Grumpy,

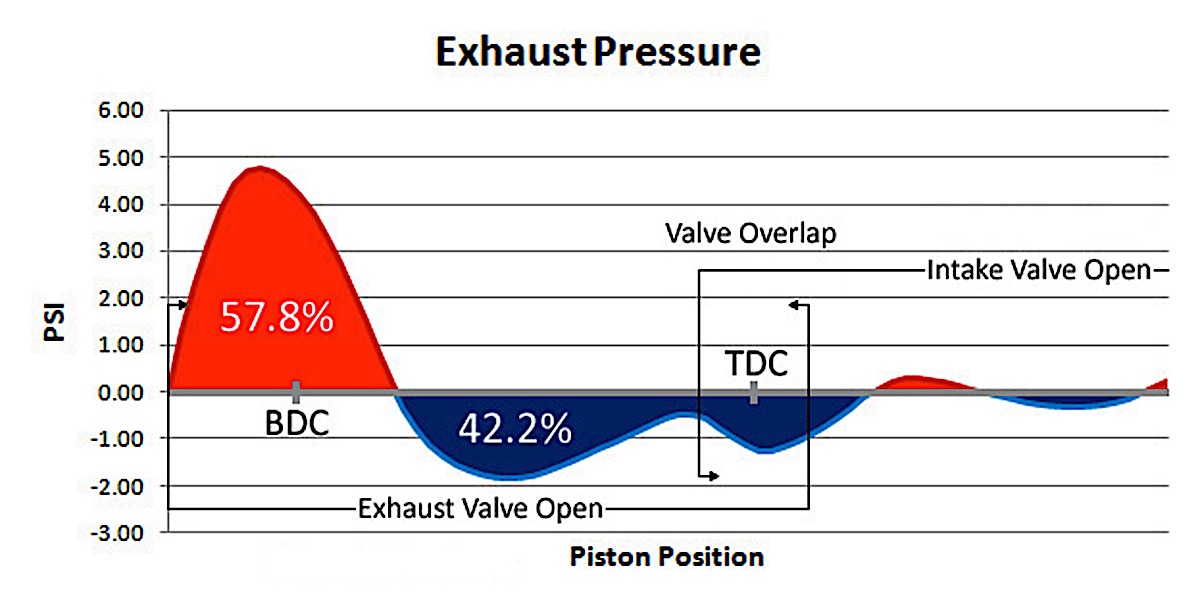

The thing with variable valve timing is that you can advance and retard the cam BUT the overlap will remain the same. Unless twin cam.

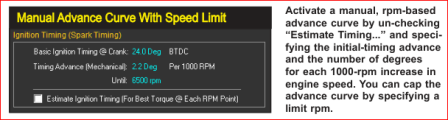

I see them talking about 30 degree change in timing events…. That might help if you had a wide LSA and advanced the cam to close the intake valve earlier than normal… and the retarded the cam from that 30 advance to say 4degree advance as RPM increases.

I’m not sure how an overlap ground into the cam would perform 30 advanced???

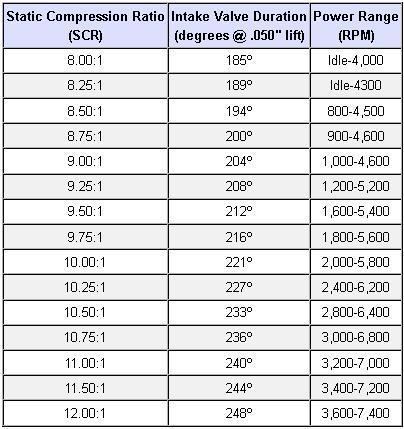

Anyway, not trying to reinvent something really just after the “next step” in DV formula. Select LSA and then???? Limited info after selecting LSA other than these large ranges of duration.

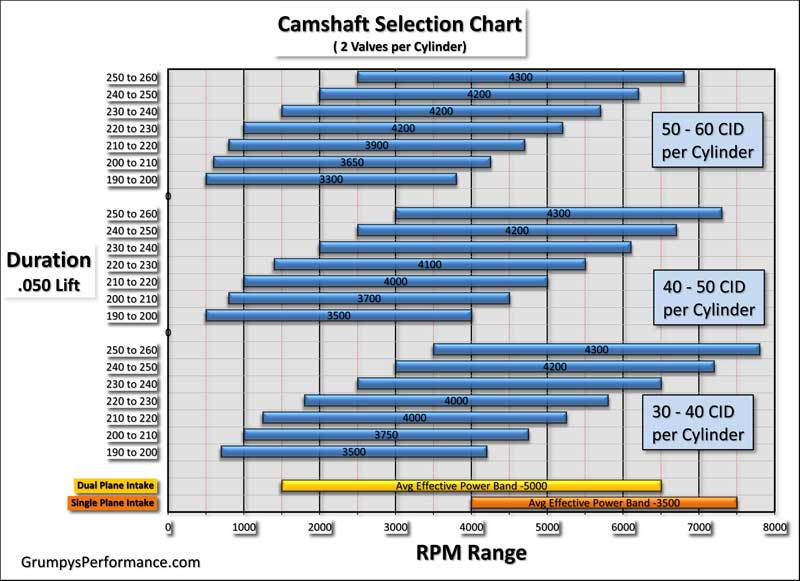

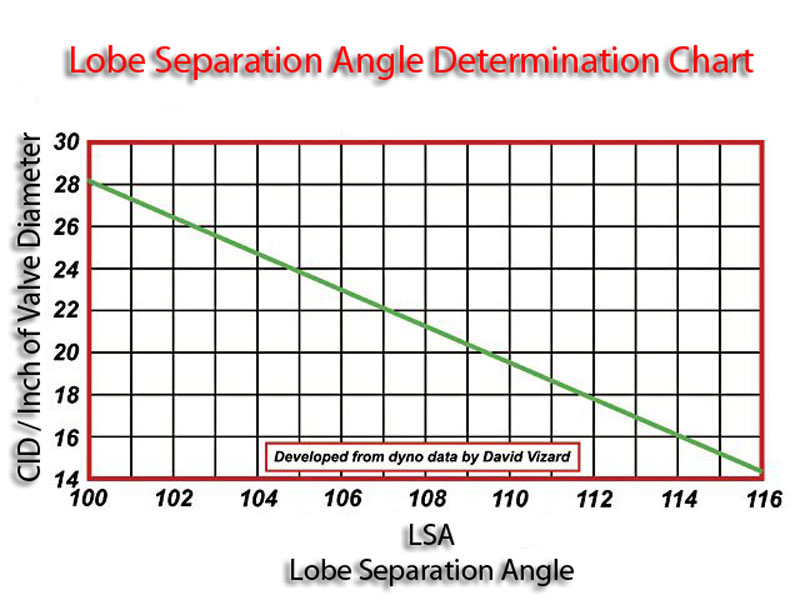

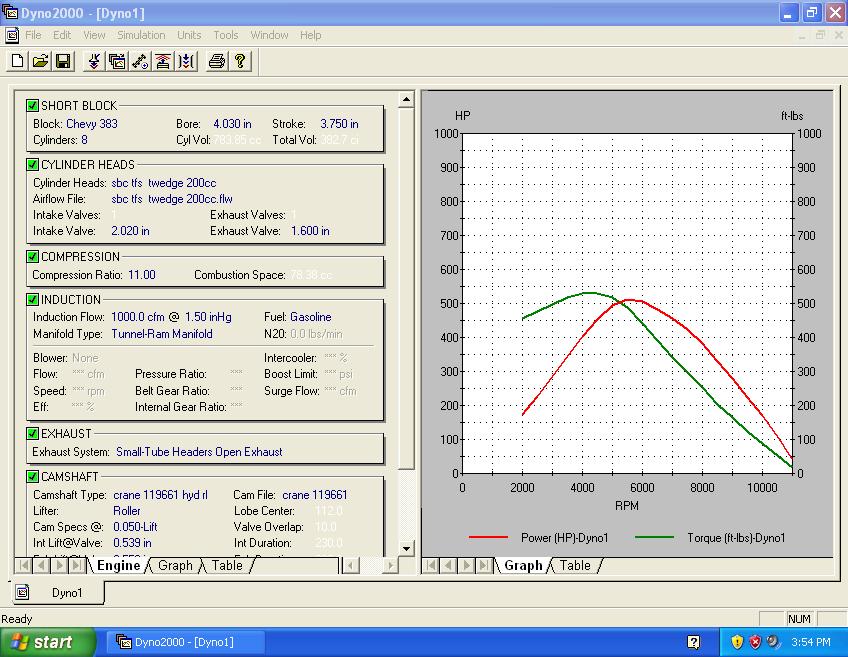

Example: The above graph has 40-50 cuin/cyl. That’s a 320/400cuin v8 engine which is a really big range of engine size and combined with a 10degree duration window real isn’t accurate enough for what I’m looking for. IE direct comparison to current camshaft.

DV formula is very “accurate” for LSA (not right word but formula gives you basically 1 answer, not a range). The next step is then select overlap that’s 20 degree duration window…. Not “accurate” at all.

Do you understand what I’m trying to say? So aside from a massive window of overlap WHAT is the second step after LSA as per DV?

I took my current cam and spec’s a custom cam based on same overlap as current advertised duration but tighter LSA. Rick was nice enough to do a couple simulations for me. THANK YOU!!!

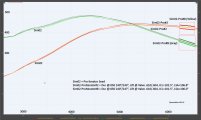

The sim showed an increase in torque (expected) but also a drop in HP (kind of expected but was hoping this DV cam formula would result in no HP loss). Again trying to maintain idle quality at same time so don’t want to deviate from current overlap too much.

So not trying to get into detail engine theory. Just looking for a better understanding of DVs can formula after LSA is spec’d.

How to say this another way….

If you keep same duration and lift but only change LSA according to DV at some point you will get better torque AND HP with a tighter LSA (cam #2) then same cam on wider LSA (cam#1)

BUT tighter LSA will affect idle quality.

THEREFORE, you should be able to spec a lower duration cam with tighter LSA (cam#3) and have same or better power than original duration wide LSA cam (cam#1) and better idle than original duration tight LSA cam (cam#2). Torque and power should be better than (cam#1) but not as good as (cam#2) but have better idle quality over (cam#2).

So how to spec that overlap and duration according to DVs theories?

The thing with variable valve timing is that you can advance and retard the cam BUT the overlap will remain the same. Unless twin cam.

I see them talking about 30 degree change in timing events…. That might help if you had a wide LSA and advanced the cam to close the intake valve earlier than normal… and the retarded the cam from that 30 advance to say 4degree advance as RPM increases.

I’m not sure how an overlap ground into the cam would perform 30 advanced???

Anyway, not trying to reinvent something really just after the “next step” in DV formula. Select LSA and then???? Limited info after selecting LSA other than these large ranges of duration.

Example: The above graph has 40-50 cuin/cyl. That’s a 320/400cuin v8 engine which is a really big range of engine size and combined with a 10degree duration window real isn’t accurate enough for what I’m looking for. IE direct comparison to current camshaft.

DV formula is very “accurate” for LSA (not right word but formula gives you basically 1 answer, not a range). The next step is then select overlap that’s 20 degree duration window…. Not “accurate” at all.

Do you understand what I’m trying to say? So aside from a massive window of overlap WHAT is the second step after LSA as per DV?

I took my current cam and spec’s a custom cam based on same overlap as current advertised duration but tighter LSA. Rick was nice enough to do a couple simulations for me. THANK YOU!!!

The sim showed an increase in torque (expected) but also a drop in HP (kind of expected but was hoping this DV cam formula would result in no HP loss). Again trying to maintain idle quality at same time so don’t want to deviate from current overlap too much.

So not trying to get into detail engine theory. Just looking for a better understanding of DVs can formula after LSA is spec’d.

How to say this another way….

If you keep same duration and lift but only change LSA according to DV at some point you will get better torque AND HP with a tighter LSA (cam #2) then same cam on wider LSA (cam#1)

BUT tighter LSA will affect idle quality.

THEREFORE, you should be able to spec a lower duration cam with tighter LSA (cam#3) and have same or better power than original duration wide LSA cam (cam#1) and better idle than original duration tight LSA cam (cam#2). Torque and power should be better than (cam#1) but not as good as (cam#2) but have better idle quality over (cam#2).

So how to spec that overlap and duration according to DVs theories?