Volume vs. Pressure

FUEL Volume and FUEL pressure are two completely different things when you talk about fuel,supplied to an engine, but they must work together to give you the proper air/fuel mixture delivery. Both carburetors and EFI systems require the proper fuel volume to make the desired horsepower, but the pressure differences between the two are quite different. A carburetor setup requires very low fuel pressure—somewhere between 5 and 6 psi,pressures higher than 6 psi can force open the flow control valve on some carbs,

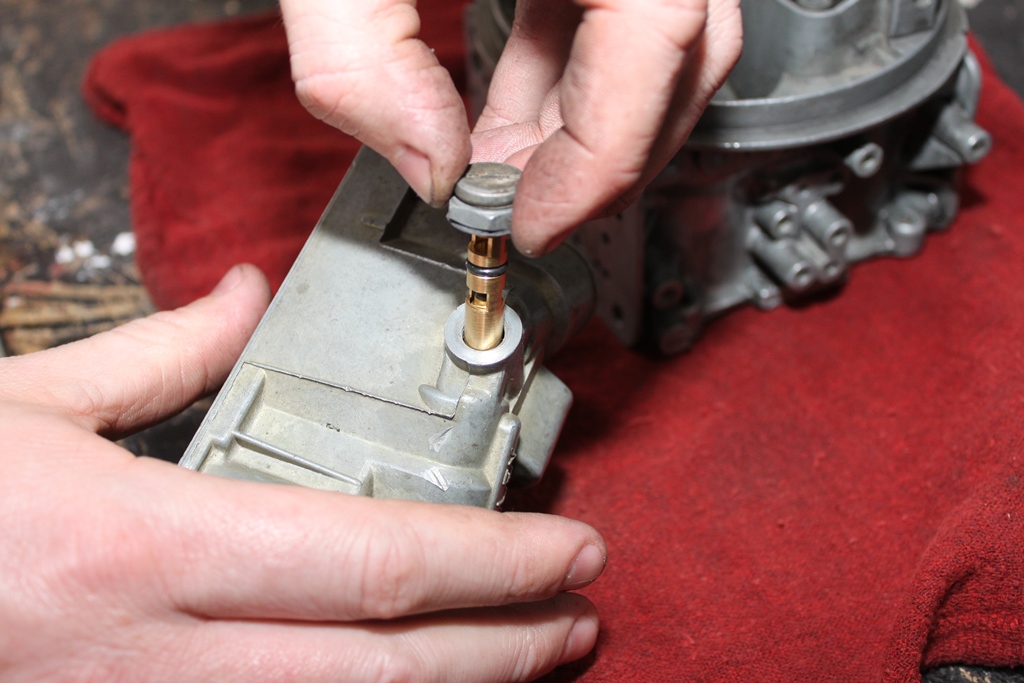

be aware that you,ll need to correctly set the carbs floats to regulate the fuel level in most carbs and the needle & seat valve

your carburetor inlet fuel pressure should be a consistent 5 psi-5.5 psi in most cases, once you get over 6 psi you'll find the carburetor float bowls tend to flood and under 3 psi the carburetor can run lean under hard acceleration.

keep in mind the internal port size is not all that large on the cheap holley fuel pressure regulators , so they work ok on near stock applications but NOT on anything close to a race application.

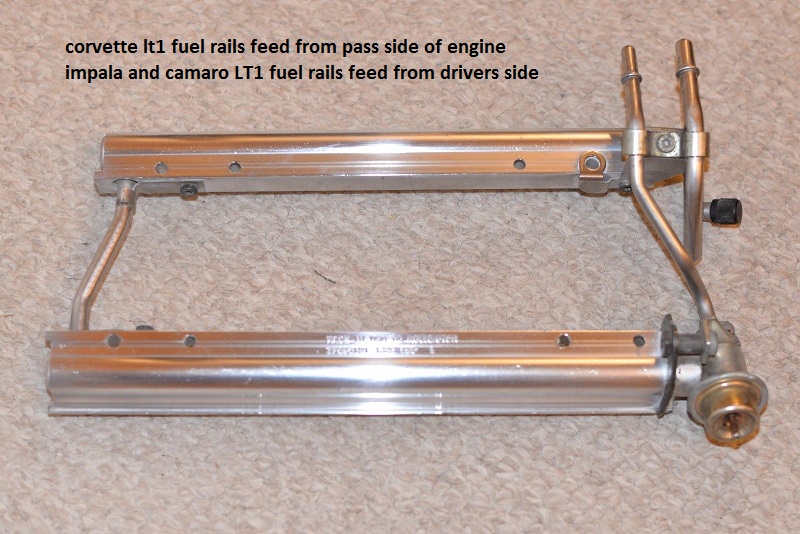

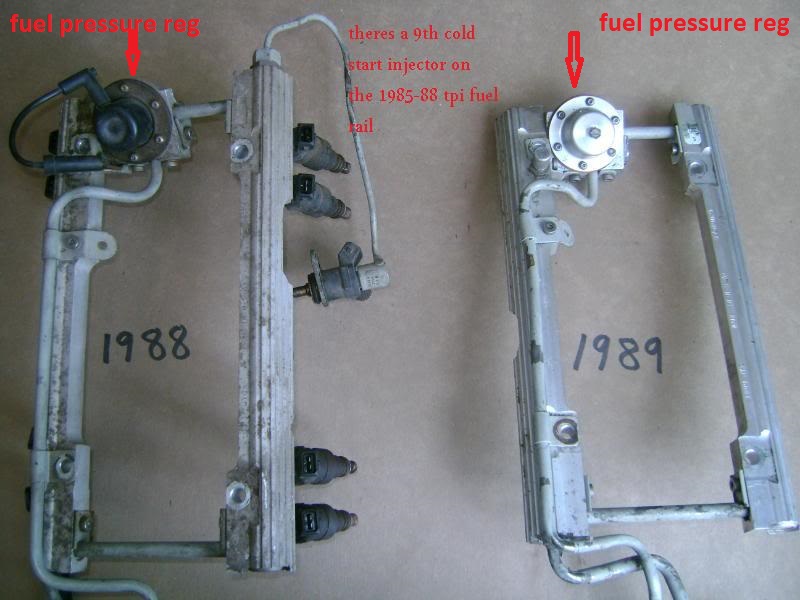

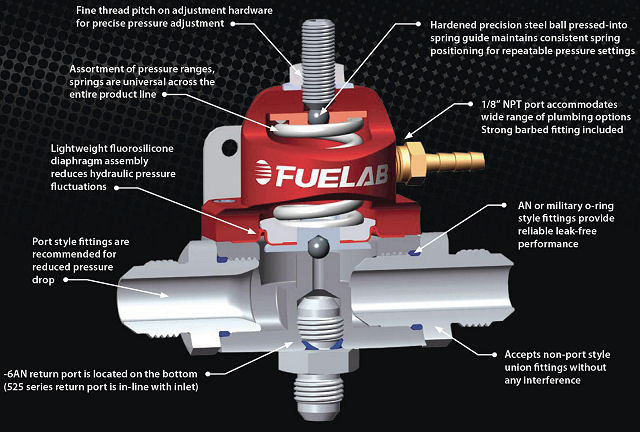

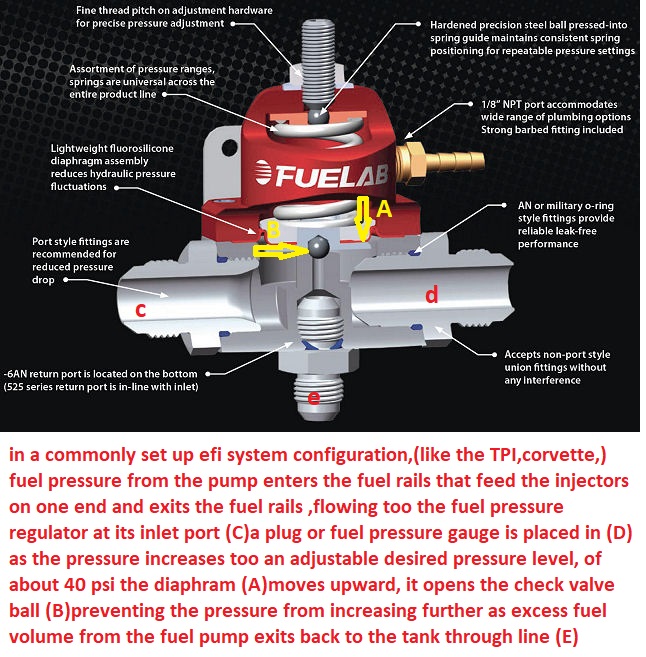

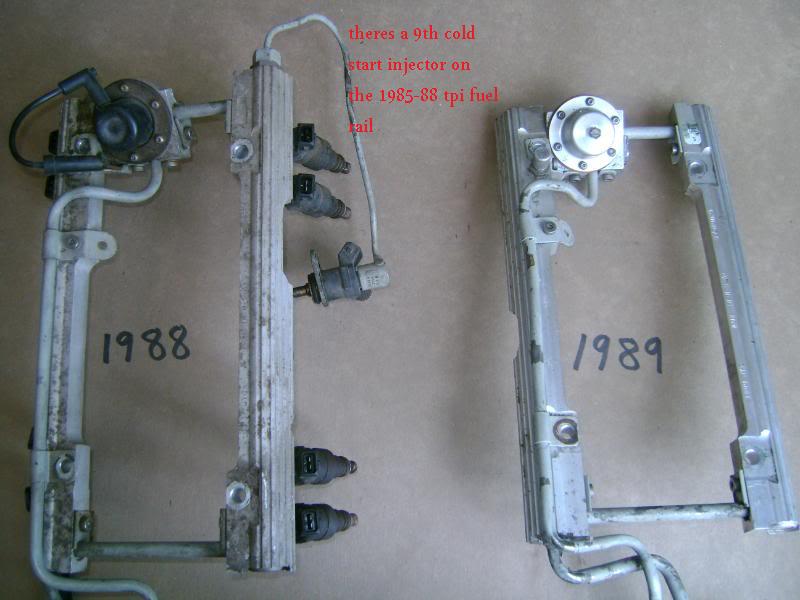

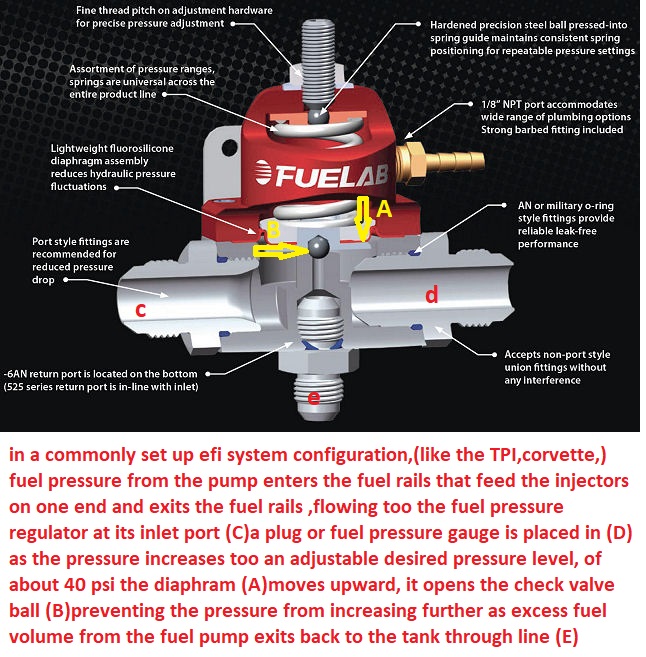

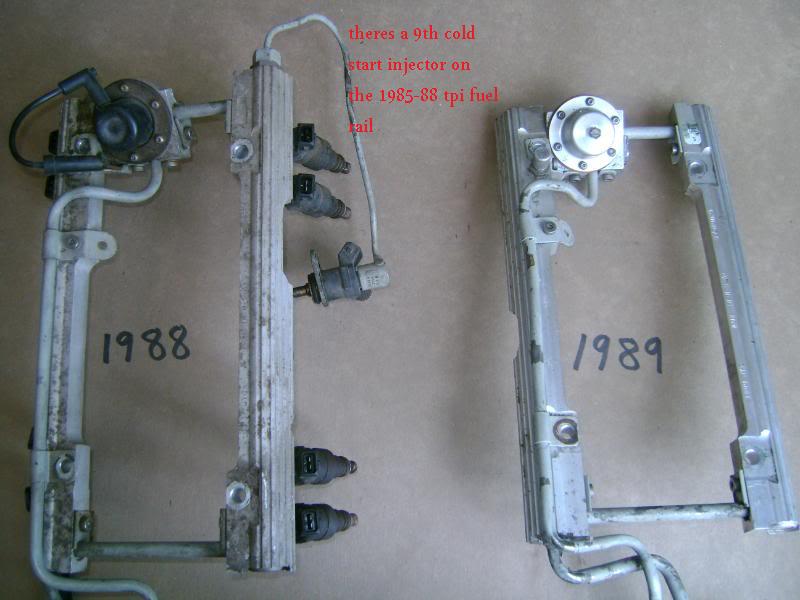

EFI works at higher pressures (a 1985-1991 TPI corvette as an example generally operates in the 38psi-42 psi fuel pressure range)

THINK,

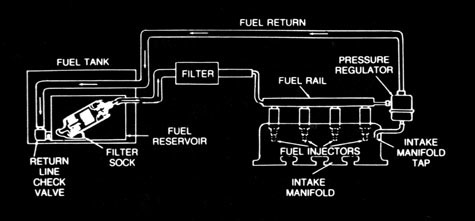

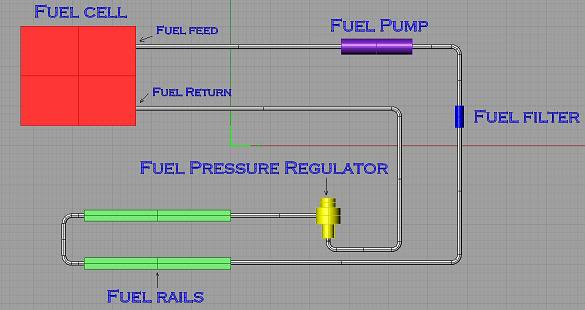

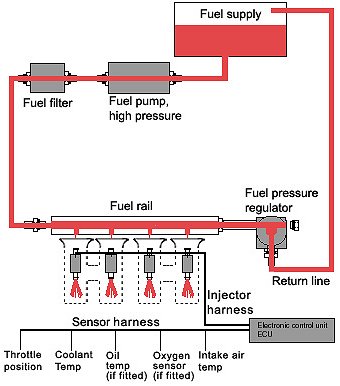

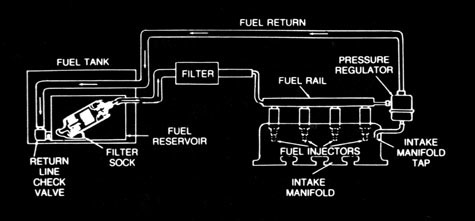

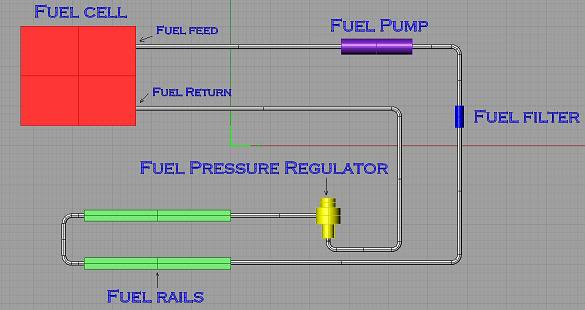

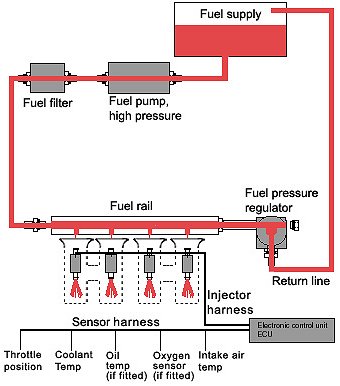

fuel tank...to .fuel filter....to .-fuel pump....to feed into fuel rail& injectors. then out too....fuel pressure regulator...then too..return line to fuel tank

shop carefully, fuel line size, fuel pressure range,

consistency of maintaining both fuel flow and pressure, component quality, and durability as well as cost varies wildly

www.jegs.com

www.jegs.com

the vacuum line to the plenum drops under full throttle,

so the diaphragm and check ball,compensate, to maintain max flow rate to the injectors,

the diaphragm and check ball in the regulator become, or are just a tiny bit harder for the fuel pressure too force open,without the plenum vacuum above the the diaphragm and check ball

thus maintaining fuel rail volume and pressure before any of the fuel can exit the return line

it might help if you think, fuel pump provides fuel flow volume,

fuel pressure is a measure of resistance to fuel flow,

the fuel pressure regulator acts as a valve that opens if the pressure exceeds about 42 psi (YES some versions like yours are manually adjustable) but the reason its there is to maintain a consistent 39 psi-42 psi to do that you allow the fuel pump to stack or pressurize fuel in the fuel rail and in theory the fuel pressure regulator only allows excess fuel volume to flow back to the fuel tank through the return line if that fuel pressure exceeds the 42 psi, the pump is designed to provide a bit more than the required 42 psi too insure fresh cool fuel is cooling the fuel pump while maintaining that consistent fuel volume at the fuel pressure, when you tromp on the throttle the flow of fuel drastically increases, the regulator momentarily restricts out going fuel to maintain the fuel rail pressure and volume, until the flow demand drops enough, for excess volume and the resulting increased pressure that results to open the regulator again,

that controls fuel flow into the carb can get crud trapped between the needle and seat causing the fuel bowl to constantly flood, so check that carefully, if thats your issue!

while most EFI setups, require 40 psi too as much as 60 psi or more on the high side limit. This means the fuel pump you select needs are entirely different, for each system and regulating pressure is handled by different components as well. youll need too select a Regulator manufacturer who makes regulators specifically for each application.

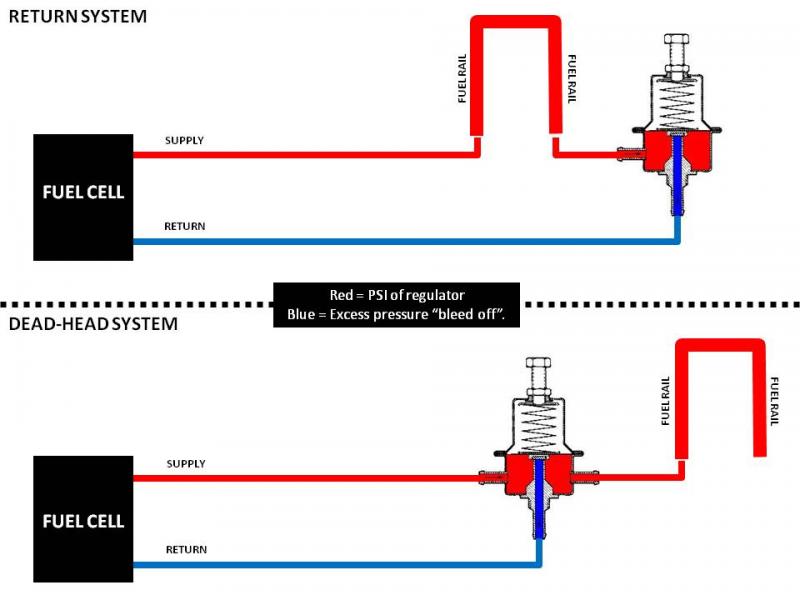

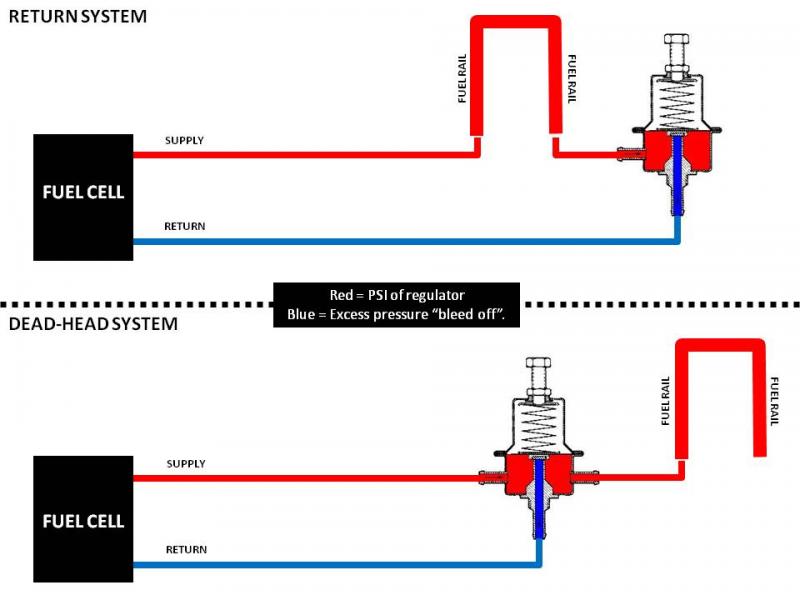

A return-style fuel system keeps the flow of fuel through the entire system at a constant,rate, keeping the fuel cooler. Constant circulation of cooler fuel will also result in less tendency to get into conditions favoring vapor lock , than a dead-head–style system, as fuel sits in the lines and carburetor absorbing heat from the engine compartment.

Ive consistently had far better results with the bye-pass style regulators ,for several reasons, the non-bye-pass regulators allow more heat to build up in the fuel and tend to be slightly more prone to get the fuel temp up into detonation range, fuel thats cool absorbs some combustion chamber heat lower burn temps very slightly, you NEED a fuel pressure regulator with a BYE-PASS CIRCUIT from the regulator at the carburetors location back to the tank,If the pump is capable of more than 7PSI you should run a regulator regardless of the engine, simply because most carburetors needle and seat valves can not control flow over 7 psi and many can,t handle even 6 psi

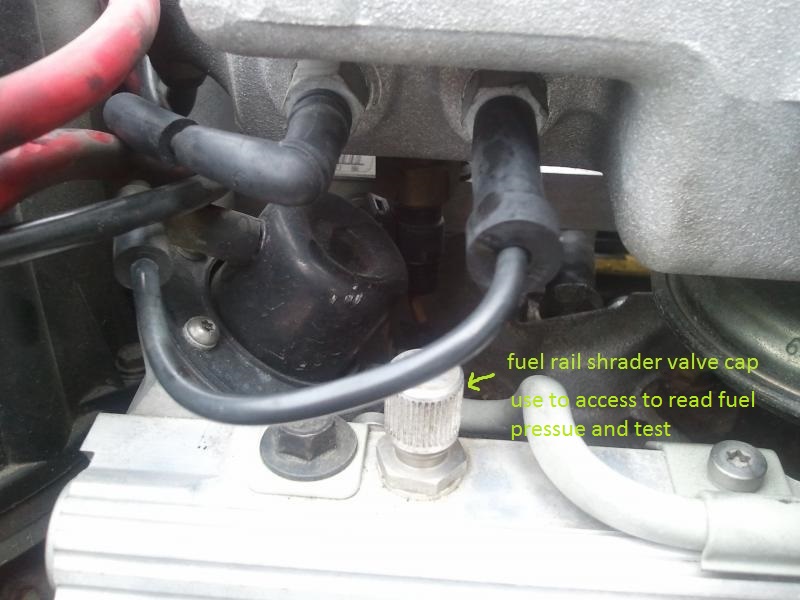

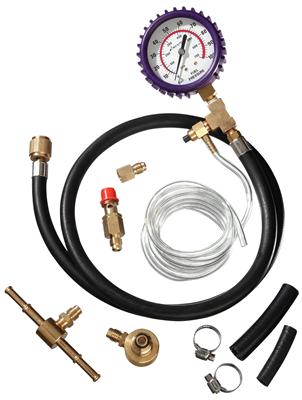

and yes, use of a small handy and accurate fuel pressure gauge, mounted on the fuel injector fuel rail (0-100 psi for FUEL INJECTION)

or carb inlet port (0-15 psi for carburetors)is almost mandatory, they generally cost under $30

The engine does not care how much pressure you push to the carburetor, but the have the carburetor will have a needle & seat valve that does, because it must maintain a near constant float level in the fuel bowls to have a consistent fuel/air ratio.

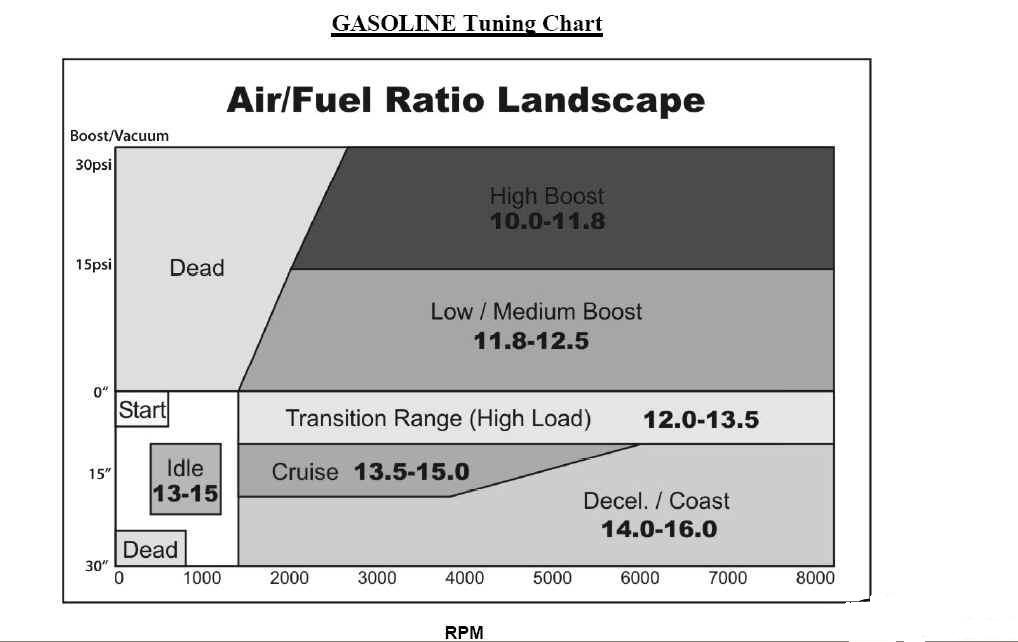

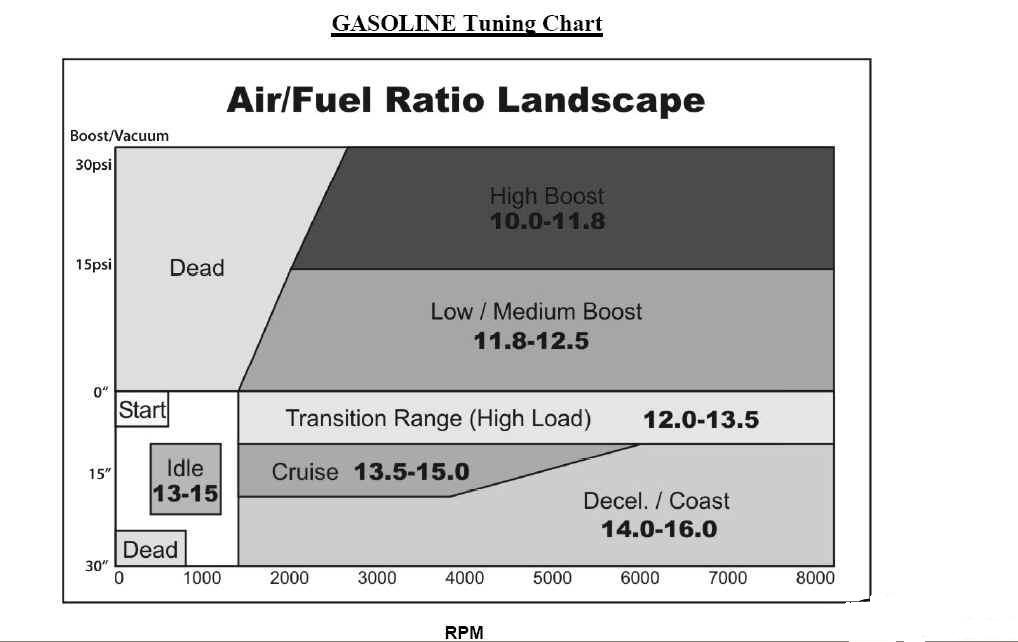

All the engine cares about is that the carburetor feeds it a controlled fuel air mix ratio between about 12.7:1-15:1 & you need to maintain enough pressure & volume to keep the carburetor fuel bowls full under all conditions, WITH OUT FLOODING or fuel starvation.

dead head regulators will frequently NOT maintain a constant pressure , it tends to surge and fall, and running a electric pump without using fuel that flows constantly thru it will USUALLY cause the pump to heat up and LOOSE some efficiency, in fact they commonly loose efficiency or fail if heated up, trying to pump the same fuel constantly, the flow thru a bye-pass regulator with its separate fuel return line to the tank allows the fuel to circulate and pull heat from the pump,the better quality, return style regulators are vastly more effective

WHEN TESTING<be sure the fuel pressure gauge reads correctly by comparing it to a second test gauge, these fuel pressure gauges are frequently defective

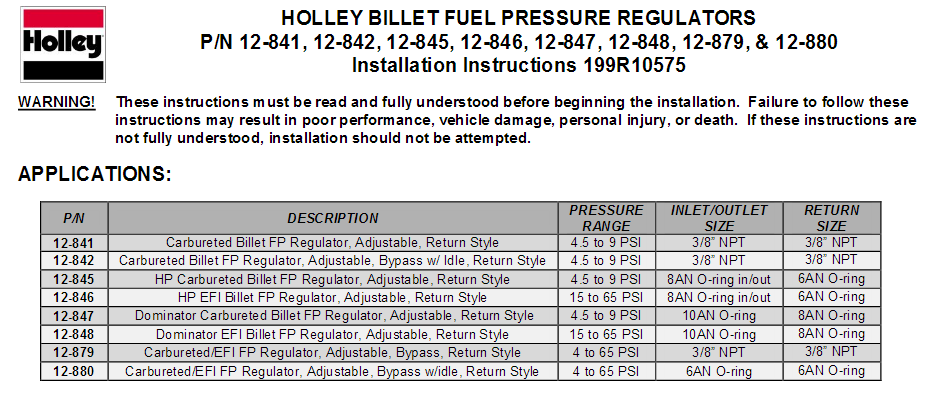

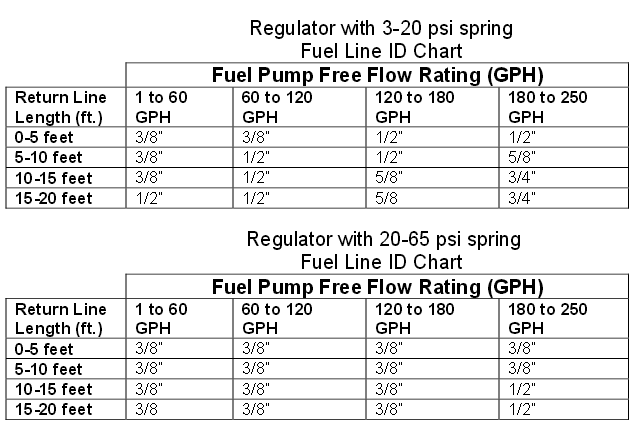

The minimum fuel line size (from the pump to the regulator) is dependent on the horsepower output of the engine (and/or Nitrous system) regardless of the size of the pump. fuel pressure regulators are normally placed as close to the fuel rail or carburetor feed inlet port as possible to maintain most of the fuel feed lines under higher pressure to reduce vapor-lock, high g -force fuel starvation and to reduce the chance of air entering the carburetor ,or injectors and keep a constant flow of cool fuel reaching the injector's or carburetor, because theres a constant flow of new fresh fuel being forced up to and some bye-passed thru the system, and fed to the engine

keep in mind TPI fuel pressure regulators maintain about 40-45 psi while carburetors require about 4.5-6.5 psi MAX, but in most cases the fuel pressure at the carb inlet port NEEDS to read 4.5-5 psi MAX and you NEED to set the float levels per the carburetor manufacturers instructions, having the pressure at 6.5 psi will in many cases cause the needle & seat valve to constantly leak excess fuel, into the carburetor while the engine runs

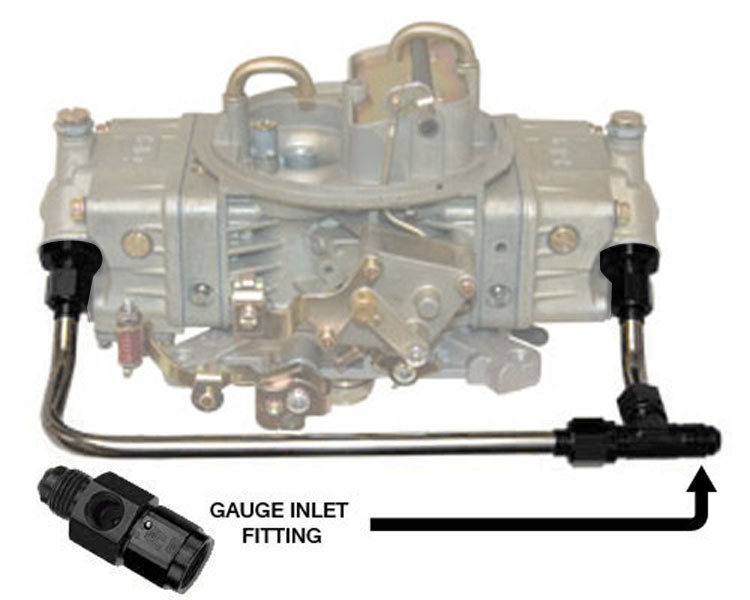

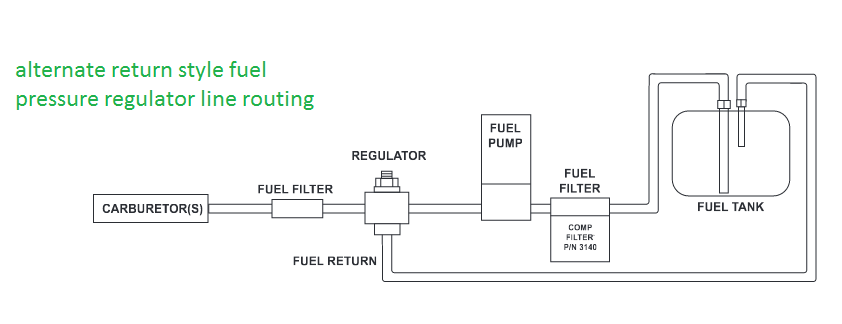

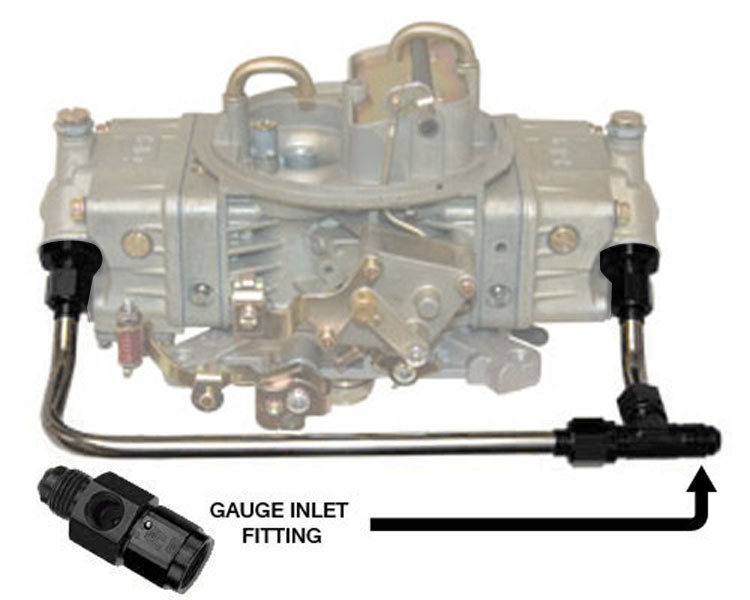

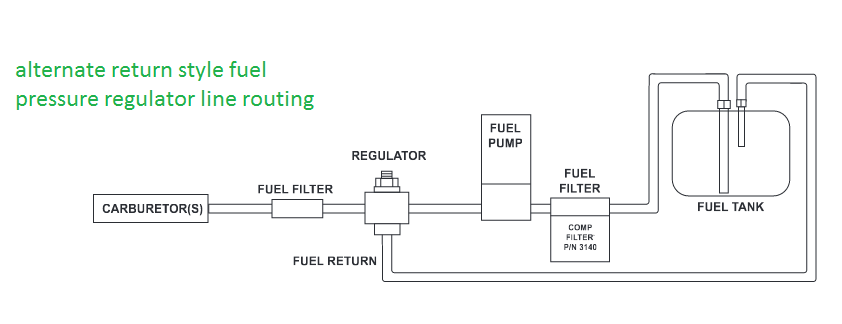

if your running a return style fuel pressure regulator it depends on the instructions that come with it and the number of ports,its usually mounted AFTER the two carb inlet fuel feeds

the pump feeds the fuel log, the fuel log feeds both carb inlets and the regulator mounted on the far end of the fuel log from the fuel feed bleeds off excess pressure to the return line to the the tank.the problem with all decent quality fuel line supply component parts is they cost more money, than the cheap low quality parts and generally take up more room and take a bit more time and thought to install correctly

http://garage.grumpysperformance.com/index.php?threads/setting-up-your-fuel-system.211/

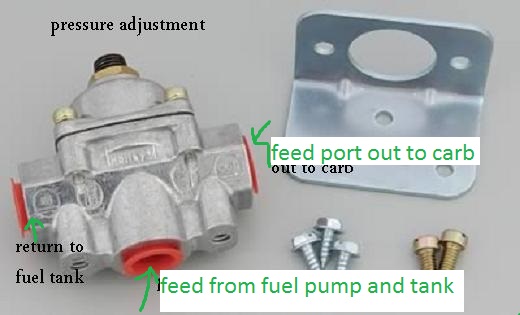

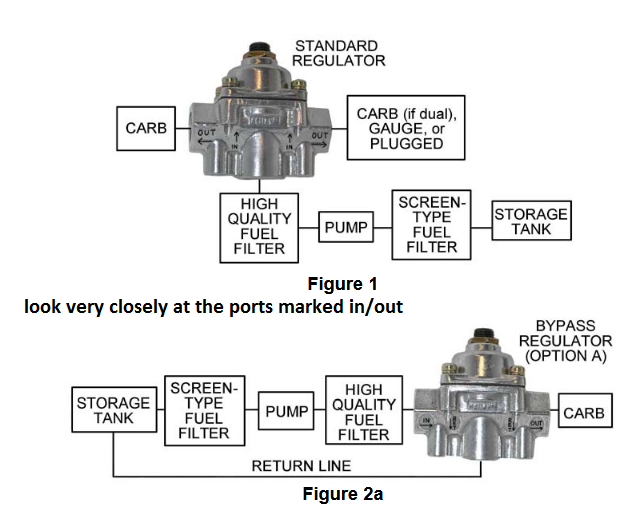

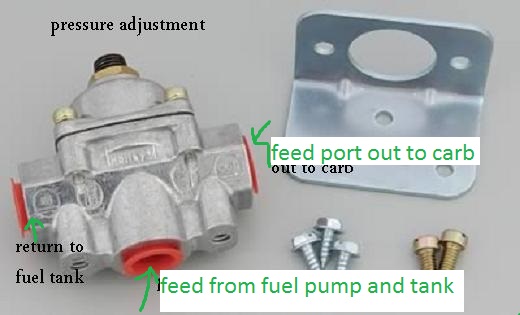

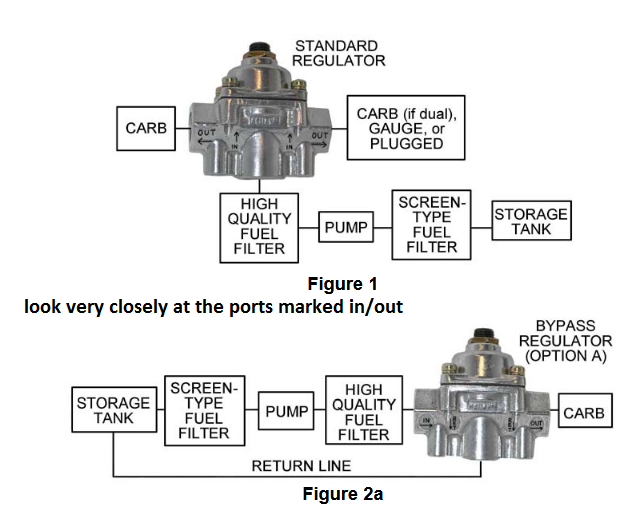

I can easily see where the diagram may be confusing ,, and while that cheap holley return style fuel pressure regulator works

the picture is correct on many of the Holley fuel pressure regulators

(these several versions)

the cheaper fuel pressure regulator feeds from the base

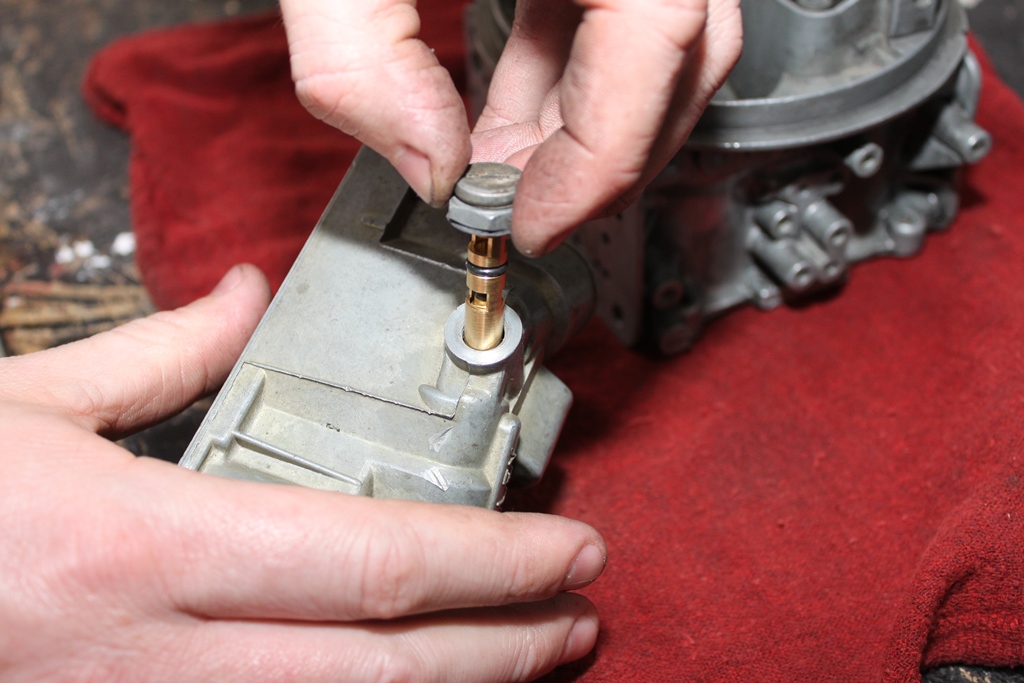

you need a fuel pressure gauge on the carb inlet port,to accurately set fuel pressure

and then you need to rev the engine and hold it at 3500 rpm for a few second's

then drop the rpms and watch the pressure gauge

DON,T ASSUME ,TEST VERIFY

at maintaining fuel pressure on the inlet port and can be used its far from the better choice

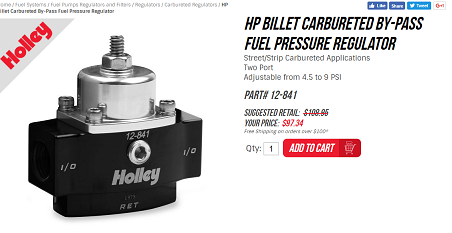

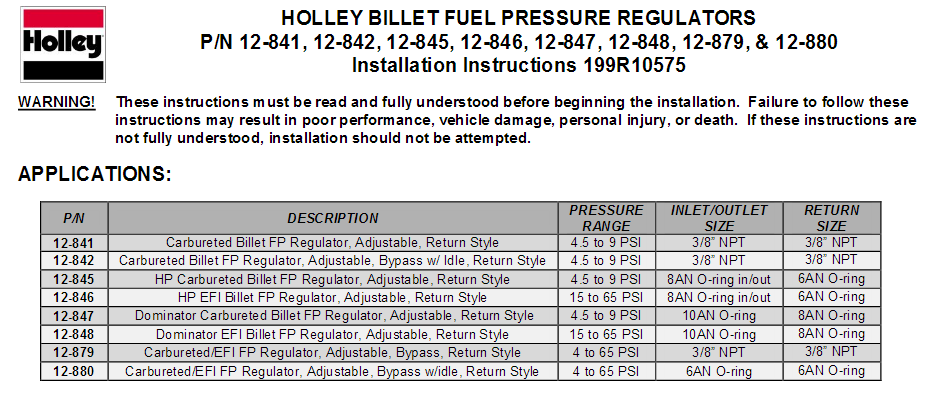

this is the type of FP regulator you want in most cases,

and it comes in AN#8 and AN#10 sizes

its simply a strait through fuel flow with a pressure release that leads to the return line that opens if the fuel pressure exceeds a set level, thus it maintains that max pressure

https://www.holley.com/products/fue...regulators/carbureted_regulators/parts/12-841

http://documents.holley.com/199r10575rev3.pdf

http://garage.grumpysperformance.com/index.php?threads/fuel-pressure-regulators.635/

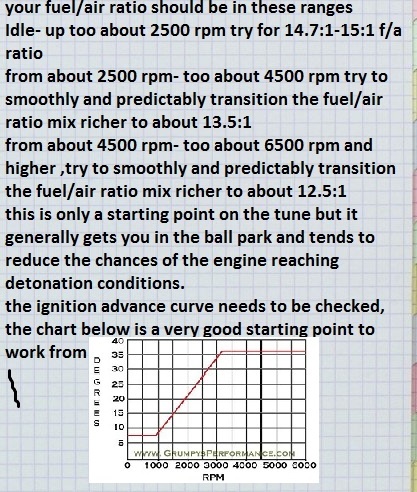

remember that on any turbo or super charged engine application the fuel pressure MUST be indexed to the engine boost, to maintain the ideal fuel/air ratio, and you'll generally want most engines to run in the fairly lean 14.7:1-13.5:1 range at idle but be tuned to transition smoothly and consistently, to a fuel/air ratio closer to about 12.6:1 as the rpms AND loads on the engine are increased,

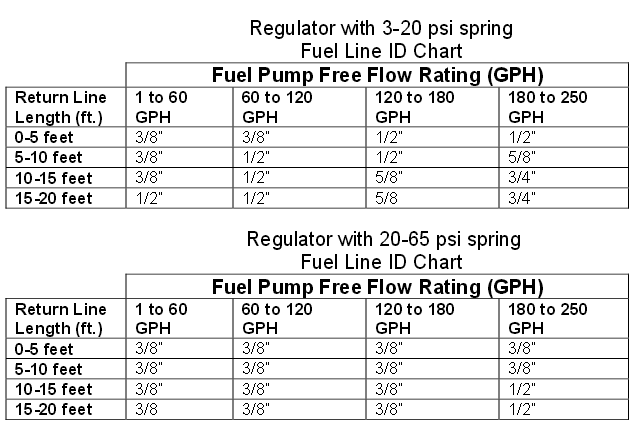

LOOK CAREFULLY AT THE CHARTS POSTED LOWER

http://www.summitracing.com/parts/aei-13301/overview/

the regulator linked above can be adapted easily from carb to EFI use

http://www.summitracing.com/parts/hly-12-841/overview/

http://www.amazon.com/Moeller-Separatin ... d_sbs_sg_1

http://www.summitracing.com/parts/edl-1792/overview/

yes the diagrams a bit confusing,pressure is a measurement of RESISTANCE to flow, the pump puts out , flow volume, theres no pressure until theres a resistance or restriction to flow,

www.jegs.com

www.jegs.com

potentially 6 -7 psi the true pressure is regulated to what ever the fuel pressure regulator is set too, IE, if the bye-pass spring setting is at 4.5 psi thats a high as the pressure ever gets, the fuel pressure potentially exceeding this forced the regulator to open,the spring resistance is over come and the fuel flows back too the tank, thus running out through the bye-pass, into the return line, limiting pressure.

[ [color]BASIC CAR FUEL SYSTEM DESIGN[/color]

but on some models its mounted just before the fuel log on the port labeled "CARB" and the two other ports are labeled "feed" for the pump and "RETURN", for the return line

OR YOU CAN GET MUCH MORE COMPLICATED

if your, looking at the diagram,and asking what pressure the fuel rail feeding the carburetor is pressurized too its obviously controlled by the fuel pressure regulator just beyond it in the diagram, which is usually located near the carburetor and fuel rail, to maintain the indicated 5psi, beyond that is the return line feeding back to the fuel tank and that should be close to zero, the main feed line from pump to the first fuel pressure regulator which ideally is located on the inner front fender or firewall maintains the 8psi-12psi the fuel pump provides , keep in mind a fuel pressure regulator can only control the pressure between it and its pressurized feed source, by bleeding off pressure above the peak its set for, it has zero control past it, it only controls pressure between it and its pressure feed source ,in that diagram the first fuel pressure regulator is NOT mandatory in some applications, its the use of the secondary nitrous feed that makes it useful in the depicted application

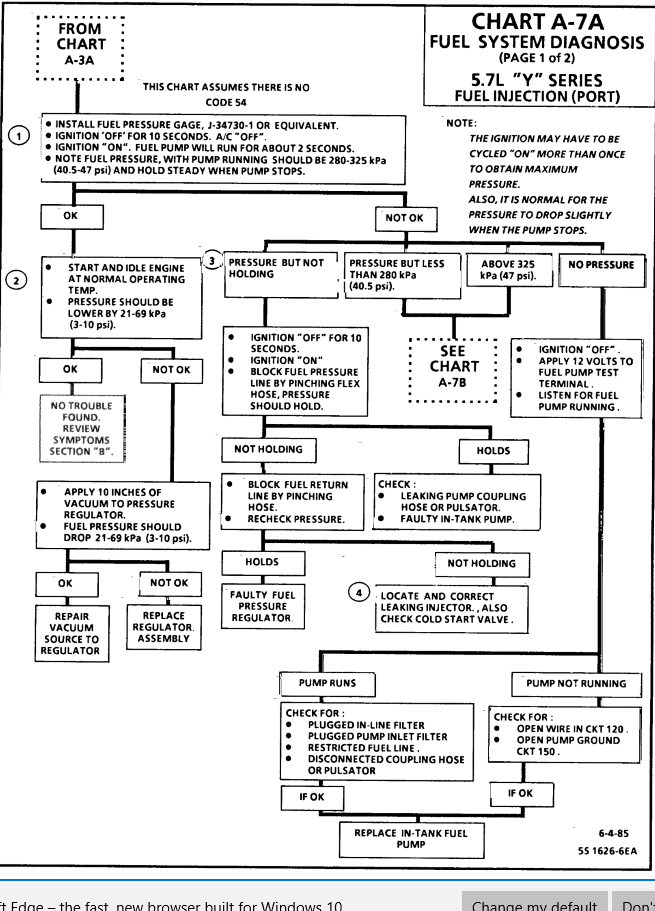

IF you have a PLENUM OR RUNNER FLOODED WITH FUEL,

http://members.shaw.ca/corvette86/FuelS ... gnosis.pdf

ok logically if your flooding fuel into the intake, its related to injectors leaking,or the fuel pressure regulator leaking or a vacuum line sucking fuel from some place like the fuel return line simply because thats how fuel can enter the plenum.

if you block the fuel return line to the tank from the fuel pressure regulator, and remove the fuel pressure regulator vacuum line temporarily, you should see the fuel pressure bump up to 40-47 psi , if not its most likely the injector(s) leaking, or fuel being sucked into a vacuum line, because your effectively eliminating a defective fuel pressure diaphragm in the regulator.

as always its a isolate and test procedure

EFI operates on a SIMILAR CONCEPT but obviously at higher pressures and generally with individual injectors spraying fuel that are usually controlled by a computer with sensor input rapidly matching fuel delivery to the engines demands

many EFI fuel pressure regulators are connected to the injector fuel rails, thus they maintain a designed fuel pressure feeding the injectors controlled by both manifold vacuum and fuel pump pressure, as plenum vacuum drops , the vacuum level above the fuel pressure regulator diaphragm has less effect on reducing fuel pressure return line psi, as it has less effect on the regulator diaphragms resistance spring, preventing the return line port opening, so fuel pressure increases slightly as demand and rpm increase.

READ THESE THREADS & linked info

http://www.useasydocs.com/details/fuelsys.htm

http://www.circletrack.com/enginetech/c ... _pressure/

http://www.circletrack.com/enginetech/c ... _pressure/

the manual fuel pump is working in direct relation to the engines rpm levels, an electric fuel pump is working against the rapid changes in inertia as the car accelerates and brakes, if you think shifting gears at high rpms won,t alter the fuel pressure curve if you don,t have a bye-pass style fuel pressure regulator and a fuel return like in use you've never watched a fuel pressure gauge on a car without those components

ideally all lines are 3/8" minimum but 1/2" id is far better

the electric fuel pump would ideally be mounted lower than the tank and as far back as practicable INSIDE the frame rails for crash protection, with a hot lead to the electric pump that only supplies electric power ,if you have oil pressure and the ignition keys in the on position, as electric pumps PUSH fuel,far more efficiently than they PULL fuel

BTW alcohol in fuel tends to cause aluminum to oxidize over time

http://video.foxbusiness.com/v/2000862202001/

as you don,t want the electric pump running if the engines NOT running.

the fuel filter should be mounted for easy access,as you should change it frequently.

the regulator should be mounted as close to the carb as easy access allows, with the return line back to the tank, ideally larger than the feed line for zero resistance to fuel flow

keep in mind the by-pass style regulators work by allowing all fuel flowing above a certain threshold pressure you set the regulator too,to return to the tank, usually that's set at 4.5-6 psi for carbs[/b] [/i]

keep in mind that the pressure sensor only makes the electrical connection once theres 5 psi of oil pressure in the blocks oil passages

"Ok G.V., need your input.

I intend to wire up 1 electric pump through an oil pressure switch (GM thought of it first that's how I got the idea). If the car sits dormant for a few weeks and the fuel evaporates in the carb the engine could be hard to start. Granted, you should be able to crank 5 psi long enough to fill the carb and start the engine but this adds wear and tear to the starter. Which of the following solutions would you recommend if any?

(1) Bypass the fuel pump circuit and power it through the start circuit so the pump powers up during engine cranking. This would need a diode so the start circuit is not back fed through the fuel pump circuit after engine start up which complicates the circuit.

(2) Wire in a toggle switch that powers the pump before cranking. Once engine starts, kill the toggle and allow the oil pressure circuit take over. The switch positions would be marked START (hot)and RUN (open). In a (heaven forbid) severe collision, the toggle could be activated (unlikely but possible) and defeat the safety built in to the oil pressure power up circuit.

What do you think?"

I would NEVER use a manual toggle switch,on an electric fuel pump they have a tendency to get thrown into the wrong position at times, causing all kinds of potential problems ranging from flooded carbs,engine stalling, dead battery's, burned out pumps etc.

if you want an over ride switch for the fuel pressure you'll want a BUTTON (normally open contacts)that connects the circuit only while the spring loaded button is MANUALLY HELD in the depressed position, similar to the older cars starter circuit buttons, thus the circuit works with or without the button depressed if the engine has oil pressure,and you have the OPTION to pre-prime the carb by MANUALLY depressing and holding the over ride button, momentarily ,sending the electricity to the electric pump to pre -prime the carb. but the fuel,system still works either way

THE DEAD HEAD STYLE REGULATOR...frequently not to be trusted

works with a spring on a valve that allows the valve to open once the DIFFERENCE IN PRESSURE between the sides of the regulator valves fuel lines has changed

think of it as a door that usually has 7-10psi on the feed side and you want lets assume 5.5 psi at the carburetor feed,

youll need to understand that the dead head regulator works on the DIFFERENCE in pressure between the feed and use sides so having 10psi on the feed and 7psi on the use side is almost exactly the same as having 12psi on the feed and 9psi on the use side to that style regulator, it uses a spring and residual fuel pressure to limit flow until the difference in pressure exceeds a set value.

as the fuel pump fills the line it eventually (fractions of a second )reaches the point where theres a volume of fuel past the valve with enough pressure to allow, BOTH the SPRING in the regulators valve and the fuel pressure past the valve to close the valve.... until the fuel pressure past the regulator is reduced to the point that the SPRING and the remaining fuel pressure/volume beyond the valve can not hold the valve closed and the valve is force open and held open until, that difference in pressure is restored. now lets launch the car hard, the pump that had maintained 8-10 psi to the regulator, 5.5 psi past the valve and the spring in the regulator is now fighting the fuel in the line feeding the regulators inertia, and the sudden drop in pressure as the throttle drops full open in the carb,what the pump sees is the full 8-10 psi or MORE the regulator sees a sudden drop off to near zero and it opens wide, if the fuel pumps able too it tends to flood the fuel bowl for a second then the valve slams shut, until the pressure drops off as you hit each gear the cycle repeats, the result is a surge in pressure and a rapid drop off in volume then a rapid flood of fuel that rapidly cycles as you go down the track

if you had a accurate fuel pressure sensor at the carb you'll see a rapidly cycling pressure/flow

if some crud gets stuck in the valve it cant close and your carb FLOODS OUT, because it must fully close every few fractions of a second to work correctly

THIS RETURN STYLES FAR MORE CONSISTENT

because fuel flows strait thru at all times but as soon as resistance to flow exceeds the set pressure level the adjustable spring seat is seat at, the relief valve to the return line is forced open and all excess pressure and flow exits into the return line maintaining the set pressure but preventing any further increase, but never interrupting fuel flow , one other advantage of the return style fuel pressure regulator is its generally going to provide a lower fuel pressure temp being delivered to the fuel rails, or carburetor.

your ideally routing your fuel line well away from your engine and exhaust so your in theory not dealing with fuel line temps at any point much above 200F.

keep in mind that most engine compartment fuel lines are metal except for the last 12"-18" of flex tube, engine compartment temps commonly run in the 160F-210F range but if you correctly plumbed your fuel line routing and used a return style fuel pressure regulator the constantly changing flow of fresh fuel thru the fuel lines will absorb and transport a good deal of that absorbed engine heat out of the fuel lines before it reaches the carburetor or inspector fuel rails..the rubber or synthetic fuel line is a poor conductor of heat and there are insulated reflective covers available.

http://www.summitracing.com/parts/tay-2593/overview/

http://www.ecstuning.com/Search/65758357417/ES1899370/

ENGINE HEAT AND THE RESTRICTIVE FLOW are both good reasons to avid using fuel filters like this one pictured below in the engine compartment

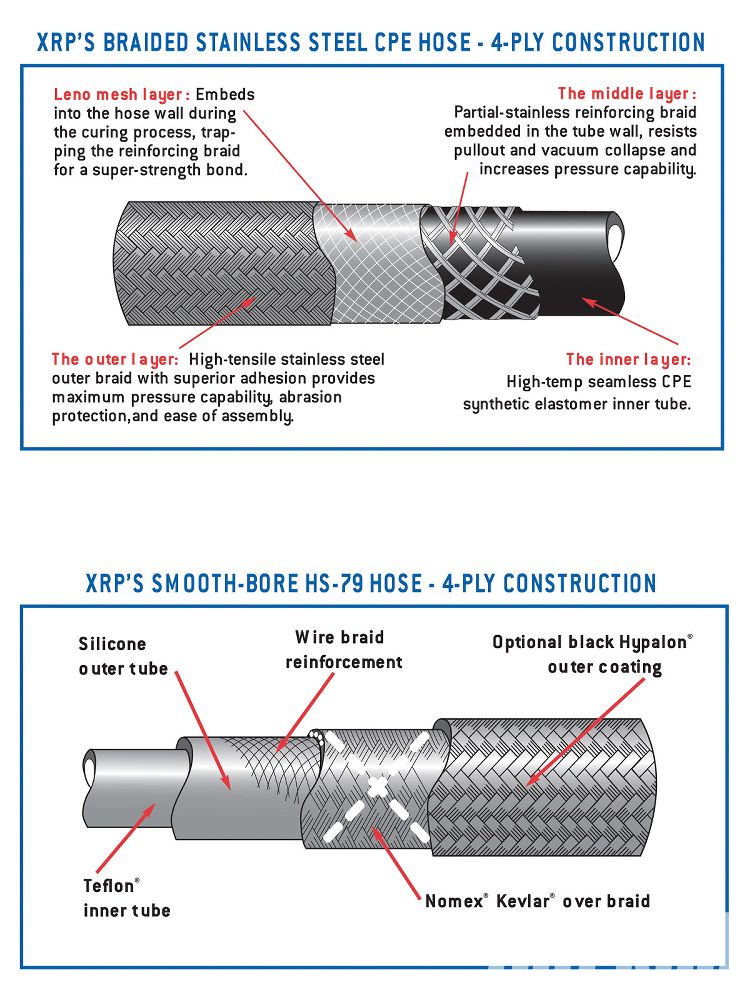

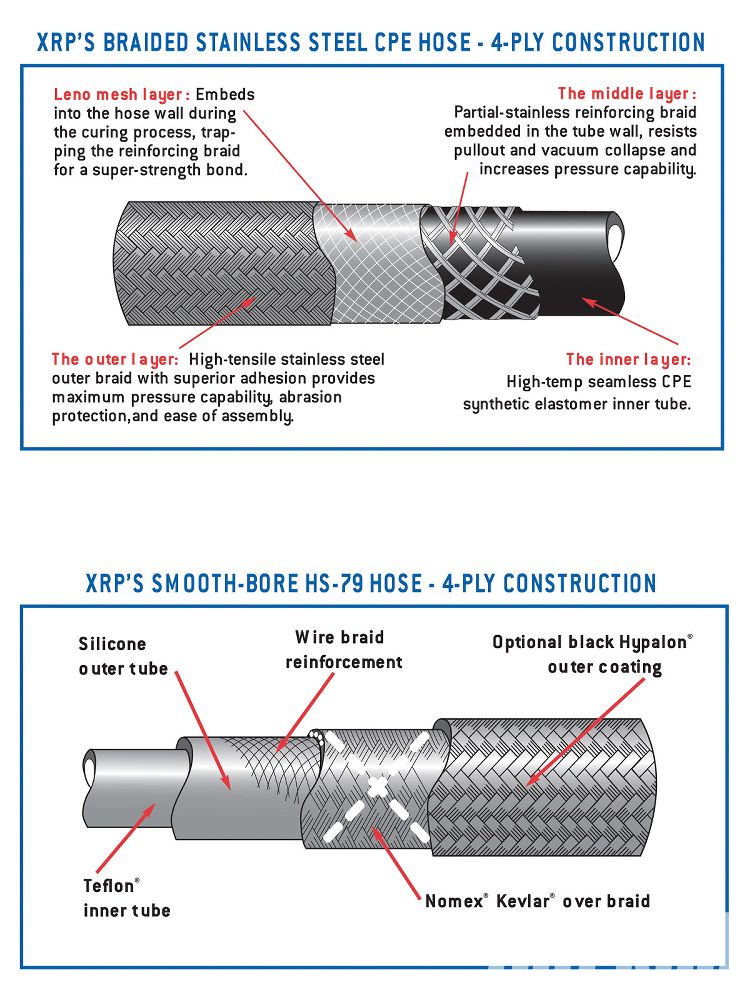

braided stainless covered flex line rated at 300 psi and 300f is a good idea, adding a heat reflective tube cover also helps reduce fuel temps

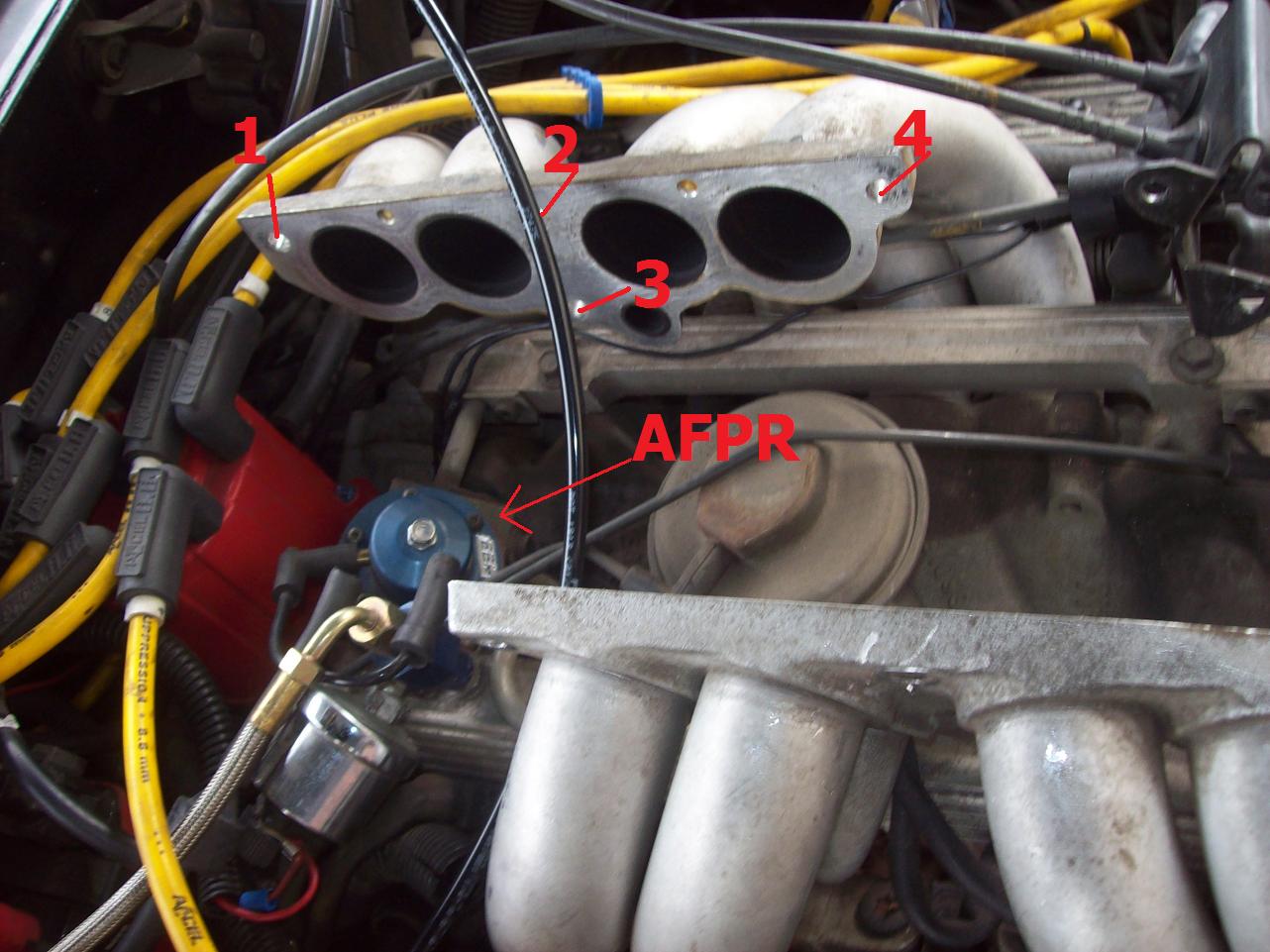

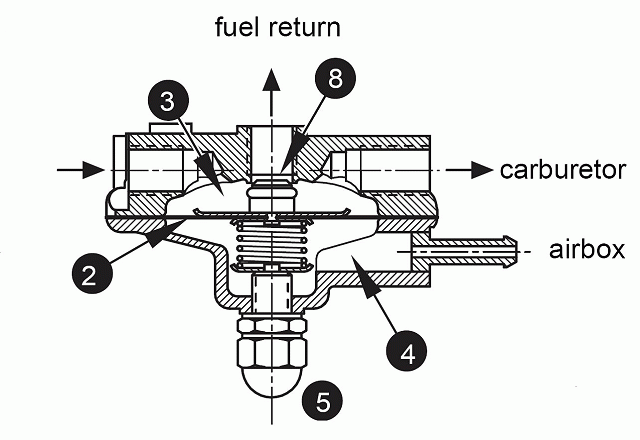

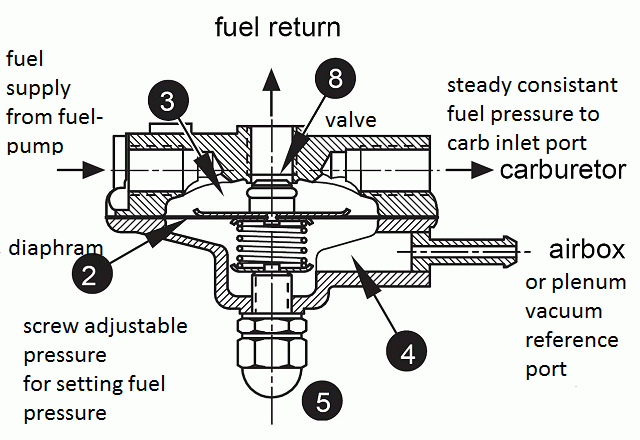

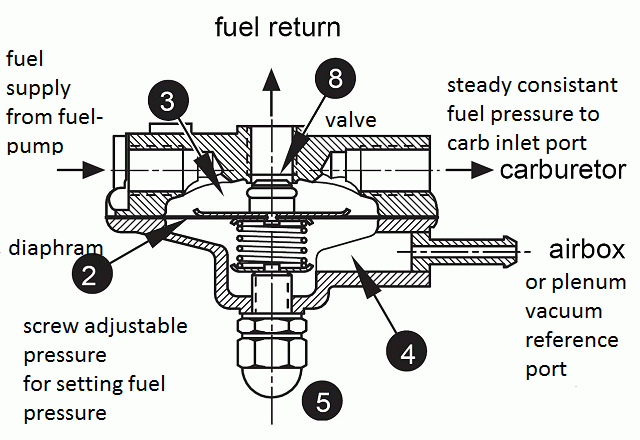

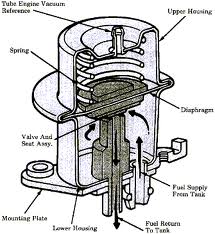

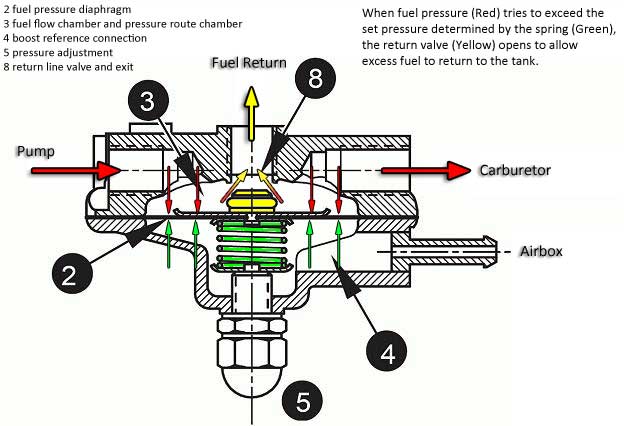

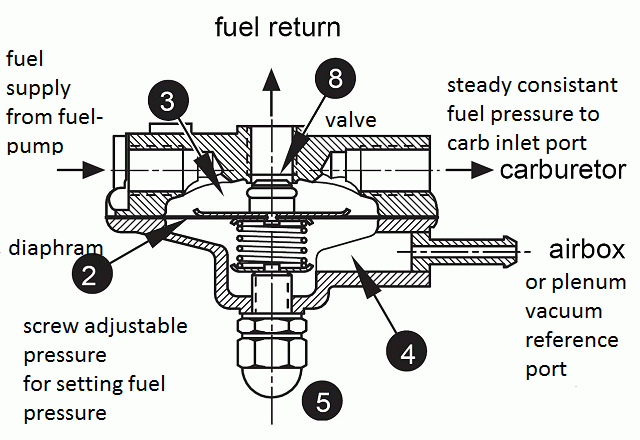

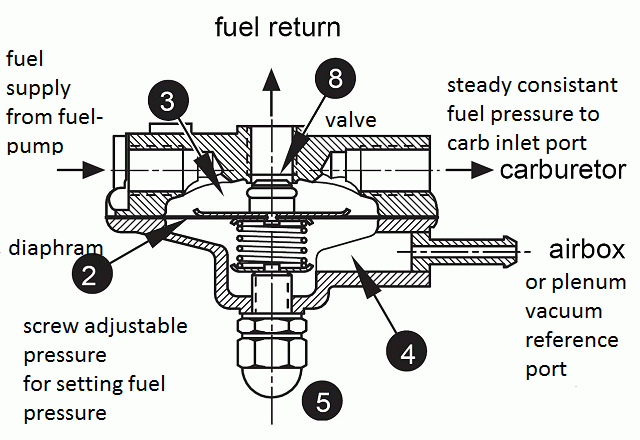

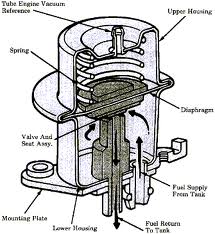

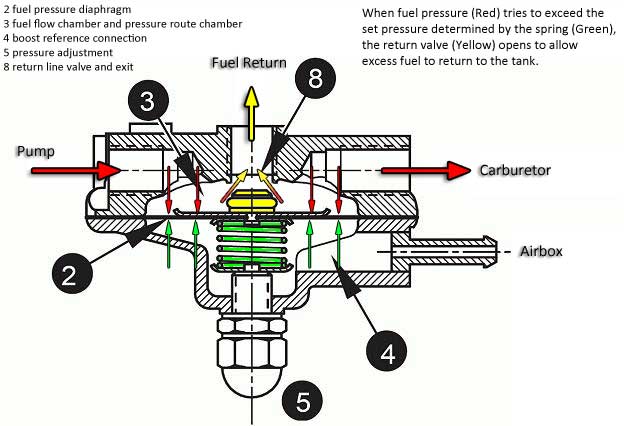

#3 in the diagram, its your OEM fuel pressure regulator the vacuum line changes the effective fuel flow and pressure slightly to compensate for the engine loads

manifold vacuum changes under engine load

http://static.summitracing.com/global/images/instructions/hly-199r10036-1.pdf

swapping to an adjustable versions usually good for a couple extra ft lbs of torque

RETURN STYLE FUEL PRESSURE REGULATOR

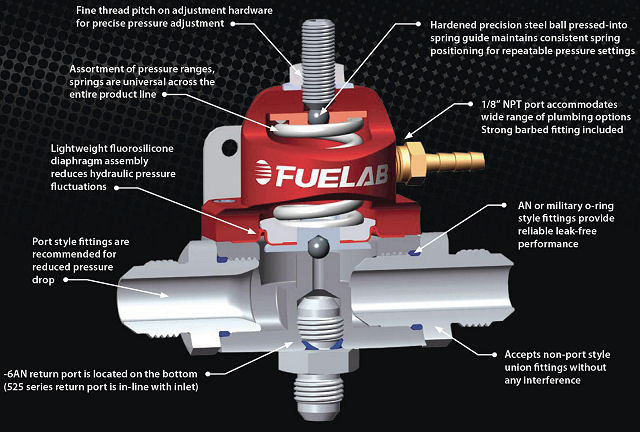

2 fuel pressure diaphragm

3 fuel flow chamber and pressure route chamber

4 boost reference connection

5 pressure adjustment

8 return line valve and exit

in the diagram fuel pressure is supplied by the fuel pump and enters the port on the upper left it fills the area ABOVE the DIAPHRAGM in area 3 , as the pressure rises it eventually reaches the point where the flexible DIAPHRAGM 2 forces the valve 8 lower and away from its seat ,allowing fuel to flow thru the return line back to the tank, until the pressure above the diaphragm drops allowing the seat spring to close the valve, this effectively causes the return line to constantly get a very rapid flow of fuel as the pressure above the diaphragm causes the valve to the return line to keep bleeding off any pressure above the springs resistance, this insures the pressure stays very consistent at the carb entrance port.

the boost or plenum vacuum pressure line 4 from the plenum adds or subtracts resistance to the diaphragm movement to open the return line as boost pressure rises or vacuum increases, thus fuel pressure stays consistent with air pressure the carb sees, on some versions, but the adjustable spring pressure makes it possible to set the minimum fuel pressure thats being maintained to feed the injector fuel rail or carb feed input port, as long as the fuel pump can at lease maintain or exceed that pressure

the far superior, bye-pass style regulator functions in a totally different manor

assuming the same set-up but you replace the regulator with a bye-pass style regulator, the bye-pass regulator works by opening a valve too a much lower pressure path for the fuel to return to the tank,,the open fuel return line. anytime the pressure exceeds the 4.0-5.5 psi,you've set it to, so the fuel line to the carb can only see a max at that 4.0-5.5 psi. now the pumps sitting there potentially supplying at 8-10psi just like before, but it can never exceed 4.0-5.5 psi because the bye pass regulator bleeds of any and all excess flow volume,the pump supplies. but lets look at your launch, if the pressure drops to 6, or 7 psi nothing changes at the carb, if it increases to 10 or 12 psi, nothing changes at the carb,if it drops to to 4.0-5.5 psi that you set the regulator bye-pass circuit too or less the valve to the bye pass line will close , but the fuel route to the carb inlet remains consistently open, but that excessive drop in pressures seldom a problem, it the sudden changes in pressure and over pressures that happen when you suddenly change the fuel flow required or the (G)loads on the system that potentially screw things up,the bye-pass regulator style regulator isolates the carb and maintains the desired 4.0-5.5 psi to the carb FAR MORE CONSISTENTLY.

this style regulator design depends on a fuel return line size large enough that there will be no significant resistance to fuel flow past the regulator, in route back to the fuel tank, because any pressure in the return line tends to reduce the regulators accuracy.

now lets assume the spring gets a bit weak over time or the adjustment gets set at 4 psi in error, with the bye-pass style you'll probably never notice ,if you had a accurate fuel pressure sensor at the carb you'll see a rock steady pressure/flow, at the 4psi.

should some crud get stuck in the valve and it can,t close 100% ,NOT MUCH HAPPENS, because its normally OPEN not closed,

if you check you'll see MOST EFI systems are BYE-PASS regulated designs also due to control and reliability issues

http://www.ws6.com/mod-7.htm

Dyno Comparisons -- Adjustable Fuel Pressure Regulator Settings

Here, the dyno shows a 16.6 horsepower and 14.6 ft/lbs torque difference between the stock fuel pressure (46psi) and 36psi with the LG Motorsports adjustable regulator. Actually, it was still making more power at 35psi than 36psi, but until I can measure my O2 sensors, I did not want to lean it out any further. The average gain here was 13.9 horsepower and 15.4 ft/lbs torque. Check out the Dynojet Race Routine between the stock and 36psi fuel pressure.

Something new: Dynojet is currently Beta testing their new WinPEP software for the dyno. With this software, they have the ability to graph up to 12 graphs at once. Check out the Dynojet WinPEP Graph of all the power between the stock and 35psi fuel pressures.

NOTE: One thing that I have found after some time with this mod is that the stock computer is quite smart. After lowering fuel pressure to achieve a better air/fuel ratio, the computer sees this at part throttle and adds injector pulsewidth to compensate. Basically, horsepower fell back off to where I started from. While normal trains of thought tell us that since O2 values are not measured during wide open throttle, that fuel pressure should have a long lasting effect here. Actually, it does not. The computer uses the last known long term fuel trim integer at WOT, which is to add fuel since at part throttle it has adjusted for being too lean.

return style typically have 3-4 ports

but on the dead head the cycle just gets about 20% more erratic and more frequent in the cycles, further weakening the spring over time

read

http://static.summitracing.com/global/i ... a-4309.pdf

btw your fuel pump tends to run under less stress and run cooler with a bye-pass style regulator also

http://static.summitracing.com/global/i ... -13301.pdf

http://aeromotiveinc.com/wp-content/upl ... ter-NN.pdf

http://static.summitracing.com/global/i ... 0036-1.pdf

most people don,t understand that the return fuel line to the tank will ideally have very low restriction to flow for the fuel pressure regulator to function correctly, if theres a restriction to flow it reduces the bye pass fuel pressure regulators accuracy and consistency.

most guys use a smaller diam. return line thinking that theres less fuel flow due to the engine use of fuel, that's not generally 100% accurate because if the fuel pressure is to remain consistent at a set pressure & volume the fuel pump must produce more fuel pressure and flow volume even at peak rpms than the engine can burn and even under high (G) loads, meaning that the return line needs to be fairly large and unrestricted to reduce the resistance, to flow in the upper rpm ranges with manual pumps that work in relation to engine rpms and all the time with electric pumps

http://centuryperformance.com/fuel.asp

Dead heads require a bigger rated pump than return style, hp for hp. They don't call them dead heads for nothing One source recommends -6 or 3/8 lines up to 375 hp, 550 with -8. Make sure the rest of your system is up to the task.Running a return style regulator is a pain, but worth the effort. Your pump will thank you by only working hard when it needs to, your pressure is stable, fuel cooler, and you can concentrate on the next problem. John

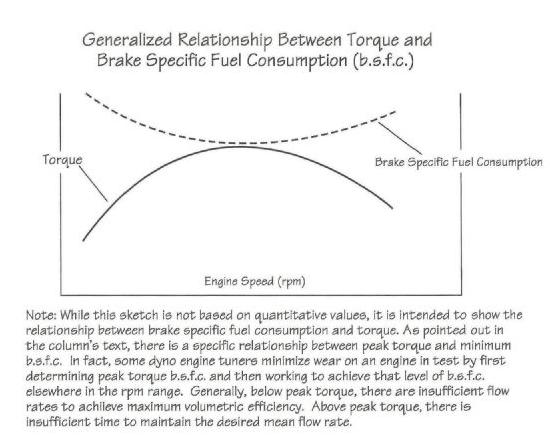

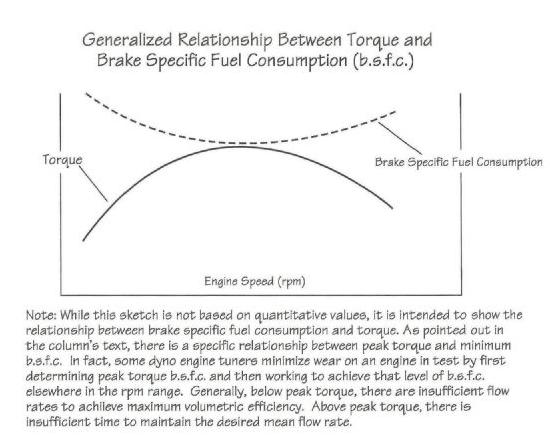

Assume a BSFC of 0.55 and gasoline at 6.25 lbs/gallon:

hp x 0.55 = pounds of fuel burned per hour

RELATED INFO

viewtopic.php?f=55&t=7787&p=26715#p26715

example

600hp x .55=330lbs

330lb /6.25lbs per gallon=52.8 gallons an hour minimum fuel used

A LINK WORTH READING

http://www.circletrack.com/enginetech/c ... _pressure/

a fuel filter with an easily replaceable filter element, a clear transparent drain, remotely mounted low and near the fuel tank,for easy access and maintenance helps fuel system durability

before you get crazy chasing some problem your sure is an intermittent fuel delivery issue

(1) Do a compression test!

(2) verify your ignition advance curve, and verify the ignition systems working correctly , the spark plugs are new, properly gaped and the ignition wires in excellent condition visually and with an OHMS meter.

(3) adjust your valves, correctly

(4) carefully verify theres no vacuum leaks, in lines or gaskets

(5)Check the fuel delivery system, WITH A GAUGE, while the engines under real operational inertial loads to verify you have a consistent 5-6 psi at the carburetor inlet port

(6) change out the fuel and air filters, especially if over 3-4 months old

(7) actually check your exhaust back-pressure levels

(8) verify your return style fuel pressure regulator and fuel lines function as intended

(9)verify your using FRESH FUEL WITHOUT MOISTURE OR PARTICULAR CONTAMINANTS

(10) actually look for and read installation instructions and rated flow and pressure limitations on fuel pumps and filters

(11) If ALL of the above are normal, only then start looking at the carburetor, and tuning issues

I think most guys would be amazed at how often, a high flow water separating fuel filter installed near the fuel tank that,s being checked and drained, with the filter medium changed regularly will cure or prevent a good many TUNING ISSUES

http://www.harborfreight.com/38-x-38-ba ... 68213.html

http://www.amazon.com/RACOR-320R-RAC-01 ... m_sbs_sg_2

http://www.amazon.com/Moeller-Separatin ... d_sbs_sg_1

FUEL Volume and FUEL pressure are two completely different things when you talk about fuel,supplied to an engine, but they must work together to give you the proper air/fuel mixture delivery. Both carburetors and EFI systems require the proper fuel volume to make the desired horsepower, but the pressure differences between the two are quite different. A carburetor setup requires very low fuel pressure—somewhere between 5 and 6 psi,pressures higher than 6 psi can force open the flow control valve on some carbs,

be aware that you,ll need to correctly set the carbs floats to regulate the fuel level in most carbs and the needle & seat valve

your carburetor inlet fuel pressure should be a consistent 5 psi-5.5 psi in most cases, once you get over 6 psi you'll find the carburetor float bowls tend to flood and under 3 psi the carburetor can run lean under hard acceleration.

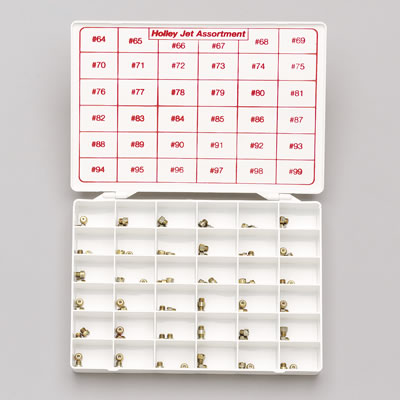

keep in mind the internal port size is not all that large on the cheap holley fuel pressure regulators , so they work ok on near stock applications but NOT on anything close to a race application.

EFI works at higher pressures (a 1985-1991 TPI corvette as an example generally operates in the 38psi-42 psi fuel pressure range)

THINK,

fuel tank...to .fuel filter....to .-fuel pump....to feed into fuel rail& injectors. then out too....fuel pressure regulator...then too..return line to fuel tank

shop carefully, fuel line size, fuel pressure range,

consistency of maintaining both fuel flow and pressure, component quality, and durability as well as cost varies wildly

Holley 12-846: 12-846 Billet Adjustable Regulator - JEGS

Get the Best Performance with Holley 12-846 Billet Adjustable Regulator 12-846 parts at JEGS. Shop Now at the Guaranteed Lowest Price!

the vacuum line to the plenum drops under full throttle,

so the diaphragm and check ball,compensate, to maintain max flow rate to the injectors,

the diaphragm and check ball in the regulator become, or are just a tiny bit harder for the fuel pressure too force open,without the plenum vacuum above the the diaphragm and check ball

thus maintaining fuel rail volume and pressure before any of the fuel can exit the return line

it might help if you think, fuel pump provides fuel flow volume,

fuel pressure is a measure of resistance to fuel flow,

the fuel pressure regulator acts as a valve that opens if the pressure exceeds about 42 psi (YES some versions like yours are manually adjustable) but the reason its there is to maintain a consistent 39 psi-42 psi to do that you allow the fuel pump to stack or pressurize fuel in the fuel rail and in theory the fuel pressure regulator only allows excess fuel volume to flow back to the fuel tank through the return line if that fuel pressure exceeds the 42 psi, the pump is designed to provide a bit more than the required 42 psi too insure fresh cool fuel is cooling the fuel pump while maintaining that consistent fuel volume at the fuel pressure, when you tromp on the throttle the flow of fuel drastically increases, the regulator momentarily restricts out going fuel to maintain the fuel rail pressure and volume, until the flow demand drops enough, for excess volume and the resulting increased pressure that results to open the regulator again,

that controls fuel flow into the carb can get crud trapped between the needle and seat causing the fuel bowl to constantly flood, so check that carefully, if thats your issue!

while most EFI setups, require 40 psi too as much as 60 psi or more on the high side limit. This means the fuel pump you select needs are entirely different, for each system and regulating pressure is handled by different components as well. youll need too select a Regulator manufacturer who makes regulators specifically for each application.

A return-style fuel system keeps the flow of fuel through the entire system at a constant,rate, keeping the fuel cooler. Constant circulation of cooler fuel will also result in less tendency to get into conditions favoring vapor lock , than a dead-head–style system, as fuel sits in the lines and carburetor absorbing heat from the engine compartment.

Ive consistently had far better results with the bye-pass style regulators ,for several reasons, the non-bye-pass regulators allow more heat to build up in the fuel and tend to be slightly more prone to get the fuel temp up into detonation range, fuel thats cool absorbs some combustion chamber heat lower burn temps very slightly, you NEED a fuel pressure regulator with a BYE-PASS CIRCUIT from the regulator at the carburetors location back to the tank,If the pump is capable of more than 7PSI you should run a regulator regardless of the engine, simply because most carburetors needle and seat valves can not control flow over 7 psi and many can,t handle even 6 psi

and yes, use of a small handy and accurate fuel pressure gauge, mounted on the fuel injector fuel rail (0-100 psi for FUEL INJECTION)

or carb inlet port (0-15 psi for carburetors)is almost mandatory, they generally cost under $30

The engine does not care how much pressure you push to the carburetor, but the have the carburetor will have a needle & seat valve that does, because it must maintain a near constant float level in the fuel bowls to have a consistent fuel/air ratio.

All the engine cares about is that the carburetor feeds it a controlled fuel air mix ratio between about 12.7:1-15:1 & you need to maintain enough pressure & volume to keep the carburetor fuel bowls full under all conditions, WITH OUT FLOODING or fuel starvation.

dead head regulators will frequently NOT maintain a constant pressure , it tends to surge and fall, and running a electric pump without using fuel that flows constantly thru it will USUALLY cause the pump to heat up and LOOSE some efficiency, in fact they commonly loose efficiency or fail if heated up, trying to pump the same fuel constantly, the flow thru a bye-pass regulator with its separate fuel return line to the tank allows the fuel to circulate and pull heat from the pump,the better quality, return style regulators are vastly more effective

WHEN TESTING<be sure the fuel pressure gauge reads correctly by comparing it to a second test gauge, these fuel pressure gauges are frequently defective

The minimum fuel line size (from the pump to the regulator) is dependent on the horsepower output of the engine (and/or Nitrous system) regardless of the size of the pump. fuel pressure regulators are normally placed as close to the fuel rail or carburetor feed inlet port as possible to maintain most of the fuel feed lines under higher pressure to reduce vapor-lock, high g -force fuel starvation and to reduce the chance of air entering the carburetor ,or injectors and keep a constant flow of cool fuel reaching the injector's or carburetor, because theres a constant flow of new fresh fuel being forced up to and some bye-passed thru the system, and fed to the engine

keep in mind TPI fuel pressure regulators maintain about 40-45 psi while carburetors require about 4.5-6.5 psi MAX, but in most cases the fuel pressure at the carb inlet port NEEDS to read 4.5-5 psi MAX and you NEED to set the float levels per the carburetor manufacturers instructions, having the pressure at 6.5 psi will in many cases cause the needle & seat valve to constantly leak excess fuel, into the carburetor while the engine runs

if your running a return style fuel pressure regulator it depends on the instructions that come with it and the number of ports,its usually mounted AFTER the two carb inlet fuel feeds

the pump feeds the fuel log, the fuel log feeds both carb inlets and the regulator mounted on the far end of the fuel log from the fuel feed bleeds off excess pressure to the return line to the the tank.the problem with all decent quality fuel line supply component parts is they cost more money, than the cheap low quality parts and generally take up more room and take a bit more time and thought to install correctly

http://garage.grumpysperformance.com/index.php?threads/setting-up-your-fuel-system.211/

I can easily see where the diagram may be confusing ,, and while that cheap holley return style fuel pressure regulator works

the picture is correct on many of the Holley fuel pressure regulators

(these several versions)

the cheaper fuel pressure regulator feeds from the base

you need a fuel pressure gauge on the carb inlet port,to accurately set fuel pressure

and then you need to rev the engine and hold it at 3500 rpm for a few second's

then drop the rpms and watch the pressure gauge

DON,T ASSUME ,TEST VERIFY

at maintaining fuel pressure on the inlet port and can be used its far from the better choice

this is the type of FP regulator you want in most cases,

and it comes in AN#8 and AN#10 sizes

its simply a strait through fuel flow with a pressure release that leads to the return line that opens if the fuel pressure exceeds a set level, thus it maintains that max pressure

https://www.holley.com/products/fue...regulators/carbureted_regulators/parts/12-841

http://documents.holley.com/199r10575rev3.pdf

http://garage.grumpysperformance.com/index.php?threads/fuel-pressure-regulators.635/

remember that on any turbo or super charged engine application the fuel pressure MUST be indexed to the engine boost, to maintain the ideal fuel/air ratio, and you'll generally want most engines to run in the fairly lean 14.7:1-13.5:1 range at idle but be tuned to transition smoothly and consistently, to a fuel/air ratio closer to about 12.6:1 as the rpms AND loads on the engine are increased,

LOOK CAREFULLY AT THE CHARTS POSTED LOWER

http://www.summitracing.com/parts/aei-13301/overview/

the regulator linked above can be adapted easily from carb to EFI use

http://www.summitracing.com/parts/hly-12-841/overview/

http://www.amazon.com/Moeller-Separatin ... d_sbs_sg_1

http://www.summitracing.com/parts/edl-1792/overview/

yes the diagrams a bit confusing,pressure is a measurement of RESISTANCE to flow, the pump puts out , flow volume, theres no pressure until theres a resistance or restriction to flow,

Holley 12-846: 12-846 Billet Adjustable Regulator - JEGS

Get the Best Performance with Holley 12-846 Billet Adjustable Regulator 12-846 parts at JEGS. Shop Now at the Guaranteed Lowest Price!

potentially 6 -7 psi the true pressure is regulated to what ever the fuel pressure regulator is set too, IE, if the bye-pass spring setting is at 4.5 psi thats a high as the pressure ever gets, the fuel pressure potentially exceeding this forced the regulator to open,the spring resistance is over come and the fuel flows back too the tank, thus running out through the bye-pass, into the return line, limiting pressure.

[ [color]BASIC CAR FUEL SYSTEM DESIGN[/color]

but on some models its mounted just before the fuel log on the port labeled "CARB" and the two other ports are labeled "feed" for the pump and "RETURN", for the return line

OR YOU CAN GET MUCH MORE COMPLICATED

if your, looking at the diagram,and asking what pressure the fuel rail feeding the carburetor is pressurized too its obviously controlled by the fuel pressure regulator just beyond it in the diagram, which is usually located near the carburetor and fuel rail, to maintain the indicated 5psi, beyond that is the return line feeding back to the fuel tank and that should be close to zero, the main feed line from pump to the first fuel pressure regulator which ideally is located on the inner front fender or firewall maintains the 8psi-12psi the fuel pump provides , keep in mind a fuel pressure regulator can only control the pressure between it and its pressurized feed source, by bleeding off pressure above the peak its set for, it has zero control past it, it only controls pressure between it and its pressure feed source ,in that diagram the first fuel pressure regulator is NOT mandatory in some applications, its the use of the secondary nitrous feed that makes it useful in the depicted application

IF you have a PLENUM OR RUNNER FLOODED WITH FUEL,

http://members.shaw.ca/corvette86/FuelS ... gnosis.pdf

ok logically if your flooding fuel into the intake, its related to injectors leaking,or the fuel pressure regulator leaking or a vacuum line sucking fuel from some place like the fuel return line simply because thats how fuel can enter the plenum.

if you block the fuel return line to the tank from the fuel pressure regulator, and remove the fuel pressure regulator vacuum line temporarily, you should see the fuel pressure bump up to 40-47 psi , if not its most likely the injector(s) leaking, or fuel being sucked into a vacuum line, because your effectively eliminating a defective fuel pressure diaphragm in the regulator.

as always its a isolate and test procedure

EFI operates on a SIMILAR CONCEPT but obviously at higher pressures and generally with individual injectors spraying fuel that are usually controlled by a computer with sensor input rapidly matching fuel delivery to the engines demands

many EFI fuel pressure regulators are connected to the injector fuel rails, thus they maintain a designed fuel pressure feeding the injectors controlled by both manifold vacuum and fuel pump pressure, as plenum vacuum drops , the vacuum level above the fuel pressure regulator diaphragm has less effect on reducing fuel pressure return line psi, as it has less effect on the regulator diaphragms resistance spring, preventing the return line port opening, so fuel pressure increases slightly as demand and rpm increase.

READ THESE THREADS & linked info

http://www.useasydocs.com/details/fuelsys.htm

http://www.circletrack.com/enginetech/c ... _pressure/

http://www.circletrack.com/enginetech/c ... _pressure/

the manual fuel pump is working in direct relation to the engines rpm levels, an electric fuel pump is working against the rapid changes in inertia as the car accelerates and brakes, if you think shifting gears at high rpms won,t alter the fuel pressure curve if you don,t have a bye-pass style fuel pressure regulator and a fuel return like in use you've never watched a fuel pressure gauge on a car without those components

ideally all lines are 3/8" minimum but 1/2" id is far better

the electric fuel pump would ideally be mounted lower than the tank and as far back as practicable INSIDE the frame rails for crash protection, with a hot lead to the electric pump that only supplies electric power ,if you have oil pressure and the ignition keys in the on position, as electric pumps PUSH fuel,far more efficiently than they PULL fuel

BTW alcohol in fuel tends to cause aluminum to oxidize over time

http://video.foxbusiness.com/v/2000862202001/

as you don,t want the electric pump running if the engines NOT running.

the fuel filter should be mounted for easy access,as you should change it frequently.

the regulator should be mounted as close to the carb as easy access allows, with the return line back to the tank, ideally larger than the feed line for zero resistance to fuel flow

keep in mind the by-pass style regulators work by allowing all fuel flowing above a certain threshold pressure you set the regulator too,to return to the tank, usually that's set at 4.5-6 psi for carbs[/b] [/i]

keep in mind that the pressure sensor only makes the electrical connection once theres 5 psi of oil pressure in the blocks oil passages

"Ok G.V., need your input.

I intend to wire up 1 electric pump through an oil pressure switch (GM thought of it first that's how I got the idea). If the car sits dormant for a few weeks and the fuel evaporates in the carb the engine could be hard to start. Granted, you should be able to crank 5 psi long enough to fill the carb and start the engine but this adds wear and tear to the starter. Which of the following solutions would you recommend if any?

(1) Bypass the fuel pump circuit and power it through the start circuit so the pump powers up during engine cranking. This would need a diode so the start circuit is not back fed through the fuel pump circuit after engine start up which complicates the circuit.

(2) Wire in a toggle switch that powers the pump before cranking. Once engine starts, kill the toggle and allow the oil pressure circuit take over. The switch positions would be marked START (hot)and RUN (open). In a (heaven forbid) severe collision, the toggle could be activated (unlikely but possible) and defeat the safety built in to the oil pressure power up circuit.

What do you think?"

I would NEVER use a manual toggle switch,on an electric fuel pump they have a tendency to get thrown into the wrong position at times, causing all kinds of potential problems ranging from flooded carbs,engine stalling, dead battery's, burned out pumps etc.

if you want an over ride switch for the fuel pressure you'll want a BUTTON (normally open contacts)that connects the circuit only while the spring loaded button is MANUALLY HELD in the depressed position, similar to the older cars starter circuit buttons, thus the circuit works with or without the button depressed if the engine has oil pressure,and you have the OPTION to pre-prime the carb by MANUALLY depressing and holding the over ride button, momentarily ,sending the electricity to the electric pump to pre -prime the carb. but the fuel,system still works either way

THE DEAD HEAD STYLE REGULATOR...frequently not to be trusted

works with a spring on a valve that allows the valve to open once the DIFFERENCE IN PRESSURE between the sides of the regulator valves fuel lines has changed

think of it as a door that usually has 7-10psi on the feed side and you want lets assume 5.5 psi at the carburetor feed,

youll need to understand that the dead head regulator works on the DIFFERENCE in pressure between the feed and use sides so having 10psi on the feed and 7psi on the use side is almost exactly the same as having 12psi on the feed and 9psi on the use side to that style regulator, it uses a spring and residual fuel pressure to limit flow until the difference in pressure exceeds a set value.

as the fuel pump fills the line it eventually (fractions of a second )reaches the point where theres a volume of fuel past the valve with enough pressure to allow, BOTH the SPRING in the regulators valve and the fuel pressure past the valve to close the valve.... until the fuel pressure past the regulator is reduced to the point that the SPRING and the remaining fuel pressure/volume beyond the valve can not hold the valve closed and the valve is force open and held open until, that difference in pressure is restored. now lets launch the car hard, the pump that had maintained 8-10 psi to the regulator, 5.5 psi past the valve and the spring in the regulator is now fighting the fuel in the line feeding the regulators inertia, and the sudden drop in pressure as the throttle drops full open in the carb,what the pump sees is the full 8-10 psi or MORE the regulator sees a sudden drop off to near zero and it opens wide, if the fuel pumps able too it tends to flood the fuel bowl for a second then the valve slams shut, until the pressure drops off as you hit each gear the cycle repeats, the result is a surge in pressure and a rapid drop off in volume then a rapid flood of fuel that rapidly cycles as you go down the track

if you had a accurate fuel pressure sensor at the carb you'll see a rapidly cycling pressure/flow

if some crud gets stuck in the valve it cant close and your carb FLOODS OUT, because it must fully close every few fractions of a second to work correctly

THIS RETURN STYLES FAR MORE CONSISTENT

because fuel flows strait thru at all times but as soon as resistance to flow exceeds the set pressure level the adjustable spring seat is seat at, the relief valve to the return line is forced open and all excess pressure and flow exits into the return line maintaining the set pressure but preventing any further increase, but never interrupting fuel flow , one other advantage of the return style fuel pressure regulator is its generally going to provide a lower fuel pressure temp being delivered to the fuel rails, or carburetor.

your ideally routing your fuel line well away from your engine and exhaust so your in theory not dealing with fuel line temps at any point much above 200F.

keep in mind that most engine compartment fuel lines are metal except for the last 12"-18" of flex tube, engine compartment temps commonly run in the 160F-210F range but if you correctly plumbed your fuel line routing and used a return style fuel pressure regulator the constantly changing flow of fresh fuel thru the fuel lines will absorb and transport a good deal of that absorbed engine heat out of the fuel lines before it reaches the carburetor or inspector fuel rails..the rubber or synthetic fuel line is a poor conductor of heat and there are insulated reflective covers available.

http://www.summitracing.com/parts/tay-2593/overview/

http://www.ecstuning.com/Search/65758357417/ES1899370/

ENGINE HEAT AND THE RESTRICTIVE FLOW are both good reasons to avid using fuel filters like this one pictured below in the engine compartment

braided stainless covered flex line rated at 300 psi and 300f is a good idea, adding a heat reflective tube cover also helps reduce fuel temps

#3 in the diagram, its your OEM fuel pressure regulator the vacuum line changes the effective fuel flow and pressure slightly to compensate for the engine loads

manifold vacuum changes under engine load

The spring pressure is what governs your fuel pressure/flow at any condition (pressure and flow are inversely related). Engine vacuum acts on the diaphragm which compresses or relaxes the spring, thereby opening or closing the valve. Under high engine loads (low vacuum) the spring overcomes the vacuum diaphragm, opens the valve and more fuel flows. Under low engine loads (high vacuum) the vacuum overcomes the spring and the valve closes (not all the way, obviously) and fuel flow is reduced.

http://static.summitracing.com/global/images/instructions/hly-199r10036-1.pdf

swapping to an adjustable versions usually good for a couple extra ft lbs of torque

2 fuel pressure diaphragm

3 fuel flow chamber and pressure route chamber

4 boost reference connection

5 pressure adjustment

8 return line valve and exit

in the diagram fuel pressure is supplied by the fuel pump and enters the port on the upper left it fills the area ABOVE the DIAPHRAGM in area 3 , as the pressure rises it eventually reaches the point where the flexible DIAPHRAGM 2 forces the valve 8 lower and away from its seat ,allowing fuel to flow thru the return line back to the tank, until the pressure above the diaphragm drops allowing the seat spring to close the valve, this effectively causes the return line to constantly get a very rapid flow of fuel as the pressure above the diaphragm causes the valve to the return line to keep bleeding off any pressure above the springs resistance, this insures the pressure stays very consistent at the carb entrance port.

the boost or plenum vacuum pressure line 4 from the plenum adds or subtracts resistance to the diaphragm movement to open the return line as boost pressure rises or vacuum increases, thus fuel pressure stays consistent with air pressure the carb sees, on some versions, but the adjustable spring pressure makes it possible to set the minimum fuel pressure thats being maintained to feed the injector fuel rail or carb feed input port, as long as the fuel pump can at lease maintain or exceed that pressure

the far superior, bye-pass style regulator functions in a totally different manor

assuming the same set-up but you replace the regulator with a bye-pass style regulator, the bye-pass regulator works by opening a valve too a much lower pressure path for the fuel to return to the tank,,the open fuel return line. anytime the pressure exceeds the 4.0-5.5 psi,you've set it to, so the fuel line to the carb can only see a max at that 4.0-5.5 psi. now the pumps sitting there potentially supplying at 8-10psi just like before, but it can never exceed 4.0-5.5 psi because the bye pass regulator bleeds of any and all excess flow volume,the pump supplies. but lets look at your launch, if the pressure drops to 6, or 7 psi nothing changes at the carb, if it increases to 10 or 12 psi, nothing changes at the carb,if it drops to to 4.0-5.5 psi that you set the regulator bye-pass circuit too or less the valve to the bye pass line will close , but the fuel route to the carb inlet remains consistently open, but that excessive drop in pressures seldom a problem, it the sudden changes in pressure and over pressures that happen when you suddenly change the fuel flow required or the (G)loads on the system that potentially screw things up,the bye-pass regulator style regulator isolates the carb and maintains the desired 4.0-5.5 psi to the carb FAR MORE CONSISTENTLY.

this style regulator design depends on a fuel return line size large enough that there will be no significant resistance to fuel flow past the regulator, in route back to the fuel tank, because any pressure in the return line tends to reduce the regulators accuracy.

now lets assume the spring gets a bit weak over time or the adjustment gets set at 4 psi in error, with the bye-pass style you'll probably never notice ,if you had a accurate fuel pressure sensor at the carb you'll see a rock steady pressure/flow, at the 4psi.

should some crud get stuck in the valve and it can,t close 100% ,NOT MUCH HAPPENS, because its normally OPEN not closed,

if you check you'll see MOST EFI systems are BYE-PASS regulated designs also due to control and reliability issues

http://www.ws6.com/mod-7.htm

Dyno Comparisons -- Adjustable Fuel Pressure Regulator Settings

Here, the dyno shows a 16.6 horsepower and 14.6 ft/lbs torque difference between the stock fuel pressure (46psi) and 36psi with the LG Motorsports adjustable regulator. Actually, it was still making more power at 35psi than 36psi, but until I can measure my O2 sensors, I did not want to lean it out any further. The average gain here was 13.9 horsepower and 15.4 ft/lbs torque. Check out the Dynojet Race Routine between the stock and 36psi fuel pressure.

Something new: Dynojet is currently Beta testing their new WinPEP software for the dyno. With this software, they have the ability to graph up to 12 graphs at once. Check out the Dynojet WinPEP Graph of all the power between the stock and 35psi fuel pressures.

NOTE: One thing that I have found after some time with this mod is that the stock computer is quite smart. After lowering fuel pressure to achieve a better air/fuel ratio, the computer sees this at part throttle and adds injector pulsewidth to compensate. Basically, horsepower fell back off to where I started from. While normal trains of thought tell us that since O2 values are not measured during wide open throttle, that fuel pressure should have a long lasting effect here. Actually, it does not. The computer uses the last known long term fuel trim integer at WOT, which is to add fuel since at part throttle it has adjusted for being too lean.

return style typically have 3-4 ports

but on the dead head the cycle just gets about 20% more erratic and more frequent in the cycles, further weakening the spring over time

read

http://static.summitracing.com/global/i ... a-4309.pdf

btw your fuel pump tends to run under less stress and run cooler with a bye-pass style regulator also

http://static.summitracing.com/global/i ... -13301.pdf

http://aeromotiveinc.com/wp-content/upl ... ter-NN.pdf

http://static.summitracing.com/global/i ... 0036-1.pdf

most people don,t understand that the return fuel line to the tank will ideally have very low restriction to flow for the fuel pressure regulator to function correctly, if theres a restriction to flow it reduces the bye pass fuel pressure regulators accuracy and consistency.

most guys use a smaller diam. return line thinking that theres less fuel flow due to the engine use of fuel, that's not generally 100% accurate because if the fuel pressure is to remain consistent at a set pressure & volume the fuel pump must produce more fuel pressure and flow volume even at peak rpms than the engine can burn and even under high (G) loads, meaning that the return line needs to be fairly large and unrestricted to reduce the resistance, to flow in the upper rpm ranges with manual pumps that work in relation to engine rpms and all the time with electric pumps

http://centuryperformance.com/fuel.asp

Dead heads require a bigger rated pump than return style, hp for hp. They don't call them dead heads for nothing One source recommends -6 or 3/8 lines up to 375 hp, 550 with -8. Make sure the rest of your system is up to the task.Running a return style regulator is a pain, but worth the effort. Your pump will thank you by only working hard when it needs to, your pressure is stable, fuel cooler, and you can concentrate on the next problem. John

Assume a BSFC of 0.55 and gasoline at 6.25 lbs/gallon:

hp x 0.55 = pounds of fuel burned per hour

RELATED INFO

viewtopic.php?f=55&t=7787&p=26715#p26715

example

600hp x .55=330lbs

330lb /6.25lbs per gallon=52.8 gallons an hour minimum fuel used

A LINK WORTH READING

http://www.circletrack.com/enginetech/c ... _pressure/

a fuel filter with an easily replaceable filter element, a clear transparent drain, remotely mounted low and near the fuel tank,for easy access and maintenance helps fuel system durability

before you get crazy chasing some problem your sure is an intermittent fuel delivery issue

(1) Do a compression test!

(2) verify your ignition advance curve, and verify the ignition systems working correctly , the spark plugs are new, properly gaped and the ignition wires in excellent condition visually and with an OHMS meter.

(3) adjust your valves, correctly

(4) carefully verify theres no vacuum leaks, in lines or gaskets

(5)Check the fuel delivery system, WITH A GAUGE, while the engines under real operational inertial loads to verify you have a consistent 5-6 psi at the carburetor inlet port

(6) change out the fuel and air filters, especially if over 3-4 months old

(7) actually check your exhaust back-pressure levels

(8) verify your return style fuel pressure regulator and fuel lines function as intended

(9)verify your using FRESH FUEL WITHOUT MOISTURE OR PARTICULAR CONTAMINANTS

(10) actually look for and read installation instructions and rated flow and pressure limitations on fuel pumps and filters

(11) If ALL of the above are normal, only then start looking at the carburetor, and tuning issues

I think most guys would be amazed at how often, a high flow water separating fuel filter installed near the fuel tank that,s being checked and drained, with the filter medium changed regularly will cure or prevent a good many TUNING ISSUES

http://www.harborfreight.com/38-x-38-ba ... 68213.html

http://www.amazon.com/RACOR-320R-RAC-01 ... m_sbs_sg_2

http://www.amazon.com/Moeller-Separatin ... d_sbs_sg_1

Last edited by a moderator: