Tried making some ingots they seem ok but I may be getting the melting pot too hot I'm getting a bluish- brownish sheen at the top of the melted lead I skim it and it reappears before I scoop the stuff off can it be too hot or could that be impureitys out still or maybe my sorting needs to get better

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Here We Go Again

- Thread starter rlphvac

- Start date

your sorting may need work, but thats not the issue,

thats very common, if you have fluxed and skimmed the lead in a couple times,

and theres no obvious crud surfacing any longer youll be ok

its just antimony content and oxidation, and if your a bit too hot it won,t hurt anything

thats very common, if you have fluxed and skimmed the lead in a couple times,

and theres no obvious crud surfacing any longer youll be ok

its just antimony content and oxidation, and if your a bit too hot it won,t hurt anything

Well I got as far as making some ingots and collecting some lead but I didn't realize the timing was terrible most molds and dies are out of stock and I'm waiting to see what happens in all this craziness but mostly everything I know I need is sold out just getting some lists together and waiting for a guy I work with to let me know what he wants to get rid of. He went to a couple of estate sales and got a lot of stuff but he's going through it and I will go through what is left. We were BSing one day at work and found out we both collected guns and reloaded and when he found out what I shot he was mad at himself for not buying other calibers that I shoot and he doesn't anyway do you use gas checks for any of your pistol loads and how do you get your tin for mixing with your lead and lastly what do you run for your 10mm I would like to find a 165g or a 160g setup to make and load and I owe you one for advising me about the EAA 10mm I was so impressed with it that I just ordered a 9mm polymer one and as soon as it comes in I will give a range report

Ok yes I use gas checks on MOST handgun bullets , the 45 acp generally works rather well even without them,

but in most cases gas checks add noticeably to consistent accuracy, especially in the 357, 500 S&W and 44 mag pistols

as Im sure youve noticed 10mm bullet molds that have been designed for gas checks are rather limited.

the 155-200 grain bullets in a 10mm are what give you the needed penetration and expansion youll want for defensive and hunting usage.

blue dot powder seems to work well in the 10mm,

I generally use non-gas check hard cast for plinking and hunting and something like this, coper plated bullet linked here for defensive use

https://www.berrysmfg.com/product/bp-40-401-180gr-hhp

http://10mm-reloaded.com/

https://www.alliantpowder.com/reloa...wderlist.aspx&type=1&powderid=10&cartridge=30

https://www.hodgdonreloading.com/data/pistol

but in most cases gas checks add noticeably to consistent accuracy, especially in the 357, 500 S&W and 44 mag pistols

as Im sure youve noticed 10mm bullet molds that have been designed for gas checks are rather limited.

the 155-200 grain bullets in a 10mm are what give you the needed penetration and expansion youll want for defensive and hunting usage.

blue dot powder seems to work well in the 10mm,

I generally use non-gas check hard cast for plinking and hunting and something like this, coper plated bullet linked here for defensive use

https://www.berrysmfg.com/product/bp-40-401-180gr-hhp

http://10mm-reloaded.com/

https://www.alliantpowder.com/reloa...wderlist.aspx&type=1&powderid=10&cartridge=30

https://www.hodgdonreloading.com/data/pistol

Last edited:

https://www.precisionreloading.com/cart.php#!l=LY&i=2670638

https://www.midwayusa.com/product/1010210259?pid=569185

https://www.midwayusa.com/product/1010212281?pid=642322

https://www.midwayusa.com/product/1010223071

a gas check design

http://www.accuratemolds.com/bullet_detail.php?bullet=40-200B-D.png

https://www.sagesoutdoors.com/40-bss-caliber-caliber-gator-gas-checks/

there are commercial ingot sales of casting alloy tin,

but most guys buy 50% tin/50% lead solder,

as a source for tin, from larger hardware stores or off the internet.

you only need 3%-5% by weight for good casting alloy

https://www.rotometals.com/tin-ingo...MIjpnM5I2g6QIV1uzjBx3fFgDXEAQYASABEgJAavD_BwE

https://www.metalshipper.com/tin-ba...MIjpnM5I2g6QIV1uzjBx3fFgDXEAQYAyABEgLkNvD_BwE

purchase of the equipment required to cast and lube bullets,

is going to rather significantly reduce the cost of reloaded ammo,

as projectiles are one of the more expensive components,

while it may not at first look like a major source of savings,

it will over time be a very noticeable help.

obviously the more you shoot,

the bigger the savings over the same number of cartridges in commercial ammo.

reloads generally will cost you less than 50% of the cost of commercial ammo,

reloads using cast bullets generally reduce that a further 20% or more,

IE down to about 30% of the cost of commercial ammo

https://www.midwayusa.com/product/1010210259?pid=569185

https://www.midwayusa.com/product/1010212281?pid=642322

https://www.midwayusa.com/product/1010223071

a gas check design

http://www.accuratemolds.com/bullet_detail.php?bullet=40-200B-D.png

https://www.sagesoutdoors.com/40-bss-caliber-caliber-gator-gas-checks/

there are commercial ingot sales of casting alloy tin,

but most guys buy 50% tin/50% lead solder,

as a source for tin, from larger hardware stores or off the internet.

you only need 3%-5% by weight for good casting alloy

https://www.rotometals.com/tin-ingo...MIjpnM5I2g6QIV1uzjBx3fFgDXEAQYASABEgJAavD_BwE

https://www.metalshipper.com/tin-ba...MIjpnM5I2g6QIV1uzjBx3fFgDXEAQYAyABEgLkNvD_BwE

purchase of the equipment required to cast and lube bullets,

is going to rather significantly reduce the cost of reloaded ammo,

as projectiles are one of the more expensive components,

while it may not at first look like a major source of savings,

it will over time be a very noticeable help.

obviously the more you shoot,

the bigger the savings over the same number of cartridges in commercial ammo.

reloads generally will cost you less than 50% of the cost of commercial ammo,

reloads using cast bullets generally reduce that a further 20% or more,

IE down to about 30% of the cost of commercial ammo

Last edited:

Cost is not a real issue to me I learned on reloading that it saves money in the longer term but requires a short term investment when I started I was going to load for 9mm and 45ACP mostly because of Omuslims policy's hurting the ammo sales but it expanded quickly I reload for 32 different calibers and I have a small fortune in equipment and it gets used weekly thats why my plan was to go ahead and buy everything I needed then expand to the things I overlooked but in looking for molds dies and things everyone is low on stock and I'm thinking that the ammo panic carried over to the casting also just like it did the reloading stuff so I will keep looking until I find a matched set of molds and dies and buy them and keep on the hunt I wanted to buy a large quanity of 9mm and 45ACP bullets just to use up some brass I have and get some time in on the progressive press but there are none to be had they're like toilet paper everyone panic bought but I did my panic buying in the last 3-4 years on ammo when it was available and cheap

Grumpy I'm having a hard time finding what I need for casting I've come across a few but cant find anything in 10mm that I like or a set of someone who has the mold ,lube/sizer and top punch in 10mm they have RN180, RN200 or SWC in 175 or SWC in 150 I really liked the 165 G plated HP that I loaded with Blue Dot any suggestions what way to go I'm wondering if 150 will be to light this is more for plinking and playing I don't see me hunting with a 10mm and if I ever decide to I'll buy whats needed

150 grain are fine for plinking, Id suggest buying only 100 of each type you care to try untill you find what you like

watch the shipping cost, it varies a great deal between vendors

https://www.usreloadingsupply.com/400-bullet-tips

https://www.powdervalleyinc.com/product/berrys-401-40-155-grain-round-shoulder/

https://www.natchezss.com/berry-s-s...ullets-40-cal-10mm-401-180-gr-rs-1000-ct.html

https://www.evergladesammo.com/bullets/10mm-180gr-hap-500ct-hornady-400421.html

https://www.nereloading.com/index.php/bulk-pistol-handgun-reloading-bullets/40-smith-wesson.html

https://www.rmrbullets.com/product-category/bullets/pistol/40-10mm/

watch the shipping cost, it varies a great deal between vendors

https://www.usreloadingsupply.com/400-bullet-tips

https://www.powdervalleyinc.com/product/berrys-401-40-155-grain-round-shoulder/

https://www.natchezss.com/berry-s-s...ullets-40-cal-10mm-401-180-gr-rs-1000-ct.html

https://www.evergladesammo.com/bullets/10mm-180gr-hap-500ct-hornady-400421.html

https://www.nereloading.com/index.php/bulk-pistol-handgun-reloading-bullets/40-smith-wesson.html

https://www.rmrbullets.com/product-category/bullets/pistol/40-10mm/

I think I settled on the 170 gr SWC now I can't find it some vendors have 1 thing some have 2 out of 3 RCBS doesn't even list the parts other vendors are selling as RCBS parts this has been a 3 month tail chase for nothing I'm getting so disgusted this whole lot is about 1 second away from the trash can not 1 vendor lists what sizer and punch you need for their molds I found a .400 mold from RCBS and they don't even list a sizer or punch foe .400 this whole deal is running out of fun real quick this isnt supposed to be work

for 10mm you should be looking for a .401 sizer and they vary depending on the lube sizer brand and model

https://www.midwayusa.com/s?userSearchQuery=.401+sizer+die&userItemsPerPage=48

top punch is generally listed with the sizing dies or bullet mold but it would certainly not hurt to call the bullet mold manufacturer to ask their suggested top punch

and they vary depending on the lube sizer brand and model

lee makes the least expensive but certainly not the best lube sizer

you don,t need a top punch with the lee sizer since each bullet is used to force the previous one through the sizer

https://www.midsouthshooterssupply.com/item/0000690060/lube-and-size-kit-point401-diameter

http://garage.grumpysperformance.co...re-a-more-durable-lube-sizer.9299/#post-56177

https://www.midwayusa.com/s?userSearchQuery=top+punch+chart&userItemsPerPage=48

https://www.midwayusa.com/s?userSearchQuery=.401+sizer+die&userItemsPerPage=48

top punch is generally listed with the sizing dies or bullet mold but it would certainly not hurt to call the bullet mold manufacturer to ask their suggested top punch

and they vary depending on the lube sizer brand and model

lee makes the least expensive but certainly not the best lube sizer

you don,t need a top punch with the lee sizer since each bullet is used to force the previous one through the sizer

https://www.midsouthshooterssupply.com/item/0000690060/lube-and-size-kit-point401-diameter

http://garage.grumpysperformance.co...re-a-more-durable-lube-sizer.9299/#post-56177

https://www.midwayusa.com/s?userSearchQuery=top+punch+chart&userItemsPerPage=48

Last edited:

I called the company and the book and website were wrong and wouldn't let me buy what I wanted to buy after 3 calls and about 1 1/2 hours on the phone we got it straightened out and I have some other dies for 9mm and 45 ACPcoming I have some dies I bought used from a guy I work with so maybe I can get started I did cast some bullets for a 45 but I couldn't get them to lube and found out that I need a heater for under the press so thats on its way too

the need for the heater , to warm your lube sizer, depends on the lube viscosity your using, and the design of the lube sizer,

some lubes are much softer at room temps than others

https://www.midwayusa.com/product/1010367232?pid=712495

https://www.midwayusa.com/product/1010265531?pid=267941

https://www.midwayusa.com/product/1010366947?pid=709079

https://www.midsouthshooterssupply....00-lube-sizerlubricator-with-gas-check-seater

most commercial lubes will work on most lube sizers other than the lee, at room temps

as they are mechanically forced through the lube sizer, yes, heated lubes flow with less effort, and if you do enough reloading making your own lube is much cheaper

the lee assumes youll size the bullets and then pour a quart or so of them in a 2 gallon ziploc bag with a couple oz of ALOX then manipulate the bag full for several minutes until all the bullets, in the bag are coated evenly with liquid alox, then you pour them out and stand them on their base to dry on a large sheet of wax paper or tinfoil, for them to dry over a few days, it works for some bullet designs but it takes 3-5 days to semi dry enough to reload without making a total mess if you touch the bullets, as even a week later they will be semi-sticky

http://garage.grumpysperformance.com/index.php?threads/bullet-lube.4835/#post-84993

btw when I cast bullets, I try to run the lead temps up where I get a bit of a frosted,

surface on the bullets, this requires the lead to be a bit higher temp than that temp,

which leaves a shiny surface, but it also tends to result in more uniform size projectiles that fill the mold out uniformly and more and harder

,hardness.

I generally drop the cast bullets into,

a taller than average 7 gallon water filled bucket thats filled, to about 4" from the rim,

doing that tends to provide a slightly harder,

cast bullet that will reduce or prevent leading the rifling as long as a good lube is used,

in any handgun or rifle ,

thus improving accuracy consistently.

I generally size and lube cast bullets within an hour or so of being cast, and store them in old plastic 3 lb coffee containers

Id suggest use of a

Plastic Pail - 7 Gallon, White

Lead-antimony alloys with low to moderate amounts of antimony can be precipitation hardened. As they solidify the antimony becomes less soluble in lead, and precipitates out. Antimony precipitating into a matrix of solidified lead stresses the crystal matrix of the lead. The prestressed lead is harder than unstressed lead. Because lead is subject to creep, or stress-relaxation over time, the hardening process reverses itself very slowly.

When you size a bullet the alloy has to flow into a new shape of smaller diameter. Depending on the amount of sizing and the bullet design, some of this deformation happens close to the surface, especially through lead flowing into the lube grooves. However the bullet also becomes longer - a process which deforms the alloy all the way to the center. Deforming prestressed lead relaxes the prestress and makes the bullet soft wherever it was deformed. So, if you just size a heat treated bullet without lubing it first, the deformation is concentrated close to the driving bands, which deform into the lube grooves. If you lube the bullet first, the lube grooves become just about incompressible and the deformation reaches deeper into the bullet. Thus heat treatment benefit is largely lost if you size the bullet after it has hardened. (But remember it takes days to weeks for the precipitation to occur after quenching, so you can lube after quenching so long as you do it within say 2 to 4 hours.)

If technical discussions bore you, skip this post

What hardens Lead when quenched is just that there are lots of incorrect Tin and perhaps Antimony atoms lost in the crystalographic latice of the Lead, plus some small islands of various precipitated compounds around the boundaries of or in Lead crystals. Both the incorrect atoms and the small islands of various Tin and Antimony compounds restrict deformation of the Lead lattice at room temperature. If quenched quickly, more of the incorrect atoms will be trapped in the lattice, and the islands will be small. The effect of aging on precipitates is for them to grow. My observation in the Lab 30 years ago was that over time, precipitate effect on resistance to deformation grew for a while until the precipitates reached an optimum size, then gradually fell off.

The effect of rapid freezing should be strongest at the edges, and lesser in the interior of a casting, but I don't know how you would get at the interior of a casting to determine what the property gradient was, because of the Recrystalization effect I mention below.

During the high temperature period of cooling right after freezing, those incorrect Tin and Antimony atoms migrate to Lead crystal boundaries. The incorrect Tin and Antimony atoms distort the Lead crystal lattice, and it is a lower energy state for them to be at the crystal boundaries.

All the metals I am familiar with have some Recrystalization temperature at which they spontaneously reorganize their crystalographic lattice in order to reduce stresses in it. For purposes of Cold Work and elimination of the effects of Cold Work by Recrystalization, Lead acts as if is at high temperatures. That temperature for all the metals I am familiar with is about one-half of the melting temperature, expressed in degrees absolute: degrees Rankin or Kelvin. Lead and its alloys are about at that temperature when at room temperature. That which fuels the recrystalization is the stresses in the lattice. Supply any Cold Work, and the recrystalization should take off, and you will lose most of the effect of improper atoms, plus precipitates, plus cold work.

There are other hardening mechanisms at work in many other metals when you quench them, such as in the Iron-Carbon system, but none of them are useful in Lead-Tin-Antimony.

Lead freezes into a closely packed 3-dimensional pattern.

Alloying elements, either through getting lost in the pattern or forming compounds, stress the pattern.

Stressed patterns bend/stretch/twist/compress less easily.

Metals patterns spontaneously reorganize at a temperature known as the Recrystallization temperature, and lose most stresses.

The Recrystalization temperature for most Lead alloys is about room temperature.

Cold Work of a metal at its Recrystalization temperature should make Recrystalization happen immediately.

Other metals have hardening mechanisms that do not happen with Lead.

Click to expand...

some lubes are much softer at room temps than others

https://www.midwayusa.com/product/1010367232?pid=712495

https://www.midwayusa.com/product/1010265531?pid=267941

https://www.midwayusa.com/product/1010366947?pid=709079

https://www.midsouthshooterssupply....00-lube-sizerlubricator-with-gas-check-seater

most commercial lubes will work on most lube sizers other than the lee, at room temps

as they are mechanically forced through the lube sizer, yes, heated lubes flow with less effort, and if you do enough reloading making your own lube is much cheaper

the lee assumes youll size the bullets and then pour a quart or so of them in a 2 gallon ziploc bag with a couple oz of ALOX then manipulate the bag full for several minutes until all the bullets, in the bag are coated evenly with liquid alox, then you pour them out and stand them on their base to dry on a large sheet of wax paper or tinfoil, for them to dry over a few days, it works for some bullet designs but it takes 3-5 days to semi dry enough to reload without making a total mess if you touch the bullets, as even a week later they will be semi-sticky

http://garage.grumpysperformance.com/index.php?threads/bullet-lube.4835/#post-84993

btw when I cast bullets, I try to run the lead temps up where I get a bit of a frosted,

surface on the bullets, this requires the lead to be a bit higher temp than that temp,

which leaves a shiny surface, but it also tends to result in more uniform size projectiles that fill the mold out uniformly and more and harder

,hardness.

I generally drop the cast bullets into,

a taller than average 7 gallon water filled bucket thats filled, to about 4" from the rim,

doing that tends to provide a slightly harder,

cast bullet that will reduce or prevent leading the rifling as long as a good lube is used,

in any handgun or rifle ,

thus improving accuracy consistently.

I generally size and lube cast bullets within an hour or so of being cast, and store them in old plastic 3 lb coffee containers

Id suggest use of a

Plastic Pail - 7 Gallon, White

Lead-antimony alloys with low to moderate amounts of antimony can be precipitation hardened. As they solidify the antimony becomes less soluble in lead, and precipitates out. Antimony precipitating into a matrix of solidified lead stresses the crystal matrix of the lead. The prestressed lead is harder than unstressed lead. Because lead is subject to creep, or stress-relaxation over time, the hardening process reverses itself very slowly.

When you size a bullet the alloy has to flow into a new shape of smaller diameter. Depending on the amount of sizing and the bullet design, some of this deformation happens close to the surface, especially through lead flowing into the lube grooves. However the bullet also becomes longer - a process which deforms the alloy all the way to the center. Deforming prestressed lead relaxes the prestress and makes the bullet soft wherever it was deformed. So, if you just size a heat treated bullet without lubing it first, the deformation is concentrated close to the driving bands, which deform into the lube grooves. If you lube the bullet first, the lube grooves become just about incompressible and the deformation reaches deeper into the bullet. Thus heat treatment benefit is largely lost if you size the bullet after it has hardened. (But remember it takes days to weeks for the precipitation to occur after quenching, so you can lube after quenching so long as you do it within say 2 to 4 hours.)

If technical discussions bore you, skip this post

What hardens Lead when quenched is just that there are lots of incorrect Tin and perhaps Antimony atoms lost in the crystalographic latice of the Lead, plus some small islands of various precipitated compounds around the boundaries of or in Lead crystals. Both the incorrect atoms and the small islands of various Tin and Antimony compounds restrict deformation of the Lead lattice at room temperature. If quenched quickly, more of the incorrect atoms will be trapped in the lattice, and the islands will be small. The effect of aging on precipitates is for them to grow. My observation in the Lab 30 years ago was that over time, precipitate effect on resistance to deformation grew for a while until the precipitates reached an optimum size, then gradually fell off.

The effect of rapid freezing should be strongest at the edges, and lesser in the interior of a casting, but I don't know how you would get at the interior of a casting to determine what the property gradient was, because of the Recrystalization effect I mention below.

During the high temperature period of cooling right after freezing, those incorrect Tin and Antimony atoms migrate to Lead crystal boundaries. The incorrect Tin and Antimony atoms distort the Lead crystal lattice, and it is a lower energy state for them to be at the crystal boundaries.

All the metals I am familiar with have some Recrystalization temperature at which they spontaneously reorganize their crystalographic lattice in order to reduce stresses in it. For purposes of Cold Work and elimination of the effects of Cold Work by Recrystalization, Lead acts as if is at high temperatures. That temperature for all the metals I am familiar with is about one-half of the melting temperature, expressed in degrees absolute: degrees Rankin or Kelvin. Lead and its alloys are about at that temperature when at room temperature. That which fuels the recrystalization is the stresses in the lattice. Supply any Cold Work, and the recrystalization should take off, and you will lose most of the effect of improper atoms, plus precipitates, plus cold work.

There are other hardening mechanisms at work in many other metals when you quench them, such as in the Iron-Carbon system, but none of them are useful in Lead-Tin-Antimony.

Lead freezes into a closely packed 3-dimensional pattern.

Alloying elements, either through getting lost in the pattern or forming compounds, stress the pattern.

Stressed patterns bend/stretch/twist/compress less easily.

Metals patterns spontaneously reorganize at a temperature known as the Recrystallization temperature, and lose most stresses.

The Recrystalization temperature for most Lead alloys is about room temperature.

Cold Work of a metal at its Recrystalization temperature should make Recrystalization happen immediately.

Other metals have hardening mechanisms that do not happen with Lead.

Click to expand...

Last edited:

WW alloy and 4-5% tin works a bit better than pure lead and 5% tin but both work fine,

the ww alloy has some antimony in the blend

the ratio of tin is not too critical as anything 4%-6% is fine

anything over about 7% adds little extra additional benefits,

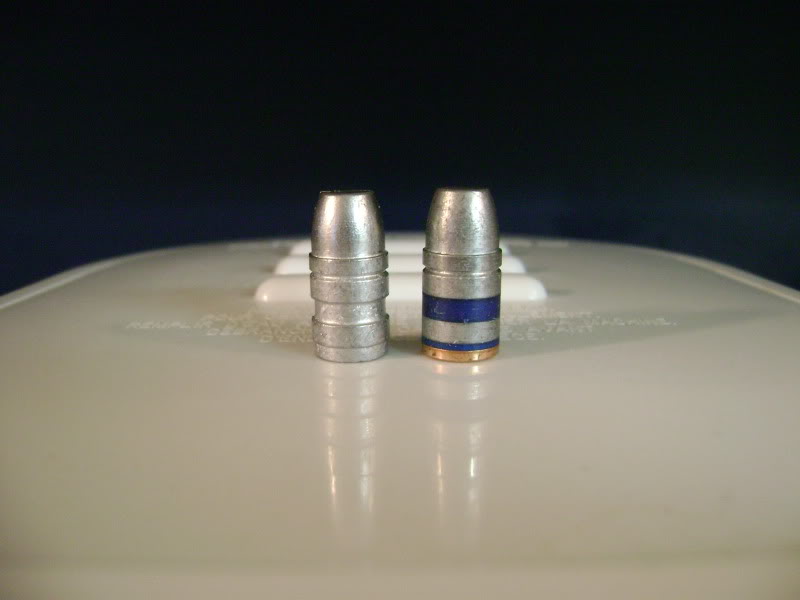

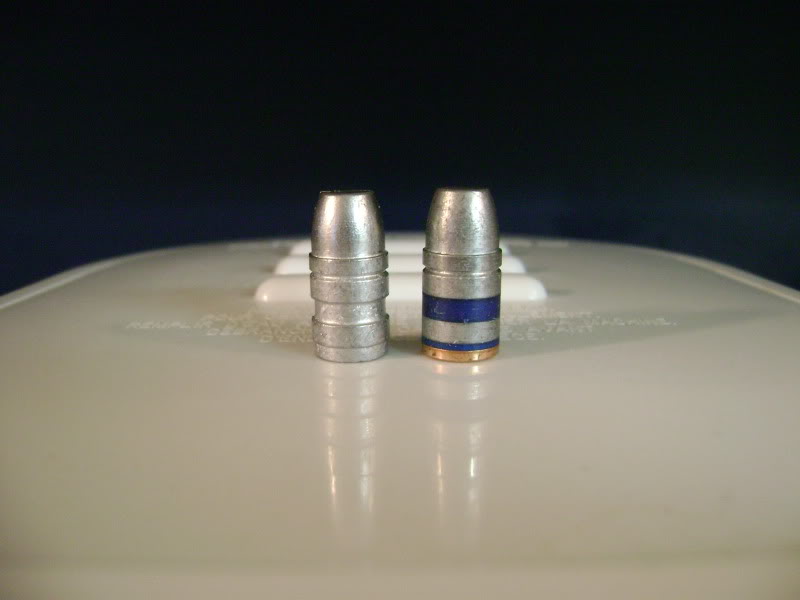

if you can do so post a few clear pictures of your cast bullets,

I can then generally tell if the casting temp and alloy

looks good, as stated earlier, drop them in a bucket of water ,

as it tends to make them harder and more uniform if cast a bit hot and marginally frosted,

bullets with wrinkles and/or shiny surfaces and rounded edge lube groves are generally less accurate and may contain voids or internal flaws

the ww alloy has some antimony in the blend

the ratio of tin is not too critical as anything 4%-6% is fine

anything over about 7% adds little extra additional benefits,

if you can do so post a few clear pictures of your cast bullets,

I can then generally tell if the casting temp and alloy

looks good, as stated earlier, drop them in a bucket of water ,

as it tends to make them harder and more uniform if cast a bit hot and marginally frosted,

bullets with wrinkles and/or shiny surfaces and rounded edge lube groves are generally less accurate and may contain voids or internal flaws

Last edited: