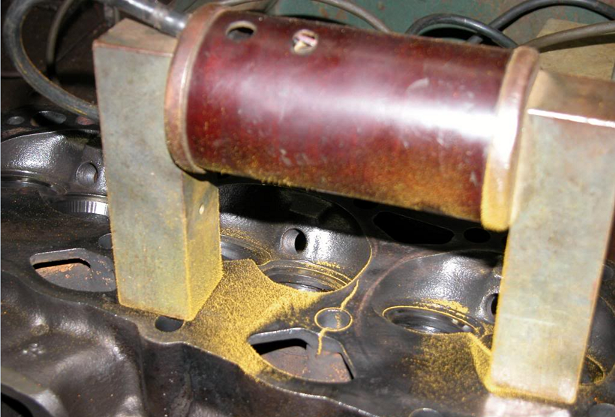

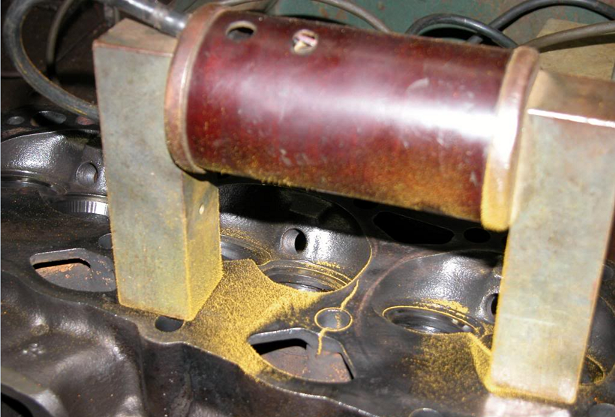

I finished grinding my block for 383 stroker assembly a couple of weeks ago. I found a tip to help cut down on metal dust particles. Take a magnet any type, and put it in a zip lock bag, then place the bag as close as you can to the area your grinding. I put mine in the direction of the flow from the grinder. When you get thru grinding remove the bag from area and then slip the magnet out, this will catch most of dust and leave you with a clean magnet afterwords.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

grinding block for stroker assembly

- Thread starter Dustytrix

- Start date

its always good to get little tips, like that!

no matter how careful you are you can, really never keep an engine clean enough to eliminate all the metallic trash, from the machine work out of an engine, so constant effort to limit or remove it is a constant process during the assembly.

and I can easily see where that could be a useful route to take under most conditions.

far to many engines get ruined because of metallic dust and trash, that the oil filter fails to trap, that gets into the bearings and rings, rockers etc.

Ive generally just used a pressure washer after grinding clearance, on the block, and cleaned the crank and the rods etc in the parts washer before final assembly, and then installed MAGNETS in the engine to trap crud that gets either missed during assembly or produced during the break-in, and painted the blocks internal surfaces to trap micro-crud and smooth the oil flow return surfaces

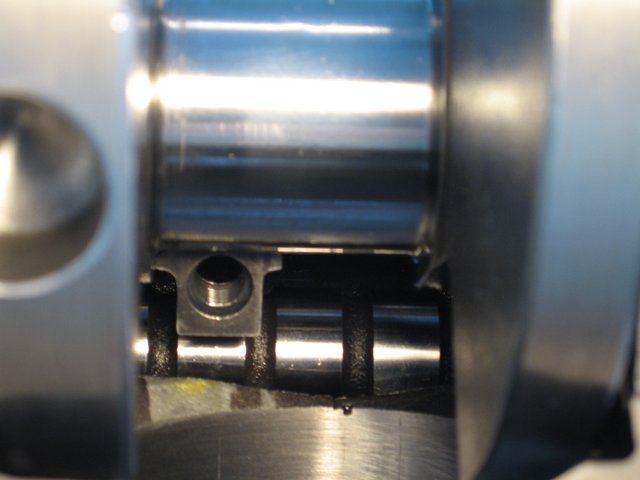

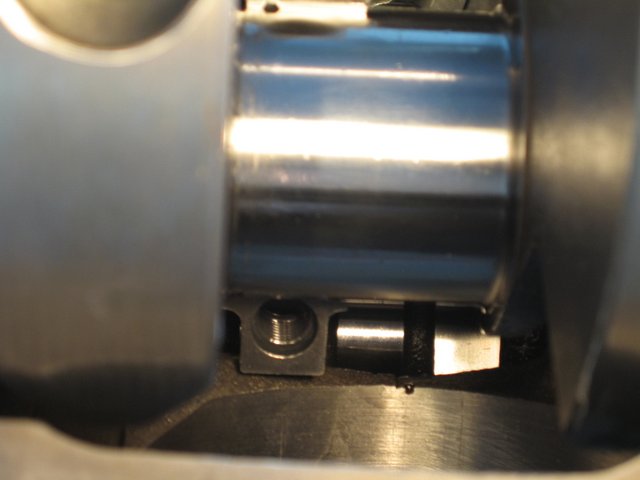

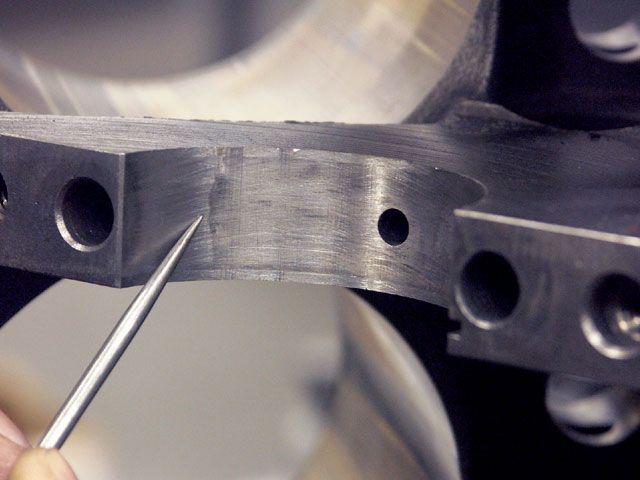

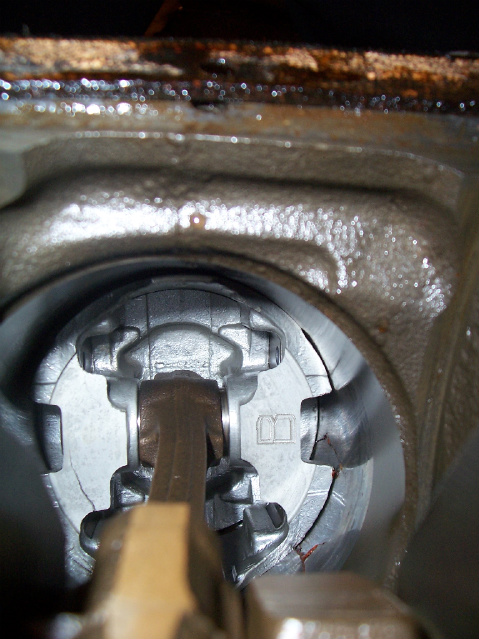

removing the rod caps during clearance checks while building your 383 ,does seem to allow you to see the clearance issues a bit easier

JUST BE AWARE A BLOCK MUST BE STORED CORRECTLY OR IT WILL RUST IN HOURS

a good spray with a quality de-greasing agent and a pressure cleaning would be my first step.

long ago I purchased a decent pressure cleaner as it makes getting the crud and grease off a block or transmission much less difficult

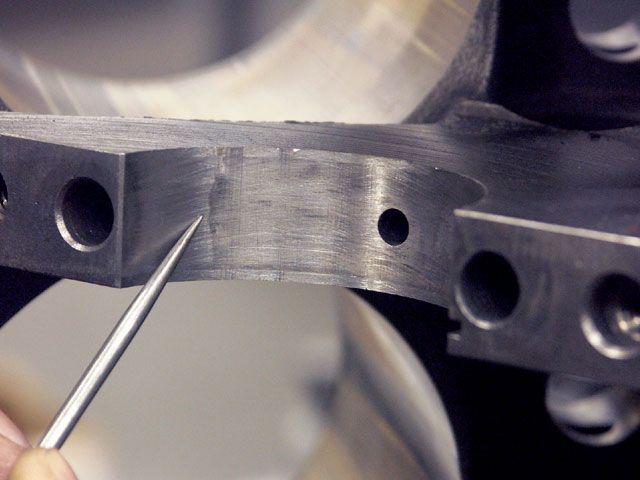

when blocks are cast the molten metal can shift locations in the casting mold slightly, the machinery that machines the block is all indexed off

specific locations as its held in place, this results in some variation in the resulting casting thickness if the core mass has shifted marginally , thus most machine shops vastly prefer to work with ,

castings that maximize all casting metal thickness, in all directions from machined surfaces.

http://www.project33.com/Categoryarticle.cfm?ID=13&Category=Engine

core shift results in one side of the cylinder bore walls tending to be noticeably thinner than ideal, this results in un-equal stress and more failures

http://www.lowes.com/pd_600025-24212-65 ... Heavy-duty

a high pressure air nozzle ,with a extended tip,

that allows you to get into and remove solvent and dry the surfaces in the the small recessed areas is a great idea

cleaning all the thread holes with the correct size tap is a very good idea

related threads

http://garage.grumpysperformance.co...oving-gaskets-the-wrong-way.10464/#post-43842

http://garage.grumpysperformance.co...needed-for-383-sbc-assembly.16041/#post-96746

READ THIS LINK AND ITS SUB LINKED INFO

http://garage.grumpysperformance.com/index.php?threads/parts-prep-cleaning.6255/#post-62107

http://garage.grumpysperformance.com/index.php?threads/carb-cleaning.12303/#post-60502

http://garage.grumpysperformance.com/index.php?threads/tap-and-die-sets.1264/#post-6141

http://garage.grumpysperformance.com/index.php?threads/bio-friendly-parts-cleaner.11547/#post-53360

http://garage.grumpysperformance.com/index.php?threads/block-prep.125/page-2#post-48605

http://garage.grumpysperformance.com/index.php?threads/thread-chaser-for-new-block.3774/#post-10002

viewtopic.php?f=54&t=120&p=150&hilit=+MAGNETS#p150

viewtopic.php?f=51&t=125

viewtopic.php?f=50&t=614

no matter how careful you are you can, really never keep an engine clean enough to eliminate all the metallic trash, from the machine work out of an engine, so constant effort to limit or remove it is a constant process during the assembly.

and I can easily see where that could be a useful route to take under most conditions.

far to many engines get ruined because of metallic dust and trash, that the oil filter fails to trap, that gets into the bearings and rings, rockers etc.

Ive generally just used a pressure washer after grinding clearance, on the block, and cleaned the crank and the rods etc in the parts washer before final assembly, and then installed MAGNETS in the engine to trap crud that gets either missed during assembly or produced during the break-in, and painted the blocks internal surfaces to trap micro-crud and smooth the oil flow return surfaces

removing the rod caps during clearance checks while building your 383 ,does seem to allow you to see the clearance issues a bit easier

383, do you clearance the 350 block, machine the crank, or both?

I hate to start a new thread when it seems that grumpy has exhaustively covered EVERYTHING when it comes to blocks and engine buildings already on this site, but this is sort of a specific question: I have been following a step by step on prepping my block to become a 383 build, and I am...

garage.grumpysperformance.com

JUST BE AWARE A BLOCK MUST BE STORED CORRECTLY OR IT WILL RUST IN HOURS

a good spray with a quality de-greasing agent and a pressure cleaning would be my first step.

long ago I purchased a decent pressure cleaner as it makes getting the crud and grease off a block or transmission much less difficult

when blocks are cast the molten metal can shift locations in the casting mold slightly, the machinery that machines the block is all indexed off

specific locations as its held in place, this results in some variation in the resulting casting thickness if the core mass has shifted marginally , thus most machine shops vastly prefer to work with ,

castings that maximize all casting metal thickness, in all directions from machined surfaces.

http://www.project33.com/Categoryarticle.cfm?ID=13&Category=Engine

core shift results in one side of the cylinder bore walls tending to be noticeably thinner than ideal, this results in un-equal stress and more failures

http://www.lowes.com/pd_600025-24212-65 ... Heavy-duty

a high pressure air nozzle ,with a extended tip,

that allows you to get into and remove solvent and dry the surfaces in the the small recessed areas is a great idea

cleaning all the thread holes with the correct size tap is a very good idea

related threads

http://garage.grumpysperformance.co...oving-gaskets-the-wrong-way.10464/#post-43842

http://garage.grumpysperformance.co...needed-for-383-sbc-assembly.16041/#post-96746

READ THIS LINK AND ITS SUB LINKED INFO

IT durability thats KEY in building a good engine

when ever I get into a discussion with many of the guys I build engines for, the younger guys especially seem to be captivated or primarily focused on the concept of having " a RADICAL CAM, that rumbles at idle, or the new brand X heads that some magazine is pushing in the latest engine build...

garage.grumpysperformance.com

http://garage.grumpysperformance.com/index.php?threads/parts-prep-cleaning.6255/#post-62107

http://garage.grumpysperformance.com/index.php?threads/carb-cleaning.12303/#post-60502

http://garage.grumpysperformance.com/index.php?threads/tap-and-die-sets.1264/#post-6141

http://garage.grumpysperformance.com/index.php?threads/bio-friendly-parts-cleaner.11547/#post-53360

http://garage.grumpysperformance.com/index.php?threads/block-prep.125/page-2#post-48605

http://garage.grumpysperformance.com/index.php?threads/thread-chaser-for-new-block.3774/#post-10002

viewtopic.php?f=54&t=120&p=150&hilit=+MAGNETS#p150

viewtopic.php?f=51&t=125

viewtopic.php?f=50&t=614

Last edited by a moderator:

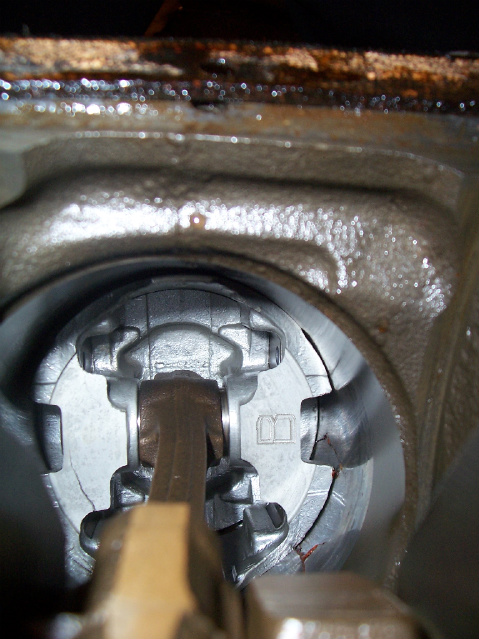

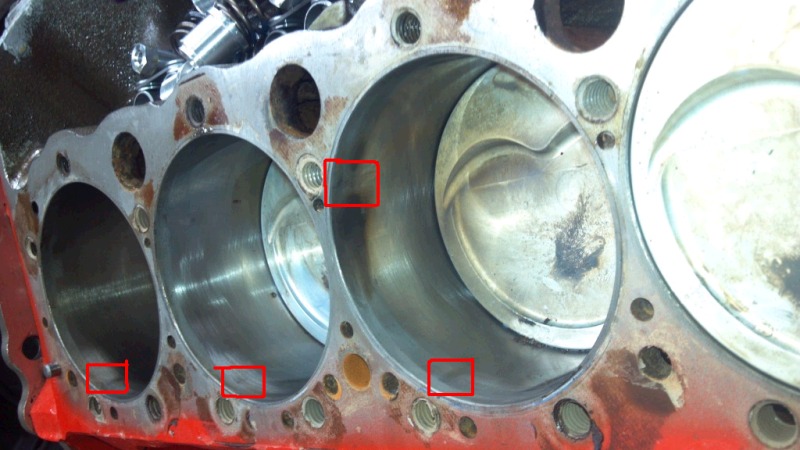

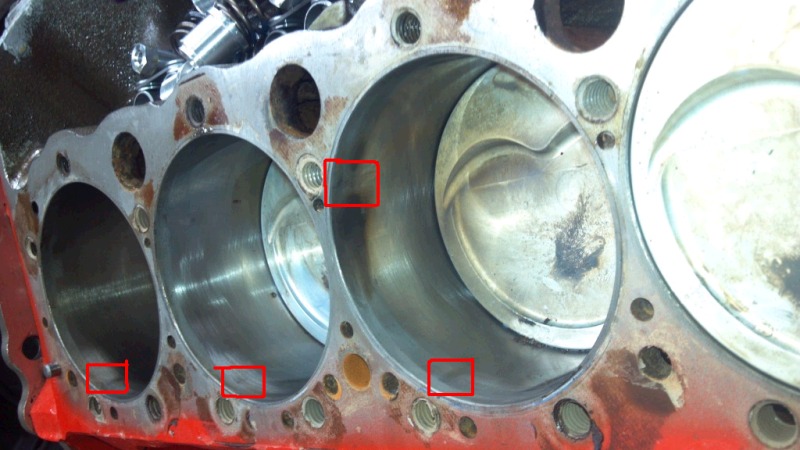

Would like an opinion on whether it is possible to repair a SBC cast iron block ground for stroker.

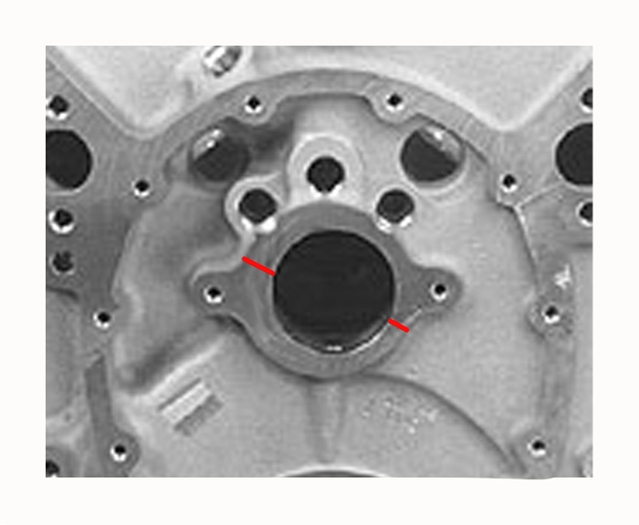

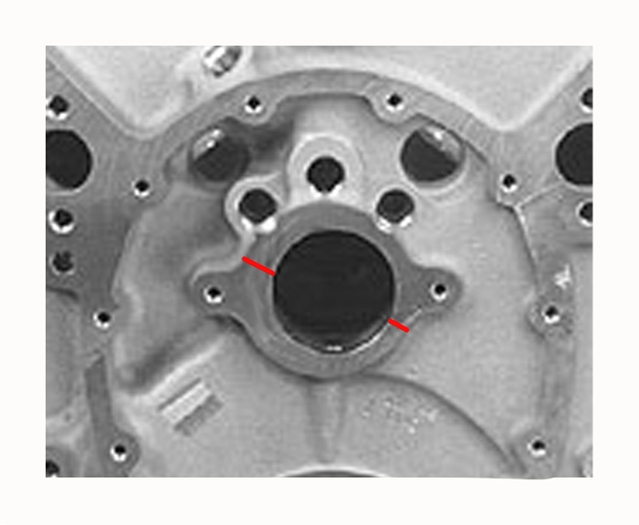

The area under the cylinder wall corner that is clearanced for rods is cut through into the water jacket area.

Would a short fill with non porous filler such as Rokblock work?

Or possibly brazing over the thin spots?

The block has full machine and prep work done; steel caps, line hone, deck, plate bore and hone, etc. The thin areas was discovered during initial mock up.

Engine will be used in a street rod with pressurized cooling system.

Appreciate any advice / suggestions.

The area under the cylinder wall corner that is clearanced for rods is cut through into the water jacket area.

Would a short fill with non porous filler such as Rokblock work?

Or possibly brazing over the thin spots?

The block has full machine and prep work done; steel caps, line hone, deck, plate bore and hone, etc. The thin areas was discovered during initial mock up.

Engine will be used in a street rod with pressurized cooling system.

Appreciate any advice / suggestions.

Maniacmechanic1

solid fixture here in the forum

I like full water jackets in the block on the Street.

A special Race only Epoxy may work.

One is made by Moroso.

Another by Dupont Chemicals.

A special Race only Epoxy may work.

One is made by Moroso.

Another by Dupont Chemicals.

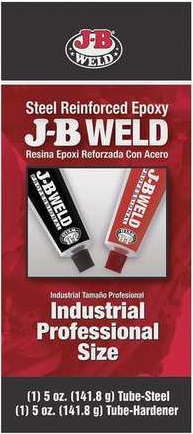

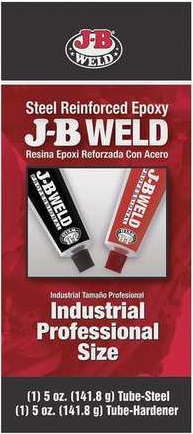

If your getting a little too enthusiastic in rod to block clearance and get a pin hole in the coolant passages, Id use a 1/2 cup of J&B epoxy weld (basically both full tubes mixed and poured into the coolant passage )

poured into the blocks previously carefully steam cleaned and heat gun dried coolant passage area

Ive seen it done several times in the last couple years without issues

https://www.amazon.com/Claytoon-Set...d=1466872286&sr=8-17&keywords=plastilina+clay

https://www.amazon.com/Claytoon-Set...d=1466872286&sr=8-17&keywords=plastilina+clay

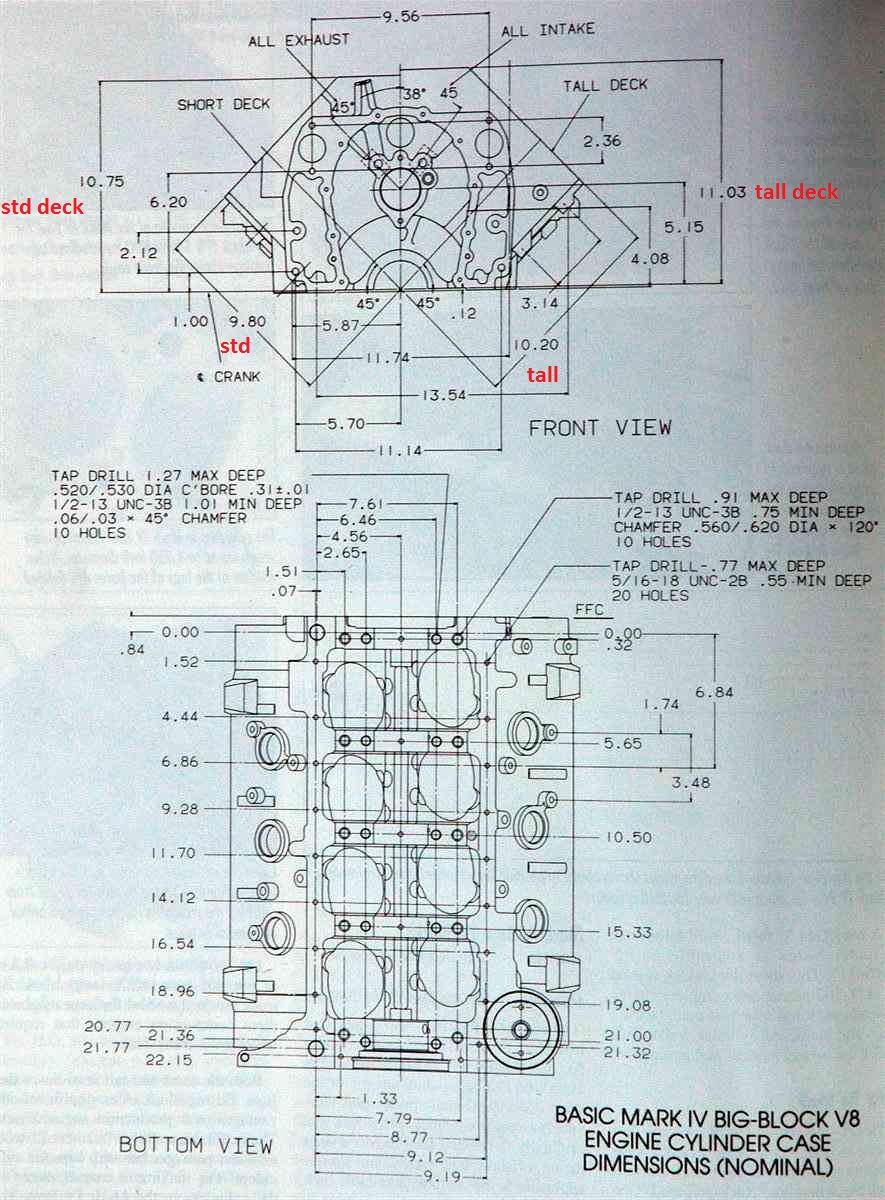

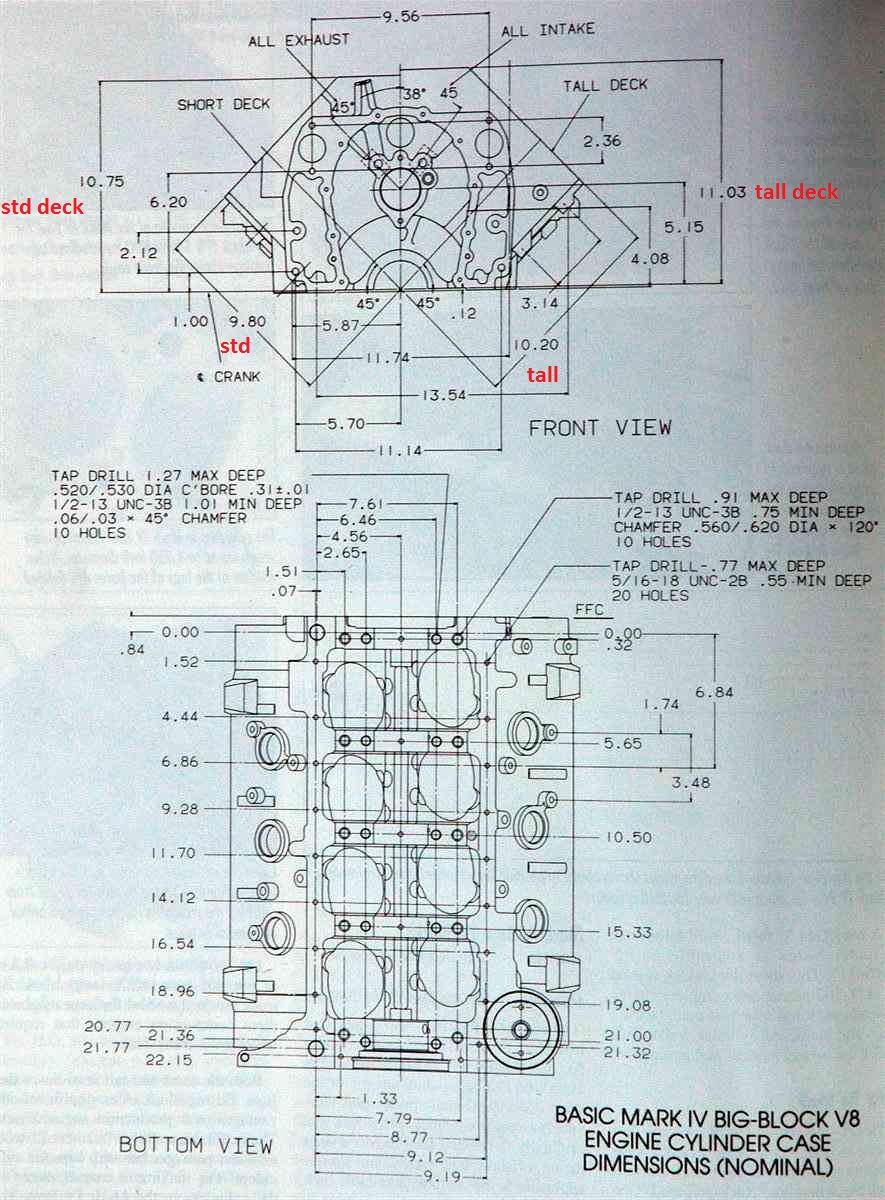

the tall deck block requires a longer reach distributor shaft thats about 0.28 longer thus the need for the adjustable collar on the distributor adding the extra reach to get the oil pump drive and drive gears to properly align and mesh.

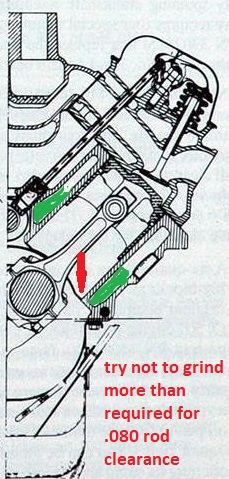

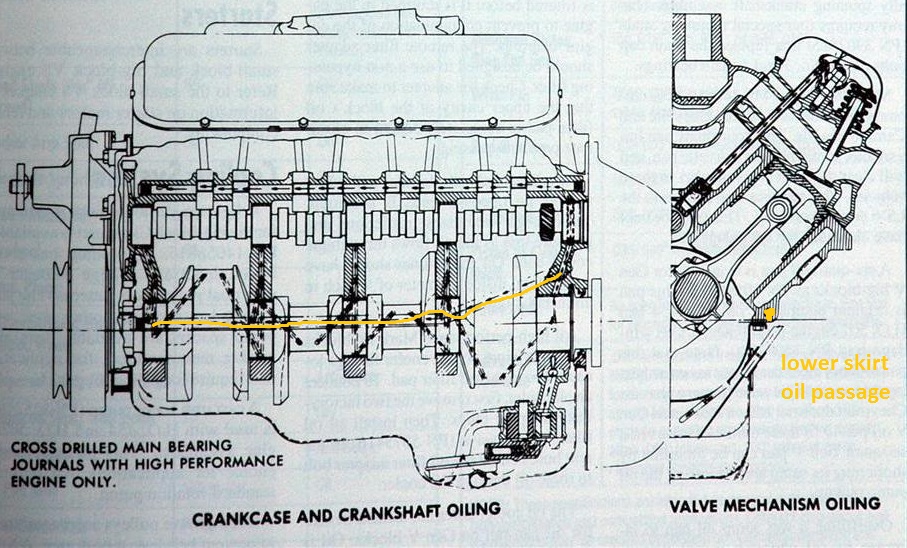

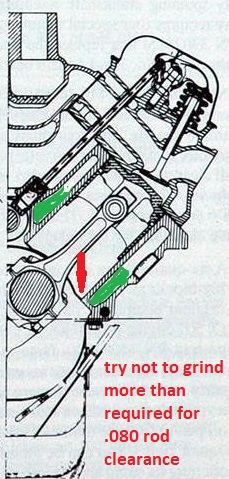

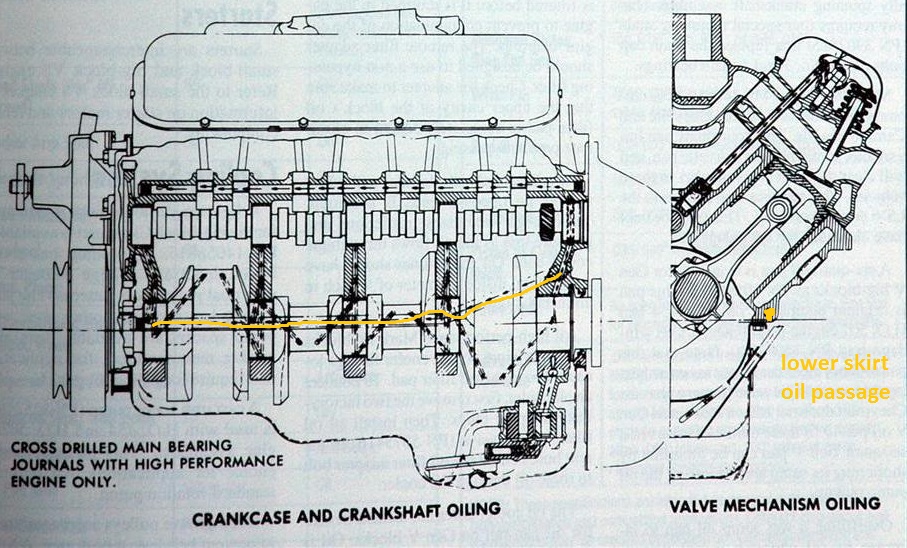

be aware theres an oil supply passage in the lower block skirt, and coolant passages that extend quite low on the mark IV blocks so you can't just grind excessive rod clearance, for crank counter weights and large, longer stroke , stroker type crank's to the same extent you can get away with on the later MARK V and VI blocks, or the far better choice of a DART aftermarket block, so you'll need to be careful,doing clearance grinding,I would advise limiting stroke lengths to a 4.375" max, even in the tall deck truck MARK IV blocks, the later Mark V and VI blocks have that passage up near the cam tunnel

if the grove youve cut for stroker rod clearance in the lower bore skirt is in error so large it starts to drip out coolant or if its cleaned and inspected you need to make repairs in that area the proper J&B epoxy will permanently seal the coolant passages, you can prevent epoxy from dripping out before it sets up and bonds with a temp plug with plastic clay, every decent machinist I know has a package to measure some clearance like oil pump pick-up to oil pan floor and valve too piston clearances.

WEARING A FULL FACE SHIELD and having a 5-6hp shop vacuum set up to suck the vast majority of the debris from the porting work out of the air is going to help prevent some accidents and getting crap in your eyes,

THIS vacuum, is THE ONE I PURCHASED AND I RECOMMEND IT,

remember to change filter elements frequently and a couple quarts of water and a couple drops of dawn dish washing liquid in the water traps a great deal of dust in the lower body before it gets to the filter, place a 2" pvc pipe extension too the opposite end of the cylinder head port or as close as you can to the area your grinding, that your working on with the burrs and die grinder, and duct tape it in place, the vacuum will control and limit much of the machine debris

http://www.homedepot.com/p/RIDGID-16-Ga ... 5yc1vZbv79

there are some good die grinders on the market, but these less expensive import versions, are a BARGAIN even if they only last for a few weeks or months,under constant use they do wear out in a few weeks or months (especially if you fail to used dry air and don,t bother to lube the tool.) because wet air and moisture tends to cause internal rust/corrosion over time. OBVIOUSLY dependent on the amount of use and abuse, I use mine almost constantly for cleaning and porting, de-burring etc.

but at under $20, I tend to look at them like sand paper,or spark plugs, its hardly worth bothering if it lasts a few weeks or months before the bushings start to wear noticeably

http://garage.grumpysperformance.co...ing-cast-iron-can-make-a-preacher-cuss.12647/

clean any block you buy and look for obvious cracks and if you have doubts get the machine shop to mag or dye test the block or heads

lifter bores

and lifter gallery

,piston bore walls,

block main cap web support areas

heads between the valves in valve seat area

look for stripped head and manifold and oil pan mounting bolt threads,

in threaded holes and cracks in block radiating from the holes

ASK LOTS TO QUESTIONS & SHOP CAREFULLY,

poured into the blocks previously carefully steam cleaned and heat gun dried coolant passage area

Ive seen it done several times in the last couple years without issues

383, do you clearance the 350 block, machine the crank, or both?

I hate to start a new thread when it seems that grumpy has exhaustively covered EVERYTHING when it comes to blocks and engine buildings already on this site, but this is sort of a specific question: I have been following a step by step on prepping my block to become a 383 build, and I am...

garage.grumpysperformance.com

the tall deck block requires a longer reach distributor shaft thats about 0.28 longer thus the need for the adjustable collar on the distributor adding the extra reach to get the oil pump drive and drive gears to properly align and mesh.

be aware theres an oil supply passage in the lower block skirt, and coolant passages that extend quite low on the mark IV blocks so you can't just grind excessive rod clearance, for crank counter weights and large, longer stroke , stroker type crank's to the same extent you can get away with on the later MARK V and VI blocks, or the far better choice of a DART aftermarket block, so you'll need to be careful,doing clearance grinding,I would advise limiting stroke lengths to a 4.375" max, even in the tall deck truck MARK IV blocks, the later Mark V and VI blocks have that passage up near the cam tunnel

if the grove youve cut for stroker rod clearance in the lower bore skirt is in error so large it starts to drip out coolant or if its cleaned and inspected you need to make repairs in that area the proper J&B epoxy will permanently seal the coolant passages, you can prevent epoxy from dripping out before it sets up and bonds with a temp plug with plastic clay, every decent machinist I know has a package to measure some clearance like oil pump pick-up to oil pan floor and valve too piston clearances.

WEARING A FULL FACE SHIELD and having a 5-6hp shop vacuum set up to suck the vast majority of the debris from the porting work out of the air is going to help prevent some accidents and getting crap in your eyes,

THIS vacuum, is THE ONE I PURCHASED AND I RECOMMEND IT,

remember to change filter elements frequently and a couple quarts of water and a couple drops of dawn dish washing liquid in the water traps a great deal of dust in the lower body before it gets to the filter, place a 2" pvc pipe extension too the opposite end of the cylinder head port or as close as you can to the area your grinding, that your working on with the burrs and die grinder, and duct tape it in place, the vacuum will control and limit much of the machine debris

http://www.homedepot.com/p/RIDGID-16-Ga ... 5yc1vZbv79

there are some good die grinders on the market, but these less expensive import versions, are a BARGAIN even if they only last for a few weeks or months,under constant use they do wear out in a few weeks or months (especially if you fail to used dry air and don,t bother to lube the tool.) because wet air and moisture tends to cause internal rust/corrosion over time. OBVIOUSLY dependent on the amount of use and abuse, I use mine almost constantly for cleaning and porting, de-burring etc.

but at under $20, I tend to look at them like sand paper,or spark plugs, its hardly worth bothering if it lasts a few weeks or months before the bushings start to wear noticeably

http://garage.grumpysperformance.co...ing-cast-iron-can-make-a-preacher-cuss.12647/

clean any block you buy and look for obvious cracks and if you have doubts get the machine shop to mag or dye test the block or heads

lifter bores

and lifter gallery

,piston bore walls,

block main cap web support areas

heads between the valves in valve seat area

look for stripped head and manifold and oil pan mounting bolt threads,

in threaded holes and cracks in block radiating from the holes

ASK LOTS TO QUESTIONS & SHOP CAREFULLY,

Last edited: