CNC BLOCKS

Member

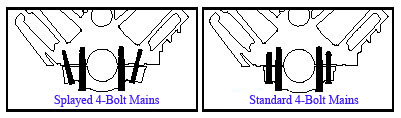

I have been asked about the installation of splayed caps many times over the years. First of all this proceedure can be done in a Bridgeport, knee mill, CNC machine ETC.

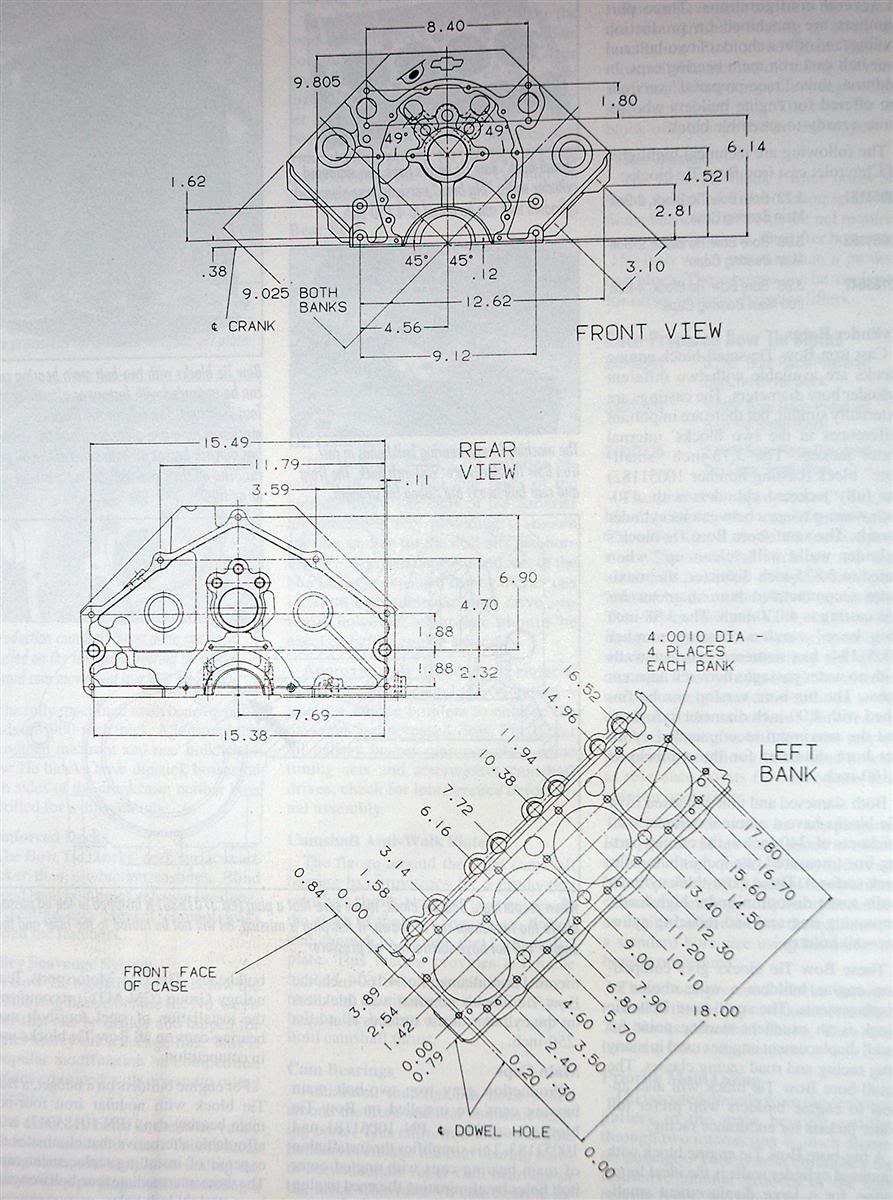

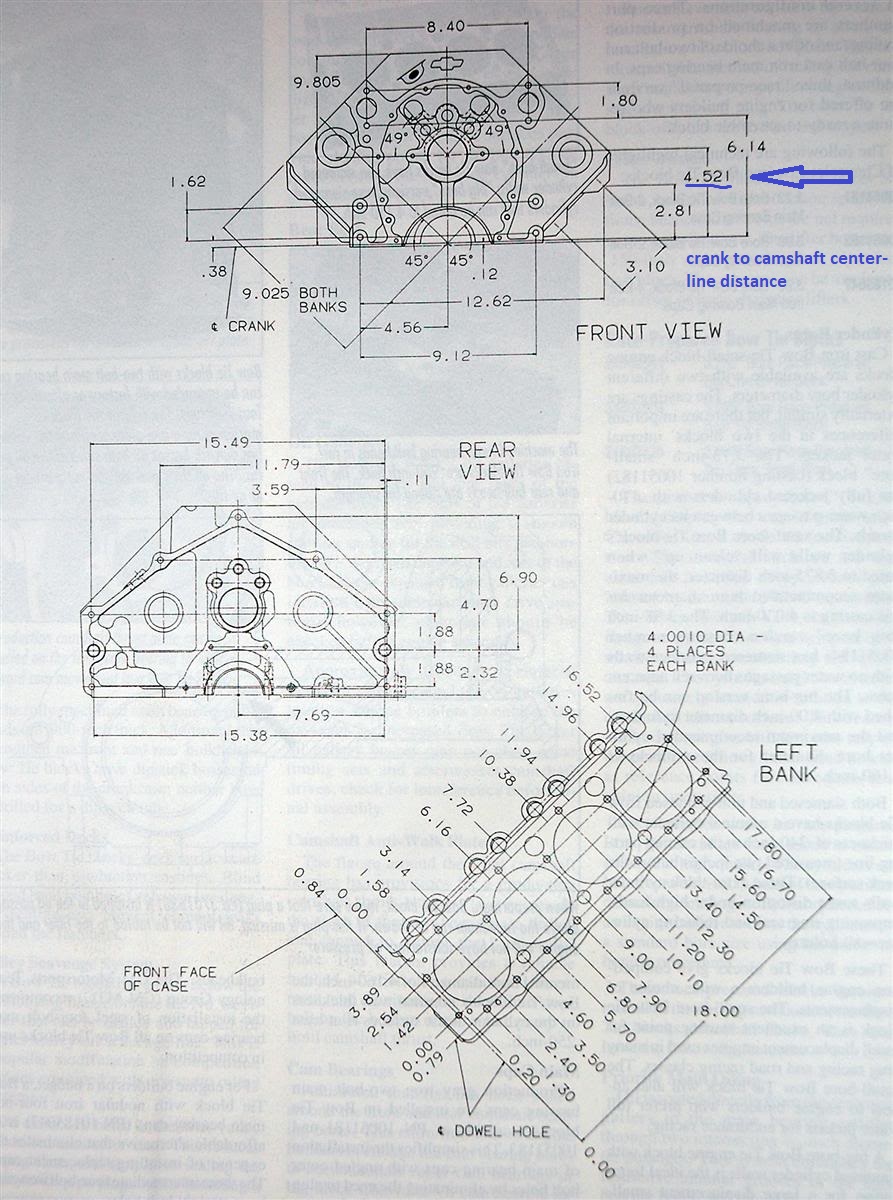

I use flat bottom caps with 10 degree angle outer bolts because with the 10 degree outter bolts you should not get into the water jackets. I have had many calls about outter bolt holes getting into the water jackets only to find out its because of the 18 or 22 degree outter bolt holes.

Alot of classes out there are restricted to run OEM blocks and most racers like the weight savings of the OEM block and 383's we are now seeing over 500 plus HP and with the added stroke its best to go to a splayed center cap, Its always best to sonic test the cylinders for thickness before spending time and money on cap work.

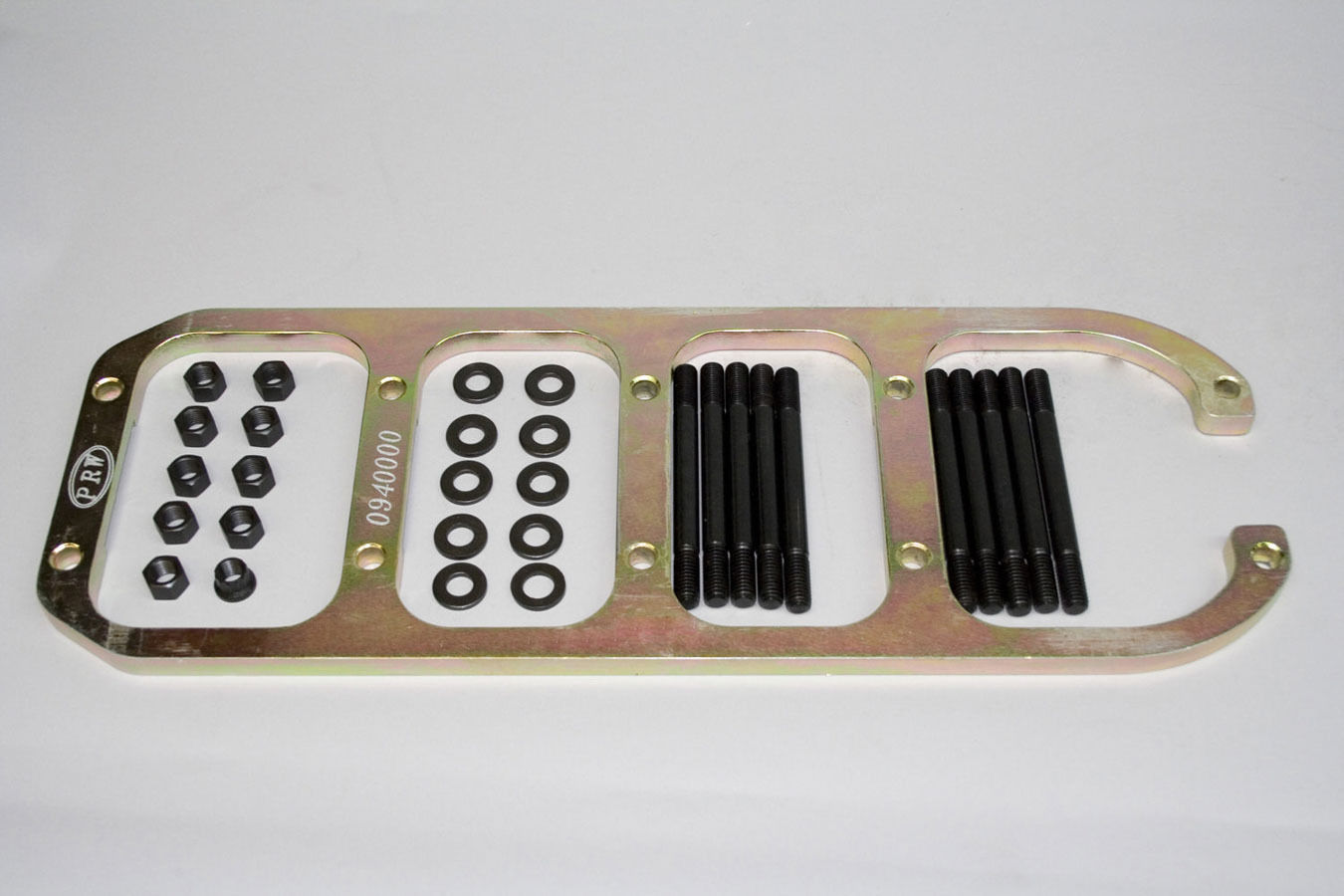

Caps I prefer are caps from http://www.cipcoindustries.com/ or http://pro-gram.com/ Price on cipco caps are right at 160.00 a set Programs are right at 210.00 a set.

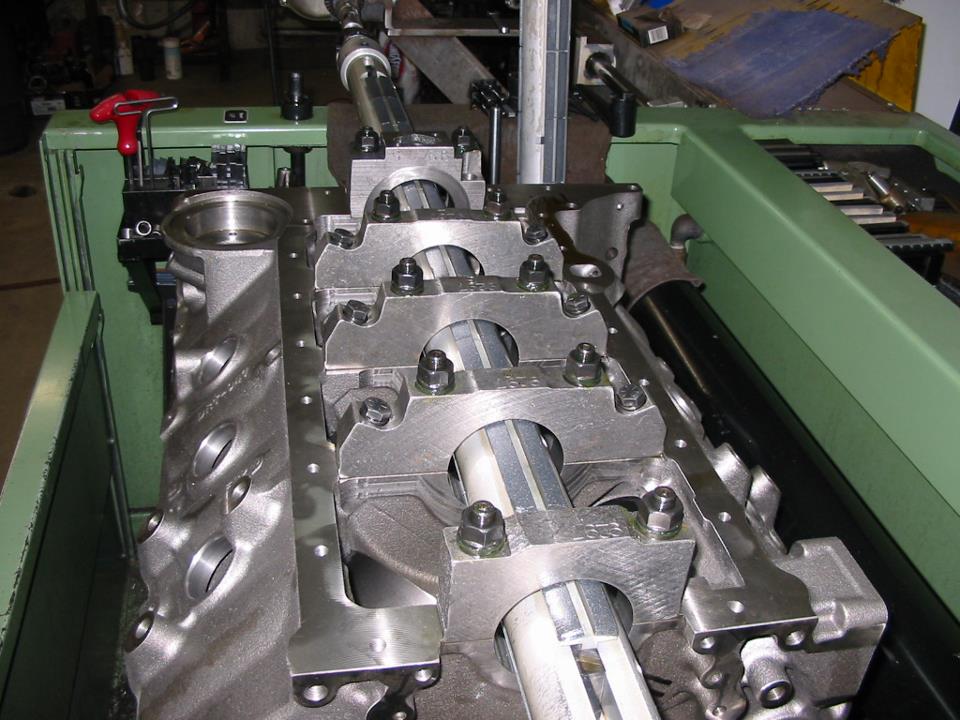

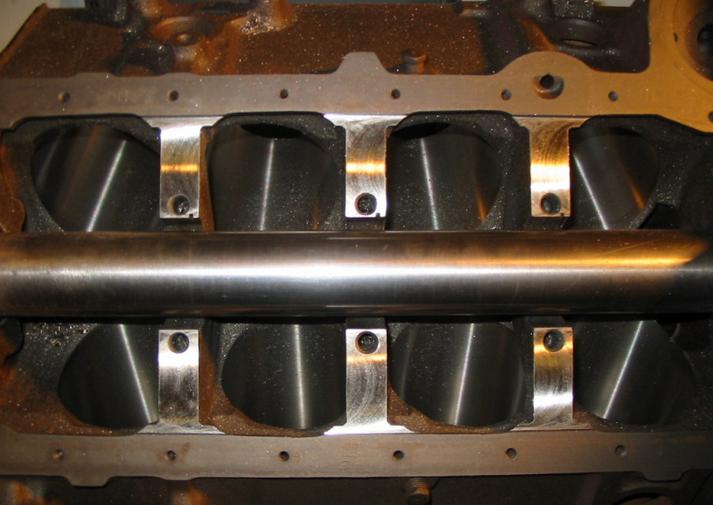

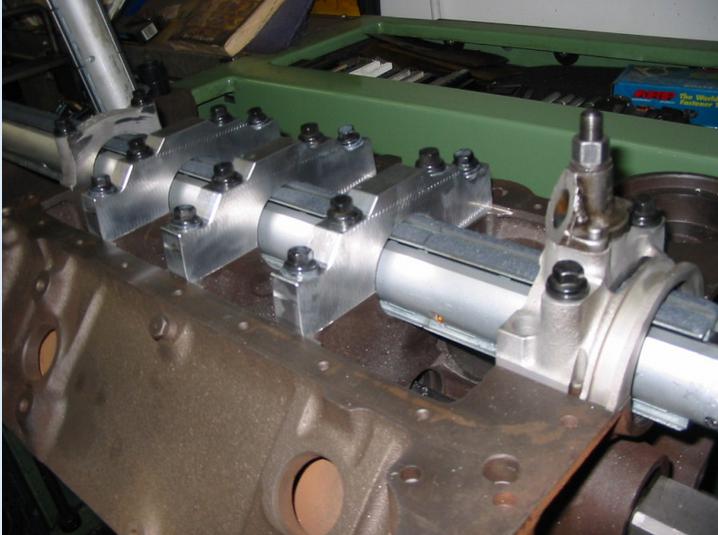

First process is to cut the register either with an end mill or I use a 2.5 shell mill on 2 bolt blocks the register has to be only cut appox. .120 deep measure of the pan and on 4 bolt blocks the register have to be cut appox. .140 deep. I like to see a .003 press fit. Both companies use a 10 degree outer angle.

READ THIS THREAD AND SUB LINKS

http://garage.grumpysperformance.com/index.php?threads/which-dart-shp-4-0-or-4-125.3219/#post-44637

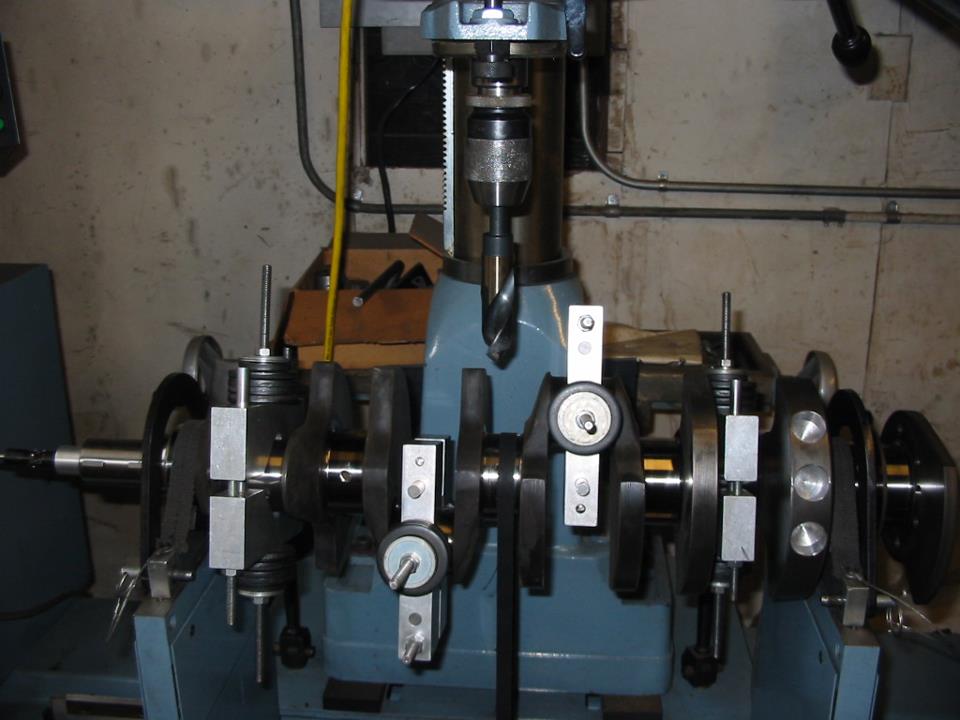

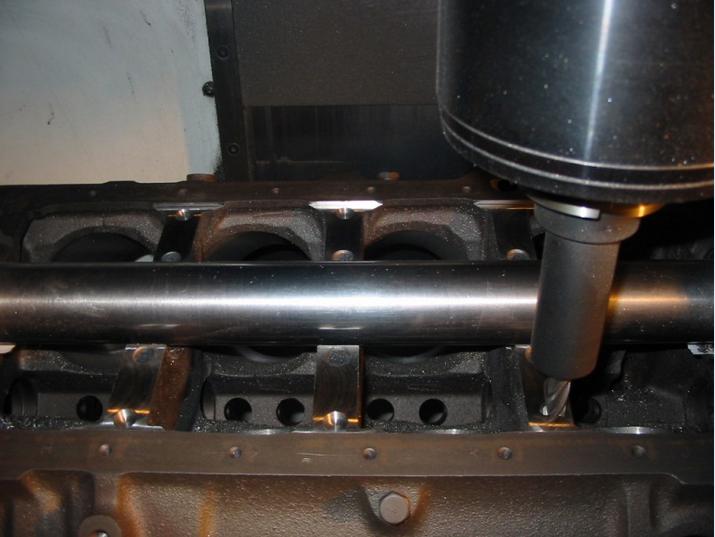

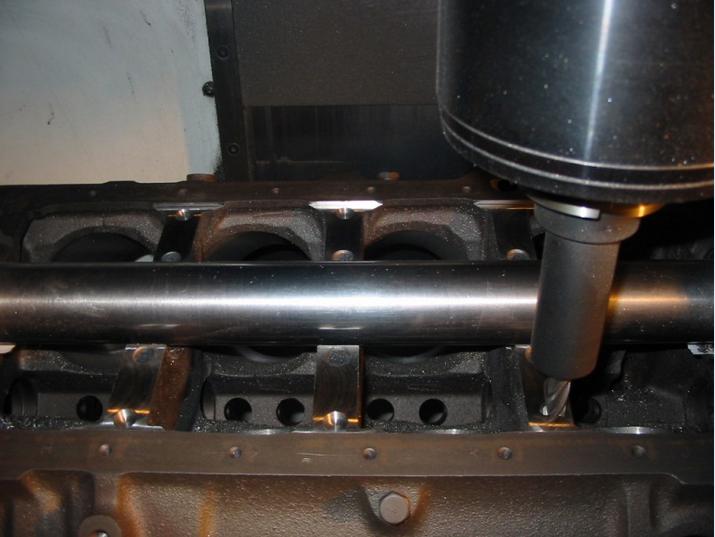

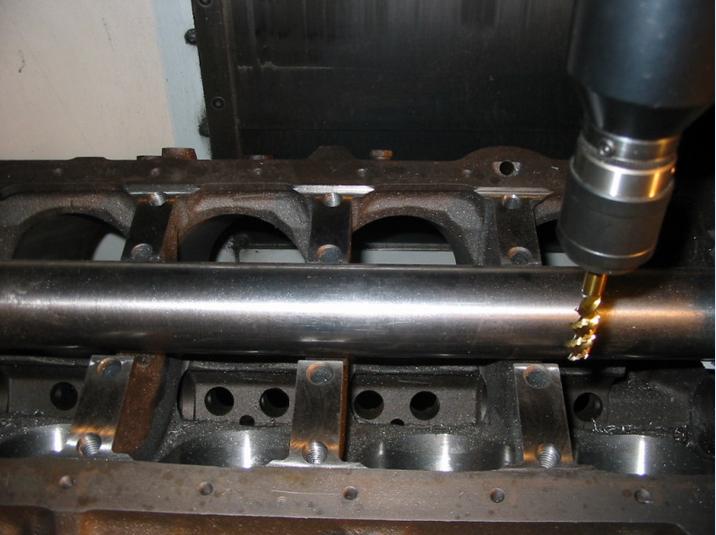

Next step is using a 1/2 in end mill at a 10 degree angle is to mill a flat spot.

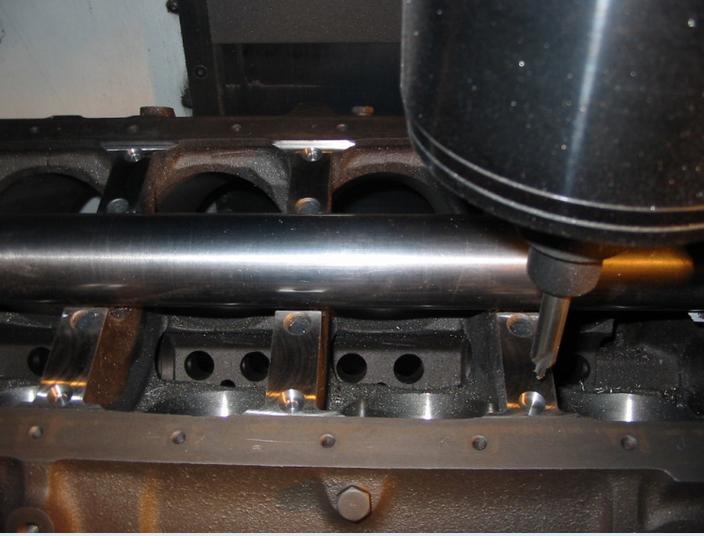

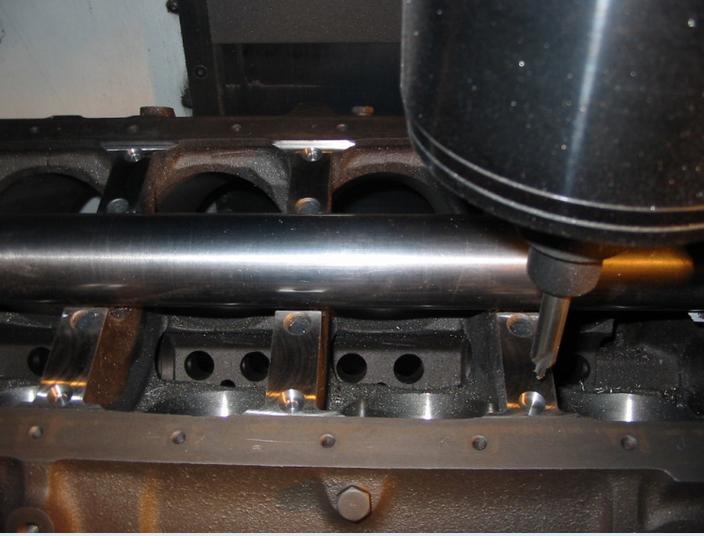

Next is to center drill

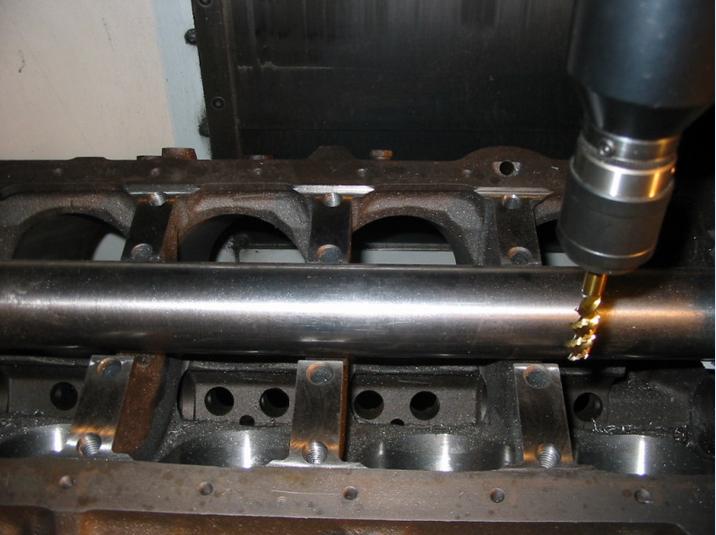

Next drill holes using a the letter U drill appox. .800 deep

Next would be taping with a spiral tap seems to work best.

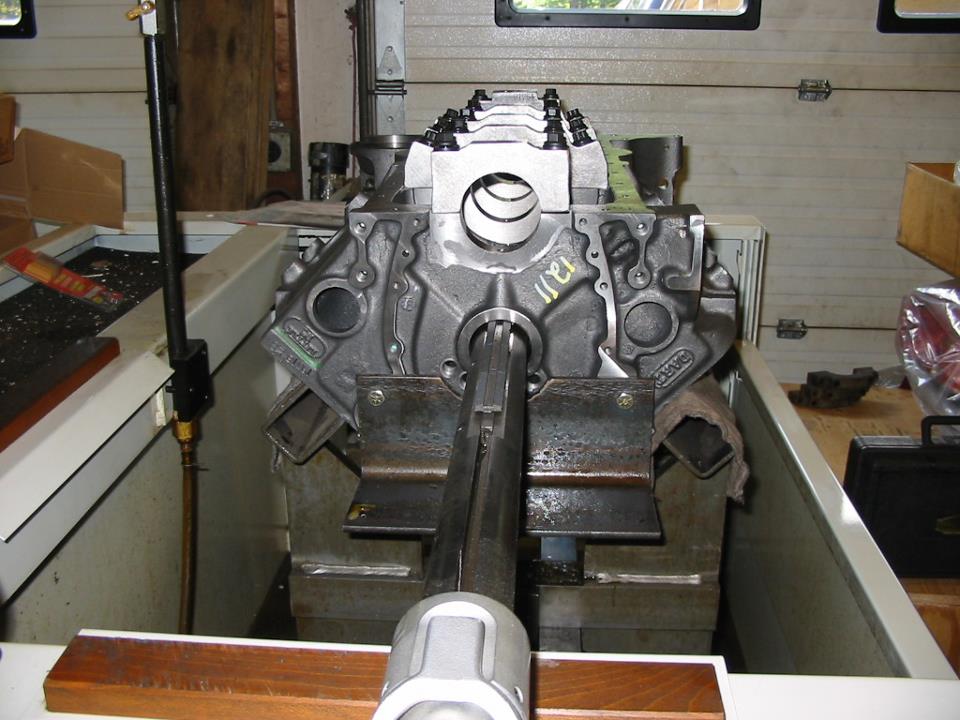

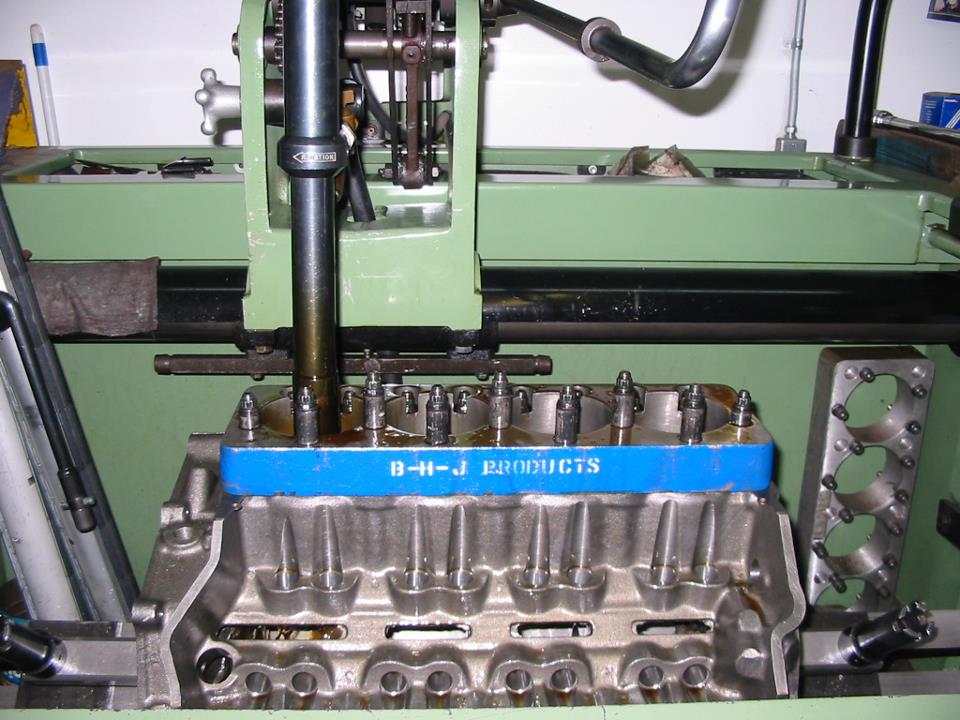

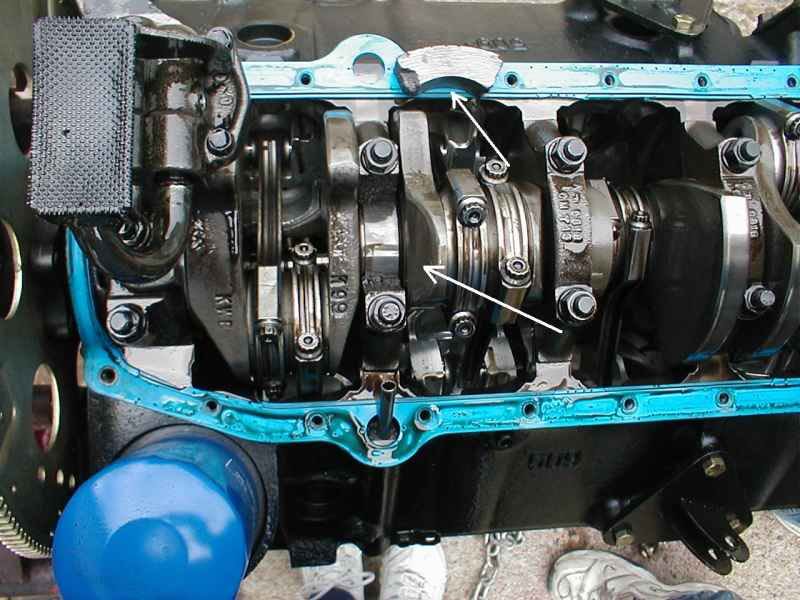

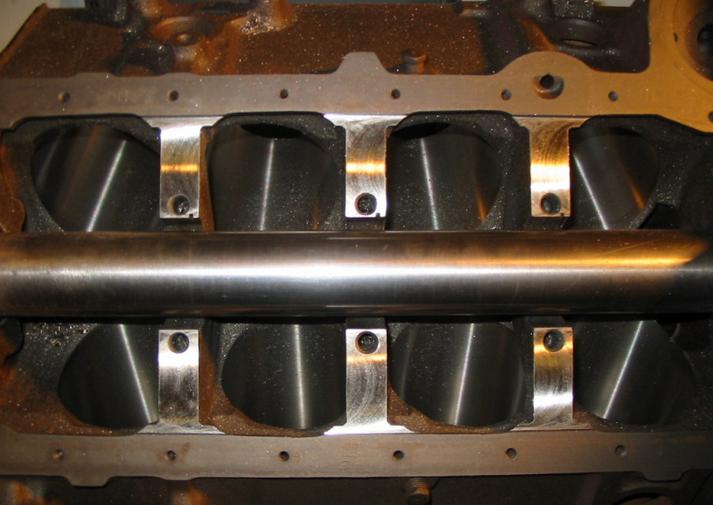

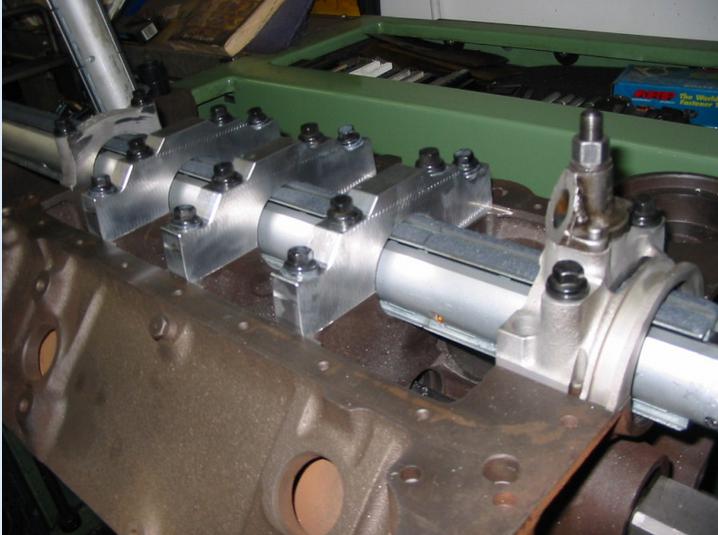

Line boring can be done with a line boring machine or I use the PLB-100 which seems to very fast and accurate, I cut the housing bores close to size.

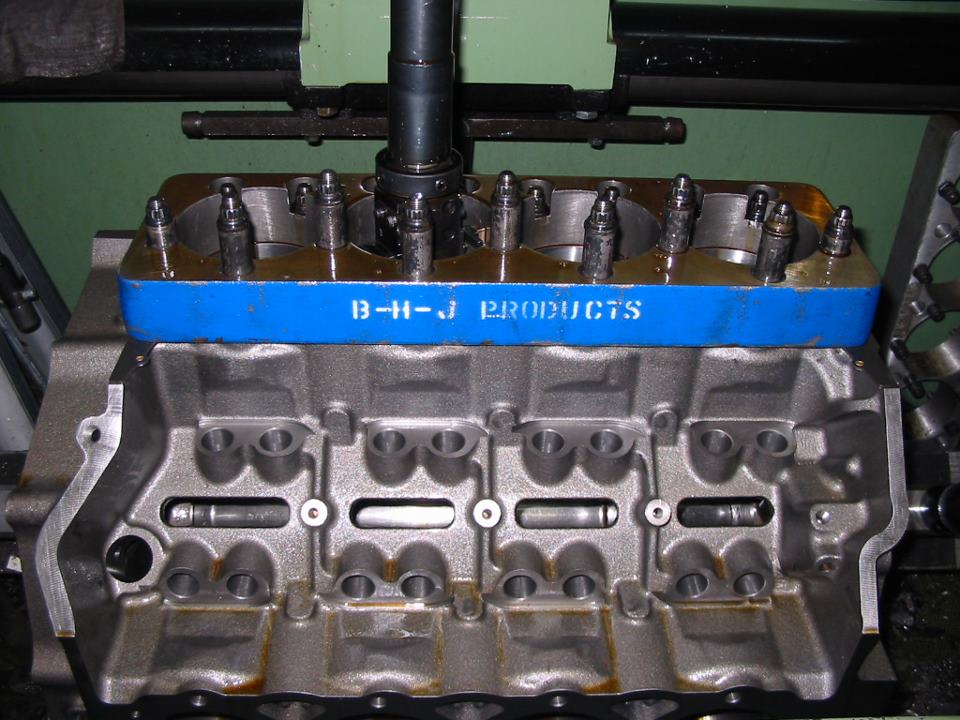

Once line boring is complete the caps are taken off and cut appox. .0025 to .003 off the bottom then then reinstalled and aligned honed to the last .001 caps are loosened retorqued to check for size and hone to size.

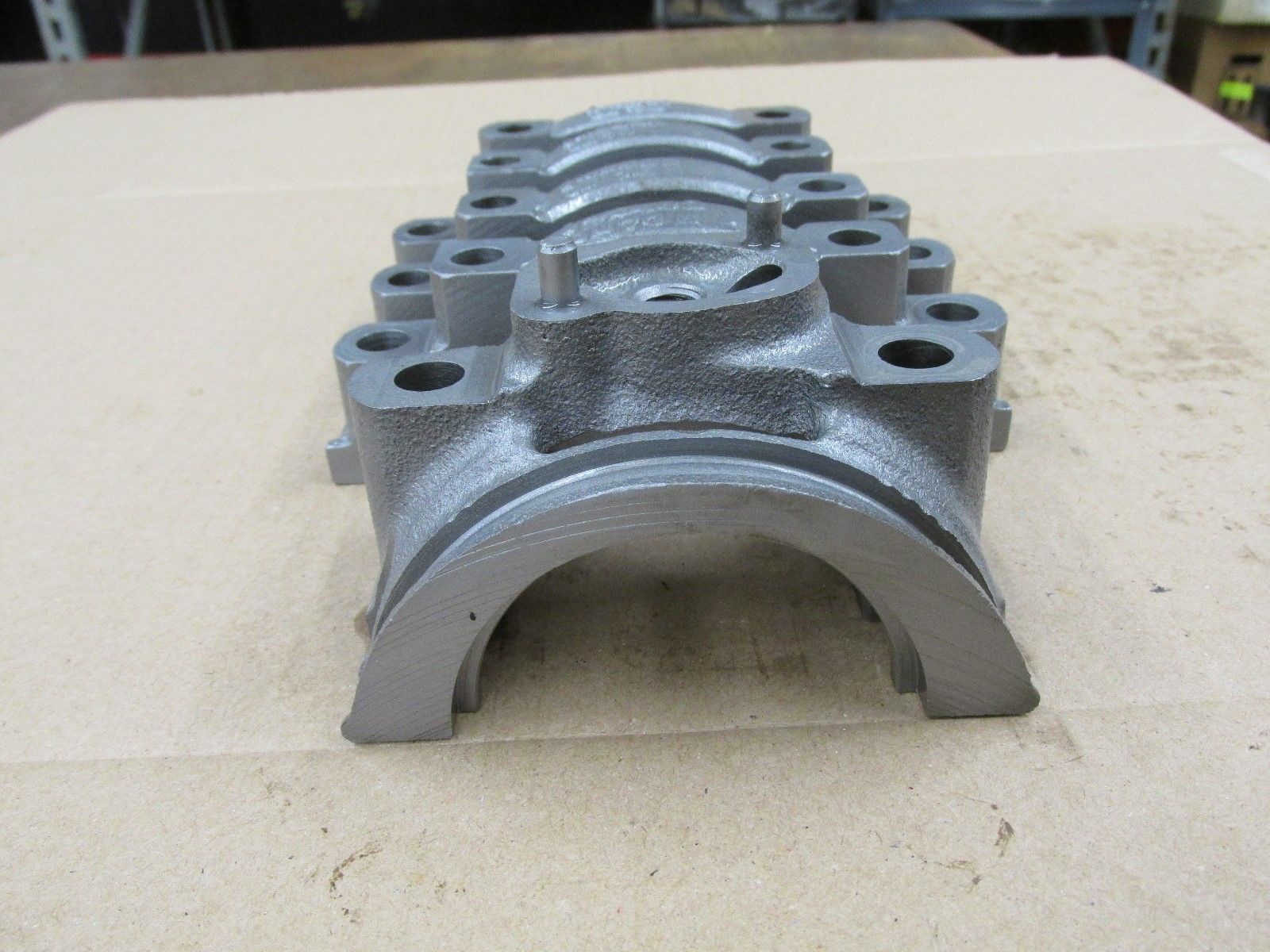

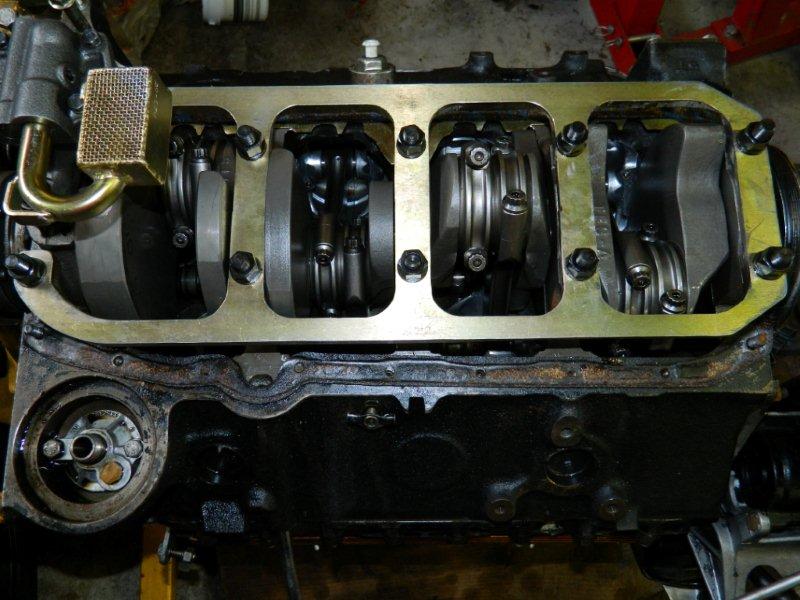

Finish product

Note: On the Cipco caps they are OEM height and you can use an ARP bolt kit and on the Porgram caps they are appox. .200 taller and would require a stud kit.

Hope this thread answers most questions about cap installation

I use flat bottom caps with 10 degree angle outer bolts because with the 10 degree outter bolts you should not get into the water jackets. I have had many calls about outter bolt holes getting into the water jackets only to find out its because of the 18 or 22 degree outter bolt holes.

Alot of classes out there are restricted to run OEM blocks and most racers like the weight savings of the OEM block and 383's we are now seeing over 500 plus HP and with the added stroke its best to go to a splayed center cap, Its always best to sonic test the cylinders for thickness before spending time and money on cap work.

Caps I prefer are caps from http://www.cipcoindustries.com/ or http://pro-gram.com/ Price on cipco caps are right at 160.00 a set Programs are right at 210.00 a set.

First process is to cut the register either with an end mill or I use a 2.5 shell mill on 2 bolt blocks the register has to be only cut appox. .120 deep measure of the pan and on 4 bolt blocks the register have to be cut appox. .140 deep. I like to see a .003 press fit. Both companies use a 10 degree outer angle.

READ THIS THREAD AND SUB LINKS

http://garage.grumpysperformance.com/index.php?threads/which-dart-shp-4-0-or-4-125.3219/#post-44637

Next step is using a 1/2 in end mill at a 10 degree angle is to mill a flat spot.

Next is to center drill

Next drill holes using a the letter U drill appox. .800 deep

Next would be taping with a spiral tap seems to work best.

Line boring can be done with a line boring machine or I use the PLB-100 which seems to very fast and accurate, I cut the housing bores close to size.

Once line boring is complete the caps are taken off and cut appox. .0025 to .003 off the bottom then then reinstalled and aligned honed to the last .001 caps are loosened retorqued to check for size and hone to size.

Finish product

Note: On the Cipco caps they are OEM height and you can use an ARP bolt kit and on the Porgram caps they are appox. .200 taller and would require a stud kit.

Hope this thread answers most questions about cap installation

Last edited by a moderator: