first DON,T PAY FOR IT ...DO IT YOURSELF!!!

IT WILL COST LESS EVEN AFTER PAYING FOR THE TOOLS, than paying for it AT MOST GARAGES.

A compression test,ALONE, IS NOT A LEAK DOWN TEST, a LEAK DOWN TEST WILL GIVE YOU THE COMPRESSION TEST INFO, ALONG WITH OTHER INFO

you'll find that you'll gain basic skills, own new tools and PAY LESS MONEY

http://en.wikipedia.org/wiki/Leak-down_tester

http://www.carcraft.com/techarticles/11 ... index.html

BEFORE YOU GET INVOLVED WITH TESTING , YOUR ENGINE,READ THRU THESE THREADS, AND LINKS AS THEY WILL HELP ISOLATE THE PROBLEM, and THEY HAVE A GOOD DEAL OF USEFUL INFO

http://www.chevyhiperformance.com/tech/ ... index.html

read this carefully, for you do it yourself types

http://www.hondatuningmagazine.com/tech ... index.html

http://www.motorcycleproject.com/motorc ... kdown.html

http://www.vmaxoutlaw.com/tech/leakdown_tester.htm

Heres, more, useful info, you'll want to know before testing

http://www.carcraft.com/techarticles/116_0406_cylinder_leakdown_tester/index.html

http://www.xs11.com/tips/misc/misc3.shtml

http://www.goodvibesracing.com/leakdown Tester.htm

http://www.globaltoolsupply.com/cgi-local/SoftCart.exe/online-store/scstore/p-P1-275.html?E+scstore

http://www.tavia.com/cat8.html#3

http://www.motorcycleproject.com/motorcycle/text/leakdown.html

http://www.xs11.com/tips/misc/misc3.shtml

http://goodvibesracing.com/Leakdown Tester.htm

1) For most accurate results, engine should be up to operating temperature.

2) Remove all spark plugs.

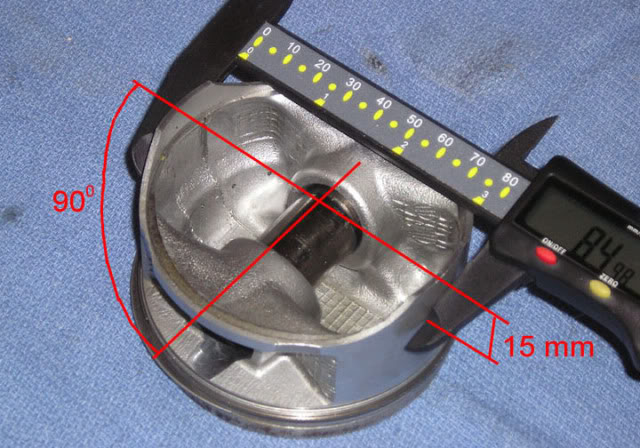

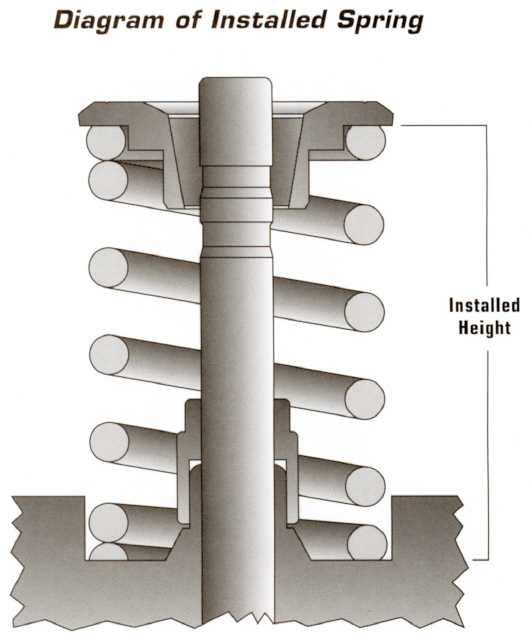

3) Rotate crankshaft until piston being tested is at top dead center of compression stroke.

4) Screw the spark plug adapter hose into spark plug hole making the sure the o-ring is seated properly.

5) Connect the spark plug adapter hose to the coupler of the leakdown tester.

6) Connect leak down tester to a good source of compressed air, preferably a filtered and water trapped source.

7) Adjust the regulator on the leak down tester so the the LEFT HAND GAUGE indicates at least 10 pounds less than your source pressure. The leak down percentage conversion table shown below is based on regulated pressures of 100, 90, or 75 psi.

8) Read the RIGHT HAND GAUGE (differential gauge), then look up gauge reading on the conversion table below to get actual leak down percentage. After noting percentage of leakage, turn the regulator knob counter-clockwise to relieve the pressure. This reduces the shock to the gauges. If you ever get an unrealistically low pressure reading on the right hand gauge, there is a finite possibility that something is blocking the small orifice located within the hex tube located between the regulator and the main body of the leak down tester.

9)To remove any obstruction that may be lodged in the metering orifice, unscrew the hose coupling assembly from the aluminum body. Utilizing a 1" wrench, remove the knob assembly from the regulator. Blow compressed air in the opposite direction (from the coupling end) to clear the orfice. Re-assemble the regulator and the coupling.

NOTE: DO NOT ATTEMPT TO REMOVE THE BRASS HEX NIPPLE BETWEEN THE REGULATOR AND THE ALUMINUM BODY. DAMAGE MAY RESULT.

http://www.maximausa.com/technical/leaktest.html

http://www.meyerracingonline.com/leak.html

http://www.compressionking.com/leakdown.htm

http://www.lcengineering.com/TechNotes/TechNote47.htm

common compression test results will fall in the 150PSI-170PSI range on nearly stock engines , and ideally all cylinders will read within 5%-10% of the rest

I don't start getting too concerned until numbers start pushing over 12% -15% for hot rod stuff. Normal car 18-22%. Most test procedures you will see say 25% acceptable , but at that point you need a ring and valve job

ID be More concerned with the cylinder to cylinder variations on individual cylinders, I want to see consistent numbers across the board, maximum variation of 10%. If one is at 12%, I want to see a total range of 11-13%. Keep in mind, gauge, engine temp, piston position in each cylinder, and should be consistently at TDC when testing each cylinder, and yes it will effect the readings.

IT WILL COST LESS EVEN AFTER PAYING FOR THE TOOLS, than paying for it AT MOST GARAGES.

A compression test,ALONE, IS NOT A LEAK DOWN TEST, a LEAK DOWN TEST WILL GIVE YOU THE COMPRESSION TEST INFO, ALONG WITH OTHER INFO

you'll find that you'll gain basic skills, own new tools and PAY LESS MONEY

http://en.wikipedia.org/wiki/Leak-down_tester

http://www.carcraft.com/techarticles/11 ... index.html

BEFORE YOU GET INVOLVED WITH TESTING , YOUR ENGINE,READ THRU THESE THREADS, AND LINKS AS THEY WILL HELP ISOLATE THE PROBLEM, and THEY HAVE A GOOD DEAL OF USEFUL INFO

http://www.chevyhiperformance.com/tech/ ... index.html

read this carefully, for you do it yourself types

http://www.hondatuningmagazine.com/tech ... index.html

http://www.motorcycleproject.com/motorc ... kdown.html

http://www.vmaxoutlaw.com/tech/leakdown_tester.htm

Heres, more, useful info, you'll want to know before testing

http://www.carcraft.com/techarticles/116_0406_cylinder_leakdown_tester/index.html

http://www.xs11.com/tips/misc/misc3.shtml

http://www.goodvibesracing.com/leakdown Tester.htm

http://www.globaltoolsupply.com/cgi-local/SoftCart.exe/online-store/scstore/p-P1-275.html?E+scstore

http://www.tavia.com/cat8.html#3

http://www.motorcycleproject.com/motorcycle/text/leakdown.html

http://www.xs11.com/tips/misc/misc3.shtml

http://goodvibesracing.com/Leakdown Tester.htm

1) For most accurate results, engine should be up to operating temperature.

2) Remove all spark plugs.

3) Rotate crankshaft until piston being tested is at top dead center of compression stroke.

4) Screw the spark plug adapter hose into spark plug hole making the sure the o-ring is seated properly.

5) Connect the spark plug adapter hose to the coupler of the leakdown tester.

6) Connect leak down tester to a good source of compressed air, preferably a filtered and water trapped source.

7) Adjust the regulator on the leak down tester so the the LEFT HAND GAUGE indicates at least 10 pounds less than your source pressure. The leak down percentage conversion table shown below is based on regulated pressures of 100, 90, or 75 psi.

8) Read the RIGHT HAND GAUGE (differential gauge), then look up gauge reading on the conversion table below to get actual leak down percentage. After noting percentage of leakage, turn the regulator knob counter-clockwise to relieve the pressure. This reduces the shock to the gauges. If you ever get an unrealistically low pressure reading on the right hand gauge, there is a finite possibility that something is blocking the small orifice located within the hex tube located between the regulator and the main body of the leak down tester.

9)To remove any obstruction that may be lodged in the metering orifice, unscrew the hose coupling assembly from the aluminum body. Utilizing a 1" wrench, remove the knob assembly from the regulator. Blow compressed air in the opposite direction (from the coupling end) to clear the orfice. Re-assemble the regulator and the coupling.

NOTE: DO NOT ATTEMPT TO REMOVE THE BRASS HEX NIPPLE BETWEEN THE REGULATOR AND THE ALUMINUM BODY. DAMAGE MAY RESULT.

http://www.maximausa.com/technical/leaktest.html

http://www.meyerracingonline.com/leak.html

http://www.compressionking.com/leakdown.htm

http://www.lcengineering.com/TechNotes/TechNote47.htm

common compression test results will fall in the 150PSI-170PSI range on nearly stock engines , and ideally all cylinders will read within 5%-10% of the rest

I don't start getting too concerned until numbers start pushing over 12% -15% for hot rod stuff. Normal car 18-22%. Most test procedures you will see say 25% acceptable , but at that point you need a ring and valve job

ID be More concerned with the cylinder to cylinder variations on individual cylinders, I want to see consistent numbers across the board, maximum variation of 10%. If one is at 12%, I want to see a total range of 11-13%. Keep in mind, gauge, engine temp, piston position in each cylinder, and should be consistently at TDC when testing each cylinder, and yes it will effect the readings.

Last edited by a moderator: