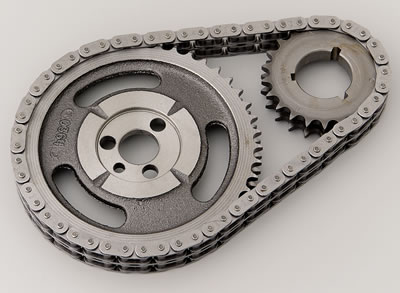

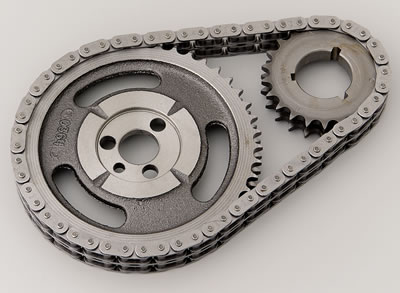

IVE used both CLOYES roller chain drives and SEVERAL DIFFERENT GEAR DRIVES FOR CAMS IN MY CORVETTES 383,SBC ENGINE,s the CLOYES chain drive is probably the best value,

http://store.summitracing.com/partdetail.asp?part=CLO-9-3100&autoview=sku

Ive run both setups on lots of motors,I'm running a Jackson gear drive with over 80K on it in my 383 now and it shows little wear, keep in mind the clearances and care in installation effect the life span, you can,t throw a gear drive on without checking alignment and clearances/lash,the QUALITY and VOLUME of the OIL FLOW too the gears,matters Ive drilled the plugs in the lifter gallery's behind the cam gear so the gears are constantly washed with extra oil,I'm using a cam button, and a 10qt oil pan with a high volume oil pump, etc.theres nothing wrong with a properly set up and clearanced gear drive ,if you get the quite version, but get the clearances wrong and they tend to howl,and if the gear drives not constantly being bathed in oil spray it tends to be louder , you might want to keep in mind theres thousands of pounds of valve spring pressure, on the cam lobes, both on the front of the lobes as the lifters rise and on the back of the lobes as they return to the seats, and both a flywheel and a damper/balancer and a great deal of mass and inertia in the spinning rotating assembly that tends to absorb, and minimize minor vibrations , and clearances that tend to, reduce effective transmission of minor secondary vibrations in the valve train, you also might want to remember you can,t PUSH a chain, to transmit a vibration, you can only pull a chain so theres less chance of effective transmission of vibration thru a chain or belt drive than a gear drive

http://store.summitracing.com/partdetail.asp?part=PJJ-327-1C&autoview=sku

http://www.jonkaaseracingengines.com/pr ... rives.html

BUT Id say 90% of the time installing a CLOYES TRUE ROLLER set is the fastest and cheapest route and best value

http://store.summitracing.com/partdetail.asp?part=CLO-9-3100&autoview=sku

and Ive had zero problems,with properly installed 3 and 4 gear,gear drive cam timing sets. but that being said, Id keep in mind timing sets are expendable like gaskets and should be replaced, or at least carefully inspected for wear, when you do cam changes and ring jobs, or anytime your pulling down the engine if the chain timing sets had more than 25-30k on it, etc, I would almost never consider re-use of a timing chain after its had 30k or more on it, unless it shower near zero wear.

now don,t think I'm against the gear drives , because I'm still running a quiet gear drive in my current 383, but Id have zero problem running a cloyes true roller chain drive, and if your not willing to carefully clearance a gear drive a CLOYES chain drive is far easier to install and less likely to cause problems

http://store.summitracing.com/partdetail.asp?part=PJJ-350-91C&autoview=sku

http://www.summersbrothersracing.com/ca ... drives.htm

http://www.milodon.com/gear-drives/gear ... -chrys.asp

but unless your very good at tuning the gear drives , and realize the knock sensor can be a problem with gear drives, but they do have slightly more stable ignition timing,that slightly more stable ignition timing doesn,t offer much if any advantage, below about 6000rpm in most cases and its very small, advantage at best while the chain drive tends to be very dependable and almost trouble free.

but don,t fall for the MYTH that gear drives cause timing problems due to transmission of crank harmonics to the cam, if you have a balanced rotating assembly and a decent harmonic balancer and the correct clearances its not likely to be a measurable issue, with the 4 gear units simply because of the clearances and slack makes transmitting small vibration's thru several gears very in-efficient , but that was and is possible with the two gear reverse rotation cam drives but the three and 4 gear systems are designed with enough clearance its basically on non-issue, every time Ive looked into that myth, it turned out to be mis matched valve train components like running the wrong springs or clearances or the cam was not degreed in correctly, or bad valve train geometry, valve float issues, electrical, components or ignition system issues once the TRUE cause was located and corrected

"A co-worker has a Jackson setup on his 383; the whine is very subdued--just enough to let you know it's there"

and if you get the quiet version, check the clearances carefully, and use a molly assembly lube during the assembly, process, youll find that after a few thousand miles the sound levels dropped off too almost un-noticeable, in fact unless its spinning up about 6000 rpm its almost not detectable

http://store.summitracing.com/partdetail.asp?part=CLO-9-3100&autoview=sku

http://store.summitracing.com/partdetail.asp?part=PJJ-327-1C&autoview=sku

http://www.jonkaaseracingengines.com/pr ... rives.html

BUT Id say 90% of the time installing a CLOYES TRUE ROLLER set is the fastest and cheapest route and best value

http://store.summitracing.com/partdetail.asp?part=CLO-9-3100&autoview=sku

and Ive had zero problems,with properly installed 3 and 4 gear,gear drive cam timing sets. but that being said, Id keep in mind timing sets are expendable like gaskets and should be replaced, or at least carefully inspected for wear, when you do cam changes and ring jobs, or anytime your pulling down the engine if the chain timing sets had more than 25-30k on it, etc, I would almost never consider re-use of a timing chain after its had 30k or more on it, unless it shower near zero wear.

now don,t think I'm against the gear drives , because I'm still running a quiet gear drive in my current 383, but Id have zero problem running a cloyes true roller chain drive, and if your not willing to carefully clearance a gear drive a CLOYES chain drive is far easier to install and less likely to cause problems

http://store.summitracing.com/partdetail.asp?part=PJJ-350-91C&autoview=sku

http://www.summersbrothersracing.com/ca ... drives.htm

http://www.milodon.com/gear-drives/gear ... -chrys.asp

but unless your very good at tuning the gear drives , and realize the knock sensor can be a problem with gear drives, but they do have slightly more stable ignition timing,that slightly more stable ignition timing doesn,t offer much if any advantage, below about 6000rpm in most cases and its very small, advantage at best while the chain drive tends to be very dependable and almost trouble free.

but don,t fall for the MYTH that gear drives cause timing problems due to transmission of crank harmonics to the cam, if you have a balanced rotating assembly and a decent harmonic balancer and the correct clearances its not likely to be a measurable issue, with the 4 gear units simply because of the clearances and slack makes transmitting small vibration's thru several gears very in-efficient , but that was and is possible with the two gear reverse rotation cam drives but the three and 4 gear systems are designed with enough clearance its basically on non-issue, every time Ive looked into that myth, it turned out to be mis matched valve train components like running the wrong springs or clearances or the cam was not degreed in correctly, or bad valve train geometry, valve float issues, electrical, components or ignition system issues once the TRUE cause was located and corrected

"A co-worker has a Jackson setup on his 383; the whine is very subdued--just enough to let you know it's there"

and if you get the quiet version, check the clearances carefully, and use a molly assembly lube during the assembly, process, youll find that after a few thousand miles the sound levels dropped off too almost un-noticeable, in fact unless its spinning up about 6000 rpm its almost not detectable

Last edited by a moderator: