you do realize that , if you want to be sure of the cam you have in that new engine you purchased, you need to verify it and not take the sellers word...(if he even remembers)you could simply pull the water pump accessories and timing chain cover and look at the cam, I realize that that may seem like a big deal to the guys that have not done that hundreds of times, but even a new guy could get it done in a single days time.fr8dog said:I finally got to degree my cam tonight. First cam I've ever done on a build. How far off the cam card timing numbers before most builders would correct with adv/ret? My cam timing numbers were withing 1 to 1.5 degrees and my intake and exhaust C.L. were withing 1/2 a degree.

http://www.totalengineairflow.com/tools

https://www.summitracing.com/parts/cca-4760

http://www.wallaceracing.com/Calculators.htm

(btw when using a piston stop tool

if your standard strait probe/stop tool is not touching the piston due to the shallow entrance angle

youll want to remove ALL the spark plugs and back off ALL the rockers

on not only cylinder number one ,

but all the cylinders ,

so you can feel the engine as it moves/rotates

and make sure the cars not in gear so that the engine can be rotated much more easily when done manually,

this prevents the valves in cylinder number one from opening and removing the other spark plugs greatly reduces resistance due to compression.

yes your problem, is FAR from rare and in fact its very common most guys simply take an old spark plug,

put it in a vise and bust out the old porcilian center and re-thread the interior of the remaining metal hex.

or buy a tool like comps

https://www.summitracing.com/parts/...-_-comp-cams&gclid=CJ3wuuyJ8tACFYOFswodCKYKvw

you then buy a 6" threaded bolt, screw it into the plug body

be aware that on BBC engines with flat top pistons that probe bolt must be extended rather deeply ,

to contact the piston, simply because the plug thread angle is so shallow, this also means you'll want to remove all the spark plugs and make damn sure the engines in neutral when you manually turn the engine over so you easily feel the probe bolt contact the piston,

you don't want to bend the piston stop probe bolt or damage a piston crown,

bending a valve, or be fighting valve spring resistance

with similar thread pitch and thread that fully threaded bolt about 3" of that bolt extending past the spark plug base,

if your wondering how to turn a crank over to do test and diagnosing and cam installs you will benefit from the proper tools

IF you remove the spark plugs and take the car out of gear its fairly safe to turn the engine over manually,

using a breaker bar on the cranks damper retainer bolt,the problem is 99.9% of us are LAZY,

and just try it as the engine sits and eventually we strip the crank bolt or the crank snout threads

If the damper been removed the crank snout socket thats designed for your crank to turn the crank.

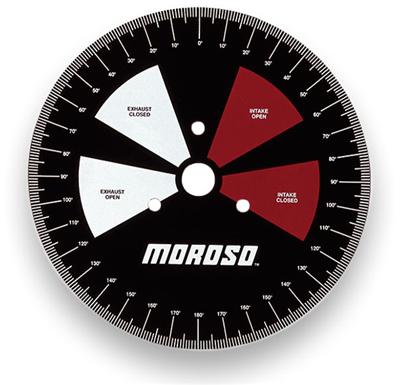

and hold the degree wheel while degreeing in the cam will be the route to take

shop carefully and ask questions the sockets and tools don,t fit universally, you'll need an assortment of several OF EACH TYPE ONCE YOU GET INTO ENGINE BUILDING SERIOUSLY

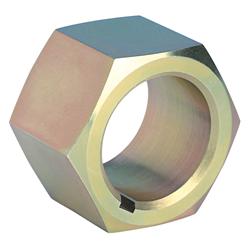

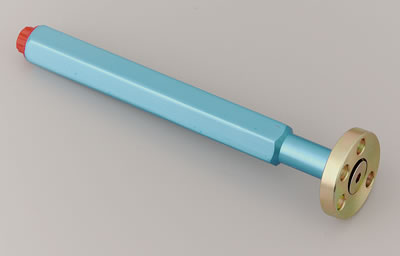

the crank socket like this that can turn the crank safely and firmly and accuratly mount a degree wheel is prefered

there are also crank turning nuts that fit individual crank sizes

most of us are too lazy to remove the damper/balancers

when purchasing a crank socket try to find one designed to easily accept and lock down a degree wheel

THE COMP SOCKETS ARE FAR MORE DURABLE STEEL

http://www.jegs.com/i/COMP+Cams/249/4914/10002/-1 LS ENGINES

http://www.jegs.com/i/COMP-Cams/249/479 ... ProductId= BBC ENGINES

http://www.jegs.com/i/COMP-Cams/249/479 ... ProductId= SBC ENGINES

there are over size extra strength damper bolts for sale that are less likely to strip

they sell an engine damper bolt on tool that fits some dampers that allows you to use a 1/2" braker bar rather easily

http://www.summitracing.com/parts/pro-66782?seid=srese1&gclid=CNqD0YXA48gCFUYYHwodBJ4DVA

IT MAKES LITTLE SENSE TO BUY the sockets that don.t have the provision for mounting the cam degree wheel to save a few dollars in my opinion

My cam card timing numbers are as follows:

Intake/exhaust lift .663/.618

Hyd Roller, @.050 duration int/exh 261/270

LSA 108, with intake C.L. of 104

@.050 timing Intake opens 26.5 closes 54.5

@.050 timing Exhaust opens 67 closes 23

Here are the numbers I got using a 14" degree wheel:

@.050 duration int/exh 260.5/267.5

@.050 intake opens 25 closes 55.5

@.050 exhaust opens 65.5 closes 22.0

intake C.L. 104.5 (measured)

exhaust C.L. 111.6 (measured)

LSA using using cam/calc =108.5

Intake C.L. using cam/calc =105.25

Are these close enough to the cam card or should I attempt to correct the differences here? Assuming my numbers here are correct, which way to correct these numbers.......advance or retard the crank key 2 degrees for 1 degree of cam correction?

Thanks,

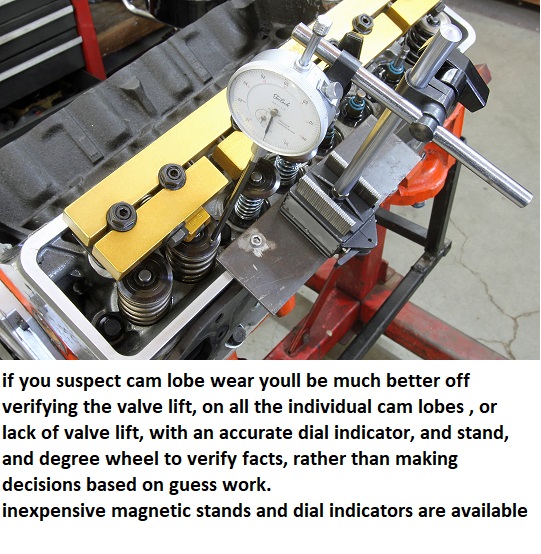

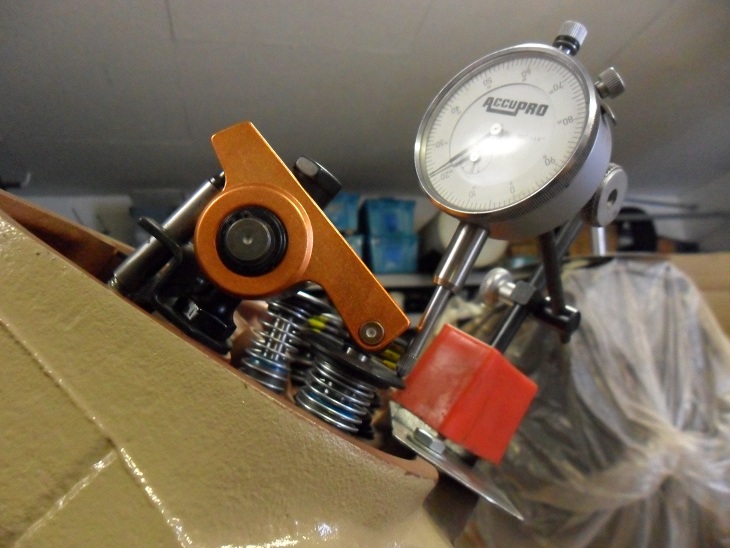

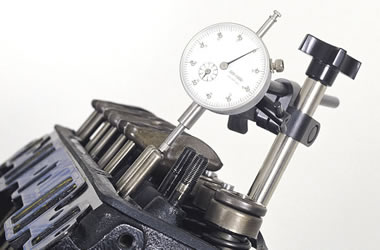

besides its a great excuse to buy a dial indicator, and a stand and degree wheel and damper puller (NEW TOOLS)

Damper tool (yes the damper needs to come off and the timing chain and upper gear too look at the end of the cam

http://www.amazon.com/OTC-4531-Harmonic-Balancer-Installer/dp/B000F5LIW4/?tag=viglink22466-20

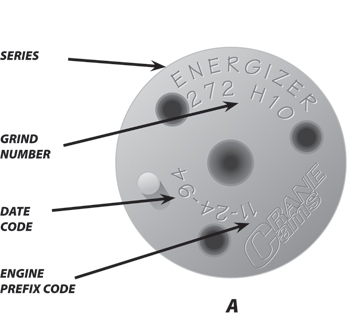

most manufacturers IDENTIFY OR mark cams under the timing gear mount surface

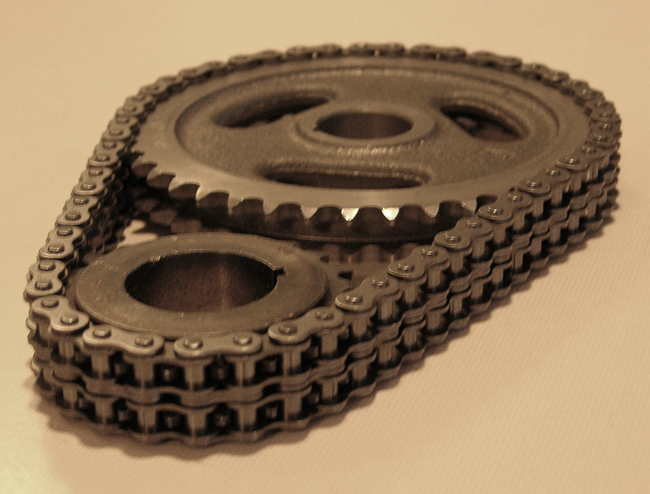

the double roller cloyes timing chains tend to last longer before they wear and have excess slack

and they can be used with the stock O.E.M timing chain cover

TRUE DOUBLE ROLLER TIMING CHAIN SETS FROM QUALITY MANUFACTURERS TEND TO BE MORE DURABLE

READ LINKs

http://garage.grumpysperformance.com/index.php?threads/identify-that-cam.8582/

http://garage.grumpysperformance.co...et-it-to-last-cam-install-info.90/#post-57942

http://garage.grumpysperformance.co...ng-cam-and-shifting-the-lca.10553/#post-44949

http://garage.grumpysperformance.com/index.php?threads/cam-degreeing.9010/#post-35474

OR

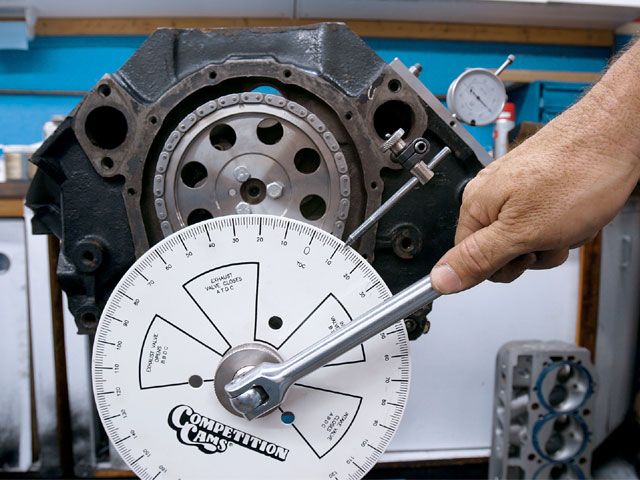

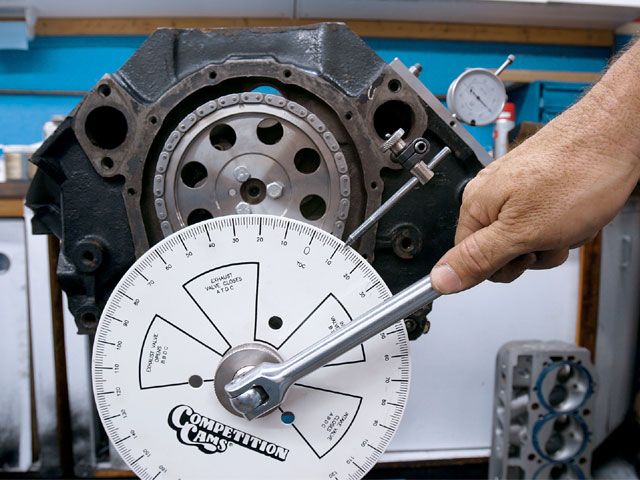

KNOWING WHAT YOUR DEALING WITH HELPS, you can use a degree wheel and a crank turning tool and graph out the lift vs degree of rotation, to verify the cam lobe lift/duration if you have the correct tools,

https://www.summitracing.com/parts/cca-4790/overview/

get the smaller 9" version for use in the car , cam degree checking

the 18" versions for checking on the engine stand

the knurled ring, on the damper crank turn tool, below, comes off the damper turn socket so the degree wheel slides on, then its replaced

https://www.summitracing.com/parts/mor-62191/overview/

a crank snout, turning socket,

http://www.summitracing.com/parts/pro-66830/overview/

https://www.harborfreight.com/multipositional-magnetic-base-with-fine-adjustment-5645.html

https://www.harborfreight.com/catalogsearch/result/index/?dir=asc&order=EAScore,f,EAFeatured+Weight,f,Sale+Rank,f&q=indicator+stand

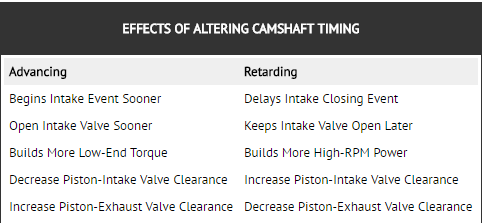

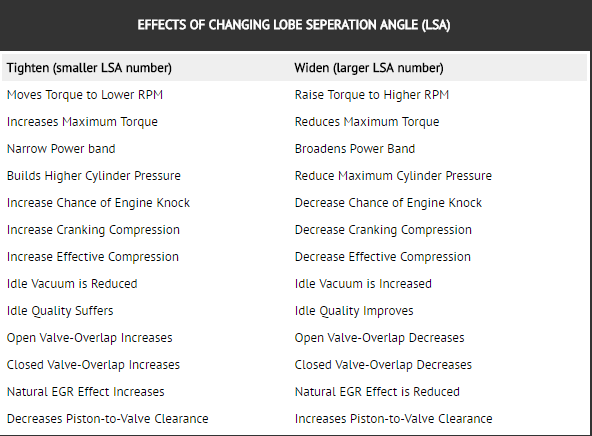

moving the cam center-line index you degree in the cam with, with an advance or retard bushing 4 degrees tends to shift the whole torque curve and power peak about 150-200rpm, now if moving that 1.5 degree timing shift with the cam index will move the peak power and torque curve 50-70 rpm are you really going to notice the difference? if it is then obviously you'll want to do whats required, keep in mind many cams are factory set up to install 4 degrees advanced if you use the factory dot-to-dot instal location

be aware that some crank gears have more than one index slot to index to the crank key and each slot is marked and you must use the correct matching marks indicating (ZERO) that match the crank slot marks.

I almost always index cams at split over lap or what youll see as about 4 degrees retarded from the dot-to-dot indexed location, advancing it seldom has the intended ,effective power range, keep in mind, the cam manufacturers got into the habit of setting the cam timing 4 degrees advanced to compensate for a good many people installing the cams dot-to-dot indexed who purchased cams that were a bit larger than ideal so they got less customer complaints.think about it it does little good to advance the cam timing to gain a bit of low rpm torque when your rarely using a 1/3 of the engines power potential in the lower rpm range, its the upper half of the rpm range thats critical to performance and advancing the cam has little effect over that rpm band UNLESS your over cammed to begin with.

retarding the existing cam lets say 4 degrees shifts the entire torque curve about 200 rpm higher in the rpm band,

so for example if the cam, runs best between

( 1900-rpm through 5400-rpm) that shift to retard it 4 more degrees would likely result in, (2100-rpm-5600-rpm)

so yes in effect it has a slight effect on the engine power curve, no question there,

but the change is much less noticable than it would be if you added enough more duration too the cam,

you select to run, too reach the identical valve close point while maintaining the same LSA (lobe seperation angle) and LCA (lobe center angle)

your engines power band will change with

displacement

,compression ratio,

the cams LSA .LCA,

and factors like runner length

runner,cross sectional area,

header primairy length and diameter,

collector length and diameter,

back pressure,

altitude, outside air temperature, and a dozen more factors,

indexing the cam is one of the most effective and least likely to cause driveability issues

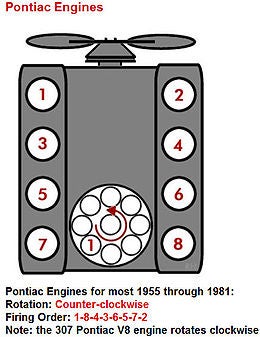

above is a picture of how a typical timing chain looks with the DOT-TO-DOT install having the crank gear at 12 o'clock ,(B) and cam gear (A)indexed at 6 o'clock, NOTICE THE WOOD RIFF KEY AT 2 O'CLOCK,IF ITS ANYPLACE ELSE YOU HAVE IT INDEXED INCORRECTLY(C) naturally youll need to rotate the engine one full revolution to get the upper gear index to 12 o'clock and the lower gear back to 12 o'clock before dropping in the distributor

use of a camshaft install handle generally reduces the chances of damaged cam bearings

IF you find the engines hard to start after a cam instal, theres a very good chance you installed the cam using the DOT-TO-DOT method and you forgot to rotate the engine one full revolution BEFORE dropping the distributor into the engine, you might be reading the info incorrectly, cams are generally installed using the DOT-TO-DOT method for easy installation without a degree wheel, this places the cam timing at TDC on the number 6 cylinder, simply rotating the engine one complete revolution after the cams installed using the DOT-TO-DOT method, brings the #1 cylinder up to TDC , thats when you drop the distributor into the engine with the distributor rotor facing cylinder #1

(remember the cam rotates at 1/2 the speed of the crank, so every other full rotation brings the cam and crank timing in alignment at TDC for number 1 cylinder.

If theres one constant fact I learned the hard way early on in this hobby its the fact that , most of us learn from our mistakes,and yes IVE made my share, but I do learn not to repeat the same ones twice,

30 minutes spent reading instructions very carefully can save hours of wasted effort

Cam degreeing

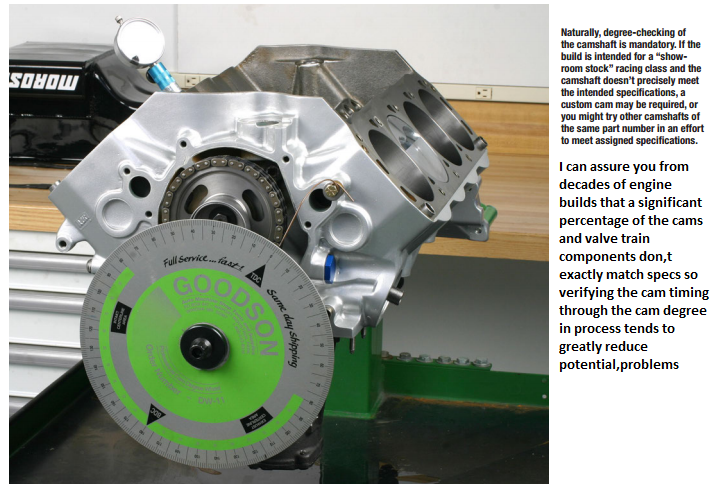

Degreeing – In the Camshaft New racing camshafts have a cam card included that shows the specifications for that camshaft. Degreeing In the cam means verifying that the valve timing and lift are close the specifications printed on the cam card. There are several reasons to degree in a...

garage.grumpysperformance.com

installing the cam strait up or even 2-3 degrees retarded ,

(what Id do, but of course you have a myriad of options)

might make more sense as it will move the whole power curve up about 150-200 rpm,

and significantly reduce any tendency toward detonation

why not try it both ways and see what you prefer

as its only going to take you a hour or two to change, to either advance or retarded or strait up,index

related threads

degree it in correctly and get it to last,cam install info,

IM frequently asked (why bother degreeing in a cam, the timing set comes with index marks to install it?) it basically comes down to, a question of do you accept a random install where the timing can be almost any place randomly or do you insist on maximizing the engines potential and know...garage.grumpysperformance.com

degreeing cam and shifting the lca

I finally got to degree my cam tonight. First cam I've ever done on a build. How far off the cam card timing numbers before most builders would correct with adv/ret? My cam timing numbers were withing 1 to 1.5 degrees and my intake and exhaust C.L. were withing 1/2 a degree...garage.grumpysperformance.com

the IDEAL cam LCA

http://www.enginebuildermag.com/Article ... teria.aspx http://www.circletrack.com/techarticles ... index.html viewtopic.php?f=52&t=2782&p=7214#p7214 viewtopic.php?f=52&t=112&p=139#p139 viewtopic.php?f=52&t=324 in case you don,t understand the chart, you take the engine displacement PER...garage.grumpysperformance.com

degree in that cam correctly

now if your like most guys if youve never done it your thinking it a huge complicated deal, ITS NOT,just follow the instructions in the links, Id advise you read them all because some are more clear on some parts of the process than others and youll get a better over/all feel for the process...garage.grumpysperformance.com

gear drives for cams

IVE used both CLOYES roller chain drives and SEVERAL DIFFERENT GEAR DRIVES FOR CAMS IN MY CORVETTES 383,SBC ENGINE,s the CLOYES chain drive is probably the best value, http://store.summitracing.com/partdetail.asp?part=CLO-9-3100&autoview=sku Ive run both setups on lots of motors,I'm running a...garage.grumpysperformance.com

chain vs gear drive cam

Gear drive VS chain cam drives, http://www.summitracing.com/parts/CLO-9-1100/ http://www.compcams.com/Technical/Instr ... es/117.pdf viewtopic.php?f=52&t=5734&p=17492#p17492 http://www.jegs.com/InstallationInstruc ... -20325.pdf http://www.jegs.com/InstallationInstruc ... 0-7892.pdf read...garage.grumpysperformance.com

http://www.jegs.com sells this KIT

Comp Cams #249-4796

http://www.jegs.com/i/Comp Cams/249/4796/10002/-1

and you can buy these

MOR-62191 $44 (wheel)

MOR-61755 $47 (SBC)

MOR-61756 $47.(BBC)crank sockets

SUM-900188 $17 (piston stop, head off)

SUM-900189 $6.95(piston stop, head on)

TFS-90000 $94.95 (degree kit)

youll also want two flat tappet solid lifters and two weak check springs

http://store.summitracing.com/partdetail.asp?autofilter=1&part=PRO-66838&N=700+115&autoview=sku

http://www.totalengineairflow.com/tools

http://www.summitracing.com/parts/cca-4760

you could buy these from summit racing or similar parts from jegs

http://garage.grumpysperformance.com/index.php?threads/timing-tabs-and-indicators.1015/

http://garage.grumpysperformance.co...our-real-advance-curve.4683/page-2#post-35828

http://garage.grumpysperformance.co...lem-getting-the-engine-started.63/#post-31920

http://garage.grumpysperformance.co...hanics-of-adv-ret-a-camshaft.4532/#post-12045

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=90&p=494&hilit=+bushings+advance#p494

http://garage.grumpysperformance.com/index.php?threads/finding-a-machine-shop.321/

http://garage.grumpysperformance.com/index.php?threads/finding-top-dead-center.967/

http://garage.grumpysperformance.co...ter-1-for-timing-ignition-cam.966/#post-18999

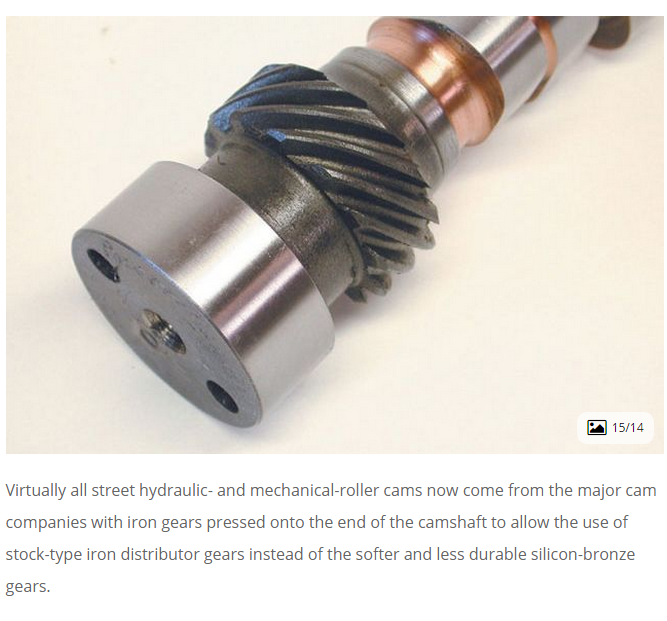

http://garage.grumpysperformance.com/index.php?threads/distributor-gear-wear.1701/

http://garage.grumpysperformance.co...hanics-of-adv-ret-a-camshaft.4532/#post-12045

http://garage.grumpysperformance.co...ectly-and-get-it-to-last-cam-install-info.90/

DETAILS AND INFO IN these threads might help

Last edited by a moderator: