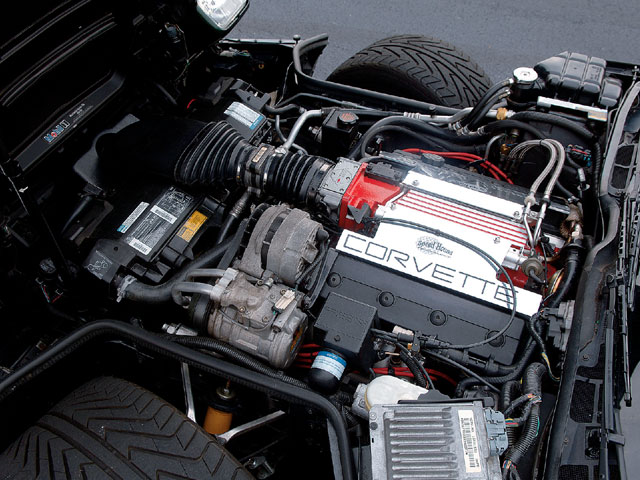

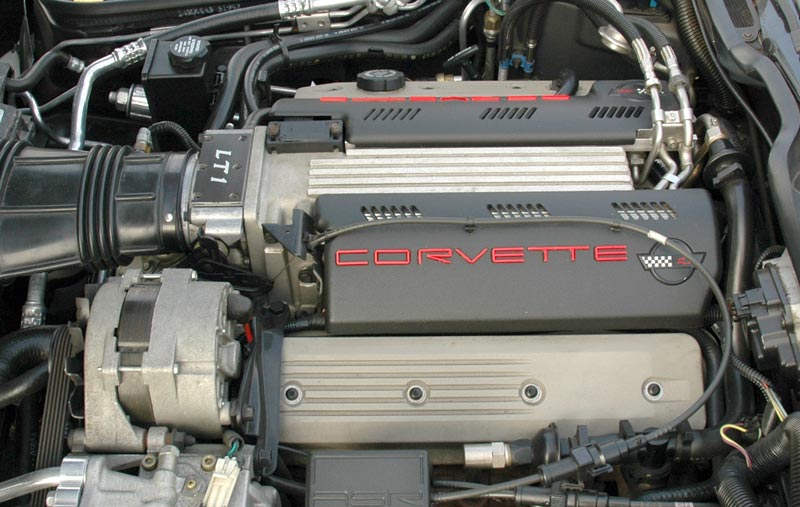

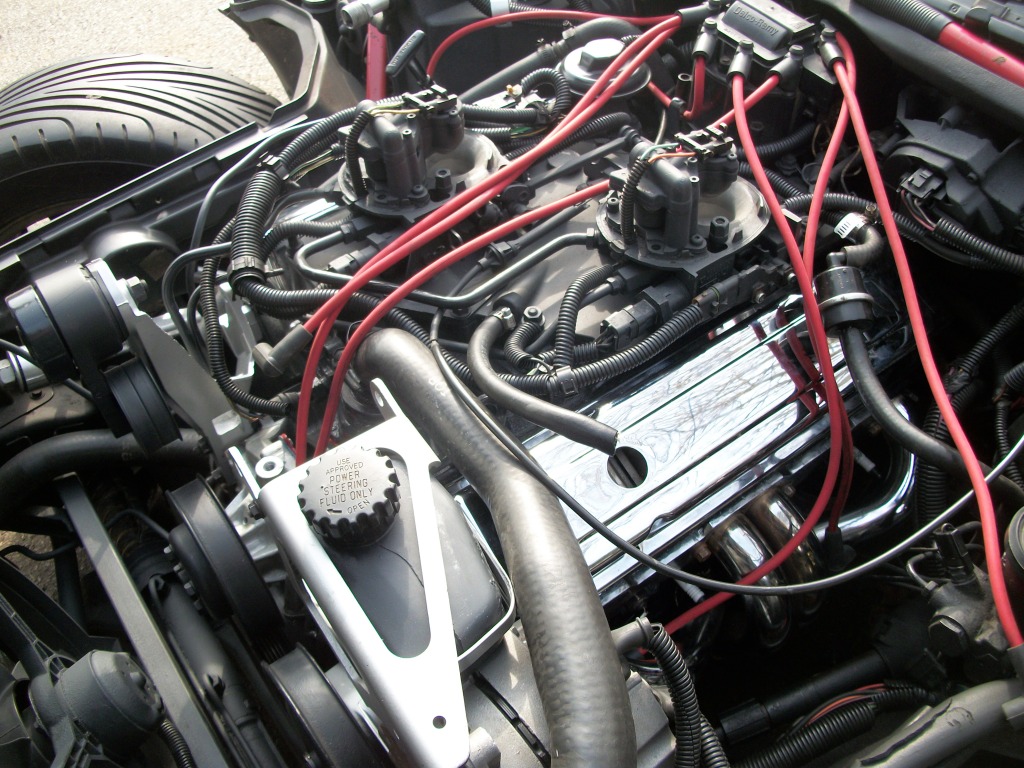

one of the more frequent complaints I hear about is c-4 corvettes that have difficulty or intermittent start problems.

or occasionally I hear about intermittent missing, that needs to be isolated and tracked down to be corrected.

READ THE THREAD THRU TO THE END

AND BE AWARE THAT THIS THREAD,

AND ALL OTHER THREADS ON THIS SITE ARE CONSTANTLY UPDATED WITH NEW LINKS AND INFO, AS IT BECOMES AVAILABLE

it is always helps to post your location,when posting questions, at least the city & state your located in because theres a good chance an experienced hobbyist or mechanic on this site may be reading this, located local to you, who is willing to help either for free or at low cost! or at least post advices and places to get parts locally

theres a great many links posted below that contain a vast amount of related info

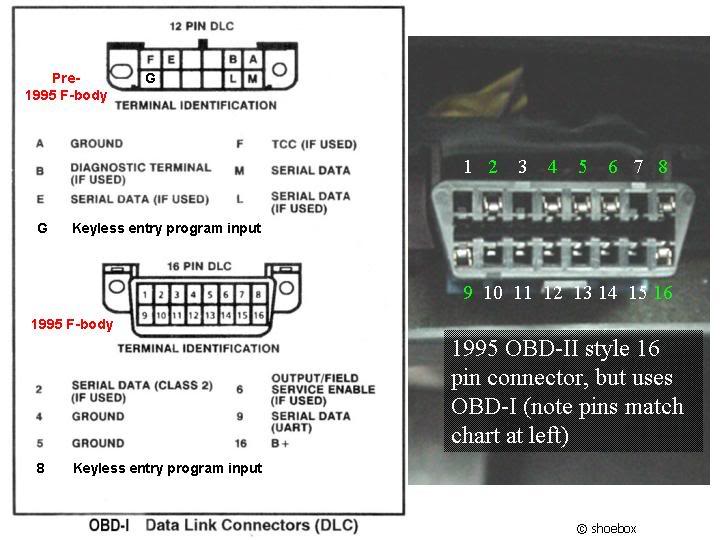

STEP ONE PULL TROUBLE CODES, MANY TIMES THE CODES POINT YOU TO THE ISSUES

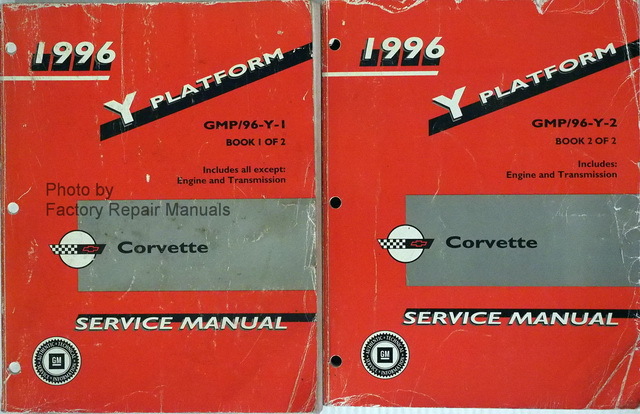

IF YOU OWN ANY CORVETTE YOU NEED TO OWN A FACTORY SHOP MANUAL  FOR THAT YEAR CORVETTE

FOR THAT YEAR CORVETTE

start by purchasing AND READING a SHOP MANUAL FOR YOUR SPECIFIC YEAR CORVETTE

http://www.helminc.com/helm

the correct matching SHOP MANUAL CAN BE VERY USEFUL

this is not a shop manual but it might be helpful

these are shop manuals

Id start by, pulling trouble codes and cleaning the battery terminals and cable connections carefully, a great many problems blamed on battery's and fuses are basically high resistance or intermittent connections, then use a multi meter to see what your dealing with.

(yes even if the engine spins over easily and has ignition spark, cleaning the battery terminals usually helps reliability)

yes IM fully aware that theres at least a few guys on the site that would rather roll around naked in broken glass, than read thru links and do in-depth research before, just jumping into a project and start randomly spend money on replacement parts :lol: :roll: :....but for those who gentlemen who would rather track down the cause of a problem with a few tests and a shop manual and logically approach the issues , in a step bye step manor theres plenty of posted info

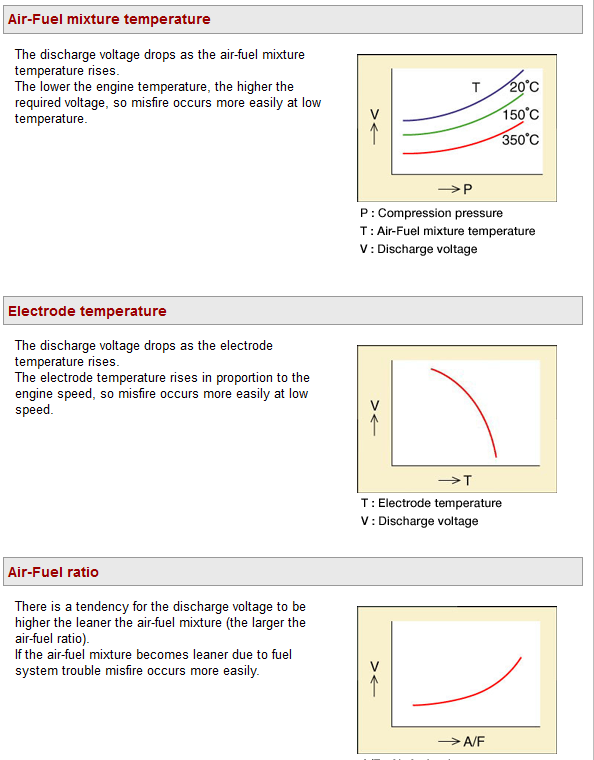

If your trying to isolate and test and get the engine tune correct, on any efi system,

Id suggest you leave the fuel pressure alone if its at least 40 psi and does not exceed about 58 psi,

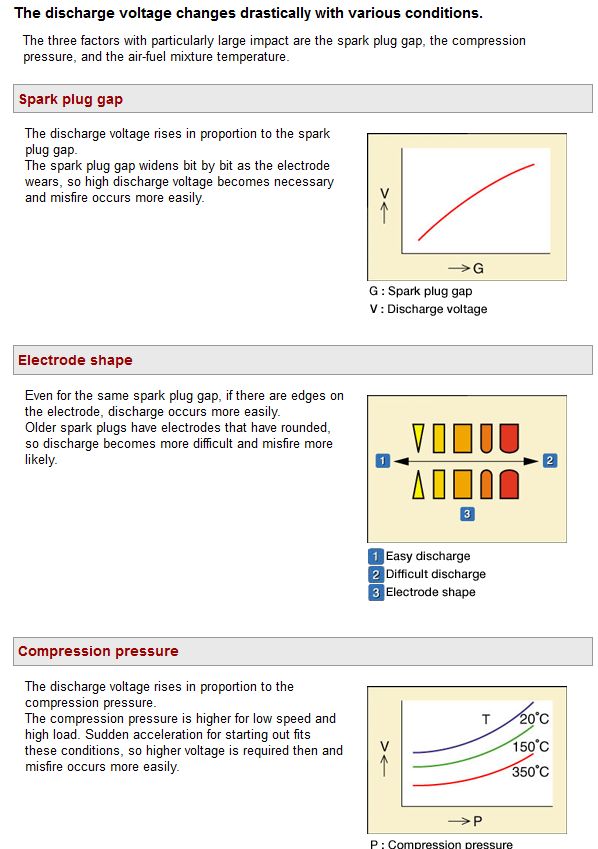

and if the fuel pressures consistent, and set the spark plug gap at .043-.045 max and keep th engine coolant temps as consistent and near about 180F-190F as you can get them,

the fewer variable your forced to deal with the better, make the changes in INJECTOR PULSE DURATION and ignition advance curves

to vary the fuel/air ratios and cylinder pressure

to avoid detonation and tuning issues

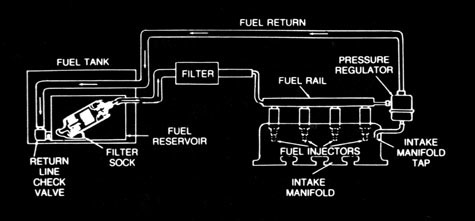

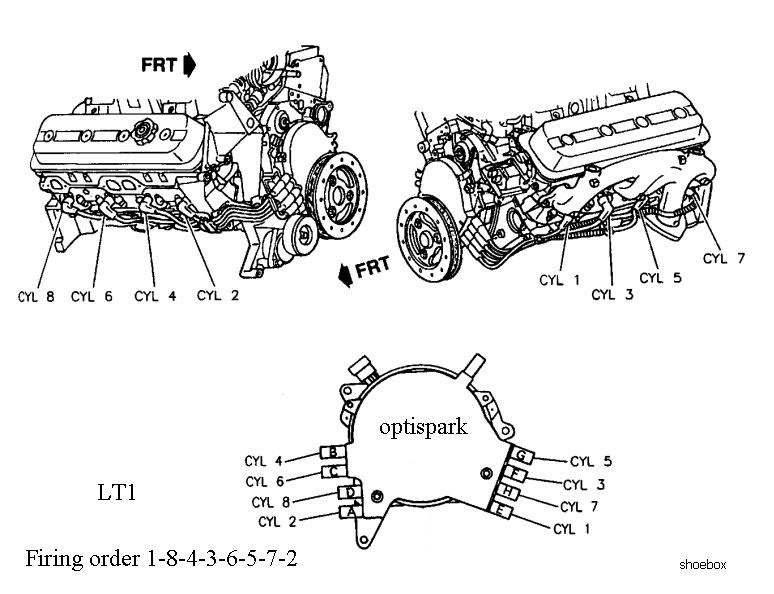

always start by verifying what your dealing with in temps fuel pressure and sensor function, pull trouble codes and read and tuning instructions, get a shop manual and verify sensor functions and electrical connections electrical grounds, ignition firing orders, do a compression test and verify the valve lash, set the valves if that's required, and make sure your not dealing with partially clogged catalytic converter carefully, verify what your dealing with, don,t guess, verify.

I can assure you that most problems are related to guessing or defective sensors, or assuming somethings working, that you fail to verify, like the ohms resistance in ignition wire or the firing order or verifying TDC, vs the damper/timing tabs

having a set of multi meter/timing light, compression gauge, vacuum and fuel pressure gauges and a shop manual is critical.

The secret of effective diagnosis and troubleshooting is to have a logical plan.

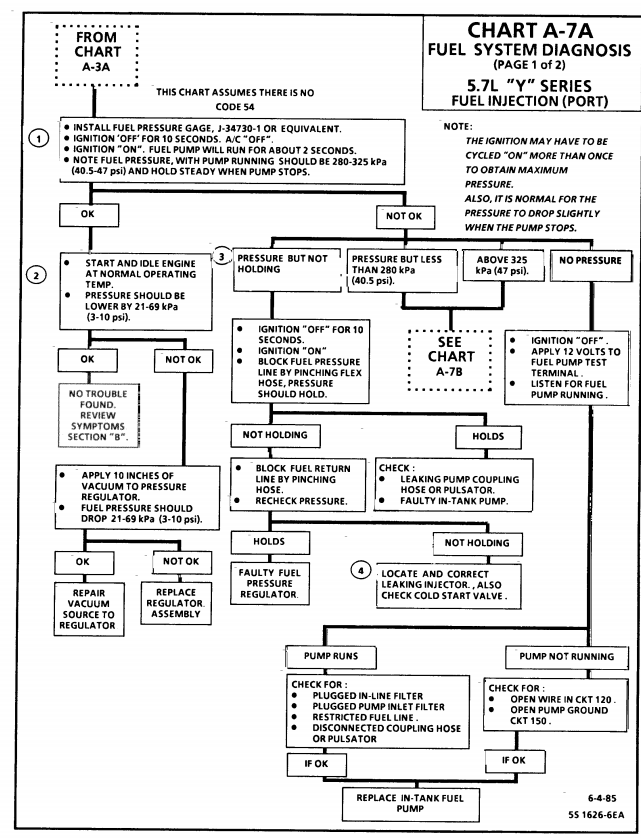

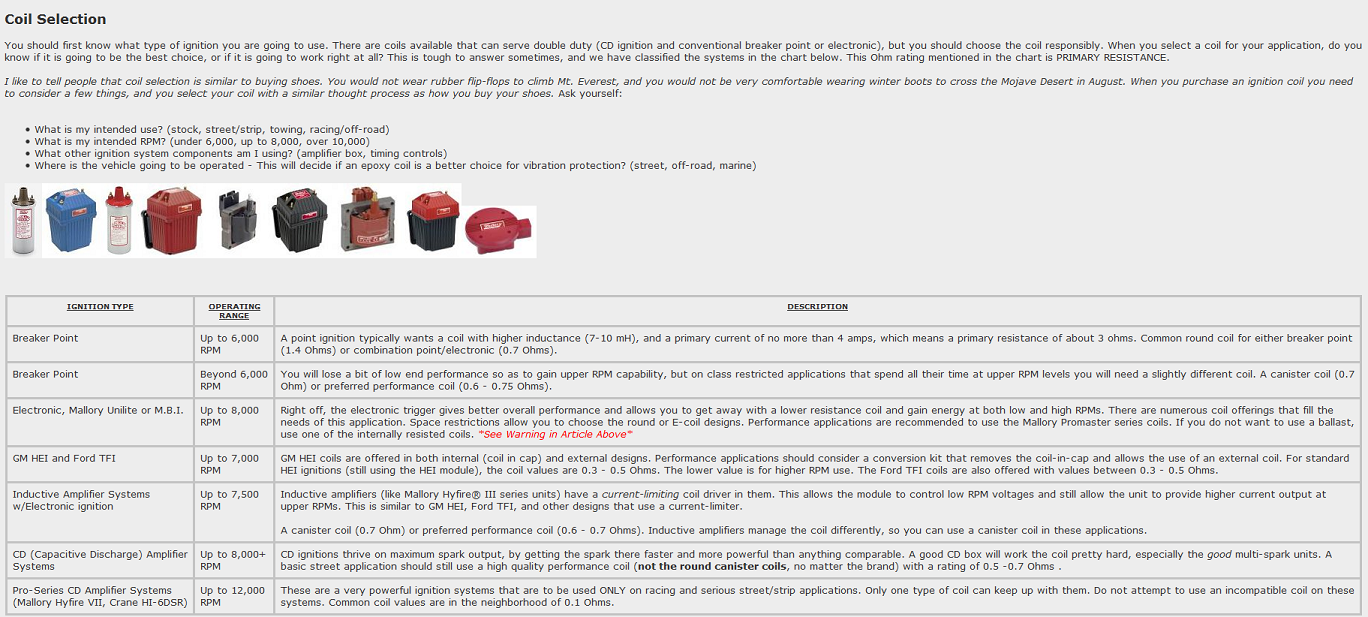

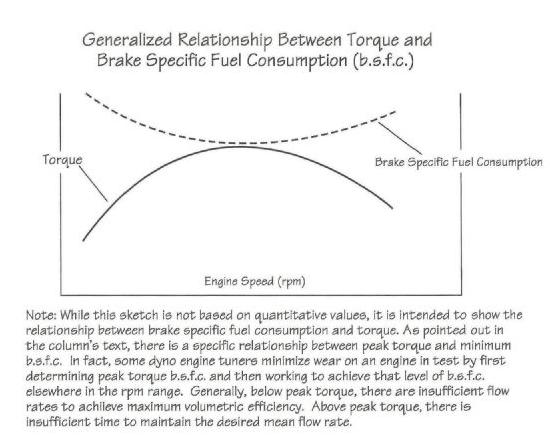

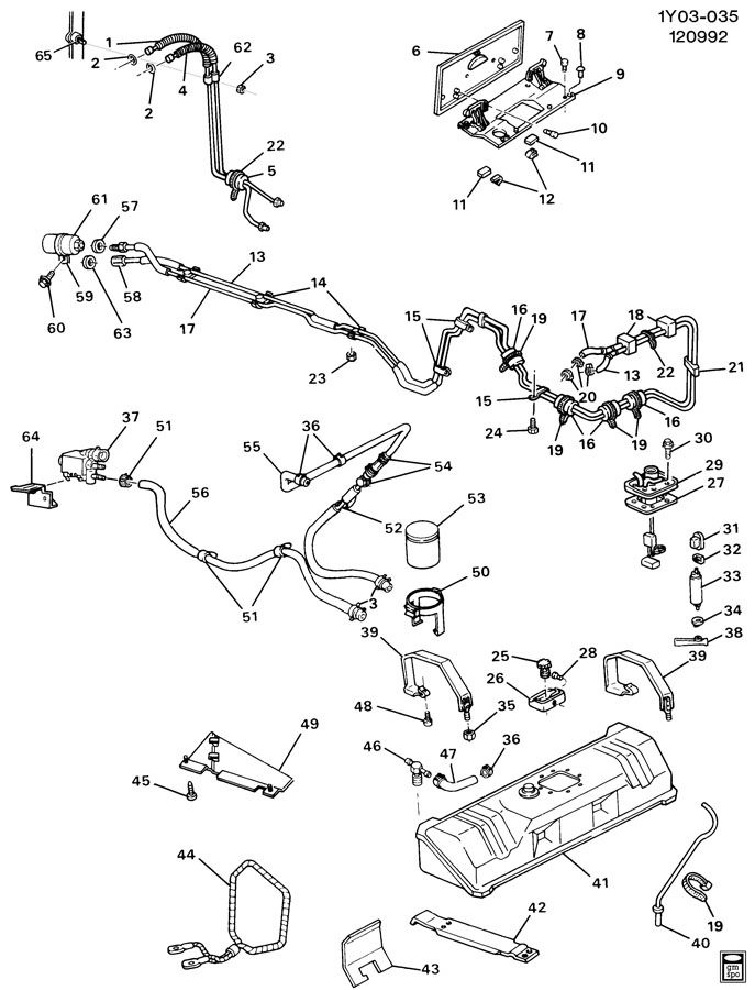

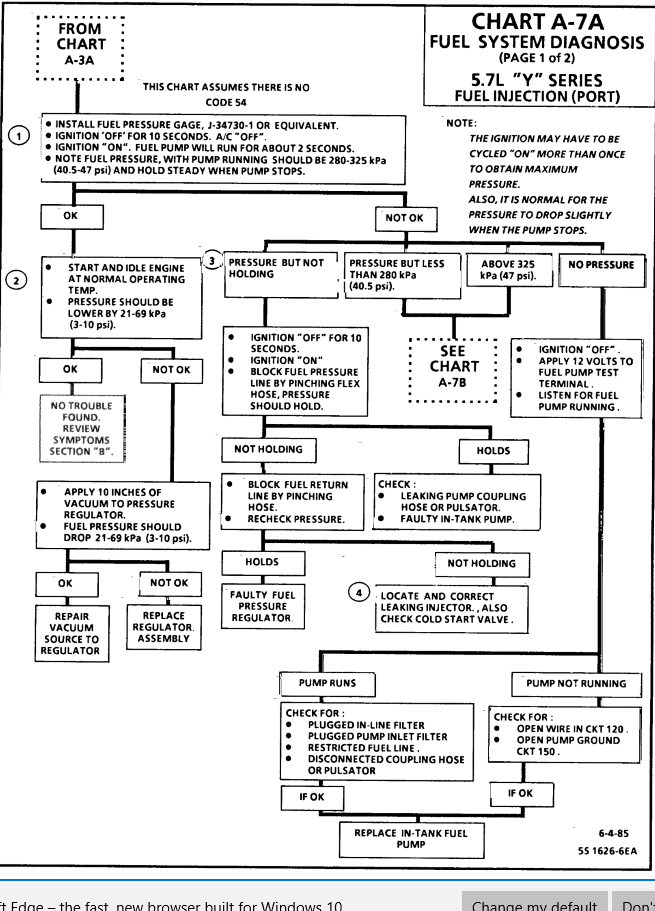

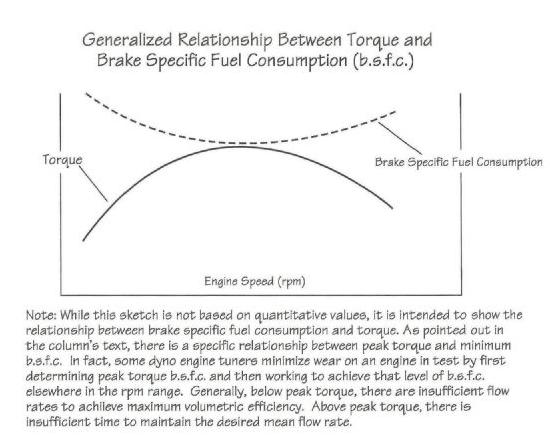

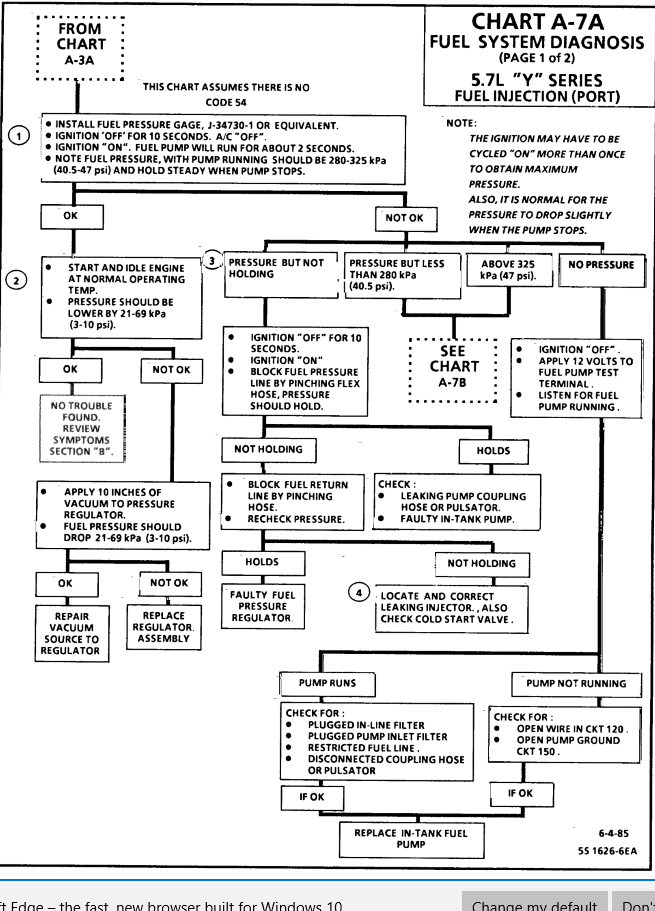

The secret of effective diagnosis and troubleshooting is to have a logical, well-ordered system. Following a logical step-by-step procedure will get you to the root cause of a problem quickly and efficiently. and you can,t go into the process assuming you know the answer before you test, let the facts you find lead you to the answers,you may waste a great deal of time chasing what you assume is a bad injector or a faulty ignition only to find its a clogged fuel filter, low fuel pressure or a loose electrical connection, Repair manuals will have a diagnostic tree that goes in a logical progression. It will ask a question, usually yes or no, and depending on the answer will branch off in two or more directions. The last box in the tree will have the problem and how to correct it. The example shown is a simple one. A more complicated system will have branches going into specific tests and then have 2 or more branches from there depending on test results.

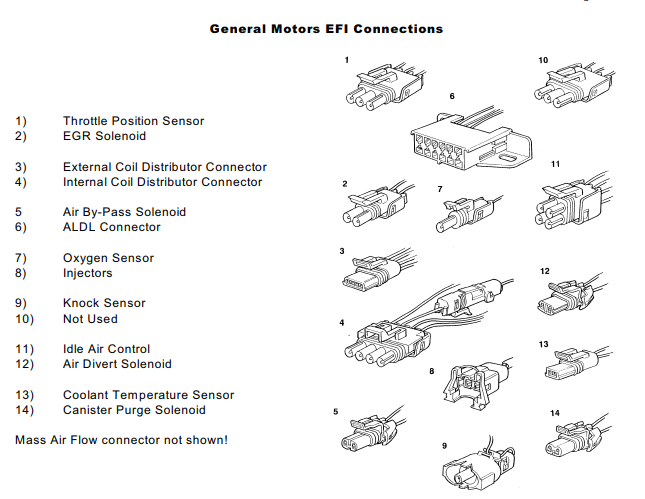

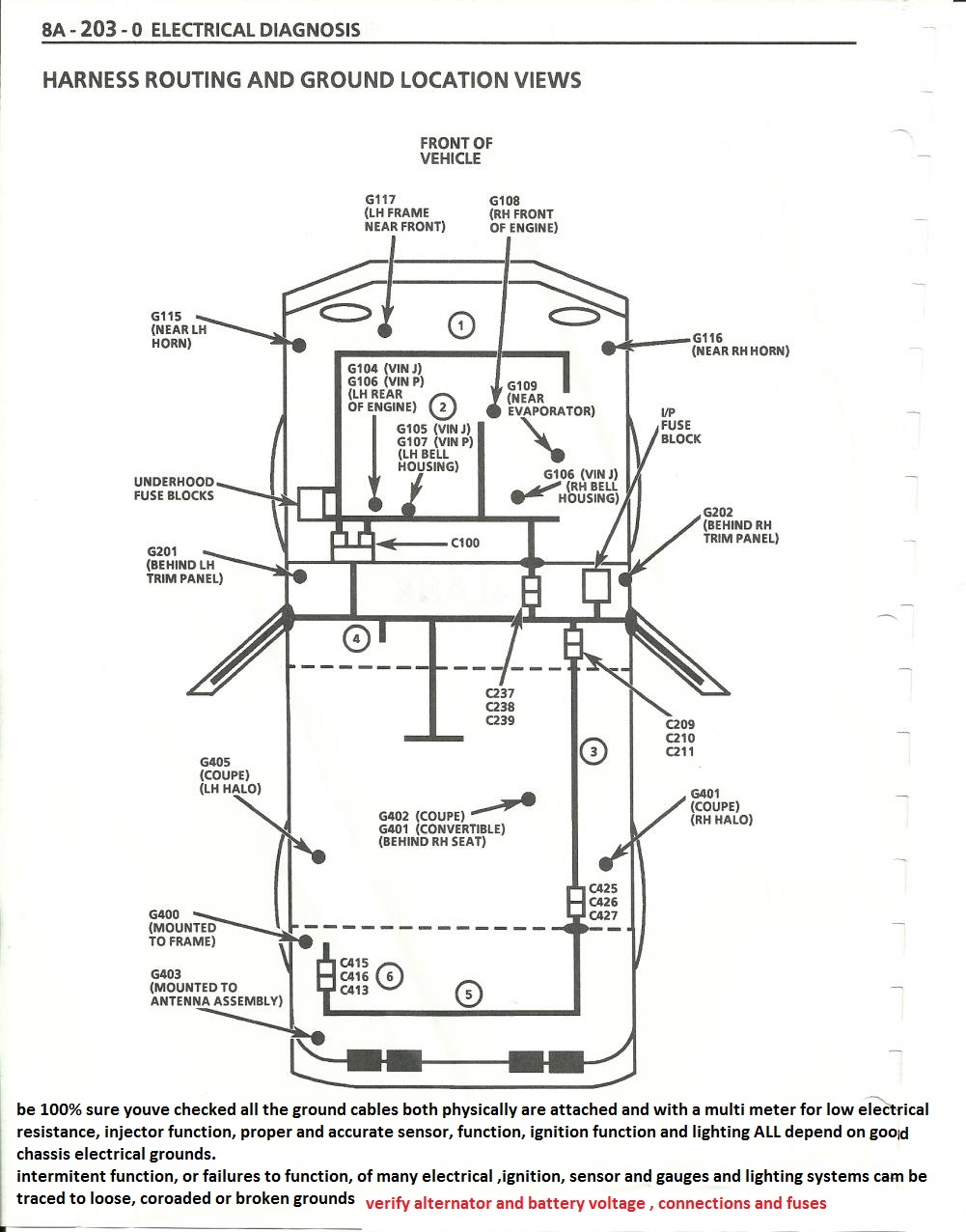

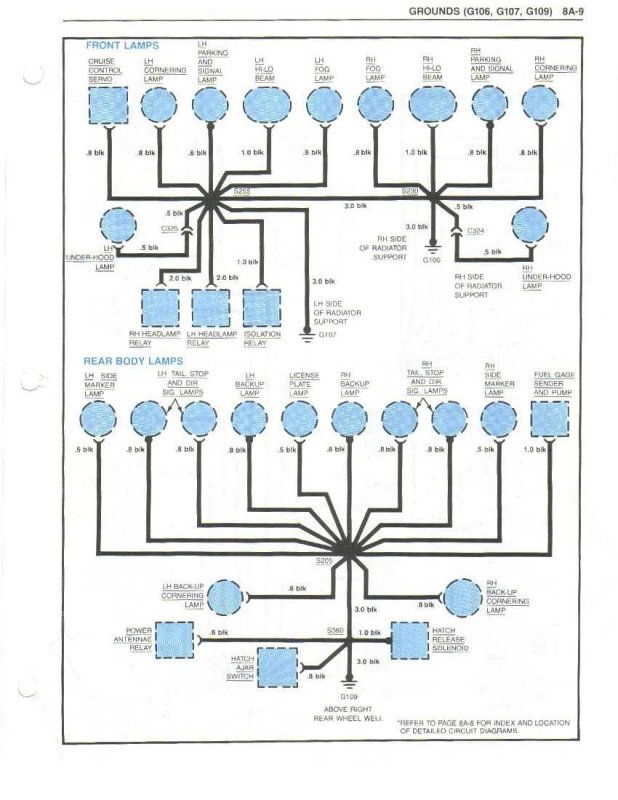

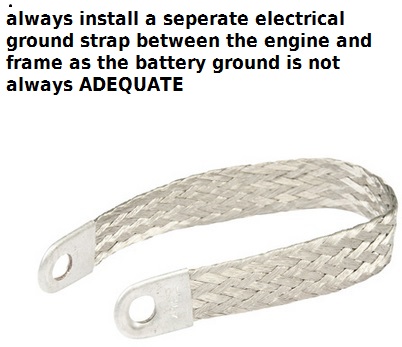

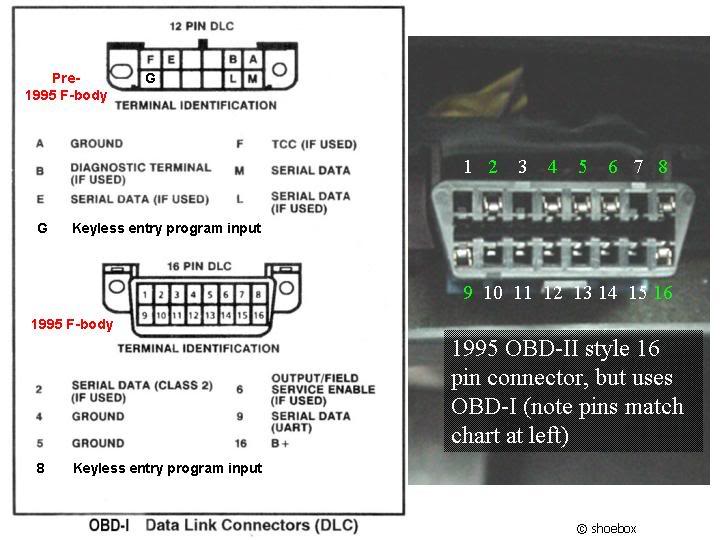

If your experiencing intermittent electrical issues you will obviously need to get out the shop manual for your year corvette, a multi meter and do some isolate and testing, but be aware that loose or corroded connections , will be hard to isolate, as they seldom present a consistent, solid open or dead short in the wire,theres several electrical connector plugs that connect thru the firewall near the battery location that are subject to corrosion issues and frame grounds that might be suspect, obviously theres sensors that can be defective.

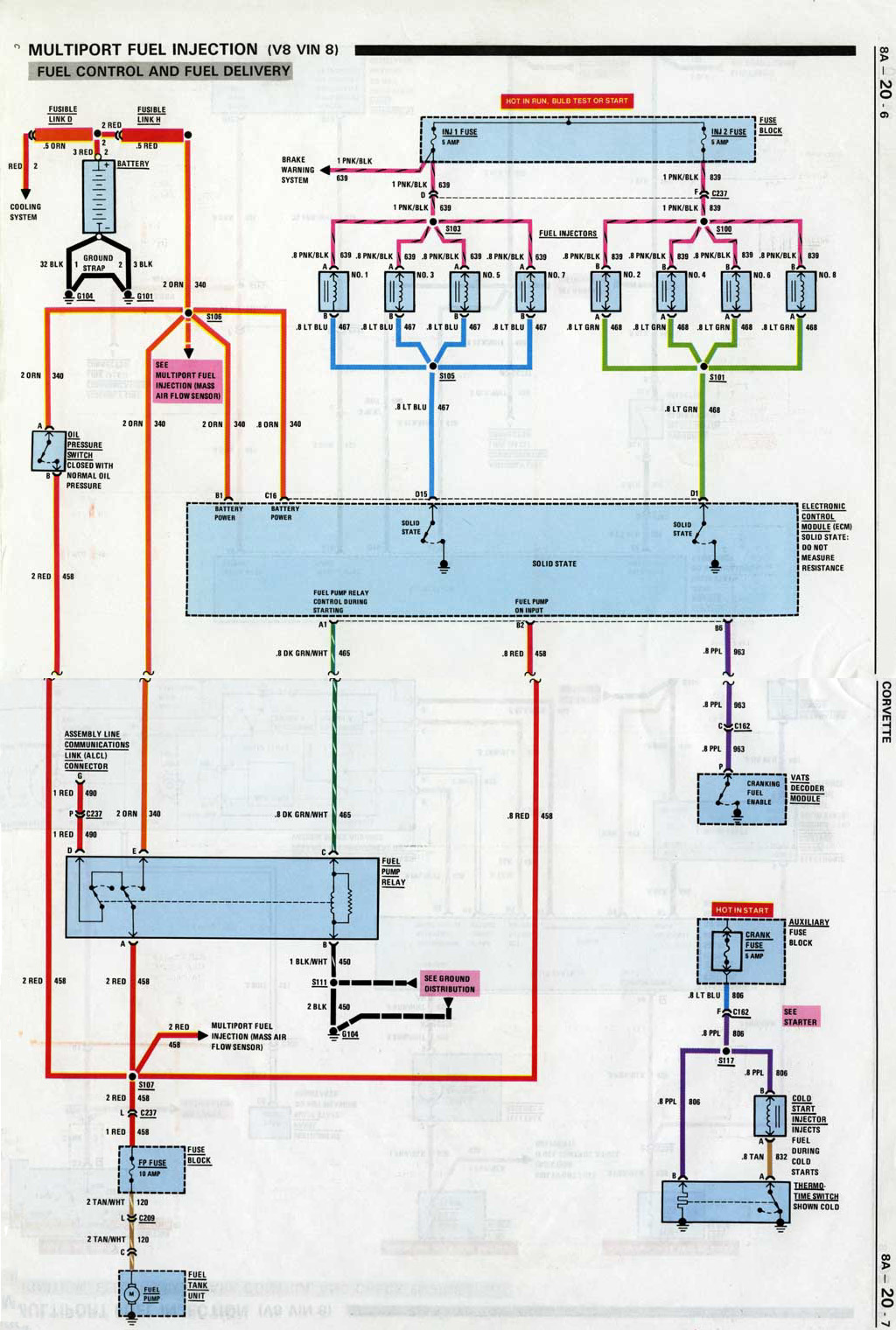

links with lots of sub-links that should be useful, most guys ,faced with isolating an electrical issue, seem to get over whelmed, but if you get out the schematics, use a multi meter and some logic in tracing the circuits, and start pulling fuses and measuring resistance and voltage, take the time to read the manual ,pull trouble codes,and if required get a scan tool or a data logging program for your lap top computer, and using the shop manual, you can generally isolate the cause, but don,t get fixated on the idea that all misses are ignition, electrical related, theres potential mechanical, and fuel delivery issues that could be involved.

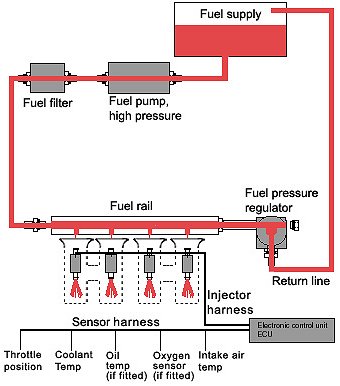

OK too trouble shoot a no start condition,you need to understand the basics, you need compression,in all cylinders, consistent fuel,pressure and volume,ignition spark, correct ignition timing, no vacuum leaks and the exhaust must not be really restrictive.

Don,t assume its a major problem, pull trouble codes and get out a multi-meter....check that your battery has 13 volts?, verify the starter spins the engine, verify your getting fuel pressure and ignition spark and when you find a problem trace it to its source. if you don,t have fuel pressure you should reasonably check in the fuel supply system, but don,t over look silly stuff like your fuel tanks empty, if your engine won,t spin over obviously check the battery and starter function,do you have an alarm or "VATS" system? if you have good battery voltage will the engine spin? are you getting spark at the plugs? and pull your spark plugs to be sure the engines not locked up hydraulically from a leaking head gasket.

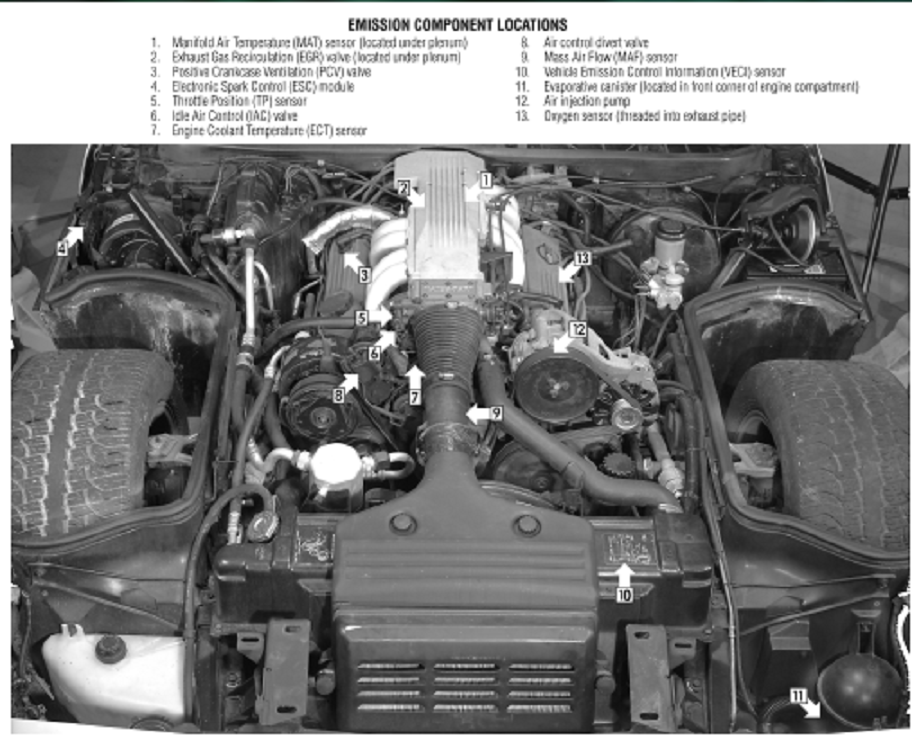

LOOK FOR LOOSE OR CORRODED ELECTRICAL WIRING CONNECTORS, in THE WIRING HARNESS, and VERIFY YOUR FIRING ORDER, YEAH I KNOW YOUR SURE ITS CORRECT, CHECK IT CAREFULLY AGAIN, YOUR NOID TEST LIGHT AND MULTI- METER CAN SAVE YOU A GREAT DEAL OF PROBLEMS AND SCRATCHING YOUR HEAD IF YOU TEST BASIC ELECTRICAL CONNECTIONS< RESISTANCE AND VOLTAGE, CHECK YOUR SENSORS AND GROUNDS, A SHOP MANUALS MANDATORY, HEAT SENSORS, MAF SENSORS, AND IGNITION MODULES AND OIL PRESSURE SENSORS HAVE A LONG TRACK RECORD OF FAILING OR PARTIALLY AND INTERMITTENTLY NOT FUNCTIONING

if you have voltage at the ignition coil, and no spark don,t assume its a defective ignition coil , but if you have a spare coil swap it out as a quick test, won,t hurt, and it will help isolate the problem source.

also be aware that a leaking injector, or fuel pressure regulator can cause the catalytic converter, to melt internally, blocking the exhaust flow or oxygen sensors to fail

remember what goes in needs to go out UNRESTRICTED, and a clogged catalytic converter can cause the engine to run very poorly or not start at all.

ANYTIME YOUR DEALING WITH THE ENGINE AND HOW IT RUNS ,

YOULL BE DEALING WITH DIFFERENT ISSUES,

COOLANT AND OIL TEMPS,& PRESSURE

FUEL PRESSURE , INJECTOR FUNCTION

FUEL DELIVERY, PRESSURE & VOLUME

RELATED FUEL / AIR RATIO

EFFECTIVE COMPRESSION & RING SEAL

VALVE TIMING LIFT & DURATION & VALVE SEAL

IGNITION SPARK TIMING & STRENGTH, & IGNITION ADVANCE CURVE

EXHAUST BACK PRESSURE

SENSOR OUTPUT TO THE CPU

VOLTAGE & GROUNDS

ITS YOUR JOB TO TEST AND ISOLATE EACH UNTIL THE CAUSE IS LOCATED

READ

THE LINKS AND SUB LINKS,

THEY CONTAIN A HUGE AMOUNT OF RELATED INFO

PULL THE TROUBLE CODES

http://garage.grumpysperformance.com/index.php?threads/c4-c5-corvette-trouble-codes.2697/

http://members.shaw.ca/corvette86/FuelS ... gnosis.pdf

http://garage.grumpysperformance.com/index.php?threads/testing-leaky-fuel-injectors.7310/

http://garage.grumpysperformance.co...ystem-trouble-shooting-flow-chart-info.11536/

http://garage.grumpysperformance.com/index.php?threads/replacing-a-c-4-fuel-pump.33/

http://garage.grumpysperformance.com/index.php?threads/chasing-a-crazy-electrical-glitch.986/

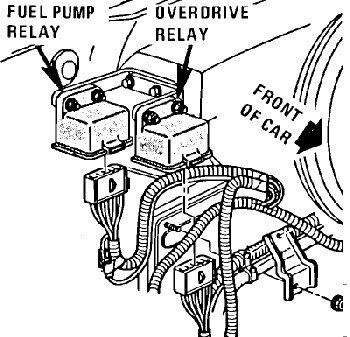

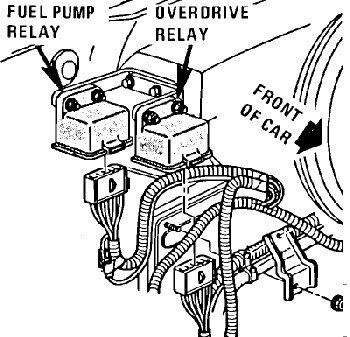

http://garage.grumpysperformance.co...lay-switch-locations-and-info.728/#post-43477

the "PROBLEM" is most people won't take the time or effort to diagnose a problem by logically isolating and testing each component before the parts are replaced,

and yeah its basically a two step problem, that having a SHOP MANUAL, for your particular year corvette ,

and a few basic tools like a FUEL PRESSURE GAUGE,MULTI METER, AND TIMING LIGHT, COMPRESSION TESTER,

and a CODE READER MAKE FAR EASIER, ISOLATE AND TEST ARE THE BASICS OF ANY REPAIR PROCESS>

you first have to understand how each component functions and how to test its functioning correctly.

it helps a great deal if you know the basics and have access to the tools required to test.

it helps a great deal if you understand how the various sub systems like ignition,

timing and terms like AMPS. VOLTS,RESISTANCE, and fuel delivery work, terms LIKE PRESSURE, VOLUME, and the basic 4 cycle engines design parameters.

theres not a single problem on a C4 CORVETTE, that can't be diagnosed with a shop manual, fuel pressure gauge, multi meter, exhaust back pressure gauge/vacuum gauge and an accurate infrared temp gun, timing light, compression/leak down tester, basic mechanics tools, a set of jack stands and a floor jack.

and a logical isolate and test mentality, if you have access to the internet to ask questions about related tests, PROVIDED you ask the correct questions and test to find the related answers,

yeah, having experience helps and tools like code scanners, degree wheels, dial indicators , a dial caliper, feeler gauges certainly help,

but you can solve problems by simply understanding how components are supposed to work, and how they can be tested to verify they are defective or not!

related info

http://garage.grumpysperformance.com/index.php?threads/c4-c5-corvette-trouble-codes.2697/

http://garage.grumpysperformance.co...oven-facts-if-your-in-doubt.13051/#post-88488

http://garage.grumpysperformance.com/index.php?threads/bare-minimum-tools.11026/#post-48779

http://garage.grumpysperformance.co...too-common-questions-can-be-found-here.12892/

http://garage.grumpysperformance.com/index.php?threads/leakdown-compression-test.881/#post-56489

http://garage.grumpysperformance.co...ard-starting-tpi-crossfire-or-lt1-vette.1401/

http://garage.grumpysperformance.com/index.php?threads/c4-and-camaro-sensor-and-relay-switch-locations-and-info.728/#post-93194

http://garage.grumpysperformance.com/index.php?threads/optispark-ignition-info.628/#post-75647

http://garage.grumpysperformance.com/index.php?threads/under-car-safety.26/

CHECK ALL YOUR FUSES and electrical connections WITH A MULTI METER, but don,t assume you know what the problem is, let the facts lead you to the answers

be aware that not all engine "MISSES" or "ticking sounds " that you might be dealing with or tying to correct, are an electrical or a fuel delivery or pressure issue, your problem might be a mechanical issue like a vacuum leak, from a busted hose,or loose gasket,a burnt valve, loose or worn timing chain,badly adjusted valves, broken or loose harmonic damper, loose flex plate, or torque converter bolt, busted valve spring, burnt or defective rocker, loose or worn valve guide, or a dozen other issues so try to logically isolate it to a cylinder or system, electrical,valve train, fuel delivery, exhaust , ignition ,etc.

WATCH THE VIDEO, READ THE LINKS

http://www.youtube.com/watch?v=9CPqbaSg ... re=related

http://www.chevythunder.com/fuel%20inje ... pg%20B.htm

IF you start with checking for loose electrical connections and vacuum leaks you might find the problem, a propane torch is both safer and easier to use as a method to locate vacuum leaks

check for vacuum leaks

(DONT LIGHT IT) just SLIGHTLY open the valve so its allowing gas to flow at a low volume,start the engine and let it idle at the lowest speed you can then place the tip of the UNLIT torch at any suspected vacuum leak and listen for the rpms to increase and watch the tachometer, gas flowing into a vacuum leak will increase engine speed.

Another possible quick test you can do relates to "clear flooded engine mode" if the car cranks but doesn't start and has fuel pressure, you can test by trying disconnecting the TPS sensor connection on the pass side of the throttle body,. This will kick the computer into limp home mode (setting a predetermined voltage) and the car will start after a time if you flooded the plenum in the intake

look for loose or missing vacuum hoses, cracked or broken power brake connections, emissions system hoses that are loose, vacuum connections to the trans or ignition, loose connectors missing or loose bolts cracked hoses missing accessory connections etc.

naturally this only locates leaks to the outside, and its possible for the intake to suck air from the lifter gallery, so that also needs to be checked if everything else seems to be ok.

read this

buy a CHEVY SHOP MANUAL FOR YOUR YEAR CORVETTE!

set and verify your ignition timing, pull trouble codes,set your tps and iac,, then check for vacuum leaks on the lines and intake,then get out your multi meter and verify all the sensors, chances are good its a defective heat sensor or defective o2 sensor, a logical step by step approach will lead you to the problem, youll be amazed at what youll learn reading links. use of a shop manual and multi meter can be very helpful

http://www.harborfreight.com/5-in-1-dig ... 98674.html

FLUKE is the brand of choice but they are expensive, shop around, Ive still got the original fluke multi meter I bought in HIGH SCHOOL and it STILL WORKSIve purchase several from harbor freight , in the last 10 years alone and only one still works

http://www.fluke-direct.com/shop/itemDe ... urer=FLUKE

http://www.fluke-direct.com/shop/catego ... TERS&path=

http://chevythunder.com/

a good quality if temp gun helps more than you might realize at diagnosing problems

http://www.grainger.com/product/EXTECH- ... _-AllPages

learn to use the factory shop manual, and a multi meter and LISTEN to the engine closely, tapping and high pitch whines can indicate defective injectors or fuel pressure regulators, fuel pumps,mis- adjusted valve train components, worn distributor parts, check all the fuses and electrical grounds and corrosion on connections thats something thats frequently over looked etc.

http://www.chevythunder.com/Flow chart index.htm

http://www.professionalequipment.com/ex ... ermometer/

https://www.summitracing.com/parts/anm-cp7838

and rev the engine a few times and watch the fuel pressure it should in theory remain in the 38 psi-42 psi range for most TPI and TUNED PORT efi

having a good cross check tool like a quality IR temp gun, and a decent multi meter, sure helps find the truth as far as a defective gauge or sensor

viewtopic.php?f=44&t=464

http://www.corvettebuyers.com/ecm2.html

http://www.hotrodlane.cc/NewTPI%20links ... ml#tpitech

http://www.mainstreamtopics.com/forums/ ... iagnostic/

http://chevythunder.com/

http://www.centuryperformance.com/tunin ... g-148.html

IF the dash lights but it won,t turn over,or just clicks,take off the battery cables and clean the connections then reassemble the trouble your describing is extremely common on theres cars if the battery connections are not cleaned occasionally, the bad connection passed enough low amp current to light up the dash but once the load increases its not able to supply the required current flow rates, if the engine spins but won,t start, obviously you'll want to check all your FUSES with the multi meter and verify the engine and ECU ground straps (usually on the back of the drivers side cylinder head)are tight connections

AND AGAIN! LOOK FOR LOOSE OR CORRODED ELECTRICAL WIRING CONNECTORS, in THE WIRING HARNESS, and VERIFY YOUR FIRING ORDER, YEAH I KNOW YOUR SURE ITS CORRECT, CHECK IT CAREFULLY AGAIN, YOUR NOID TEST LIGHT AND MULTI- METER CAN SAVE YOU A GREAT DEAL OF PROBLEMS AND SCRATCHING YOUR HEAD IF YOU TEST BASIC ELECTRICAL CONNECTIONS< RESISTANCE AND VOLTAGE, CHECK YOUR SENSORS AND GROUNDS, A SHOP MANUALS MANDATORY, HEAT SENSORS AND IGNITION MODULES AND OIL PRESSURE SENSORS HAVE A LONG TRACK RECORD OF FAILING OR PARTIALLY AND INTERMITTENTLY NOT FUNCTIONING

learn to use the factory shop manual, and a multi meter and LISTEN to the engine closely, tapping and high pitch whines can indicate defective injectors or fuel pressure regulators, fuel pumps,mis- adjusted valve train components, worn distributor parts, check all the fuses and electrical grounds and corrosion on connections thats something thats frequently over looked etc.

it helps a great deal to know what your working with ,ID suggest starting, by verifying TDC and having the correct timing tape on your damper then,start with 8 degrees btdc and verifying the full advance of 36 degrees total is all in at 3200rpm as a base line, once youve got that, as a standard you can tune and run the car and eventually try tweaks to the basic ignition curve if needed, once you have an ignition base line, move on to the carbs tuning, you also need to keep in mind that what goes in as a fuel /air mix needs to go out as a much expended volume of hot gases and a restrictive exhaust will effectively block most attempts to get more power from an engine, so measure exhaust back pressure. you might be amazed at what a couple hours research into the subject will do to help you build a much more durable engine, and actually reading thru links and sub-links and asking questions helps a great deal

you might be amazed at the number of times "CARBURETOR PROBLEMS" are cured with getting the IGNITION, TIMING AND ADVANCE CURVE WORKING CORRECTLY, and check out the simply things your 100% sure you did correctly, because I can,t begin to tell you how many times I see guys who have the firing order on the ignition wrong, or guys that install a 4/7 swap cam and still use the standard ignition firing order or guys that never verify TDC and ignition advance curves.

get an IR temp gun and check for wild variations in exhaust temps, get a compression test done, do a logical check to verify each cylinder fires etc.

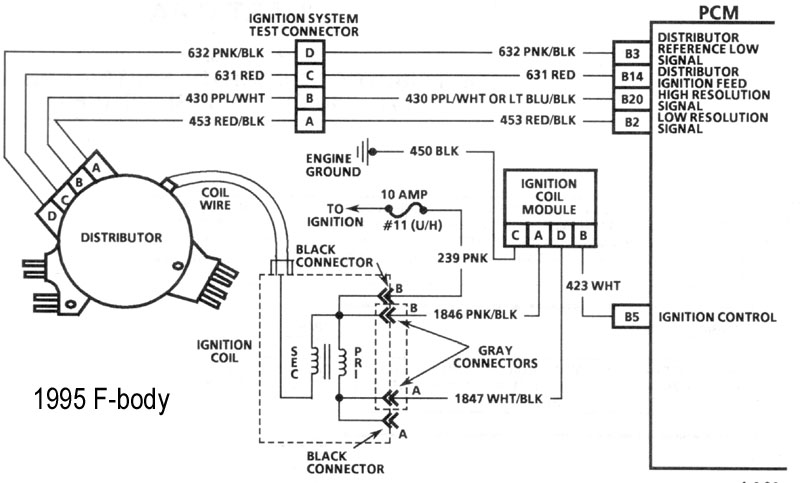

The ignition control module in the distributor is another item that normally fails when hot, that needs to be replaced is you suspect its defective

http://www.chevythunder.com/fuel_pump_diagnosis_chart.htm

http://www.chevythunder.com/fuel_system_diagnosis.htm

http://www.chevythunder.com/fuel_pump_code_54.htm

http://www.chevythunder.com/Flow chart index.htm

get out your shop manual and multi meter

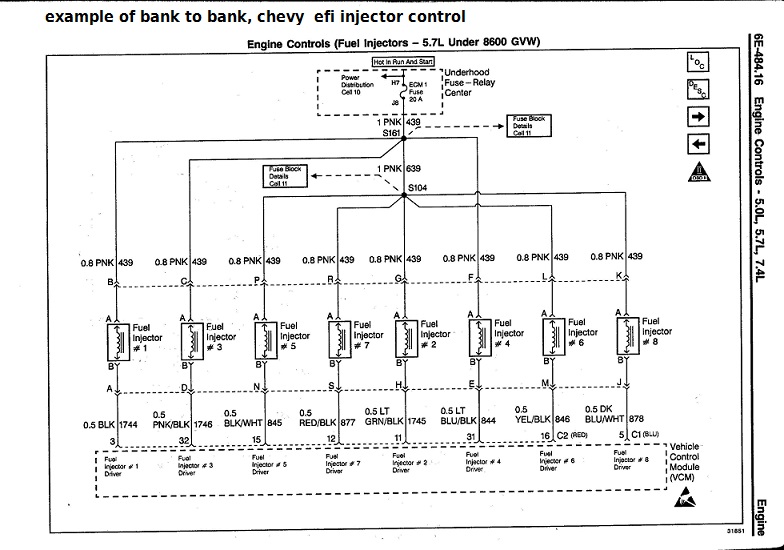

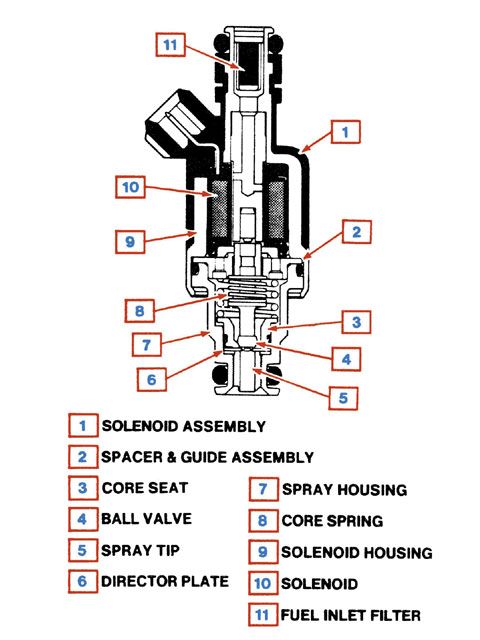

if you suspect the injectors , you first use a multi meter to verify every injector reads the same ohms (usually near 11-16 ohms, and yes they should all read very closely) then you need a noid kit for a G.M. fuel injection system, these are basically little lights that light as the injector pulse hits them that you plug into the injector harness,after you remove the harness from the injectors, they plug into the harness just like an injector, if you try to start the engine and they blink on and off the pulse is reaching the injectors thus proving that the injectors get the pulse

ANY TIME YOU SUSPECT FUEL INJECTOR OR FUEL SYSTEM RELATED ISSUES ,A REASONABLE START POINT IS TO USE A GOOD QUALITY FUEL INJECTION CLEANER ADDITIVE IN THE FUEL TANK AND SWAP TO A NEW FUEL FILTER

http://www.bgprod.com/catalog/gasoline- ... m-cleaner/

http://www.bgprod.com/catalog/gasoline- ... m-cleaner/

http://www.harborfreight.com/11-piece-n ... 97959.html

http://www.chevythunder.com/Flow chart index.htm

http://www.digitalcorvettes.com/forums/ ... p?t=197337

http://www.mainstreamtopics.com/forums/ ... iagnostic/

http://members.shaw.ca/corvette86/FuelS ... gnosis.pdf

[/color][/b]

keep in mind oil temp sensors and oil pressure sensors are notorious for going defective and reading wrong

then as always ,always drop back to the basics of compression,

air flow in and exhaust out of the engine,

ignition spark, strength and timing,

and fuel delivery,volume and pressure

oil pressure and temp

cooling,temps and fluid levels (fuel,oil,coolant)

computer controls and sensors

always drop back to the basics

have you verified theres no vacuum leaks

have you verified theres at least 37 psi of fuel pressure?

have you verified theres constantly ignition spark at the plugs?

have you verified theres spark at OR NEAR TDC on the power stroke with a timing light, timing tape on the damper and verified the timing marks are correct?

have you verified theres 12 volts at the coil?

have you verified the coil fires?

have you verified there spark at the plugs?

have you verified the injectors get voltage with a noid light?

have you verified the fuel injection fuses are good?

have you verified all the sensors are good?

all electrical connections are correct?

have you pulled trouble codes?

have you verified the firing order?

have you readjusted the valves so you know 100% that they are not too tight?

are you getting about 10psi of oil pressure or more as the engine turns over?

have you set tha TPS and IAC?

if you have not done a compression check and verified the valves are lashed correctly thats a good place to look , but only after the basics of ignition timing, spark, strength and fuel delivery are checked. your fuel pressure regulator , dirty injectors,clogged fuel filters loose connectors on injectors and sensors and ignition wire are frequently the cause as are corrosion on electrical connections, defective sensors., loose or broken vacuum lines.

Id check for fuel pressure is steady and spark is consistent first and verify the spark plug condition as clear pictures of the plugs numbered by cylinder can give a great deal of info

Id check for vacuum leaks , and loose battery connections and loose grounds

http://forum.grumpysperformance.com/viewtopic.php?f=80&t=728

http://www.corvettephotographs.com/c4vettes/codes.htm

http://www.international-auto.com/fiat- ... gauges.cfm

http://members.shaw.ca/corvette86/FuelS ... gnosis.pdf

http://www.thirdgen.org/injectorswap injector swap

http://www.thirdgen.org/tpimod2 IAC/ TPS

http://forum.grumpysperformance.com/viewtopic.php?f=32&t=168

http://forum.grumpysperformance.com/viewtopic.php?f=32&t=596

http://www.corvettebuyers.com/ecm.html

http://forum.grumpysperformance.com/viewtopic.php?f=32&t=3954

http://corvetteactioncenter.com/tech/c4 ... Z1XqJwcC10

http://tech.corvettecentral.com/2007/08 ... diagnosis/

get out your shop manual and multi meter

[/b][/color]

read thru these links

http://members.shaw.ca/agent86/Fuel Control And Delivery-8A.pdf

http://members.shaw.ca/corvette86/EngineCranksButWontRun.pdf

http://members.shaw.ca/corvette86/FuelSystemDiagnosis.pdf

http://members.shaw.ca/corvette86/No-Service Engine Soon - Light.pdf

http://members.shaw.ca/corvette86/SES Light On Steady.pdf

http://members.shaw.ca/corvette86/Non Scan Diagnostic Circuit Check.pdf

http://members.shaw.ca/corvette86/Engine to ECM Wiring Diagram 86.pdf

http://members.shaw.ca/corvette86/Component Location View 86.pdf

http://members.shaw.ca/corvette86/FuelSystemDiagnosis.pdf

http://garage.grumpysperformance.co...questions-can-be-found-here.12892/#post-66934

good info

http://www.go-fast.org/z28/diagnostics.html

http://www.corvetterecycling.com/category_s/63.htm

this process of finding the cause of a problem, is basically a detailed check list and once you understand what your looking at and what its supposed to do after each components tested, is basically a simple procedure if you test, and eliminating potential sources until you narrow it down to the cause, where you prove it then re-place, repair or adjust as required.

yes youll need to have some test equipment like, a shop manual, multi- meters and pressure gauges, timing lights etc. but its not that difficult

[b]STEP ONE IS ALWAYS GET A FACTORY SHOP MANUAL, AND READ THE LINKS BELOW

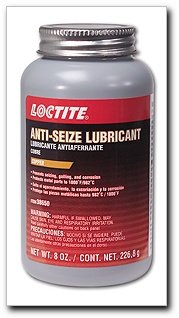

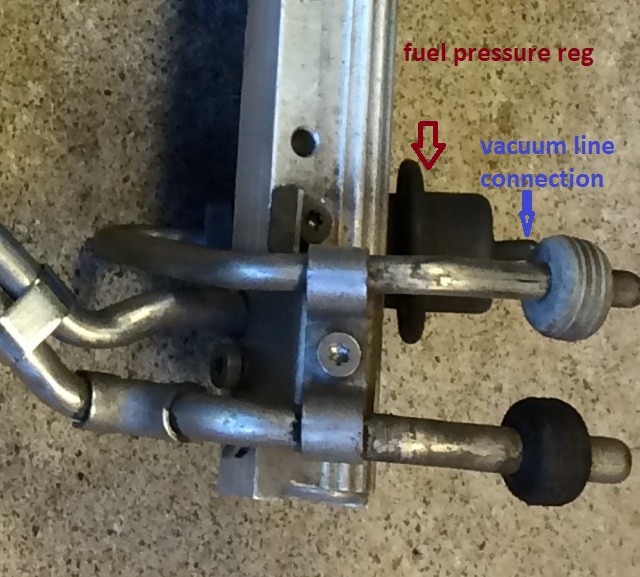

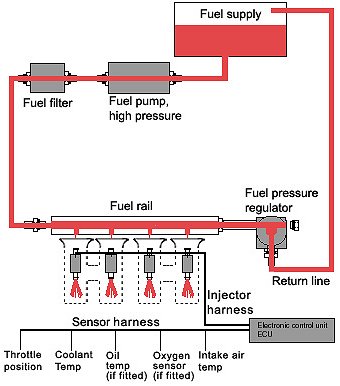

Verify fuel pressure,. by using a fuel pressure gauge on the shrader valve on the fuel rail, with a pressure gauge,

Verify injector pulse by using a noid light, & spark at the plugs by using a spark tester.

verify timing with a timing light

pull the trouble codes and check all fuses[/B]

http://www.mamotorworks.com/corvette.ht ... %20manuals

http://www.helminc.com/helm/Result.asp? ... ted_media=

http://www.factoryautomanuals.com/p-912 ... -only.aspx

http://members.shaw.ca/corvette86/FuelS ... gnosis.pdf

I frequently get questions about why cars, most of us own that are used mostly as weekend toys and not as daily transportation,cars that sit for a few days between use seem to be plagued with battery's that won,t stay charged, well ive gone over this a few times so heres a few links of related info

http://forum.grumpysperformance.com/viewtopic.php?f=36&t=3453&p=26193&hilit=vats#p26193

http://forum.grumpysperformance.com/viewtopic.php?f=36&t=520&p=645&hilit=vats+resistor#p645

http://forum.grumpysperformance.com/viewtopic.php?f=36&t=63&p=31920&hilit=starter+rebuild#p31920

http://forum.grumpysperformance.com/viewtopic.php?f=32&t=5926&p=18562&hilit=starter+rebuild#p18562

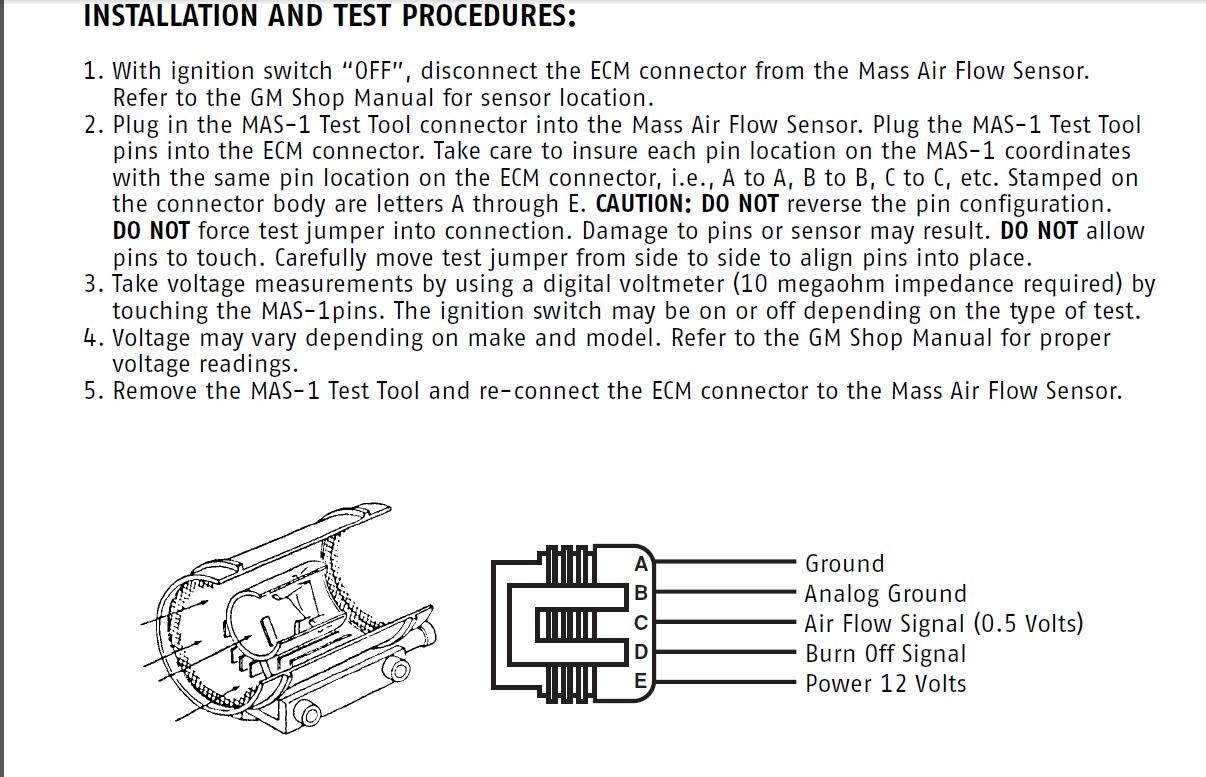

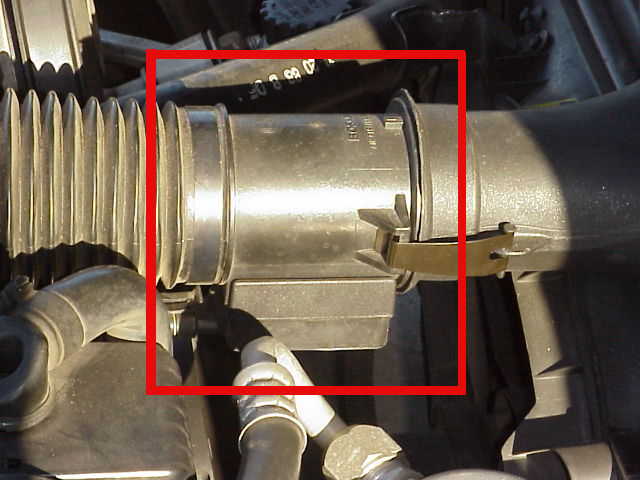

MAF SENSORS AND RELAYS ARE EASILY DAMAGED SO ALWAYS CHECK AND SUSPECT THOSE

BEFORE you start going nuts look at the obvious stuff first!

CHECK THAT YOUR IAC and TPS sensors are set and adjusted correctly, set your ignition timing, make sure theres fuel in the gas tank,and theres no blown fuses and see if youve got a STEADY 37-40 psi on the fuel rail

WHEN TESTING<be sure the fuel pressure gauge reads correctly by comparing it to a second test gauge, these fuel pressure gauges are frequently defective

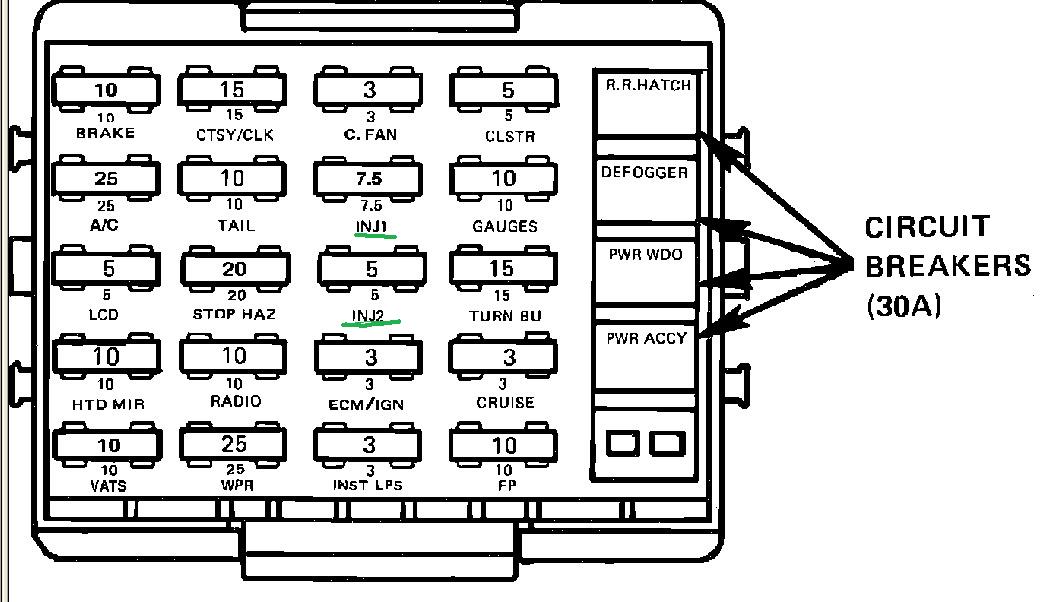

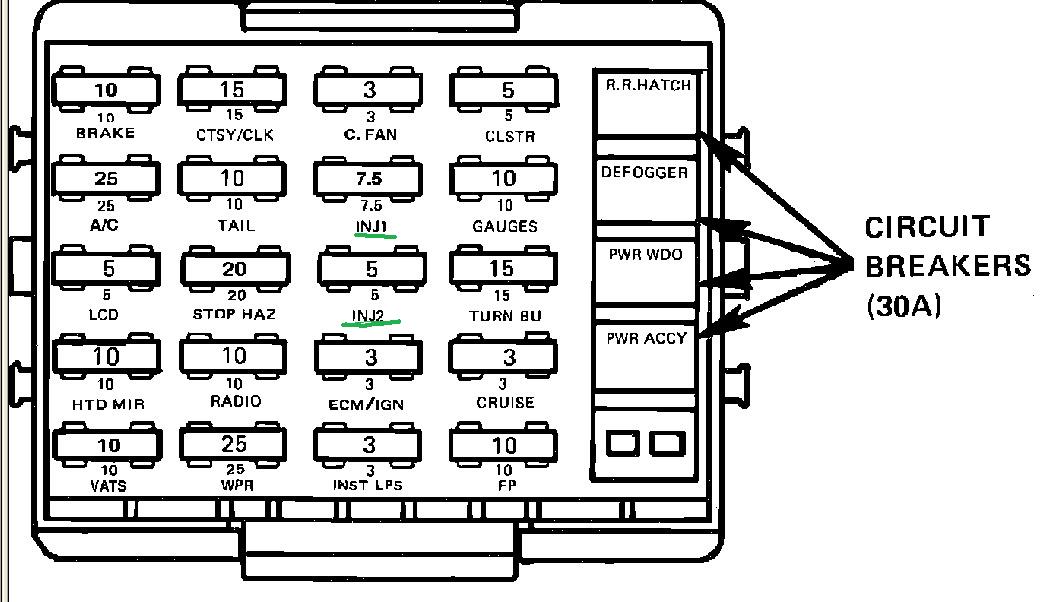

CHECK ALL YOUR FUSES WITH A MULTI METER

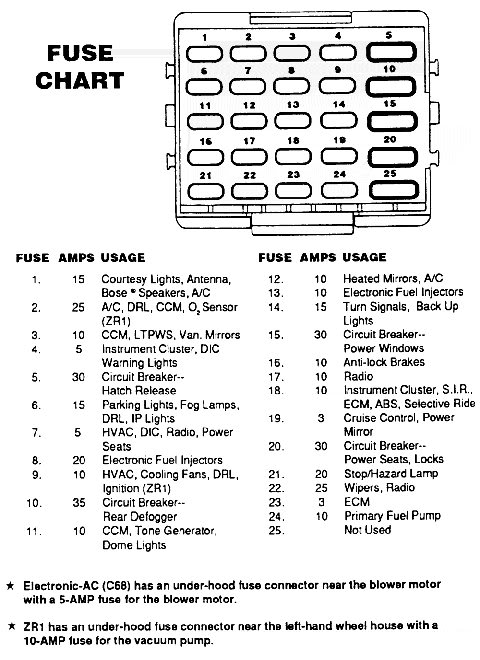

check your fuse block with a meter , if the car won,t start, a common issue is blown injector fuses

theres two fuses one controls the drivers side one controls the pass side injectors

The secret of effective diagnosis and troubleshooting is to have a logical plan, and to follow it without skipping any steps.when ever you get into unexplained symptoms the answer remains the same....in every case,.... you drop back to the basics and do a few tests, (and until you gain experience you need the FACTORY SHOP MANUAL TO INDICATE THE TESTS, NEEDED AND THE EXPECTED RESULTS LISTED) get out a multi meter and verify every fuse is good, and you have 13 volts at the battery and youve got at least a 1/2 tank of fresh fuel, before you start chasing your tail, thinking about more complicated problems

find the cause, you isolate, each function or system or malfunction to its related components then test, each individually, use of the shop manual is almost mandatory

the next step is to get out your multi meter and carefully verify that ALL YOUR FUSES AND RELAYS WORK

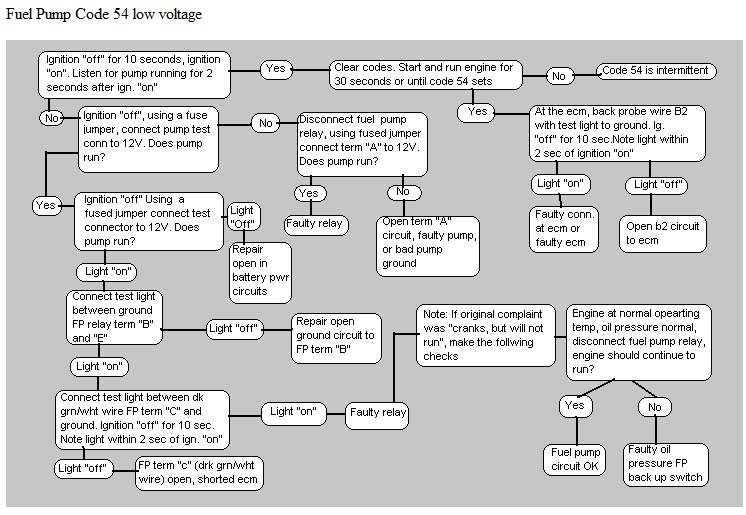

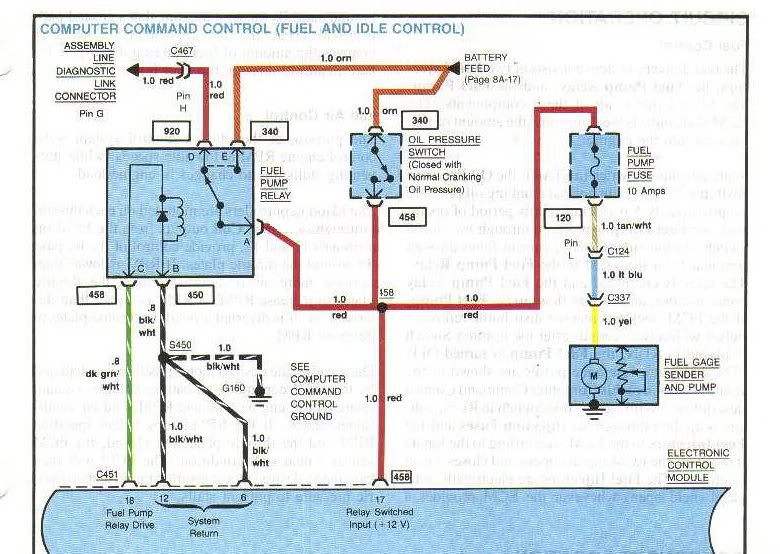

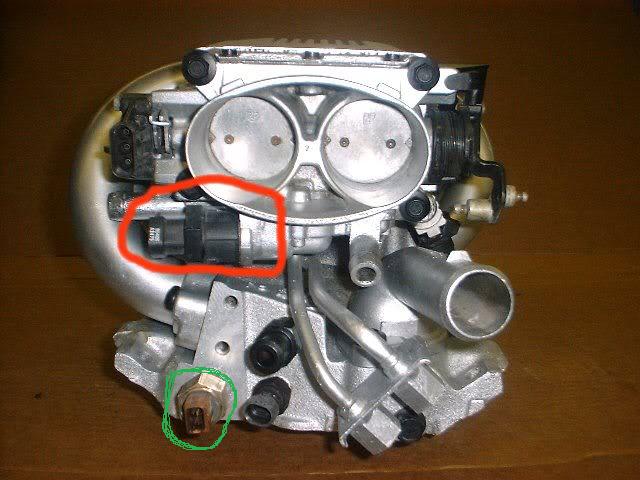

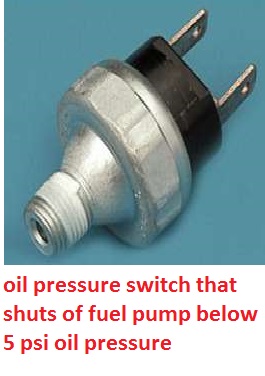

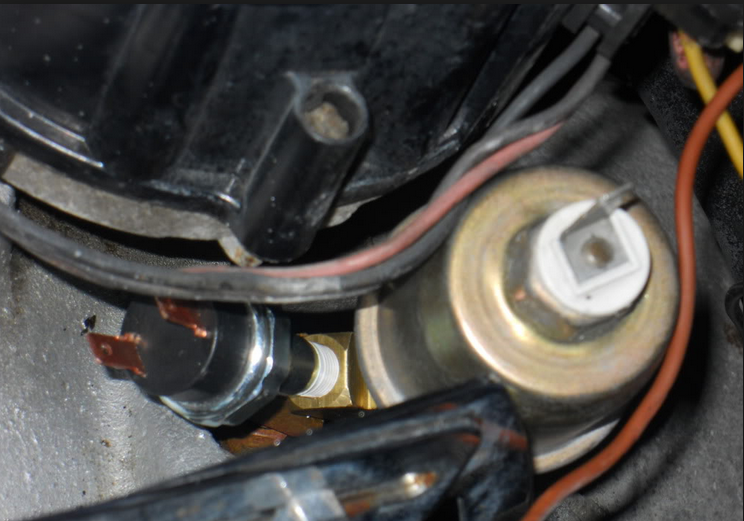

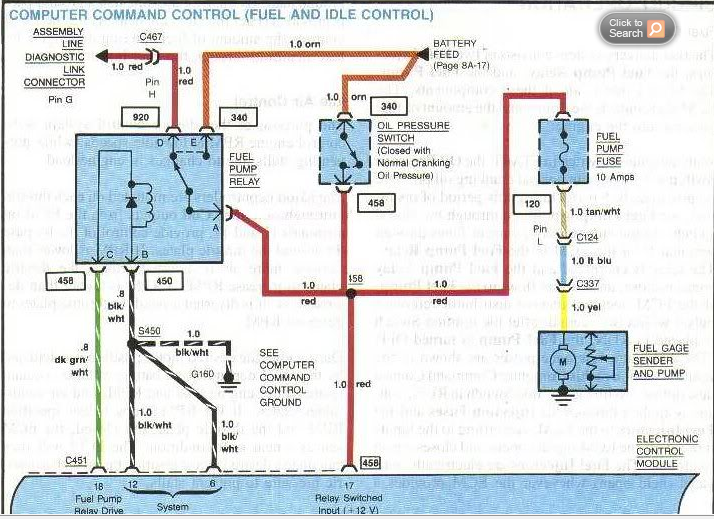

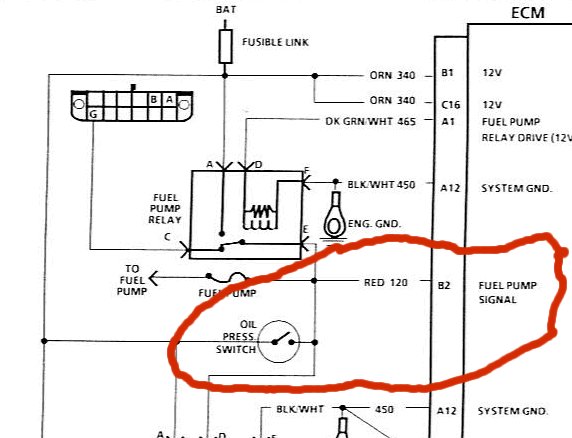

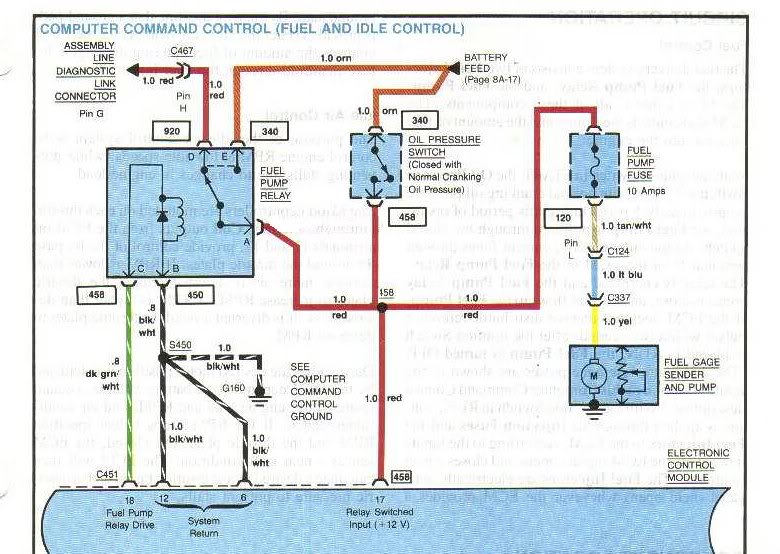

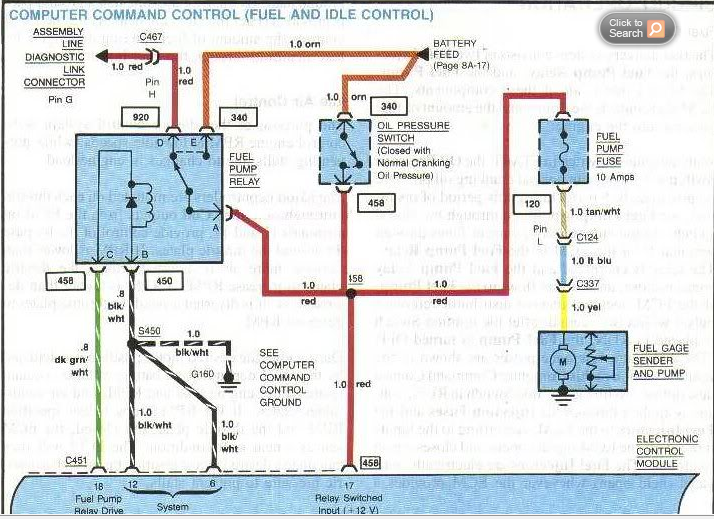

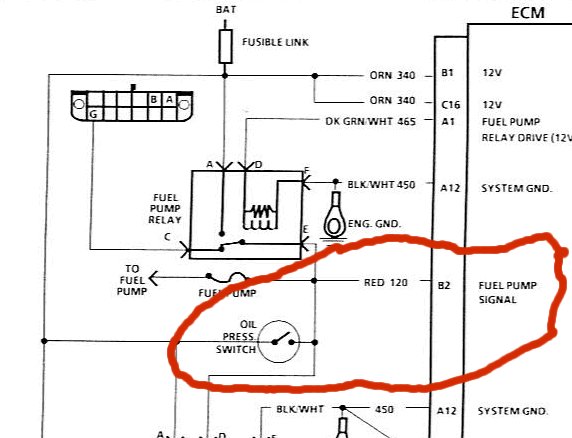

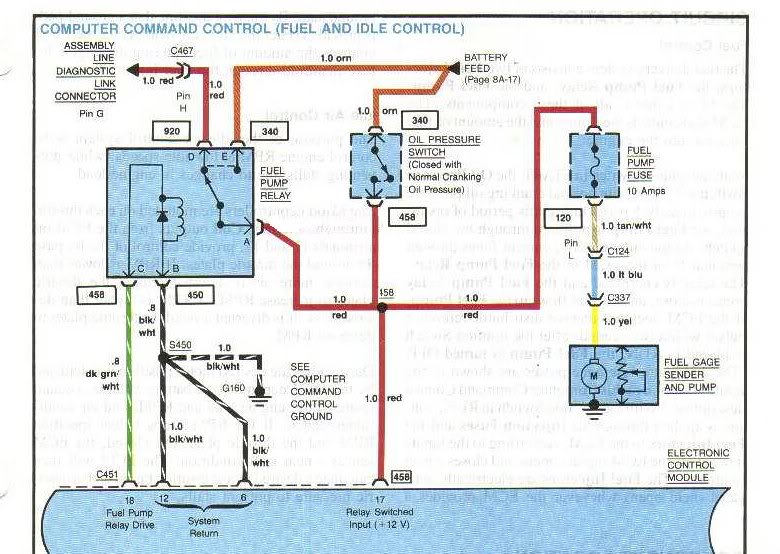

if they check out and its very likely that they WILL NOT DO SO, ID suggest checking the connections on oil pressure sensor at the rear of the block next to the distributor, if they look ok,ID replace the oil pressure sensor at the rear of the block next to the distributor, the fuel pump will only continue to run after the first few seconds and you only get voltage to the ignition if this sensor tells the CPU youve got 5 PSI of oil pressure during the start-up procedure

Ive seen several corvettes with similar start, then stall issues that cleared up after replacing those sensors, Im reasonably sure the sensor INCORRECTLY and INTERMITTENTLY, indicate the oil pressure momentarily drops to ZERO causing the problem, but what IM sure of is that replacing the sensors cure the issue occasionally

http://forum.grumpysperformance.com/viewtopic.php?f=32&t=1401&p=8895&hilit=start+sequence#p8895

http://forum.grumpysperformance.com/viewtopic.php?f=32&t=2697

http://forum.grumpysperformance.com/viewtopic.php?f=32&t=596

http://www.73-87.com/7387garage/drivetrain/pkupcoil.htm

http://www.aa1car.com/library/dis.htm

http://members.shaw.ca/corvette86/Component Location View 86.pdf

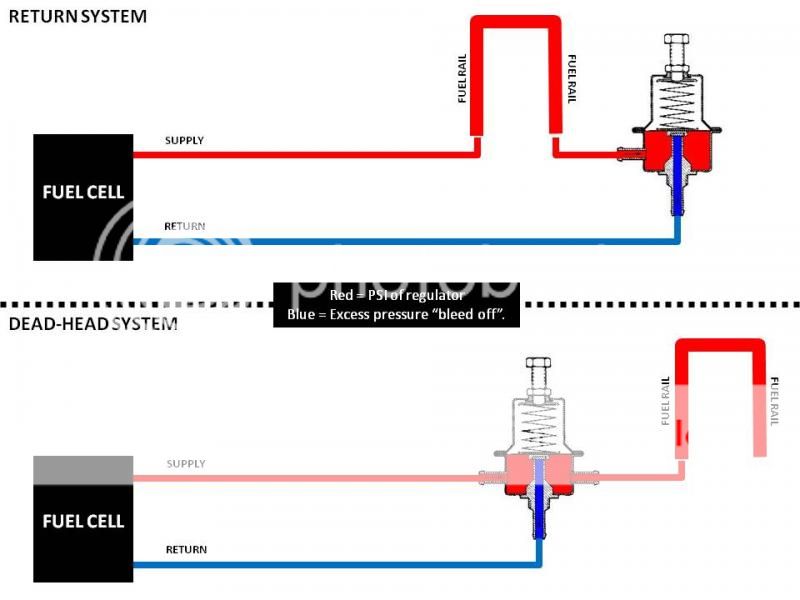

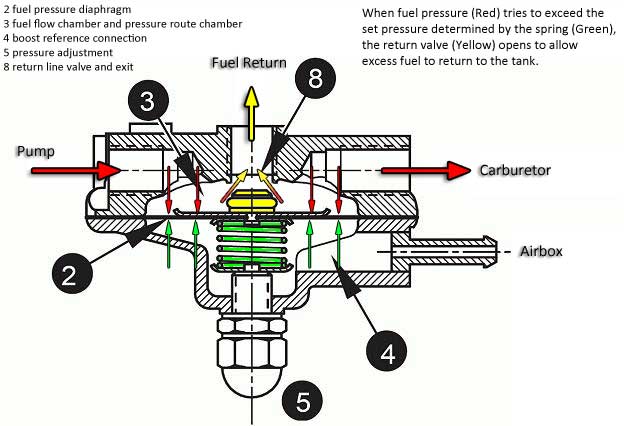

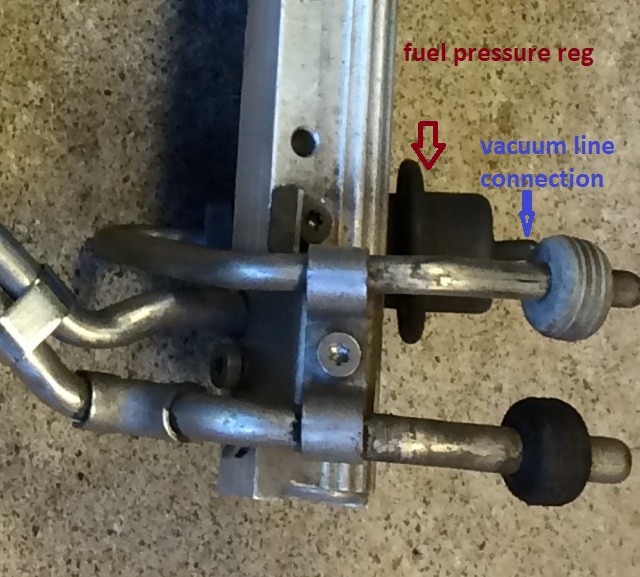

verify your fuel pressure stays up in the 37-40 psi range without falling much after the cars shut off for at least 5 full minutes, and it should stay at 37-42 psi if the fuel rail pressure does drop off in the first few minutes its almost always a leaky injector or bad fuel pressure regulator, and check for vacuum leaks either could cause your symptoms, remember the fuel pressure should stay fairly consistent while the cars running regardless of how fast or long the throttles quickly blipped or held wide open,and be sure the throttle linkage and blades move smoothly and don,t bind or stick at any point in the movement arc.

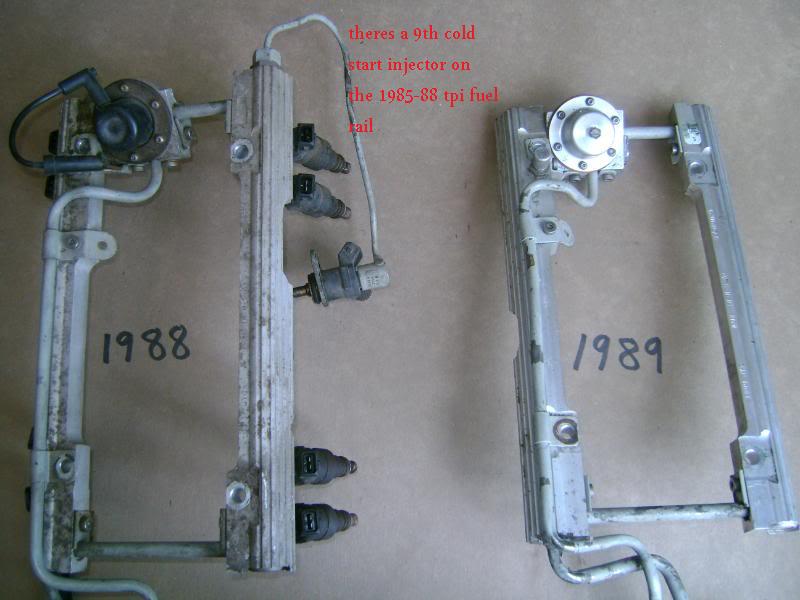

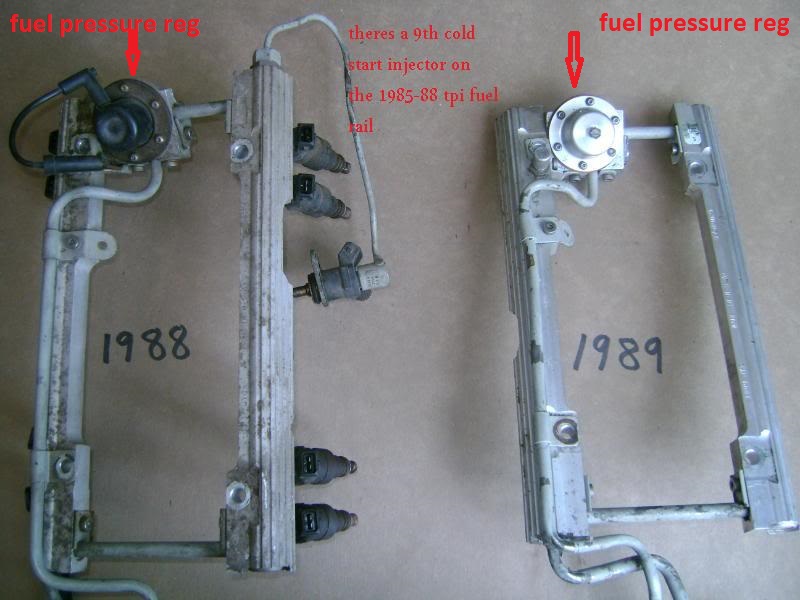

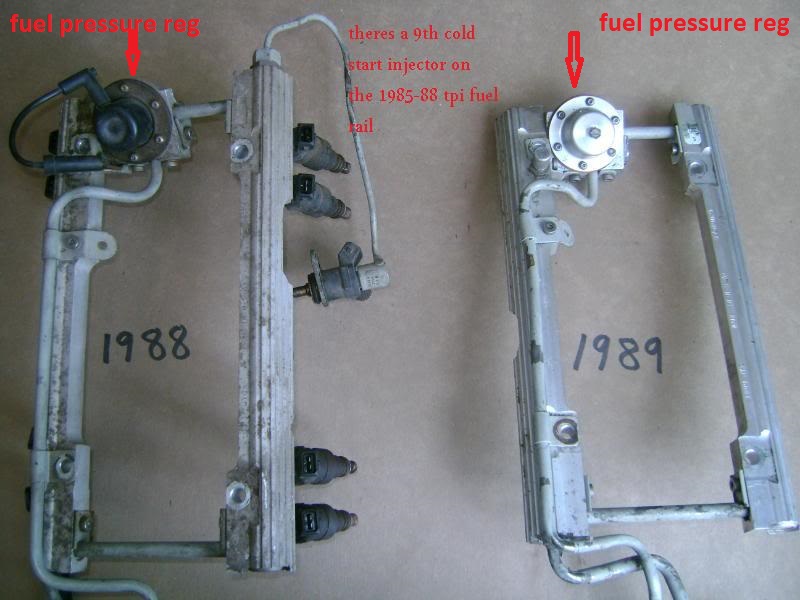

If you've got an early year TPI , that's designed to use a 9th cold start injector,check the cold start injector as its a potential problem source if its not working correctly.if your TPI won,t start, easily on the first try but starts easily on the second or third attempt, that's a very common indication of EITHER a leaking fuel pressure regulator (about 70% of the time), or less commonly a defective fuel pump(about 10%, of the time the pressures low or they leak internally) or leaking injector(s) (about 20% of the time)

but it can also indicate a partly clogged fuel filter, or rarely air filter , and in rare cases a defective oil pressure sensor switch which won,t let the ignition work until theres more than 5 psi of oil pressure

The secret of effective diagnosis and trouble shooting is to have a logical, well-ordered system. Following a logical step-by-step procedure will get you to the root cause of a problem quickly and efficiently. Repair manuals will have a diagnostic tree that goes in a logical progression. It will ask a question, usually yes or no, and depending on the answer will branch off in two or more directions. The last box in the tree will have the problem and how to correct it. The example shown is a simple one. A more complicated system will have branches going into specific tests and then have 2 or more branches from there depending on test results.

first check your shop manual for the fuse and fuse able link locations

fuses are located in several locations and fuse-able links near the battery

start with testing the fuel pressure in the fuel rails, that symptom is frequently the result of a DEFECTIVE fuel pressure regulator,or leaky injectors ,or a blown fuse or the blown fuse-able link near the battery, get a fuel gauge, installed on the fuel rail , it should reach 40psi almost instantly when you try to start the car and maintain 40psi or more at the fuel rail for at least 15 minutes, on the early TPI theres a 9th injector thats used to richen the f/a mix that might be defective, latter TPI versions just added pulse width to the injectors during the first few minutes of run time. keep in mind,wet, loose, or broken electrical connectors or corrosion on connectors, is also possibly a cause of intermittent problems

BTW To remove the connector from the injector, push carefully in the middle of the locking clip, with your thumb, This will make the sides, and tips move OUT WARD in their connector slots allowing the tips that hold the injector into the connector to slide out of the way from the injector body, and you can then pull the sides away. WATCH the locking clip - IT can and WILL come off and get lost, if your not careful

IVE generally found no problem with any corvette LT1 or TPI efi if it will quickly build a minimum of 38-40PSI on start up and MAINTAIN at LEAST 38-40 psi for a MINIMUM of 10 minutes after the engines turned off, 40-42 lbs is what the factory tests want and expect so if your getting 38-40psi your pressure readings indicate a normal, perhaps even better than average pressure reading, and more than expected pressure retention,

IF you suspect a TPI has a defective injector that's leaking or not flowing fuel,or partly clogged...You can also test this, to a degree, with a fuel pressure gauge

you can install a fuel pressure gauge on the fuel rail, and turn on the ignition key then watch the gauge, it should jump to 37-42 psi then remain fairly steady for at least 5 minutes before gradually loosing pressure.

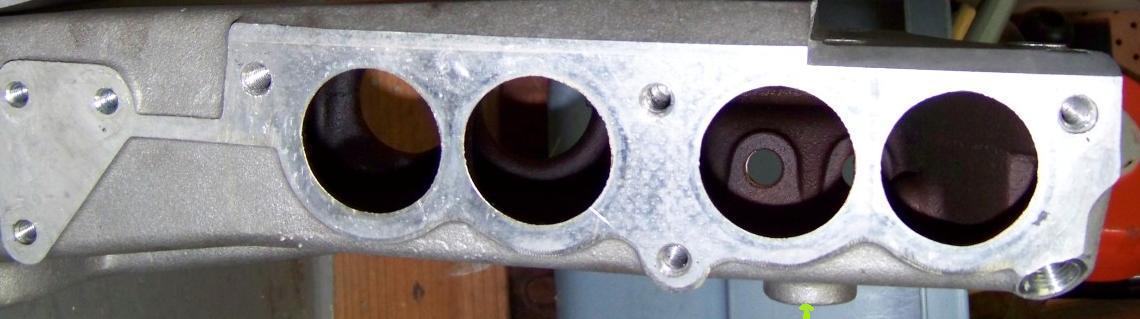

If you can - and this is a pain in the butt to do, temporarily- remove the injectors. Leave them on the rail, but remove the rail. from the intake itself, This requires removing the majority of the TPI (P.I.T.A. but required).

HERES HOW

http://www.thirdgen.org/injectorswap

Remove the rail, but leave it connected to the fuel lines.

Next up, put a strip of cardboard under each bank. Then, have a buddy turn the ignition key on but not try to start the engine , you should hear the fuel pump run for 3 seconds while you look to see what happens. You should get an immediate spray of fuel.(all should be about equal and no injector remains dripping fuel) now have your buddy Turn off the key, while you watch closely to see which injectors are leaking.

youll be amazed at what you can learn, by reading thru links and sub links provided below

http://forum.grumpysperformance.com/viewtopic.php?f=32&t=596

http://members.shaw.ca/corvette86/FuelS ... gnosis.pdf

The first thing ID do is VERIFY the CAUSE, OF THE PROBLEM FOR THAT, THRU ISOLATING AND TESTING, COMPONENTS AND SYSTEMS , ignition spark should be bright blue and impressive, if its, weak,narrow, yellow or red theres a problem so research the cause, verify the coil and voltage

always drop back to basics and verify all the sensors first,verify that the TDC on the damper and the timing tab, are correct,and you've set the ignition timing correctly, set the IAC and TPS sensor and check for vacuum leaks, verify the voltage, at the battery both running and before you start the car, it should be over 13 volts running and over 12.5 volts on just the battery.

verify the plug gap is at about .045 inches (1.15mm) and the plugs are burning correctly, and set your ignition timing at 6

btdc at about a 700-750rpm idle.

use the timing light to verify the ignition advances as the rpms are increased, if its not advancing smoothly the distributor, might need work or the cpu might be defective

owning a shop manual, a vacuum gauge and a V.O.M. meter and a timing light will be mandatory

http://forum.grumpysperformance.com/viewtopic.php?f=32&t=1836

A SHOP MANUAL IS ALMOST MANDATORY,

THESE LINKS should help, EACH LINK PROVIDES DOZENS OF ANSWERS AND SUB LINKED TESTS ETC, since you can,t cure a problem until you understand whats wrong, read through the linked info

viewtopic.php?f=80&t=728

viewtopic.php?f=55&t=2055&p=5481#p5481

viewtopic.php?f=55&t=1475&p=3325&hilit=testing+sensor#p3325

http://tpiparts.net/85_89_maf_sensors/

http://chevythunder.com/

You will need some basic test equipment to perform your diagnosis.

take notes your memory may not hold the exact numbers & results you need to refer back too.

always drop back to the basics,

get the starter to spin the engine

verify theres compression

verify your getting oil pressure

verify the exhaust is not clogged, catalytic converters are not melted

verify the cars fuel is clean and water free

verify your getting fuel pressure

verify your injectors are working

verify your getting ignition spark at the plugs

verify the valves are correctly adjusted

verify the cams correctly indexed

verify all the rockers are moving

verify the distributor spins

always drop back to basics

have you verified TDC on the damper and timing tab?

have you done a compression test?

are all the spark plugs firing correctly?

did you degree in the cam or just DOT-to-dot install it?

whats your fuel pressure?

have you verified the carbs float levels?

does fuel run out the site holes at idle?

are the needle& seat valves working correctly?

whats your ignition timing?

do you have voltage at the coil?

whats your plenum vacuum?

have you verified the engine got no vacuum leaks?

whats the oil pressure?(did you check the dip stick?)

have you adjusted the valves at idle?

does the distributor timing advance with rpm increases?

have you tried a different carb?

what are the plugs gaped at?

does this happen without an air filter?

have you verified you've have functioning power valves?

what jets are you using?

is there visible fuel flow from the boosters?

whats your battery voltage?

whats your exhaust back pressure?

are you totally sure the fuel free of water and fresh?

have you pulled trouble codes?

knowing whats going on and WHY can help , and a V.O.M. meter , code scanner, timing light, vacuum/fuel pressure gauge and a shop manually are basic tools

MORE GOOD INFO

http://www.corvettefever.com/techarticl ... index.html

http://members.shaw.ca/corvette86/Compo ... w%2086.pdf

http://members.shaw.ca/corvette86/FuelS ... gnosis.pdf

http://chevythunder.com/lt1_electrical_page.htm

http://chevythunder.com/Flow%20chart%20 ... rt%20Pages

http://chevythunder.com/fuel%20injectio ... 20DIAGRAMS

Ill assume that youve verified the ignition timing PER THE SHOP MANUAL and that your getting spark plug electric SPARK,and your just having a slow or intermitant start most of the time, and it doesn,t seem to matter if the engines cold, warm or hot, and that at times it starts regularly but most of the time it requires several tries but once started it runs decently?

Now by that IM referring to cars that when the ignition spins the engine over freely the engine takes its own sweet time catching, in most cases a simple test will indicate a common source of that problem.

step one

get in the car and turn the ignition key only far enought that the fuel pump runs, and pressurizes the fuel rails and shuts off, don,t turn the key to the point the engine spins on the starter, remove the key and repeat three times.

step two

on the fourth try on the start process attempt to start the car, by spining the engine over, if you find that it almost always starts under that condition its a strong indicator that the fuel rail pressure is dropping off and the prime suspect is the fuel pressure regulator, and a leaking diaphragm.

you should see a minimum of 37 psi on a tpi, 40psi-42 psi on a LT1 at the fuel rails.

replacing the OEM fuel pressure regulator with an adjustable aftermarket fuel pressure regulator will generally result in the problem being reduced or eliminated.

other common potential problems are clogged/defective fuel filters or defective fuel pumps, fuel pump relays or fuses, leaky injectors fuel pump inlet screens or a bad fuel pump.

drop back to the basics

your shop manual will be a big help, and having a code reader and a vom meter will prove to be very useful.

check that youve got 40-47 psi on an LT1 fuel rail and no less than 37 psi on a TPI fuel rail, injectors should read about 12-14 ohms resistance, spark plugs should look like they are burning correctly, the ignition wire should have similar resistance readings, the fuel pump should run once theres 5 psi or oil pressure and the engines spinning, read thru the links below carefully

related useful linked info, you really should read thru as the sub links contain a ton of useful info

viewtopic.php?f=32&t=764

http://www.chevyhiperformance.com/howto ... index.html

http://www.gmhightechperformance.com/te ... index.html

TPI Torque Specifications

Below are the torque specifications as designated by GM for Tuned Port Injection intakes. Please note that some specifications are in lb. ft., and some are in lb. in.

Manifold to Runner Bolts 25 lb. ft.

Runner to Manifold Bolts 25 lb. ft.

Fuel Rail Attaching Bolts 15 lb. ft.

Throttle Body Attaching Bolts 18 lb. ft.

Throttle Position Sensor 18 lb. in.

Idle Air Control Valve 13 lb. ft.

Throttle Body Coolant Plate 27 lb. in.

Throttle Body Cover Plate 30 lb. in.

Power Brake Vacuum Fitting 108 lb. in.

Fuel Line Nuts 20 lb. ft.

Fuel Tube Bracket Bolt 25 lb. ft.

Fuel Pressure Connection 115 lb. in.

Pressure Regulator Base to Rail 44 lb. in.

Pressure Regulator Bracket 44 lb. in.

Outlet Tube to R/H Rail Retainer 44 lb. in.

USE THE DATA BASE SEARCH FEATURE, Search FOR ANSWERS DON,T GUESS

http://forum.grumpysperformance.com/viewtopic.php?f=57&t=853&p=1320#p1320

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=196

http://forum.grumpysperformance.com/viewtopic.php?f=70&t=1411

http://forum.grumpysperformance.com/viewtopic.php?f=70&t=967

http://forum.grumpysperformance.com/viewtopic.php?f=50&t=1912

http://forum.grumpysperformance.com/viewtopic.php?f=32&t=1148

viewtopic.php?f=32&t=1773

viewtopic.php?f=32&t=596

viewtopic.php?f=32&t=303

this info may help

http://www.corvettebuyers.com/ecm.html

http://www.aldlcable.com/

don,t forget to pull trouble codes in your search for answers

BTW SUSPECT A VACUUM LEAK?

get out your oxy-acetylene torch or a propane torch, don,t light it but turn it on so gas is flowing and place the tip near any suspected leak points, while a buddy watches the tach, anytime the gas gets sucked thru a crack the rpms will jump higher in direct relation to the amount of extra fuel the engines getting, no, oil, fluid,or cruds or stains are left on the intake and its simple too do process

take it a step at a time,set the fuel pressure at 40psi, check for vacuum leaks, and adjust the IAC and TPS and set the timing at 8 degrees per the manual,then drive it for 30 minutes to let the computer learn the conditions it operates in

http://forum.grumpysperformance.com/viewtopic.php?f=32&t=168

http://forum.grumpysperformance.com/viewtopic.php?f=70&t=875

http://forum.grumpysperformance.com/viewtopic.php?f=50&t=821&p=1212&hilit=propane+leaks#p1212

http://forum.grumpysperformance.com/viewtopic.php?f=32&t=1401

viewtopic.php?f=50&t=10623&p=45691#p45691

http://forum.grumpysperformance.com/viewtopic.php?f=70&t=1809

or occasionally I hear about intermittent missing, that needs to be isolated and tracked down to be corrected.

READ THE THREAD THRU TO THE END

AND BE AWARE THAT THIS THREAD,

AND ALL OTHER THREADS ON THIS SITE ARE CONSTANTLY UPDATED WITH NEW LINKS AND INFO, AS IT BECOMES AVAILABLE

it is always helps to post your location,when posting questions, at least the city & state your located in because theres a good chance an experienced hobbyist or mechanic on this site may be reading this, located local to you, who is willing to help either for free or at low cost! or at least post advices and places to get parts locally

theres a great many links posted below that contain a vast amount of related info

STEP ONE PULL TROUBLE CODES, MANY TIMES THE CODES POINT YOU TO THE ISSUES

c4 & c5 corvette trouble codes

if your corvette won,t start or run, don,t panic its usually easy to locate the problems source, buy a CHEVY SHOP MANUAL FOR YOUR YEAR CORVETTE! RULE#1 never assume a damn thing ISOLATE ,TEST AND VERIFY...

garage.grumpysperformance.com

replacing a c-4 fuel pump

IF YOUR LOOKING TO JUST REPLACE A DEFECTIVE PUMP ILL OUTLINE THE BASIC STEPS YEAH I KNOW YOU WANT TO SKIP OVER AND IGNORE THE SUB LINKS... THAT WOULD BE A MISTAKE!! https://garage.grumpysperformance.com/index.php?threads/my-current-corvettes-383-combo.430/...

garage.grumpysperformance.com

FOR THAT YEAR CORVETTE

FOR THAT YEAR CORVETTEstart by purchasing AND READING a SHOP MANUAL FOR YOUR SPECIFIC YEAR CORVETTE

http://www.helminc.com/helm

the correct matching SHOP MANUAL CAN BE VERY USEFUL

this is not a shop manual but it might be helpful

these are shop manuals

Id start by, pulling trouble codes and cleaning the battery terminals and cable connections carefully, a great many problems blamed on battery's and fuses are basically high resistance or intermittent connections, then use a multi meter to see what your dealing with.

(yes even if the engine spins over easily and has ignition spark, cleaning the battery terminals usually helps reliability)

yes IM fully aware that theres at least a few guys on the site that would rather roll around naked in broken glass, than read thru links and do in-depth research before, just jumping into a project and start randomly spend money on replacement parts :lol: :roll: :....but for those who gentlemen who would rather track down the cause of a problem with a few tests and a shop manual and logically approach the issues , in a step bye step manor theres plenty of posted info

If your trying to isolate and test and get the engine tune correct, on any efi system,

Id suggest you leave the fuel pressure alone if its at least 40 psi and does not exceed about 58 psi,

and if the fuel pressures consistent, and set the spark plug gap at .043-.045 max and keep th engine coolant temps as consistent and near about 180F-190F as you can get them,

the fewer variable your forced to deal with the better, make the changes in INJECTOR PULSE DURATION and ignition advance curves

to vary the fuel/air ratios and cylinder pressure

to avoid detonation and tuning issues

always start by verifying what your dealing with in temps fuel pressure and sensor function, pull trouble codes and read and tuning instructions, get a shop manual and verify sensor functions and electrical connections electrical grounds, ignition firing orders, do a compression test and verify the valve lash, set the valves if that's required, and make sure your not dealing with partially clogged catalytic converter carefully, verify what your dealing with, don,t guess, verify.

I can assure you that most problems are related to guessing or defective sensors, or assuming somethings working, that you fail to verify, like the ohms resistance in ignition wire or the firing order or verifying TDC, vs the damper/timing tabs

having a set of multi meter/timing light, compression gauge, vacuum and fuel pressure gauges and a shop manual is critical.

The secret of effective diagnosis and troubleshooting is to have a logical plan.

The secret of effective diagnosis and troubleshooting is to have a logical, well-ordered system. Following a logical step-by-step procedure will get you to the root cause of a problem quickly and efficiently. and you can,t go into the process assuming you know the answer before you test, let the facts you find lead you to the answers,you may waste a great deal of time chasing what you assume is a bad injector or a faulty ignition only to find its a clogged fuel filter, low fuel pressure or a loose electrical connection, Repair manuals will have a diagnostic tree that goes in a logical progression. It will ask a question, usually yes or no, and depending on the answer will branch off in two or more directions. The last box in the tree will have the problem and how to correct it. The example shown is a simple one. A more complicated system will have branches going into specific tests and then have 2 or more branches from there depending on test results.

If your experiencing intermittent electrical issues you will obviously need to get out the shop manual for your year corvette, a multi meter and do some isolate and testing, but be aware that loose or corroded connections , will be hard to isolate, as they seldom present a consistent, solid open or dead short in the wire,theres several electrical connector plugs that connect thru the firewall near the battery location that are subject to corrosion issues and frame grounds that might be suspect, obviously theres sensors that can be defective.

links with lots of sub-links that should be useful, most guys ,faced with isolating an electrical issue, seem to get over whelmed, but if you get out the schematics, use a multi meter and some logic in tracing the circuits, and start pulling fuses and measuring resistance and voltage, take the time to read the manual ,pull trouble codes,and if required get a scan tool or a data logging program for your lap top computer, and using the shop manual, you can generally isolate the cause, but don,t get fixated on the idea that all misses are ignition, electrical related, theres potential mechanical, and fuel delivery issues that could be involved.

OK too trouble shoot a no start condition,you need to understand the basics, you need compression,in all cylinders, consistent fuel,pressure and volume,ignition spark, correct ignition timing, no vacuum leaks and the exhaust must not be really restrictive.

Don,t assume its a major problem, pull trouble codes and get out a multi-meter....check that your battery has 13 volts?, verify the starter spins the engine, verify your getting fuel pressure and ignition spark and when you find a problem trace it to its source. if you don,t have fuel pressure you should reasonably check in the fuel supply system, but don,t over look silly stuff like your fuel tanks empty, if your engine won,t spin over obviously check the battery and starter function,do you have an alarm or "VATS" system? if you have good battery voltage will the engine spin? are you getting spark at the plugs? and pull your spark plugs to be sure the engines not locked up hydraulically from a leaking head gasket.

LOOK FOR LOOSE OR CORRODED ELECTRICAL WIRING CONNECTORS, in THE WIRING HARNESS, and VERIFY YOUR FIRING ORDER, YEAH I KNOW YOUR SURE ITS CORRECT, CHECK IT CAREFULLY AGAIN, YOUR NOID TEST LIGHT AND MULTI- METER CAN SAVE YOU A GREAT DEAL OF PROBLEMS AND SCRATCHING YOUR HEAD IF YOU TEST BASIC ELECTRICAL CONNECTIONS< RESISTANCE AND VOLTAGE, CHECK YOUR SENSORS AND GROUNDS, A SHOP MANUALS MANDATORY, HEAT SENSORS, MAF SENSORS, AND IGNITION MODULES AND OIL PRESSURE SENSORS HAVE A LONG TRACK RECORD OF FAILING OR PARTIALLY AND INTERMITTENTLY NOT FUNCTIONING

if you have voltage at the ignition coil, and no spark don,t assume its a defective ignition coil , but if you have a spare coil swap it out as a quick test, won,t hurt, and it will help isolate the problem source.

also be aware that a leaking injector, or fuel pressure regulator can cause the catalytic converter, to melt internally, blocking the exhaust flow or oxygen sensors to fail

remember what goes in needs to go out UNRESTRICTED, and a clogged catalytic converter can cause the engine to run very poorly or not start at all.

ANYTIME YOUR DEALING WITH THE ENGINE AND HOW IT RUNS ,

YOULL BE DEALING WITH DIFFERENT ISSUES,

COOLANT AND OIL TEMPS,& PRESSURE

FUEL PRESSURE , INJECTOR FUNCTION

FUEL DELIVERY, PRESSURE & VOLUME

RELATED FUEL / AIR RATIO

EFFECTIVE COMPRESSION & RING SEAL

VALVE TIMING LIFT & DURATION & VALVE SEAL

IGNITION SPARK TIMING & STRENGTH, & IGNITION ADVANCE CURVE

EXHAUST BACK PRESSURE

SENSOR OUTPUT TO THE CPU

VOLTAGE & GROUNDS

ITS YOUR JOB TO TEST AND ISOLATE EACH UNTIL THE CAUSE IS LOCATED

READ

THE LINKS AND SUB LINKS,

THEY CONTAIN A HUGE AMOUNT OF RELATED INFO

http://garage.grumpysperformance.com/index.php?threads/c4-c5-corvette-trouble-codes.2697/

http://members.shaw.ca/corvette86/FuelS ... gnosis.pdf

http://garage.grumpysperformance.com/index.php?threads/testing-leaky-fuel-injectors.7310/

http://garage.grumpysperformance.co...ystem-trouble-shooting-flow-chart-info.11536/

http://garage.grumpysperformance.com/index.php?threads/replacing-a-c-4-fuel-pump.33/

http://garage.grumpysperformance.com/index.php?threads/chasing-a-crazy-electrical-glitch.986/

http://garage.grumpysperformance.co...lay-switch-locations-and-info.728/#post-43477

the "PROBLEM" is most people won't take the time or effort to diagnose a problem by logically isolating and testing each component before the parts are replaced,

and yeah its basically a two step problem, that having a SHOP MANUAL, for your particular year corvette ,

and a few basic tools like a FUEL PRESSURE GAUGE,MULTI METER, AND TIMING LIGHT, COMPRESSION TESTER,

and a CODE READER MAKE FAR EASIER, ISOLATE AND TEST ARE THE BASICS OF ANY REPAIR PROCESS>

you first have to understand how each component functions and how to test its functioning correctly.

it helps a great deal if you know the basics and have access to the tools required to test.

it helps a great deal if you understand how the various sub systems like ignition,

timing and terms like AMPS. VOLTS,RESISTANCE, and fuel delivery work, terms LIKE PRESSURE, VOLUME, and the basic 4 cycle engines design parameters.

theres not a single problem on a C4 CORVETTE, that can't be diagnosed with a shop manual, fuel pressure gauge, multi meter, exhaust back pressure gauge/vacuum gauge and an accurate infrared temp gun, timing light, compression/leak down tester, basic mechanics tools, a set of jack stands and a floor jack.

and a logical isolate and test mentality, if you have access to the internet to ask questions about related tests, PROVIDED you ask the correct questions and test to find the related answers,

yeah, having experience helps and tools like code scanners, degree wheels, dial indicators , a dial caliper, feeler gauges certainly help,

but you can solve problems by simply understanding how components are supposed to work, and how they can be tested to verify they are defective or not!

related info

http://garage.grumpysperformance.com/index.php?threads/c4-c5-corvette-trouble-codes.2697/

http://garage.grumpysperformance.co...oven-facts-if-your-in-doubt.13051/#post-88488

http://garage.grumpysperformance.com/index.php?threads/bare-minimum-tools.11026/#post-48779

http://garage.grumpysperformance.co...too-common-questions-can-be-found-here.12892/

http://garage.grumpysperformance.com/index.php?threads/leakdown-compression-test.881/#post-56489

http://garage.grumpysperformance.co...ard-starting-tpi-crossfire-or-lt1-vette.1401/

http://garage.grumpysperformance.com/index.php?threads/c4-and-camaro-sensor-and-relay-switch-locations-and-info.728/#post-93194

http://garage.grumpysperformance.com/index.php?threads/optispark-ignition-info.628/#post-75647

http://garage.grumpysperformance.com/index.php?threads/under-car-safety.26/

CHECK ALL YOUR FUSES and electrical connections WITH A MULTI METER, but don,t assume you know what the problem is, let the facts lead you to the answers

be aware that not all engine "MISSES" or "ticking sounds " that you might be dealing with or tying to correct, are an electrical or a fuel delivery or pressure issue, your problem might be a mechanical issue like a vacuum leak, from a busted hose,or loose gasket,a burnt valve, loose or worn timing chain,badly adjusted valves, broken or loose harmonic damper, loose flex plate, or torque converter bolt, busted valve spring, burnt or defective rocker, loose or worn valve guide, or a dozen other issues so try to logically isolate it to a cylinder or system, electrical,valve train, fuel delivery, exhaust , ignition ,etc.

WATCH THE VIDEO, READ THE LINKS

http://www.youtube.com/watch?v=9CPqbaSg ... re=related

http://www.chevythunder.com/fuel%20inje ... pg%20B.htm

IF you start with checking for loose electrical connections and vacuum leaks you might find the problem, a propane torch is both safer and easier to use as a method to locate vacuum leaks

check for vacuum leaks

(DONT LIGHT IT) just SLIGHTLY open the valve so its allowing gas to flow at a low volume,start the engine and let it idle at the lowest speed you can then place the tip of the UNLIT torch at any suspected vacuum leak and listen for the rpms to increase and watch the tachometer, gas flowing into a vacuum leak will increase engine speed.

Another possible quick test you can do relates to "clear flooded engine mode" if the car cranks but doesn't start and has fuel pressure, you can test by trying disconnecting the TPS sensor connection on the pass side of the throttle body,. This will kick the computer into limp home mode (setting a predetermined voltage) and the car will start after a time if you flooded the plenum in the intake

look for loose or missing vacuum hoses, cracked or broken power brake connections, emissions system hoses that are loose, vacuum connections to the trans or ignition, loose connectors missing or loose bolts cracked hoses missing accessory connections etc.

naturally this only locates leaks to the outside, and its possible for the intake to suck air from the lifter gallery, so that also needs to be checked if everything else seems to be ok.

read this

buy a CHEVY SHOP MANUAL FOR YOUR YEAR CORVETTE!

set and verify your ignition timing, pull trouble codes,set your tps and iac,, then check for vacuum leaks on the lines and intake,then get out your multi meter and verify all the sensors, chances are good its a defective heat sensor or defective o2 sensor, a logical step by step approach will lead you to the problem, youll be amazed at what youll learn reading links. use of a shop manual and multi meter can be very helpful

http://www.harborfreight.com/5-in-1-dig ... 98674.html

FLUKE is the brand of choice but they are expensive, shop around, Ive still got the original fluke multi meter I bought in HIGH SCHOOL and it STILL WORKSIve purchase several from harbor freight , in the last 10 years alone and only one still works

http://www.fluke-direct.com/shop/itemDe ... urer=FLUKE

http://www.fluke-direct.com/shop/catego ... TERS&path=

http://chevythunder.com/

a good quality if temp gun helps more than you might realize at diagnosing problems

http://www.grainger.com/product/EXTECH- ... _-AllPages

learn to use the factory shop manual, and a multi meter and LISTEN to the engine closely, tapping and high pitch whines can indicate defective injectors or fuel pressure regulators, fuel pumps,mis- adjusted valve train components, worn distributor parts, check all the fuses and electrical grounds and corrosion on connections thats something thats frequently over looked etc.

http://www.chevythunder.com/Flow chart index.htm

http://www.professionalequipment.com/ex ... ermometer/

https://www.summitracing.com/parts/anm-cp7838

and rev the engine a few times and watch the fuel pressure it should in theory remain in the 38 psi-42 psi range for most TPI and TUNED PORT efi

having a good cross check tool like a quality IR temp gun, and a decent multi meter, sure helps find the truth as far as a defective gauge or sensor

viewtopic.php?f=44&t=464

http://www.corvettebuyers.com/ecm2.html

http://www.hotrodlane.cc/NewTPI%20links ... ml#tpitech

http://www.mainstreamtopics.com/forums/ ... iagnostic/

http://chevythunder.com/

http://www.centuryperformance.com/tunin ... g-148.html

IF the dash lights but it won,t turn over,or just clicks,take off the battery cables and clean the connections then reassemble the trouble your describing is extremely common on theres cars if the battery connections are not cleaned occasionally, the bad connection passed enough low amp current to light up the dash but once the load increases its not able to supply the required current flow rates, if the engine spins but won,t start, obviously you'll want to check all your FUSES with the multi meter and verify the engine and ECU ground straps (usually on the back of the drivers side cylinder head)are tight connections

AND AGAIN! LOOK FOR LOOSE OR CORRODED ELECTRICAL WIRING CONNECTORS, in THE WIRING HARNESS, and VERIFY YOUR FIRING ORDER, YEAH I KNOW YOUR SURE ITS CORRECT, CHECK IT CAREFULLY AGAIN, YOUR NOID TEST LIGHT AND MULTI- METER CAN SAVE YOU A GREAT DEAL OF PROBLEMS AND SCRATCHING YOUR HEAD IF YOU TEST BASIC ELECTRICAL CONNECTIONS< RESISTANCE AND VOLTAGE, CHECK YOUR SENSORS AND GROUNDS, A SHOP MANUALS MANDATORY, HEAT SENSORS AND IGNITION MODULES AND OIL PRESSURE SENSORS HAVE A LONG TRACK RECORD OF FAILING OR PARTIALLY AND INTERMITTENTLY NOT FUNCTIONING

learn to use the factory shop manual, and a multi meter and LISTEN to the engine closely, tapping and high pitch whines can indicate defective injectors or fuel pressure regulators, fuel pumps,mis- adjusted valve train components, worn distributor parts, check all the fuses and electrical grounds and corrosion on connections thats something thats frequently over looked etc.

it helps a great deal to know what your working with ,ID suggest starting, by verifying TDC and having the correct timing tape on your damper then,start with 8 degrees btdc and verifying the full advance of 36 degrees total is all in at 3200rpm as a base line, once youve got that, as a standard you can tune and run the car and eventually try tweaks to the basic ignition curve if needed, once you have an ignition base line, move on to the carbs tuning, you also need to keep in mind that what goes in as a fuel /air mix needs to go out as a much expended volume of hot gases and a restrictive exhaust will effectively block most attempts to get more power from an engine, so measure exhaust back pressure. you might be amazed at what a couple hours research into the subject will do to help you build a much more durable engine, and actually reading thru links and sub-links and asking questions helps a great deal

you might be amazed at the number of times "CARBURETOR PROBLEMS" are cured with getting the IGNITION, TIMING AND ADVANCE CURVE WORKING CORRECTLY, and check out the simply things your 100% sure you did correctly, because I can,t begin to tell you how many times I see guys who have the firing order on the ignition wrong, or guys that install a 4/7 swap cam and still use the standard ignition firing order or guys that never verify TDC and ignition advance curves.

get an IR temp gun and check for wild variations in exhaust temps, get a compression test done, do a logical check to verify each cylinder fires etc.

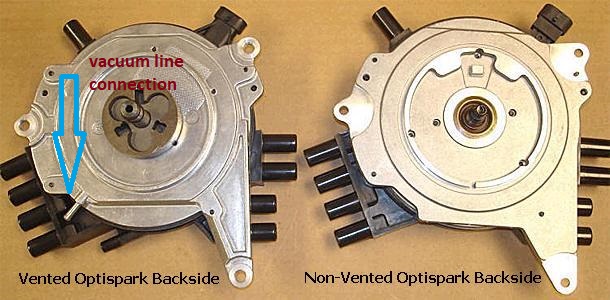

The ignition control module in the distributor is another item that normally fails when hot, that needs to be replaced is you suspect its defective

http://www.chevythunder.com/fuel_system_diagnosis.htm

http://www.chevythunder.com/fuel_pump_code_54.htm

http://www.chevythunder.com/Flow chart index.htm

get out your shop manual and multi meter

if you suspect the injectors , you first use a multi meter to verify every injector reads the same ohms (usually near 11-16 ohms, and yes they should all read very closely) then you need a noid kit for a G.M. fuel injection system, these are basically little lights that light as the injector pulse hits them that you plug into the injector harness,after you remove the harness from the injectors, they plug into the harness just like an injector, if you try to start the engine and they blink on and off the pulse is reaching the injectors thus proving that the injectors get the pulse

ANY TIME YOU SUSPECT FUEL INJECTOR OR FUEL SYSTEM RELATED ISSUES ,A REASONABLE START POINT IS TO USE A GOOD QUALITY FUEL INJECTION CLEANER ADDITIVE IN THE FUEL TANK AND SWAP TO A NEW FUEL FILTER

http://www.bgprod.com/catalog/gasoline- ... m-cleaner/

http://www.bgprod.com/catalog/gasoline- ... m-cleaner/

http://www.harborfreight.com/11-piece-n ... 97959.html

http://www.chevythunder.com/Flow chart index.htm

http://www.digitalcorvettes.com/forums/ ... p?t=197337

http://www.mainstreamtopics.com/forums/ ... iagnostic/

http://members.shaw.ca/corvette86/FuelS ... gnosis.pdf

[/color][/b]

keep in mind oil temp sensors and oil pressure sensors are notorious for going defective and reading wrong

then as always ,always drop back to the basics of compression,

air flow in and exhaust out of the engine,

ignition spark, strength and timing,

and fuel delivery,volume and pressure

oil pressure and temp

cooling,temps and fluid levels (fuel,oil,coolant)

computer controls and sensors

always drop back to the basics

have you verified theres no vacuum leaks

have you verified theres at least 37 psi of fuel pressure?

have you verified theres constantly ignition spark at the plugs?

have you verified theres spark at OR NEAR TDC on the power stroke with a timing light, timing tape on the damper and verified the timing marks are correct?

have you verified theres 12 volts at the coil?

have you verified the coil fires?

have you verified there spark at the plugs?

have you verified the injectors get voltage with a noid light?

have you verified the fuel injection fuses are good?

have you verified all the sensors are good?

all electrical connections are correct?

have you pulled trouble codes?

have you verified the firing order?

have you readjusted the valves so you know 100% that they are not too tight?

are you getting about 10psi of oil pressure or more as the engine turns over?

have you set tha TPS and IAC?

if you have not done a compression check and verified the valves are lashed correctly thats a good place to look , but only after the basics of ignition timing, spark, strength and fuel delivery are checked. your fuel pressure regulator , dirty injectors,clogged fuel filters loose connectors on injectors and sensors and ignition wire are frequently the cause as are corrosion on electrical connections, defective sensors., loose or broken vacuum lines.

Id check for fuel pressure is steady and spark is consistent first and verify the spark plug condition as clear pictures of the plugs numbered by cylinder can give a great deal of info

Id check for vacuum leaks , and loose battery connections and loose grounds

http://forum.grumpysperformance.com/viewtopic.php?f=80&t=728

http://www.corvettephotographs.com/c4vettes/codes.htm

http://www.international-auto.com/fiat- ... gauges.cfm

http://members.shaw.ca/corvette86/FuelS ... gnosis.pdf

http://www.thirdgen.org/injectorswap injector swap

http://www.thirdgen.org/tpimod2 IAC/ TPS

http://forum.grumpysperformance.com/viewtopic.php?f=32&t=168

http://forum.grumpysperformance.com/viewtopic.php?f=32&t=596

http://www.corvettebuyers.com/ecm.html

http://forum.grumpysperformance.com/viewtopic.php?f=32&t=3954

http://corvetteactioncenter.com/tech/c4 ... Z1XqJwcC10

http://tech.corvettecentral.com/2007/08 ... diagnosis/

get out your shop manual and multi meter

[/b][/color]

read thru these links

http://members.shaw.ca/agent86/Fuel Control And Delivery-8A.pdf

http://members.shaw.ca/corvette86/EngineCranksButWontRun.pdf

http://members.shaw.ca/corvette86/FuelSystemDiagnosis.pdf

http://members.shaw.ca/corvette86/No-Service Engine Soon - Light.pdf

http://members.shaw.ca/corvette86/SES Light On Steady.pdf

http://members.shaw.ca/corvette86/Non Scan Diagnostic Circuit Check.pdf

http://members.shaw.ca/corvette86/Engine to ECM Wiring Diagram 86.pdf

http://members.shaw.ca/corvette86/Component Location View 86.pdf

http://members.shaw.ca/corvette86/FuelSystemDiagnosis.pdf

http://garage.grumpysperformance.co...questions-can-be-found-here.12892/#post-66934

good info

http://www.go-fast.org/z28/diagnostics.html

http://www.corvetterecycling.com/category_s/63.htm

this process of finding the cause of a problem, is basically a detailed check list and once you understand what your looking at and what its supposed to do after each components tested, is basically a simple procedure if you test, and eliminating potential sources until you narrow it down to the cause, where you prove it then re-place, repair or adjust as required.

yes youll need to have some test equipment like, a shop manual, multi- meters and pressure gauges, timing lights etc. but its not that difficult

[b]STEP ONE IS ALWAYS GET A FACTORY SHOP MANUAL, AND READ THE LINKS BELOW

Verify fuel pressure,. by using a fuel pressure gauge on the shrader valve on the fuel rail, with a pressure gauge,

Verify injector pulse by using a noid light, & spark at the plugs by using a spark tester.

verify timing with a timing light

pull the trouble codes and check all fuses[/B]

http://www.mamotorworks.com/corvette.ht ... %20manuals

http://www.helminc.com/helm/Result.asp? ... ted_media=

http://www.factoryautomanuals.com/p-912 ... -only.aspx

http://members.shaw.ca/corvette86/FuelS ... gnosis.pdf

I frequently get questions about why cars, most of us own that are used mostly as weekend toys and not as daily transportation,cars that sit for a few days between use seem to be plagued with battery's that won,t stay charged, well ive gone over this a few times so heres a few links of related info

http://forum.grumpysperformance.com/viewtopic.php?f=36&t=3453&p=26193&hilit=vats#p26193

http://forum.grumpysperformance.com/viewtopic.php?f=36&t=520&p=645&hilit=vats+resistor#p645

http://forum.grumpysperformance.com/viewtopic.php?f=36&t=63&p=31920&hilit=starter+rebuild#p31920

http://forum.grumpysperformance.com/viewtopic.php?f=32&t=5926&p=18562&hilit=starter+rebuild#p18562

MAF SENSORS AND RELAYS ARE EASILY DAMAGED SO ALWAYS CHECK AND SUSPECT THOSE

BEFORE you start going nuts look at the obvious stuff first!

CHECK THAT YOUR IAC and TPS sensors are set and adjusted correctly, set your ignition timing, make sure theres fuel in the gas tank,and theres no blown fuses and see if youve got a STEADY 37-40 psi on the fuel rail

WHEN TESTING<be sure the fuel pressure gauge reads correctly by comparing it to a second test gauge, these fuel pressure gauges are frequently defective

CHECK ALL YOUR FUSES WITH A MULTI METER

check your fuse block with a meter , if the car won,t start, a common issue is blown injector fuses

theres two fuses one controls the drivers side one controls the pass side injectors

The secret of effective diagnosis and troubleshooting is to have a logical plan, and to follow it without skipping any steps.when ever you get into unexplained symptoms the answer remains the same....in every case,.... you drop back to the basics and do a few tests, (and until you gain experience you need the FACTORY SHOP MANUAL TO INDICATE THE TESTS, NEEDED AND THE EXPECTED RESULTS LISTED) get out a multi meter and verify every fuse is good, and you have 13 volts at the battery and youve got at least a 1/2 tank of fresh fuel, before you start chasing your tail, thinking about more complicated problems

find the cause, you isolate, each function or system or malfunction to its related components then test, each individually, use of the shop manual is almost mandatory

the next step is to get out your multi meter and carefully verify that ALL YOUR FUSES AND RELAYS WORK

if they check out and its very likely that they WILL NOT DO SO, ID suggest checking the connections on oil pressure sensor at the rear of the block next to the distributor, if they look ok,ID replace the oil pressure sensor at the rear of the block next to the distributor, the fuel pump will only continue to run after the first few seconds and you only get voltage to the ignition if this sensor tells the CPU youve got 5 PSI of oil pressure during the start-up procedure

Ive seen several corvettes with similar start, then stall issues that cleared up after replacing those sensors, Im reasonably sure the sensor INCORRECTLY and INTERMITTENTLY, indicate the oil pressure momentarily drops to ZERO causing the problem, but what IM sure of is that replacing the sensors cure the issue occasionally

http://forum.grumpysperformance.com/viewtopic.php?f=32&t=1401&p=8895&hilit=start+sequence#p8895

http://forum.grumpysperformance.com/viewtopic.php?f=32&t=2697

http://forum.grumpysperformance.com/viewtopic.php?f=32&t=596

http://www.73-87.com/7387garage/drivetrain/pkupcoil.htm

http://www.aa1car.com/library/dis.htm

http://members.shaw.ca/corvette86/Component Location View 86.pdf

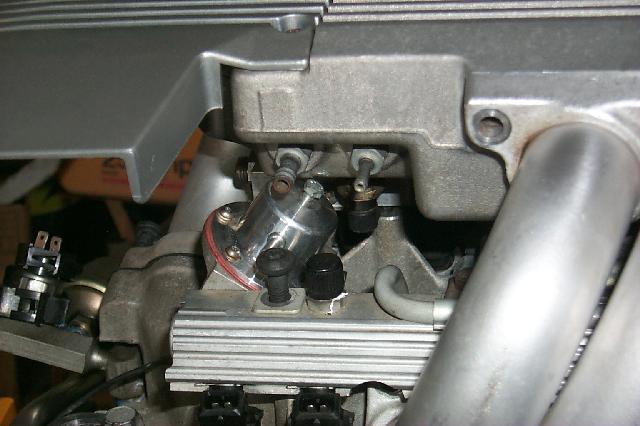

verify your fuel pressure stays up in the 37-40 psi range without falling much after the cars shut off for at least 5 full minutes, and it should stay at 37-42 psi if the fuel rail pressure does drop off in the first few minutes its almost always a leaky injector or bad fuel pressure regulator, and check for vacuum leaks either could cause your symptoms, remember the fuel pressure should stay fairly consistent while the cars running regardless of how fast or long the throttles quickly blipped or held wide open,and be sure the throttle linkage and blades move smoothly and don,t bind or stick at any point in the movement arc.

If you've got an early year TPI , that's designed to use a 9th cold start injector,check the cold start injector as its a potential problem source if its not working correctly.if your TPI won,t start, easily on the first try but starts easily on the second or third attempt, that's a very common indication of EITHER a leaking fuel pressure regulator (about 70% of the time), or less commonly a defective fuel pump(about 10%, of the time the pressures low or they leak internally) or leaking injector(s) (about 20% of the time)

but it can also indicate a partly clogged fuel filter, or rarely air filter , and in rare cases a defective oil pressure sensor switch which won,t let the ignition work until theres more than 5 psi of oil pressure

The secret of effective diagnosis and trouble shooting is to have a logical, well-ordered system. Following a logical step-by-step procedure will get you to the root cause of a problem quickly and efficiently. Repair manuals will have a diagnostic tree that goes in a logical progression. It will ask a question, usually yes or no, and depending on the answer will branch off in two or more directions. The last box in the tree will have the problem and how to correct it. The example shown is a simple one. A more complicated system will have branches going into specific tests and then have 2 or more branches from there depending on test results.

first check your shop manual for the fuse and fuse able link locations

fuses are located in several locations and fuse-able links near the battery

start with testing the fuel pressure in the fuel rails, that symptom is frequently the result of a DEFECTIVE fuel pressure regulator,or leaky injectors ,or a blown fuse or the blown fuse-able link near the battery, get a fuel gauge, installed on the fuel rail , it should reach 40psi almost instantly when you try to start the car and maintain 40psi or more at the fuel rail for at least 15 minutes, on the early TPI theres a 9th injector thats used to richen the f/a mix that might be defective, latter TPI versions just added pulse width to the injectors during the first few minutes of run time. keep in mind,wet, loose, or broken electrical connectors or corrosion on connectors, is also possibly a cause of intermittent problems

BTW To remove the connector from the injector, push carefully in the middle of the locking clip, with your thumb, This will make the sides, and tips move OUT WARD in their connector slots allowing the tips that hold the injector into the connector to slide out of the way from the injector body, and you can then pull the sides away. WATCH the locking clip - IT can and WILL come off and get lost, if your not careful

IVE generally found no problem with any corvette LT1 or TPI efi if it will quickly build a minimum of 38-40PSI on start up and MAINTAIN at LEAST 38-40 psi for a MINIMUM of 10 minutes after the engines turned off, 40-42 lbs is what the factory tests want and expect so if your getting 38-40psi your pressure readings indicate a normal, perhaps even better than average pressure reading, and more than expected pressure retention,

IF you suspect a TPI has a defective injector that's leaking or not flowing fuel,or partly clogged...You can also test this, to a degree, with a fuel pressure gauge

you can install a fuel pressure gauge on the fuel rail, and turn on the ignition key then watch the gauge, it should jump to 37-42 psi then remain fairly steady for at least 5 minutes before gradually loosing pressure.

If you can - and this is a pain in the butt to do, temporarily- remove the injectors. Leave them on the rail, but remove the rail. from the intake itself, This requires removing the majority of the TPI (P.I.T.A. but required).

HERES HOW

http://www.thirdgen.org/injectorswap

Remove the rail, but leave it connected to the fuel lines.

Next up, put a strip of cardboard under each bank. Then, have a buddy turn the ignition key on but not try to start the engine , you should hear the fuel pump run for 3 seconds while you look to see what happens. You should get an immediate spray of fuel.(all should be about equal and no injector remains dripping fuel) now have your buddy Turn off the key, while you watch closely to see which injectors are leaking.

youll be amazed at what you can learn, by reading thru links and sub links provided below

http://forum.grumpysperformance.com/viewtopic.php?f=32&t=596