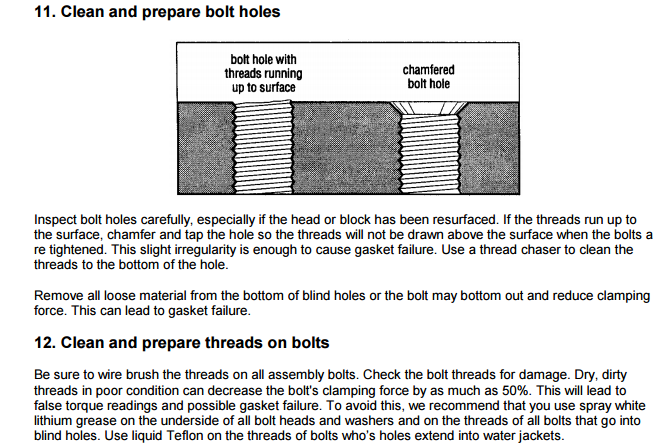

notice how the valve seat supporting casting in the cylinder head, throat extends out into the port and restricts the valve flow, a critical area that port and bowl clean -up can usually gain significant flow improvements

viewtopic.php?f=27&t=1831&p=4763&hilit=die+grinders+burrs#p4763

viewtopic.php?f=52&t=462&hilit=die+grinders+burrs

http://www.abs-products.com/specialty-tools/hogs-carbide-burrs.shtml

viewtopic.php?f=27&t=3379&p=8946&hilit=die+grinders+burrs#p8946

viewtopic.php?f=55&t=858&p=2669&hilit=burrs#p2669

viewtopic.php?f=27&t=24

viewtopic.php?f=59&t=6246&p=20376&hilit=drier#p20376

viewtopic.php?f=50&t=1266&p=2717&hilit=die+grinders+burrs#p2717

http://www.eastwood.com/engine-port...er&utm_medium=Merchant-Centre&SRCCODE=1SE1530

https://www.summitracing.com/int/par...1060/overview/

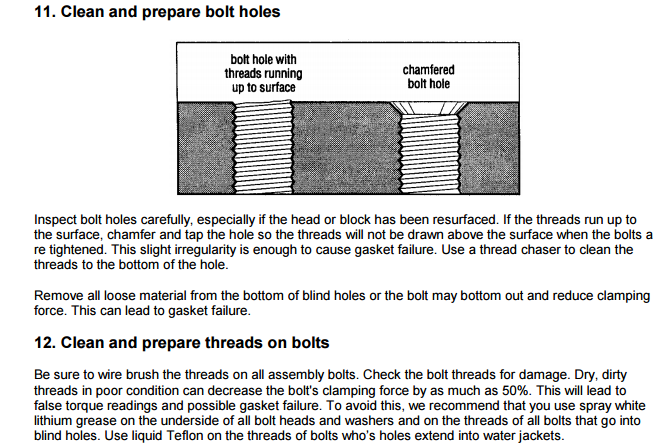

https://www.summitracing.com/int/parts/sum-900630

https://www.summitracing.com/int/parts/sum-900240

Stage 4 Melanoma Therapy

A Treatment for

Metastatic Melanoma.

melanomatreatmentpossibility.com

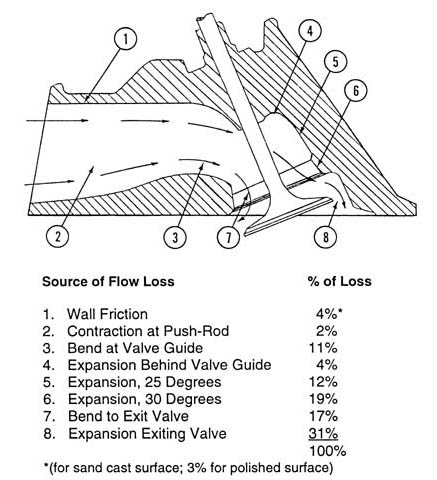

btw it helps a great deal to dip the burr in a shot glass of WD.40 about every 20-30 seconds as it helps keep it from picking up crud sticking to the burrs cutting edges

http://www.harborfreight.com/air-die-gr ... 99698.html

I usually buy these three at a time, they last a long time but think of them as disposable like the BURRS because they do wear out and at roughly $20 each are a bargain even if you need to occasionally pitch one in the dumpster

you can order this set of these long carbide burrs for about $36-$40

http://www.abs-products.com/specialty-tools/hogs-carbide-burrs.shtml

http://www.mcsdepot.com/browseproducts/ ... REACH.HTML

http://www.browntool.com/Default.aspx?t ... ductNumber

http://www.grainger.com/category/carbid ... alog/N-9o0

http://www.eastwood.com/8pc-dual-cut-ca ... shank.html

http://www.victornet.com/subdepartments ... /2150.html

http://www.carbideprocessors.com/sgs/long-shank/

http://www.pferdusa.com/products/202a/index.html

http://dewitt-tool.com/b_dc_oval.aspx

http://boroburrs.com/14-shank-burs/

http://www.falcontool.com/Falcon_Carbide_burs.pdf

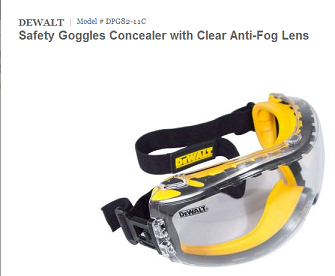

most of the time you'll find a few seconds time to put on safety equipment and the minimal cost spent is far FAR less than it costs in time and money to deal with the medical cost resulting from rushing into a job without their use!Ive generally used and strongly suggest you consider using, one or both of these when using angle grinders or while porting heads due to learning from past experiences

btw it helps a great deal to dip the burr in a shot glass of WD.40 about every 20-30 seconds as it helps keep it from picking up crud sticking to the burrs cutting edges

http://www.homedepot.com/p/DEWALT-Safet ... 220499-_-N

http://www.harborfreight.com/adjustable ... 46526.html

Speeds & Feeds for Carbide Burrs

Carbide burrs should typically be run at

1,500 - 3,000 Surface Feet Per Minute (SFPM)

SFPM = (RPM) (3.14) (DIAMETER) divided by 12

RPM = (SFPM) (12) divided by (3.14) (DIAMETER)

The following are general speed recommendations and may need to be adjusted to your specific application.

Carbide burrs and carbide rotary files, like high speed steel burrs and rotary files, are safest when used with the shank all the way into the collet and only the head is exposed.

Extreme care should be exercised when the head of the burr extends farther out. Too much pressure or too much speed might cause the shank to vibrate or bend while the burr is spinning, or teeth to break.

Carbide burrs up to 1/8" (3mm) diameter may be run at speeds up to 75,000 RPM, depending on the material being cut and amount of shank exposed. Go slower if the shank is exposed.

Extra long carbide burrs should be run 25% slower than a standard burr

Carbide burrs ranging in size from 3/16" (4.75mm) diameter to 3/8" (9.5mm) diameter, a 30,000 RPM die grinder is recommended.

Carbide burrs ranging in size from 1/4" (6.3mm) diameter to 1/2" (12.5mm) diameter can usually be run effectively with a 22,000 RPM die grinder.

1/8" (3mm) diameter: 45,000 - 90,000 RPM

1/4" (6mm) diameter: 23,000 - 45,000 RPM

1/4” (6mm) x 6” long: 17,000 – 33,000 RPM

3/8" (10mm) diameter: 15,000 - 30,000 RPM

1/2" (12mm) diameter: 11,000 - 22,000 RPM

3/4" (20mm) diameter: 7,500 - 15,000 RPM

1" (25mm) diameter: 5,500 - 10,000 RPM

If the shank is exposed, slow it down

Carbide burrs, like all cutting tools, are dangerous. Use caution when using any cutting tool, and always wear appropriate eye protection and safety equipment. Never exceed the manufacturer's recommended speeds and feeds for any cutting tools.

Never, ever, grab a spinning burr. Let the burr come to a complete stop before touching it. The fingers you save may be your own.

ALWAYS WEAR EYE PROTECTION WHEN USING A CARBIDE BURR

THE question about buying bare heads and having a local shop you trust add the valve train components and do the machine work , VS buying ready to run, off-the-shelf cylinder heads, comes up frequently.

the manufacturers can buy in volume and purchase valve train components a good deal cheaper than you can, and they can have heads machined in large batch jobs that also reduce machine work costs, but they are also trying to be competitive so they rarely select the top quality components, thus there's always a trade-off and you,ll rarely see top quality machine work, and the better components used in off the shelf heads for sale....that does not indicate the off-the-shelf heads are junk, but the manufacturers must balance quality and price to remain competitive.

Youll almost always find that the larger and better known brand name suppliers like

AFR,

DART,

BRODIX

EDELBROCK,

PROFILER,

TRICKFLOW,

have listed upgrades as options

yes quality varies and your going to be doing research or your not likely to get the best value per dollar or best potential performance.it would be foolish to not ask about the options cost and potential benefits of those upgrades.

related threads and sub linked info

http://garage.grumpysperformance.co...u-buy-bare-or-assembled-heads.534/#post-57612

http://garage.grumpysperformance.com/index.php?threads/ccing-my-heads.14187/#post-71989

http://garage.grumpysperformance.com/index.php?threads/sellecting-cylinder-heads.796/

http://garage.grumpysperformance.com/index.php?threads/porting-can-help.462/

http://garage.grumpysperformance.co...ng-combustion-chambers.2630/page-2#post-54342

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.com/index.php?threads/finding-a-machine-shop.321/#post-55314

http://garage.grumpysperformance.com/index.php?threads/multi-angle-valve-job-related.3143/#post-8387

http://garage.grumpysperformance.com/index.php?threads/how-to-lap-valve-seats.1159/#post-2362

ID suggest you select from heads from these sources

Jegs; 800/345-4545; Jegs.com

Summit Racing; 800/230-3030; SummitRacing.com

Scoggin-Dickey Parts Center; 800/456-0211; ScogginDickey.com

TRJ

http://trjperformance.com/cylinder-heads-top-end-kits-components/complete-heads/

TRICKFLOW

http://www.trickflow.com/egnsearch.asp? ... 4294867081

http://www.trickflow.com/customerservice

1-330-630-1555 • 1-888-841-6556

BRODIX

http://www.brodix.com/heads/heads.html

479.394.1075

DART

http://www.dartheads.com/products/cylinder-heads

Dart Machinery; 248/362-1188; DartHeads.com

AIR FLOW RESEARCH

http://www.airflowresearch.com/

toll free: 877-892-8844

tel: 661-257-8124

Patriot Performance

Patriot Performance; 888/462-8276; Patriot-Performance.com

PROMAX

http://www.competitionproducts.com/...c-Bare-Pair/productinfo/PMX9317/#.V2m23PkrLcc

RHS

http://www.racingheadservice.com/rhs/cylinder-headshtml

Toll Free: 877-776-4323

Local: 901-259-1134

EDELBROCK

http://www.edelbrock.com/automotive_new ... main.shtml

Edelbrock; 310/781-2222; Edelbrock.com

BMP (world products)

http://www.theengineshop.com/products/cylinder-heads

Tel: 631-737-0372

Fax: 631-737-0467

BUTLER PERFORMANCE

http://www.butlerperformance.com/products/cylinder_heads/cylinder_head_labor.html

866-762-7527

BLUE PRINT ENGINES

http://www.blueprintengines.com/ind...sb-chevy-aluminum-cylinder-heads-cnc-machined

1800-483-4263

PRO-FILER

https://www.profilerperformance.com/

937‐846‐1333