" hey PAUL?

, getting ready to reassemble the TPI system on my 1988 TransAm. Engine is completely rebuilt and has less than 100 miles on it. Everything is completely disassembled and I am in the cleaning part of the job. Are there any items that require measuring before assembly? I plan to use a set of the SLP runners. What is your opinion of using rtv on the gasket surfaces, or is it better to assemble dry ( except for the front and rear rails of the manifold and the water ports)? Any tricks to ensure a leak free reassemble? I have a Felpro gasket set and an SLP set for the runners. "

http://www.amazon.com/GearWrench-80588- ... g+torx+bit

youll need several torx bits in various lengths in T40 and T45

READ THRU THIS LINK

viewtopic.php?f=55&t=1378

viewtopic.php?f=44&t=366&p=448#p448

viewtopic.php?f=55&t=2773&p=7802&hilit=gasket+runner+port#p7802

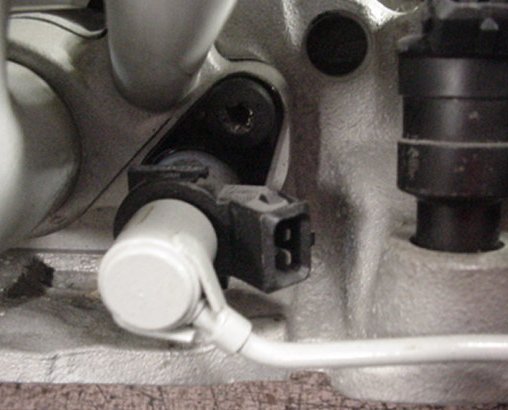

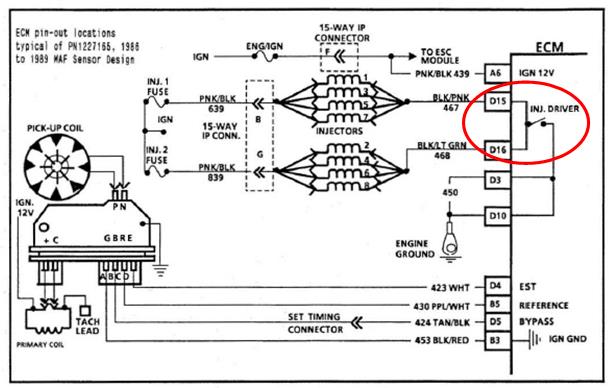

viewtopic.php?f=44&t=6204&p=19420&hilit=cold+start+injector#p19420

in most cases youll need a long torxs bit (#40 if I remember correctly)and a 1/4" drive with a swivel plus ratchet and extension to reach the inner bolts

http://www.zdmak.com/wbstore/main.asp?a ... =1&LowCt=0

remember the inner bolts holding the intake runners to the base, need to be accessed from the opposite side of the intake if the runners won,t come off easily

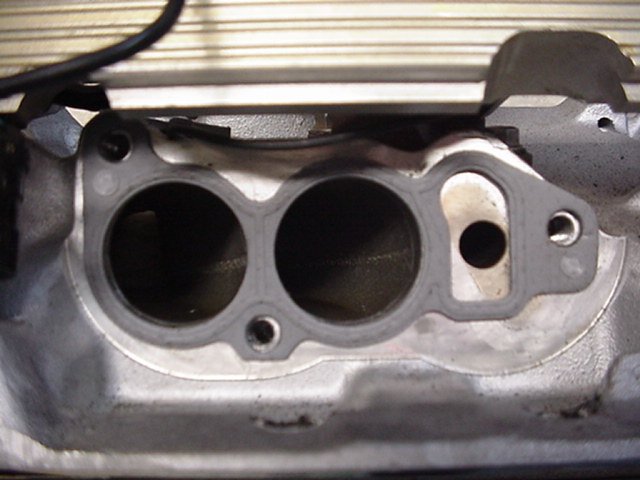

TPI intakes are notorious for minor vacuum leaks, but if you clean the gasket surfaces, and use a decent gasket sealant on both sides of the runner gaskets and carefully tighten the runners to both the base and plenum your very unlikely to have leaks

the best sealant I've found is this 3M BLACK weather strip adhesive

be VERY sure its the newer BLACK type not the older YELLOW version

remember the stuffs basically contact cement so you apply it to all gasket surfaces, let it dry for 5 minutes THEN assemble

READ THRU THIS LINK ALSO

http://www.corvettefever.com/techarticl ... to_08.html

most people find a set of extended torx bits very useful

http://www.superchevy.com/how-to/corp-0 ... epair.html

you simply run a 1/8" bead on both the runner ends and the plenum and base runner contact areas and a thin matching bead on both sides of the gasket surface then place align and install the runners and get ALL the bolts started before you tighten ANY of them, to make sure every things lined up correctly

be VERY sure its the newer BLACK type not the older YELLOW version

remember the stuffs basically contact cement so you apply it to all gasket surfaces, let it dry for 5 minutes THEN assemble

theres useful info in this link

http://www.thirdgen.org/injectorswap

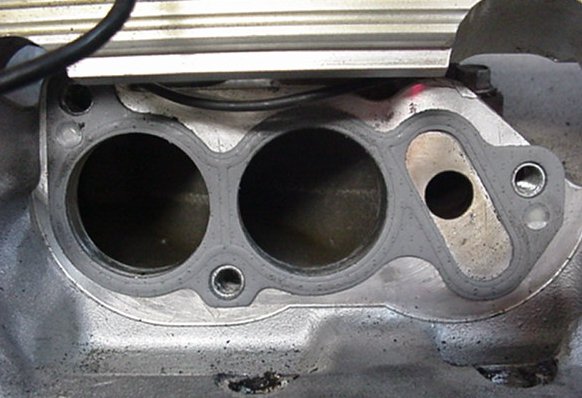

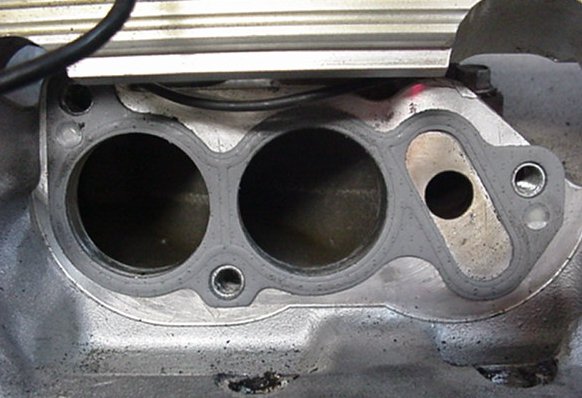

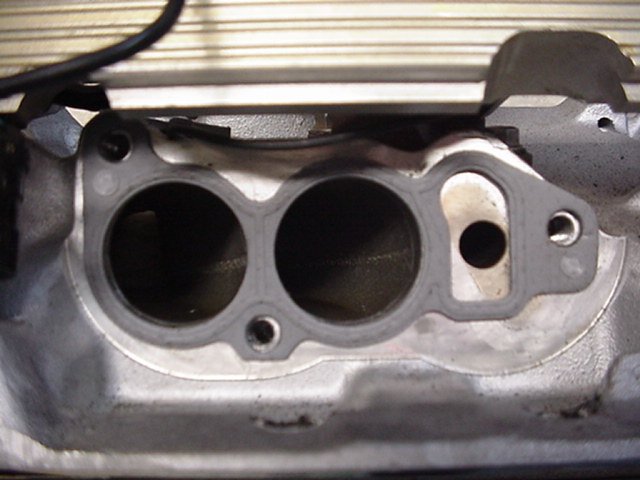

be aware that the lower runner gasket is not interchangeable between the drivers and pass sides of the engine on a tpi and if installed incorrectly that results in hard starts a big vacuum leak and an engine that won,t idle

, getting ready to reassemble the TPI system on my 1988 TransAm. Engine is completely rebuilt and has less than 100 miles on it. Everything is completely disassembled and I am in the cleaning part of the job. Are there any items that require measuring before assembly? I plan to use a set of the SLP runners. What is your opinion of using rtv on the gasket surfaces, or is it better to assemble dry ( except for the front and rear rails of the manifold and the water ports)? Any tricks to ensure a leak free reassemble? I have a Felpro gasket set and an SLP set for the runners. "

http://www.amazon.com/GearWrench-80588- ... g+torx+bit

youll need several torx bits in various lengths in T40 and T45

READ THRU THIS LINK

viewtopic.php?f=55&t=1378

viewtopic.php?f=44&t=366&p=448#p448

viewtopic.php?f=55&t=2773&p=7802&hilit=gasket+runner+port#p7802

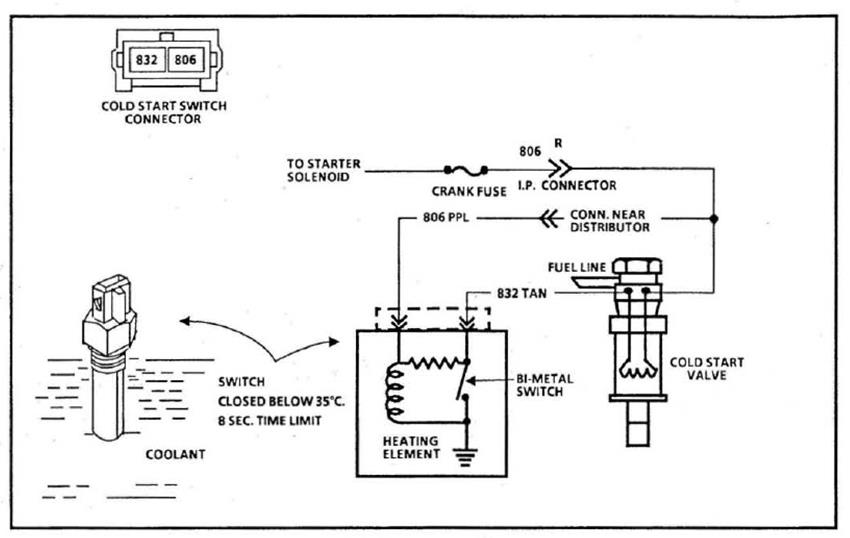

viewtopic.php?f=44&t=6204&p=19420&hilit=cold+start+injector#p19420

in most cases youll need a long torxs bit (#40 if I remember correctly)and a 1/4" drive with a swivel plus ratchet and extension to reach the inner bolts

http://www.zdmak.com/wbstore/main.asp?a ... =1&LowCt=0

remember the inner bolts holding the intake runners to the base, need to be accessed from the opposite side of the intake if the runners won,t come off easily

TPI intakes are notorious for minor vacuum leaks, but if you clean the gasket surfaces, and use a decent gasket sealant on both sides of the runner gaskets and carefully tighten the runners to both the base and plenum your very unlikely to have leaks

the best sealant I've found is this 3M BLACK weather strip adhesive

be VERY sure its the newer BLACK type not the older YELLOW version

remember the stuffs basically contact cement so you apply it to all gasket surfaces, let it dry for 5 minutes THEN assemble

READ THRU THIS LINK ALSO

http://www.corvettefever.com/techarticl ... to_08.html

most people find a set of extended torx bits very useful

http://www.superchevy.com/how-to/corp-0 ... epair.html

you simply run a 1/8" bead on both the runner ends and the plenum and base runner contact areas and a thin matching bead on both sides of the gasket surface then place align and install the runners and get ALL the bolts started before you tighten ANY of them, to make sure every things lined up correctly

be VERY sure its the newer BLACK type not the older YELLOW version

remember the stuffs basically contact cement so you apply it to all gasket surfaces, let it dry for 5 minutes THEN assemble

theres useful info in this link

http://www.thirdgen.org/injectorswap

be aware that the lower runner gasket is not interchangeable between the drivers and pass sides of the engine on a tpi and if installed incorrectly that results in hard starts a big vacuum leak and an engine that won,t idle