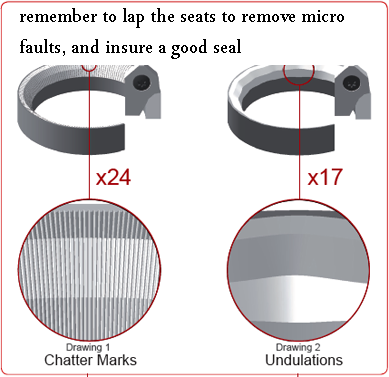

when you get a valve job they are supposed to seat and carefully test the seal of the valves, But you can test the valve to seat seal yourself by holding the heads so the ports are vertical and pouring in a bit of alcohol,or toluene and looking for leaks around the valve seats.

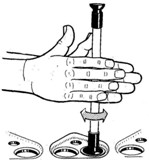

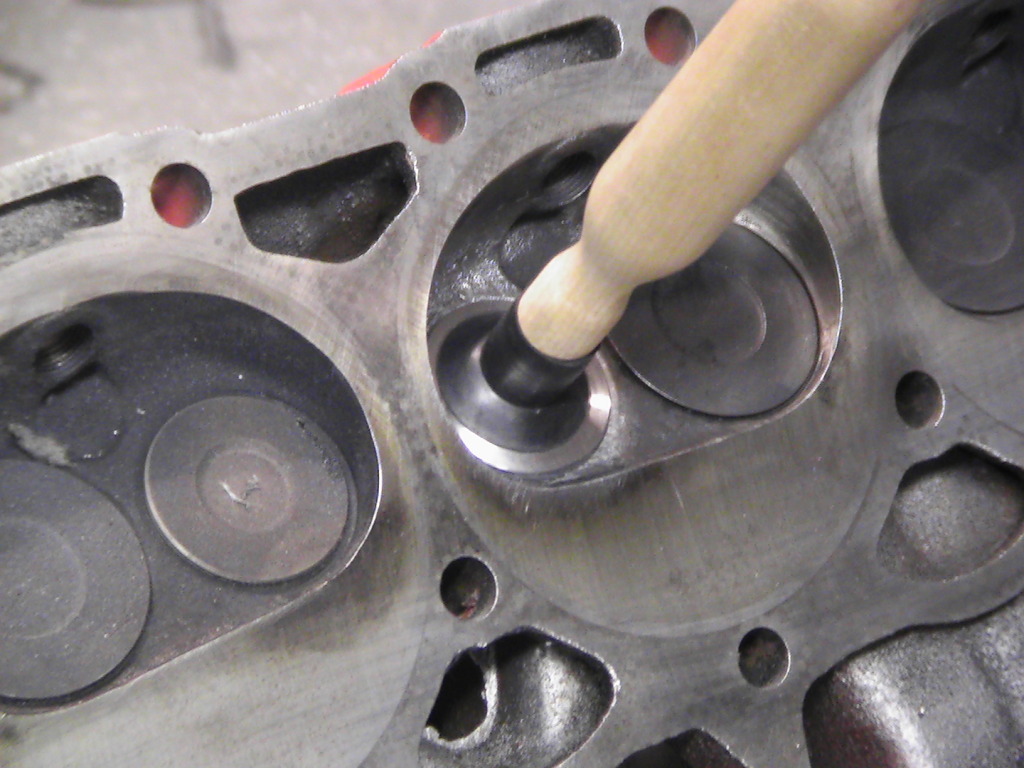

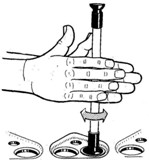

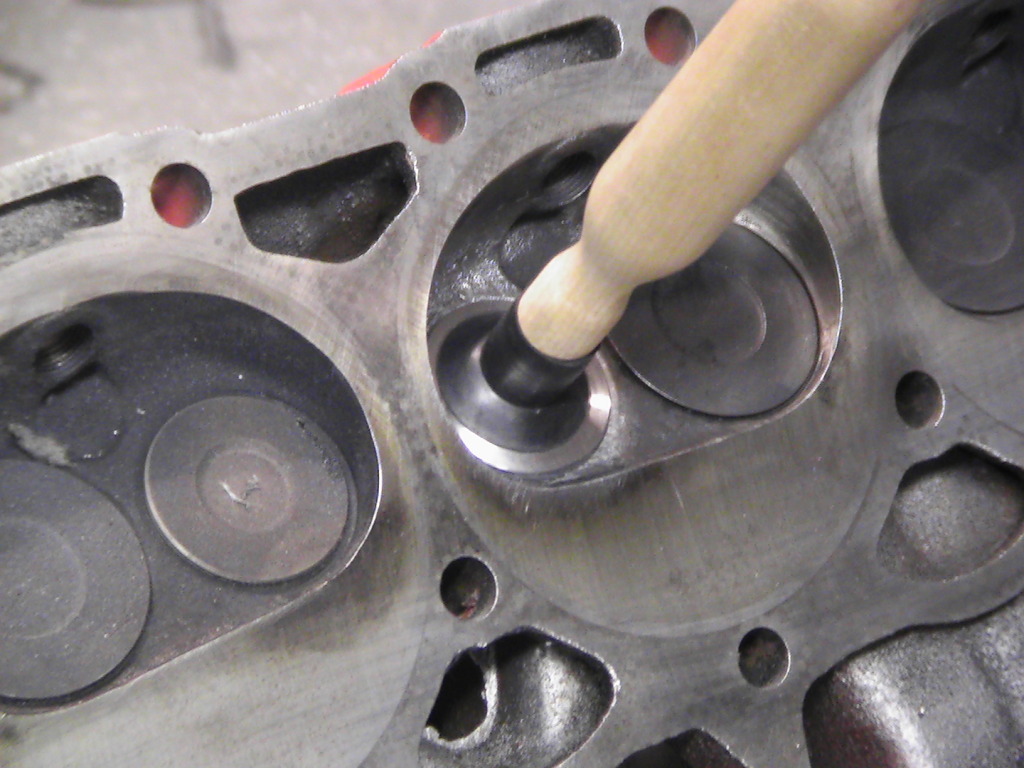

don,t get stupid and think you can check the valve in a drill and lap it into place, to be done correctly its done on low speed by hand in a constantly reversing rotation, so you don,t build heat and burn the seat

leaking or non-sealing valve seats lead to un-even heat on the valve, and can warp the valve and eventually can result in a burnt valve or ruined valve seat.

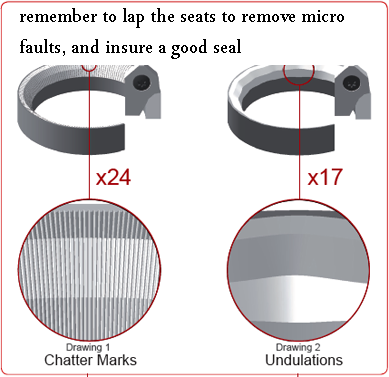

hot air mixed with fuel under pressures going to find minor leak points a whole lot faster than a bit of alcohol, so lap the valves into the seats so you get a good seal, during any test, its important you get a good seal, as you may as well prevent potential problems by making sure you get a good seal, rather than needing to replace a burnt valve.. now lapping valves by hand or with a hand held drill is very (OLD SCHOOL) and YES you can SCREW UP YOUR HEADS if you get a a good bit excessive, so use of a hand spun tool is advised as a drill is rarely useful,especially in un experienced hands, and the hand held tool does a good job with less worries about screwing up the seats, but you can also prevent a few problems if you know what your doing, so its an option, and checking your heads for leakage before you install them is always a good idea, in many cases a few minutes with 280 and 400 grit lapping compound will allow the valves to fully seat ,and seal.

DON,T FORGET THE EXTENSIVE CLEANING AND DE GREASING AFTER A FULL DISASSEMBLE ONCE THE JOBS DONE AND YOU MUST LABEL THE VALVES AND GET THEM PLACED BACK IT THE MATCHING LOCATION AFTER LUBING THE VALVE STEMS AND VERIFYING VALVE TRAIN CLEARANCES

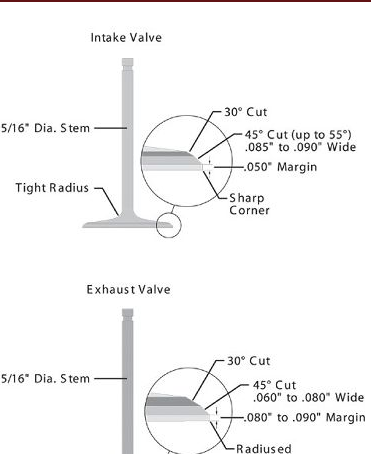

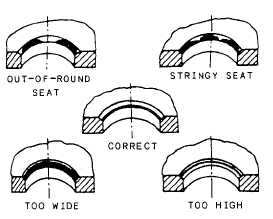

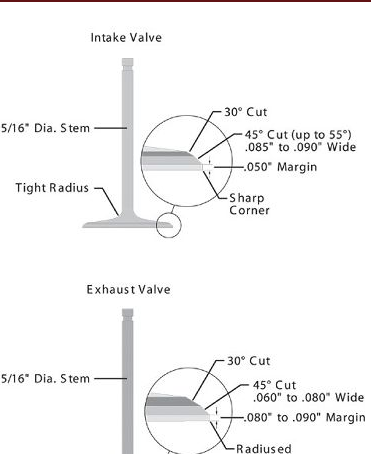

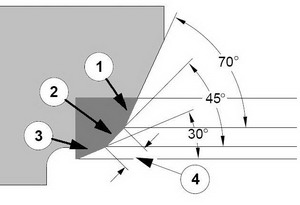

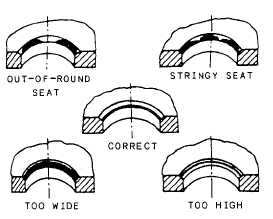

Most of the machinists prefer an intake-seat width of 0.040-0.060 inch. Narrower seats generally improve flow but are also less durable. Narrow seats work best on drag-race applications where the engine is freshened often, I generally try to go for durability and try to lap the seats to fall in the .050-.055 range on intake valve seats and .070-.080 on exhaust seat widths. Harder seat materials (e.g., induction-hardened seats) allow you to run slightly narrower seat widths than in the past while retaining excellent durability. Since exhaust valves operate at extreme temperatures, they require a wider seat to conduct heat away from the valve through the seat. Most shops specify 0.060- to 0.080-inch seat width for the exhaust side.

READ THIS RELATED THREAD CAREFULLY,

http://garage.grumpysperformance.com/index.php?threads/ccing-my-heads.14187/#post-71989

viewtopic.php?f=52&t=8460&p=29682#p29682

http://www.stockcarracing.com/techartic ... to_04.html

https://www.enginebuildermag.com/2013/10/cautioning-on-valve-seat-concentricity/

http://www.youtube.com/watch?v=96a44Qxy ... re=related

http://www.youtube.com/watch?v=fhXsH12R ... re=related

https://goodson.com/collections/cylinder-head-rebuilding-tools

http://www.cylinderheadsupply.com/kl8540.html

viewtopic.php?f=52&t=2091&p=5600&hilit=tools+valve+train#p5600

http://www.youtube.com/watch?v=I6o3BJFx ... re=related

viewtopic.php?f=52&t=1005&p=1818&hilit=tools+valve+train#p1818

http://garage.grumpysperformance.co...lve-seat-angles-and-air-flow.8460/#post-29682

viewtopic.php?f=52&t=1751&p=4387&hilit=tools+valve+train#p4387

youll need a few tools

http://store.summitracing.com/partdetai ... toview=sku

http://store.summitracing.com/partdetai ... toview=sku

http://www.newmantools.com/clover.htm

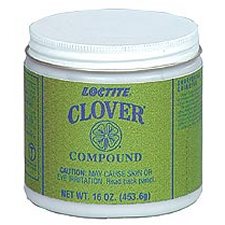

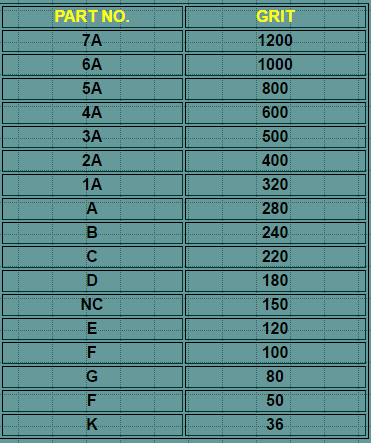

LAPPING COMPOUNDS

American Lap Company's lapping compounds are manufactured to exact specifications so a consistent finish is produced. We have our stock compounds listed below and make compounds to any specifications.

American Lap Company lapping compounds come mixed with a petroleum base or water base lapping vehicle. Our premium compounds come in one pound cans.

LAPPING ABRASIVES AND THEIR USES

Aluminum Oxide:Aluminum Oxide should be used on soft metals because of it's unusual grain structure, relatively high degree of hardness, sharpness and malleability. Aluminum Oxide will also cut hardened steels up to Rc 62. This compound is also adapted to the lapping of; machine spindles, bearings, dies, precision tools, hydraulic valves, injectors, spools and bodies and has many more uses.

Silicon Carbide:Silicon Carbide is only suited for the lapping of hardened metals due to its characteristics of extreme hardness and sharpness. But because of its brittleness and tendency to break down into very sharp pieces, thus produces scratches. Silicon Carbide's use is restricted to the lapping of most gears and large valves.

Boron Carbide:Boron Carbide is a very hard abrasive and is used for the lapping of materials with a high degree of hardness. Typical applications are for the lapping of carbides, ceramics and very hard tool steels.

Diamond iamond Lapping Compound is used to quickly lap the most difficult to cut materials. Diamond powders can be produced to very fine micron sizes therefore can produce finest finishes in difficult to cut materials.

iamond Lapping Compound is used to quickly lap the most difficult to cut materials. Diamond powders can be produced to very fine micron sizes therefore can produce finest finishes in difficult to cut materials.

ALUMINUM OXIDE LAPPING COMPOUNDS

GRADE 320 500 600 700 900 1000 1200

PART # AL321N AL501N AL601N AL701N AL901N AL1001N AL1201N

SILICON CARBIDE LAPPING COMPOUNDS

GRADE 320 500 600 700 900 1000 1200

PART # SI321N SI501N SI601N SI701N SI901N SI1001N SI1201N

BORON CARBIDE LAPPING COMPOUND

GRADE 400 500 600 800

PART # BC401N BC501N BC601N BC801N

DIAMOND LAPPING COMPOUND

American Lap Company Diamond Lapping Compounds are precision graded and offered in different concentrations making it cost effective. The compounds are color coded for easy identification and come in 5 or 10 gram syringes. The Diamond Lapping Compound can also be packaged in jars or tubes.

MICRON SIZE PART NUMBER MESH COLOR CONCENTRATION

0-1/2 DC1/4 120,000 BROWN HEAVY

0-1 DC1/2 60,000 LIGHT BLUE HEAVY

0-2 DC1 14,000 PURPLE HEAVY

2-4 DC2 12,000 LIGHT GREEN HEAVY & MEDIUM

3-5 DC3 8000 OFF WHITE HEAVY & MEDIUM

4-8 DC6 3000 YELLOW HEAVY & MEDIUM

6-10 DC8 1500 RED HEAVY & MEDIUM

10-20 DC15 1200 BLUE HEAVY & MEDIUM

20-30 DC25 600 DARK GREEN HEAVY & MEDIUM

20-40 DC30 500 ORANGE HEAVY & MEDIUM

30-50 DC40 325 LIGHT RED HEAVY & MEDIUM

40-70 DC60 230 DARK GREY HEAVY & MEDIUM

60-90 DC90 170 BLACK HEAVY & MEDIUM

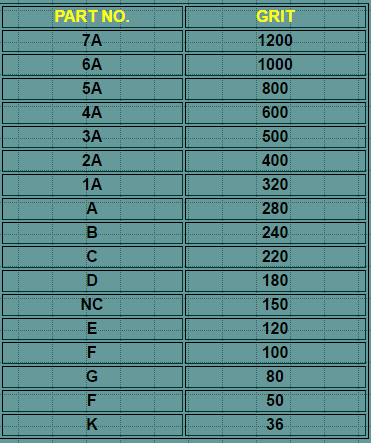

BEAVER ECONOMY LAPPING COMPOUND

Beaver Lapping Compound is a silicon carbide grease base lapping compound. Silicon carbide is a very sharp pointed abrasive grain that continually breaks down to leave a fine finish. The petroleum base vehicle keeps the abrasive in suspension therefore no mixing is required. Typical applications are: automobile valves, gears, blade sharpening and some precision lapping. The compound is available in 1 pound cans (6 per case) 2000ml pails and 5 gallon pails. To order 2000ml pails add "2000ml" to part number. To order 5 gallon pails add " 5gal" to part number.

http://www.americanlap.com/Lapping Compound.htm

http://www.cylinderheadsupply.com/kl1241-1.html

watch this video

http://www.wonderhowto.com/how-to/video ... 6527/view/

read thru this

http://home.hiwaay.net/~langford/corvair/valvejob.html

a good deal of the info applies to most engines, (not the clearances necessarily)

http://www.amazon.com/Motor-Medic-Gunk-M5012-Substitute/dp/B002008NWA

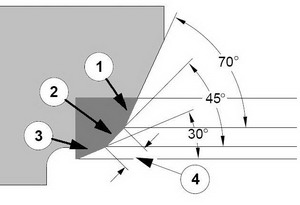

add both the lead substitute and 4 oz of marvel mystery oil to each tank of fuel, the combo will greatly reduce valve seat wear, if you ever pull the heads to get a valve job insist on the machine shop installing hardened valve seats and new valve guides, valve seals and checking all the valve train clearances, and I highly recommend a 3 angle valve job and a 30 degree back cut on the valves

http://garage.grumpysperformance.co...olishing-combustion-chambers.2630/#post-50247

http://garage.grumpysperformance.co...t-compressed-when-installed.11356/#post-51869

http://garage.grumpysperformance.co...-loads-and-installed-height.10709/#post-46627

http://garage.grumpysperformance.com/index.php?threads/valve-seal-selection.10469/#post-43881

http://garage.grumpysperformance.co...lve-seat-angles-and-air-flow.8460/#post-29682

http://garage.grumpysperformance.com/index.php?threads/multi-angle-valve-job-related.3143/#post-8387

http://garage.grumpysperformance.co...oper-valve-spring-seats-shims.1005/#post-1818

http://garage.grumpysperformance.com/index.php?threads/how-to-lap-valve-seats.1159/#post-2362

non-hardened valve seats regress into the head over time if used with non-leaded gas.

heads can be machined for hardened seats to allow use of unleaded fuel

hardened seats are then machined to properly seat the valves and ideally port and bowl work done to increase flow and reduce turbulance

http://www.rlengines.com/Web_Pages/Valve_Seat_Installation.html

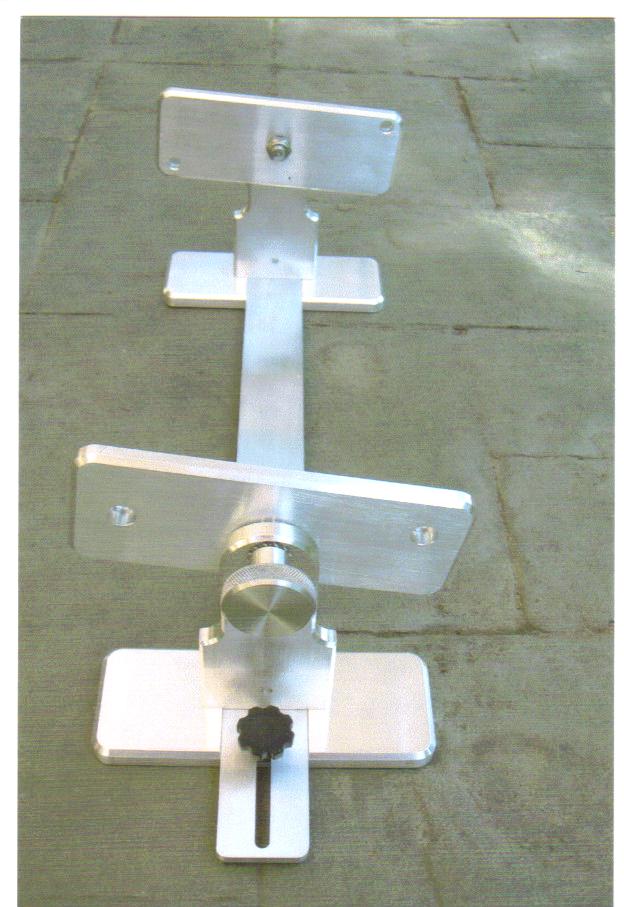

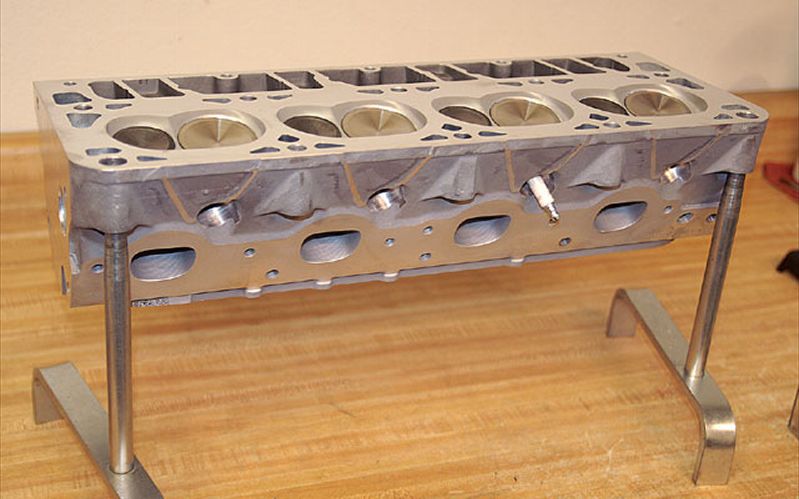

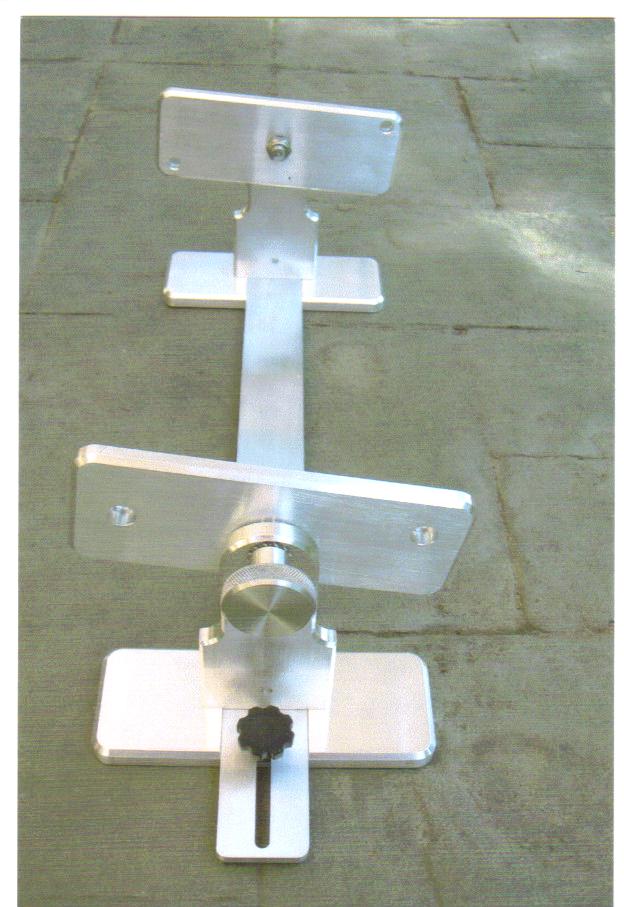

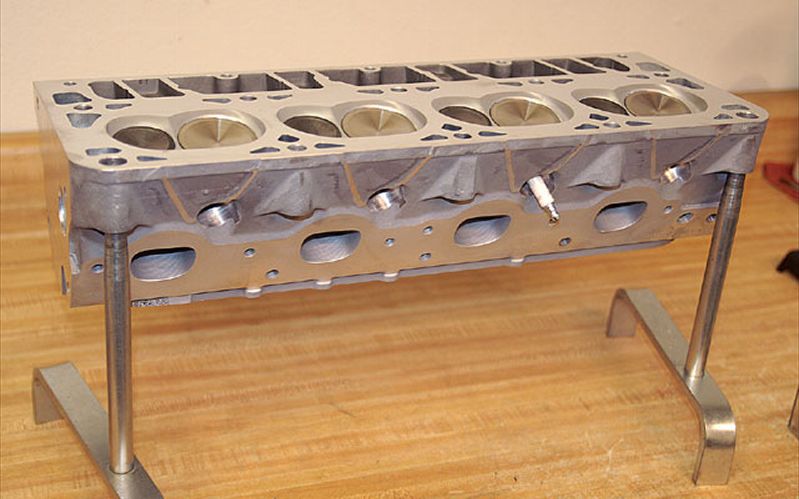

if you've ever ported heads , lapped valve seats or CC ed heads you quickly found that you,ll need some type of cylinder head stand to position the heads and lock them in the exact location and angle you need to easily access the ports and combustion chambers to maintain the correct angle and if you bothered to shop around youll find the stands available are either pure crap, or far to expensive so you generally find you use sand bags or fabricate your own custom cylinder head holding stands once you get fed up with them moving while your working on the heads.

don,t get stupid and think you can check the valve in a drill and lap it into place, to be done correctly its done on low speed by hand in a constantly reversing rotation, so you don,t build heat and burn the seat

leaking or non-sealing valve seats lead to un-even heat on the valve, and can warp the valve and eventually can result in a burnt valve or ruined valve seat.

hot air mixed with fuel under pressures going to find minor leak points a whole lot faster than a bit of alcohol, so lap the valves into the seats so you get a good seal, during any test, its important you get a good seal, as you may as well prevent potential problems by making sure you get a good seal, rather than needing to replace a burnt valve.. now lapping valves by hand or with a hand held drill is very (OLD SCHOOL) and YES you can SCREW UP YOUR HEADS if you get a a good bit excessive, so use of a hand spun tool is advised as a drill is rarely useful,especially in un experienced hands, and the hand held tool does a good job with less worries about screwing up the seats, but you can also prevent a few problems if you know what your doing, so its an option, and checking your heads for leakage before you install them is always a good idea, in many cases a few minutes with 280 and 400 grit lapping compound will allow the valves to fully seat ,and seal.

DON,T FORGET THE EXTENSIVE CLEANING AND DE GREASING AFTER A FULL DISASSEMBLE ONCE THE JOBS DONE AND YOU MUST LABEL THE VALVES AND GET THEM PLACED BACK IT THE MATCHING LOCATION AFTER LUBING THE VALVE STEMS AND VERIFYING VALVE TRAIN CLEARANCES

Most of the machinists prefer an intake-seat width of 0.040-0.060 inch. Narrower seats generally improve flow but are also less durable. Narrow seats work best on drag-race applications where the engine is freshened often, I generally try to go for durability and try to lap the seats to fall in the .050-.055 range on intake valve seats and .070-.080 on exhaust seat widths. Harder seat materials (e.g., induction-hardened seats) allow you to run slightly narrower seat widths than in the past while retaining excellent durability. Since exhaust valves operate at extreme temperatures, they require a wider seat to conduct heat away from the valve through the seat. Most shops specify 0.060- to 0.080-inch seat width for the exhaust side.

READ THIS RELATED THREAD CAREFULLY,

http://garage.grumpysperformance.com/index.php?threads/ccing-my-heads.14187/#post-71989

viewtopic.php?f=52&t=8460&p=29682#p29682

http://www.stockcarracing.com/techartic ... to_04.html

https://www.enginebuildermag.com/2013/10/cautioning-on-valve-seat-concentricity/

http://www.youtube.com/watch?v=96a44Qxy ... re=related

http://www.youtube.com/watch?v=fhXsH12R ... re=related

https://goodson.com/collections/cylinder-head-rebuilding-tools

http://www.cylinderheadsupply.com/kl8540.html

viewtopic.php?f=52&t=2091&p=5600&hilit=tools+valve+train#p5600

http://www.youtube.com/watch?v=I6o3BJFx ... re=related

viewtopic.php?f=52&t=1005&p=1818&hilit=tools+valve+train#p1818

http://garage.grumpysperformance.co...lve-seat-angles-and-air-flow.8460/#post-29682

viewtopic.php?f=52&t=1751&p=4387&hilit=tools+valve+train#p4387

youll need a few tools

http://store.summitracing.com/partdetai ... toview=sku

http://store.summitracing.com/partdetai ... toview=sku

http://www.newmantools.com/clover.htm

LAPPING COMPOUNDS

American Lap Company's lapping compounds are manufactured to exact specifications so a consistent finish is produced. We have our stock compounds listed below and make compounds to any specifications.

American Lap Company lapping compounds come mixed with a petroleum base or water base lapping vehicle. Our premium compounds come in one pound cans.

LAPPING ABRASIVES AND THEIR USES

Aluminum Oxide:Aluminum Oxide should be used on soft metals because of it's unusual grain structure, relatively high degree of hardness, sharpness and malleability. Aluminum Oxide will also cut hardened steels up to Rc 62. This compound is also adapted to the lapping of; machine spindles, bearings, dies, precision tools, hydraulic valves, injectors, spools and bodies and has many more uses.

Silicon Carbide:Silicon Carbide is only suited for the lapping of hardened metals due to its characteristics of extreme hardness and sharpness. But because of its brittleness and tendency to break down into very sharp pieces, thus produces scratches. Silicon Carbide's use is restricted to the lapping of most gears and large valves.

Boron Carbide:Boron Carbide is a very hard abrasive and is used for the lapping of materials with a high degree of hardness. Typical applications are for the lapping of carbides, ceramics and very hard tool steels.

Diamond

ALUMINUM OXIDE LAPPING COMPOUNDS

GRADE 320 500 600 700 900 1000 1200

PART # AL321N AL501N AL601N AL701N AL901N AL1001N AL1201N

SILICON CARBIDE LAPPING COMPOUNDS

GRADE 320 500 600 700 900 1000 1200

PART # SI321N SI501N SI601N SI701N SI901N SI1001N SI1201N

BORON CARBIDE LAPPING COMPOUND

GRADE 400 500 600 800

PART # BC401N BC501N BC601N BC801N

DIAMOND LAPPING COMPOUND

American Lap Company Diamond Lapping Compounds are precision graded and offered in different concentrations making it cost effective. The compounds are color coded for easy identification and come in 5 or 10 gram syringes. The Diamond Lapping Compound can also be packaged in jars or tubes.

MICRON SIZE PART NUMBER MESH COLOR CONCENTRATION

0-1/2 DC1/4 120,000 BROWN HEAVY

0-1 DC1/2 60,000 LIGHT BLUE HEAVY

0-2 DC1 14,000 PURPLE HEAVY

2-4 DC2 12,000 LIGHT GREEN HEAVY & MEDIUM

3-5 DC3 8000 OFF WHITE HEAVY & MEDIUM

4-8 DC6 3000 YELLOW HEAVY & MEDIUM

6-10 DC8 1500 RED HEAVY & MEDIUM

10-20 DC15 1200 BLUE HEAVY & MEDIUM

20-30 DC25 600 DARK GREEN HEAVY & MEDIUM

20-40 DC30 500 ORANGE HEAVY & MEDIUM

30-50 DC40 325 LIGHT RED HEAVY & MEDIUM

40-70 DC60 230 DARK GREY HEAVY & MEDIUM

60-90 DC90 170 BLACK HEAVY & MEDIUM

BEAVER ECONOMY LAPPING COMPOUND

Beaver Lapping Compound is a silicon carbide grease base lapping compound. Silicon carbide is a very sharp pointed abrasive grain that continually breaks down to leave a fine finish. The petroleum base vehicle keeps the abrasive in suspension therefore no mixing is required. Typical applications are: automobile valves, gears, blade sharpening and some precision lapping. The compound is available in 1 pound cans (6 per case) 2000ml pails and 5 gallon pails. To order 2000ml pails add "2000ml" to part number. To order 5 gallon pails add " 5gal" to part number.

http://www.americanlap.com/Lapping Compound.htm

http://www.cylinderheadsupply.com/kl1241-1.html

watch this video

http://www.wonderhowto.com/how-to/video ... 6527/view/

read thru this

http://home.hiwaay.net/~langford/corvair/valvejob.html

a good deal of the info applies to most engines, (not the clearances necessarily)

http://www.amazon.com/Motor-Medic-Gunk-M5012-Substitute/dp/B002008NWA

add both the lead substitute and 4 oz of marvel mystery oil to each tank of fuel, the combo will greatly reduce valve seat wear, if you ever pull the heads to get a valve job insist on the machine shop installing hardened valve seats and new valve guides, valve seals and checking all the valve train clearances, and I highly recommend a 3 angle valve job and a 30 degree back cut on the valves

http://garage.grumpysperformance.co...olishing-combustion-chambers.2630/#post-50247

http://garage.grumpysperformance.co...t-compressed-when-installed.11356/#post-51869

http://garage.grumpysperformance.co...-loads-and-installed-height.10709/#post-46627

http://garage.grumpysperformance.com/index.php?threads/valve-seal-selection.10469/#post-43881

http://garage.grumpysperformance.co...lve-seat-angles-and-air-flow.8460/#post-29682

http://garage.grumpysperformance.com/index.php?threads/multi-angle-valve-job-related.3143/#post-8387

http://garage.grumpysperformance.co...oper-valve-spring-seats-shims.1005/#post-1818

http://garage.grumpysperformance.com/index.php?threads/how-to-lap-valve-seats.1159/#post-2362

non-hardened valve seats regress into the head over time if used with non-leaded gas.

heads can be machined for hardened seats to allow use of unleaded fuel

hardened seats are then machined to properly seat the valves and ideally port and bowl work done to increase flow and reduce turbulance

http://www.rlengines.com/Web_Pages/Valve_Seat_Installation.html

if you've ever ported heads , lapped valve seats or CC ed heads you quickly found that you,ll need some type of cylinder head stand to position the heads and lock them in the exact location and angle you need to easily access the ports and combustion chambers to maintain the correct angle and if you bothered to shop around youll find the stands available are either pure crap, or far to expensive so you generally find you use sand bags or fabricate your own custom cylinder head holding stands once you get fed up with them moving while your working on the heads.

Last edited by a moderator: