Balancing Equipment: a weighty matter

http://www.enginebuildermag.com/Article ... atter.aspx

Balance doesn’t matter with a manifold because it is a stationary engine component that doesn’t move. But balance does matter with everything that spins or reciprocates in the engine and drivetrain

By Larry Carley

Larry Carley

Everybody knows what balance is, right? You maintain your own balance by centering your body mass over your feet. If you lean too far forward or backward, or too far to the left or right, you’ll lose your balance and fall unless you grab hold of something or reposition your feet. Moving your center of gravity creates an imbalance that must be offset or corrected to maintain your balance.

It’s the same with engines.

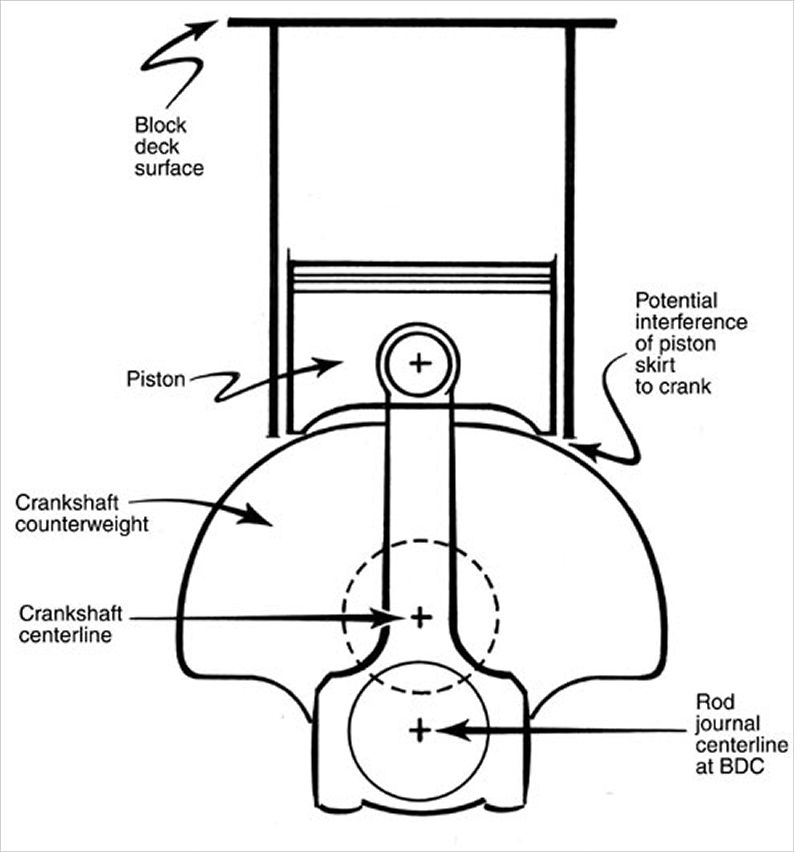

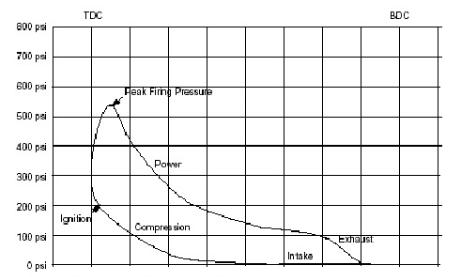

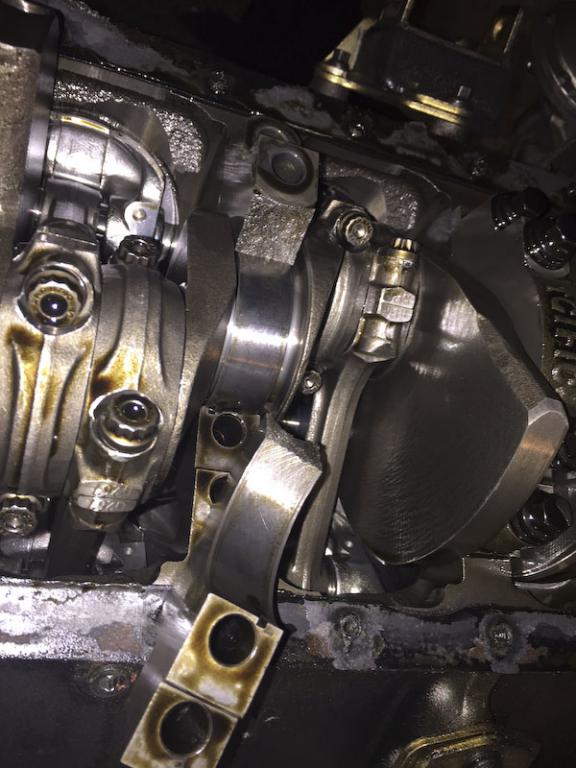

Reciprocating piston engines have a crankshaft that rotates at high speed, and pistons and connecting rods that oscillate up and down with every revolution of the crank. Both generate forces inside the engine that can cause unwanted vibrations and even engine damage if the forces are too great.

When an object rotates, it naturally rotates around its own center of gravity. That’s just the way nature works. Every solid object has a natural center of gravity regardless of its size or dimensions, even an odd-shaped object like an exhaust manifold. Toss an old manifold off a cliff and give it a spin as you do so, and the manifold will rotate around its own center of gravity. Balance doesn’t matter with a manifold because it is a stationary engine component that doesn’t move. But balance does matter with everything that spins or reciprocates in the engine and drivetrain.

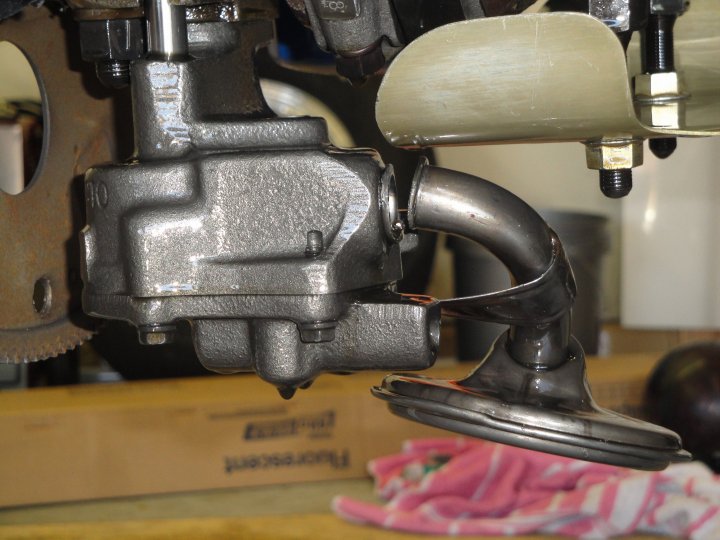

This includes the crankshaft, connecting rods and pistons, as well as the flywheel or flex plate, clutch or torque converter, the harmonic balancer and drive pulleys, the cooling fan, the turbocharger impeller shaft, the driveshaft, brake rotors and drums, the wheels and tires, and even the camshaft(s).

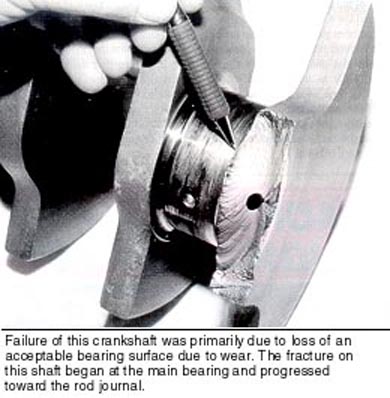

The forces generated by an imbalance in any of these parts depend on two things: the magnitude of the imbalance and the speed of the object. The larger and heavier the object, and the faster it spins, the greater the force generated by any imbalance that exists. For a rotating crankshaft, the force at the main bearings is proportional to the speed of the engine squared. Also, the further the imbalance is located from the center of gravity, the greater its effect on the part as it rotates.

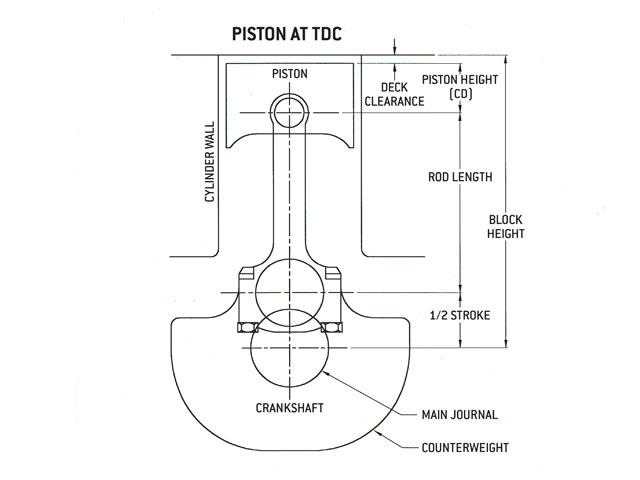

With crankshafts, large heavy counterweights are used to offset the forces generated by the reciprocating weight of the pistons and rods. The crank must not only maintain its own balance as it spins around inside the block, it must also offset the forces generated by the mass of the pistons and rods as they pump up and down.

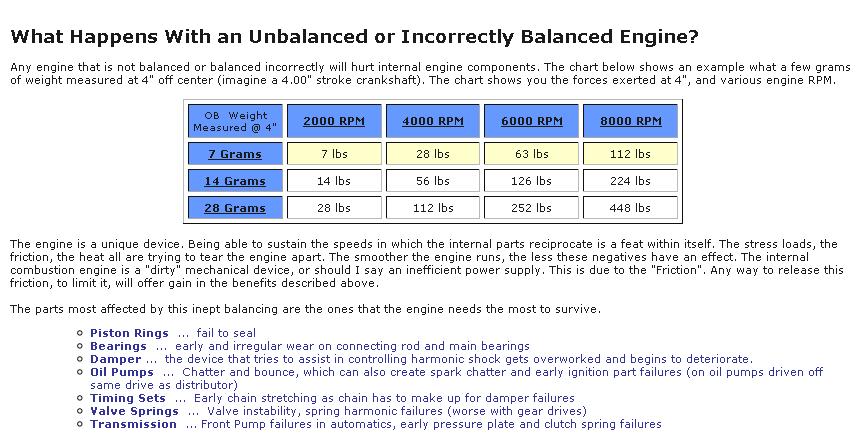

So what does this actually mean in terms of the forces generated inside an engine? An imbalance of only 1/4 oz. (7 grams) located four inches out from the center of the crank on a counterweight will generate a force of about 7 lbs. at 2,000 rpm. At low rpm, you would hardly feel a thing. But at 8,000 rpm, that same force would grow to 114 lbs. with every revolution of the crank. If this same engine had one ounce (28 grams) of imbalance, the forces generated would be multiplied by a factor of four, generating 456 lbs. of unwanted gyrations at 8,000 rpm! That’s enough vibration to rattle your teeth and pound the heck out of the main bearings. It’s also wasted motion that goes into shaking the block instead of spinning the crankshaft. Consequently, imbalance hurts horsepower as well as smoothness and engine longevity.

The factory balance of crankshafts can vary a great deal depending on the application and the OEM tolerances. For a low rpm stock engine, plus or minus 8 to 10 grams or more may be close enough for the average Joe. For a street performance engine, those numbers should come down to plus or minus 3 grams or less. And for a high revving NASCAR engine that spends most of its time at 8,500 to 9,500 rpm, plus or minus 1 gram or less is the rule.

The longer the stroke on the crankshaft, the more important balance becomes because of the distance factor. A longer stroke moves metal further from the axis of rotation and magnifies its effect on balance. It’s not unusual to find imported stroker cranks with as much as 80 to 90 grams of imbalance! These cranks obviously need to be reworked if they’re going into a high revving performance engine.

In recent years, some racers are even scrutinizing camshaft balance. Cam balance is usually not much of a factor because the cam only turns at half the speed of the crankshaft, and the lobes do not protrude very far from the shaft itself. But in a high revving NASCAR engine, cam imbalance can cost the engine as much as 20 horsepower because of the valvetrain harmonics it creates.

ALWAYS CHECK BALANCE

One thing to remember about engine balance is that anytime you replace parts or assemble parts from various suppliers, it affects balance. No two parts are manufactured exactly the same and there will always be some variation in weight. Stock OEM piston weights can vary quite a bit, and even aftermarket performance pistons may not be perfectly matched in a set (though most high quality performance parts are weight-matched). Even so, balance should always be checked and corrected as needed to match the needs of the application. On a stock engine, close enough may be good enough, but on a performance engine there’s much less margin for error.

Changing bore sizes or piston types will affect balance. Changing piston heights, rod lengths or the type of rods (steel, powder metal or forged aluminum) will affect balance. Replacing a stock crank with an aftermarket performance crank or a crank with a different stoke will affect balance. You can’t just throw the parts together and hope the engine will be in balance (which is what a lot of mail order DIY engine builders do!). You have to weigh and balance the individual parts and make sure they work harmoniously together.

BALANCING FUNDAMENTALS

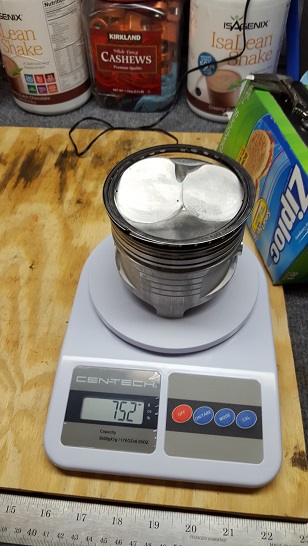

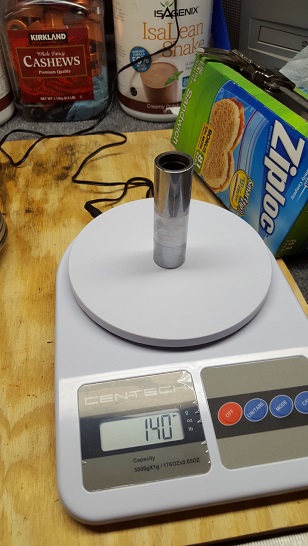

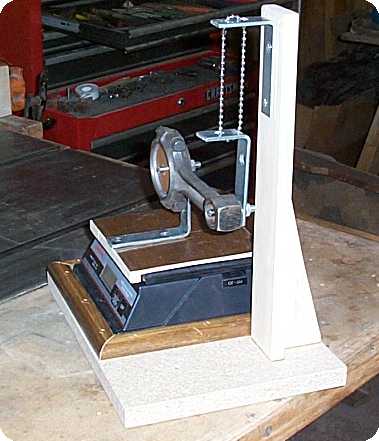

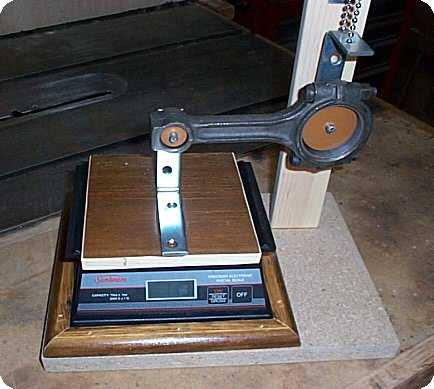

Balancing requires several pieces of equipment: a highly accurate digital scale for weighing pistons, wrist pins and connecting rods, and a spin balancer for rotating parts such as the crankshaft, flywheel or flex plate, torque converter or clutch, harmonic balancer and crank pulley. You’ll also need a drill stand and/or milling machine to make corrections.

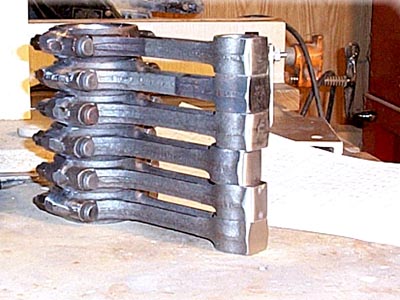

The first step in balancing a crankshaft is to weigh all the reciprocating parts starting with the pistons, wrist pins and ring sets. The idea here is to determine the weight of each part, find the lightest pistons, then match the weights of all the remaining pistons to the lightest one by grinding or machining metal off the balancing pads, skirts and/or pin bosses of the heavier pistons. The goal is to match weights to within one gram or less.

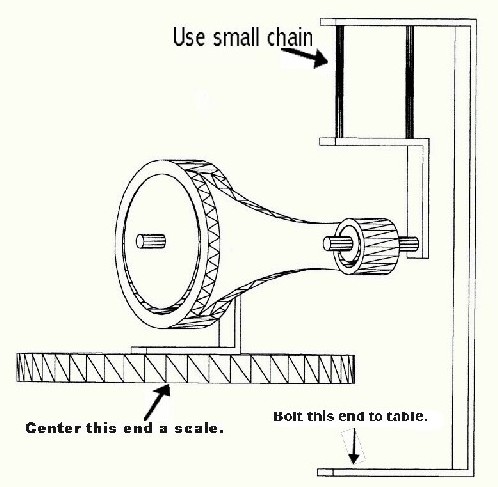

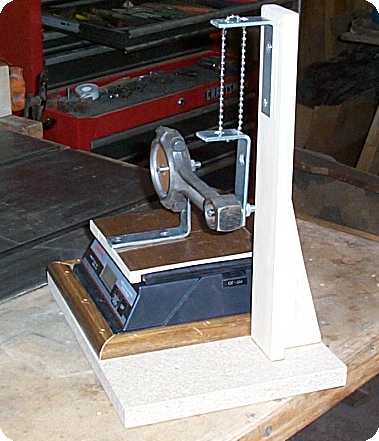

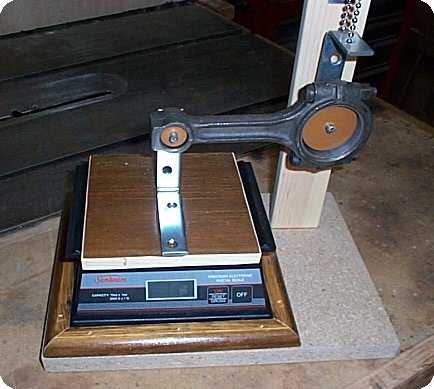

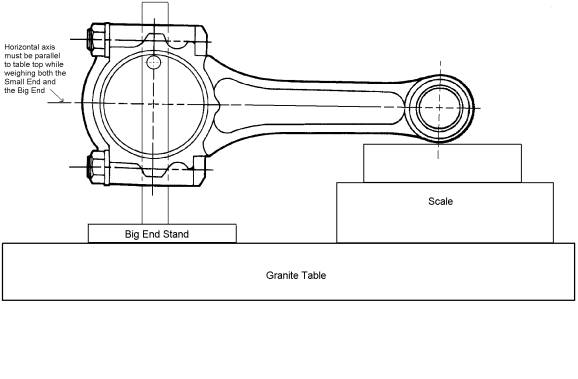

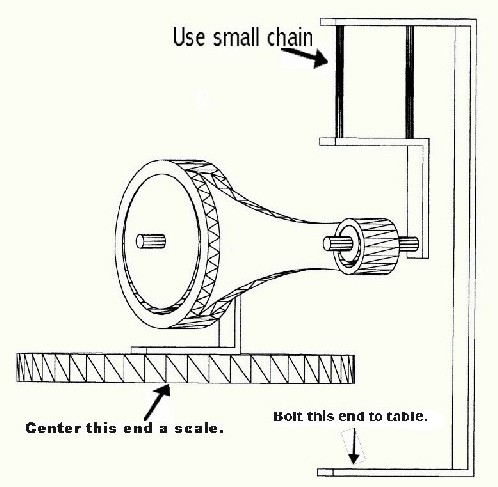

The next step is to weigh the big ends and small ends of the connecting rods. The small end is reciprocating weight while the big end is rotating weight. Each end must be weighed separately by supporting one end on the scale while the other end is supported by a stand. The small ends of the rods can then be equalized by grinding metal off the balance pads at the top of the rods. The weights for the large end of the rods can be equalized by grinding metal off the balance pads on the rod cap. As before, the goal is to equalize all weights to one gram or less.

NOTE: Removing metal from the big end of the rod will change the overall weight of the rod slightly, so it may be necessary to go back and recheck the small end weights and do some additional grinding to keep the small end weights equal.

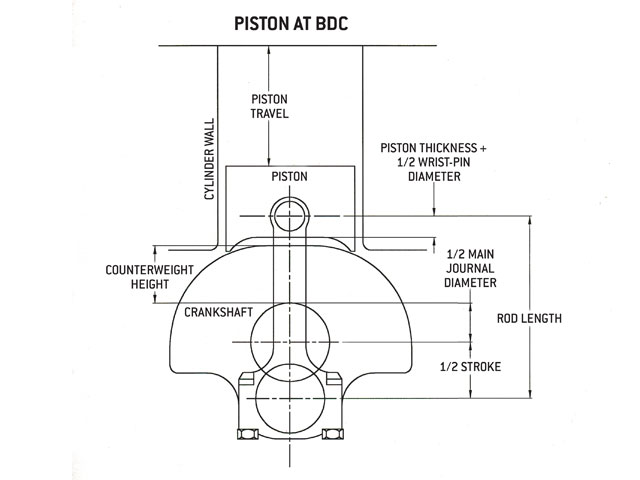

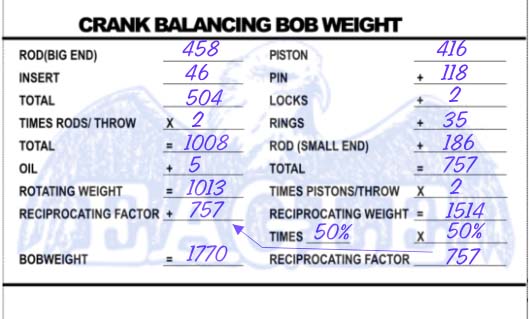

Next comes some math. The weight of the reciprocating parts (the piston, ring set, wrist pin and small end of the rod) must be added together to calculate the amount of bobweight needed to balance the crank. Bobweights are attached to each of the crank’s rod journals to simulate the reciprocating mass of the pistons and rods. On a V8 engine, the bobweight will usually be 100 percent of the weight of the rotating components (the big end of the rod, the rod bolts and bearings) plus 50 percent of the reciprocating weight (pistons, rings, wrist pin and small end of the rod). On many racing engines, “overbalancing” the crank by using 55 percent to as much as 70 percent of the reciprocating weight can help smooth out high rpm vibrations. On straight four and six cylinder engines no bobweights are required. With V6 engines, a different fraction of the reciprocating weight is needed because of the angularity of the crank (typically 39.4 percent of the reciprocating weight on a 90° V6).

On some balancers, it is also possible to use “simulated” bobweights via the balancer software if you’re balancing a run of identical crankshafts. Once you’ve determined the required bobweight for one journal, you can simply enter that value for each succeeding crank without having to actually bolt weights on the crank. This saves time and improves consistency.

SPIN BALANCING

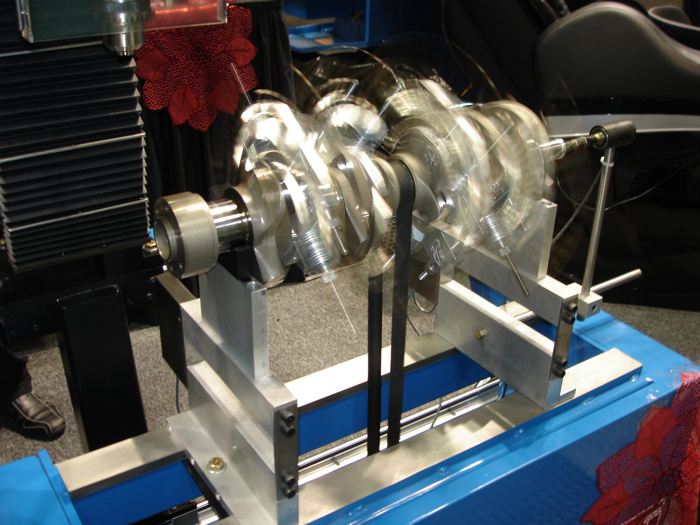

To spin balance the crank, the crank is mounted on the balancing machine support stanchions. The crankshaft should be checked for straightness because a bent crank will wobble as it rotates – which may fool the balancer into thinking the wobble is due to imbalance. Straightness can be checked with a dial indicator at the center journal.

The balancer will then spin the crank to about 500 rpm and determine the magnitude and location of any imbalance it detects. Many balancers today can detect imbalance as small as .01 grams, which is far more than what’s actually needed to achieve a balance of plus or minus one gram or less. The balancer detects imbalance by measuring the displacement of the support stanchion sensors while the crank is spinning. Readings are taken in 1 to 3 degree increments (6 degrees on older balancers), and compared to the position of the crank as it rotates. Imbalance changes the crank’s center of gravity, causing it to wobble off center as it rotates, and the greater the imbalance, the more it wobbles and shakes.

Now comes the magic part. The balancer software looks at the sensor inputs and calculates the amount of the imbalance and its location. The weight is then displayed in ounce-inches or gram-centimeters, and its estimated location is shown in degrees from a reference position.

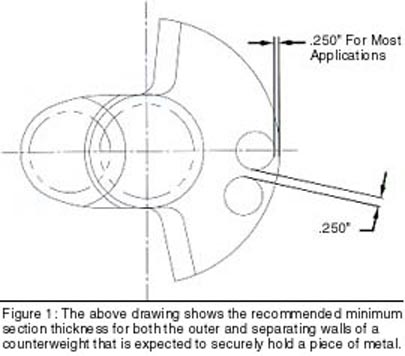

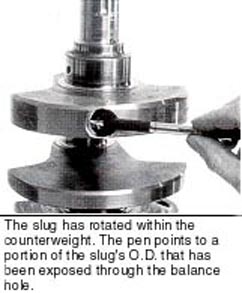

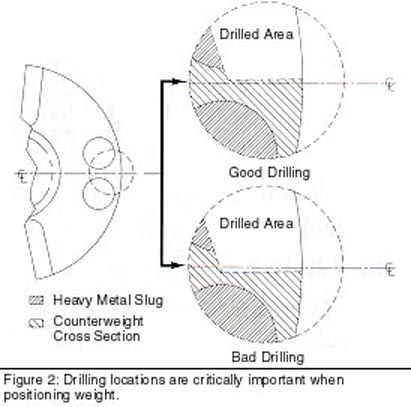

Corrections can then be made by drilling holes or machining down the outside diameter of the counterweights to remove metal. Or, if more weight is needed, you can weld metal to the counterweights, or drill holes (or use existing holes) to add plugs of heavy metal to the counterweights (Mallory metal is 1.5 times as heavy as lead, and is often needed on stroker cranks and ultra-light racing cranks).

Removing weight requires locating the drill bit precisely and drilling to an exact depth. The software on many newer balancers can calculate the size and exact depth of the hole(s) to be drilled, as well as the best place to locate heavy metal if weight needs to be added. On older machines, corrections typically require much more skill and guesswork. You drill out what you think is the right amount of metal to remove, then cross your fingers and spin the crank again to check the balance. Then you drill or plug some more, spin again, and repeat as many times as needed until you finally get it right. This can sometimes leave the crank looking like a piece of Swiss cheese, which is not good because too many holes may weaken the crank or create windage and drag problems at high rpm.

Making corrections also involves separating one end of the crank from the other because imbalance at one end will affect the other. On older balancers, corrections made at one end of the crank often upset the balance at the other end, requiring repeated spins and corrections until both ends are in balance. On most newer balancers, the software takes this into account and splits the forces apart so corrections that are made on one end won’t upset balance on the other end. It’s like cutting the crank in half and balancing each half separately while also taking into account the balance on the other end. This is called “dynamic plane separation” and is a time-saving feature you want if you’re shopping for a new balancer. The main advantage of dynamic plane separation is that it does a superior job of isolating vibrations so corrections can be made more quickly and accurately. It reduces the back and forth corrections and repeat spins that can eat up valuable shop time.

Multi-plane balancing is also possible on some machines to segment the crankshaft electronically into even smaller sections. This can be helpful in situations where one area of a crank has a lot of imbalance (one end or near the middle).

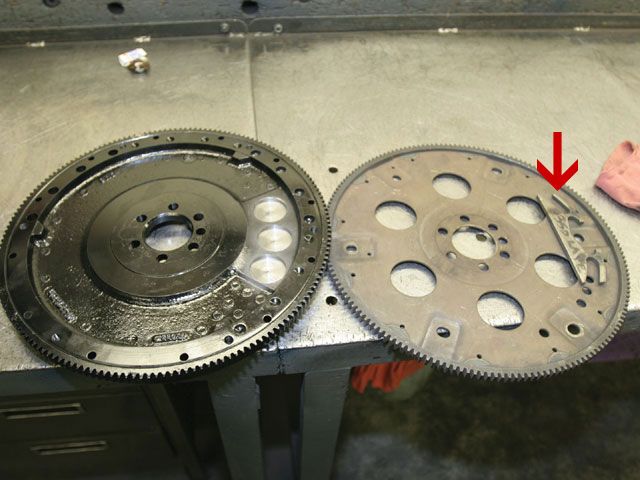

If a crank is externally balanced, the flywheel and harmonic balancer must be bolted to the crank for a final balance check, and corrections made as needed by adding or removing weight on the flywheel or harmonic balancer to even out the forces. Externally balanced cranks typically have smaller counterweights that are not sufficient by themselves to cancel out all the vibrations of the pistons and rods. An externally balanced crank can sometimes be converted to an internally balanced crank by adding heavy metal to the counterweights. Otherwise, the index position of the flywheel must be maintained with respect to the crank if the flywheel is removed and reinstalled to maintain proper balance.

SHOPPING FOR NEW EQUIPMENT

Whether you’re shopping for your first balancer, adding an additional balancer to expand your business, or replacing an ancient balancer that has outlived its usefulness, there are a variety of machines from which to choose. Balancers have improved a great deal in recent years thanks to better software, better hardware and more user friendly controls. Many balancers now have full color displays and Windows-based software that make them easier to use, even novice users. Graphic displays that show you exactly where the corrections are needed reduce errors and save time.

Balancer manufacturers typically sell two kinds of equipment: balancers for use with existing milling machines, and stand-alone units that include a milling stand or drill press as standard equipment or an option. Balancers come with basic digital displays or PC-based full color displays and various software packages. Bobweights may be included or available at extra cost. Obviously, the more features you want, the more you’ll pay.

CWT INDUSTRIES

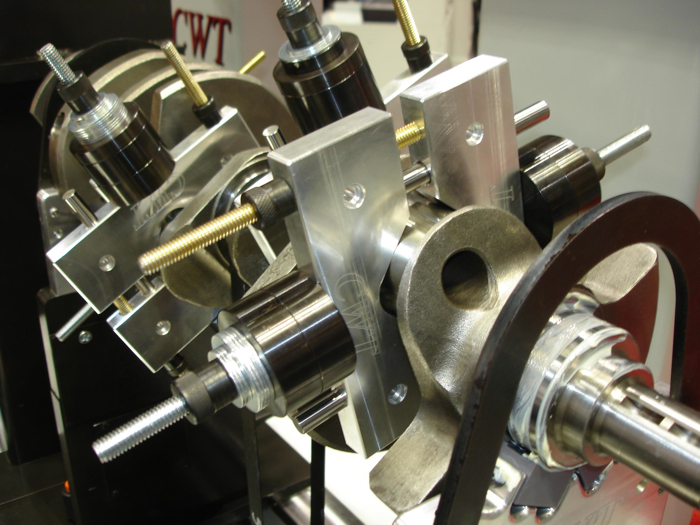

Randy Neal of CWT has been making waves in the industry with his “three plane” balancer. He says dynamic two-plane balancers can sometimes be fooled by certain kinds of crankshaft imbalance. His “third plane analysis” software and hardware does a better job of isolating and identifying force vectors to reduce the time it takes to balance a crank by a third or more. Additional software includes unlimited parts and history data base, “PDQ” (Precision Drill Qualifying) to help the user determine the best locations for drilling correction holes (to minimize the number of holes that have to be drilled), and “HMV” (Heavy Metal Vector) to plot the best locations for adding metal if more weight is needed.

CWT sells three balancers: the Multi-Bal 1000 for Mill mounted applications and the stand-alone Multi-Bal 2000, are both standard two-plane balancers with polar and vector displays at a base price of $9,995 and $12,500. The Multi-Bal 5000, which is CWT’s three-plane balancer starts at $15,900. The Multi-Bal 5000 comes with touch screen controls, heavy duty work cabinet and a 4,100-lb resin-filled steel base for added rigidity, which eliminates any residual vibrations that could affect balancing accuracy. Neal says the balancer’s sensors can detect motions as small as .25 microns (.00000975?) and inspects imbalance position 720 times per revolution, which adds to the machine’s high degree of accuracy. Options include; heavy duty gear head mill/drill, digital drill depth monitoring, heavy metal drill stand and “moment-matched bobweights,” universal flywheel arbor and direct communication weight scales system.

G & H BALANCER SERVICE

Gary Hildreth says his company does not make their own balancers, but they do sell Turner balancers. “Our niche is balancer repair and service. We have belts for every balancer ever built and can service any brand of balancer.” The company also sells bobweights and other balancing accessories.

Hildreth says that within the next 10 to 12 months, he will be introducing a new electronics package to upgrade older Stewart Warner balancers. He estimates there’s still 4,000 of these older balancers out there, and most could benefit from an electronics upgrade. No word yet on the selling price of the upgrade package.

HINES

Hines sells three basic models of balancers: the “Eliminator,” a $12,495 hard bearing balancer with a black and white LCD plasma display, the $14,900 “Dominator,” which is a PC-based hard bearing balancer, and the $15,900 “Liberator,” their top-of-the-line PC-based balancer.

John Witt of Hines says the Dominator and Liberator both include a Graphic Depth Encoder which ties the drill quill to the display screen to show the operator where and how deep to drill correction holes. Both machines also offer dynamic plane separation for faster, more accurate corrections – a capability, Witt says, that Hines has had since 1979. The Liberator also includes a 19? flat screen color display, 24? x 36? workstation cabinet so new rod and piston corrections can be done without leaving the machine.

SCHENCK TREBEL

Rich Idtensohn says his company is the world’s largest manufacturer of dynamic balancing equipment. Its CS30 Balancer is an industrial-based, multi-plane, hard bearing balancer that starts at $18,000 and can go as has high as $30,000 depending on options. The CS30 Balancer has two options for instrumentation, the CAB 700 digital display or the CAB 803 PC-based Windows NT touch screen display.

Both instrumentation packages provide an automatic tolerance calculation for each plane, and provide an electronic protractor so the operator can visually pinpoint the exact location to make corrections. The system includes optional drill depth indicator software that shows how much drilling is needed to make a correction. The machine also comes with a heavy-duty drill correction unit that rotates 360°.

“Many manufacturers offer similar features that make balancing easy,” says Idtensohn. “But the real difference is a matter of accuracy, sensitivity and repeatability. The fact of the matter is, if engine builders take a closer look at their results many just aren’t getting what they think they’re getting. A few simple repeatability tests can be very revealing and can make a substantial difference in performance.”

Schenck is also offering a new balancing certification program, the first of its kind says Idtensohn. The three-tiered program offers Level 1 Balancing Operator Certification, Level II Balancing Technician Certification, and Level III Balancing Specialist Certification. The program is designed to provide a standard benchmark for excellence and productivity, as well as individual recognition for technical skill and aptitude. Anyone who has completed their Fundamentals of Balancing, Jet Engine Balancing or Pump & Impeller Balancing seminars are eligible for Level 1 or II certification. Candidates for Level III certification is open to those who can demonstrate in-depth knowledge of balancing theory principles and practices, vibration analysis, rotor dynamics and measuring instrumentation.

SUNNEN

Sunnen sells two balancers, a DCB-750 with digital controls that starts at around $17,000 and a DCB-2000 with Windows XP instrumentation touch screen display that starts at around $20,000. Tim Meara of Sunnen says both machines are mechanically the same except for the controls. New features on the DCB-2000 include counterweight cutting software for calculating how much metal to remove from the counterweights if a user prefers to turn down the counterweights rather than drill holes in them. New vectoring software shows where to add heavy metal to cranks and allows the use of existing holes to save extra drilling.

Meara says Sunnen’s balancers are two-plane balancers. The DCB series balancers are extremely precise, measuring unbalance from .01 to 1,000 grams on work pieces weighing up to 500 lbs. (226 kg.). The balancers can handle anything from small engine cranks to diesel cranks. Also included is a heavy-duty drill tower and steel base that is concrete-filled for extra stability for more precise results.

T & S MACHINE

Tim Whitley says his company has a marketing agreement with Pro-Bal to sell their balancers. The PB500 is a basic microprocessor controlled hard bearing balancer that starts at $11,000 bare up to $23,000 complete with the drill press and automotive tooling package while the “Edge” bolts to a vertical milling machine and sells for $7,500.

Placing the “Edge” on a milling machine saves floor space and offers the best drilling machine possible when correcting the imbalance.

“These balancers are capable of force and couple balancing, which some people now call three plane balancing. Separating the forces out allows the user to better understand what’s going on so corrections are easier and faster to make,” said Whitley.

Accuracy is to .01 oz./in. detectable unbalance, and spins take only 20 seconds. The compact design of The Edge takes up less space than other balancers and can be converted to surface heads and blocks, and do seat and guide work.

TURNER TECHNOLOGIES

Turner Technology sells three models of balancers. The Series 1 balancer is for automotive and small engine parts, and can handle cranks up to 7? in stroke and flywheels up to 16-1/2? in diameter over the table. The Series 2 balancer is a heavier, taller machine that can handle cranks of greater stroke with larger flywheels. The Series 3 balancer is taller yet to handle even larger shafts. Series 2 and 3 balancers can have optional roller bearing tops for balancing very heavy shafts.

Turner Technology’s Michael Turner says its balancers offer powerful dynamic plane separation with third plane analysis for fast, accurate balancing, even with a large amount of couple. “Our software allows you to balance any section of a crankshaft without changing the balance elsewhere, so fewer corrections are needed. We also use a closed-loop motor control design for improved accuracy.”

The machines use an interface system that allows the balancers to be connected to any laptop or desktop running Windows 98 through XP. This helps keep the cost of the equipment down, says Turner, and simplifies upgrades. Turner says heavy metal software is included in the standard package along with free lifetime software upgrades. Digital scale readings are automatically transferred into the control software to save time and reduce errors. Balancer packages start around $8,000. You also get one of the best warranties in the industry with an option to extend the warranty at any time, according to Turner.