most guys know by now that the sbc 400 block was cast without coolant passage clearance between the cylinders, unlike those other 265-350 sbc blocks (siamesed castings)

what many guys don,t know is that installing sbc heads on a 400 block without drilling additional steam holes in the heads that will be used can OCASIONALLY cause heat related problems if the engines used at lower engine speeds for extended periods of time, for example in traffic at low speeds where both the coolant flow rates thru the block and air flow thru the radiator is a good deal slower than if your cruising along at 70mph on the interstate highway and the engines spinning 2500rpm or better.keep in mind good aftermarket aluminum heads and a high flow water pump and an aluminum radiator go a long way toward cooling an engine that the marginal factory components won,t.

IM forced to point out that the DART aftermarket block has far thicker decks .main cap webs, main caps and larger water passages making it a far better choice for a 400 style sbc base engine block.

If your seriously thinking of builoding a 400 based sbc that will exceed about 550 horse power Id sure suggest use of the far stronger DART block before you dump hundreds of dollars into machining a 35-40 plus year old casting.

generally having heads with steam holes and a matching head gasket is the best route with an engine based on a 400 block with its siamesed cylinder bore casting, yes youll find lots of guys running 400 base engines with a decent radiator and aluminum heads, a high volume water pump and yes they get away with it. that doesn,t mean it won,t tend to run cooler with the steam holes in the heads and the correct gasket.

__________________

http://garage.grumpysperformance.co...ng-piston-pin-height-compression-height.5064/

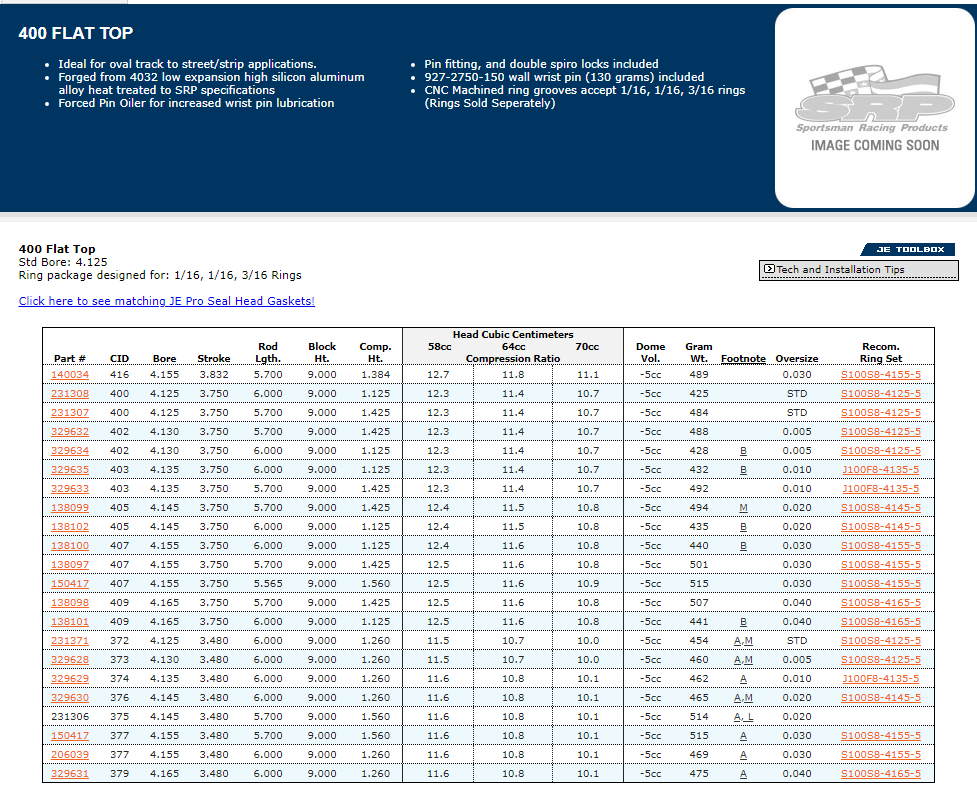

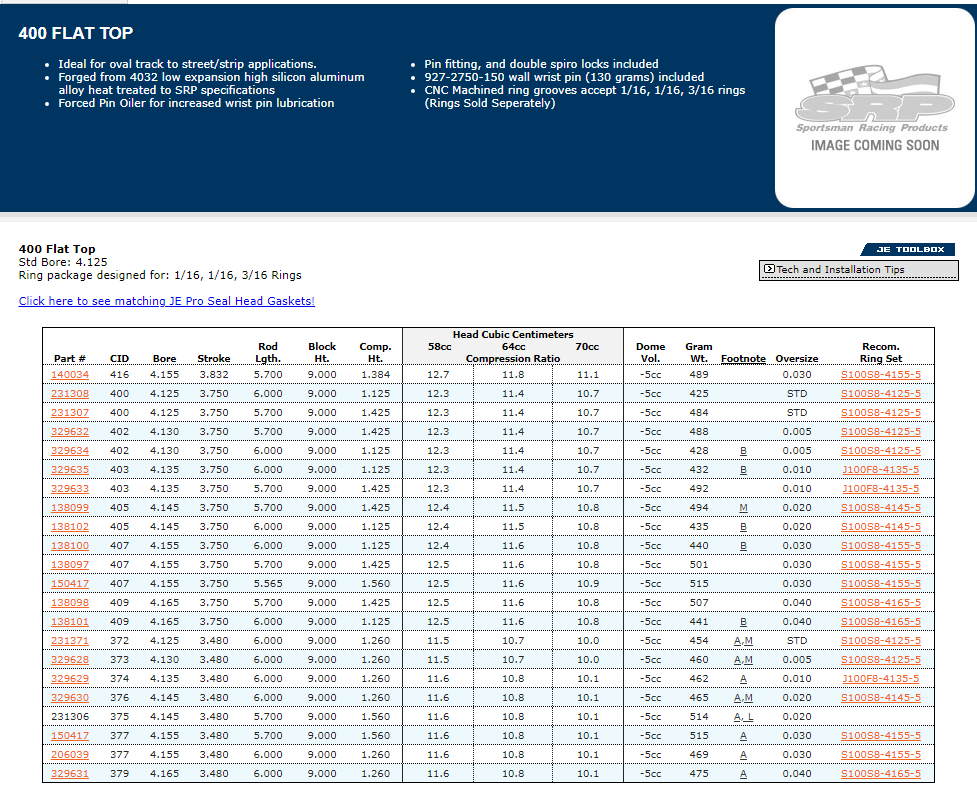

Specs

if you change to much cheaper and much stronger 5.7" connecting rods the less common compression height pistons are not an issue

youll have dozens of choices in a 4.125-4.165 bore diam. with a 5.7" rod

keep in mind the old O.E.M. rods have already been through millions of stress cycles and they are a weak design

resizing, , refurbishing the original 400 connecting rods, and replacing

just the connecting rod bolts will cost far more than the SCAT 5.7" aftermarket rods that are at least TWICE as strong

.

http://www.scatcrankshafts.com/rods/

https://www.speedwaymotors.com/KB-Claimer-Chevy-400-Hypereutectic-Pistons-Flat-Top-57-Rod,33222.html

5.565 rods

http://www.herbertcams.com/espcrs5565b-3d-sb-chevy-5-565-4340-forged-h-beam-rods/

https://www.stevemorrisengines.com/...cks/sbc/sbc-4340-forged-h-beam-rods-5565.html

5.7" rods

https://www.speedwaymotors.com/Smal...el-I-Beam-Rods-5-7-Inch-Bushed-Pin,29376.html

https://www.speedwaymotors.com/Scat...340-I-Beam-Rods-5-7-Inch-Bushed-Pin,6608.html

piston for 5.7 rod

https://www.summitracing.com/parts/slp-h615cp

piston for 5.565 rods

https://www.summitracing.com/parts/slp-h400cp

read thru this link

http://www.gregsengine.com/350to400.htm

RB69SS396Conv posted this info

--------------------------------------------------------------------------------

There are only 3 400 block castings; 511, 509, 817. The 511 is the early one (70-72), the 509 & 817 are the later ones.

The later ones are possibly "better", which is NOT the same as saying that the 511 is "not good". Maybe, just not quite as good, for SOME things. But for a street or moderate racing application, it's not a significant difference, and I wouldn't let that bother me if I was you. For a budget hot street motor it'll be perfectly fine.

It'll almost certainly have factory 4-bolt main caps installed on it.

The later blocks had more metal around the main webbing area, so they're "stronger". People talk about "4-bolt" vs "2-bolt", but that's not really the difference; the # of bolts is incidental. It happens that the factory put 4-bolt caps on the early ones and 2-bolt caps on the later. But the REAL difference in the blocks is early vs late, not 2- vs 4-bolt. The bolts themselves aren't what makes the ones "better" than the other.

Yes the heads that came on 400s are absolute crap. If it still has the original heads, throw then in the trash, they're pretty much hopeless; and get something decent. Vortecs wouldn't be a bad choice. Other than that, you pretty much need to go to the aftermarket. Double-humps are marginal at best. If you use them, be sure that they have the accessory holes in the ends, if your car's accessories need them, as anything from 69 up will; it's nearly impossible to fake those holes. You can't just "drill" them in heads that don't have them, because there's nothing there to drill into.

It's VERY VERY easy to get 400 HP out of a 400, with the right heads. Hard to avoid getting that much in fact. A Comp XE or a Voodoo cam in the 224-230° kind of range, NOT a Summit cam, "RPM" cam, or any of the old stock cams like the 151 or other similar garbage, are the best choice with Vortecs or other stock heads, or even alot of the aftermarket ones. The large CID needs the added exhaust flow from the larger exh lobe.

Yes, virtually all 350 parts will fit a 400; the specific exceptions being the crank damper and flywheel, if you stick with the factory "external balance" stuff. Also you'll need to drill the steam holes in the heads if they don't already have them, which you can do yourself with a hand drill, no sense in paying somebody else to do that if you don't have to or it's not just a matter of convenience (like, they're already doing some other machine work, and you get them to do that at the same time).

OTOH, "fit" is not the same as "is the right thing". Remember, you're dealing with a motor that's on up into the big block cubes range, so all of the parts have to be chosen to support that kind of size. Stuff that's borderline radical in a 350, tends to be mild street stuff in a 400.

You'll get best results with a small chamber head (64cc) and pistons with a small dish or (ideally) a "reverse dome", to put the ACTUAL CR (calculated including the ACTUAL MEASURED deck clearance) in the high 9s if the heads are iron, or mid 10s with aluminum heads. Deck clearance is CRUCIAL: don't be fooled by the "catalog" CR listings, or just "assume" that there is no deck clearance. With most "rebuilder" type pistons including TRWs for example, the deck clearance, which is how far "down in the hole" the pistons are at TDC, can be nearly .050" in some blocks, which in turn can cause the ACTUAL CR to be a full point lower than some randomly guessed and "calculated" CR. Any CR calculator is only as accurate as theh numbers you put into it. "

what many guys don,t know is that installing sbc heads on a 400 block without drilling additional steam holes in the heads that will be used can OCASIONALLY cause heat related problems if the engines used at lower engine speeds for extended periods of time, for example in traffic at low speeds where both the coolant flow rates thru the block and air flow thru the radiator is a good deal slower than if your cruising along at 70mph on the interstate highway and the engines spinning 2500rpm or better.keep in mind good aftermarket aluminum heads and a high flow water pump and an aluminum radiator go a long way toward cooling an engine that the marginal factory components won,t.

IM forced to point out that the DART aftermarket block has far thicker decks .main cap webs, main caps and larger water passages making it a far better choice for a 400 style sbc base engine block.

If your seriously thinking of builoding a 400 based sbc that will exceed about 550 horse power Id sure suggest use of the far stronger DART block before you dump hundreds of dollars into machining a 35-40 plus year old casting.

generally having heads with steam holes and a matching head gasket is the best route with an engine based on a 400 block with its siamesed cylinder bore casting, yes youll find lots of guys running 400 base engines with a decent radiator and aluminum heads, a high volume water pump and yes they get away with it. that doesn,t mean it won,t tend to run cooler with the steam holes in the heads and the correct gasket.

__________________

http://garage.grumpysperformance.co...ng-piston-pin-height-compression-height.5064/

Specs

- Comp Height 5.565" Rod - 1.561

- Comp Height 5.7" Rod - 1.433

- Comp Height 6.0" Rod - 1.13

- Pin Diameter - 0.9272

if you change to much cheaper and much stronger 5.7" connecting rods the less common compression height pistons are not an issue

youll have dozens of choices in a 4.125-4.165 bore diam. with a 5.7" rod

keep in mind the old O.E.M. rods have already been through millions of stress cycles and they are a weak design

resizing, , refurbishing the original 400 connecting rods, and replacing

just the connecting rod bolts will cost far more than the SCAT 5.7" aftermarket rods that are at least TWICE as strong

.

http://www.scatcrankshafts.com/rods/

https://www.speedwaymotors.com/KB-Claimer-Chevy-400-Hypereutectic-Pistons-Flat-Top-57-Rod,33222.html

5.565 rods

http://www.herbertcams.com/espcrs5565b-3d-sb-chevy-5-565-4340-forged-h-beam-rods/

https://www.stevemorrisengines.com/...cks/sbc/sbc-4340-forged-h-beam-rods-5565.html

5.7" rods

https://www.speedwaymotors.com/Smal...el-I-Beam-Rods-5-7-Inch-Bushed-Pin,29376.html

https://www.speedwaymotors.com/Scat...340-I-Beam-Rods-5-7-Inch-Bushed-Pin,6608.html

piston for 5.7 rod

https://www.summitracing.com/parts/slp-h615cp

piston for 5.565 rods

https://www.summitracing.com/parts/slp-h400cp

read thru this link

http://www.gregsengine.com/350to400.htm

RB69SS396Conv posted this info

--------------------------------------------------------------------------------

There are only 3 400 block castings; 511, 509, 817. The 511 is the early one (70-72), the 509 & 817 are the later ones.

The later ones are possibly "better", which is NOT the same as saying that the 511 is "not good". Maybe, just not quite as good, for SOME things. But for a street or moderate racing application, it's not a significant difference, and I wouldn't let that bother me if I was you. For a budget hot street motor it'll be perfectly fine.

It'll almost certainly have factory 4-bolt main caps installed on it.

The later blocks had more metal around the main webbing area, so they're "stronger". People talk about "4-bolt" vs "2-bolt", but that's not really the difference; the # of bolts is incidental. It happens that the factory put 4-bolt caps on the early ones and 2-bolt caps on the later. But the REAL difference in the blocks is early vs late, not 2- vs 4-bolt. The bolts themselves aren't what makes the ones "better" than the other.

Yes the heads that came on 400s are absolute crap. If it still has the original heads, throw then in the trash, they're pretty much hopeless; and get something decent. Vortecs wouldn't be a bad choice. Other than that, you pretty much need to go to the aftermarket. Double-humps are marginal at best. If you use them, be sure that they have the accessory holes in the ends, if your car's accessories need them, as anything from 69 up will; it's nearly impossible to fake those holes. You can't just "drill" them in heads that don't have them, because there's nothing there to drill into.

It's VERY VERY easy to get 400 HP out of a 400, with the right heads. Hard to avoid getting that much in fact. A Comp XE or a Voodoo cam in the 224-230° kind of range, NOT a Summit cam, "RPM" cam, or any of the old stock cams like the 151 or other similar garbage, are the best choice with Vortecs or other stock heads, or even alot of the aftermarket ones. The large CID needs the added exhaust flow from the larger exh lobe.

Yes, virtually all 350 parts will fit a 400; the specific exceptions being the crank damper and flywheel, if you stick with the factory "external balance" stuff. Also you'll need to drill the steam holes in the heads if they don't already have them, which you can do yourself with a hand drill, no sense in paying somebody else to do that if you don't have to or it's not just a matter of convenience (like, they're already doing some other machine work, and you get them to do that at the same time).

OTOH, "fit" is not the same as "is the right thing". Remember, you're dealing with a motor that's on up into the big block cubes range, so all of the parts have to be chosen to support that kind of size. Stuff that's borderline radical in a 350, tends to be mild street stuff in a 400.

You'll get best results with a small chamber head (64cc) and pistons with a small dish or (ideally) a "reverse dome", to put the ACTUAL CR (calculated including the ACTUAL MEASURED deck clearance) in the high 9s if the heads are iron, or mid 10s with aluminum heads. Deck clearance is CRUCIAL: don't be fooled by the "catalog" CR listings, or just "assume" that there is no deck clearance. With most "rebuilder" type pistons including TRWs for example, the deck clearance, which is how far "down in the hole" the pistons are at TDC, can be nearly .050" in some blocks, which in turn can cause the ACTUAL CR to be a full point lower than some randomly guessed and "calculated" CR. Any CR calculator is only as accurate as theh numbers you put into it. "

Last edited by a moderator: