http://www.amazon.com/Miller-300185-Tor ... B001PSAVXW

http://store.cyberweld.com/350ampwattig ... productads

http://store.cyberweld.com/coolmate3.html

http://weldingdirect.com/migwacocoac.html

I can,t imagine using a NON-LIQUID COOLED TIG TORCH, as they heat up far too rapidly too do much welding, but a factory water cooled tig torch and coolant pump can easily cost $1200 plus , over the cost of the already expensive TIG welder and gas tank, regulator , cart,etc. now I have not tried this personally as I purchased my water cooled TIG torch and pump used as part of my USED TIG welder package deal, but I don,t see where it would not work after looking over the miller coolant pump, etc.

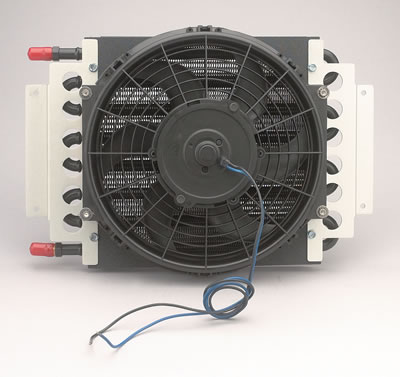

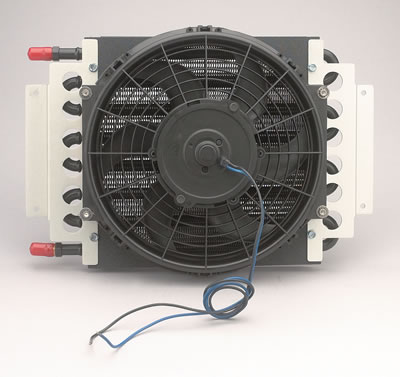

yes it will take a bit of fabrication, but both the 7 gallon capacity and the oil cooler with electric fan are larger and far more efficient than the factory miller pump and cooler radiator fan combo

http://www.youtube.com/watch?v=PZ1V8ewTRlo

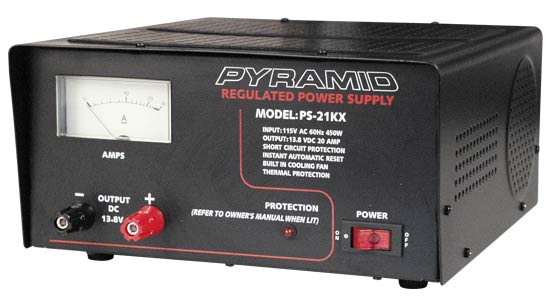

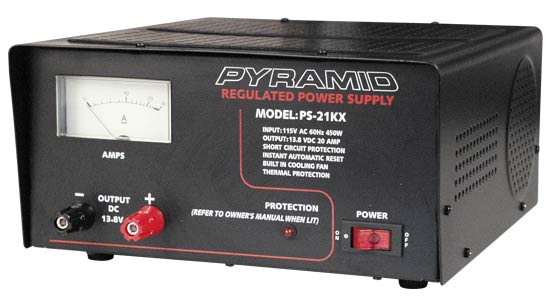

http://www.sportsimportsltd.com/ac-to-d ... upply.html 110volt AC to 12 volt DC power for FAN $100

http://www.summitracing.com/parts/DER-13720/?rtype=10

$146

$146

http://www.youtube.com/watch?v=5gAZoYhEe4U

http://www.arc-zone.com/pdf/WhyUPgrade.pdf

http://www.grizzly.com/products/7-Gallo ... 2Bproducts

$170

$170

http://weldingdirect.com/sr1825.html

http://weldingdirect.com/sr18v25.html TORCH AND CABLES UNDER $200

this info above might be useful in a similar custom fabrication of a coolant pump for a tig

http://store.cyberweld.com/350ampwattig ... productads

http://store.cyberweld.com/coolmate3.html

http://weldingdirect.com/migwacocoac.html

I can,t imagine using a NON-LIQUID COOLED TIG TORCH, as they heat up far too rapidly too do much welding, but a factory water cooled tig torch and coolant pump can easily cost $1200 plus , over the cost of the already expensive TIG welder and gas tank, regulator , cart,etc. now I have not tried this personally as I purchased my water cooled TIG torch and pump used as part of my USED TIG welder package deal, but I don,t see where it would not work after looking over the miller coolant pump, etc.

yes it will take a bit of fabrication, but both the 7 gallon capacity and the oil cooler with electric fan are larger and far more efficient than the factory miller pump and cooler radiator fan combo

http://www.youtube.com/watch?v=PZ1V8ewTRlo

http://www.sportsimportsltd.com/ac-to-d ... upply.html 110volt AC to 12 volt DC power for FAN $100

http://www.summitracing.com/parts/DER-13720/?rtype=10

http://www.youtube.com/watch?v=5gAZoYhEe4U

http://www.arc-zone.com/pdf/WhyUPgrade.pdf

http://www.grizzly.com/products/7-Gallo ... 2Bproducts

http://weldingdirect.com/sr1825.html

http://weldingdirect.com/sr18v25.html TORCH AND CABLES UNDER $200

this info above might be useful in a similar custom fabrication of a coolant pump for a tig