LOOK THRU THE LINKED INFO ITS WORTH THE TIME AND EFFORT

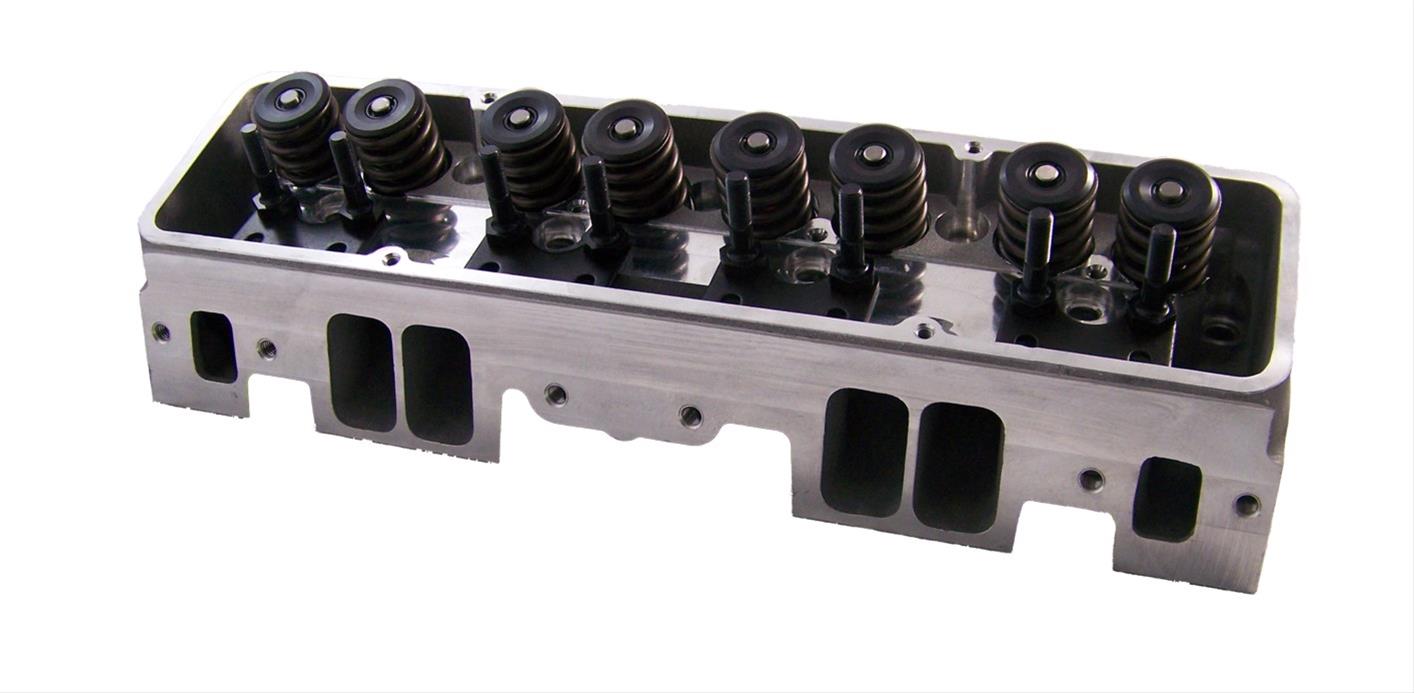

keep in mind vortec heads without push rod guide plates or press-in rocker studs used with the push-rods MUST use self aligning rockers, standard rockers used without push rod guide plates will not maintain proper alignment and only screw in rocker studs can be used with push rod guide plates

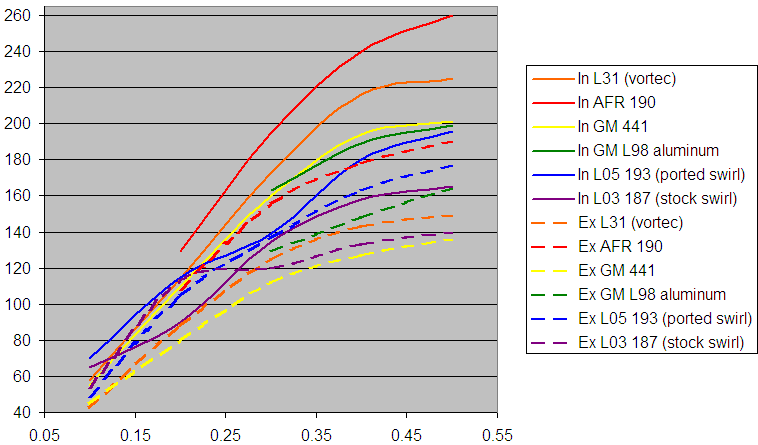

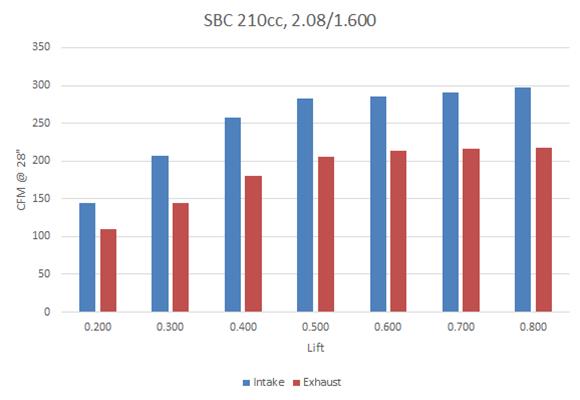

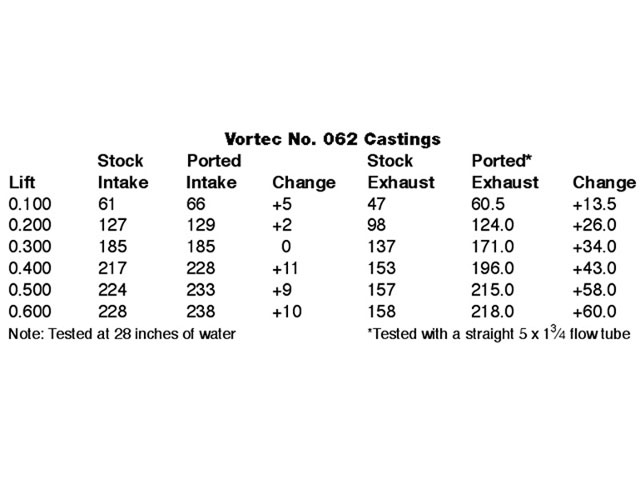

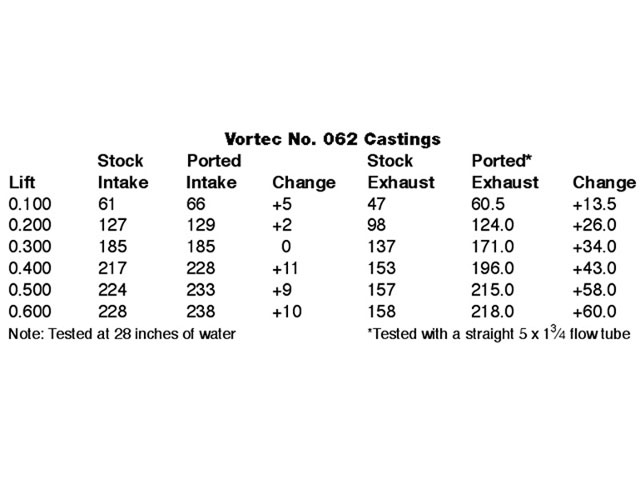

I thought I post these flow numbers on ported vortec heads ive seen posted , just in case anyone has ever wondered or wanted to know the flow numbers a set of stock vortecs. I was also curious if any of you have any guesses on what gains I picked up on the port work.

INTAKE LIFT------- STOCK---- PORTED-- GAIN

.1---------- 59--------- 64--------- +5

.2---------- 117------- 132------- +15

.3---------- 170------- 187------- +17

.4---------- 214------- 236------- +22

.5---------- 226------- 255------- +29

.6---------- 219------- 259------- +40

EXHAUST

LIFT STOCK PORTED GAIN

.1---------- 42----------46--------- +4

.2---------- 83----------90--------- +7

.3---------- 123--------139--------+16

.4---------- 136--------161--------+25

.5---------- 143--------174--------+31

.6-----------147------- 178--------+31

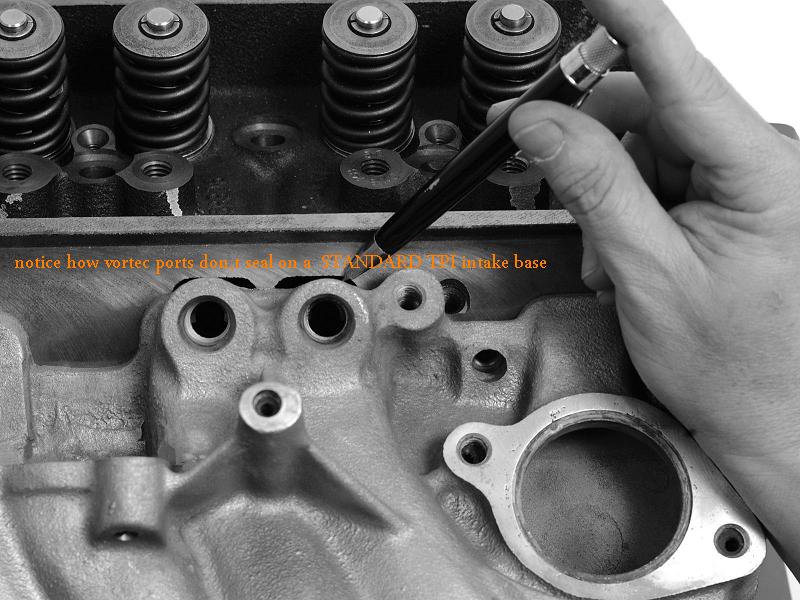

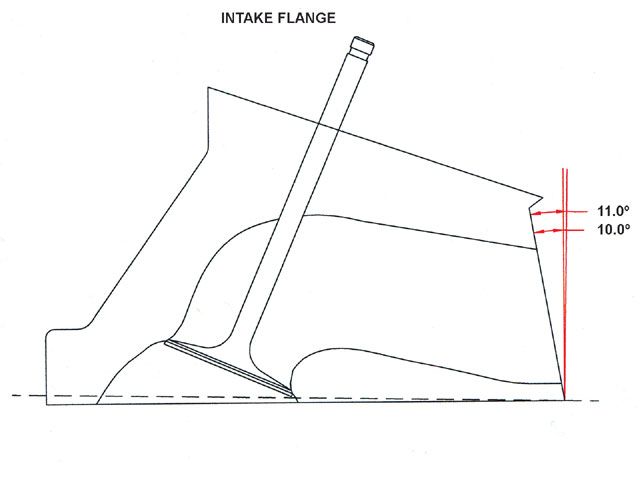

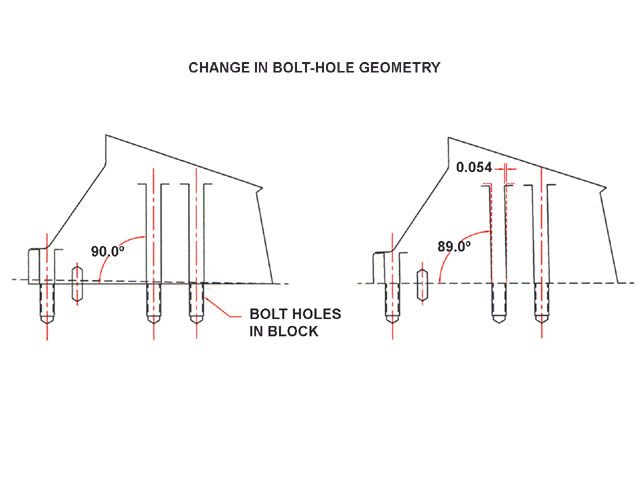

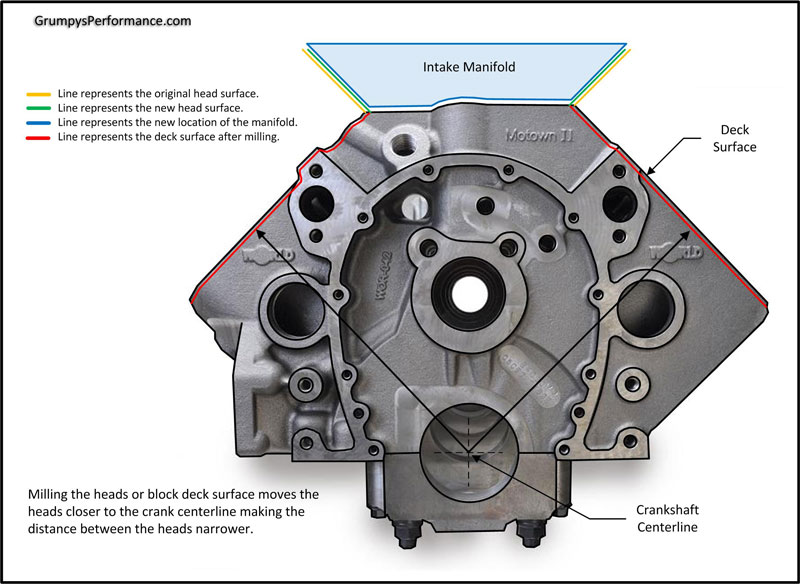

YOU MIGHT NEED A DRILL PRESS TO RE-DRILL SOME INTAKES TO GET THE CORRECT BOLT ANGLES

viewtopic.php?f=27&t=970&p=1691#p1691

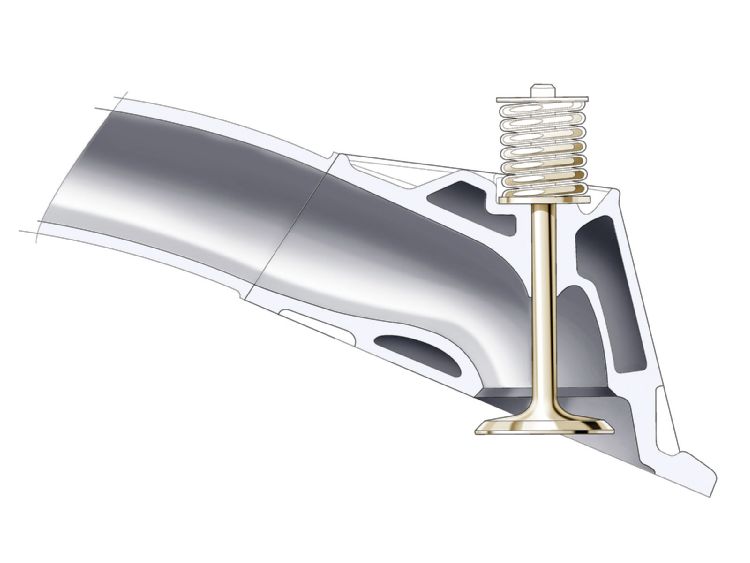

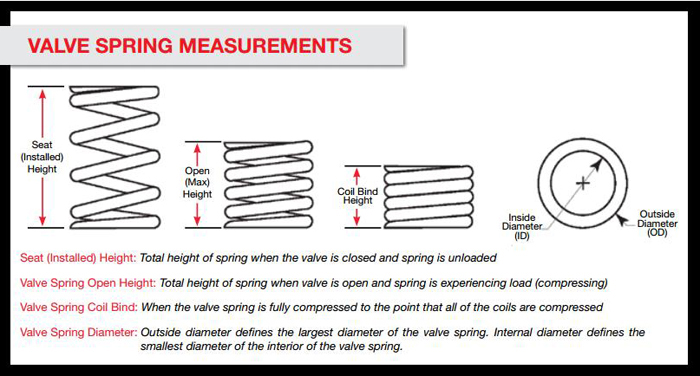

you might also want to keep in mind theres a great deal more to setting up a valve train than slapping some springs and retainers and keepers on the valves.

read thru the links and sub links as theres a great deal of useful info, that youll want to know.

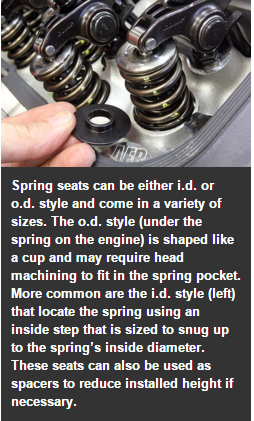

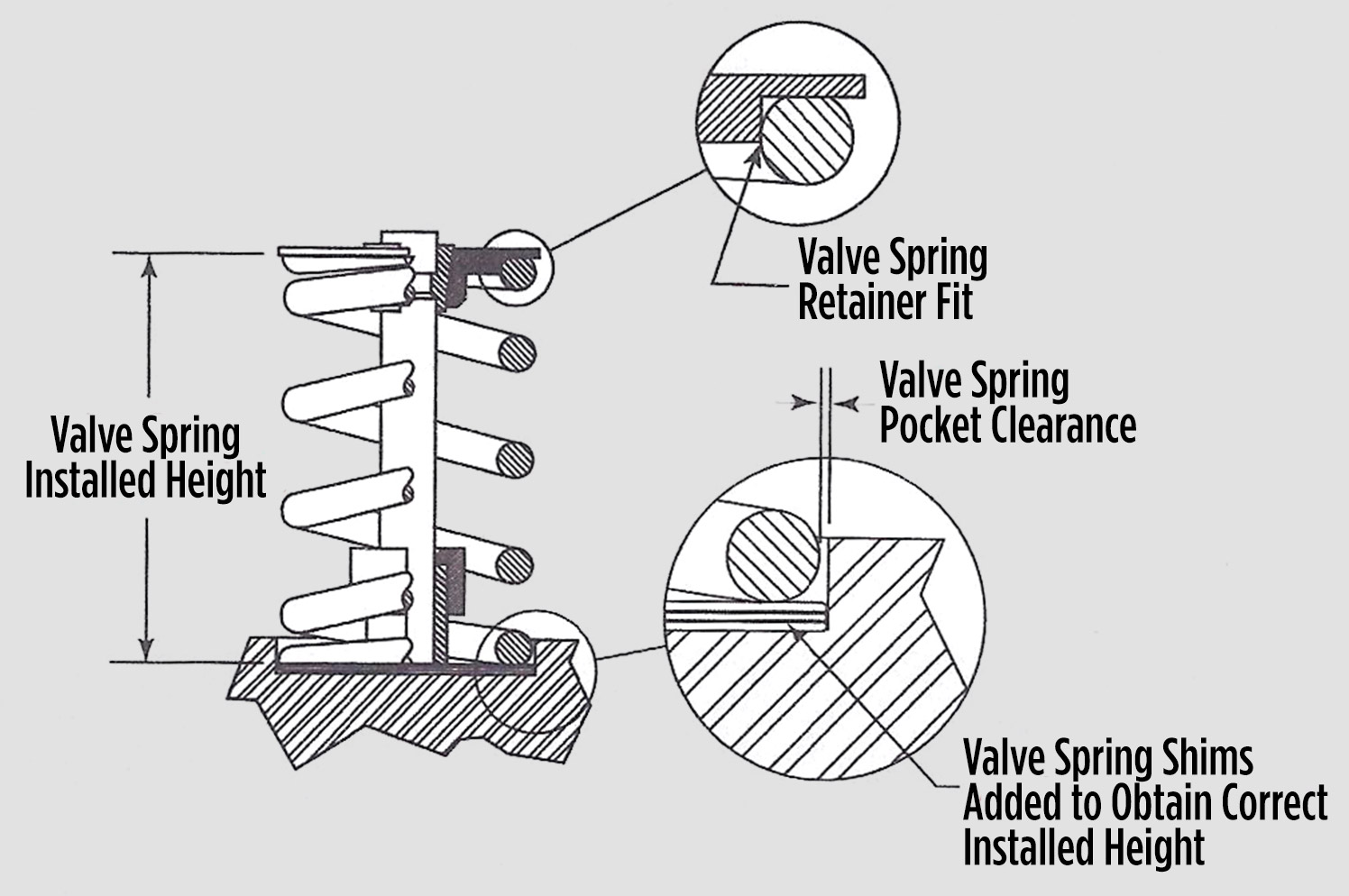

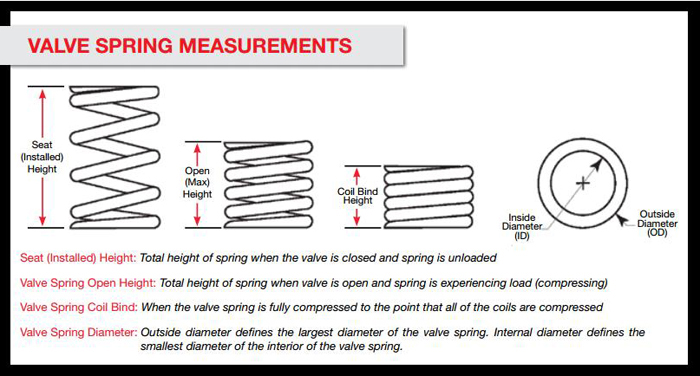

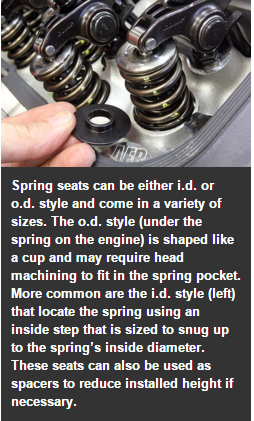

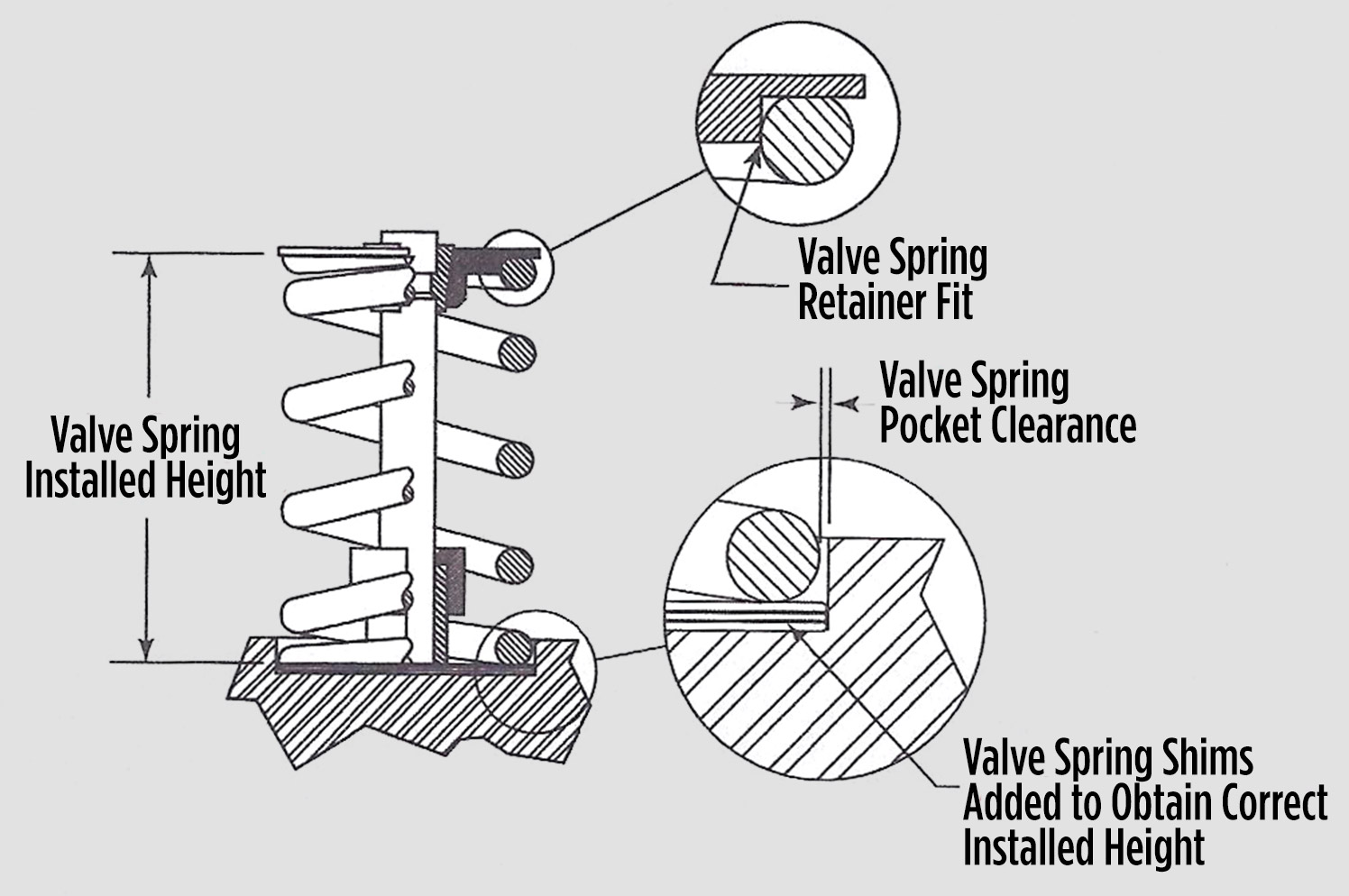

btw just a bit more info, there are valve spring retainers, valve spring seats, shims, valve retainer keepers etc. that can be used that have different sizes or depths that allow you to change the installed height, or relation of the spring to the valve stem , it compressed height, or the valve springs location in relationship to the stems locking groove

keep in mind shims under the valve springs can be used to raise the spring or shorten the valves installed height, valve locks and retainers can be purchased with non-O.E.M dimensions to adjust the valves installed height or spring load rates

you use either or both depending on the application

a .050 PLUS valve lock moves the retainer .050 higher on the valve stem with no other changes, a plus .050 retainer would move the retainer .050 higher with stock valve locks or an additional .050 if matched to .050 plus locks

if you used a plus .o50 retainer with a set of minus .o50 valve locks the retainer would remain at the stock height on the valve stem

http://www.jegs.com/p/Crane/746983/10002/-1

http://www.jegs.com/p/Moroso/764349/10002/-1

http://www.jegs.com/p/Manley/940089/10002/-1

http://www.jegs.com/p/Comp+Cams/757964/10002/-1

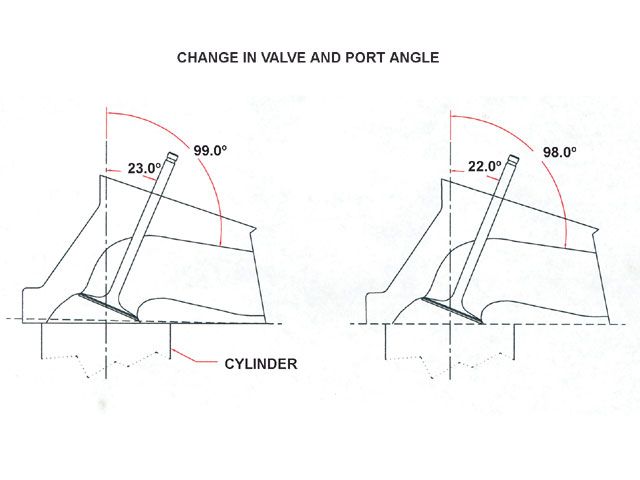

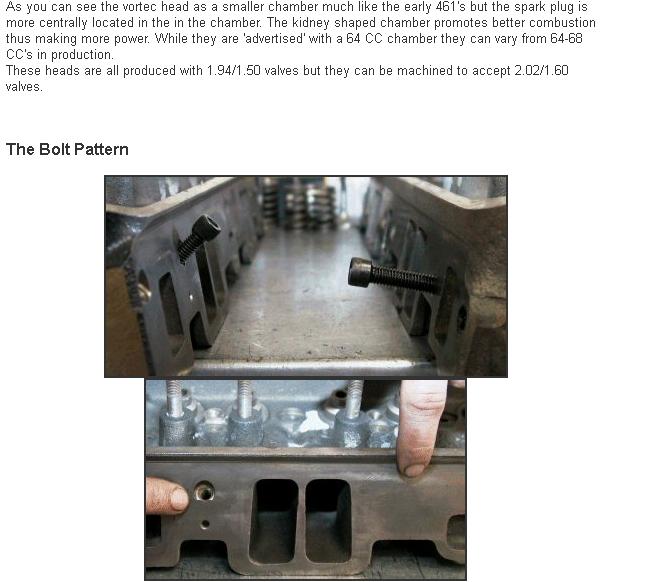

VORTEC HEADS HAVE A DIFFERENT INTAKE BOLT ANGLE ON SOME BOLT LOCATIONS

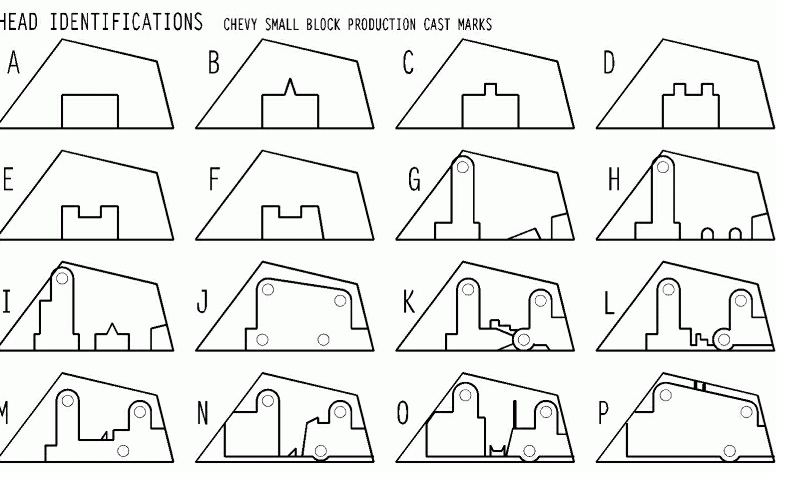

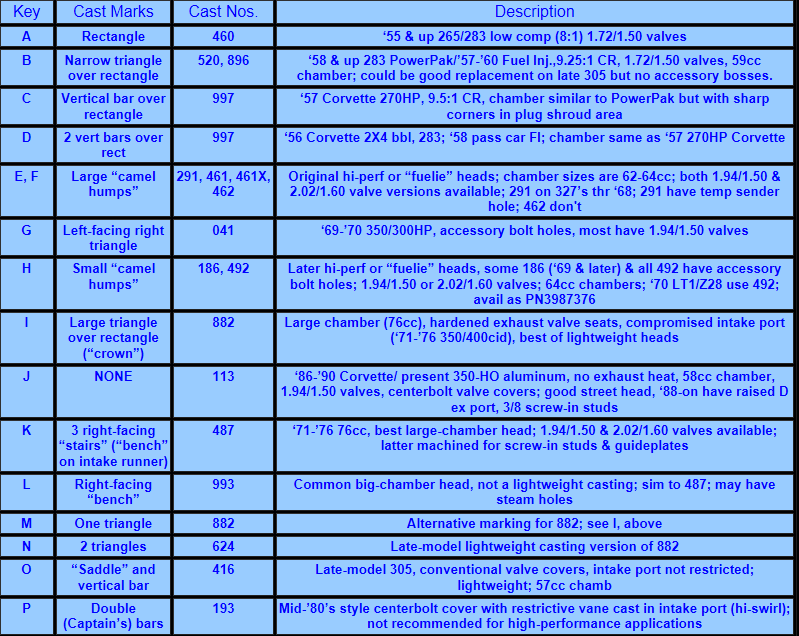

VORTEC HEADS YOULL FIND IN SALVAGE YARDS HAVE THESE HEAD MARKINGS

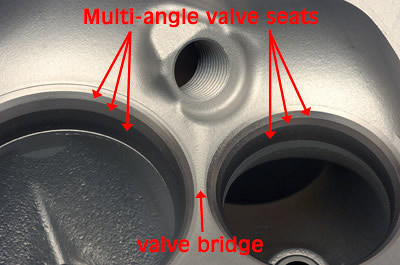

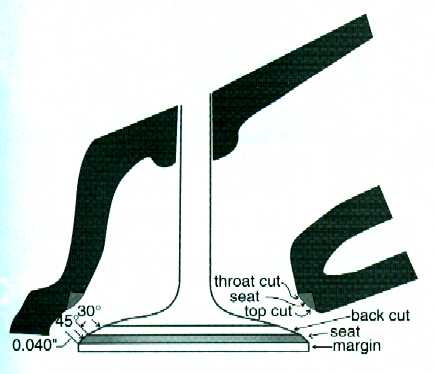

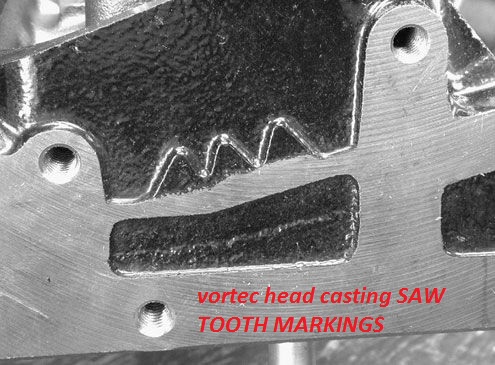

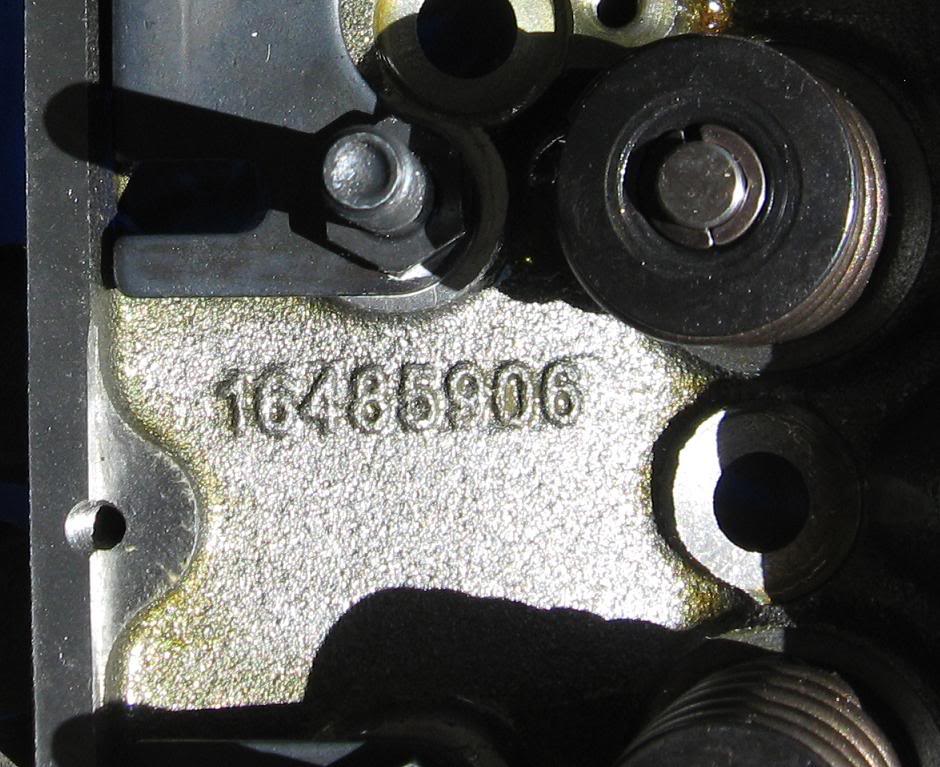

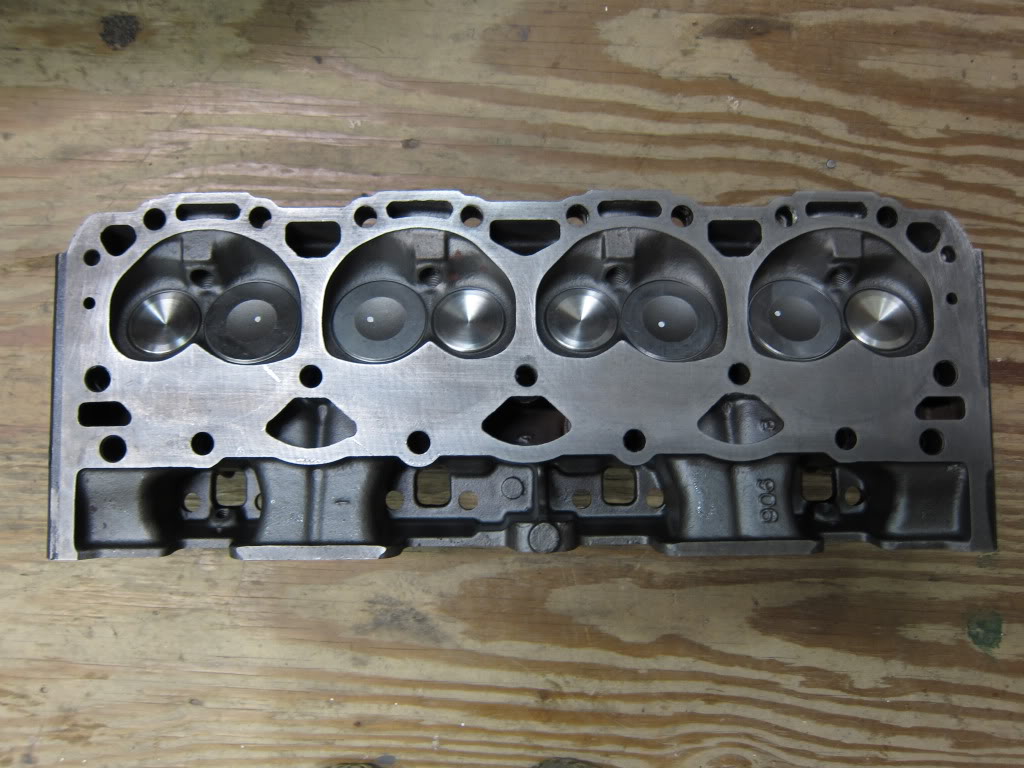

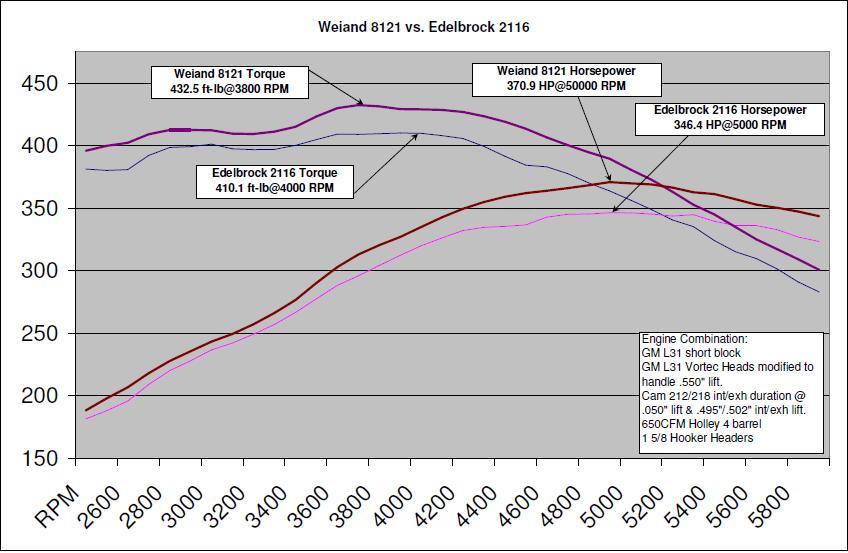

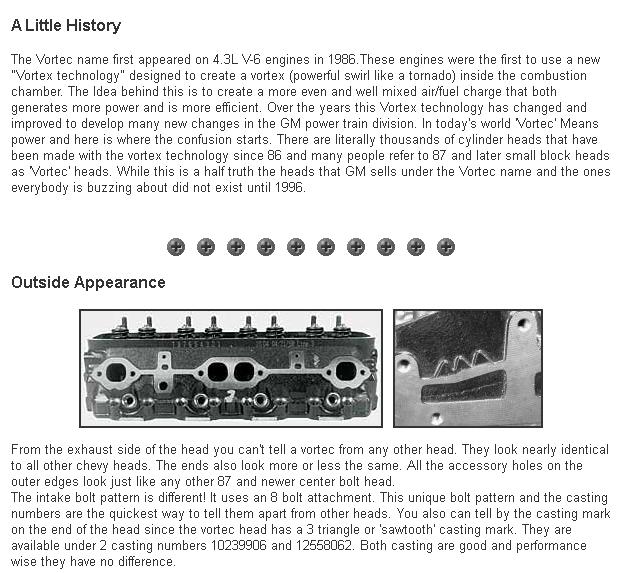

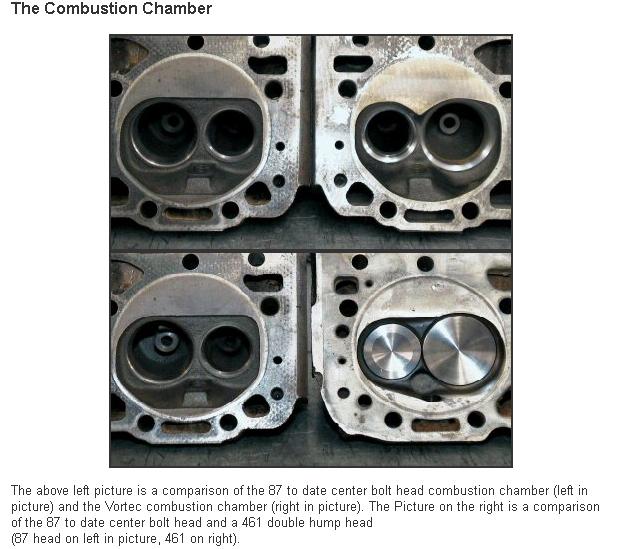

The L31 Vortec comes in two different casting numbers, 10239906 (#906) or 12558062 (#062). Originally, the stock #906 casting head was available in two versions. One version had an Inconel exhaust seat with single angle valve grind and was available on 1 ton trucks. The other version was the traditional three angle valve grind. Other than that, the #906 is the same as the #062 head.

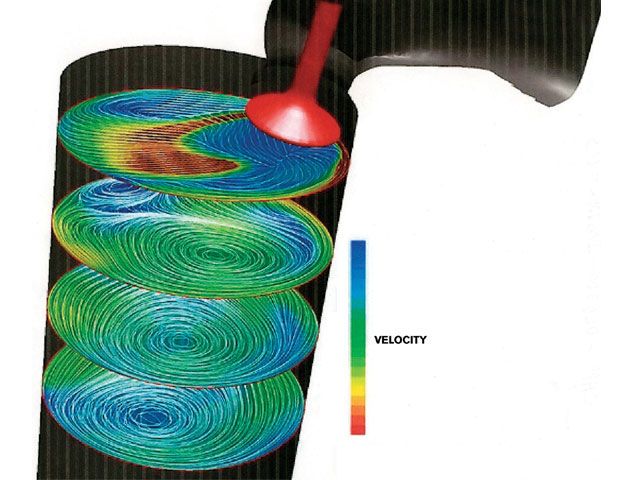

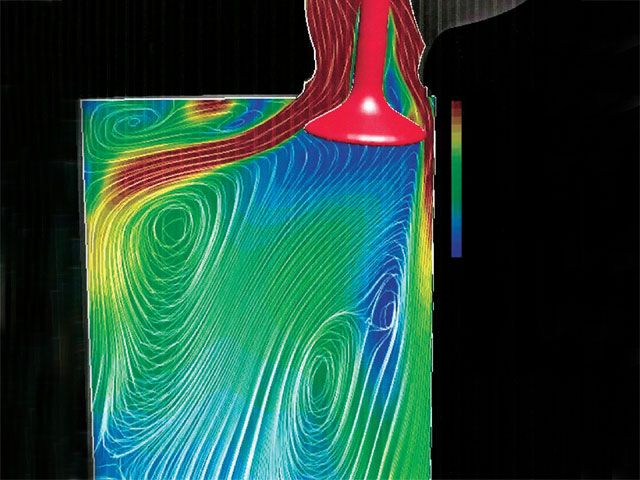

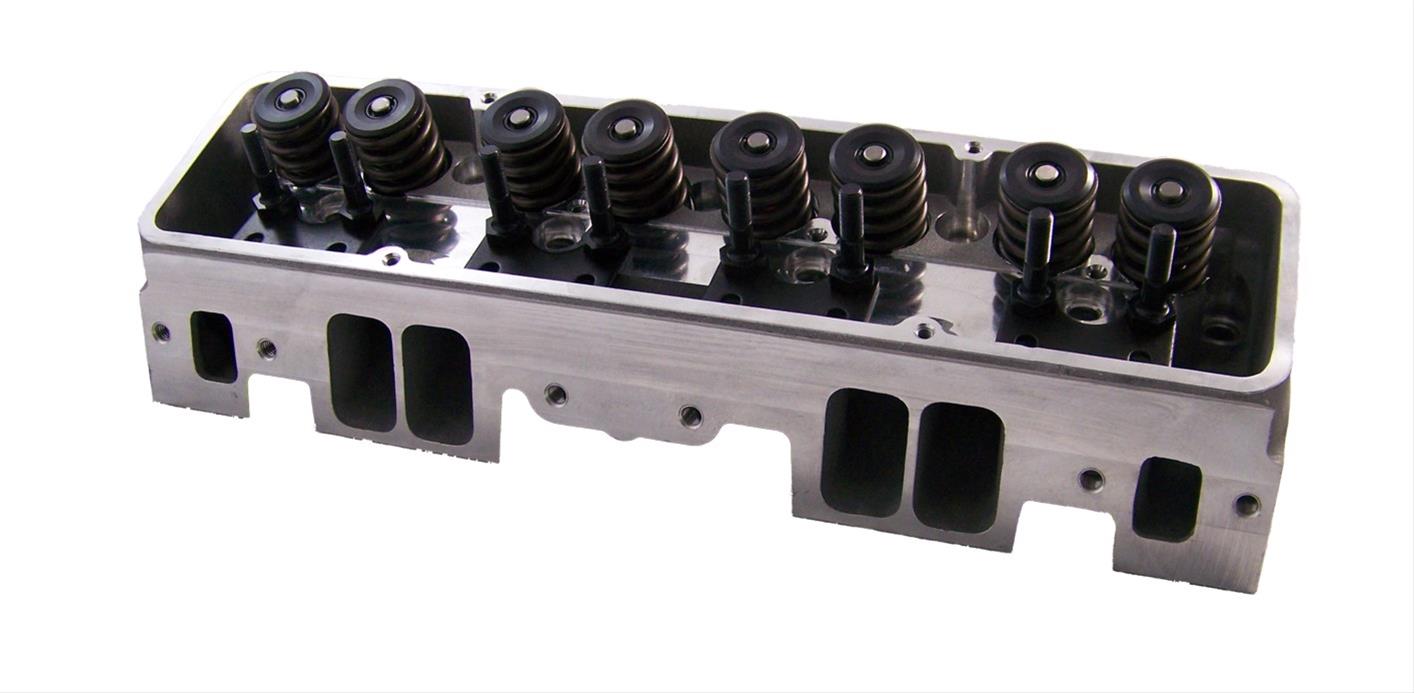

GM Performance Parts Bowtie Vortecs are offered in “small port” (#25534351), which has 185cc intake ports/65cc exhaust ports, or the “large port” (#25534445), which features 225cc intake ports/77cc exhaust ports. Both GM factory and GM Performance Parts Vortecs come with 1.94 intake/1.50 exhaust valves. According to the engineers at GM, “Stepping them up to 2.02 valves doesn’t help them any, so it’s not recommended. The port was designed to match the 1.94 valves. With the Vortec flow velocity,

things that can cause the guides to go bad are

1) Improper valve train component geometry in the rocker arm sweep on the tip of the valve stem.

viewtopic.php?f=44&t=2839&p=12739#p12739

2) Lack of oil flow to the valve stems and lack of assembly lube on the valve stem before firing the engine.

3) cheap parts that are not clearanced correctly

4) improperly installed valve seals or the wrong valve seals

youll miss a TON OF INFO IF YOU DON,T READ THE SUB LINKS

http://www.chevyhiperformance.com/howto ... index.html

viewtopic.php?f=52&t=266&p=322&hilit=215cc+vortec#p322

http://www.onedirt.com/tech-stories/eng ... evy-heads/

http://www.carcraft.com/techarticles/vo ... index.html

viewtopic.php?f=44&t=6175&p=19304#p19304

http://www.sallee-chevrolet.com/Cylinde ... Vortec.cfm

http://www.strokerengine.com/SBCHeadsFlow.html

http://www.jegs.com/i/Patriot+Performan ... 1/10002/-1

viewtopic.php?f=44&t=6181&p=19320&hilit=vortec+port#p19320

viewtopic.php?f=52&t=322&p=9895&hilit=flow+numbers#p9895

viewtopic.php?f=52&t=5537

http://racingfeed.com/downloads/chevy_flow_data.pdf

http://www.carcraft.com/techarticles/vo ... index.html

http://www.customclassictrucks.com/tech ... index.html

http://carcraft.automotive.com/9794/vor ... index.html

http://www.crustyquinns.com/tech/easyout.html

viewtopic.php?f=52&t=1053&p=1989#p1989

http://www.chevyhiperformance.com/techa ... index.html

http://www.customclassictrucks.com/tech ... to_04.html

http://www.goodson.com/

http://www.goodson.com/technical_support/

theres alot of good info in the links guys

http://www.chevyhiperformance.com/techa ... index.html

http://www.chevyhiperformance.com/howto ... index.html

http://www.popularhotrodding.com/engine ... index.html

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=528

http://www.chevymania.com/tech/vortec.htm

viewtopic.php?f=52&t=2077&p=44546&hilit=ccing+heads#p44546

viewtopic.php?f=52&t=2630&p=6788&hilit=+shrouding#p6788

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=528

viewtopic.php?f=52&t=401

Got questions? We've got the answers. Call 1-800-533-8010 from 8:00 am to 5:00 pm (central time), Monday through Friday

YOULL NEED TO KNOW YOUR SPRING DIAM. SPRING BIND HEIGHT,, MAX CAM LIFT, CURRENT RETAINER TO VALVE GUIDE CLEARANCE, THE TYPE AND DIAM. OF THE VALVE SEALS YOU WANT TO USE, IN MOST CASES ALL THAT INFO CAN BE OBTAINED FROM THE CAM MANUFACTURERS AND THE PARTS THEY SUGGEST TO USE WITH THEIR CAMS, THE VORTEC HEADS DON,T FLOW EXTREMELY WELL OVER .550 LIFT SO THERE'S LITTLE SENSE IN EXCEEDING THAT AND THE PORTS WON,T FLOW WELL ON A 350-383 AT OVER 6000RPM EVEN PORTED SO THAT'S GOING TO LIMIT THE CAM SELECTION ALSO

in theory brass/bronze valve guides are minimally softer and wear faster,than iron valve guides, but in reality if your using the proper valve seals, and have your oil flow to the upper valve train functioning correctly with reasonably clean oil, theres a thin coat of oil between the valve stems and the surface of the inner valve guides, that prevents any wear if your valve train geometry has the main loads centered on the valves centerline. keep in mind having proper valve train geometry, and having constant clean oil flowing over and cooling the valve springs, and rockers, plays a huge part in valve wear issues.remember the surface Finnish, clearances, valve seals and oil viscosity along with proper valve train geometry and material used in the valves also effects valve wear

btw coating the valve stems with a mixed slurry of marvel mystery oil and crane cams MOLY assembly lube during the cylinder head assembly process, tends to prevent dry start issues with the guides seizing valve stems

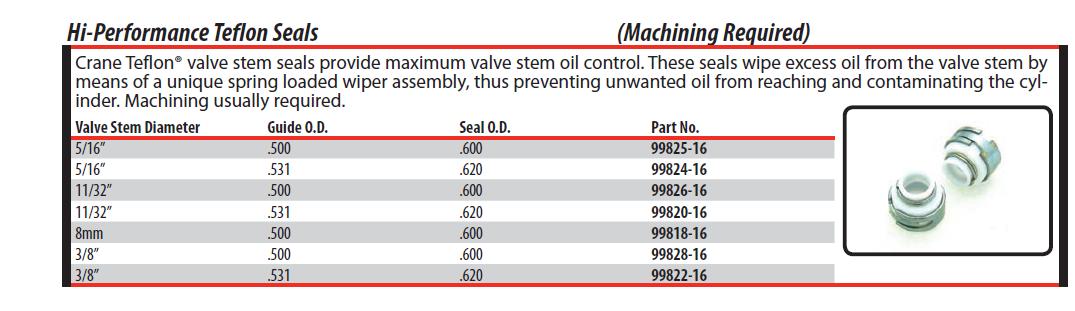

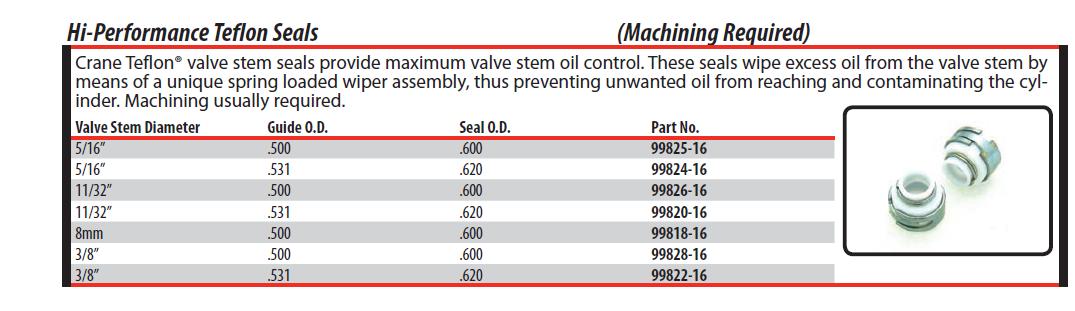

CRANE CAMS SELLS TEFLON VALVE SEALS,they are commonly packaged on blister packs

crane Tech Line - 386-258-6174

CROWER http://www.crower.com/index.php/contacts/

ERSON CAMS http://pbmperformance.com/store.php?catId=327

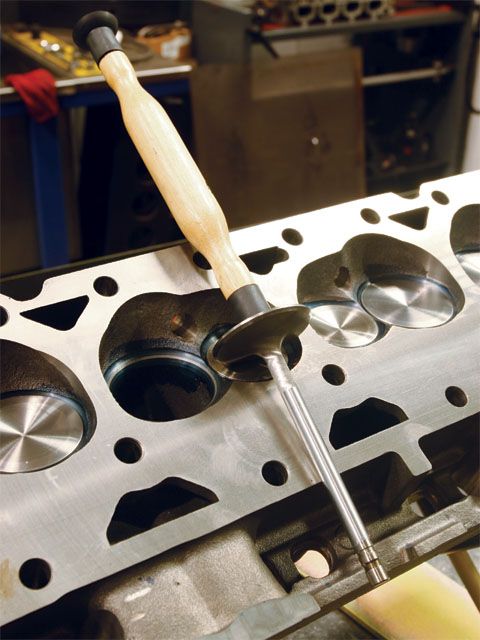

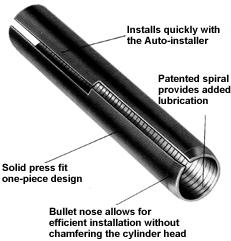

the two striped things are plastic valve seal alignment guides that are temporarily placed over the top of the valve stem, then oiled lightly, they are placed over the valve keeper lock grooves to prevent the seals being damaged during the valve seal installation process.

both tools and info here(ABOVE)ANY TIME YOU NEED TOOLS OR ENGINE MACHINING ADVICE ASK THESE GUYS, THEY USUALLY KNOW EXACTLY THE RIGHT INFO.

this info below might help

http://www.customclassictrucks.com/tech ... index.html

http://www.carcraft.com/techarticles/11 ... index.html

http://www.chevyhiperformance.com/howto/97458/index.html

http://www.carcraft.com/techarticles/vortec_valve_spring_upgrade/index.html

http://www.competitionproducts.com/prodinfo.asp?number=4716

http://www.2quicknovas.com/vortecheads.html

http://www.chevymania.com/tech/vortec.htm

http://www.nastyz28.com/forum/showthread.php?t=56505

http://store.summitracing.com/partdetail.asp?part=CCA-5306&autoview=sku

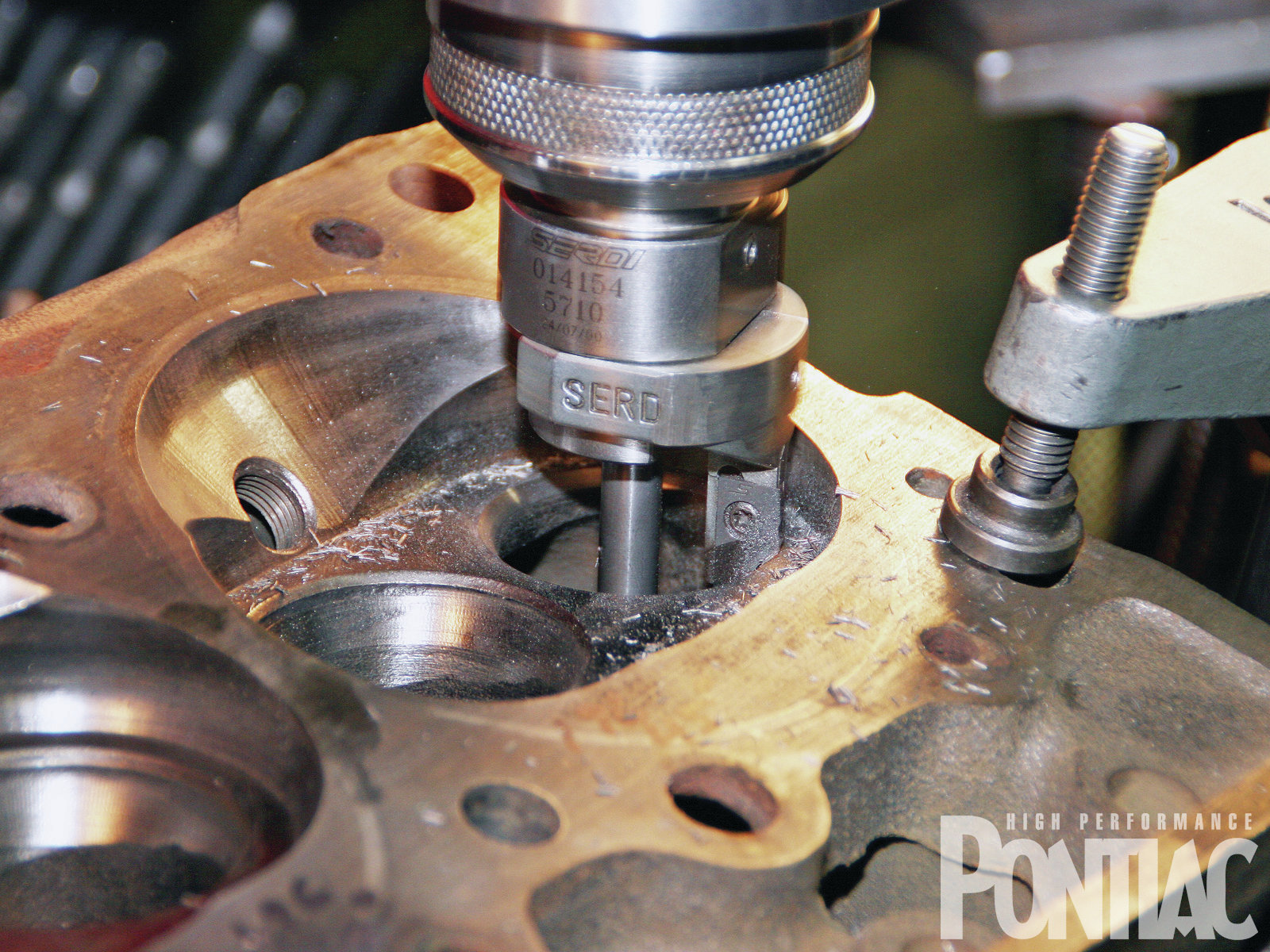

The best way to get the right installed spring height is to get a spring height micrometer. Both Crane and Comp sell tools for machining the guides in various diameters. I ordered mine from Summit. Here are the p/n's"

Comp Spring Seat Cutter 1.440" OD

CCA4718

Comp Valve Guide Cutting Tool 0.530" OD

CCA4726

Comp Arbor for Cutting Tools 11/32" ID

CCA4732

If you want a spring seat locator with your springs (keeps the spring from moving around on the seat and protects the seat surface of the head)

then you can order Comp p/n CCA478316 seat locators and use CCA4719 (1.550" seat cutter) instead of the one listed above. The tools are used with a low-speed drill press using the arbor in the valve guide to keep it lined up (make sure your guides are good first). You slowly remove material and check the height constantly durring the process with the spring height micrometer until you get it right distance between the spring seat and the under side of the retainer (spring height can be adjusted with shims if you go a bit too deep but try to avoid that as youll cut into the heads and cause problems ). After the seat is at the correct height, you machine the guide to fit the valve seals and for the correct clearance.

keep in mind vortec heads without push rod guide plates or press-in rocker studs used with the push-rods MUST use self aligning rockers, standard rockers used without push rod guide plates will not maintain proper alignment and only screw in rocker studs can be used with push rod guide plates

I thought I post these flow numbers on ported vortec heads ive seen posted , just in case anyone has ever wondered or wanted to know the flow numbers a set of stock vortecs. I was also curious if any of you have any guesses on what gains I picked up on the port work.

INTAKE LIFT------- STOCK---- PORTED-- GAIN

.1---------- 59--------- 64--------- +5

.2---------- 117------- 132------- +15

.3---------- 170------- 187------- +17

.4---------- 214------- 236------- +22

.5---------- 226------- 255------- +29

.6---------- 219------- 259------- +40

EXHAUST

LIFT STOCK PORTED GAIN

.1---------- 42----------46--------- +4

.2---------- 83----------90--------- +7

.3---------- 123--------139--------+16

.4---------- 136--------161--------+25

.5---------- 143--------174--------+31

.6-----------147------- 178--------+31

YOU MIGHT NEED A DRILL PRESS TO RE-DRILL SOME INTAKES TO GET THE CORRECT BOLT ANGLES

viewtopic.php?f=27&t=970&p=1691#p1691

you might also want to keep in mind theres a great deal more to setting up a valve train than slapping some springs and retainers and keepers on the valves.

read thru the links and sub links as theres a great deal of useful info, that youll want to know.

btw just a bit more info, there are valve spring retainers, valve spring seats, shims, valve retainer keepers etc. that can be used that have different sizes or depths that allow you to change the installed height, or relation of the spring to the valve stem , it compressed height, or the valve springs location in relationship to the stems locking groove

keep in mind shims under the valve springs can be used to raise the spring or shorten the valves installed height, valve locks and retainers can be purchased with non-O.E.M dimensions to adjust the valves installed height or spring load rates

you use either or both depending on the application

a .050 PLUS valve lock moves the retainer .050 higher on the valve stem with no other changes, a plus .050 retainer would move the retainer .050 higher with stock valve locks or an additional .050 if matched to .050 plus locks

if you used a plus .o50 retainer with a set of minus .o50 valve locks the retainer would remain at the stock height on the valve stem

http://www.jegs.com/p/Crane/746983/10002/-1

http://www.jegs.com/p/Moroso/764349/10002/-1

http://www.jegs.com/p/Manley/940089/10002/-1

http://www.jegs.com/p/Comp+Cams/757964/10002/-1

VORTEC HEADS HAVE A DIFFERENT INTAKE BOLT ANGLE ON SOME BOLT LOCATIONS

VORTEC HEADS YOULL FIND IN SALVAGE YARDS HAVE THESE HEAD MARKINGS

The L31 Vortec comes in two different casting numbers, 10239906 (#906) or 12558062 (#062). Originally, the stock #906 casting head was available in two versions. One version had an Inconel exhaust seat with single angle valve grind and was available on 1 ton trucks. The other version was the traditional three angle valve grind. Other than that, the #906 is the same as the #062 head.

GM Performance Parts Bowtie Vortecs are offered in “small port” (#25534351), which has 185cc intake ports/65cc exhaust ports, or the “large port” (#25534445), which features 225cc intake ports/77cc exhaust ports. Both GM factory and GM Performance Parts Vortecs come with 1.94 intake/1.50 exhaust valves. According to the engineers at GM, “Stepping them up to 2.02 valves doesn’t help them any, so it’s not recommended. The port was designed to match the 1.94 valves. With the Vortec flow velocity,

things that can cause the guides to go bad are

1) Improper valve train component geometry in the rocker arm sweep on the tip of the valve stem.

viewtopic.php?f=44&t=2839&p=12739#p12739

2) Lack of oil flow to the valve stems and lack of assembly lube on the valve stem before firing the engine.

3) cheap parts that are not clearanced correctly

4) improperly installed valve seals or the wrong valve seals

youll miss a TON OF INFO IF YOU DON,T READ THE SUB LINKS

http://www.chevyhiperformance.com/howto ... index.html

viewtopic.php?f=52&t=266&p=322&hilit=215cc+vortec#p322

http://www.onedirt.com/tech-stories/eng ... evy-heads/

http://www.carcraft.com/techarticles/vo ... index.html

viewtopic.php?f=44&t=6175&p=19304#p19304

http://www.sallee-chevrolet.com/Cylinde ... Vortec.cfm

http://www.strokerengine.com/SBCHeadsFlow.html

http://www.jegs.com/i/Patriot+Performan ... 1/10002/-1

viewtopic.php?f=44&t=6181&p=19320&hilit=vortec+port#p19320

viewtopic.php?f=52&t=322&p=9895&hilit=flow+numbers#p9895

viewtopic.php?f=52&t=5537

http://racingfeed.com/downloads/chevy_flow_data.pdf

http://www.carcraft.com/techarticles/vo ... index.html

http://www.customclassictrucks.com/tech ... index.html

http://carcraft.automotive.com/9794/vor ... index.html

http://www.crustyquinns.com/tech/easyout.html

viewtopic.php?f=52&t=1053&p=1989#p1989

http://www.chevyhiperformance.com/techa ... index.html

http://www.customclassictrucks.com/tech ... to_04.html

http://www.goodson.com/

http://www.goodson.com/technical_support/

theres alot of good info in the links guys

http://www.chevyhiperformance.com/techa ... index.html

http://www.chevyhiperformance.com/howto ... index.html

http://www.popularhotrodding.com/engine ... index.html

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=528

http://www.chevymania.com/tech/vortec.htm

viewtopic.php?f=52&t=2077&p=44546&hilit=ccing+heads#p44546

viewtopic.php?f=52&t=2630&p=6788&hilit=+shrouding#p6788

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=528

viewtopic.php?f=52&t=401

Got questions? We've got the answers. Call 1-800-533-8010 from 8:00 am to 5:00 pm (central time), Monday through Friday

YOULL NEED TO KNOW YOUR SPRING DIAM. SPRING BIND HEIGHT,, MAX CAM LIFT, CURRENT RETAINER TO VALVE GUIDE CLEARANCE, THE TYPE AND DIAM. OF THE VALVE SEALS YOU WANT TO USE, IN MOST CASES ALL THAT INFO CAN BE OBTAINED FROM THE CAM MANUFACTURERS AND THE PARTS THEY SUGGEST TO USE WITH THEIR CAMS, THE VORTEC HEADS DON,T FLOW EXTREMELY WELL OVER .550 LIFT SO THERE'S LITTLE SENSE IN EXCEEDING THAT AND THE PORTS WON,T FLOW WELL ON A 350-383 AT OVER 6000RPM EVEN PORTED SO THAT'S GOING TO LIMIT THE CAM SELECTION ALSO

in theory brass/bronze valve guides are minimally softer and wear faster,than iron valve guides, but in reality if your using the proper valve seals, and have your oil flow to the upper valve train functioning correctly with reasonably clean oil, theres a thin coat of oil between the valve stems and the surface of the inner valve guides, that prevents any wear if your valve train geometry has the main loads centered on the valves centerline. keep in mind having proper valve train geometry, and having constant clean oil flowing over and cooling the valve springs, and rockers, plays a huge part in valve wear issues.remember the surface Finnish, clearances, valve seals and oil viscosity along with proper valve train geometry and material used in the valves also effects valve wear

btw coating the valve stems with a mixed slurry of marvel mystery oil and crane cams MOLY assembly lube during the cylinder head assembly process, tends to prevent dry start issues with the guides seizing valve stems

CRANE CAMS SELLS TEFLON VALVE SEALS,they are commonly packaged on blister packs

crane Tech Line - 386-258-6174

CROWER http://www.crower.com/index.php/contacts/

ERSON CAMS http://pbmperformance.com/store.php?catId=327

the two striped things are plastic valve seal alignment guides that are temporarily placed over the top of the valve stem, then oiled lightly, they are placed over the valve keeper lock grooves to prevent the seals being damaged during the valve seal installation process.

both tools and info here(ABOVE)ANY TIME YOU NEED TOOLS OR ENGINE MACHINING ADVICE ASK THESE GUYS, THEY USUALLY KNOW EXACTLY THE RIGHT INFO.

this info below might help

http://www.customclassictrucks.com/tech ... index.html

http://www.carcraft.com/techarticles/11 ... index.html

http://www.chevyhiperformance.com/howto/97458/index.html

http://www.carcraft.com/techarticles/vortec_valve_spring_upgrade/index.html

http://www.competitionproducts.com/prodinfo.asp?number=4716

http://www.2quicknovas.com/vortecheads.html

http://www.chevymania.com/tech/vortec.htm

http://www.nastyz28.com/forum/showthread.php?t=56505

http://store.summitracing.com/partdetail.asp?part=CCA-5306&autoview=sku

The best way to get the right installed spring height is to get a spring height micrometer. Both Crane and Comp sell tools for machining the guides in various diameters. I ordered mine from Summit. Here are the p/n's"

Comp Spring Seat Cutter 1.440" OD

CCA4718

Comp Valve Guide Cutting Tool 0.530" OD

CCA4726

Comp Arbor for Cutting Tools 11/32" ID

CCA4732

If you want a spring seat locator with your springs (keeps the spring from moving around on the seat and protects the seat surface of the head)

then you can order Comp p/n CCA478316 seat locators and use CCA4719 (1.550" seat cutter) instead of the one listed above. The tools are used with a low-speed drill press using the arbor in the valve guide to keep it lined up (make sure your guides are good first). You slowly remove material and check the height constantly durring the process with the spring height micrometer until you get it right distance between the spring seat and the under side of the retainer (spring height can be adjusted with shims if you go a bit too deep but try to avoid that as youll cut into the heads and cause problems ). After the seat is at the correct height, you machine the guide to fit the valve seals and for the correct clearance.

Last edited by a moderator: