its obvious some of the guys on this site need to understand the difference between static and dynamic compression ratios, and that's understandable as its a difficult concept to grasp at first.

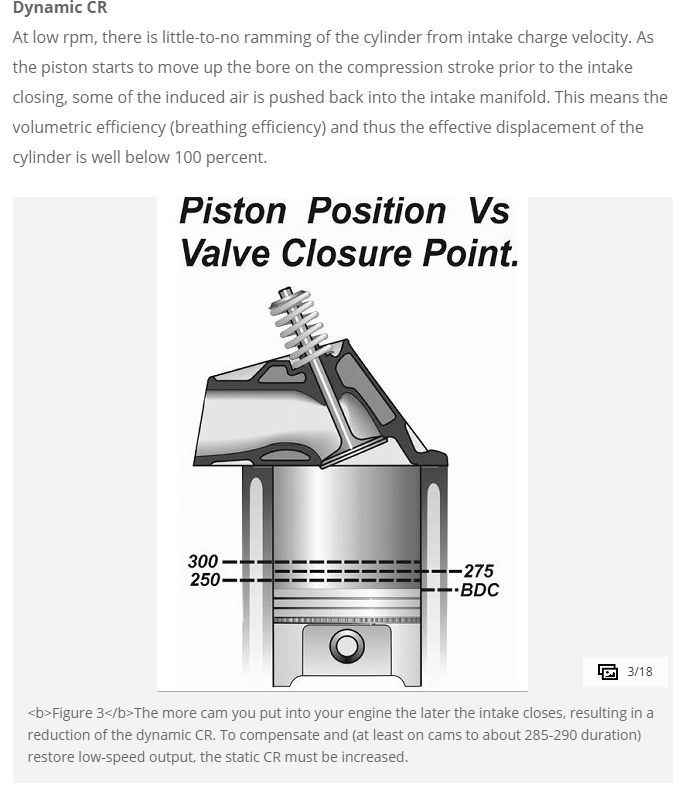

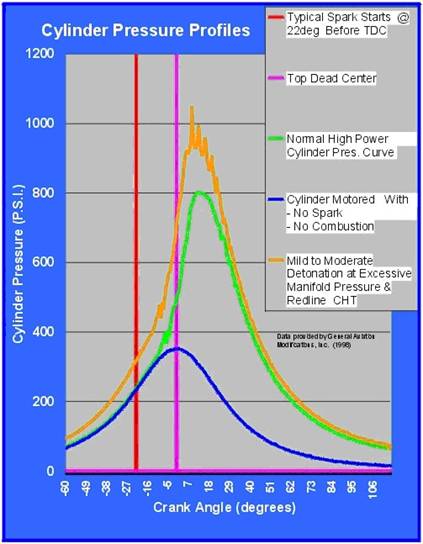

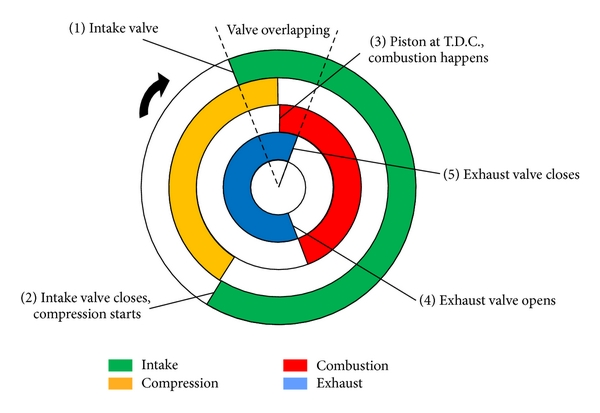

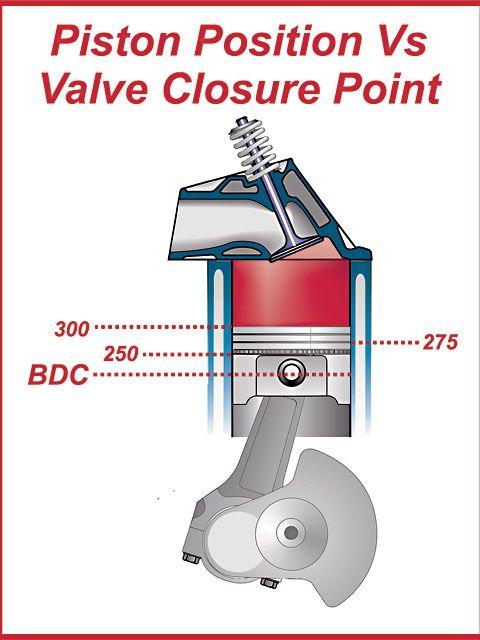

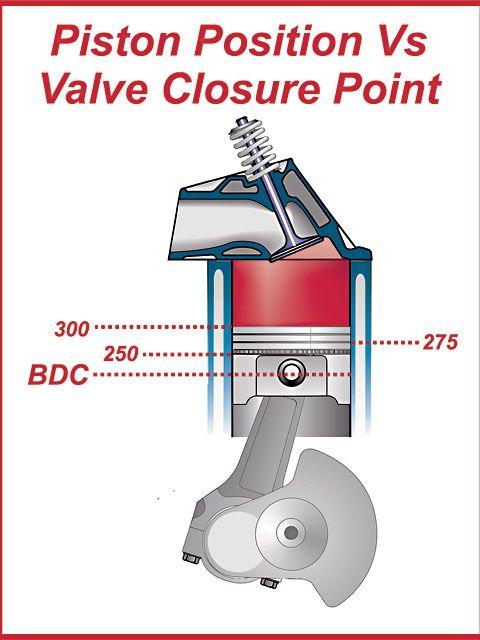

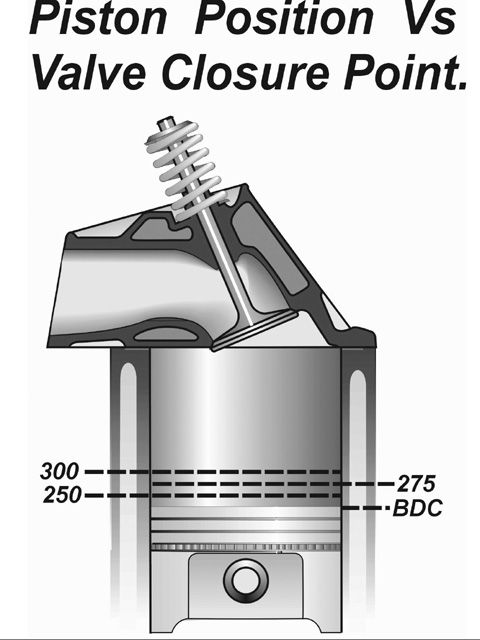

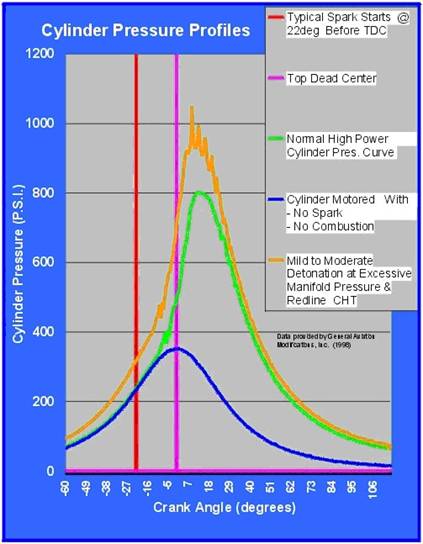

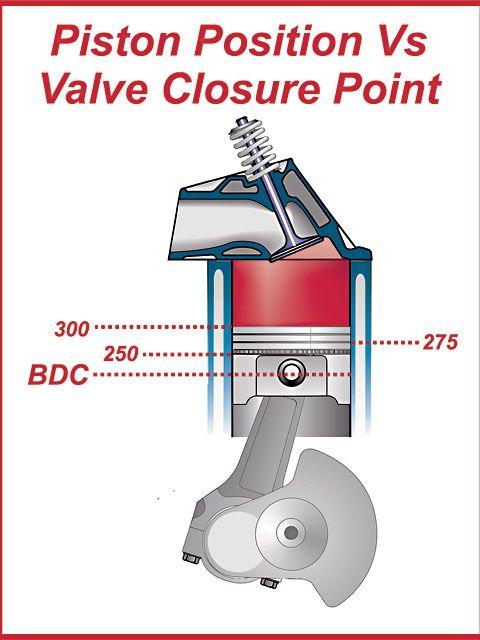

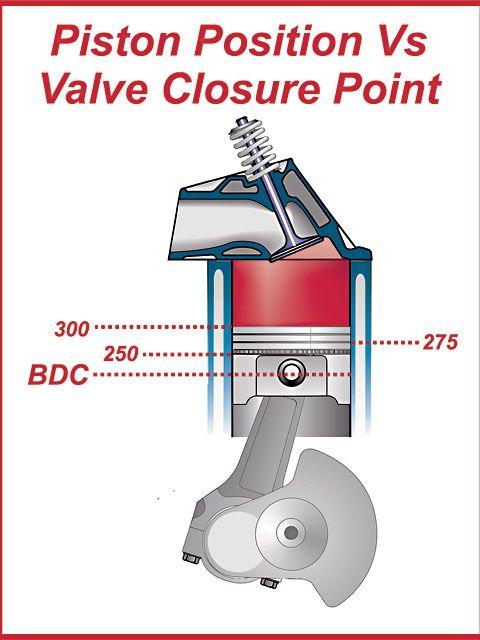

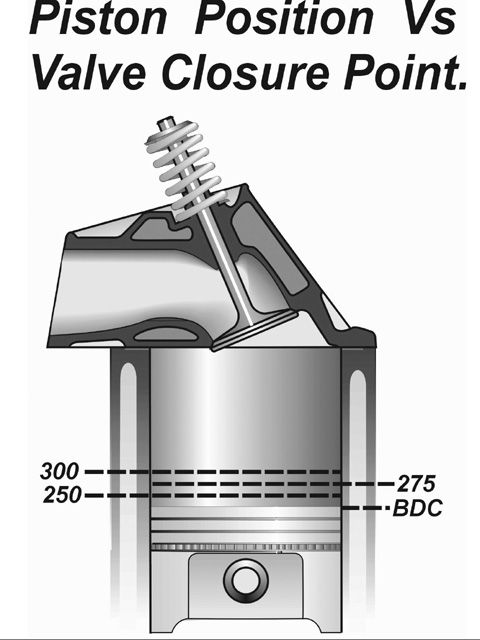

your engines tendency to get into detonation is the result of higher effective compression that the fuel octane your using can permit, but your piston is only compressing the fuel air mix, trapped between the rising piston and combustion chamber, AFTER both valves seat.and that normally happeneds well after the piston passes BDC and starts back up the bore.

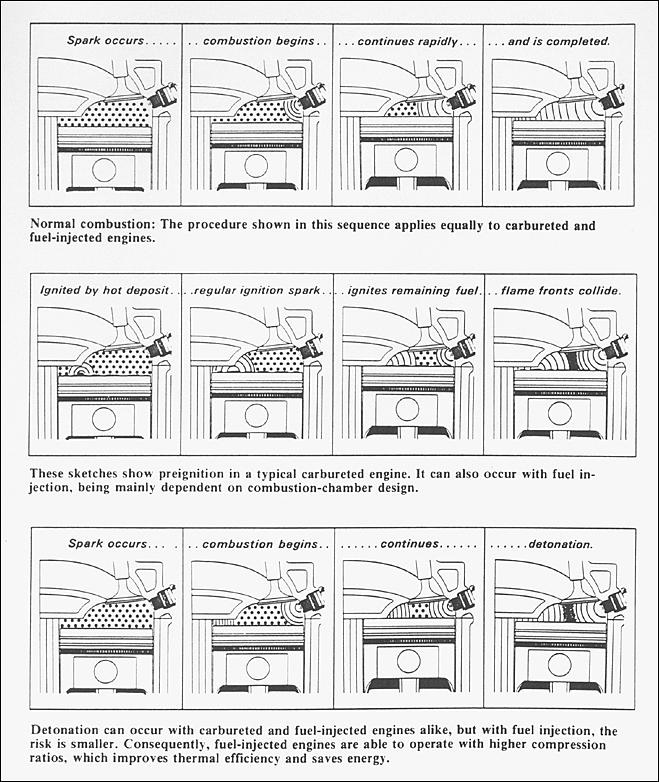

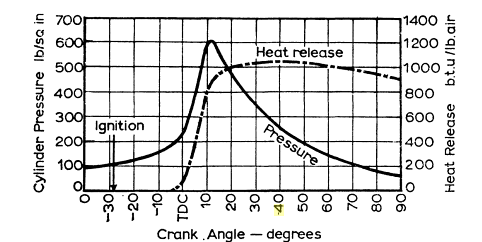

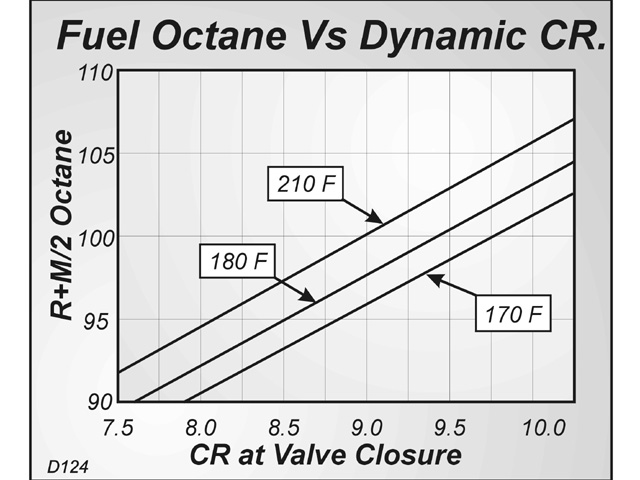

detonation is a condition that occurs as the result of both cylinder temperature compressions effect on your fuel/air ratio and several other factors that cause fuel to self ignite under some conditions, lowering the EFFECTIVE compression , lowering the heat in the combustion chamber , or designing the engines quench,squish,turbulence and other factors to greatly reduce the engines tendency to get into detonation will obviously help prevent it.

but you need to understand it before selecting a combos components ,

keep in mind a huge percentage of the details you need to understand is contained in the sub links so don,t just skim thru, take the effort to read the links also as youll save hundreds of dollars and weeks or nu-necessary work doing so in avoiding potential problems

http://www.wallaceracing.com/dynamic-cr.php

http://victorylibrary.com/mopar/cam-tech-c.htm

http://www.empirenet.com/pkelley2/DynamicCR.html

http://www.not2fast.com/turbo/compression/cranking_pressure.shtml

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/

https://www.uempistons.com/index.ph...e=comp&zenid=1e826335bfac0f356463eabed4958558

https://www.uempistons.com/index.ph...=comp2&zenid=1e826335bfac0f356463eabed4958558

https://www.rbracing-rsr.com/compstaticcalc.html

http://www.diamondracing.net/tools/

http://www.hotrod.com/events/coverage/0311em-power-squeeze/

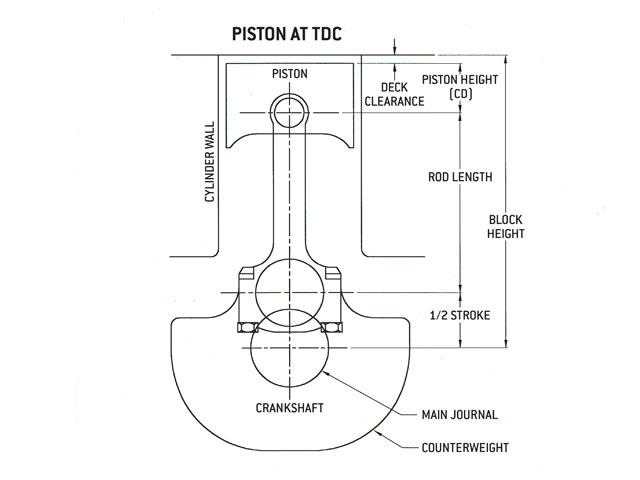

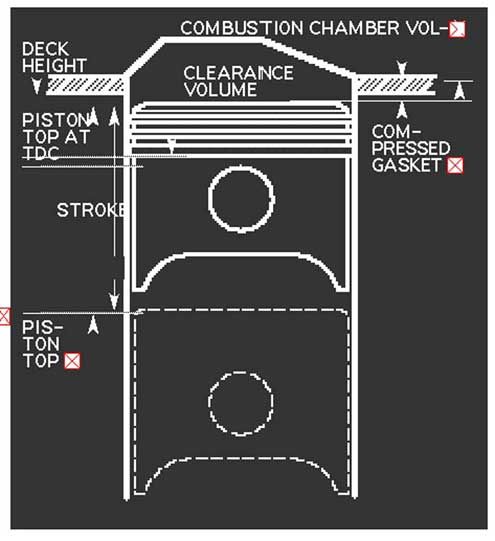

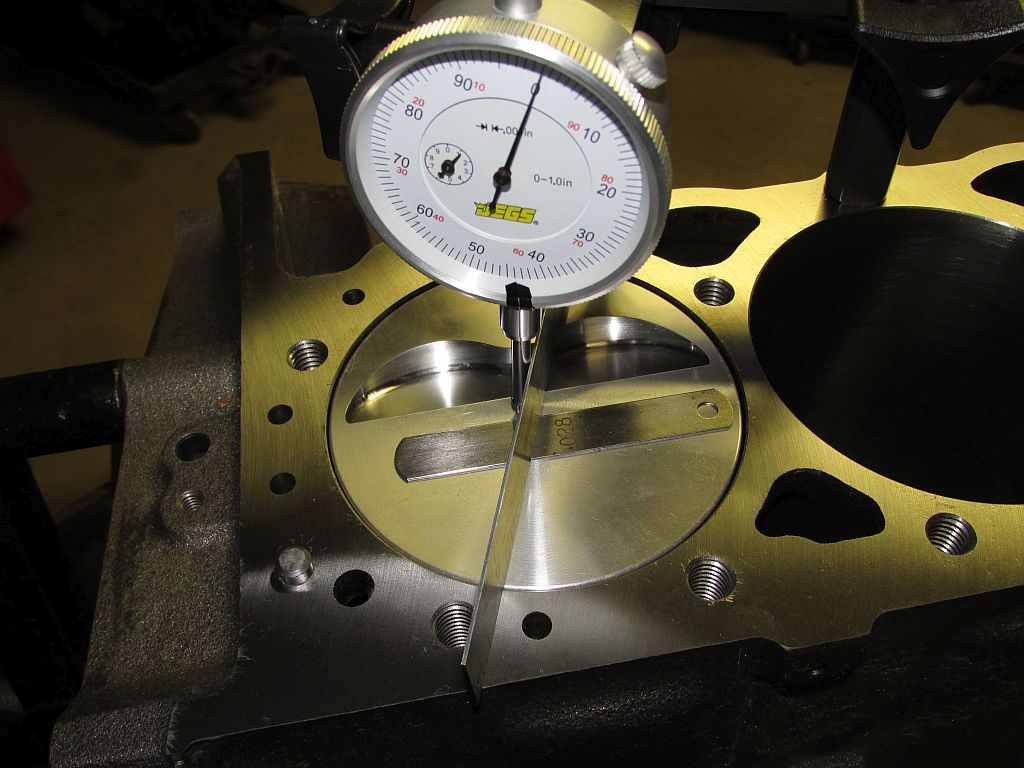

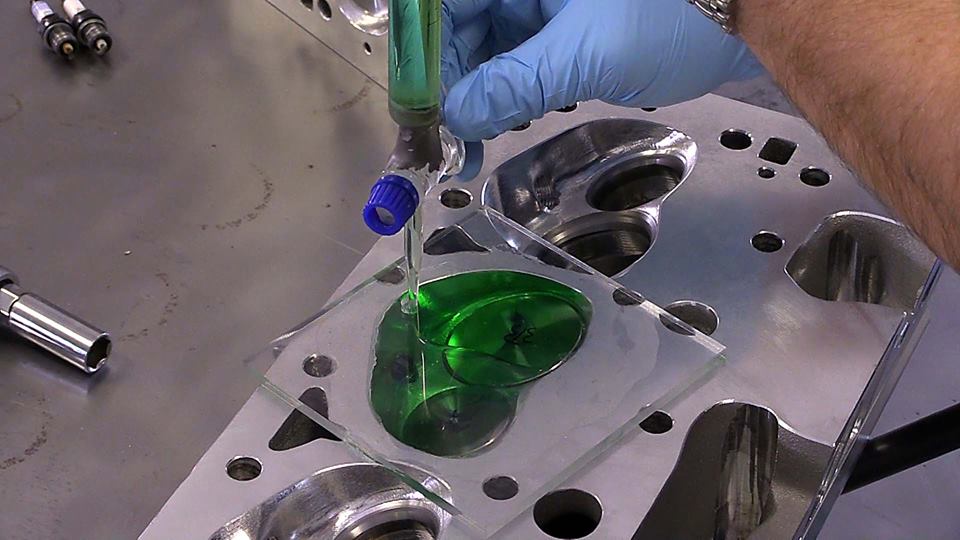

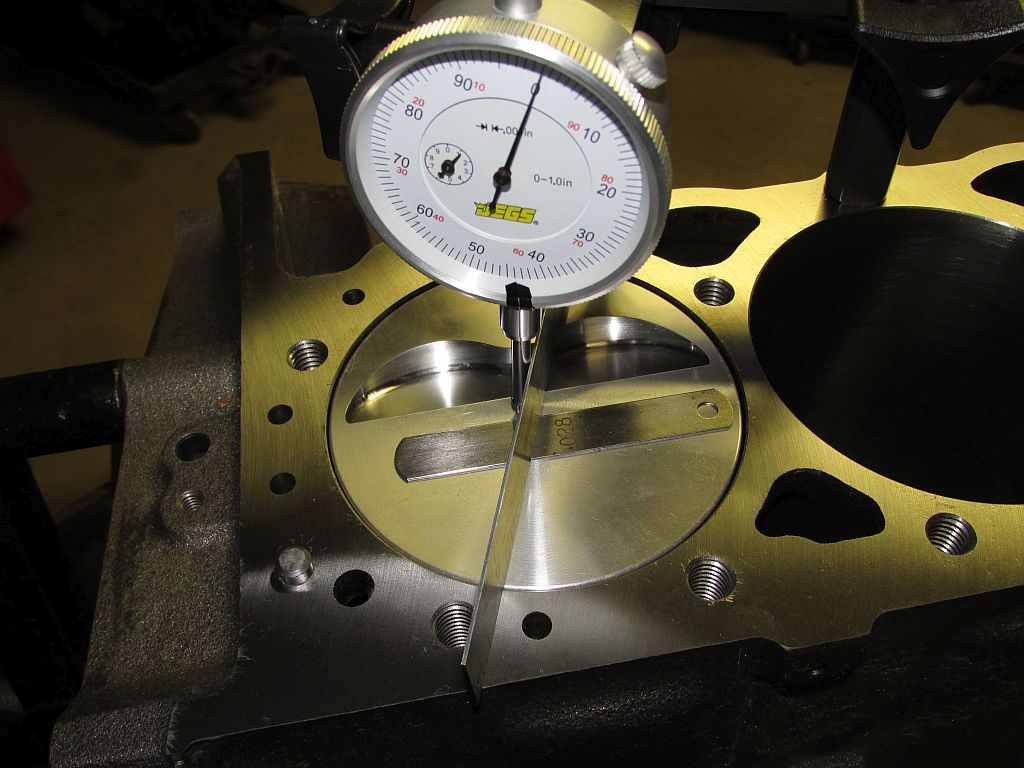

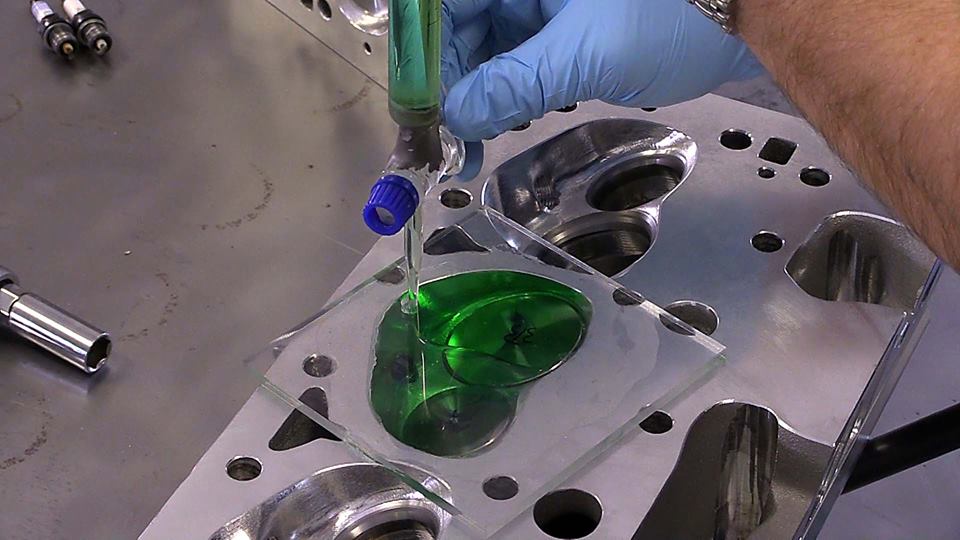

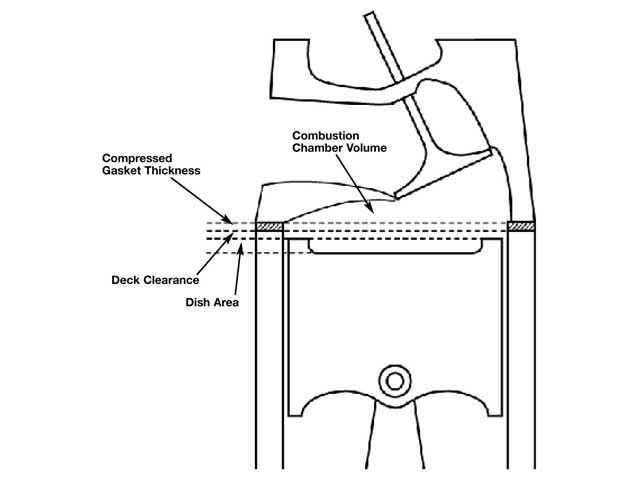

, if you have any engine and want too find the true compression you need to deal in verified fact, not assume what the manufacturers suggest is always correct.

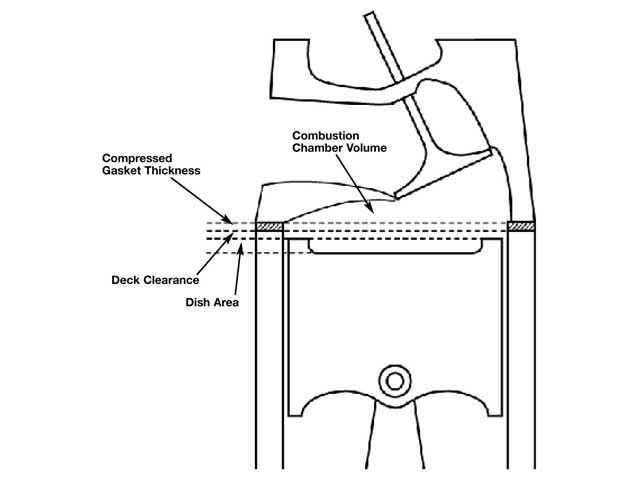

you just cc the heads, combustion chamber volume, place the piston 1" down the bore and seal the rings gap around the pistons,

above the rings with moly grease or Vaseline and measure that volume and calculate what a bore diameter cylinder 1" tall would

contain, minus the volume you,ve measured, the piston dome took up.then calculate the true compression.

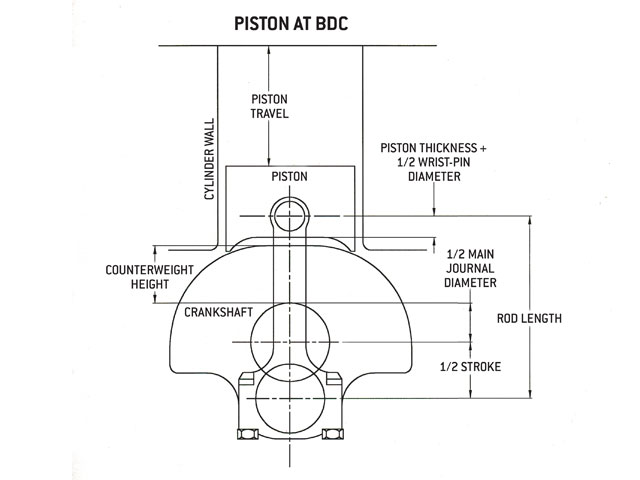

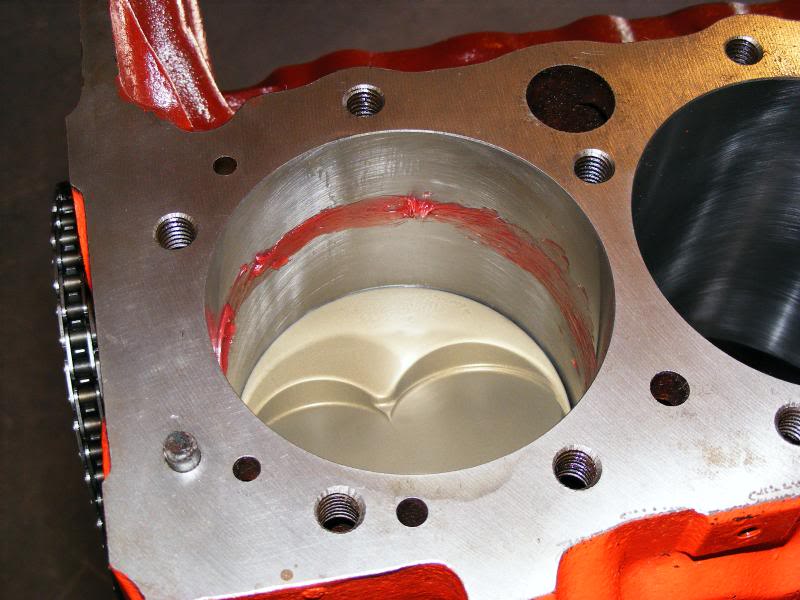

measure the piston deck height after the machined block has the rotating assembly test fitted

read related linked info

http://garage.grumpysperformance.co...n-chamber-or-piston-dome-or-port-volume.2077/

http://garage.grumpysperformance.com/index.php?threads/ccing-my-heads.14187/#post-71989

http://garage.grumpysperformance.co...ng-combustion-chambers.2630/page-3#post-77963

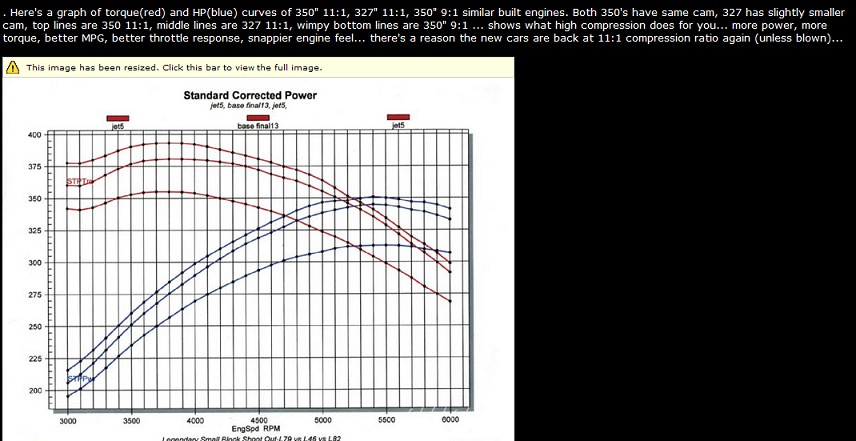

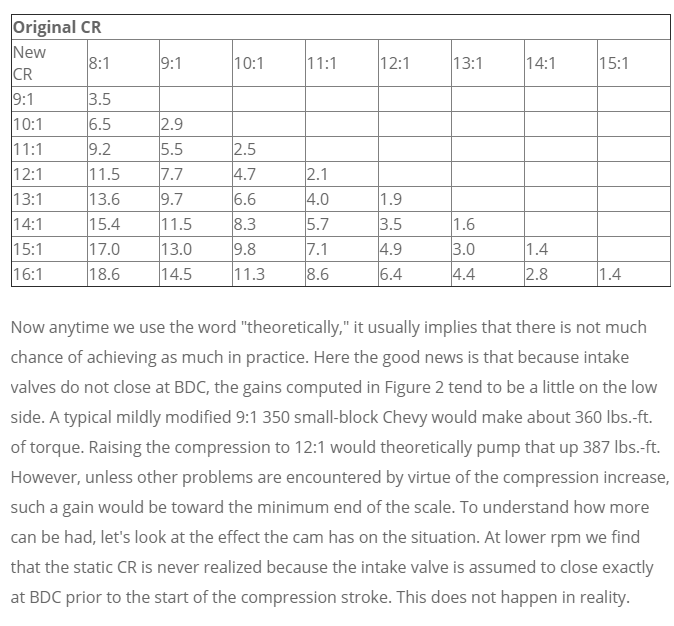

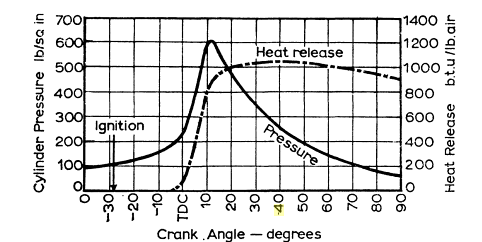

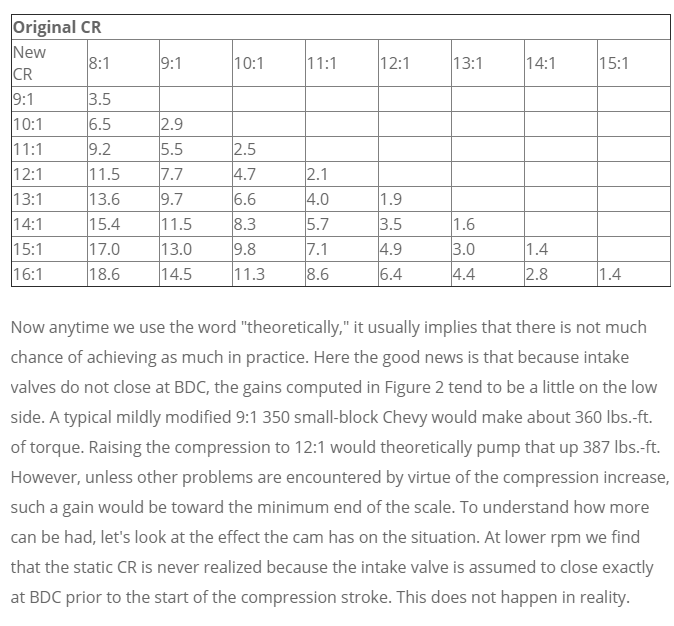

what the chart below shows is the theoretical gain in torque with an increase in compresion

example

if you had 8:1 compression, and boosted compression to 12:1 you could theoretically expect a 11.5% boost in torque as a result

Ive built enough engines that I think I can post a bit of info regarding the effect of the need to consider dynamic compression, in the engine planing

fact

usable torque the engine produces tends to go up as cylinder pressure increases

fact

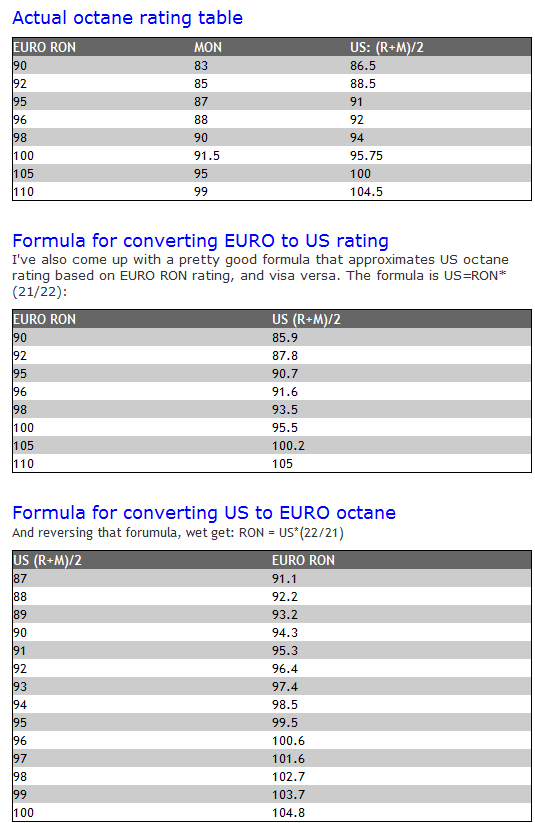

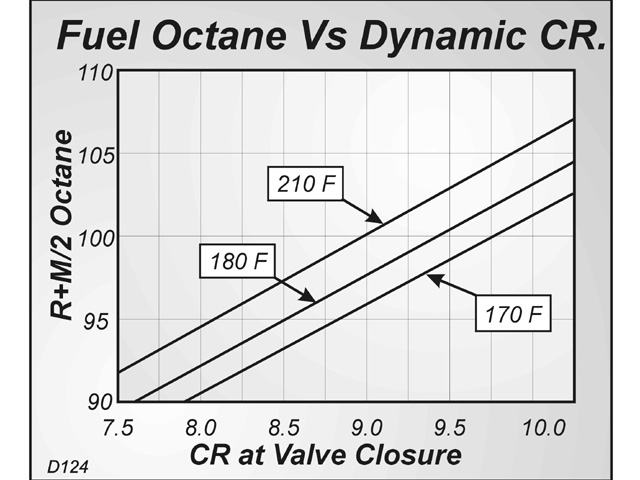

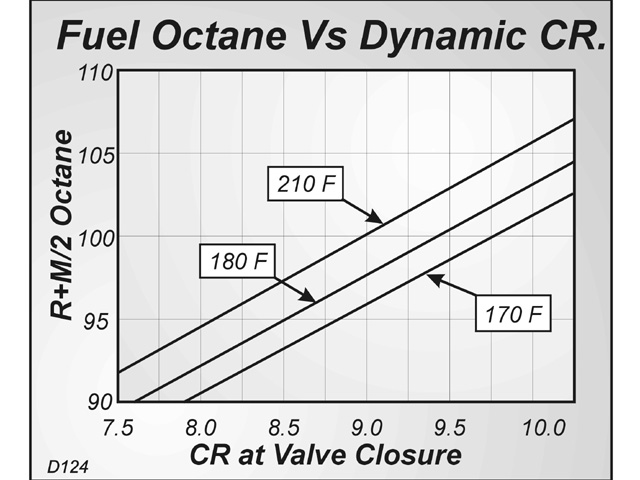

your fuels OCTANE or tolerance, to heat before you tend to get into potential detonation, issues limits the effective compression.

fact

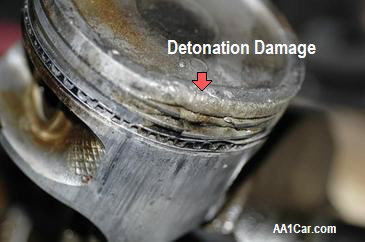

uncontrolled detonation will rather quickly damage pistons and rings

fact

cylinder pressure is greatly influenced by the cylinders,displacement, and valve timing as well as the static compression ratio

fact

on a N/A engine you'll rarely if ever exceed the static compression, with the effective dynamic compression, but you can markedly reduce it with cam timing changes, that delay the valves closing as the piston compresses the cylinder volume.

you might want to read thru these link's carefully

http://victorylibrary.com/mopar/cam-tech-c.htm

http://members.uia.net/pkelley2/DynamicCR.html

http://www.wallaceracing.com/dynamic-cr.php

http://www.projectpontiac.com/ppsite15/compression-ratio-calculator

http://www.pcengines.com.au/calculators/Calculate dynamic Comp Ratio.htm

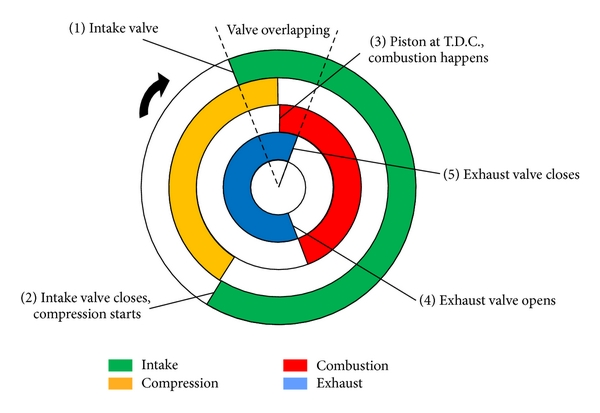

OK, first fact! the piston can,t compress anything being trapped in the cylinder by the piston compressing it as it raises,until both valves seat & seal

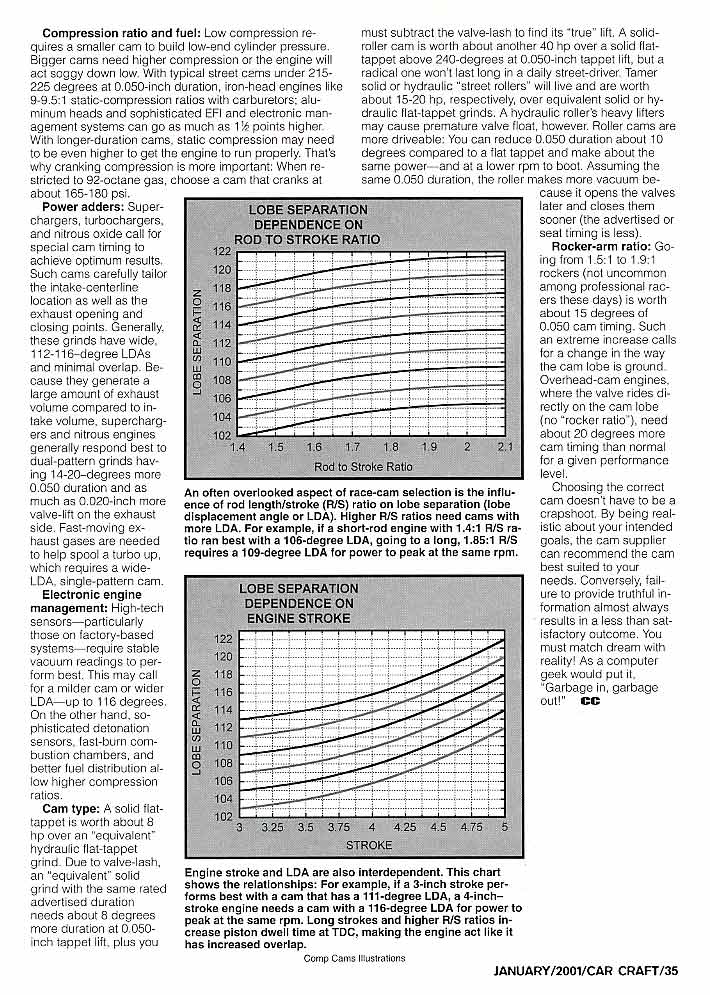

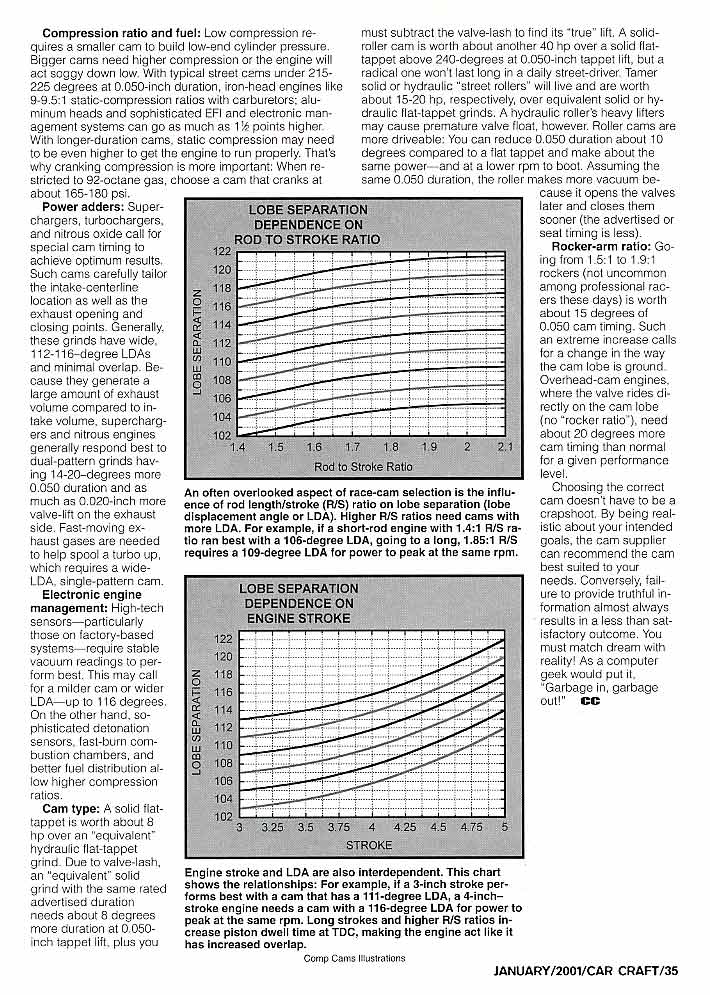

the chart above can be used as a rough guide to match cam duration at .050 lift and static compression in engines obviously other factors come into play so its only a rough guide

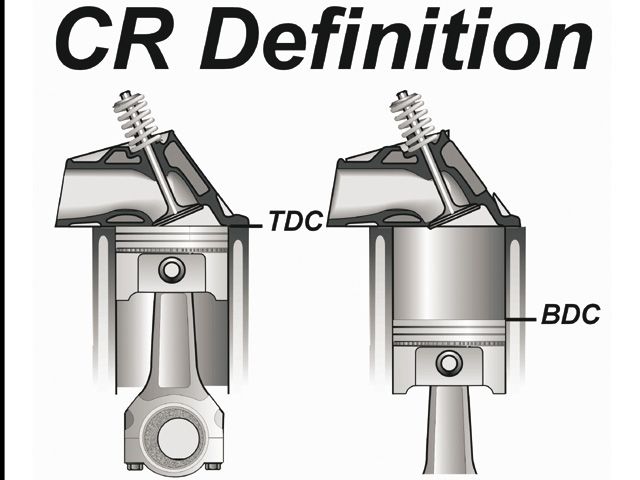

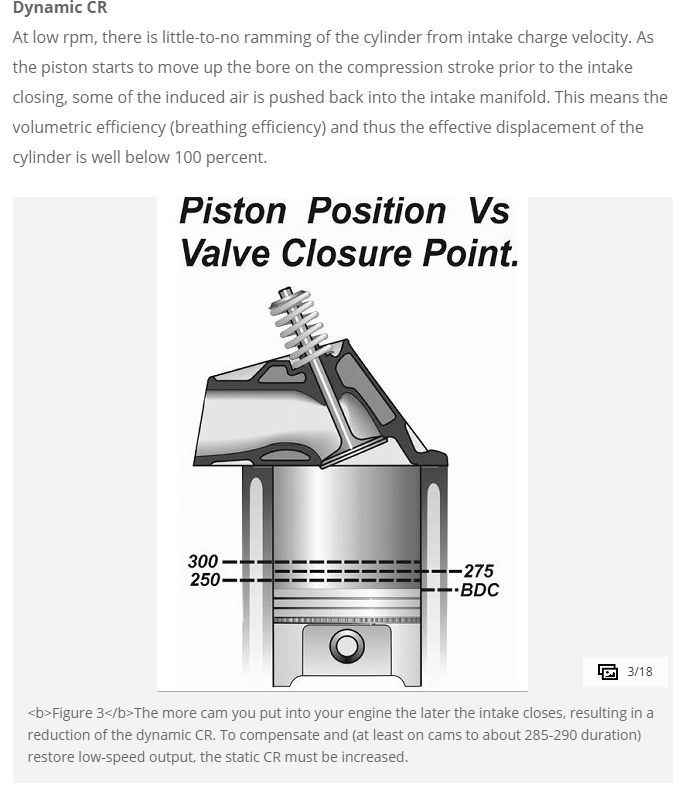

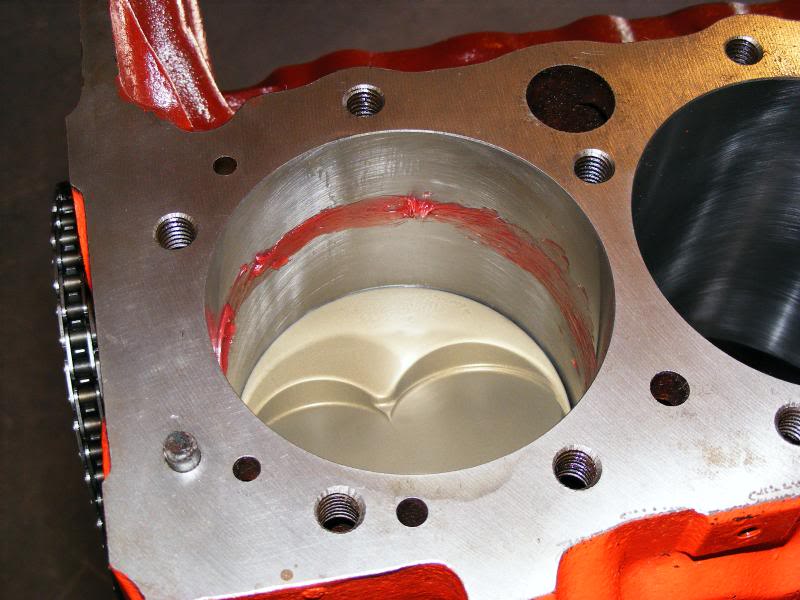

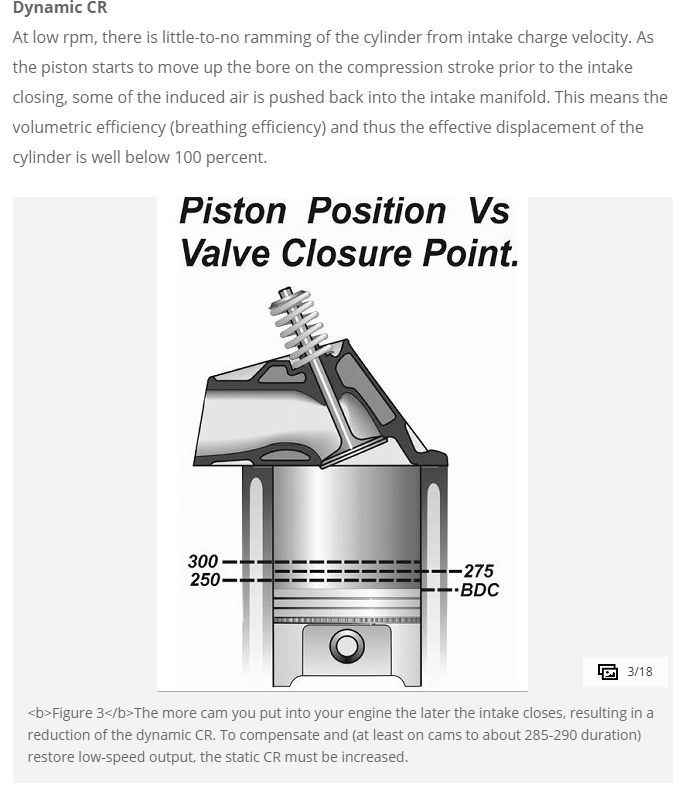

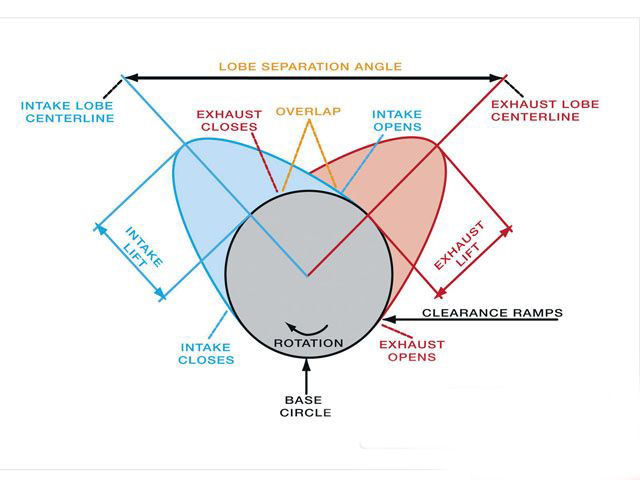

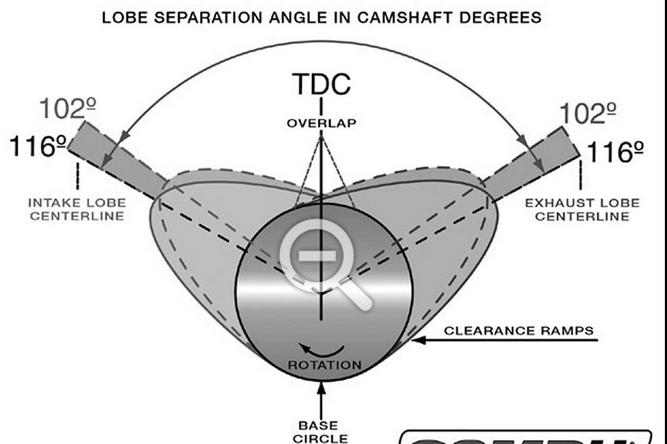

an engines static compression is calculated from the pistons sweep volume from bottom dead center to top dead center , compressing that volume into the remaining combustion chamber volume., if the valves don,t set until the piston reaches lets say 280 degrees past bottom dead center, that greatly reduces the volume of fuel air mix trapped in the cylinder at lower rpms

READ THESE RELATED LINKS

viewtopic.php?f=55&t=2718&p=12119&hilit=calculate+octane#p12119

viewtopic.php?f=52&t=4081&p=10861#p10861

http://victorylibrary.com/mopar/cam-tech-c.htm

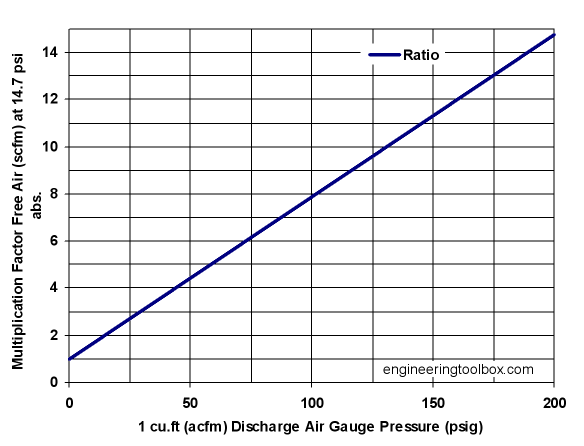

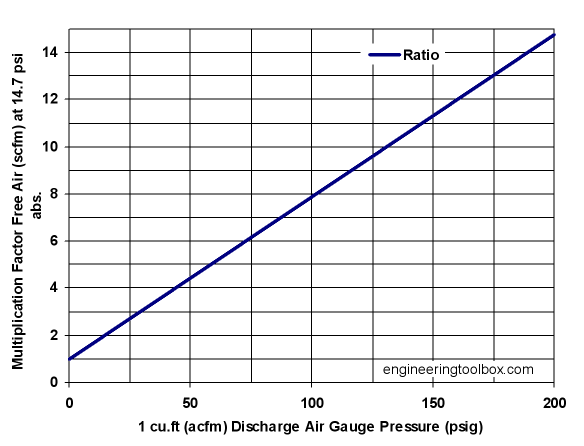

http://www.engineeringtoolbox.com/free- ... _1190.html

http://www.wallaceracing.com/dynamic-cr.php

http://victorylibrary.com/mopar/otto-c.htm

http://www.pcengines.com.au/calculators ... 0Ratio.htm

viewtopic.php?f=99&t=4458&p=12155#p12155

http://www.projectpontiac.com/ppsite15/ ... calculator

http://www.enginebasics.com/Advanced%20 ... namic.html

Ive found the KB calculator to give good results

https://www.uempistons.com/index.php?ma ... bed4958558

try this also

http://www.projectpontiac.com/ppsite15/ ... calculator

http://www.wallaceracing.com/dynamic-cr.php

http://cochise.uia.net/pkelley2/DynamicCR.html

http://www.steigerperformance.com/products/sp90005.html

I generally look to see about 145-160 psi on a street gas compatible engine compression test, but even if the reading are down near 120-130 psi I look more at cylinder consistency that the number

viewtopic.php?f=50&t=41&p=49&hilit=leak+down#p49

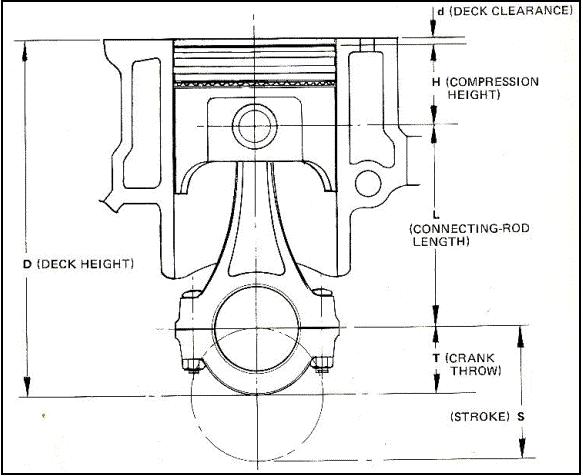

static compression is theoretical , in that its based on the piston stroke compressing the cylinder volume trapped above the piston from bottom dead center to top dead center being compressed into the combustion chamber and head gasket volume and you also need the piston deck to block deck heights and piston dome or dish volume, you need to know that static compression volume to start your calculations, its theoretical because all modern cams use timing figures that don,t close both the valves at BDC, allowing the full cylinder volume to be compressed.

when you build an engine you generally have some idea as to its intended operational rpm range and the octane level of the fuel you want to use.

normal quality blended gasoline tends to produce its best power at about a 12.5:1 fuel/air ratio, and lowest exhaust emissions at about a 14.7:1 f/a ratio

the higher the effective compression ratio (up to about 13:1) the more torque you can expect to produce from an engine,if you use, high octane gas or race fuels, but the octane of the fuel currently available from pump gas drops the max effective dynamic compression ratio to about 8:1

obviously the components selected must work in the desired rpm and intended power range.

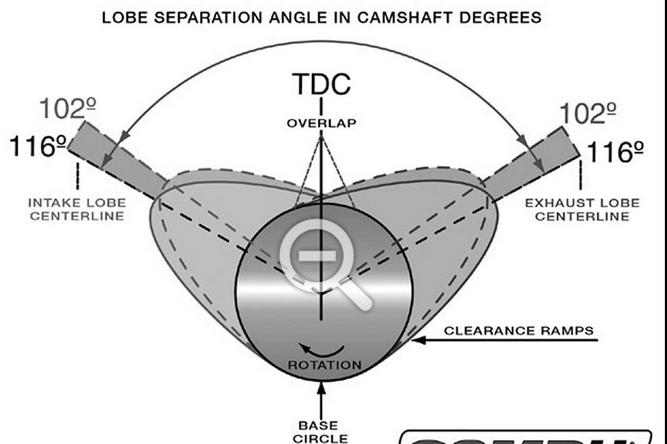

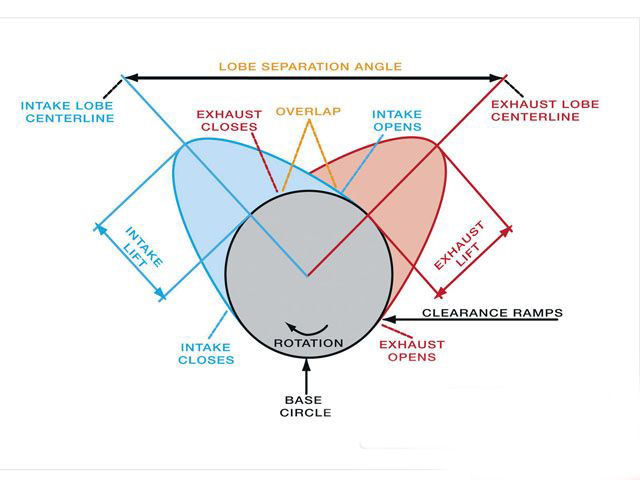

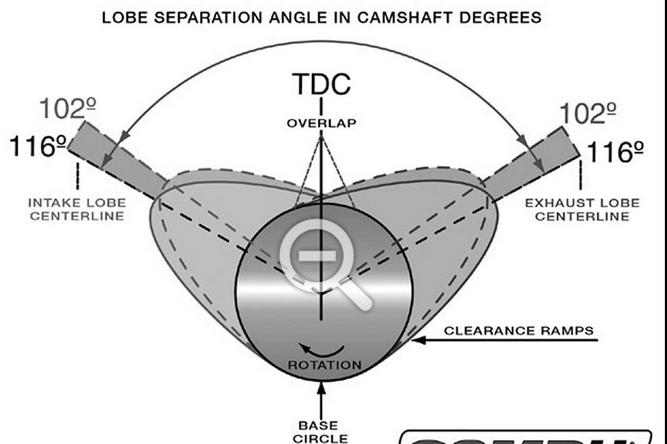

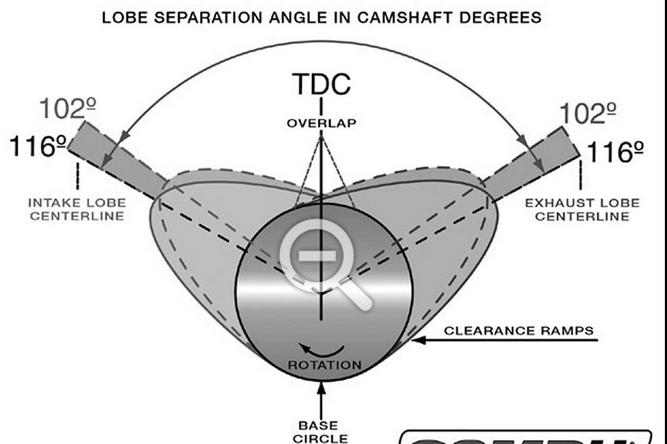

you need to select a cam duration and LSA , and static compression that BOTH matches the static compression ratio and your cars gearing so the effective dynamic compression ratio falls in that range, and intended rpm/power band

viewtopic.php?f=55&t=2718&p=12119&hilit=octane#p12119

viewtopic.php?f=52&t=1070

http://www.jeepstrokers.com/calculator/

viewtopic.php?f=52&t=82

viewtopic.php?f=71&t=741

http://www.projectpontiac.com/ppsite15/ ... calculator

http://www.technovelocity.com/chevyhack ... cation.htm

http://www.pcengines.com.au/calculators/Calculate dynamic Comp Ratio.htm

viewtopic.php?f=55&t=109

read thru this thread

viewtopic.php?f=52&t=1477

https://www.uempistons.com/index.php?ma ... bed4958558

viewtopic.php?f=52&t=5078&p=14433#p14433

dynamic compression uses that that static compression volume as a base calculation but factors in the fact that the pistons not compressing a darn thing until both valves seat, and thats always AFTER BOTTOM DEAD CENTER, as the piston moves upward. so you compress a good deal less cylinder volume as the cams duration and LSA change the valve seat timing

http://garage.grumpysperformance.com/index.php?threads/crowers-valve-timing-charts.4299/

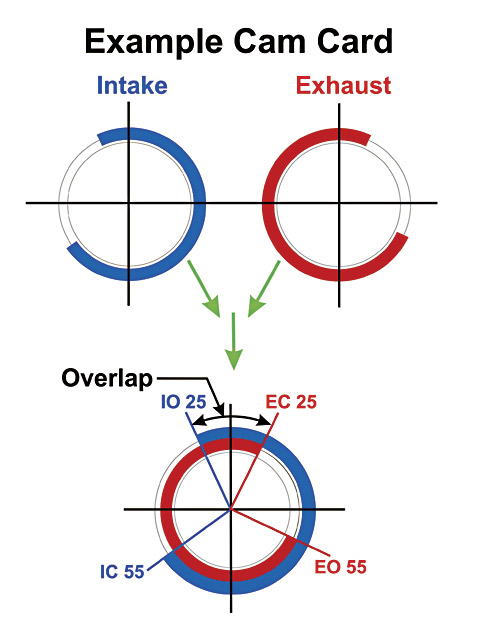

heres an extremely useful chart giving cam timing info

viewtopic.php?f=52&t=2782&p=7214#p7214

viewtopic.php?f=52&t=2077&p=9049#p9049

viewtopic.php?f=53&t=726&p=8809&hilit=quench+squish#p8809

you really might want to read thru these threads and links also, as theres a ton of good info included in the links

http://www.empirenet.com/pkelley2/DynamicCR.html

http://www.empirenet.com/pkelley2/DCR_FAQ.html

http://www.jeepstrokers.com/calculator/

viewtopic.php?f=52&t=4299

http://www.projectpontiac.com/ppsite15/ ... calculator

viewtopic.php?f=53&t=726&p=2302#p2302

http://victorylibrary.com/mopar/rod-tech-c.htm

http://www.circletrack.com/techarticles ... index.html

http://www.not2fast.com/turbo/compressi ... sure.shtml

viewtopic.php?f=55&t=2718

https://www.uempistons.com/index.php?ma ... bed4958558

http://www.cswnet.com/~carother/compression_ratio.htm

http://www.skipwhiteperformance.com/det ... 3831P-1230

http://victorylibrary.com/mopar/piston_position-c.htm

http://www.empirenet.com/pkelley2/DynamicCR.html

http://www.cpgnation.com/category/produ ... comp-cams/

viewtopic.php?f=52&t=1477

http://victorylibrary.com/mopar/cam-tech-c.htm

the difference between STATIC COMPRESSION RATIO AND DYNAMIC COMPRESSION RATIO is where the piston is in the cylinder when the valves close and the piston can actually start compressing the REMAINING VOLUME IN THE CYLINDER VS the STATIC COMPRESSION THAT ASSUMES THE PISTON STARTS COMPRESSING THE INSTANT IT LEAVES BOTTOM DEAD CENTER AND STARTS UPWARD ON THE COMPRESSION STROKE!

let me try and explain, the short version is that the PISTON COMPRESSES NOTHING untill BOTH VALVES ARE CLOSED, ....higher compression INCREASE the engines mechanical efficiency up to a point...that's the only compression ratio that matters,.... since its the only compression ratio the engine ever sees.

btw your max effective STATIC compression ratio naturally vary with the cylinder heat and fuel octane,ETC. but after about 13.7:1 the percentage of gains in hp from compression increases tend to drop off fairly rapidly, with most comon (GAS)

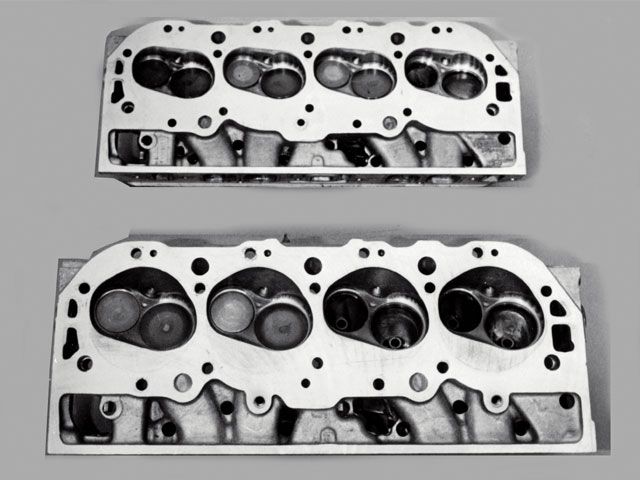

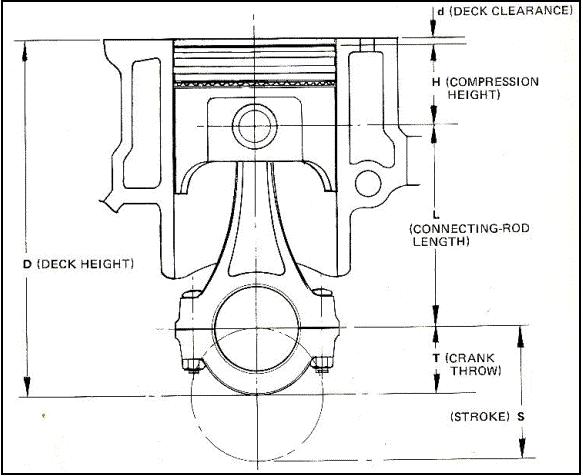

static compression is simply the difference between the cylinder volume at BOTTOM DEAD CENTER(BDC) and its compressed volume at TOP DEAD CENTER (TDC), into the combustion chambers,... dynamic compression takes into account that on the pistons upward compression stroke the valves have not yet closed and nothing gets compressed by the piston until they do, that of course depends on the cam and rockers, pistons and connecting rods, the cylinder volume, the rod/stroke ratio, ETC.,used, in the combo, and the rpm levels to some extent BTW, ALUMINUM HEADS can usually operate at a higher dynamic compression simply because ALUMINUM releases heat to the coolant much faster than iron, its the lower heat levels that remain in the cylinder that help prevent detonation..when you increase the dynamic compression the heat levels in the heads combustion chamber rise , the difference in the RATE heat leaves the cylinder allows a slightly higher dynamic compression level from aluminum before the same HEAT levels are REACHED & MAINTAINED in the combustion chambers , KEEP IN MIND ENGINE TEMP AND YOUR FUELS OCTANE , YOUR TRUE AIR/FUEL RATIO,YOUR IGNITION TIMING ADVANCE CURVE,HOW FAST YOUR KNOCK SENSOR REACTS, and THE ENGINES GENERAL CONDITION, EFFECT THE RESULTS AND WHEN DETONATION BECOMES A PROBLEM

!aluminum cylinder heads tend to allow you to run about 1/4-to-1/2 point more effective compression, IE, if iron heads get into detonation at 10:1 ALUMINUM might ALLOW YOU TO RUN 10.3-10.4:1 BEFORE GETTING INTO DETONATION, BUT ON THE PLUS SIDE AT LEAST IN THEORY IRON HEADS AT ANY GIVEN CPR WILL HAVE A SLIGHT ADVANTAGE IN HP

but in my real world testing the difference is much closer almost non-existent

the main advantage I see in aluminum heads is lighter weight and their much easier to repair when damaged

an aluminum cylinder head allows heat transfer to the engine coolant at a significantly higher rate than an iron head, and generally about .25-.50 higher compression can be tolerated but theres No absolute real definite answer, depends on quench, cam LSA, cylinder head design, advance curve, fuel/air mixture, intake temperature, coolant temp, spark plug design, piston design, heat barrier coatings, combustion chamber surface texture, and a bunch of other parameters.

here is a calculator for static cpr, which you need to figure first

http://www.rbracing-rsr.com/compstaticcalc.html

then lets assume your 350 sbc engine has a static compression ratio of 11:1 but youve installed this cam

http://www.cranecams.com/?show=brows...81&lvl=2&prt=5

first look at this chart

http://www.iskycams.com/ART/techinfo/ncrank1.pdf

and this one

viewtopic.php?f=52&t=4299

looking at the cam specs we see that the effective stroke is not the 3.48" that the static compression ratio is measured from ,at BDC, BUT from about 2.6 inches from tdc where the valves close as the piston moves upward, so your true working compression is closer to 8.1:1 NOT 11:1

heres some different calculators

viewtopic.php?f=52&t=4299

heres an extremely useful chart giving cam timing info

http://www.projectpontiac.com/ppsite/co ... iew/16/30/

https://www.uempistons.com/index.php?ma ... bed4958558

http://www.wallaceracing.com/dynamic-cr.php

http://members.uia.net/pkelley2/DynamicCR.html

average the results..of all four calculators.

READ thru THESE LINKS CAREFULLY

https://www.uempistons.com/index.php?ma ... bed4958558

http://cochise.uia.net/pkelley2/DynamicCR.html

viewtopic.php?f=55&t=2718&p=7057#p7057

http://www.kennedysdynotune.com/Dynamic Compression Tech.htm

viewtopic.php?f=55&t=613&hilit=boosters

http://www.popularhotrodding.com/tech/0 ... index.html

http://victorylibrary.com/mopar/cam-tech-c.htm

http://www.daytona-sensors.com/tech_tuning.html

read these

viewtopic.php?f=52&t=2077

viewtopic.php?f=52&t=2630&hilit=+valves

viewtopic.php?f=52&t=1159&hilit=lapping

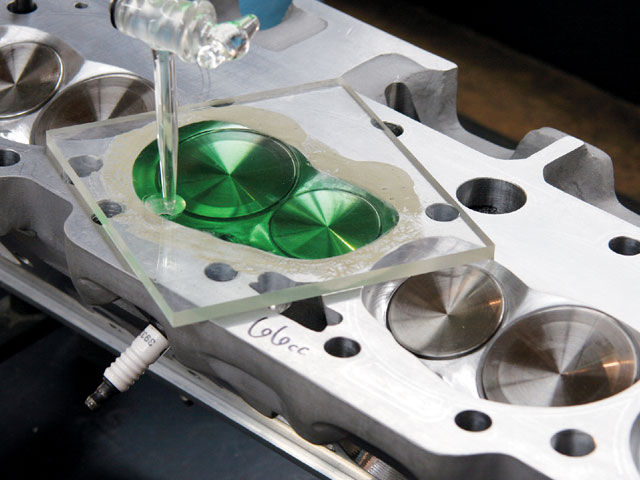

I think back on the many dozens of times Ive pocket ported,heads un-shrouded combustion chambers, port matched, intakes and checked deck to piston heights

and I can,t help but grin, if you guys are discussing the potential for mis-reading the burret level when CCing your cylinder heads ,

and I can,t help but grin, if you guys are discussing the potential for mis-reading the burret level when CCing your cylinder heads ,

http://74.125.93.132/search?q=cache:I5W ... clnk&gl=us

a potential mistake that might result in a 1/2cc difference, now in an ideal world we all strive to get things exactly correct, but,

lets assume you do find a full cc difference ,between combustion chamber volumes,the real question is, what do you do to correct that, mis-match and if you don,t how much does it matter, to your engines performance?

http://www.csgnetwork.com/compcalc.html

input your average 70cc sbc heads on a 9:1 cpr sbc then change the chamber volume 1 cc and see how it changes the true results, in most production engines youll be very lucky to be within that range

just keep in mind the piston can,t compress a darn thing UNTIL both valves are closed, so your cam timing effects the true volume compressed in the cylinders

ok lets start from the basics

EACH COMPONENT YOU SELECT IS A COMPROMISE IN SOME AREA

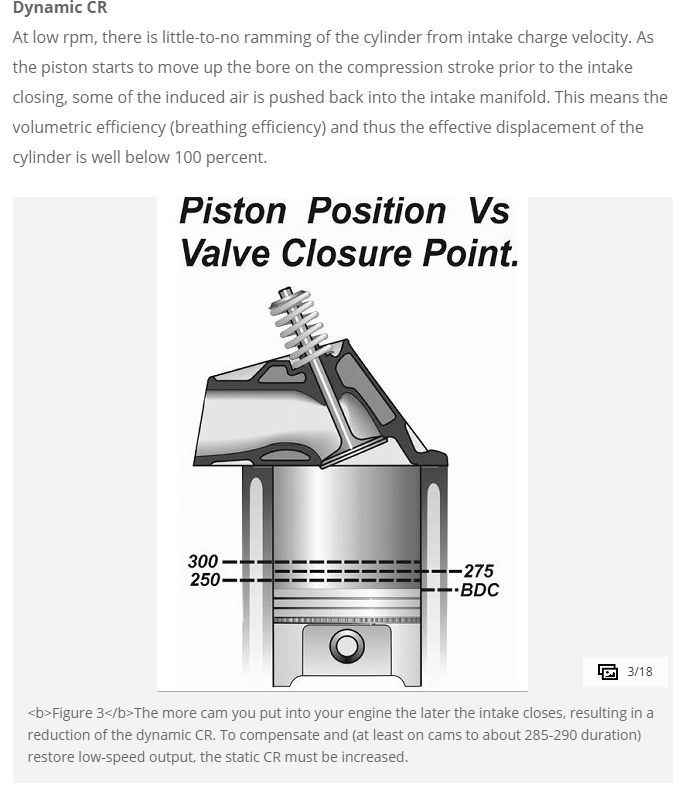

If you've selected a cam that's got too much duration , for your application and rear gear ratio,

if you say the lopey, idle and lack of low rpm torque its a problem,its frequently the result of the cam, you've selected as TORQUE is the result of the EFFECTIVE USE of both DISPLACEMENT and cylinder pressure, so your compression ratio maters here in relation to cam timing, and the longer the cams duration the further up the cylinder the pistons traveled BEFORE the valves fully close, the less trapped volume or displacement you compress, hurting the low rpm torque. to much cam duration is effectively wasting a good percentage of your EFFECTIVE DISPLACEMENT

reducing duration and tightening the LSA tends to increase low rpm torque because for a GIVEN DURATION the valves close sooner in the crank rotation trapping more displacement and resulting in a higher percentage of the fuel/air mix being trapped, burnt and resulting in cylinder pressure turning the crank, but it also results in the valves being open less time so it tends to restrict high rpm breathing or cylinder fill efficiency

IF your running out of high end power it can be the result of a restrictive intake, carb, restrictive exhaust or lack of valve control, but its also common for a cam with too little duration to effectively restrict the cylinders from filling due to there being less time to fill and empty the cylinders

look heres a chart displaying piston location in crank degrees

http://www.iskycams.com/ART/techinfo/ncrank1.pdf

heres a chart showing valve timing in relation to duration

viewtopic.php?f=52&t=4299

look at the chart,

heres free cam selection software to narrow your choices

http://www.compcams.com/Pages/409/camquest-6.aspx

AS your displacement per cylinder increases the effective valve size per cubic inch decreases so you need a slightly tighter LSA and these charts should help.

he following are different static compression ratios (SCR) with a 3.48" stroke and different camshaft intake closing points @ 0.050" tappet lift on Keith Black's dynamic compression ratio calculator. The calculator, starting at 8.25:1 SCR. The dynamic compression ratio (DCR) has been kept at just over 8.0:1, a figure that is acceptable for use with today's pump gas with a little cushion:

heres a chart I found that I don,t fully agree with, I think its a bit conservative, by about 3%-5% on the required cam duration ,required to avoid detonation with todays crappy octane fuel, but it at least gives you a base to work from, but Id suggest selecting a bit more duration

viewtopic.php?f=52&t=1070

viewtopic.php?f=52&t=324

viewtopic.php?f=52&t=727

your engines tendency to get into detonation is the result of higher effective compression that the fuel octane your using can permit, but your piston is only compressing the fuel air mix, trapped between the rising piston and combustion chamber, AFTER both valves seat.and that normally happeneds well after the piston passes BDC and starts back up the bore.

detonation is a condition that occurs as the result of both cylinder temperature compressions effect on your fuel/air ratio and several other factors that cause fuel to self ignite under some conditions, lowering the EFFECTIVE compression , lowering the heat in the combustion chamber , or designing the engines quench,squish,turbulence and other factors to greatly reduce the engines tendency to get into detonation will obviously help prevent it.

but you need to understand it before selecting a combos components ,

keep in mind a huge percentage of the details you need to understand is contained in the sub links so don,t just skim thru, take the effort to read the links also as youll save hundreds of dollars and weeks or nu-necessary work doing so in avoiding potential problems

http://www.wallaceracing.com/dynamic-cr.php

http://victorylibrary.com/mopar/cam-tech-c.htm

http://www.empirenet.com/pkelley2/DynamicCR.html

http://www.not2fast.com/turbo/compression/cranking_pressure.shtml

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/

https://www.uempistons.com/index.ph...e=comp&zenid=1e826335bfac0f356463eabed4958558

https://www.uempistons.com/index.ph...=comp2&zenid=1e826335bfac0f356463eabed4958558

https://www.rbracing-rsr.com/compstaticcalc.html

http://www.diamondracing.net/tools/

http://www.hotrod.com/events/coverage/0311em-power-squeeze/

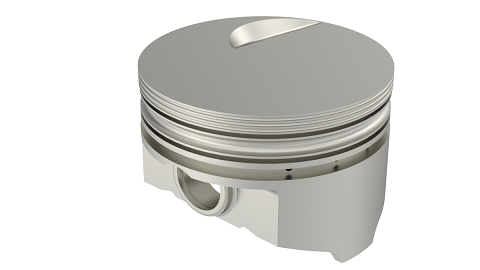

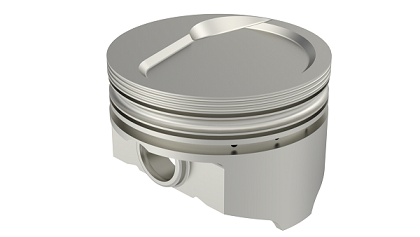

, if you have any engine and want too find the true compression you need to deal in verified fact, not assume what the manufacturers suggest is always correct.

you just cc the heads, combustion chamber volume, place the piston 1" down the bore and seal the rings gap around the pistons,

above the rings with moly grease or Vaseline and measure that volume and calculate what a bore diameter cylinder 1" tall would

contain, minus the volume you,ve measured, the piston dome took up.then calculate the true compression.

measure the piston deck height after the machined block has the rotating assembly test fitted

read related linked info

http://garage.grumpysperformance.co...n-chamber-or-piston-dome-or-port-volume.2077/

http://garage.grumpysperformance.com/index.php?threads/ccing-my-heads.14187/#post-71989

http://garage.grumpysperformance.co...ng-combustion-chambers.2630/page-3#post-77963

what the chart below shows is the theoretical gain in torque with an increase in compresion

example

if you had 8:1 compression, and boosted compression to 12:1 you could theoretically expect a 11.5% boost in torque as a result

Ive built enough engines that I think I can post a bit of info regarding the effect of the need to consider dynamic compression, in the engine planing

fact

usable torque the engine produces tends to go up as cylinder pressure increases

fact

your fuels OCTANE or tolerance, to heat before you tend to get into potential detonation, issues limits the effective compression.

fact

uncontrolled detonation will rather quickly damage pistons and rings

fact

cylinder pressure is greatly influenced by the cylinders,displacement, and valve timing as well as the static compression ratio

fact

on a N/A engine you'll rarely if ever exceed the static compression, with the effective dynamic compression, but you can markedly reduce it with cam timing changes, that delay the valves closing as the piston compresses the cylinder volume.

you might want to read thru these link's carefully

http://victorylibrary.com/mopar/cam-tech-c.htm

http://members.uia.net/pkelley2/DynamicCR.html

http://www.wallaceracing.com/dynamic-cr.php

http://www.projectpontiac.com/ppsite15/compression-ratio-calculator

http://www.pcengines.com.au/calculators/Calculate dynamic Comp Ratio.htm

OK, first fact! the piston can,t compress anything being trapped in the cylinder by the piston compressing it as it raises,until both valves seat & seal

the chart above can be used as a rough guide to match cam duration at .050 lift and static compression in engines obviously other factors come into play so its only a rough guide

an engines static compression is calculated from the pistons sweep volume from bottom dead center to top dead center , compressing that volume into the remaining combustion chamber volume., if the valves don,t set until the piston reaches lets say 280 degrees past bottom dead center, that greatly reduces the volume of fuel air mix trapped in the cylinder at lower rpms

READ THESE RELATED LINKS

viewtopic.php?f=55&t=2718&p=12119&hilit=calculate+octane#p12119

viewtopic.php?f=52&t=4081&p=10861#p10861

http://victorylibrary.com/mopar/cam-tech-c.htm

http://www.engineeringtoolbox.com/free- ... _1190.html

http://www.wallaceracing.com/dynamic-cr.php

http://victorylibrary.com/mopar/otto-c.htm

http://www.pcengines.com.au/calculators ... 0Ratio.htm

viewtopic.php?f=99&t=4458&p=12155#p12155

http://www.projectpontiac.com/ppsite15/ ... calculator

http://www.enginebasics.com/Advanced%20 ... namic.html

Ive found the KB calculator to give good results

https://www.uempistons.com/index.php?ma ... bed4958558

try this also

http://www.projectpontiac.com/ppsite15/ ... calculator

http://www.wallaceracing.com/dynamic-cr.php

http://cochise.uia.net/pkelley2/DynamicCR.html

http://www.steigerperformance.com/products/sp90005.html

I generally look to see about 145-160 psi on a street gas compatible engine compression test, but even if the reading are down near 120-130 psi I look more at cylinder consistency that the number

viewtopic.php?f=50&t=41&p=49&hilit=leak+down#p49

static compression is theoretical , in that its based on the piston stroke compressing the cylinder volume trapped above the piston from bottom dead center to top dead center being compressed into the combustion chamber and head gasket volume and you also need the piston deck to block deck heights and piston dome or dish volume, you need to know that static compression volume to start your calculations, its theoretical because all modern cams use timing figures that don,t close both the valves at BDC, allowing the full cylinder volume to be compressed.

when you build an engine you generally have some idea as to its intended operational rpm range and the octane level of the fuel you want to use.

normal quality blended gasoline tends to produce its best power at about a 12.5:1 fuel/air ratio, and lowest exhaust emissions at about a 14.7:1 f/a ratio

the higher the effective compression ratio (up to about 13:1) the more torque you can expect to produce from an engine,if you use, high octane gas or race fuels, but the octane of the fuel currently available from pump gas drops the max effective dynamic compression ratio to about 8:1

obviously the components selected must work in the desired rpm and intended power range.

you need to select a cam duration and LSA , and static compression that BOTH matches the static compression ratio and your cars gearing so the effective dynamic compression ratio falls in that range, and intended rpm/power band

viewtopic.php?f=55&t=2718&p=12119&hilit=octane#p12119

viewtopic.php?f=52&t=1070

http://www.jeepstrokers.com/calculator/

viewtopic.php?f=52&t=82

viewtopic.php?f=71&t=741

http://www.projectpontiac.com/ppsite15/ ... calculator

http://www.technovelocity.com/chevyhack ... cation.htm

http://www.pcengines.com.au/calculators/Calculate dynamic Comp Ratio.htm

viewtopic.php?f=55&t=109

read thru this thread

viewtopic.php?f=52&t=1477

https://www.uempistons.com/index.php?ma ... bed4958558

viewtopic.php?f=52&t=5078&p=14433#p14433

dynamic compression uses that that static compression volume as a base calculation but factors in the fact that the pistons not compressing a darn thing until both valves seat, and thats always AFTER BOTTOM DEAD CENTER, as the piston moves upward. so you compress a good deal less cylinder volume as the cams duration and LSA change the valve seat timing

http://garage.grumpysperformance.com/index.php?threads/crowers-valve-timing-charts.4299/

heres an extremely useful chart giving cam timing info

viewtopic.php?f=52&t=2782&p=7214#p7214

viewtopic.php?f=52&t=2077&p=9049#p9049

viewtopic.php?f=53&t=726&p=8809&hilit=quench+squish#p8809

you really might want to read thru these threads and links also, as theres a ton of good info included in the links

http://www.empirenet.com/pkelley2/DynamicCR.html

http://www.empirenet.com/pkelley2/DCR_FAQ.html

http://www.jeepstrokers.com/calculator/

viewtopic.php?f=52&t=4299

http://www.projectpontiac.com/ppsite15/ ... calculator

viewtopic.php?f=53&t=726&p=2302#p2302

http://victorylibrary.com/mopar/rod-tech-c.htm

http://www.circletrack.com/techarticles ... index.html

http://www.not2fast.com/turbo/compressi ... sure.shtml

viewtopic.php?f=55&t=2718

https://www.uempistons.com/index.php?ma ... bed4958558

http://www.cswnet.com/~carother/compression_ratio.htm

http://www.skipwhiteperformance.com/det ... 3831P-1230

http://victorylibrary.com/mopar/piston_position-c.htm

http://www.empirenet.com/pkelley2/DynamicCR.html

http://www.cpgnation.com/category/produ ... comp-cams/

viewtopic.php?f=52&t=1477

http://victorylibrary.com/mopar/cam-tech-c.htm

the difference between STATIC COMPRESSION RATIO AND DYNAMIC COMPRESSION RATIO is where the piston is in the cylinder when the valves close and the piston can actually start compressing the REMAINING VOLUME IN THE CYLINDER VS the STATIC COMPRESSION THAT ASSUMES THE PISTON STARTS COMPRESSING THE INSTANT IT LEAVES BOTTOM DEAD CENTER AND STARTS UPWARD ON THE COMPRESSION STROKE!

let me try and explain, the short version is that the PISTON COMPRESSES NOTHING untill BOTH VALVES ARE CLOSED, ....higher compression INCREASE the engines mechanical efficiency up to a point...that's the only compression ratio that matters,.... since its the only compression ratio the engine ever sees.

btw your max effective STATIC compression ratio naturally vary with the cylinder heat and fuel octane,ETC. but after about 13.7:1 the percentage of gains in hp from compression increases tend to drop off fairly rapidly, with most comon (GAS)

static compression is simply the difference between the cylinder volume at BOTTOM DEAD CENTER(BDC) and its compressed volume at TOP DEAD CENTER (TDC), into the combustion chambers,... dynamic compression takes into account that on the pistons upward compression stroke the valves have not yet closed and nothing gets compressed by the piston until they do, that of course depends on the cam and rockers, pistons and connecting rods, the cylinder volume, the rod/stroke ratio, ETC.,used, in the combo, and the rpm levels to some extent BTW, ALUMINUM HEADS can usually operate at a higher dynamic compression simply because ALUMINUM releases heat to the coolant much faster than iron, its the lower heat levels that remain in the cylinder that help prevent detonation..when you increase the dynamic compression the heat levels in the heads combustion chamber rise , the difference in the RATE heat leaves the cylinder allows a slightly higher dynamic compression level from aluminum before the same HEAT levels are REACHED & MAINTAINED in the combustion chambers , KEEP IN MIND ENGINE TEMP AND YOUR FUELS OCTANE , YOUR TRUE AIR/FUEL RATIO,YOUR IGNITION TIMING ADVANCE CURVE,HOW FAST YOUR KNOCK SENSOR REACTS, and THE ENGINES GENERAL CONDITION, EFFECT THE RESULTS AND WHEN DETONATION BECOMES A PROBLEM

!aluminum cylinder heads tend to allow you to run about 1/4-to-1/2 point more effective compression, IE, if iron heads get into detonation at 10:1 ALUMINUM might ALLOW YOU TO RUN 10.3-10.4:1 BEFORE GETTING INTO DETONATION, BUT ON THE PLUS SIDE AT LEAST IN THEORY IRON HEADS AT ANY GIVEN CPR WILL HAVE A SLIGHT ADVANTAGE IN HP

but in my real world testing the difference is much closer almost non-existent

the main advantage I see in aluminum heads is lighter weight and their much easier to repair when damaged

an aluminum cylinder head allows heat transfer to the engine coolant at a significantly higher rate than an iron head, and generally about .25-.50 higher compression can be tolerated but theres No absolute real definite answer, depends on quench, cam LSA, cylinder head design, advance curve, fuel/air mixture, intake temperature, coolant temp, spark plug design, piston design, heat barrier coatings, combustion chamber surface texture, and a bunch of other parameters.

here is a calculator for static cpr, which you need to figure first

http://www.rbracing-rsr.com/compstaticcalc.html

then lets assume your 350 sbc engine has a static compression ratio of 11:1 but youve installed this cam

http://www.cranecams.com/?show=brows...81&lvl=2&prt=5

first look at this chart

http://www.iskycams.com/ART/techinfo/ncrank1.pdf

and this one

viewtopic.php?f=52&t=4299

looking at the cam specs we see that the effective stroke is not the 3.48" that the static compression ratio is measured from ,at BDC, BUT from about 2.6 inches from tdc where the valves close as the piston moves upward, so your true working compression is closer to 8.1:1 NOT 11:1

heres some different calculators

viewtopic.php?f=52&t=4299

heres an extremely useful chart giving cam timing info

http://www.projectpontiac.com/ppsite/co ... iew/16/30/

https://www.uempistons.com/index.php?ma ... bed4958558

http://www.wallaceracing.com/dynamic-cr.php

http://members.uia.net/pkelley2/DynamicCR.html

average the results..of all four calculators.

READ thru THESE LINKS CAREFULLY

https://www.uempistons.com/index.php?ma ... bed4958558

http://cochise.uia.net/pkelley2/DynamicCR.html

viewtopic.php?f=55&t=2718&p=7057#p7057

http://www.kennedysdynotune.com/Dynamic Compression Tech.htm

viewtopic.php?f=55&t=613&hilit=boosters

http://www.popularhotrodding.com/tech/0 ... index.html

http://victorylibrary.com/mopar/cam-tech-c.htm

http://www.daytona-sensors.com/tech_tuning.html

read these

viewtopic.php?f=52&t=2077

viewtopic.php?f=52&t=2630&hilit=+valves

viewtopic.php?f=52&t=1159&hilit=lapping

I think back on the many dozens of times Ive pocket ported,heads un-shrouded combustion chambers, port matched, intakes and checked deck to piston heights

http://74.125.93.132/search?q=cache:I5W ... clnk&gl=us

a potential mistake that might result in a 1/2cc difference, now in an ideal world we all strive to get things exactly correct, but,

lets assume you do find a full cc difference ,between combustion chamber volumes,the real question is, what do you do to correct that, mis-match and if you don,t how much does it matter, to your engines performance?

http://www.csgnetwork.com/compcalc.html

input your average 70cc sbc heads on a 9:1 cpr sbc then change the chamber volume 1 cc and see how it changes the true results, in most production engines youll be very lucky to be within that range

just keep in mind the piston can,t compress a darn thing UNTIL both valves are closed, so your cam timing effects the true volume compressed in the cylinders

ok lets start from the basics

EACH COMPONENT YOU SELECT IS A COMPROMISE IN SOME AREA

If you've selected a cam that's got too much duration , for your application and rear gear ratio,

if you say the lopey, idle and lack of low rpm torque its a problem,its frequently the result of the cam, you've selected as TORQUE is the result of the EFFECTIVE USE of both DISPLACEMENT and cylinder pressure, so your compression ratio maters here in relation to cam timing, and the longer the cams duration the further up the cylinder the pistons traveled BEFORE the valves fully close, the less trapped volume or displacement you compress, hurting the low rpm torque. to much cam duration is effectively wasting a good percentage of your EFFECTIVE DISPLACEMENT

reducing duration and tightening the LSA tends to increase low rpm torque because for a GIVEN DURATION the valves close sooner in the crank rotation trapping more displacement and resulting in a higher percentage of the fuel/air mix being trapped, burnt and resulting in cylinder pressure turning the crank, but it also results in the valves being open less time so it tends to restrict high rpm breathing or cylinder fill efficiency

IF your running out of high end power it can be the result of a restrictive intake, carb, restrictive exhaust or lack of valve control, but its also common for a cam with too little duration to effectively restrict the cylinders from filling due to there being less time to fill and empty the cylinders

look heres a chart displaying piston location in crank degrees

http://www.iskycams.com/ART/techinfo/ncrank1.pdf

heres a chart showing valve timing in relation to duration

viewtopic.php?f=52&t=4299

look at the chart,

heres free cam selection software to narrow your choices

http://www.compcams.com/Pages/409/camquest-6.aspx

AS your displacement per cylinder increases the effective valve size per cubic inch decreases so you need a slightly tighter LSA and these charts should help.

he following are different static compression ratios (SCR) with a 3.48" stroke and different camshaft intake closing points @ 0.050" tappet lift on Keith Black's dynamic compression ratio calculator. The calculator, starting at 8.25:1 SCR. The dynamic compression ratio (DCR) has been kept at just over 8.0:1, a figure that is acceptable for use with today's pump gas with a little cushion:

- Static CR....Intake closing point @ 0.050"....Dynamic CR.

- 8.25........10* ABDC......8.010........................................................................................................

- 8.50........20............8.012........................................................................................................

- 8.75........27............8.022........................................................................................................

- 9.00........33............8.018........................................................................................................

- 9.25........37............8.061........................................................................................................

- 9.50........42............8.029........................................................................................................

- 9.75........46............8.016........................................................................................................

- 10.00.......49............8.038........................................................................................................

- 10.25.......52............8.043........................................................................................................

- 10.50.......55............8.029........................................................................................................

- 10.75.......57............8.069........................................................................................................

- 11.00.......60............8.022........................................................................................................

- 11.25.......62............8.038........................................................................................................

- 11.50.......64............8.042........................................................................................................

- 11.75.......66............8.035........................................................................................................

- 12.00.......68............8.017........................................................................................................

heres a chart I found that I don,t fully agree with, I think its a bit conservative, by about 3%-5% on the required cam duration ,required to avoid detonation with todays crappy octane fuel, but it at least gives you a base to work from, but Id suggest selecting a bit more duration

viewtopic.php?f=52&t=1070

viewtopic.php?f=52&t=324

viewtopic.php?f=52&t=727

Last edited by a moderator: