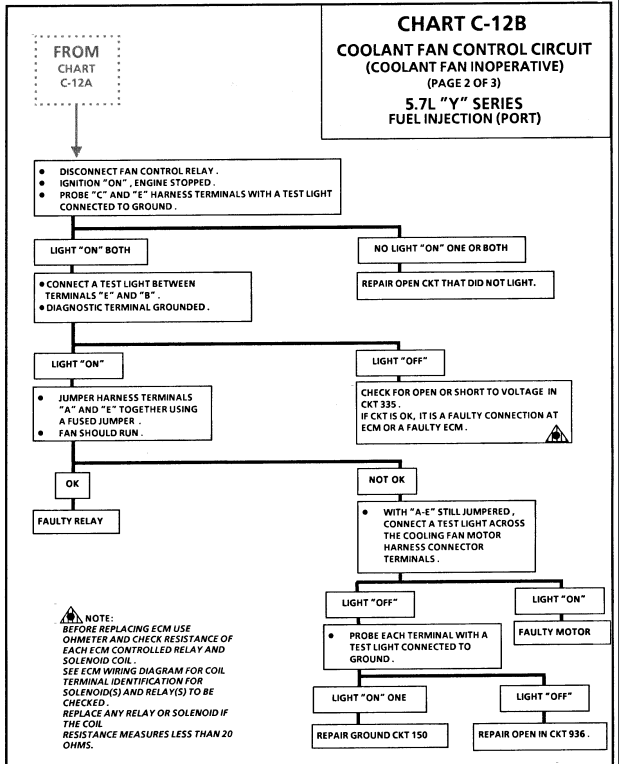

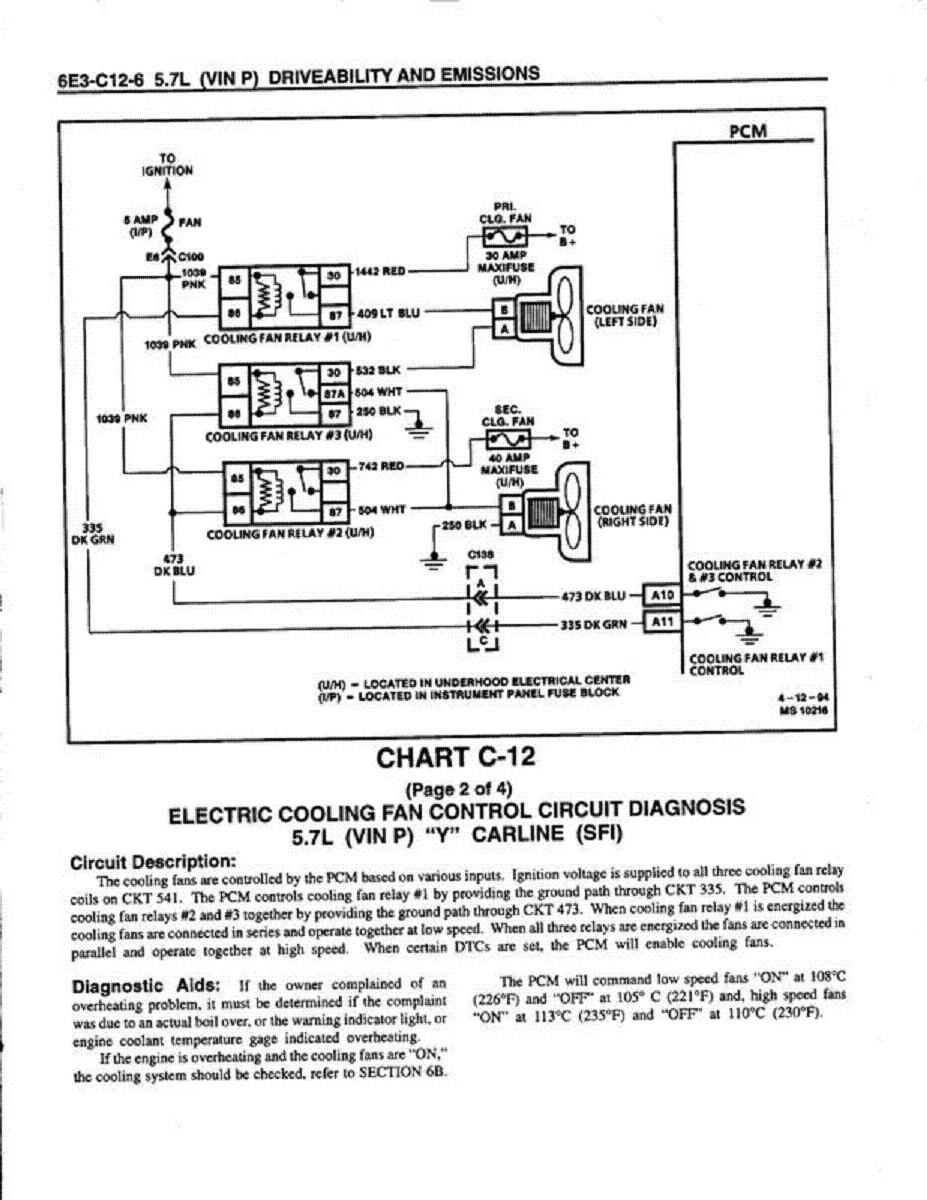

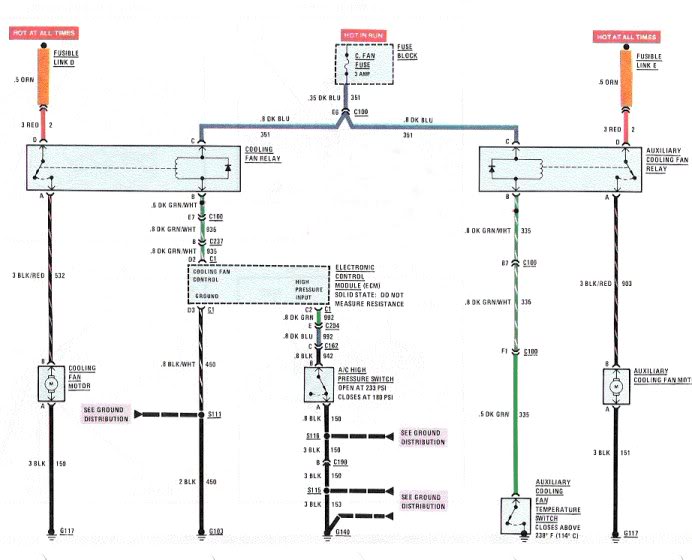

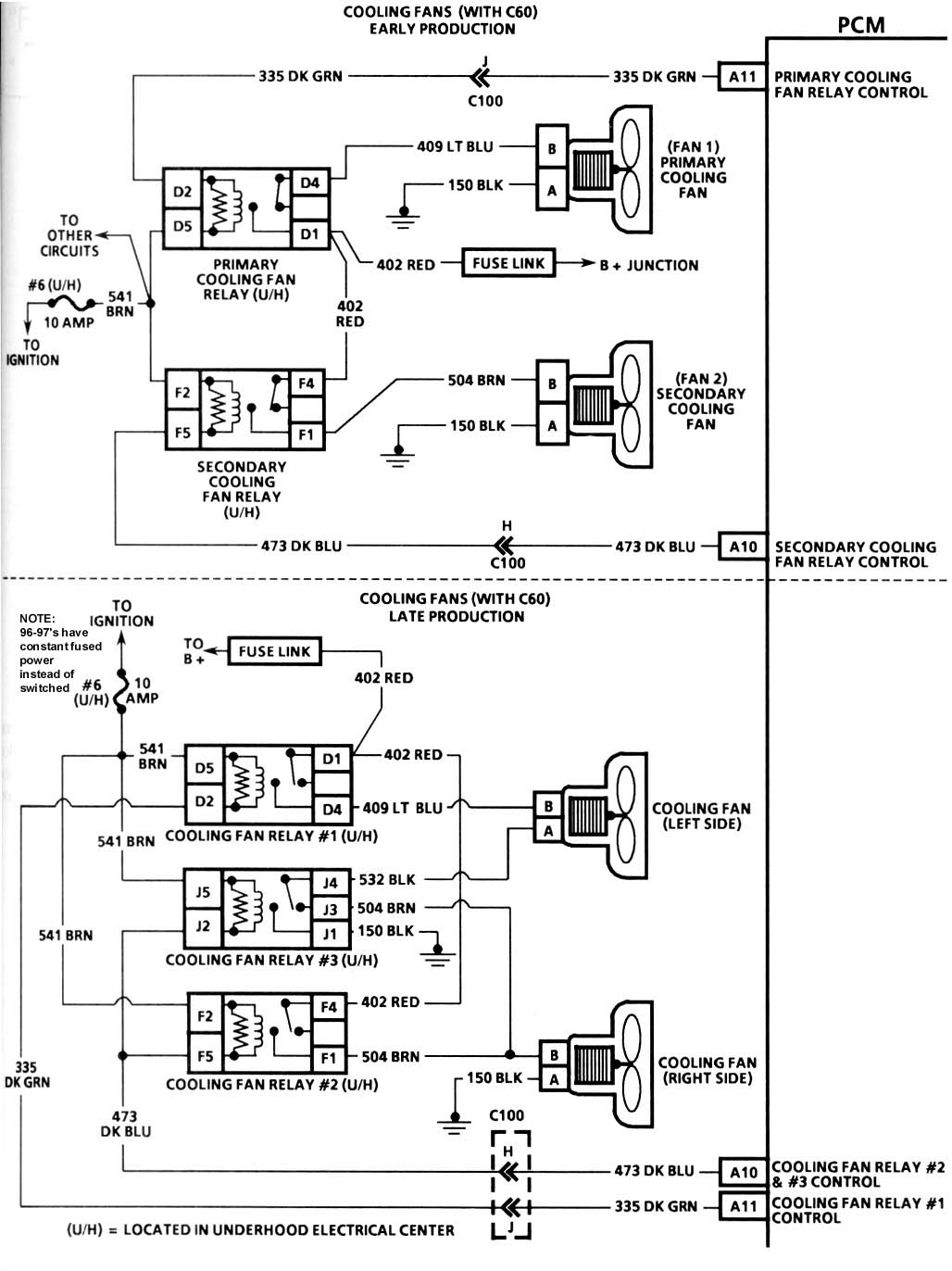

these charts are for the 1985-89 vette cooling fans

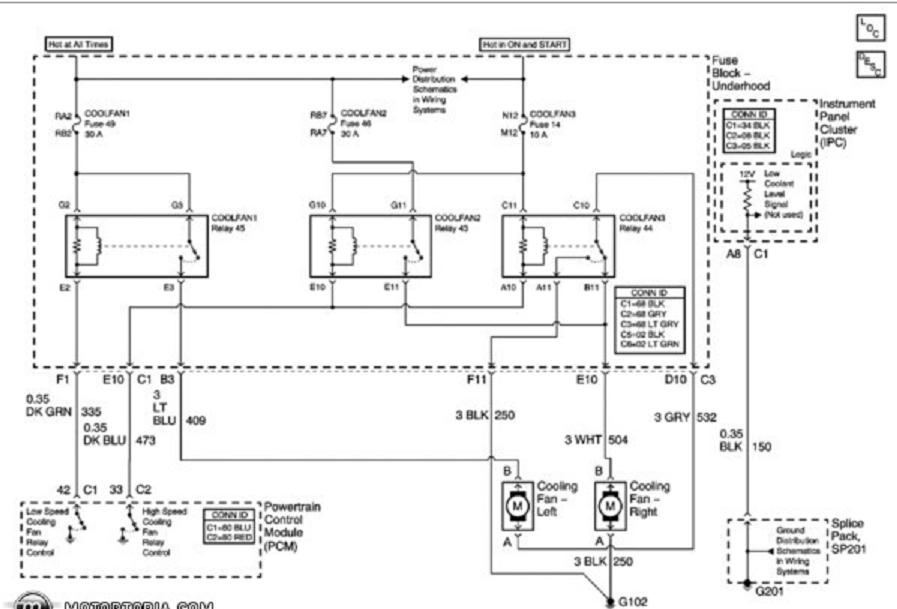

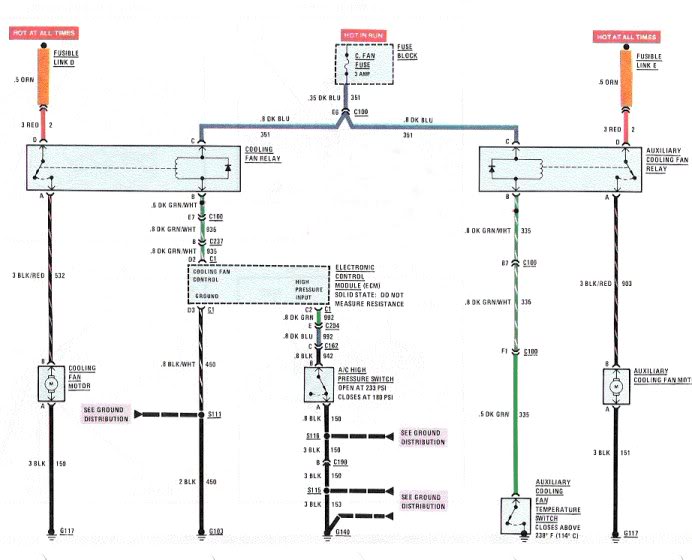

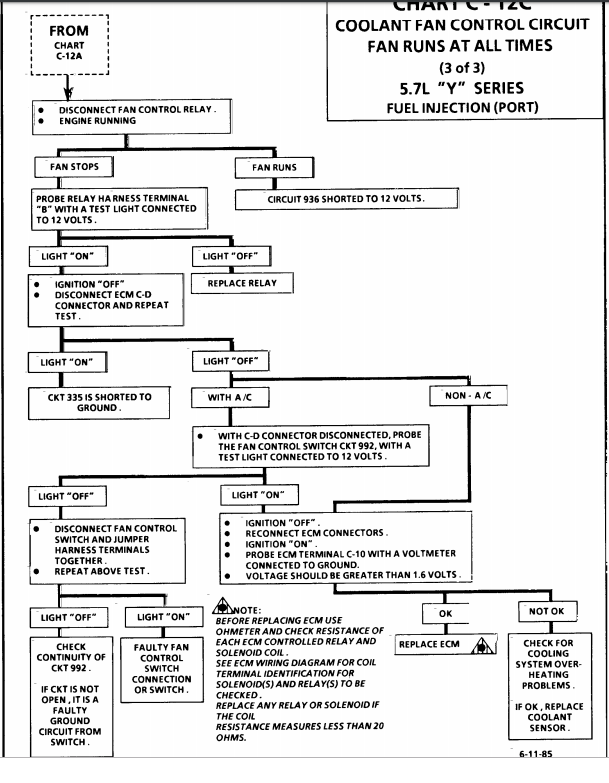

later corvette 1996

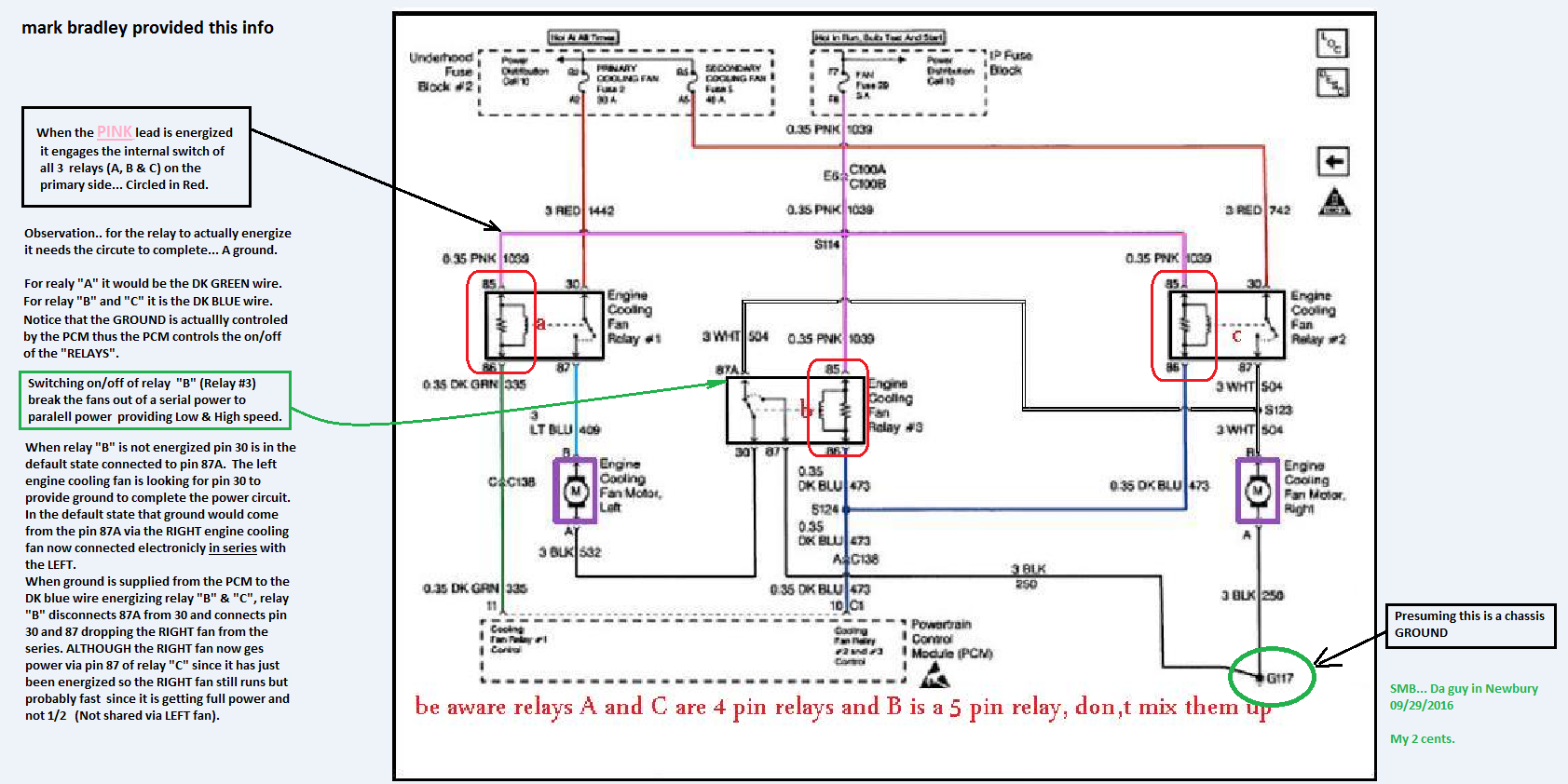

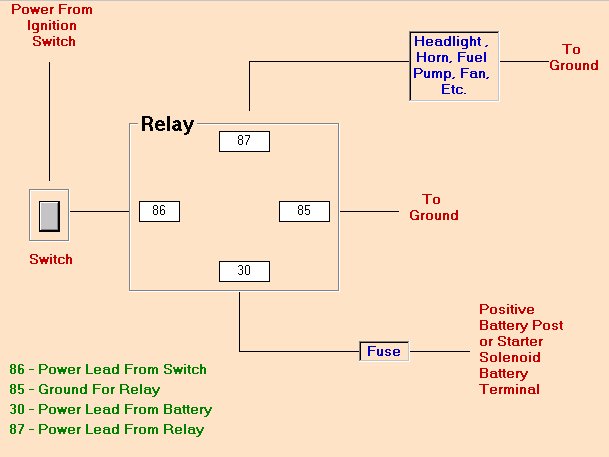

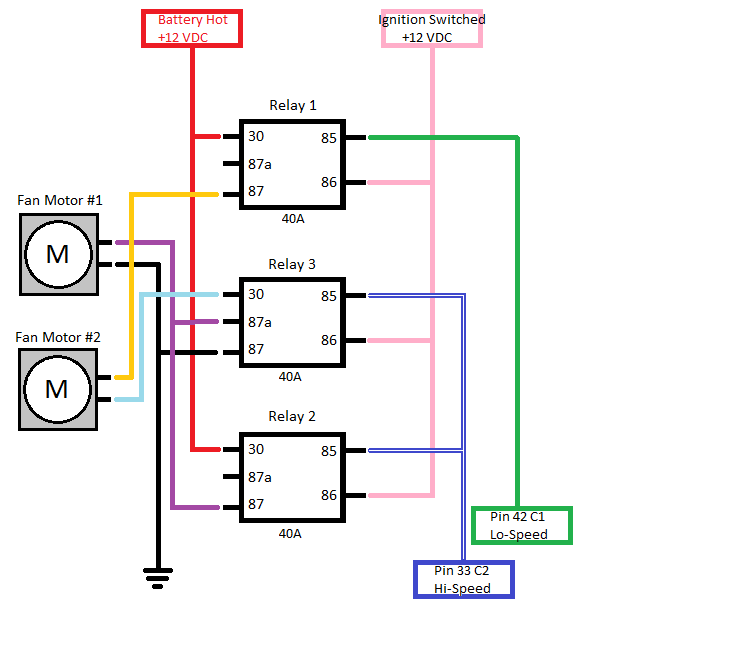

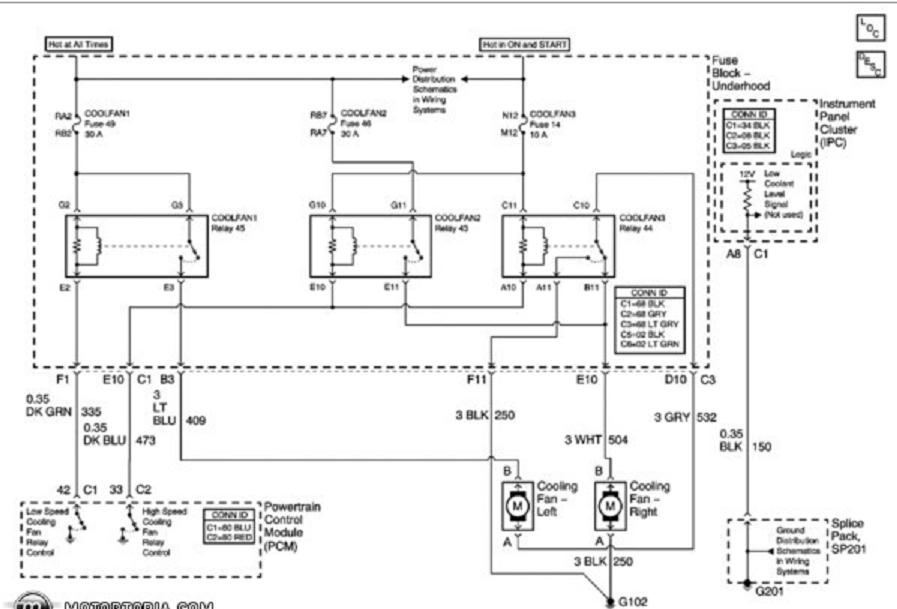

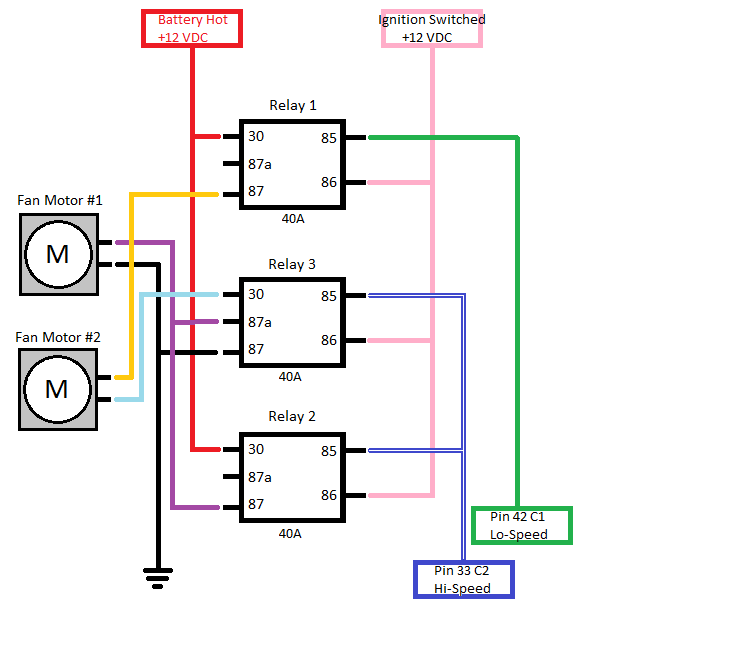

Pro tip before starting - Label your relays Relay 1, Relay 2, and Relay 3 according to the wiring diagram (your first post) and what your physical relays represent. Even if its just a sticky note. Get it all straight and stick to the same annotation while you troubleshoot.

You'll need a multimeter than can measure DC voltage and continuity:

Remove all three relays so you're only dealing with the sockets

DC Voltage tests:

1. Confirm 12V between the socket for pin 85 and the negative battery terminal on all 3 relay sockets

2. Confirm 12v between the socket for pin 30 and the negative battery terminal on relay sockets 1 and 2

Continuity tests:

1. Confirm continuity with the end of the dark green wire and the socket for pin 86 for relay 1

2. Confirm continuity with the end of the dark blue wire and the socket for pin 86 for relay 2 AND relay 3.

3. Confirm continuity between the socket for pin 87 for relay 1 and side B of the left cooling fan connector

4. Confirm continuity between side A of the left cooling fan connector and side B of the right cooling fanconnector AND the socket for pin 87 for relay #2.

5. Confirm continuity between the socket for pin 87 for relay #3 and Negative Battery Terminal

6. Confirm continuity between side A of the right cooling connector and Negative Battery Terminal.

Do the steps in order and use the negative battery terminal for your connection when I specify to. Verifying at the negative battery terminal will ensure you're circuit is making a good connection to the chassis ground. If it doesn't make it all the way back to the battery, it's a crap ground and testing it my way will reveal the problem

https://www.youtube.com/watch?v=vTl6UNMKjLc

THE DIAGRAM ABOVE HAS THE CORRECT WIRE COLORS

heres a bit of info I found posted elseware

" Next on the order of useless LT1 items is the 160 degree hermostat. GM made the LT1 engine run very hot, temperatures of 230 degrees are not at all uncommon. These hot temperatures promote reduced emissions and a cleaner burn. Research has also shown that engine wear is related to temperature and that too low a temperature can cause premature engine wear. The stock thermostat in an LT1 is 180 degrees, the only reason the car runs so hot is that the computer controlled fans allow it to do so. From the factory the cooling fans are not programmed to come on until the vehicle approaches 240 degrees. While the vehicle is moving temperatures are easily maintained near 180 degrees, the temperatures only climb when the car sits at idle. If one so desires the computer can be reprogrammed to turn the cooling fans on at a much lower temperature, it is possible to maintain a temperature of below 200 degrees with the stock thermostat in place. The question then becomes, why does the engine need to run cooler? Racers have long known that cooler air is denser than hot air, denser air means more fuel and more fuel and air means more power. So if the engine is kept cooler it doesn't heat up the incoming air charge as much and more power is made. The theory is sound and very much proven, but the LT1 throws a small wrench in the theory. Because of the nature of the LT1's reverse flow cooling system the intake manifold does not have coolant flowing through it. So although the LT1 intake still gets plenty hot, it does not vary with respect to coolant temperature nearly as much as a traditional intake manifold does. The result is an engine that is far less sensitive to it's own temperature as far as horsepower is concerned. I would not have believed this myself until I tried an experiment at the dyno. I iced down my intake until it was actually cold to the touch. I then proceeded to make back to back dyno runs until the car was very hot. From this experiment I found that there was absolutely no reduction in power output until engine temperature exceeded 230 degrees, a condition that will never occur as long as there is sufficient airflow over the radiator. As such I can say with certainty that a 160 degree thermostat makes no difference in power. I cannot prove the lower temperature thermostat increases engine wear, but at the very least it decreases your heater output in the winter. "

obviously you'll want to put the car up on a lift and clean out the radiator fins both in front and behind as the cars tend to vacuum up road trash, blocking air flow.

your fans are controlled by sensors and the ECU, so you might want to install a sensor that turns the fan on as soon as the car reaches about 180F rather than the stock 230F.

swapping to a 140-160-200 amp alternator makes a very noticeable difference in fan speed in some cars

http://www.dbelectrical.com/p-4436-corv ... -7888.aspx

http://www.ecklerscorvette.com/corvette ... -1995.html

viewtopic.php?f=36&t=1169

http://store.alternatorparts.com/extrem ... ifier.aspx

those temp switches come in a variety of temp ranges

http://www.summitracing.com/parts/HFM-ZFSWF/

185 f sensor

http://www.racerpartswholesale.com/prod ... cessories2

IF YOU DON,T HAVE THE SHOP MANUAL , AND YOUR HAVING COOLING ISSUES,THIS IS AN EXCELLENT TIME TO BUY ONE, BECAUSE THE SENSORS AND WIRING AND RELAYS ARE NOT EASILY TRACED & TESTED WITHOUT THE MANUAL

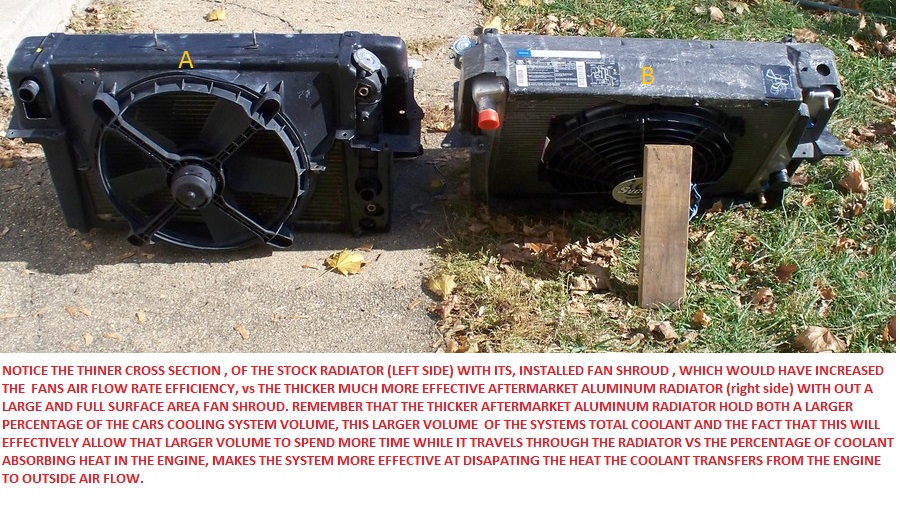

obviously your engines tune, air/fuel ratio and ignition timing have a large effect on your cars operation temperature,moving the coolant thru the block efficiently and allowing the heat to rapidly dissipate, to the outside air flow with an efficient large capacity aluminum radiator will greatly improve the cars cooling.

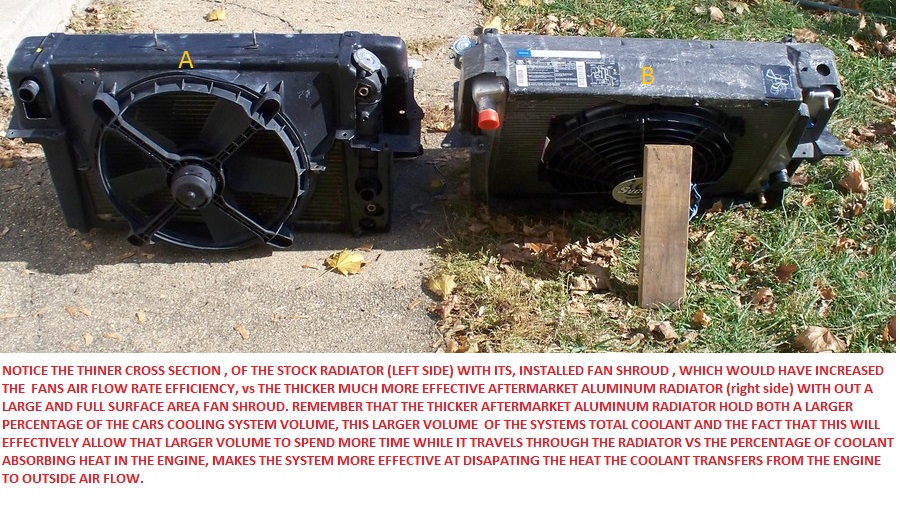

the stock radiator is barely adequate for an engine putting out significantly more power as more hp creates more heat.

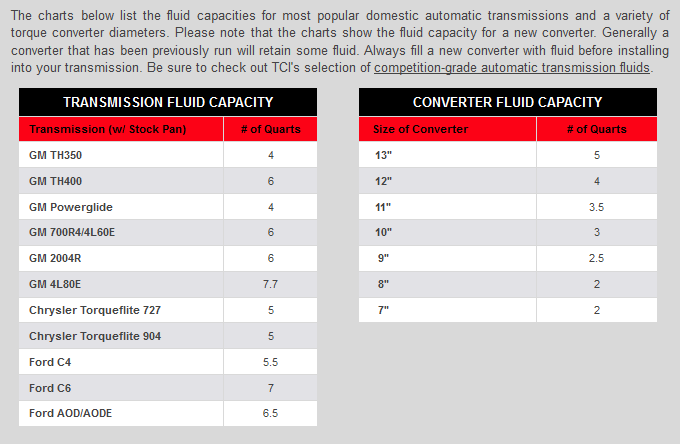

a stock transmission cooler won,t keep up with an aftermarket high stall converter, if you drive the car hard either.

One factor many guys overlook is that the SENSORS and RELAYS controlling the fans and the VOLTAGE the ALTERNATOR supply's to the car have a huge effect on both when the fans kick on and how fast they spin, which in turn has a major effect on the low speed air flow thru the radiator

keep in mind a great deal of the heat in a radiator is generated by the transmission fluid cooling, requirement on auto trans cars so adding a large AUXILIARY trans cooler helps a great deal, if you add an engine OIL COOLER that further reduces the heat load on the radiator

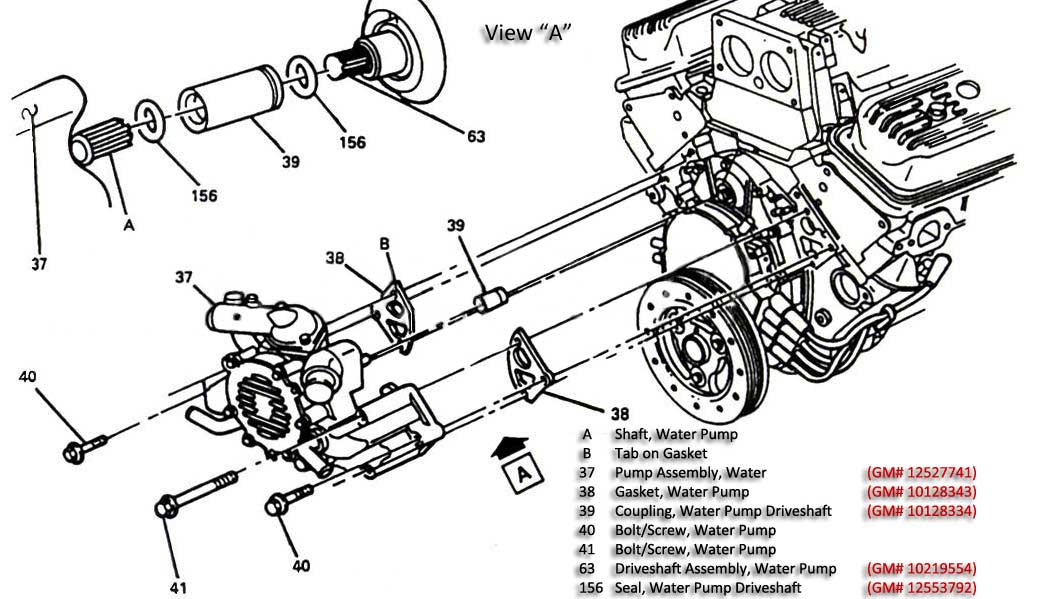

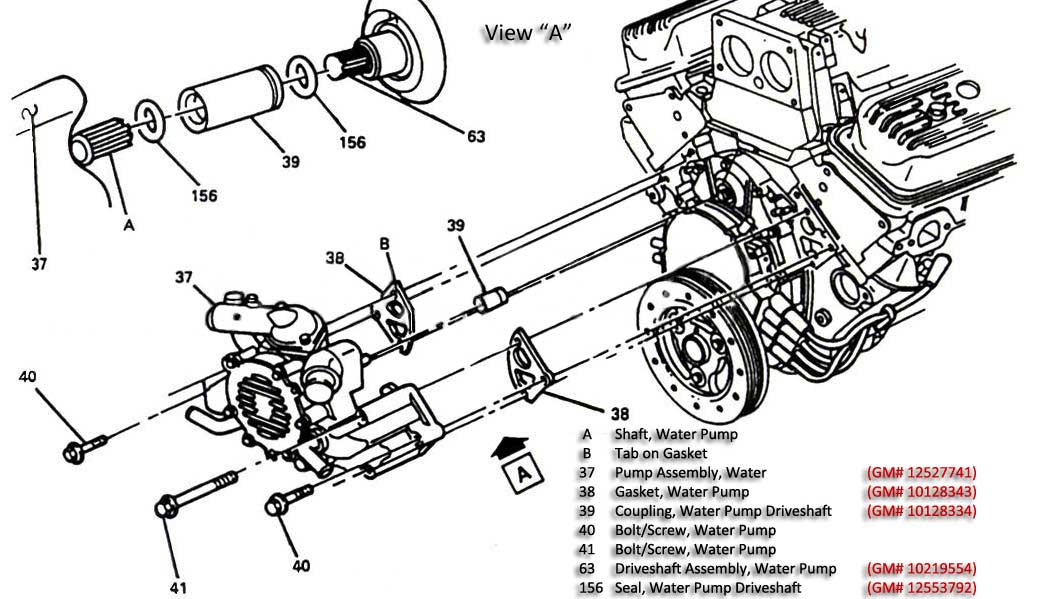

keep in mind that the standard C4 corvette uses a REVERSE rotation water pump, and its not a true high volume design, aluminum water pumps will reduce weight on the front of the car,so think about that when selecting a water pump

Here are some causes of overheating:

* Bad Thermostat or clogged t-stat

* Cooling system leaks/low coolant levels

* mixing two non-compatible anti-freeze types

* defective or the wrong water pump

* Leaky Head Gasket

* vacuum leaks in intake

* wrong fuel/air mix ratio

* incorrectly installed belts

* crud blocking the airflow thru radiator

* blocked or restricted air flow,missing duct work

* defective sensors or connections too sensors

* slime or sediment in radiator tubes

* one or both Fans Not Working correctly

* Leaky Water pump

* defective fan relays

* blown fuses

* over heated transmission coolant

* low alternator voltage

* low oil levels in engine

* incorrect ignition timing

* partly blocked catalytic converters

* Lower Radiator Hose Collapsing

* *Slipping Belt - Check belt tension and condition. A loose belt that slips may prevent the water pump from circulating coolant fast enough

Your engine may not be overheating at all. Your temperature gauge or warning lamp may be coming on because of a faulty coolant sensor. Sometimes this can be caused by a low coolant level or air trapped under the sensor.

READ THIS THREAD

viewtopic.php?f=57&t=149&p=1078&hilit=t+stat+drill#p1078

http://tech.corvettecentral.com/2011/02/1984-1996-corvette-cooling-fan-control-modifications/

https://www.youtube.com/watch?v=YEaWeEtOeJ8

https://www.amazon.com/VIOFO-Circui...ocphy=9012039&hvtargid=pla-586493323860&psc=1

as mentioned you could use a fuse power tap,, but.. Ive generally just found a source for a switched power with a multi meter,

or tapped off the battery terminal and added a manual switch...depends on what I was trying to accomplish, Ive generally run 10 ga wire to a relay is any significant amp loads were anticipated,

and soldered in a relay and fuse as required.

https://www.summitracing.com/parts/...MI-rP_gp6F5AIVyAOGCh3PWAB_EAQYASABEgKCevD_BwE

https://www.amazon.com/PACK-AMP-Wat...DJGHS4MHT2D&psc=1&refRID=SDXCB01E5DJGHS4MHT2D

https://www.amazon.com/Ehdis-Truck-...=B01KFKEHMG&psc=1&refRID=SDXCB01E5DJGHS4MHT2D

https://www.youtube.com/watch?v=nbqa5gr4IA4

https://www.youtube.com/watch?v=swJOn64vBuE

https://www.youtube.com/watch?v=-bqIdUVBsMU

WATER PUMP

a quality radiator will be made from aluminum and have large cross flow tubes, read thru the links below,

theres several dozen sources but the better brand names, tend to have a better quality product than the cheaper imported versions

RADIATOR

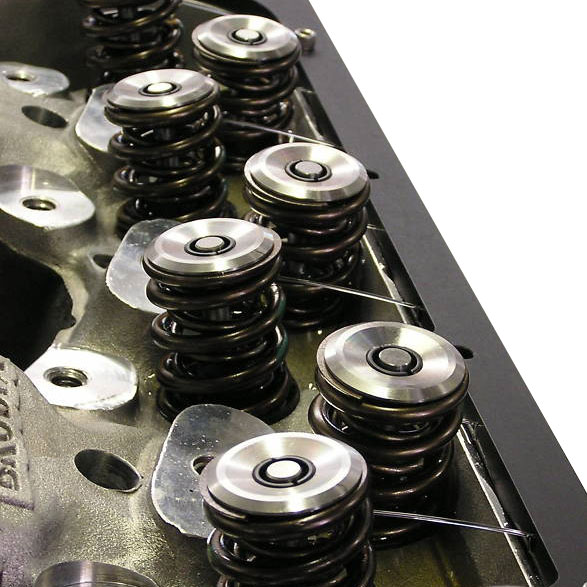

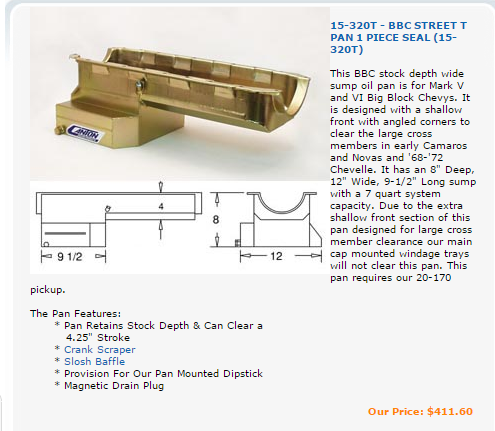

OIL PAN & OIL COOLER

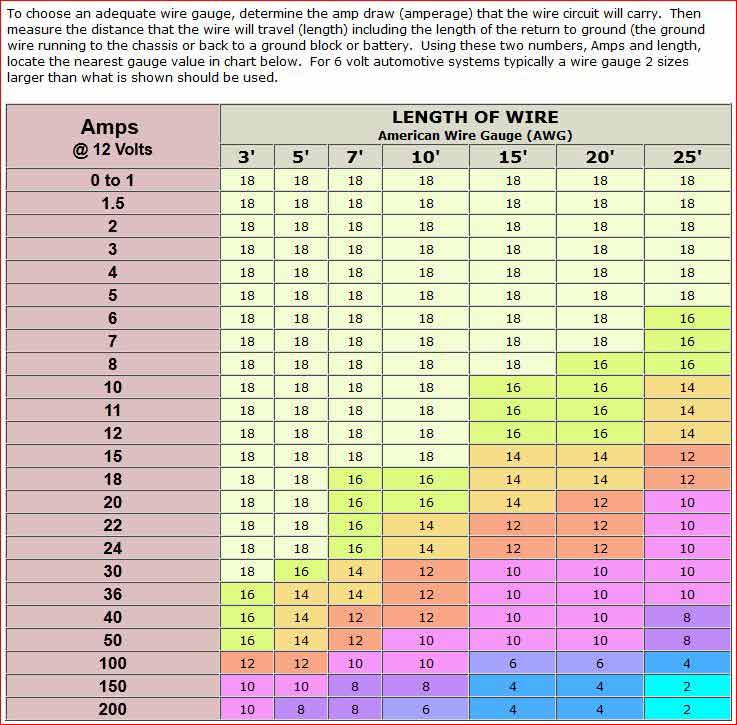

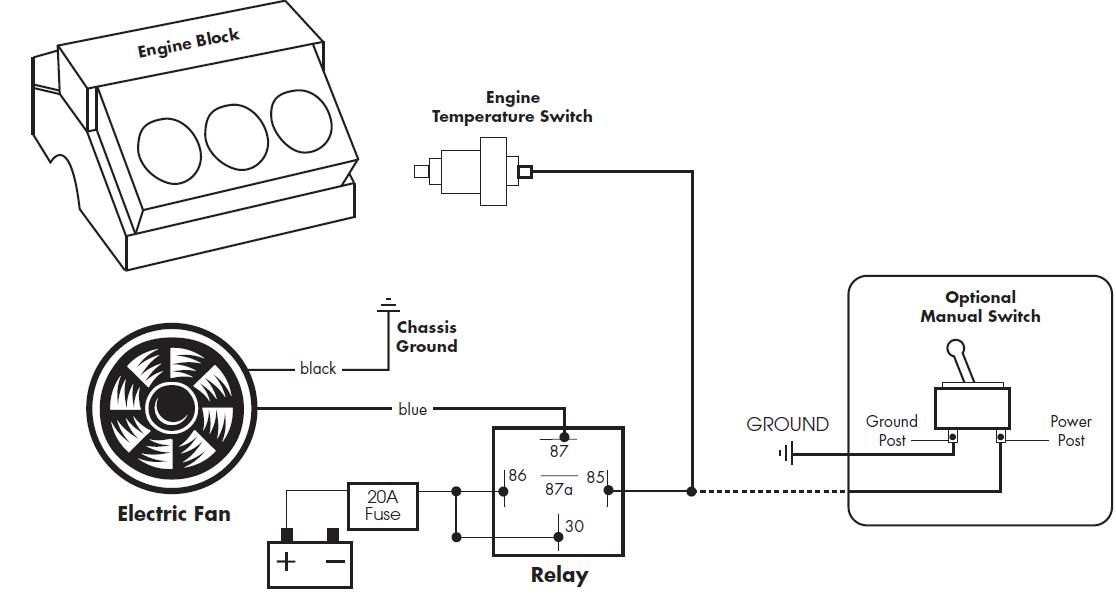

If your wiring up an aux electric fan ,yes I know your likely to just use the 14 ga or 12 ga you have, but after you do feel the wire after the fans run for 15 minutes and youll see why I strongly suggest 10ga stranded wire on any aux fan application

[color]

look thru this linked info, the links help

viewtopic.php?f=70&t=3504&p=9220&hilit=relay#p9220

viewtopic.php?f=50&t=3110&hilit=relay

5670.html

TRANSMISSION COOLER

many guys fail to realize that the combo of a high capacity baffled oil pan and an oil cooler can remove a great deal of your engine heat before the radiator, and coolant in the engine ever needs to start absorbing and transferring that heat to the outside air flow , ITS, high volumes of OIL FLOWING over the valve train and thru the bearing clearances and lubricating the rotating assembly , that is cooling many of the hotter components, and keeping that oil cool and flowing over those components is your first layer of defense on cooling the engine. its the volume of oil , and how effectively you keep the oil temps stable in the 210F-240F ranges and the quality and how well the oils filtered,more than the pressure that's important to your engines durability

heres some RELATED THREADS, with MUCH MORE DETAILED INFO

http://garage.grumpysperformance.com/index.php?threads/i-need-a-new-lt1-water-pump.10723/#post-47422

http://www.racerpartswholesale.com/prod ... cessories2

http://tpiparts.net/90_92_speed_density_sensors/

http://garage.grumpysperformance.com/index.php?threads/a-few-lt1-related-part-numbers-and-info.6224/

keep in mind theres DOZENS OF DIFFERENT CHEVY TEMP SENSORS, for OIL AND COOLANT AND AIR, SO BE SURE YOU SELECT THE ONE DESIGNED TO MATCH YOUR GAUGE AND APPLICATION

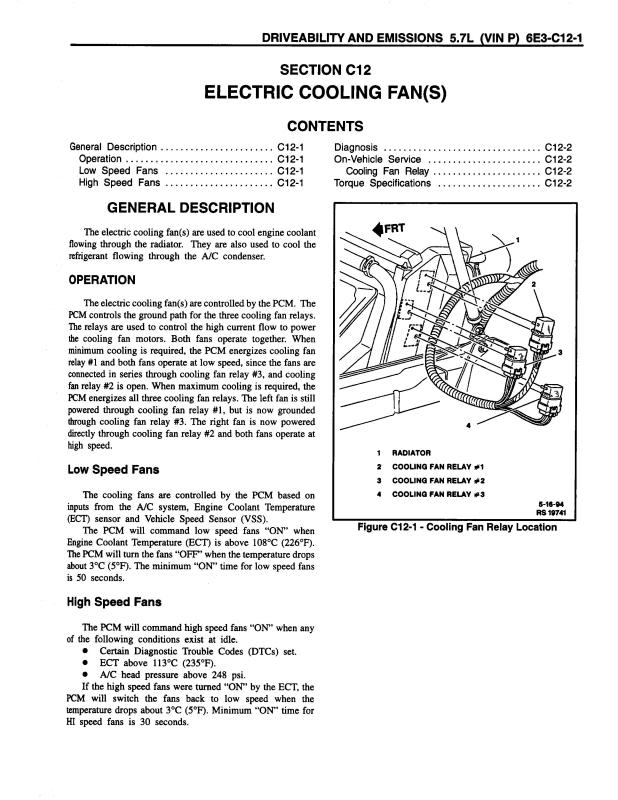

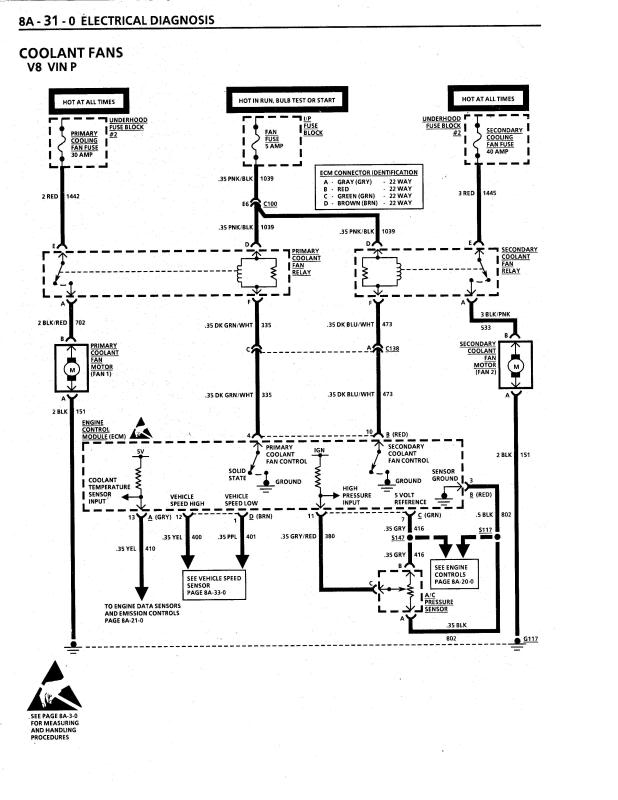

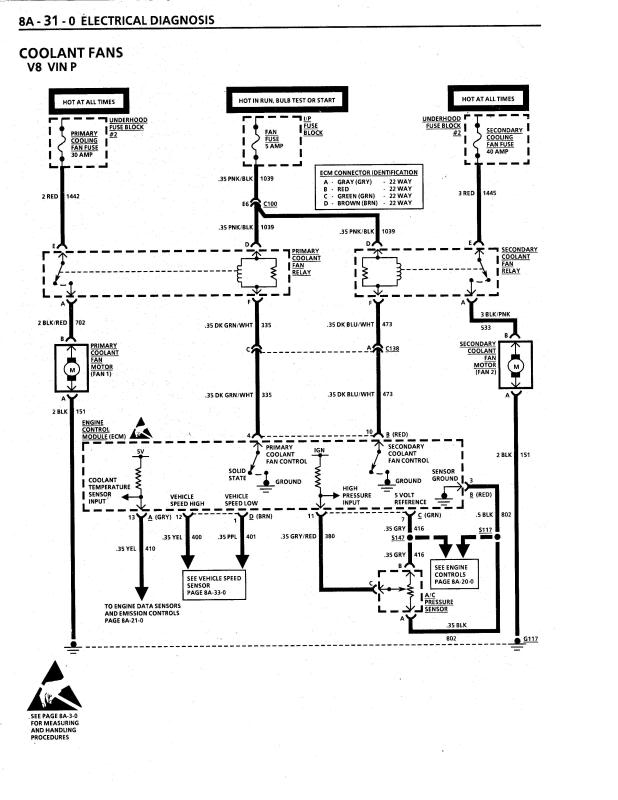

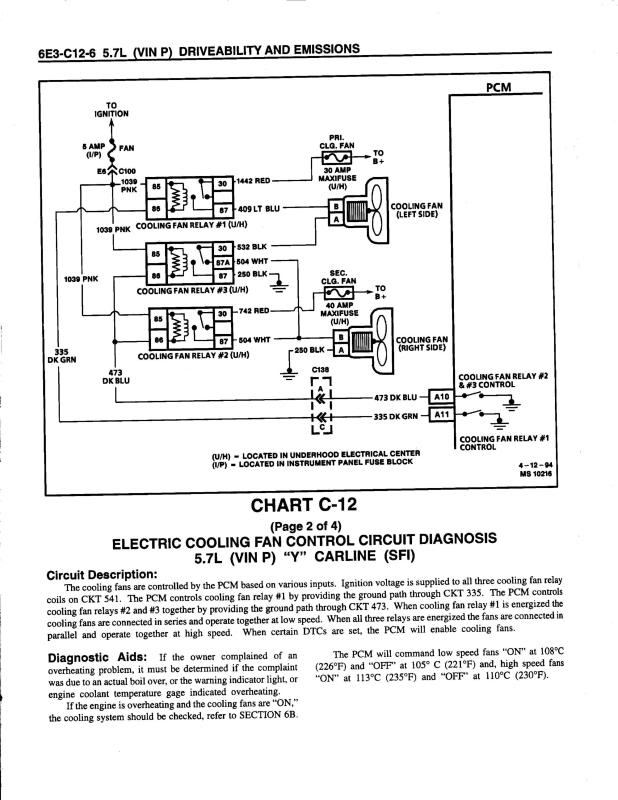

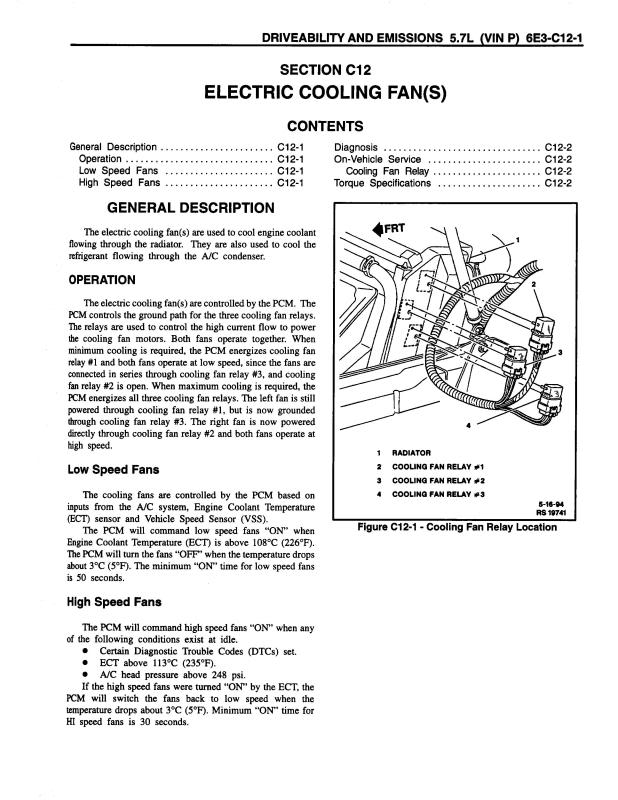

OPERATION

The electric cooling fan(s) are controlled by the PCM. The PCM controls the ground path for the three cooling fan relays. The relays are used to control the high current flow to power the cooling fan motors. Both fans operate together. When minimum cooling is required, the PCM energizes cooling fan relay #1 and both fans operate at low speed, since the fans are connected in series through cooling fan relay #3, and cooling fan relay #2 is open. When maximum cooling is required, the PCM energizes all three cooling fan relays. The left fan is still powered through cooling fan relay #1, but is now grounded through cooling fan relay #3. The right fan is now powered directly through cooling fan relay #2 and both fans operate at high speed.

LOW SPEED FANS

The cooling fans are controlled by the PCM based on inputs from the A/C system, Engine Coolant Temperature (ECT) sensor and Vehicle Speed Sensor (VSS).

The PCM will command low speed fans "ON" when Engine Coolant Temperature (ECT) is above 108°C (226°F). The PCM will turn the fans "OFF" when the temperature drops about 3°C (5°F). The minimum "ON" time for low speed fans is 50 seconds.

HIGH SPEED FANS

The PCM will command high speed fans "ON," when any of the following conditions exist at idle.

Certain Diagnostic Trouble Codes (DTCs) set.

ECT above 113°C (235°F).

A/C head pressure above 248 psi.

If the high speed fans were turned "ON," by the ECT, the PCM will switch the fans back to low speed when the temperature drops about 3°C (5°F). Minimum "ON" time for HI speed fans is 30 seconds.

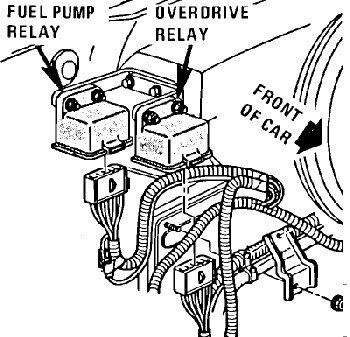

86-89 fan wiring

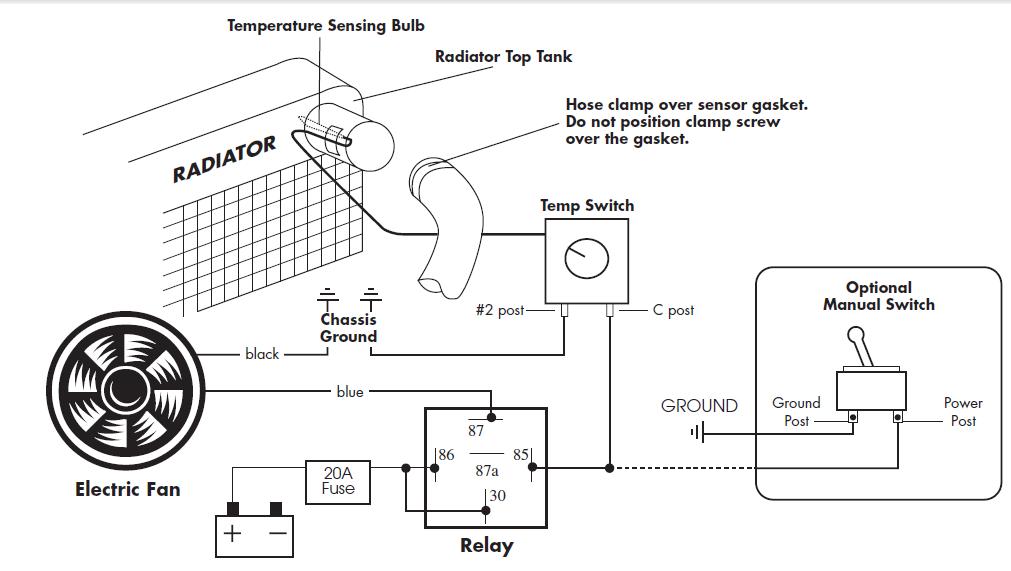

GENERIC VERSION(above)

AUTOWIZ posted this bit of info, youll need

" There are 2 temp sensors. Or rather a sensor and a sender. The sender is for the gauge and has 1 wire and goes into the rear of bank 2 cylinder head in between cylinders 6 and 8 spark plugs. And the other is a 2 wire sensor for the ecu. This sensor mounts in the water pump on the front face of the engine. It is very possible to have a failed sensor for the ecu or a damaged harness or unplugged sensor and have the ecu read -40f for coolant temp. If this were the case then your fans would never be commanded on even though their circuits were intact. And also if this were the case then your gauge on the dash would still work because the 1 wire sender is still working. A scantool will show you. And a good scantool will let you command the fans on for testing the control circuit."

RELATED INFO

http://garage.grumpysperformance.com/index.php?threads/efi-and-scan-tool-software-links.469/

HIB POSTED THIS

"A 96 has two fans. Both run at the same time. The fans have two speeds low and high. When low fans are commanded the fans are wired in series. When high fans are commanded they are wired in parallel. There are three fan relays which operate the fans and which are controlled by the ECM.

"Low fans" is commanded by the ECM when either: certain DTCs are set, ECT is above 219°F, engine oil temp is above 270°F or A/C head pressure is above 189 psi. Also, when engine speed is over 3500 rpm and oil temperature is over 261°F low fans will come on. The fans will go off once CT drops about 11°F. If A/C head pressure kicks the fans on, it must drop to 150psi before the ECM will shut them off. Min. on time is about 50 seconds

IVE SEEN THIS INFO POSTED BUT NEED TO VERIFY IT

Go to the fan relays on the driver side of the radiator support. You will find the little green wires going into the relays are the ground signals from the computer to trigger the fan. Splice in a hard ground to the frame, and the fans will run as soon as you turn on the key, regardless of temp.

"High fans" is commanded by the ECM when either: certain DTCs are set, ECT is above 228°F, engine oil temp is above 277°F or A/C head pressure is above 225-psi. Also, when engine speed is over 3500 rpm and oil temp is over 266°F, the ECM will request high fans. The ECM will turn off high fans once coolant temp drops about 11° or A/C head pressure drops below 189 psi.

If you saw 260 on the digital display and the coolant boiled over, obviously the car was way overheating. If you ran the car like that for any length of time, engine damage is possible. Hopefully that's not the case.

I'd be looking for cooling system problems other than just the fans such as restricted air flow through the cooling stack. Also, overheating really stresses cooling system parts such as radiator hoses, heater hoses, belts, radiator caps and so forth. Considering the car is 15 years old, if those parts are original, I'd carefully inspect them for damage.

But, again, the best way to troubleshoot the cooling fans on a 90-96 is using the diagnostic table in the Service Manual. "

thoughts on cooling

sometimes things "stick" to the threads and just rip out and totally wreck the threads. Even when you use an Anti-Seize ? How about using an anti-seize and thread cleaner tap, run that thru there a several times before installing the anode. Here is a quick option...

garage.grumpysperformance.com

has a rather marginal cooling system if your engines been modified for significantly higher hp levels, that cooling system can be significantly improved upon.I run into this frequently, and theres several sources or causes for an engine to run hotter than you might want it to,and cures, obviously you'll need to check fluid levels and your ignition timing.

Your Corvette’s main cooling fan is controlled by the PCM. The PCM sends a ground signal to the fan relay when it sees the desired temperature from a sensor to run the fan has been met. You need to check the sensors and fan relays and make sure you are getting your battery 12V and ignition 12V when the key is on. get a shop manual, and a bulti meter youll need them, now with the key on, jump the ground wire in the relay. If the fan turns on, you have an issue in the PCM and it may be time for a rebuild. If it does not turn on, then your problem lies in the fan circuit between the relay and the fans.

keep in mind a corvette draws air from under the car so its prone to pick up a good deal of street trash like leaves and plastic bags , so inspect and clean off any trash in the radiator fins before you assume the systems defective

also be aware that you can attack the heat control issues you might have from two directions, you can concentrate on removing heat from the engine more effectively with a larger more efficient radiator, bigger fans,, adding an alternator that allows more AMPS to spin those fans , adding more effective duct work, adding oil coolers, transmission coolers or a larger capacity baffled oil pan, adding heat exhaust vents to the hood,adding additives to the coolant that reduce the tendency to boil, like WATER WETTER, etc. or you can concentrate on reducing the heat generated thru control of your fuel/air mix ratio, ignition advance curve, timing and exhaust restriction.Id also point out that chevy water pumps can be purchased that are designed to spin in either clock wise or counter clock wire rotation and installing the wrong part number will cause big problems

obviously the first step in testing an over heating issue would be to verify the coolant and oil levels and verify the fans turn on and the water pumps pushing fluid thru the engine, and your not dealing with a defective t-stat or clogged radiator.

if those are correct it may be a sensor or tuning issue so verify sensor outputs with a good multi meter.

just a point many guys seem to over look, the fans run on electricity and a higher amp capacity alternator provides a good deal more current to spin those cooling fans, Ive seen several cars with marginal cooling that had that cooling issue disappear once a 160-200 amp alternator replaced the stock alternator, the increased current allowed the cooling fans to spin a good deal faster at low engine speeds and the result was more efficient cooling.

The key to C4 electrical is the checking for good solid low ohm resistance GROUNDS. They control almost everything, as sensors complete grounds or sense resistance. Voltage takes a backseat to good low ohm resistance grounds on these cars.

Locate the ground bundle of 5 wires on a bolt near the oil filter. (G104-107) Clean and repair. Also clean and repair the hot wires to the jumper post behind the battery.

Check the connections on the various temp sensors/switches. There is a different sensor for the gauge than the ecm or fan control. Some cars have as many as 4 or 5 temp sensors. What you see on the dash is not always what the ECM is seeing.

buy a CHEVY SHOP MANUAL FOR YOUR YEAR CORVETTE!

a logical step by step approach will lead you to the problem, youll be amazed at what youll learn reading links. use of a shop manual and multi meter can be very helpful,the cooling system tests are listed in shop manual book 2 of 2 in section engine controls 6-640 thru 6-645

http://www.professionalequipment.com/ex ... ermometer/

Wide temperature range from -58 to 1832°F (-50 to 1000°C)

any time that your dealing with a potential temperature issue or a trouble issue where , knowing the exact temperature vs what a gauge might say, it helps to have a handy and accurate infrared temp gun handy to locate and confirm heat, levels.

http://www.harborfreight.com/5-in-1-dig ... 98674.html

learn to use the factory shop manual, and a multi meter

https://www.youtube.com/watch?v=CQylm1IvmYk

read this related linked info post carefully

http://garage.grumpysperformance.co...es-got-me-scratching-my-head.7499/#post-25434

http://www.summitracing.com/parts/tff-8173nep/applications/year/1996

Engineered Cooling Products

Aluminum Radiators For Classic Muscle Cars, Trucks and Jeeps

speedcooling.com

speedcooling.com

http://garage.grumpysperformance.com/index.php?threads/lots-of-wiring-info-diagrams.317/#post-83877

READ THRU THIS THREAD AND SUB LINKS

viewtopic.php?f=80&t=728&p=1025&hilit=sensors+camaro#p1025

http://garage.grumpysperformance.com/index.php?threads/head-scratcher-cooling-issue.3010/#post-84329

http://garage.grumpysperformance.co...996-corvettes-got-me-scratching-my-head.7499/

http://garage.grumpysperformance.co...-air-conditioner-on-cooling.12232/#post-59597

Mounting An Effective Trans Cooler On A C4 Corvette

now I know few cars with less room to mount an efficient oil cooler with a fan than a c4 corvette, and after I installed a 3200 rpm stall converter in my corvette it became obvious I needed an aux trans fluid cooler. theres very little under the hood room and ground clearance is already minimal...

garage.grumpysperformance.com

the coolant temp sensor is located on the Pass side head between # 6 and 8 plugs.

Fan control varies by year.

As I recall.

'84 has temp switch for fan only ,no ECM control;

'85 has ECM control but temp switch acts as over ride backup direct to fan

'86- '89 as stated above

'90 onward ; both fans on ECM ; no temp switch.

And all have provision to turn the fans on with A/c on.

ve had good results with a 200F T-stat with the holes drilled (READ THE LINK) but many guys select a 180F t-stat

I don,t remember, where I purchased most of the oil/trans fluid coolers Ive used ,

but I've purchased and installed several oil and trans fluid coolers

over the decades, almost all were used 1/2" or an#8 connections and were purchased from summit or jegs

as always read carefully,

and measure accurately, remembering you must be leaving room for the hot oil or trans fluid hose and connections

and access to get the cooler in and mounted and connections made too it!

you would certainly not be the first or last guy to buy a cooler that will not fit in the space you though it would,

due to the connections and hoses required or forgetting about the thickness or lack of easy access.

https://www.summitracing.com/parts/der-15820

https://www.summitracing.com/search?PageSize=100&SortBy=BestKeywordMatch&SortOrder=Ascending&keyword=oil cooler with fan

https://www.jegs.com/i/Derale/259/15850/10002/-1

https://www.jegs.com/webapp/wcs/sto...&submodel=&engine=&Nrpp=&No=&persistYmm=false

one factor thats frequently over looked is the oil feed and return line internal size and line heat rating,THINK IT THRU, now it should be obvious that fittings tend to have smaller more restrictive holes thru them than the hose internal dimensions of the fittings used with that hose, a fitting designed for 3/8" hose wont allow full 3/8"hose or component oil flow rates, AN-6 is normally considered about equal to 3/8" but thats doesn,t tend to be true, AN-8 size fittings are usually used to get decent flow in a 3/8" oil cooler , if your oil cooler has 3/8" internal passages youll want an AN#8 line size too insure the MINIMUM 3/8" internal passage size is maintained , and you really NEED a full 1/2" or AN#10 size fittings and internal fluid transmission cooler lines to a fan cooled trans fluid cooler rated at at least a 24000 lb vehicle weight for race /performance use, and not restricted by use of the internal passage size of AN#6 fittings which are at best minimal and only delay the heat build-up related problems.

http://www.summitracing.com/parts/prm-13182

If I did it again Id select this trans cooler (pictured below) as the larger line size would help reduce flow restriction, its smaller width would make it easier to install,

THATS IMPORTANT!, MEASURE VERY CAREFULLY BEFORE ORDERING

I know several people that ordered trans coolers and found they would not fit into the originally intended location because they failed to correctly measure the intended location space, in ALL three dimensions,and over the whole space, before ordering , I know I failed to measure carefully so I was forced to place it where the spare tires normally mounted

http://www.summitracing.com/parts/FLD-DB30901/?rtype=10

Fluidyne High Performance DB30901 - Fluidyne Oil Cooler with Fan Kits

Engineered Cooling Products

Aluminum Radiators For Classic Muscle Cars, Trucks and Jeeps

speedcooling.com

speedcooling.com

BTW you may find freeze plugs that look like this on blocks and cylinder heads, especially from engine rebuilder machine shops, the "exterior outside BUTTONs are made from a very special low melt metal like bismuth thats specifically designed too melt and distort if the blocks coolant temp reaches about 250-260F indicating and proving beyond question that you over heated the engine and voided your warranty

http://www.silver-seal.com/category/shop.1_cylinder_head_rebuilding.2_heat_tabs/

http://www.engineheattabs.com/products

btw torque converters are frequently painted with a very special paint that changes color at a specific temperature for the exact same reason, proof you voided the warranty and failed to run the transmission fluid thats supposed to act as a lubricant and coolant within the designed temperature range, they did not select the pink or purple because they like the color, its done to reduce warranty cost issues , if you over heat the converter its waranty is void

https://www.paintwithpearl.com/shop-custom-paint/temperature-changing-paint/

https://www.paintwithpearl.com/shop-custom-paint/temperature-changing-paint/

http://garage.grumpysperformance.co...sion-and-oil-cooler-increases-durability.176/

http://garage.grumpysperformance.co...n-cooler-info-and-derale-trans-cool-pans.662/

http://garage.grumpysperformance.co...ans-cooler-on-a-c4-corvette.10514/#post-44478

the lower white over flow tank under the hood near the pass side head light (#638 below) is not directly involved in cooling, its simply the overflow puke tank that the radiator will siphon coolant from as the radiator cools and the coolant contracts while it sits.

yes the radiator will pull coolant from that tank if the radiator level gets low , the coolant will only be warm or hot if the radiator over heats to the level where it forces coolant out, which it normally won,t doe every time the cars driven, normally its just sucking coolant in far more than trapping excess over heated coolant, if your seeing coolant in this tank every time you drive somethings wrong, and Id be looking for a problem like a defective t-stat, leaking hose or leaking head gasket.

the coolant temp sensor for the PCM is on the water pump a black and a yellow wire.

Engineered Cooling Products

Aluminum Radiators For Classic Muscle Cars, Trucks and Jeeps

speedcooling.com

speedcooling.com

http://www.griffinrad.com/load_details3.php?PartID=441&year=1987&make=Chevrolet&model=Corvette

swapping to a 200 amp alternator will frequently improve the operation of both the cars ignition and electric cooling fans

https://www.summitracing.com/parts/tff-8173nep/applications/year/1996

http://tech.corvettecentral.com/2011/02 ... fications/

http://www.dbelectrical.com/casearch.as ... ageSize=60

http://members.shaw.ca/corvette86/Cooli ... ontrol.pdf

http://www.dbelectrical.com/p-9594-alte ... -1993.aspx

http://forums.superchevy.com/corvette-f ... mediately/

http://www.dbelectrical.com/p-3478-ford ... t-101.aspx

http://www.hotrodlane.cc/NewTPI%20links ... ml#tpitech

viewtopic.php?f=32&t=2697&p=7100#p7100

http://www.justanswer.com/uploads/carfi ... vette1.pdf

http://www.justanswer.com/uploads/carfi ... vette2.pdf

http://www.racerpartswholesale.com/prod ... cessories2

http://tech.corvettecentral.com/2011/02 ... fications/

http://www.racerpartswholesale.com/prod ... cessories2

http://garage.grumpysperformance.co...sh-out-of-the-radiator-fins.11712/#post-54986

http://tech.corvettecentral.com/2011/02/1984-1996-corvette-cooling-fan-control-modifications/

http://www.summitracing.com/parts/prf-30111/overview/

http://www.stewartcomponents.net/Mercha ... Code=Therm

http://www.racerpartswholesale.com/prod ... cessories2

http://www.chevythunder.com/cts_diagnostics.htm

http://www.chevythunder.com/cts_diagnostic_pg2.htm

http://tech.corvettecentral.com/2011/02 ... fications/

http://members.shaw.ca/corvette86/Cooli ... ontrol.pdf

https://www.youtube.com/watch?v=YEaWeEtOeJ8

viewtopic.php?f=80&t=728&p=9217&hilit=sensor+mass#p9217

http://aspwholesale.com/index.php?act=v ... uctId=5159

viewtopic.php?f=57&t=149

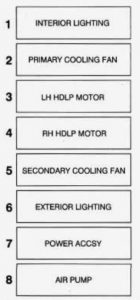

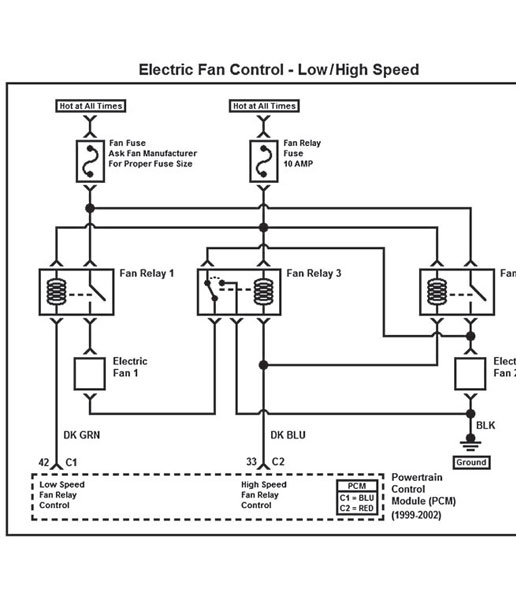

Manually spin the fan blade of the fan that doesn't work to

verify the fan motor isn't seized.

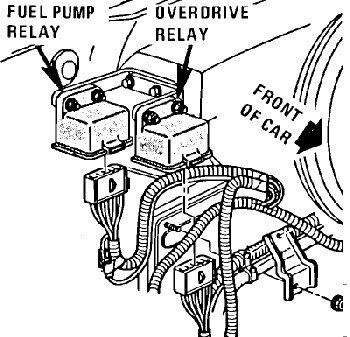

The fans use 3 relays mounted on the driver side

on the end of the radiator.

Primary cooling fan is an the driver side.

Secondary cooling fan is on the passenger side.

There are two modes of fan operation.

Both fans at half speed. 6 volts

Both fans at high speed. 12 volts.

There are two control lines the PCM grounds to

enable the fans.

PCM grounds the Dark Green wire for low speed.

Relay #1 is energized.

PCM grounds both the Dark Green wire and a Dark Blue

wire for high speed.

All three relays #1, #2 and #3 are energized.

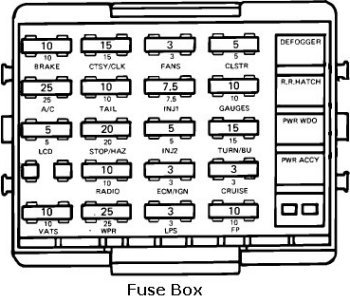

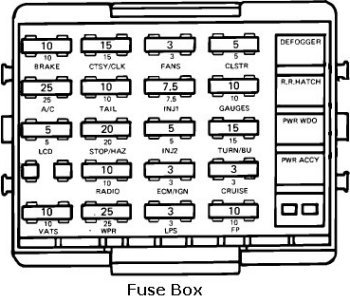

Three fuses protect the circuits.

Fan fuse 5 amp located on passenger side of the dash.

This must be good because you say one fan does run.

Primary coolant fan 30 amp Maxifuse located under the hood.

Must be good if the driver side fan works.

Secondary coolant fan 40 amp Maxifuse located under the hood.

You can identify the relays by the color of the wires that

go to the relay sockets.

Relay #1 has the following colored wires.

Pink, Dark Green, Red and a Light blue wire.

Relay #2

Pink, Dark Blue, White and 2 Black wires.

Relay #3

Pink, Dark Blue, Red and a White wire.

To test the fans turn the ignition On.

Manually ground the control lines. Stick a nail

or probe, jumper wire etc... into the bottom of

the relay socket and ground the Dark Green wire.

Both fans should run at low speed.

Ground the Dark Green wire and the Dark Blue

wire and both fans should run at high speed.

Another method you can use is to carefully pry/remove

the plastic cover off of the relays. You can then

manually energize the relays by pushing down

on the metal plate.

Push down on the plate on #1 relay and both fans

should run at slow speed.

Push down the metal plate on all relays and both

fans should run at high speed.

these charts are for the 1985-89 vette cooling fans

later corvette 1996

Pro tip before starting - Label your relays Relay 1, Relay 2, and Relay 3 according to the wiring diagram (your first post) and what your physical relays represent. Even if its just a sticky note. Get it all straight and stick to the same annotation while you troubleshoot.

You'll need a multimeter than can measure DC voltage and continuity:

Remove all three relays so you're only dealing with the sockets

DC Voltage tests:

1. Confirm 12V between the socket for pin 85 and the negative battery terminal on all 3 relay sockets

2. Confirm 12v between the socket for pin 30 and the negative battery terminal on relay sockets 1 and 2

Continuity tests:

1. Confirm continuity with the end of the dark green wire and the socket for pin 86 for relay 1

2. Confirm continuity with the end of the dark blue wire and the socket for pin 86 for relay 2 AND relay 3.

3. Confirm continuity between the socket for pin 87 for relay 1 and side B of the left cooling fan connector

4. Confirm continuity between side A of the left cooling fan connector and side B of the right cooling fanconnector AND the socket for pin 87 for relay #2.

5. Confirm continuity between the socket for pin 87 for relay #3 and Negative Battery Terminal

6. Confirm continuity between side A of the right cooling connector and Negative Battery Terminal.

Do the steps in order and use the negative battery terminal for your connection when I specify to. Verifying at the negative battery terminal will ensure you're circuit is making a good connection to the chassis ground. If it doesn't make it all the way back to the battery, it's a crap ground and testing it my way will reveal the problem

https://www.youtube.com/watch?v=vTl6UNMKjLc

THE DIAGRAM ABOVE HAS THE CORRECT WIRE COLORS

heres a bit of info I found posted elseware

" Next on the order of useless LT1 items is the 160 degree hermostat. GM made the LT1 engine run very hot, temperatures of 230 degrees are not at all uncommon. These hot temperatures promote reduced emissions and a cleaner burn. Research has also shown that engine wear is related to temperature and that too low a temperature can cause premature engine wear. The stock thermostat in an LT1 is 180 degrees, the only reason the car runs so hot is that the computer controlled fans allow it to do so. From the factory the cooling fans are not programmed to come on until the vehicle approaches 240 degrees. While the vehicle is moving temperatures are easily maintained near 180 degrees, the temperatures only climb when the car sits at idle. If one so desires the computer can be reprogrammed to turn the cooling fans on at a much lower temperature, it is possible to maintain a temperature of below 200 degrees with the stock thermostat in place. The question then becomes, why does the engine need to run cooler? Racers have long known that cooler air is denser than hot air, denser air means more fuel and more fuel and air means more power. So if the engine is kept cooler it doesn't heat up the incoming air charge as much and more power is made. The theory is sound and very much proven, but the LT1 throws a small wrench in the theory. Because of the nature of the LT1's reverse flow cooling system the intake manifold does not have coolant flowing through it. So although the LT1 intake still gets plenty hot, it does not vary with respect to coolant temperature nearly as much as a traditional intake manifold does. The result is an engine that is far less sensitive to it's own temperature as far as horsepower is concerned. I would not have believed this myself until I tried an experiment at the dyno. I iced down my intake until it was actually cold to the touch. I then proceeded to make back to back dyno runs until the car was very hot. From this experiment I found that there was absolutely no reduction in power output until engine temperature exceeded 230 degrees, a condition that will never occur as long as there is sufficient airflow over the radiator. As such I can say with certainty that a 160 degree thermostat makes no difference in power. I cannot prove the lower temperature thermostat increases engine wear, but at the very least it decreases your heater output in the winter. "

obviously you'll want to put the car up on a lift and clean out the radiator fins both in front and behind as the cars tend to vacuum up road trash, blocking air flow.

your fans are controlled by sensors and the ECU, so you might want to install a sensor that turns the fan on as soon as the car reaches about 180F rather than the stock 230F.

swapping to a 140-160-200 amp alternator makes a very noticeable difference in fan speed in some cars

http://www.dbelectrical.com/p-4436-corv ... -7888.aspx

http://www.ecklerscorvette.com/corvette ... -1995.html

viewtopic.php?f=36&t=1169

http://store.alternatorparts.com/extrem ... ifier.aspx

those temp switches come in a variety of temp ranges

http://www.summitracing.com/parts/HFM-ZFSWF/

185 f sensor

http://www.racerpartswholesale.com/prod ... cessories2

IF YOU DON,T HAVE THE SHOP MANUAL , AND YOUR HAVING COOLING ISSUES,THIS IS AN EXCELLENT TIME TO BUY ONE, BECAUSE THE SENSORS AND WIRING AND RELAYS ARE NOT EASILY TRACED & TESTED WITHOUT THE MANUAL

obviously your engines tune, air/fuel ratio and ignition timing have a large effect on your cars operation temperature,moving the coolant thru the block efficiently and allowing the heat to rapidly dissipate, to the outside air flow with an efficient large capacity aluminum radiator will greatly improve the cars cooling.

the stock radiator is barely adequate for an engine putting out significantly more power as more hp creates more heat.

a stock transmission cooler won,t keep up with an aftermarket high stall converter, if you drive the car hard either.

One factor many guys overlook is that the SENSORS and RELAYS controlling the fans and the VOLTAGE the ALTERNATOR supply's to the car have a huge effect on both when the fans kick on and how fast they spin, which in turn has a major effect on the low speed air flow thru the radiator

keep in mind a great deal of the heat in a radiator is generated by the transmission fluid cooling, requirement on auto trans cars so adding a large AUXILIARY trans cooler helps a great deal, if you add an engine OIL COOLER that further reduces the heat load on the radiator

keep in mind that the standard C4 corvette uses a REVERSE rotation water pump, and its not a true high volume design, aluminum water pumps will reduce weight on the front of the car,so think about that when selecting a water pump

Here are some causes of overheating:

* Bad Thermostat or clogged t-stat

* Cooling system leaks/low coolant levels

* mixing two non-compatible anti-freeze types

* defective or the wrong water pump

* Leaky Head Gasket

* vacuum leaks in intake

* wrong fuel/air mix ratio

* incorrectly installed belts

* crud blocking the airflow thru radiator

* blocked or restricted air flow,missing duct work

* defective sensors or connections too sensors

* slime or sediment in radiator tubes

* one or both Fans Not Working correctly

* Leaky Water pump

* defective fan relays

* blown fuses

* over heated transmission coolant

* low alternator voltage

* low oil levels in engine

* incorrect ignition timing

* partly blocked catalytic converters

* Lower Radiator Hose Collapsing

* *Slipping Belt - Check belt tension and condition. A loose belt that slips may prevent the water pump from circulating coolant fast enough

Your engine may not be overheating at all. Your temperature gauge or warning lamp may be coming on because of a faulty coolant sensor. Sometimes this can be caused by a low coolant level or air trapped under the sensor.

READ THIS THREAD

viewtopic.php?f=57&t=149&p=1078&hilit=t+stat+drill#p1078

http://tech.corvettecentral.com/2011/02/1984-1996-corvette-cooling-fan-control-modifications/

https://www.youtube.com/watch?v=YEaWeEtOeJ8

https://www.amazon.com/VIOFO-Circui...ocphy=9012039&hvtargid=pla-586493323860&psc=1

as mentioned you could use a fuse power tap,, but.. Ive generally just found a source for a switched power with a multi meter,

or tapped off the battery terminal and added a manual switch...depends on what I was trying to accomplish, Ive generally run 10 ga wire to a relay is any significant amp loads were anticipated,

and soldered in a relay and fuse as required.

https://www.summitracing.com/parts/...MI-rP_gp6F5AIVyAOGCh3PWAB_EAQYASABEgKCevD_BwE

https://www.amazon.com/PACK-AMP-Wat...DJGHS4MHT2D&psc=1&refRID=SDXCB01E5DJGHS4MHT2D

https://www.amazon.com/Ehdis-Truck-...=B01KFKEHMG&psc=1&refRID=SDXCB01E5DJGHS4MHT2D

https://www.youtube.com/watch?v=nbqa5gr4IA4

https://www.youtube.com/watch?v=swJOn64vBuE

https://www.youtube.com/watch?v=-bqIdUVBsMU

WATER PUMP

a quality radiator will be made from aluminum and have large cross flow tubes, read thru the links below,

theres several dozen sources but the better brand names, tend to have a better quality product than the cheaper imported versions

RADIATOR

OIL PAN & OIL COOLER

If your wiring up an aux electric fan ,yes I know your likely to just use the 14 ga or 12 ga you have, but after you do feel the wire after the fans run for 15 minutes and youll see why I strongly suggest 10ga stranded wire on any aux fan application

[color]

look thru this linked info, the links help

viewtopic.php?f=70&t=3504&p=9220&hilit=relay#p9220

viewtopic.php?f=50&t=3110&hilit=relay

5670.html

TRANSMISSION COOLER

many guys fail to realize that the combo of a high capacity baffled oil pan and an oil cooler can remove a great deal of your engine heat before the radiator, and coolant in the engine ever needs to start absorbing and transferring that heat to the outside air flow , ITS, high volumes of OIL FLOWING over the valve train and thru the bearing clearances and lubricating the rotating assembly , that is cooling many of the hotter components, and keeping that oil cool and flowing over those components is your first layer of defense on cooling the engine. its the volume of oil , and how effectively you keep the oil temps stable in the 210F-240F ranges and the quality and how well the oils filtered,more than the pressure that's important to your engines durability

heres some RELATED THREADS, with MUCH MORE DETAILED INFO

http://garage.grumpysperformance.com/index.php?threads/i-need-a-new-lt1-water-pump.10723/#post-47422

http://www.racerpartswholesale.com/prod ... cessories2

http://tpiparts.net/90_92_speed_density_sensors/

Mounting An Effective Trans Cooler On A C4 Corvette

now I know few cars with less room to mount an efficient oil cooler with a fan than a c4 corvette, and after I installed a 3200 rpm stall converter in my corvette it became obvious I needed an aux trans fluid cooler. theres very little under the hood room and ground clearance is already minimal...

garage.grumpysperformance.com

http://garage.grumpysperformance.com/index.php?threads/a-few-lt1-related-part-numbers-and-info.6224/

keep in mind theres DOZENS OF DIFFERENT CHEVY TEMP SENSORS, for OIL AND COOLANT AND AIR, SO BE SURE YOU SELECT THE ONE DESIGNED TO MATCH YOUR GAUGE AND APPLICATION

OPERATION

The electric cooling fan(s) are controlled by the PCM. The PCM controls the ground path for the three cooling fan relays. The relays are used to control the high current flow to power the cooling fan motors. Both fans operate together. When minimum cooling is required, the PCM energizes cooling fan relay #1 and both fans operate at low speed, since the fans are connected in series through cooling fan relay #3, and cooling fan relay #2 is open. When maximum cooling is required, the PCM energizes all three cooling fan relays. The left fan is still powered through cooling fan relay #1, but is now grounded through cooling fan relay #3. The right fan is now powered directly through cooling fan relay #2 and both fans operate at high speed.

LOW SPEED FANS

The cooling fans are controlled by the PCM based on inputs from the A/C system, Engine Coolant Temperature (ECT) sensor and Vehicle Speed Sensor (VSS).

The PCM will command low speed fans "ON" when Engine Coolant Temperature (ECT) is above 108°C (226°F). The PCM will turn the fans "OFF" when the temperature drops about 3°C (5°F). The minimum "ON" time for low speed fans is 50 seconds.

HIGH SPEED FANS

The PCM will command high speed fans "ON," when any of the following conditions exist at idle.

Certain Diagnostic Trouble Codes (DTCs) set.

ECT above 113°C (235°F).

A/C head pressure above 248 psi.

If the high speed fans were turned "ON," by the ECT, the PCM will switch the fans back to low speed when the temperature drops about 3°C (5°F). Minimum "ON" time for HI speed fans is 30 seconds.

86-89 fan wiring

GENERIC VERSION(above)

AUTOWIZ posted this bit of info, youll need

" There are 2 temp sensors. Or rather a sensor and a sender. The sender is for the gauge and has 1 wire and goes into the rear of bank 2 cylinder head in between cylinders 6 and 8 spark plugs. And the other is a 2 wire sensor for the ecu. This sensor mounts in the water pump on the front face of the engine. It is very possible to have a failed sensor for the ecu or a damaged harness or unplugged sensor and have the ecu read -40f for coolant temp. If this were the case then your fans would never be commanded on even though their circuits were intact. And also if this were the case then your gauge on the dash would still work because the 1 wire sender is still working. A scantool will show you. And a good scantool will let you command the fans on for testing the control circuit."

RELATED INFO

http://garage.grumpysperformance.com/index.php?threads/efi-and-scan-tool-software-links.469/

HIB POSTED THIS

"A 96 has two fans. Both run at the same time. The fans have two speeds low and high. When low fans are commanded the fans are wired in series. When high fans are commanded they are wired in parallel. There are three fan relays which operate the fans and which are controlled by the ECM.

"Low fans" is commanded by the ECM when either: certain DTCs are set, ECT is above 219°F, engine oil temp is above 270°F or A/C head pressure is above 189 psi. Also, when engine speed is over 3500 rpm and oil temperature is over 261°F low fans will come on. The fans will go off once CT drops about 11°F. If A/C head pressure kicks the fans on, it must drop to 150psi before the ECM will shut them off. Min. on time is about 50 seconds

IVE SEEN THIS INFO POSTED BUT NEED TO VERIFY IT

Go to the fan relays on the driver side of the radiator support. You will find the little green wires going into the relays are the ground signals from the computer to trigger the fan. Splice in a hard ground to the frame, and the fans will run as soon as you turn on the key, regardless of temp.

"High fans" is commanded by the ECM when either: certain DTCs are set, ECT is above 228°F, engine oil temp is above 277°F or A/C head pressure is above 225-psi. Also, when engine speed is over 3500 rpm and oil temp is over 266°F, the ECM will request high fans. The ECM will turn off high fans once coolant temp drops about 11° or A/C head pressure drops below 189 psi.

If you saw 260 on the digital display and the coolant boiled over, obviously the car was way overheating. If you ran the car like that for any length of time, engine damage is possible. Hopefully that's not the case.

I'd be looking for cooling system problems other than just the fans such as restricted air flow through the cooling stack. Also, overheating really stresses cooling system parts such as radiator hoses, heater hoses, belts, radiator caps and so forth. Considering the car is 15 years old, if those parts are original, I'd carefully inspect them for damage.

But, again, the best way to troubleshoot the cooling fans on a 90-96 is using the diagnostic table in the Service Manual. "

Last edited by a moderator: