My L98 became increasingly hard to start in the morning. It acted like it was starting in a lean condition. Once I got it going it would run fine for the rest of the day. Putting a fuel pressure gauge on it revealed that it only pumped up to 30 pounds when the key was turned to ignition. It started, but with great difficulty. After getting it running and switching it off, the pressure would bleed down relatively quickly and I thought it may be a check valve in fuel pump or fuel pressure regulator, but this was not the problem. I elected to install a new fuel sending unit, which includes the pump, pulsator, fuel tubing, and fuel level sending parts. Cost me 280 from Amazon for a Delphi unit. This has solved the cold start problem. I did a 8 minute video of the removal and install. On youtube if you want to take a look. Not the best quality, but it may be helpful to someone. The task was really not too difficult. Keeping trash from falling into the tank was the hardest part.

steve

"quote"since I deleted my 9th injector"

- thats a bit like saying I pounded a 6" spike through my big toe with a sledge hammer and now it hurts when I walk

- LINKS AND INFO THAT MAY HELP

reading these links will be helpful

yes I know it will take some time and effort to isolate and test

but its the only 100% sure route to finding and fixing your problem,

don,t get over whelmed,

simply break the problem down to testing each basic sub system,

test each related sensor and electrical component and electrical sensor and connection.

some reading on the threads posted below, a bit of logic and deductive reasoning, and a multi meter and a shop manual will go a long way toward finding and fixing the problem.

Measured Value

Engine Coolant Temperature Sensor. 185 Ohms @ 210F, 3400 Ohms @ 68F, 7,500 Ohms @ 39 F.

Engine Oil Temperature Sensor. 185 Ohms @ 210 F, 3400 Ohms @ 68 F, 7,500 Ohms @39 F.

Oil Pressure Sender/Switch. 1 Ohms @ 0 PSI, 43 Ohms @ 30 PSI, 86 Ohms @ 60 PSI.

Fuel Quantity Sender. 0 Ohms @ Empty, 45 Ohms @ 1/2 Full, 90 Ohms @ Full.

MAT (Manifold Absolute Temperature Sensor). 185 Ohms @ 210 F, 3400 Ohms @ 70 F, 15,000 Ohms @ 40 F.

Outside Temperature Sensor. 4400 Ohms @ 60 F, 2200 Ohms @ 85 F.

In Car Temp Temperature Sensor. 4400 Ohms @ 60 F, 2200 Ohms @ 85 F.

MAF (Mass Air Flow) Sensor. .4 Volts @ idle, 5 Volts @ Full Throttle.

Oxygen (O2) Sensor. .1 Volt Lean Mixture, .9 Volt Rich Mixture.

TPS (Throttle Position Sensor). .54 Volts Idle, ~ 5 Volts Full Throttle.

Sensor Locations

Sensor

Location

Engine Coolant Temperature Sensor. Front of engine, below Throttle Body.

Engine Oil Temperature Sensor. Left rear of engine, just above the oil filter.

Oil Pressure Sender/Switch. Top, left hand rear of engine.

Fuel Quantity Sender. Top of fuel tank, beneath filler pipe escutcheon panel.

MAT (Manifold Absolute Temperature Sensor). Underside of manifold air plenum at rear.

Outside Temperature Sensor. Right side of engine, top right corner of radiator.

In Car Temp Temperature Sensor. Coupe: above left seat near interior courtesy light, Convertible: center of cargo compartment lid.

MAF (Mass Air Flow) Sensor. Front of engine ahead of throttle body.

Oxygen (O2) Sensor. Left side of engine, in exhaust pipe.

TPS (Throttle Position Sensor). Right side of throttle body at the front.

ignition wires & getting the header clearance

Good spark plug wire usually has less than about 400-500ohms ohms resistance per ft. Your correct that less resistance tends to allow more SPARK energy a crossed the plug gap, which in most cases is best set in the .040-.045 range in my experience, for HEI ignitions and .030 plug gap for a...

garage.grumpysperformance.com

you always need a base line to start from, on a corvette.

a logical step by step approach and keeping accurate notes helps.

youll NEED a multi meter, a shop manual

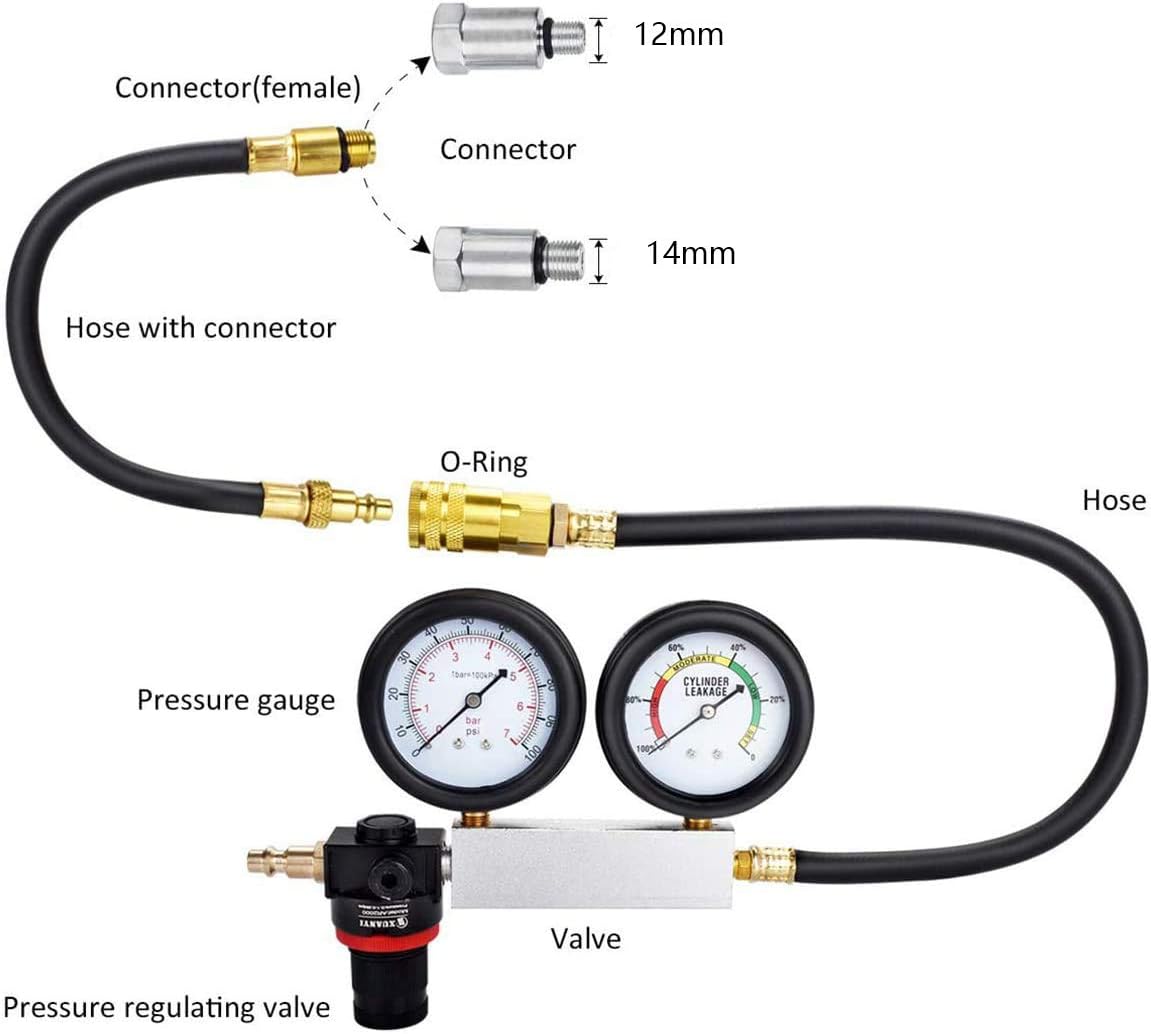

and a timing light and fuel pressure gauge at a minimum,

set and verify your ignition timing, pull trouble codes,set your tps and iac,, then check for vacuum leaks on the lines and intake,then get out your multi meter and verify all the sensors, chances are good a logical step by step approach will lead you to the problem, youll be amazed at what youll learn reading links. use of a shop manual and multi meter can be very helpful

helpful links

http://garage.grumpysperformance.com/index.php?threads/replacing-a-c-4-fuel-pump.33/

http://garage.grumpysperformance.co...g-tpi-crossfire-or-lt1-vette.1401/#post-34392

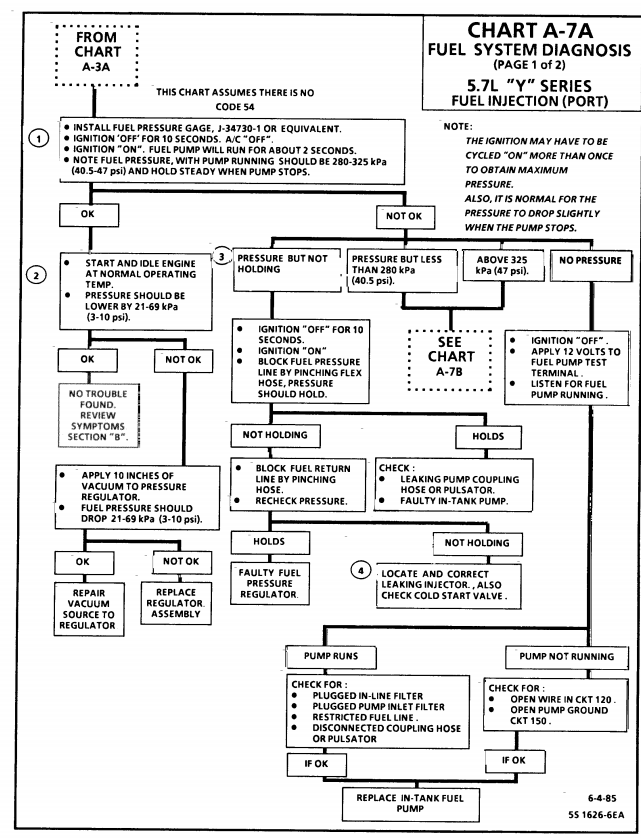

http://garage.grumpysperformance.co...-system-trouble-shooting-flow-chart-info.596/

http://garage.grumpysperformance.com/index.php?threads/c4-c5-corvette-trouble-codes.2697/

http://garage.grumpysperformance.com/index.php?threads/testing-1985-89-m-a-f-sensor.1475/#post-43635

http://garage.grumpysperformance.co...asic-trouble-shooting-on-the-c4.302/#post-697

http://garage.grumpysperformance.com/index.php?threads/replacing-c-4-or-tpi-fuel-injectors.1378/

http://garage.grumpysperformance.co...too-common-questions-can-be-found-here.12892/

http://garage.grumpysperformance.co...-cranks-but-won-t-start-intermittently.14212/

http://garage.grumpysperformance.co...s-air-flow-vs-speed-density.11952/#post-56852

if your early l98 corvette engine is set up to use that 9th injector to enrich the start up procedure,

and you removed it

without upgrading to the more recent EFI controller,

designed to run without that 9th injector...

you will have cold start issues unless the other injector flow rates compensate by flowing a bit richer mix.

both the MAF and plenum temp sensors could be partly responsible and Id certainly check the 02 sensors

having a shop manual and basic tools like a fuel pressure gauge and multi-meter will help

ID certainly verify your fuel pressure at start-up,(when you turn on the key but before you start the car is running in the 38-42 psi range and your fuel pressure regulator, and fuel pump are in good condition)

86 pacer....have you verified for closed loop operation? If you don't have a multi-meter, you can use the car's built in field test mode using a paper clip.

The same as pulling codes but you start the car this time when jumping the A&B terminals of the ALDL plug. Two flashes per second on the engine light means the car is in open loop. If the flashes drop to 1 time per second, the car is entering closed loop.

Vacuum leaks can introduce unmetered air entering the motor bypassing the MAF sensor, which throws off the mixture as the ECM tries to compensate.

Last edited: