There is without doubt a strong desire on the part of most guys who are rather new to the hobby of performance cars, to want to boost performance.

this frequently results in guys reading magazine articles that promote the sale and purchase of those components, that they perceive, and see prmoted as the keys to providing that power increase.

and that frequently results in purchasing parts that are badly mis-matched too the intended application.

Many of those guy's who are lacking real practical, hands on, experience, read an engine build in some magazine, where some guys wanting to see the parts they manufacture , where they carefully select and install a old school flat tappet solid lifter cam,or similar component,

in a 12.1 compression 350 used for a dirt track race car , where they are restricted to "stock iron heads" and the article says they gained miraculously 45 hp over the previous combo.

well our reader thinks...I've got a 350, just like his,

my heads are stock, hell, I could gain 45 hp if I swap to that cam!

what he does not comprehend is that the "stock head" rule,

does not mean the heads used are similar,

or that there was not a great deal of expensive valve train and valve spring upgrades,

done to the race cars "stock heads", or that a 12:1 compression ratio is far more tolerant of a big increase in duration,

and that dirt track racer is not concerned with ,

any thing the engine does below about 4000 rpm, and he will certainly run the cars engine up well over the 5500 rpm,

with his manual trans,in a 2000 lb striped out race car, vs a 3700 lb street driven car.

If your prone to follow the

"hell, lets install it and see what happens" route of performance engine building,

your going to have to learn through a long list of broken parts and disappointing and expensive parts purchases,

and you'll spend a great deal of time replacing busted parts, but the local machine shop will get to know you and recognize your name on sight,

you'll make regular and consistent donations.

but if your willing to read, research, ask questions, about how and why things work,

how they are effecting the other parts, proper clearances, and related factors, and never assume, anything until you verify it is or was done correctly,

in the long run you'll find you waste less time and money and have a much faster car as a result.

Nor that the O.E.M. car he has has other limitations, where the stock auto,

transmission shifts, preventing the engine from reaching and operating, in the cams intended power band.

clearances are a added concern, most O.E.M engines were not designed,

for constant full load,operation well above 5000 rpm, while a dirt track engine is exactly designed for that.

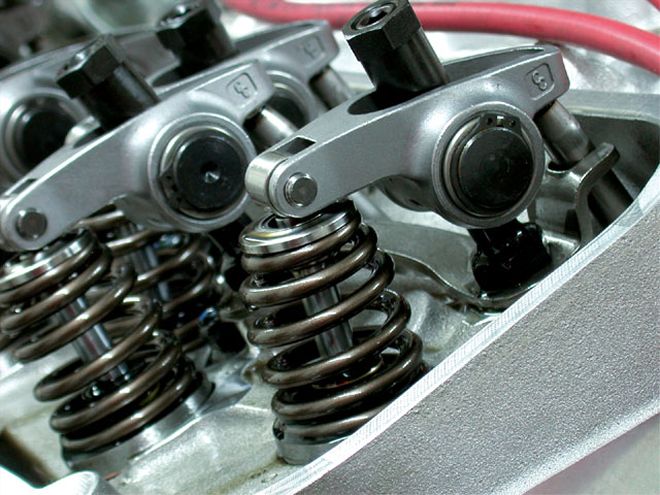

theres a great deal more than just your cams design and the head flow that becomes critical in a properly designed engine.

its the total combo of well matched parts operating in the combined power band, and durability thats critical.

if your going to get your info on parts selection solely from magazine articles ,

you'll be in for a lot of confusion and

disappointments

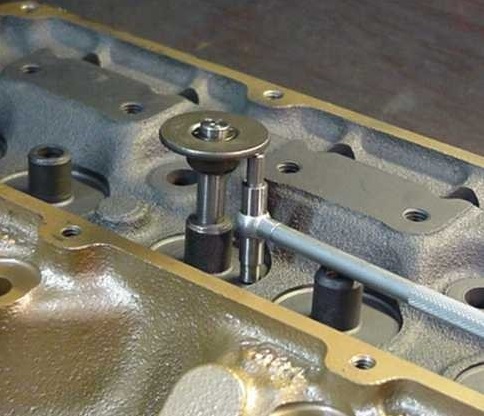

If the valve springs are to be removed with the heads still on the car,

the last thing you want is too remove a valve spring and have the valve to drop into the cylinder,

if you use air the crank tends to want to spin the crank to BDC, youll want to verify TDC ,

and make sure the flywheels temporarily prevented from turning from that the TDC position,

Ive used both methods both work,you can put 6 ft of rope in the cylinder while its in BDC then turn it to TDC, Ive used both with zero issues,

If you use the compressor youll want to keep it at 120 psi and constantly feeding pressurized air to keep the valves held in place,

and theres a small chance the compressor pushes enough moisture to allow water to accumulate in the cylinders,

so be sure you spin the engine with the starter with the spark plugs removed several times before you re-install plugs.

if you use the rope, theres a very low chance that the rope will tangle and form a knot that makes removal difficult,

in either case be sure the pistons locked at tdc,

before removing the valve springs, on each cylinder.

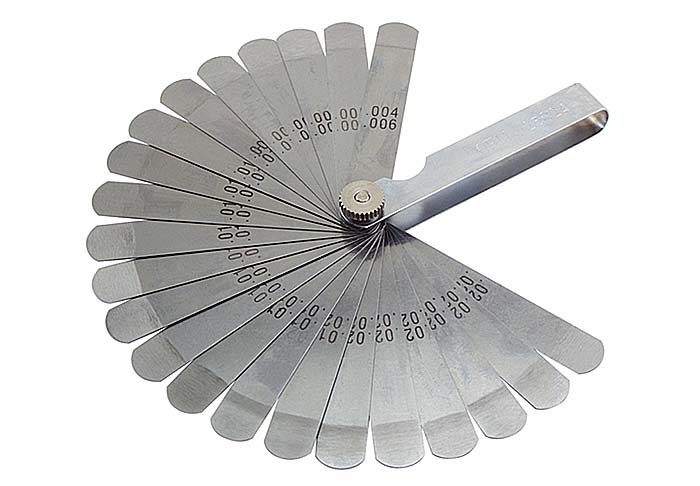

yes you need to as stated, many times on this and other websites, check all your valve train clearances carefully, the cam spec. card that came with your cam should indicate the ideal matching spring load rates and clearances required.

those heads (keep in mind that price is for a single (1) cylinder head)

https://www.summitracing.com/parts/tfs-30410001/overview/

OBVIOUSLY YOULL WANT THE CORRECT VALVE SPRINGS

http://garage.grumpysperformance.co...steam-holes-posted-by-dennyw.2991/#post-57455

http://www.competitionproducts.com/1500-1585-OD-Valve-Springs/products/2631/1/0

http://www.buxtonengineering.com/on_head_valve_spring_tester.php

https://www.summitracing.com/search/part-type/valve-springs

https://www.iskycams.com/cart/valve-springs-c-99.html

http://www.cranecams.com/userfiles/file/334-343.pdf

https://www.racingsprings.com/Valve-Spring/Store/13

http://www.lunatipower.com/Category.aspx?id=23

http://www.pspring.com/products/engine-valve-springs/

http://www.competitionproducts.com/Valve-Springs/departments/49/

http://psisprings.com/products/

http://www.compcams.com/Products/CC-'Valve Springs By Usage'-0.aspx

http://www.racingsprings.com/Beehive-Valve-Springs

https://www.supertechperformance.com/valve-springs-p109

http://www.cvproducts.com/index.php/psi-springs/

you might also want to keep in mind theres a great deal more to setting up a valve train than slapping some springs and retainers and keepers on the valves.

read thru the links and sub links as theres a great deal of useful info, that youll want to know.

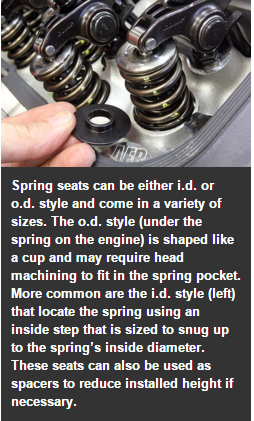

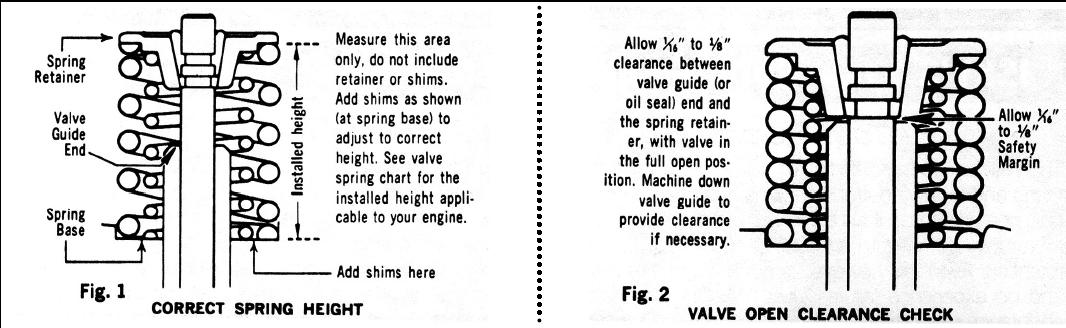

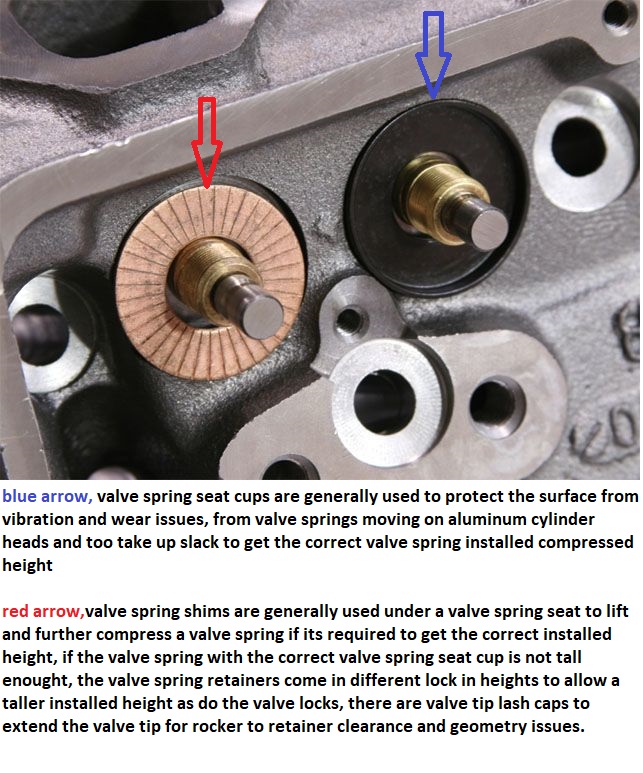

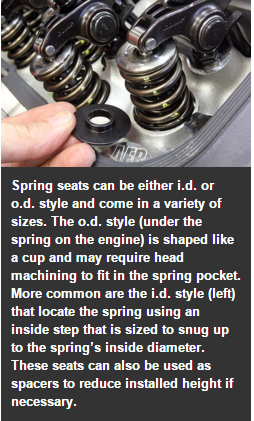

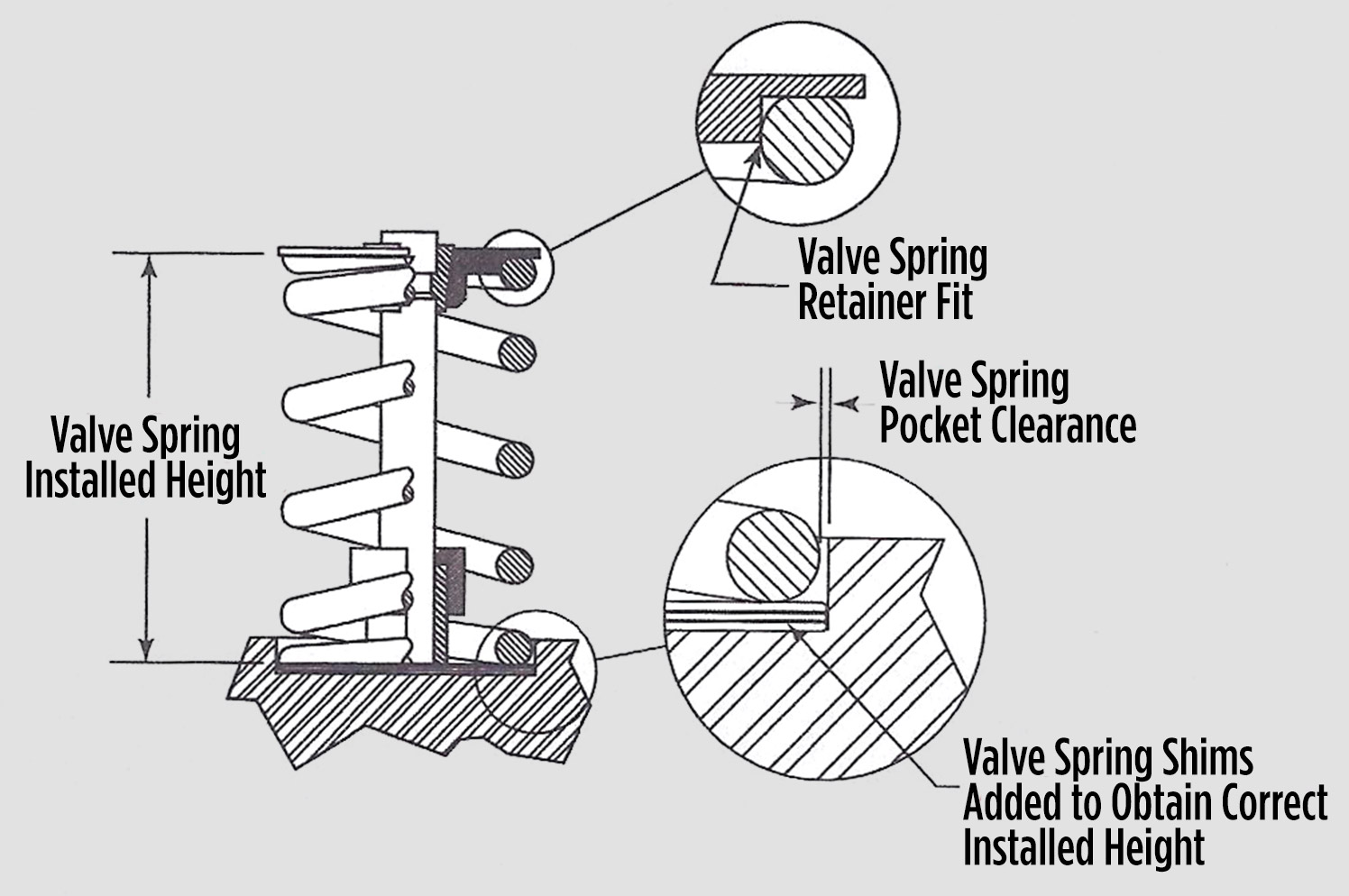

btw just a bit more info, there are valve spring retainers, valve spring seats, shims, valve retainer keepers etc. that can be used that have different sizes or depths that allow you to change the installed height, or relation of the spring to the valve stem , it compressed height, or the valve springs location in relationship to the stems locking groove

keep in mind shims under the valve springs can be used to raise the spring or shorten the valves installed height, valve locks and retainers can be purchased with non-O.E.M dimensions to adjust the valves installed height or spring load rates

you use either or both depending on the application

a .050 PLUS valve lock moves the retainer .050 higher on the valve stem with no other changes, a plus .050 retainer would move the retainer .050 higher with stock valve locks or an additional .050 if matched to .050 plus locks

if you used a plus .o50 retainer with a set of minus .o50 valve locks the retainer would remain at the stock height on the valve stem

viewtopic.php?f=52&t=181

http://www.jegs.com/p/Crane/746983/10002/-1

http://www.jegs.com/p/Moroso/764349/10002/-1

http://www.jegs.com/p/Manley/940089/10002/-1

http://www.jegs.com/p/Comp+Cams/757964/10002/-1

youll have to correctly measure the clearance on your heads with the valve springs and cam specs you selected too use to know if you have the correct valve spring installed height and clearances, failure to accurately check frequently results in very expensive repairs and to what new guys frequently blame on the cam when it was a installers ignorance that was the true cause.

https://www.summitracing.com/parts/pro-66902/overview/

https://www.summitracing.com/parts/sum-900032/overview/

https://www.summitracing.com/parts/rsc-pac-t902/overview/

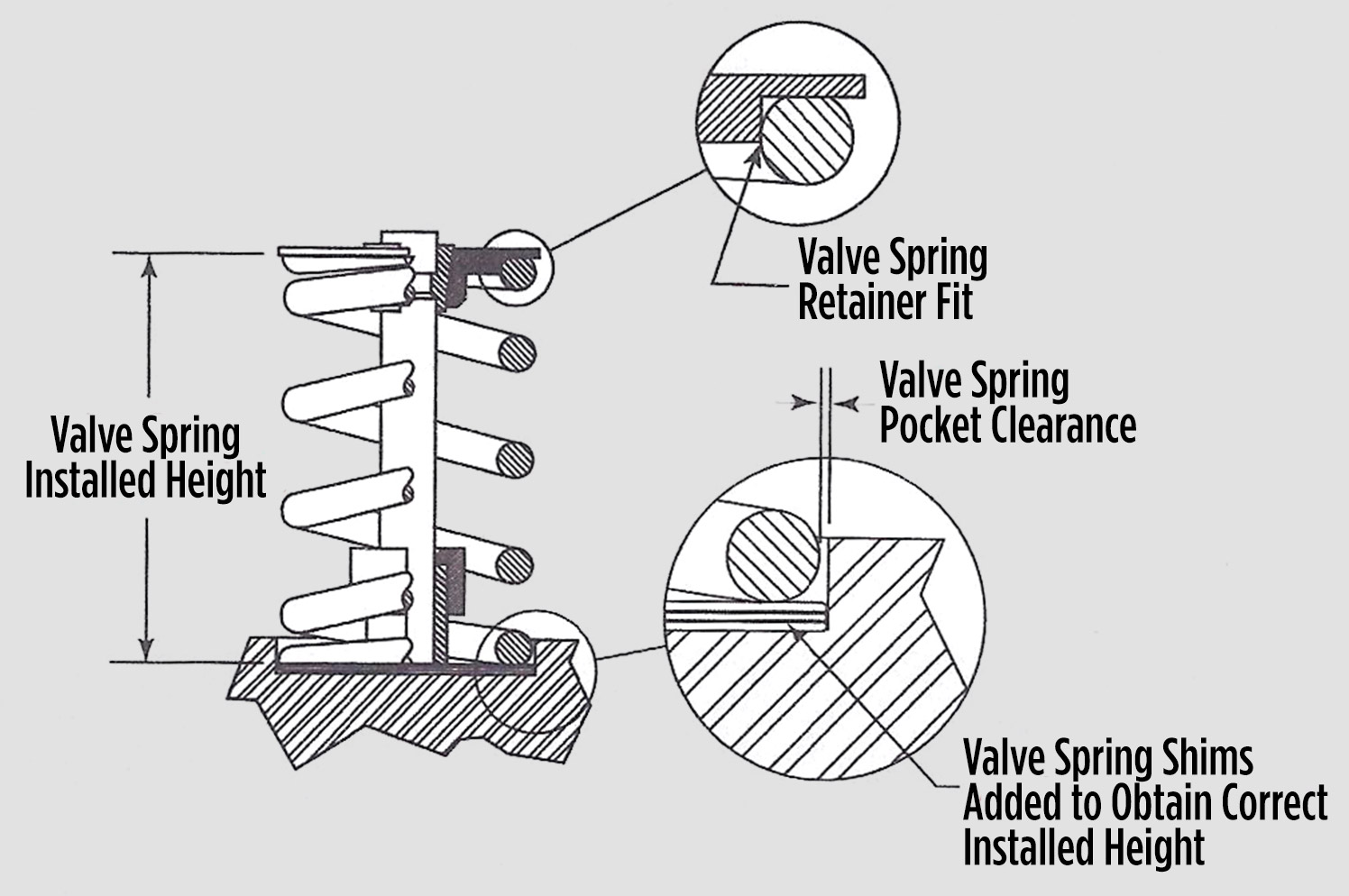

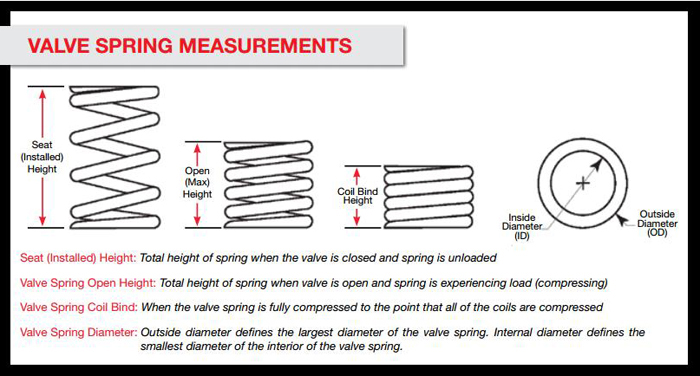

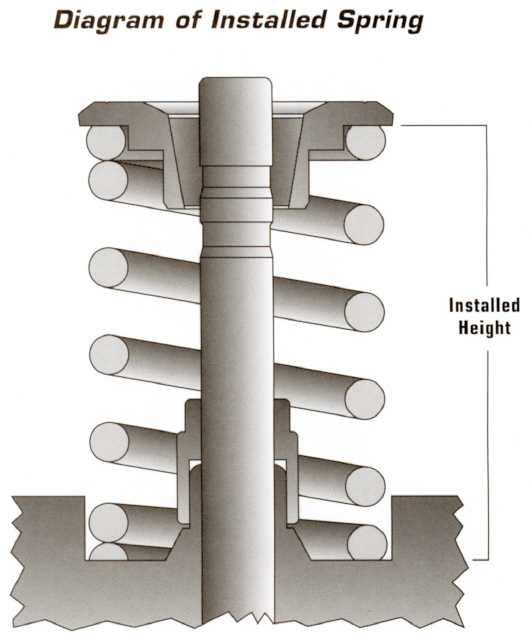

valve springs must be installed at a specific semi compressed and listed installed height,

to provide the listed load rates and clearances,

example

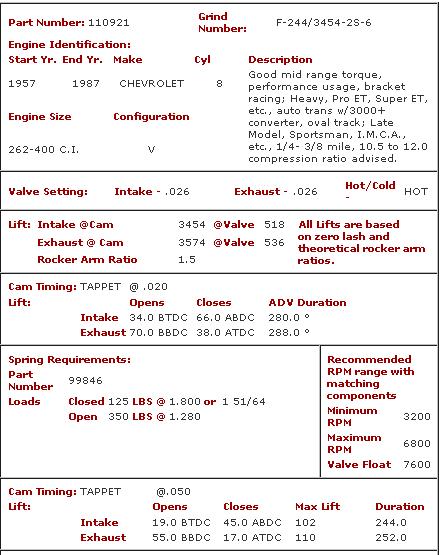

the cam you select will generally come with a suggested listed valve spring load rate and installed height,

(NOTICE THE SUGGESTED INSTALLED HEIGHT WITH THIS CAM IS 1.800"

and the loads are listed)

you must maintain minimum coil bind and retainer to valve seal clearance and proper push-rod and rocker geometry

the distance between the lower edge of the valve spring retainer and the cylinder head is adjustable to achieve the desired valve spring height through the use of valve spring seat cups and shims placed under the valve spring which can be purchased to lock into a stock height, or plus or minus about .050, and valve locks that cam move the retainer (stock or aftermarket) an additional .050 either tighter or longer allowing the valve spring to expand taller, shims can be placed under the valve seat hardened cups that are almost always mandatory on aluminum head but may be optional on iron heads,(O.E.M. cast iron and lower valve spring load rates)

max lift is installed height minus .060 minus coil bind

related info you really need to read

http://garage.grumpysperformance.co...ring-installation-questions.12833/#post-66460

http://garage.grumpysperformance.co...-loads-and-installed-height.10709/#post-46658

http://garage.grumpysperformance.co...ve-spring-iinstalled-height.12791/#post-66038

http://garage.grumpysperformance.co...im-good-to-go-on-valve-clearance-right.15160/

http://garage.grumpysperformance.co...train-clearances-and-problems.528/#post-57678

http://garage.grumpysperformance.com/index.php?threads/valve-springs.9613/#post-50556

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

push rod to short

WIDE SWEEP ON VALVE TIP FROM ROCKER ADDS ADDITIONAL,

SIDE LOAD WEAR

push rod to long

at times lash caps or longer push rods will be needed to change the valve train geometry to gain rocker clearance or get the proper geometry

push rod length correct

AS CLOSE TO CENTER AS POSIABLE BUT BEING CENTERED IS LESS IMPORTANT THAN MINIMAL SWEEP ON THE VALVE TIP< INDICATING MINIMAL SIDE LOADING

http://garage.grumpysperformance.co...-pushrods-and-check-info-you-might-need.5931/

http://www.summitracing.com/search/...d-length-checkers?autoview=SKU&ibanner=SREPD5

Proform Pushrod Length Checkers 66789 SBC 3/8" rocker studs

Proform Pushrod Length Checkers 66790 SBC 7/16" rocker studs

Proform Pushrod Length Checkers 66806 BBC 7/16" rocker studs

a few simple tools will tell you if clearances are ok

READ THESE LINKS CAREFULLY

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.com/index.php?threads/rocker-push-rod-wear-issues.9815/

http://garage.grumpysperformance.co...steam-holes-posted-by-dennyw.2991/#post-57455

http://garage.grumpysperformance.com/index.php?threads/checking-piston-to-valve-clearances.399/

http://garage.grumpysperformance.com/index.php?threads/two-loose-valve-locks.9687/#post-36006

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

http://garage.grumpysperformance.com/index.php?threads/two-loose-valve-locks.9687/#post-47884