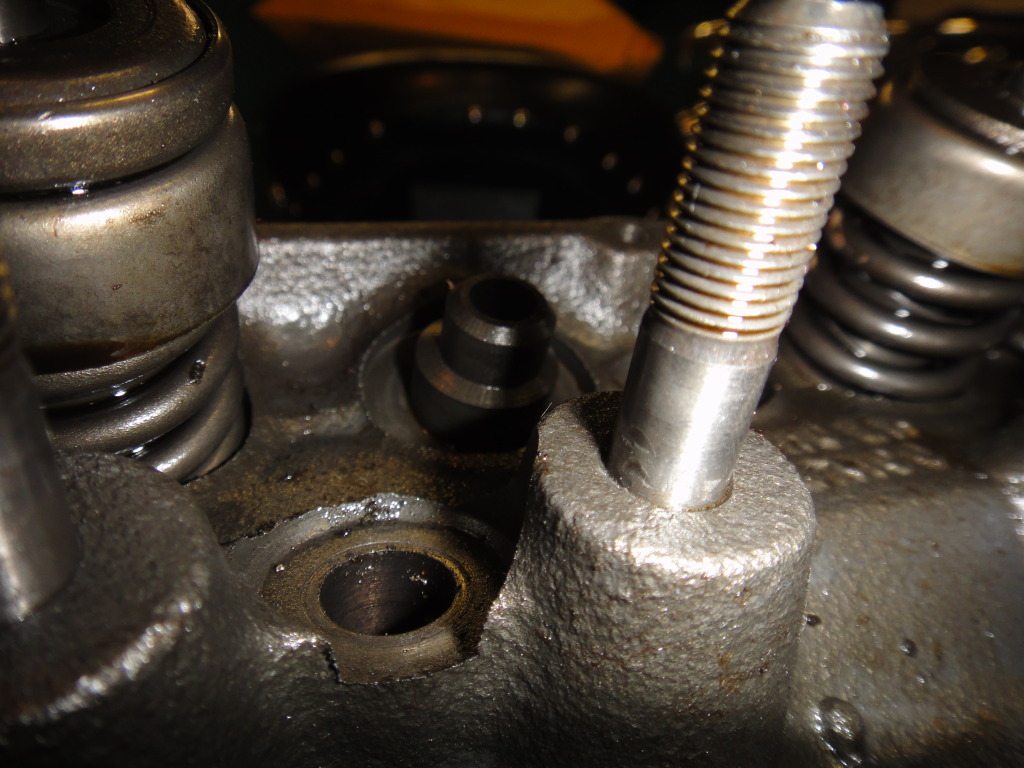

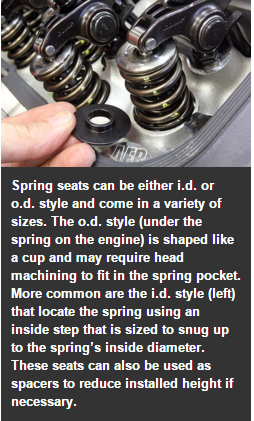

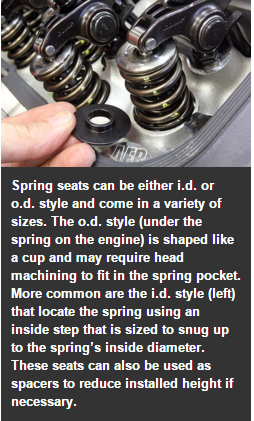

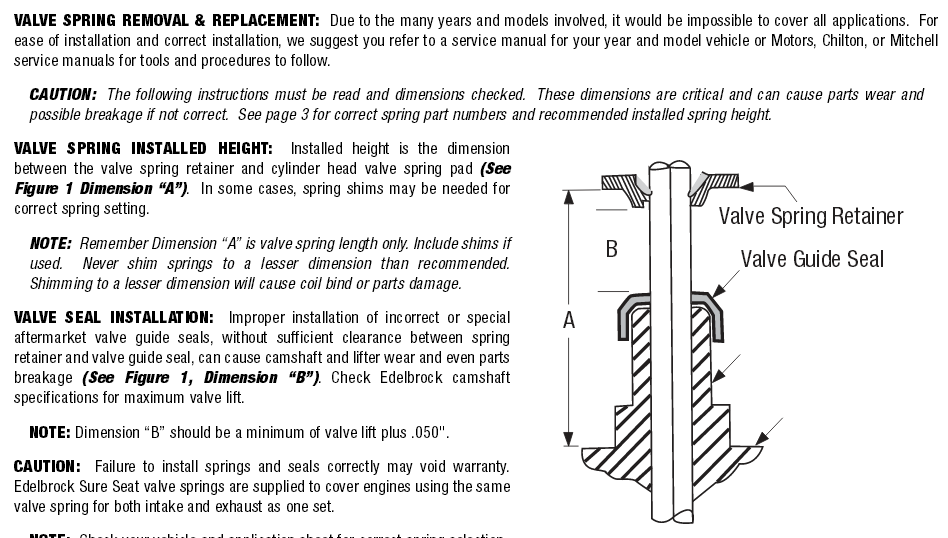

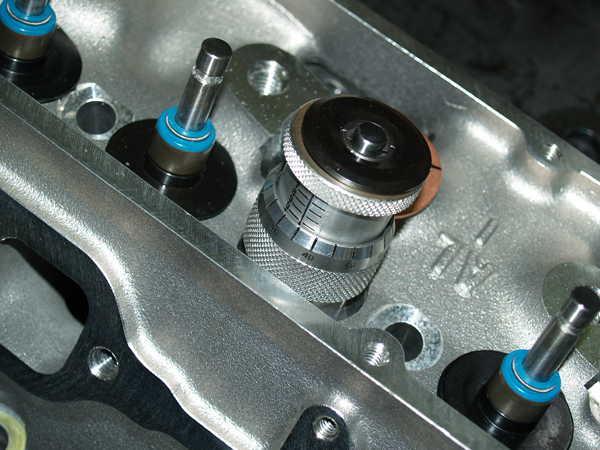

now you may not need these, on all applications, but aluminum heads can be damaged if the valve spring is run directly on the head surface ,and if the springs base can move around due to harmonics at high rpms it can cause valve control issues and wear issues and they are a good idea on even cast iron heads as they tend to stabilize the valve spring base in some applications, so a hardened steel spring seat or cup (WHICH YOU USE, DEPENDS ON APPLICATION) is used to allow the spring to spread its load against the head without damaging the heads machined surface.

one valve spring seat holds the inner diam. or the spring cup design can be used ,the other uses the outer diam. to locate the spring, and your heads machined pocket and valve spring diameter will usually be the deciding factor in the style used.

they also come in handy if the spring diam. you select is smaller that the machined seat in the heads, to locate the spring base and your shims (IF REQUITED) go UNDER the valve seat cup/seat

you might also want to keep in mind theres a great deal more to setting up a valve train than slapping some springs and retainers and keepers on the valves.

read thru the links and sub links as theres a great deal of useful info, that youll want to know.

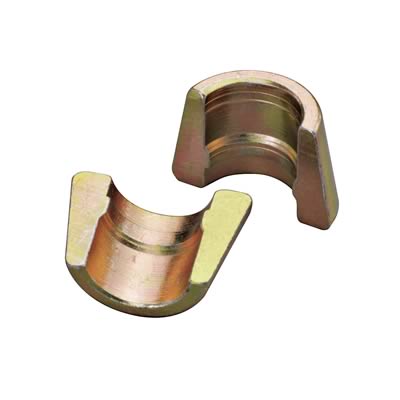

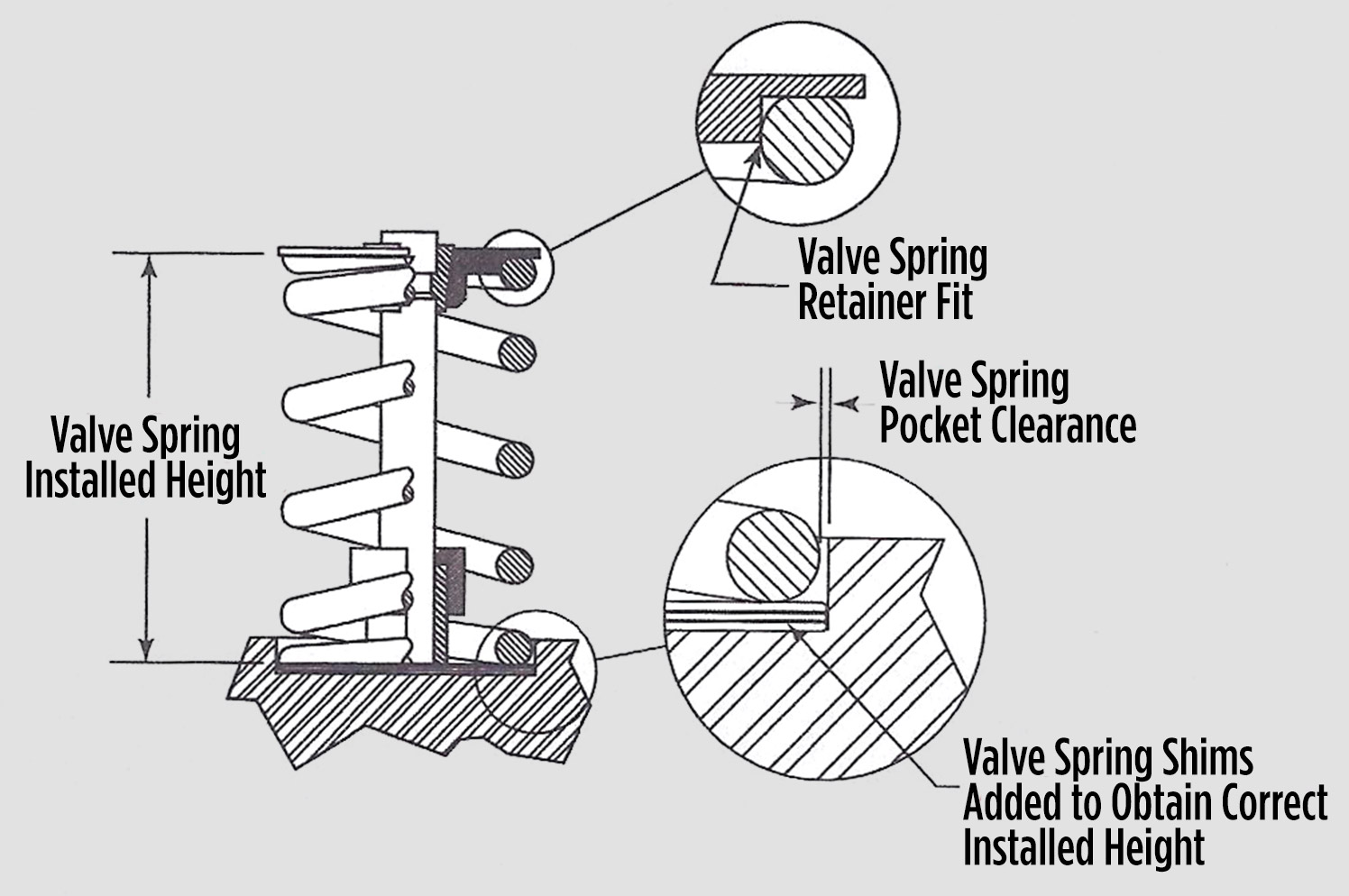

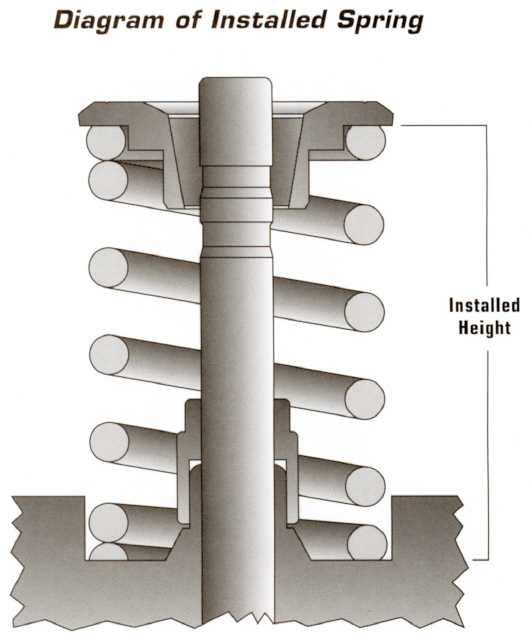

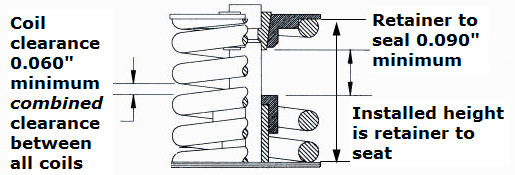

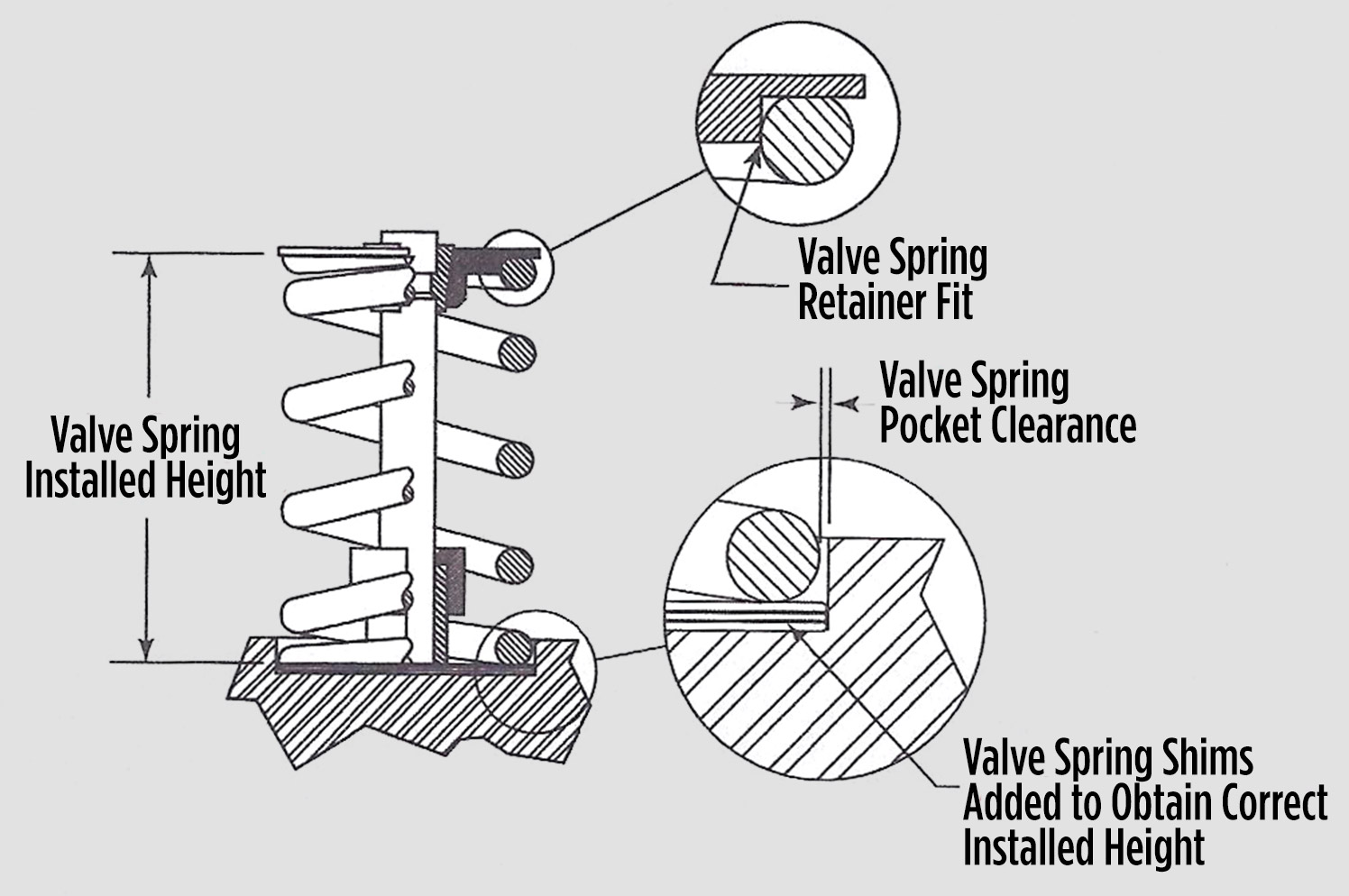

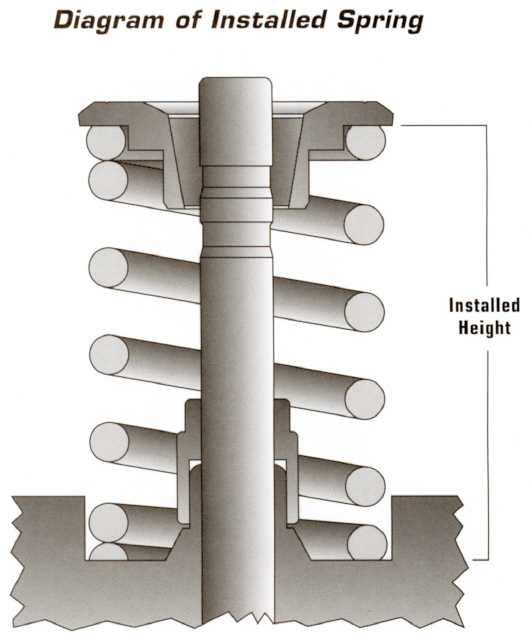

btw just a bit more info, there are valve spring retainers, valve spring seats, shims, valve retainer keepers etc. that can be used that have different sizes or depths that allow you to change the installed height, or relation of the spring to the valve stem , it compressed height, or the valve springs location in relationship to the stems locking groove

keep in mind shims under the valve springs can be used to raise the spring or shorten the valves installed height, valve locks and retainers can be purchased with non-O.E.M dimensions to adjust the valves installed height or spring load rates

you use either or both depending on the application

a .050 PLUS valve lock moves the retainer .050 higher on the valve stem with no other changes, a plus .050 retainer would move the retainer .050 higher with stock valve locks or an additional .050 if matched to .050 plus locks

if you used a plus .o50 retainer with a set of minus .o50 valve locks the retainer would remain at the stock height on the valve stem

http://www.jegs.com/p/Crane/746983/10002/-1

http://www.jegs.com/p/Moroso/764349/10002/-1

http://www.jegs.com/p/Manley/940089/10002/-1

http://www.jegs.com/p/Comp+Cams/757964/10002/-1

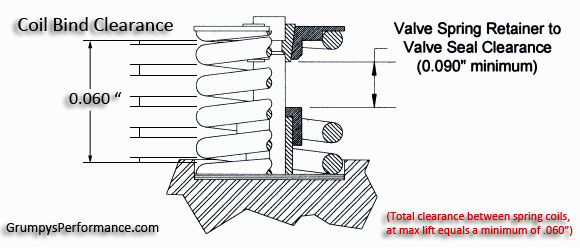

ID bet upwards of 70% of the people reading this have no clue what valve train clearance issues are or how they can effect engine durability ,so heres some linked related

info posted below

GET THIS valve spring clearance or spring bind clearance WRONG

EXPECT THIS AS A RESULT

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=1005

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=181

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=401

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=399

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=528

http://garage.grumpysperformance.com/index.php?threads/valve-springs.9613/#post-50556

valve spring seats or cups protect the heads, locate and maintain the spring base and restrict movement that can damage heads

theres a great deal more related info in these LINKED threads below,and their SUB LINKED INFO....yes it takes time to read thru the info,, (links and sub links) but would you rather spend the time reading now, building your engine correctly and kicking butt at the track,......or replacing expensive broken components later????

viewtopic.php?f=52&t=697

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=528

viewtopic.php?f=52&t=90

http://www.circletrack.com/techarticles ... index.html

viewtopic.php?f=52&t=974

testing valve springs is a WHOLE LOT EASIER with the correct tools like those linked in this thread

http://www.summitracing.com/parts/PRO-6 ... toview=sku

http://www.summitracing.com/parts/CCA-5333/?image=large

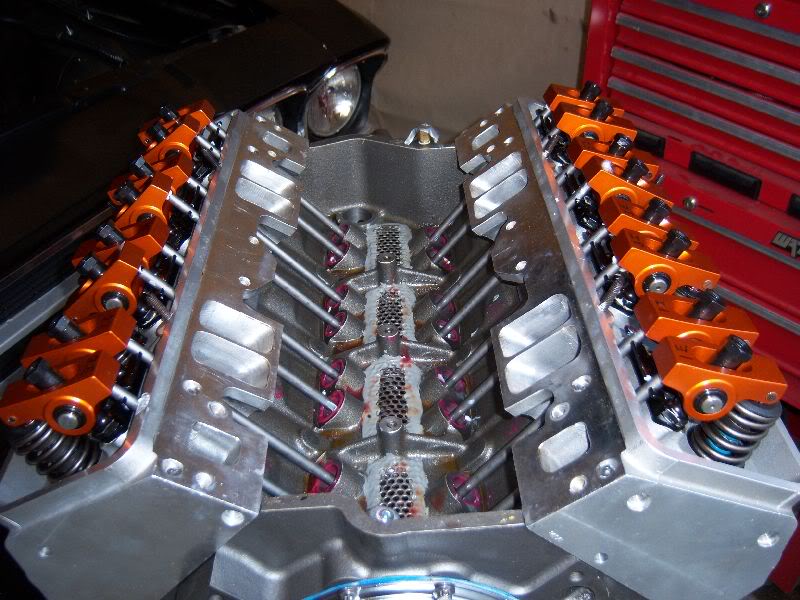

when the push rod geometry is correct, this is what the rocker rub marks look like on the valve tip

like Ive stated, many times youll need to verify ALL clearances, and the rocker stud to rocker slot clearance and the rocker polylocks to rocker body are usually overlooked

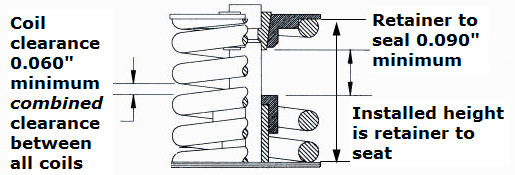

retainer to valve guide and retainer to rocker, coil bind and measuring the installed height are all required, its very common for some shops to just throw on valve springs without measuring the installed spring height and just reinstall seat shims., you can NEVER just assume your average machine shops done everything correctly...you need to verify, thats why you need a basic understanding of what your looking at and a few tools

it should be obvious that the slot clearance in some rockers , especially with poly locks significantly limits rocker movement before clearances become an issue

http://www.buxtonengineering.com/on_head_valve_spring_tester.php

A VALVE SPRING LOAD TESTER IS EXPENSIVE, BUT A GREAT TOOL TO HAVE

http://streetperformanceusa.com/i-72754 ... ester.html

http://www.summitracing.com/parts/pro-66775

http://www.summitracing.com/parts/pro-66776/overview/

I buy most of my replacement valve springs from these guys

http://www.racingsprings.com/

(866) 799-9417

http://www.racingsprings.com/Staff

heres their ph#

Toll Free (866) 799-9417

I always just order the springs retainers valve locks and spring seats as a package deal (NOT CHEAP BUT EVERYTHING WORKS AND FITS) then you just need shims under the valve spring seats occasionally to get the correct installed height

http://www.summitracing.com/parts/sum-900013/overview/

http://www.summitracing.com/parts/sum-900012/overview/

I watched that video, and my first thought was......

hey I'm a tool junky, so what will this new tool do for me?

great, she has a rocker and she is depressing a valve spring and it reads 100 psi?

NOW what?

what does that tell her?

how far was the valve spring depressed too read 100 psi? if the valve retainer moved with that tool on the rocker at 100 psi, then thats a ROUGH guide to finding valve seat pressure

what she has there is a tool that might easily be used to locate a cracked or broken valve spring,

but not much else in the way of useful data, could be found with it, so what good is it? you could most likely do that the old way with a quick push down on each valve spring retainer with an educated/ experienced thumb!

it sure looks like these gals were selected because they look good in a video, and they probably had a 3 minute long ..Q-card based education on what to say and do, for the VIDEO.....if it was my choice and looking at the tools vs what they do for me I'm rather inclined to spend $515 and get something REALLY USEFUL

$220 for this

http://www.summitracing.com/parts/pro-67597/overview/

$268 for this

http://www.summitracing.com/parts/pro-66774/overview/

$515 for this

http://www.summitracing.com/parts/pro-66776/overview/

PROFORM's new billet aluminum 1000 lb digital bench top spring tester is the most accurate way to check spring pressure. Check springs up to 1.5" in diameter and 3 7/8" in height. Digital display reads in 1 lb (0.5 kg) increments, and has a back lighting feature. Peak hold and automatic shutoff are other included features. Search part number 66776 at ProformParts.com for more information.

http://www.summitracing.com/parts/pro-66776

http://www.buxtonengineering.com/on_head_valve_spring_tester.php

http://www.racingsprings.com/1300-Series-/1300-Series-/sku/33

http://www.racingsprings.com/1500-series/sku/34

good quality valve springs are fairly expensive, youll generally pay $250-$450 for decent valve springs and many guys start looking for far cheaper imported sets, that are of lower quality, at bargain prices, the problem is that you generally find a set, and comparing the price it makes it hard for some guys to remember YOU GENERALLY GET WHAT YOU PAY FOR AND THERE'S A DARN GOOD REASON THE IMPORTED PARTS ARE CHEAPER

one valve spring seat holds the inner diam. or the spring cup design can be used ,the other uses the outer diam. to locate the spring, and your heads machined pocket and valve spring diameter will usually be the deciding factor in the style used.

they also come in handy if the spring diam. you select is smaller that the machined seat in the heads, to locate the spring base and your shims (IF REQUITED) go UNDER the valve seat cup/seat

you might also want to keep in mind theres a great deal more to setting up a valve train than slapping some springs and retainers and keepers on the valves.

read thru the links and sub links as theres a great deal of useful info, that youll want to know.

btw just a bit more info, there are valve spring retainers, valve spring seats, shims, valve retainer keepers etc. that can be used that have different sizes or depths that allow you to change the installed height, or relation of the spring to the valve stem , it compressed height, or the valve springs location in relationship to the stems locking groove

keep in mind shims under the valve springs can be used to raise the spring or shorten the valves installed height, valve locks and retainers can be purchased with non-O.E.M dimensions to adjust the valves installed height or spring load rates

you use either or both depending on the application

a .050 PLUS valve lock moves the retainer .050 higher on the valve stem with no other changes, a plus .050 retainer would move the retainer .050 higher with stock valve locks or an additional .050 if matched to .050 plus locks

if you used a plus .o50 retainer with a set of minus .o50 valve locks the retainer would remain at the stock height on the valve stem

http://www.jegs.com/p/Crane/746983/10002/-1

http://www.jegs.com/p/Moroso/764349/10002/-1

http://www.jegs.com/p/Manley/940089/10002/-1

http://www.jegs.com/p/Comp+Cams/757964/10002/-1

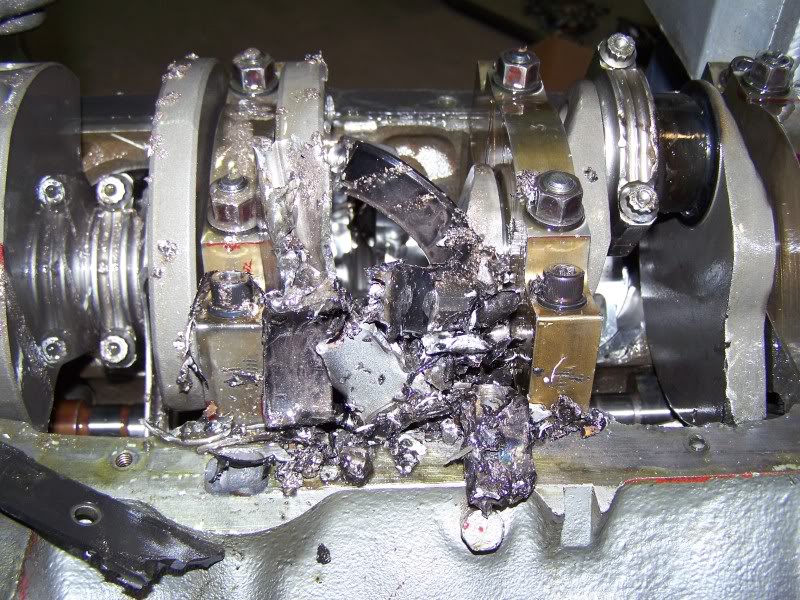

ID bet upwards of 70% of the people reading this have no clue what valve train clearance issues are or how they can effect engine durability ,so heres some linked related

info posted below

GET THIS valve spring clearance or spring bind clearance WRONG

EXPECT THIS AS A RESULT

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=1005

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=181

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=401

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=399

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=528

http://garage.grumpysperformance.com/index.php?threads/valve-springs.9613/#post-50556

valve spring seats or cups protect the heads, locate and maintain the spring base and restrict movement that can damage heads

theres a great deal more related info in these LINKED threads below,and their SUB LINKED INFO....yes it takes time to read thru the info,, (links and sub links) but would you rather spend the time reading now, building your engine correctly and kicking butt at the track,......or replacing expensive broken components later????

viewtopic.php?f=52&t=697

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=528

viewtopic.php?f=52&t=90

http://www.circletrack.com/techarticles ... index.html

viewtopic.php?f=52&t=974

testing valve springs is a WHOLE LOT EASIER with the correct tools like those linked in this thread

http://www.summitracing.com/parts/PRO-6 ... toview=sku

http://www.summitracing.com/parts/CCA-5333/?image=large

when the push rod geometry is correct, this is what the rocker rub marks look like on the valve tip

like Ive stated, many times youll need to verify ALL clearances, and the rocker stud to rocker slot clearance and the rocker polylocks to rocker body are usually overlooked

retainer to valve guide and retainer to rocker, coil bind and measuring the installed height are all required, its very common for some shops to just throw on valve springs without measuring the installed spring height and just reinstall seat shims., you can NEVER just assume your average machine shops done everything correctly...you need to verify, thats why you need a basic understanding of what your looking at and a few tools

it should be obvious that the slot clearance in some rockers , especially with poly locks significantly limits rocker movement before clearances become an issue

http://www.buxtonengineering.com/on_head_valve_spring_tester.php

A VALVE SPRING LOAD TESTER IS EXPENSIVE, BUT A GREAT TOOL TO HAVE

http://streetperformanceusa.com/i-72754 ... ester.html

http://www.summitracing.com/parts/pro-66775

http://www.summitracing.com/parts/pro-66776/overview/

I buy most of my replacement valve springs from these guys

http://www.racingsprings.com/

(866) 799-9417

http://www.racingsprings.com/Staff

heres their ph#

Toll Free (866) 799-9417

I always just order the springs retainers valve locks and spring seats as a package deal (NOT CHEAP BUT EVERYTHING WORKS AND FITS) then you just need shims under the valve spring seats occasionally to get the correct installed height

http://www.summitracing.com/parts/sum-900013/overview/

http://www.summitracing.com/parts/sum-900012/overview/

I watched that video, and my first thought was......

hey I'm a tool junky, so what will this new tool do for me?

great, she has a rocker and she is depressing a valve spring and it reads 100 psi?

NOW what?

what does that tell her?

how far was the valve spring depressed too read 100 psi? if the valve retainer moved with that tool on the rocker at 100 psi, then thats a ROUGH guide to finding valve seat pressure

what she has there is a tool that might easily be used to locate a cracked or broken valve spring,

but not much else in the way of useful data, could be found with it, so what good is it? you could most likely do that the old way with a quick push down on each valve spring retainer with an educated/ experienced thumb!

it sure looks like these gals were selected because they look good in a video, and they probably had a 3 minute long ..Q-card based education on what to say and do, for the VIDEO.....if it was my choice and looking at the tools vs what they do for me I'm rather inclined to spend $515 and get something REALLY USEFUL

$220 for this

http://www.summitracing.com/parts/pro-67597/overview/

$268 for this

http://www.summitracing.com/parts/pro-66774/overview/

$515 for this

http://www.summitracing.com/parts/pro-66776/overview/

PROFORM's new billet aluminum 1000 lb digital bench top spring tester is the most accurate way to check spring pressure. Check springs up to 1.5" in diameter and 3 7/8" in height. Digital display reads in 1 lb (0.5 kg) increments, and has a back lighting feature. Peak hold and automatic shutoff are other included features. Search part number 66776 at ProformParts.com for more information.

http://www.summitracing.com/parts/pro-66776

http://www.buxtonengineering.com/on_head_valve_spring_tester.php

http://www.racingsprings.com/1300-Series-/1300-Series-/sku/33

http://www.racingsprings.com/1500-series/sku/34

good quality valve springs are fairly expensive, youll generally pay $250-$450 for decent valve springs and many guys start looking for far cheaper imported sets, that are of lower quality, at bargain prices, the problem is that you generally find a set, and comparing the price it makes it hard for some guys to remember YOU GENERALLY GET WHAT YOU PAY FOR AND THERE'S A DARN GOOD REASON THE IMPORTED PARTS ARE CHEAPER

Last edited by a moderator: