honestly, if you've got a decent welder and a tape measure, a chop/miter metal saw, and some time, to kill,

this is a reasonably easy project, if you can weld and have easy local access to various metal tube sizes and types

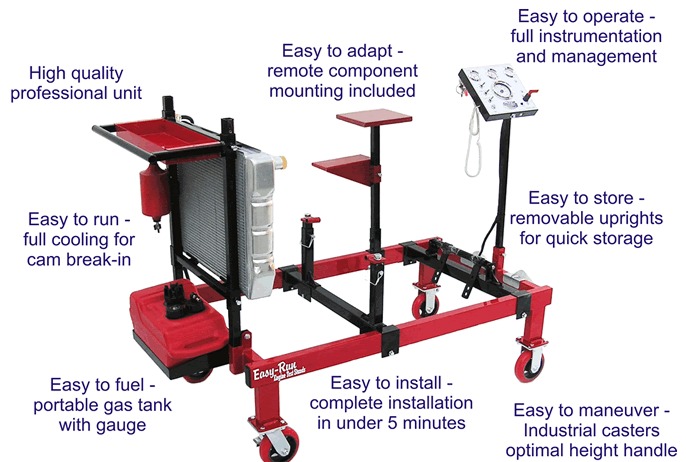

, and it sure beats paying $2k. or more for a commercial version, and personally Id mount the engine so the oil pan bottom surface, was no more than 1 foot off the floor for increased stability

there's several design options but Id suggest you design one that's very wide and stabile,

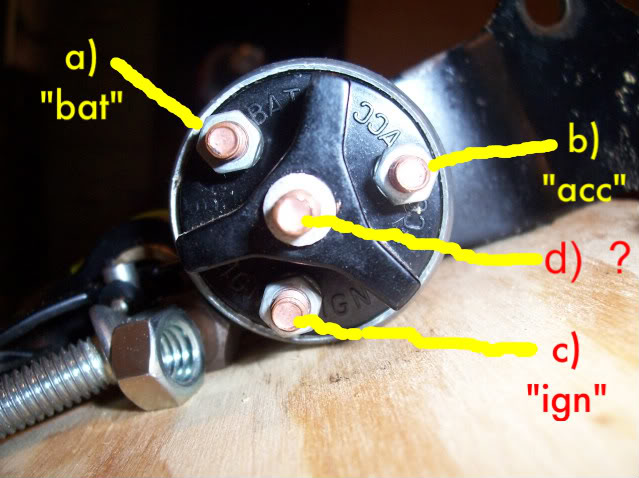

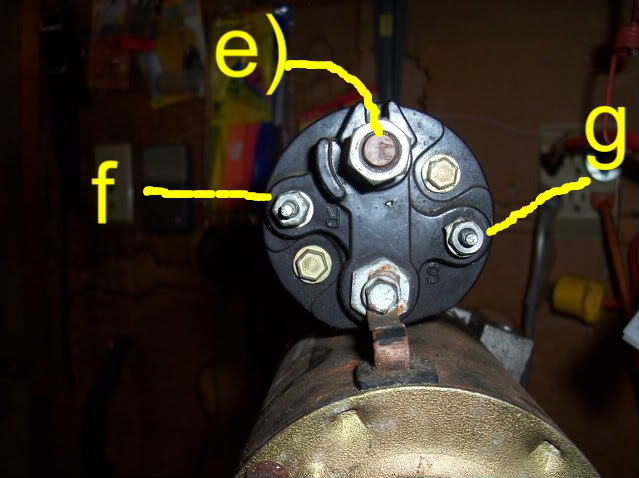

and easy to access all the components and gages and parts like the starter, battery tray, fuel pump, radiator etc.

and having a strong separate cooling fan to augment the engines fan belt driven fan may help.

http://mycorvetterestoration.com/side-projects/engine-test-stand.php#.VZXATPlViko

http://www.hotrod.com/how-to/additional-how-to/hppp-1103-diy-engine-break-in-stand/

http://www.tommackieracing.com/projects/articles/engine-test-stand/

http://www.averagejoesautos.com/engineteststandpage.html

http://www.ebay.com/itm/Easy-Run-En...hash=item41985f6d11&item=281729264913&vxp=mtr

WATCH VIDEO,s

LOOK AT THE VIDEO THEN THE PRICES AND IF YOU OWN A WELDER AND CAN FABRICATE< AND SHOP CAREFULLY FOR GAUGES ETC. YOU CAN SAVE A GOOD DEAL OF MONEY

http://www.easy-run.net/

http://www.prwonlinestore.com/low-profilesetsaccessorizedunit.aspx

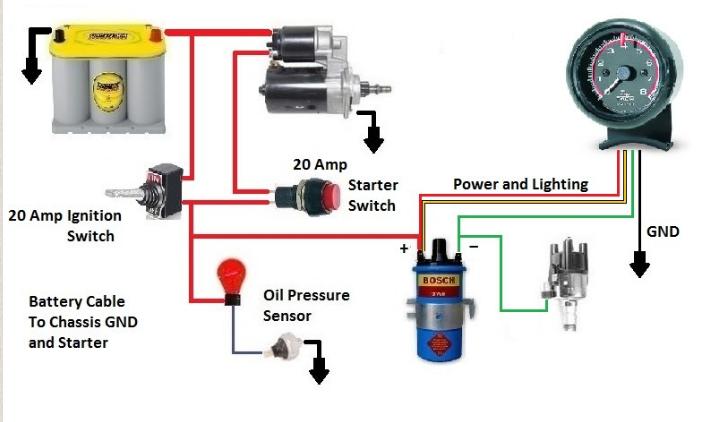

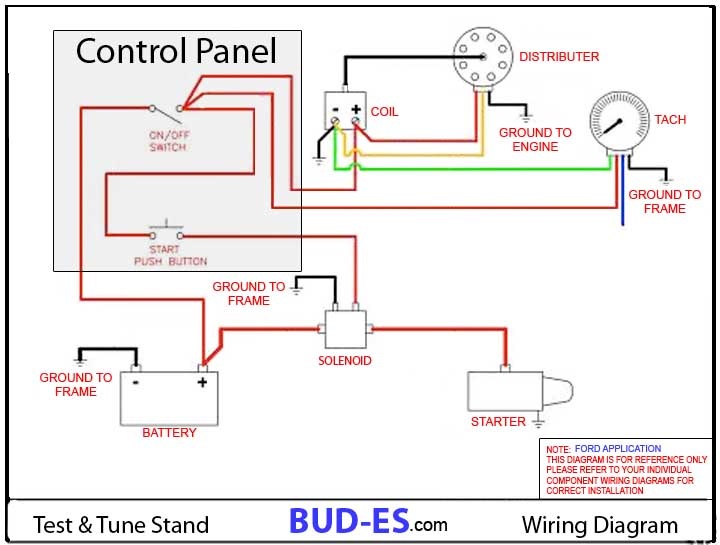

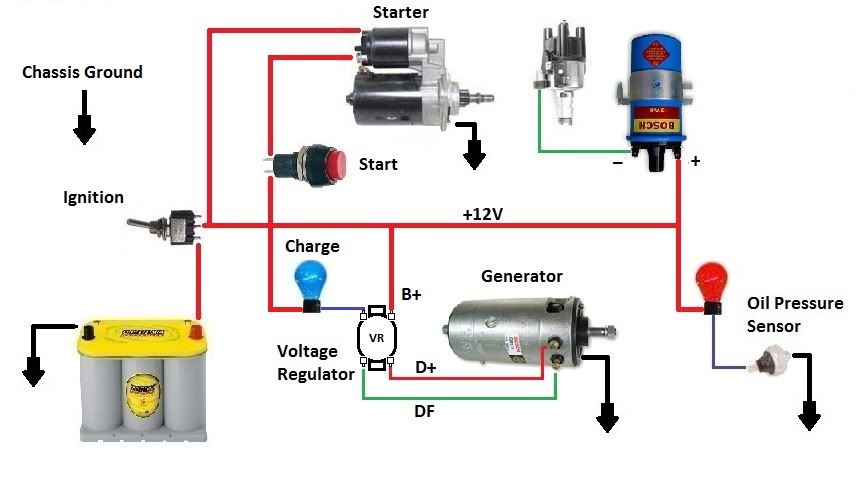

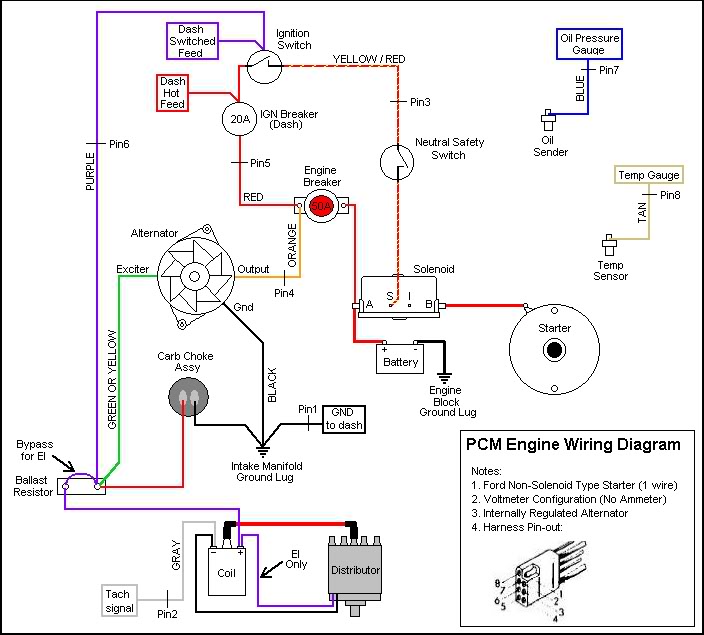

heres some basic design ideas from pictures

http://www.lainefamily.com/EngineStandProject.htm

http://www.mightymount.com/

http://www.hotstands.com/

http://www.rivasteststand.com/

http://www.fordmuscle.com/forums/tech-exchange/471021-homemade-engine-run-stand.html

viewtopic.php?f=80&t=728&p=9217&hilit=sensors+camaro#p9217

http://cgi.ebay.com/ebaymotors/Engi...Z230310166282QQptZMotorsQ5fAutomotiveQ5fTools

http://cgi.ebay.com/ebaymotors/SB-B...Z320324798487QQptZMotorsQ5fAutomotiveQ5fTools

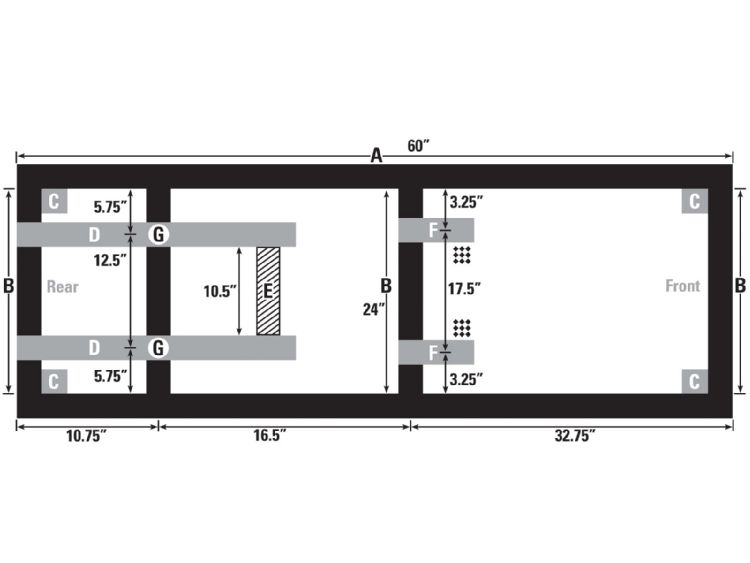

IF i was going to fabricate one ID start with this

http://www.northerntool.com/webapp/wcs/stores/servlet/product_6970_406688_406688

ID buy (2) 3 ft long, and (2) 5 ft long sections of 1.5"x 3" box steel too weld as a base,

and about 20 feet of 1" x 2" box steel as uprights for the gauges, and radiator,battery box, ETC. into. plus a section of 1/8" thick 1ft x 2 ft aluminum diamond plate to mount the gauges,

ID buy (4) of these wheels

http://www.northerntool.com/webapp/wcs/stores/servlet/product_6970_200337096_200337096

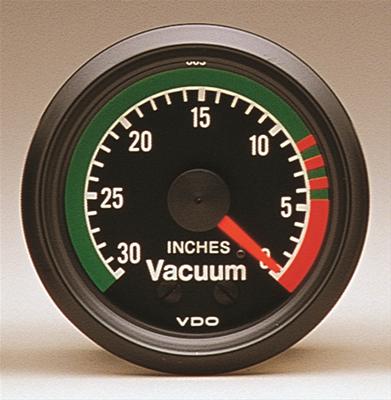

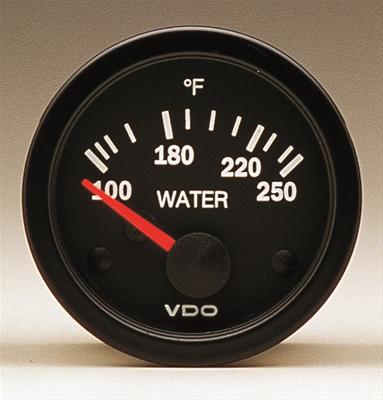

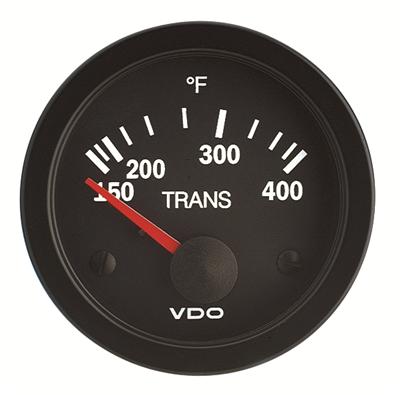

and find a decent radiator from a salvage yard, Id get these gauges

http://store.summitracing.com/partdetail.asp?autofilter=1&part=ATM-4337&N=700+115&autoview=sku

http://store.summitracing.com/partdetail.asp?autofilter=1&part=ATM-4327&N=700+115&autoview=sku

http://store.summitracing.com/partdetail.asp?autofilter=1&part=ATM-4391&N=700+115&autoview=sku

http://store.summitracing.com/partdetail.asp?autofilter=1&part=AVM-30-4100&N=700+115&autoview=sku

http://store.summitracing.com/partdetail.asp?autofilter=1&part=ATM-4498&N=700+115&autoview=sku

http://store.summitracing.com/partdetail.asp?autofilter=1&part=ATM-4301&N=700+115&autoview=sku

http://store.summitracing.com/partdetail.asp?autofilter=1&part=NEX-15512&N=700+115&autoview=sku

for UNDER about $750 and most of thats the cost of GAUGES, and matched sensors you can have a decent engine stand built, the steels reasonably priced its the measurements and fabrication that takes time and precision

heres an example for ideas

http://www.prw-usa.com/category/products/test-stands

this is a reasonably easy project, if you can weld and have easy local access to various metal tube sizes and types

, and it sure beats paying $2k. or more for a commercial version, and personally Id mount the engine so the oil pan bottom surface, was no more than 1 foot off the floor for increased stability

Links To Several Welder Tests Reviews And Related Info

https://www.everlastgenerators.com/sites/everlastgenerators/files/5fff551626d4b1ad242c7fa957d940d6.pdf I don't know how any serious person in this hobby can get along, without a decent TIG, or a MIG welder and an ACETYLENE TORCH SET YES IT HELPS A GREAT DEAL IF YOU KNOW WHAT YOUR DOING...

garage.grumpysperformance.com

in the market for a metal cutting miter saw

I'm in the market for a 12" or 14" metal cutting miter saw,or radial arm saw , to cut 3"-4"-6" wide and 3-4" deep rectangular aluminum tubing and channel up to 1/2" thick on the walls. Ive talked with several fabrication shops and metal supply shops and they all suggested rather expensive saws...

garage.grumpysperformance.com

there's several design options but Id suggest you design one that's very wide and stabile,

and easy to access all the components and gages and parts like the starter, battery tray, fuel pump, radiator etc.

and having a strong separate cooling fan to augment the engines fan belt driven fan may help.

http://mycorvetterestoration.com/side-projects/engine-test-stand.php#.VZXATPlViko

http://www.hotrod.com/how-to/additional-how-to/hppp-1103-diy-engine-break-in-stand/

http://www.tommackieracing.com/projects/articles/engine-test-stand/

http://www.averagejoesautos.com/engineteststandpage.html

http://www.ebay.com/itm/Easy-Run-En...hash=item41985f6d11&item=281729264913&vxp=mtr

Do You Stop And Logically Isolate And Test Or Just Start Swapping Parts?

Honestly, I have to wonder at times about the thought process or in many cases the lack of thought and research that I see going on.I don,t know about the guys you might know, but it seems all too common for guys I know to find something amiss, or out of adjustment and they immediately just...

garage.grumpysperformance.com

WATCH VIDEO,s

http://www.easy-run.net/

http://www.prwonlinestore.com/low-profilesetsaccessorizedunit.aspx

heres some basic design ideas from pictures

http://www.lainefamily.com/EngineStandProject.htm

http://www.mightymount.com/

http://www.hotstands.com/

http://www.rivasteststand.com/

http://www.fordmuscle.com/forums/tech-exchange/471021-homemade-engine-run-stand.html

viewtopic.php?f=80&t=728&p=9217&hilit=sensors+camaro#p9217

http://cgi.ebay.com/ebaymotors/Engi...Z230310166282QQptZMotorsQ5fAutomotiveQ5fTools

http://cgi.ebay.com/ebaymotors/SB-B...Z320324798487QQptZMotorsQ5fAutomotiveQ5fTools

IF i was going to fabricate one ID start with this

http://www.northerntool.com/webapp/wcs/stores/servlet/product_6970_406688_406688

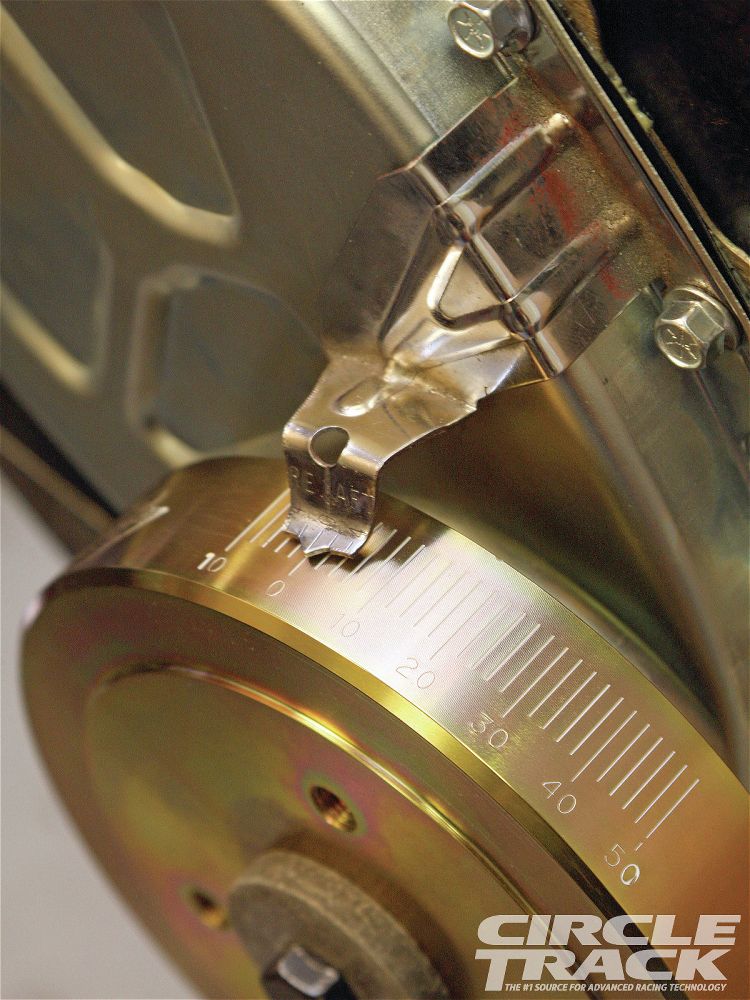

ID buy (2) 3 ft long, and (2) 5 ft long sections of 1.5"x 3" box steel too weld as a base,

and about 20 feet of 1" x 2" box steel as uprights for the gauges, and radiator,battery box, ETC. into. plus a section of 1/8" thick 1ft x 2 ft aluminum diamond plate to mount the gauges,

ID buy (4) of these wheels

http://www.northerntool.com/webapp/wcs/stores/servlet/product_6970_200337096_200337096

and find a decent radiator from a salvage yard, Id get these gauges

http://store.summitracing.com/partdetail.asp?autofilter=1&part=ATM-4337&N=700+115&autoview=sku

http://store.summitracing.com/partdetail.asp?autofilter=1&part=ATM-4327&N=700+115&autoview=sku

http://store.summitracing.com/partdetail.asp?autofilter=1&part=ATM-4391&N=700+115&autoview=sku

http://store.summitracing.com/partdetail.asp?autofilter=1&part=AVM-30-4100&N=700+115&autoview=sku

http://store.summitracing.com/partdetail.asp?autofilter=1&part=ATM-4498&N=700+115&autoview=sku

http://store.summitracing.com/partdetail.asp?autofilter=1&part=ATM-4301&N=700+115&autoview=sku

http://store.summitracing.com/partdetail.asp?autofilter=1&part=NEX-15512&N=700+115&autoview=sku

for UNDER about $750 and most of thats the cost of GAUGES, and matched sensors you can have a decent engine stand built, the steels reasonably priced its the measurements and fabrication that takes time and precision

heres an example for ideas

http://www.prw-usa.com/category/products/test-stands

Last edited by a moderator: