\" how do you measure piston dome volume"

I just bought a 454 from a yard sale,

the seller has no clue as to the pistons used"

Compression Calculator

Get fast, Free Standard Shipping on orders over Summit Racing Equipment from $109 -- no shipping, handling, or rural fees! Exclusions apply.

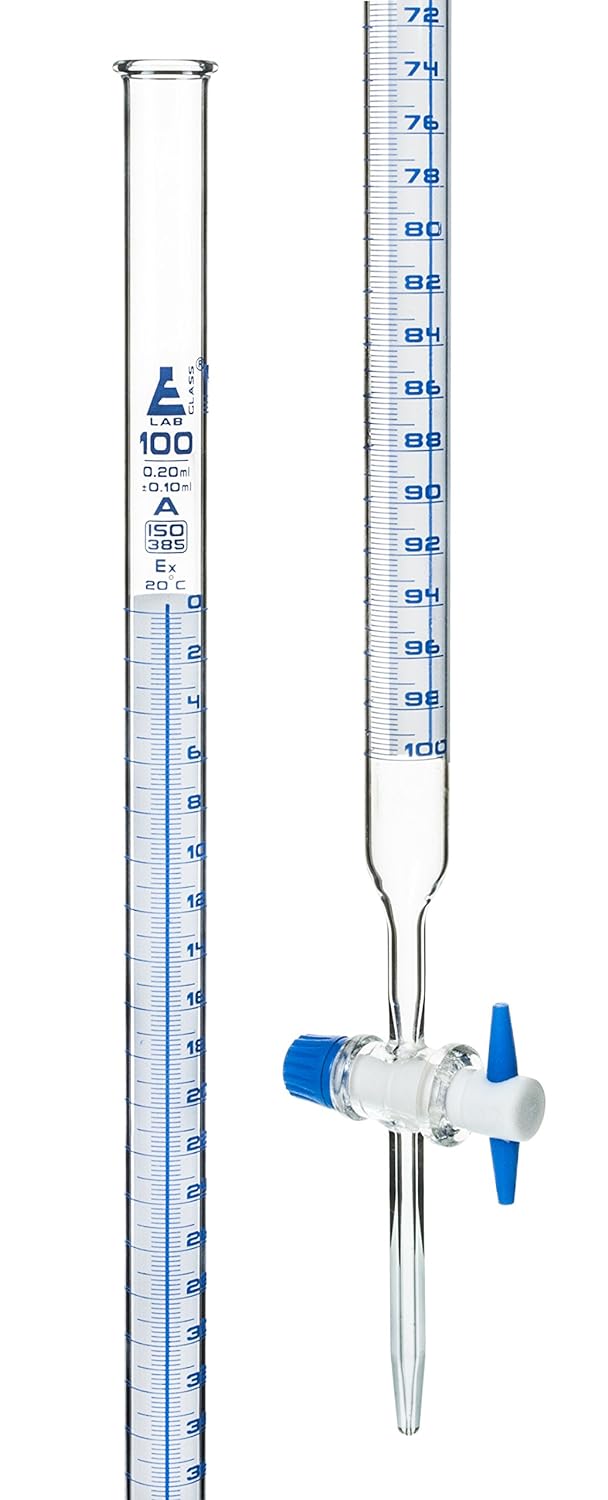

Class B Glass Burettes, 10mL - 2000mL

These Class B burettes are made from bore tubing and offer accurate measuring as well as reliability. Featuring amber graduations and glass stopcocks.

ok first some facts

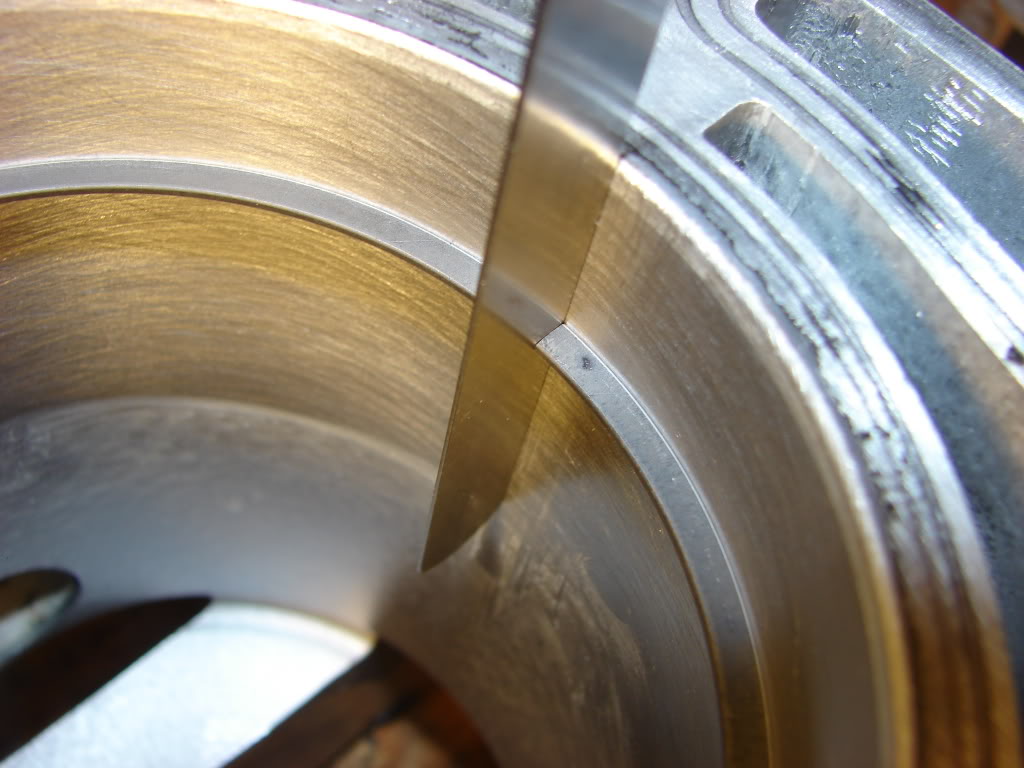

(1)cylinders will not be honed to true round as they will be in use with out the use of a deck plate to simulate and duplicate the bolt clamp stress on the cylinder walls, bores in blocks without a head or deck plate with the bolts or studs torqued to spec are not nearly the same shape before having the torqued studs bolts stress applied, theres almost no chance of getting a good ring seal without having the bores honed with a deck plate

always read, understand and follow the piston manufacturers guide for piston to bore clearance and how you measure that correctly

YOU NEED TO KNOW what is the piston to bore side clearance, where on the piston in relation to the pin,it will need to be accurately measured,in relation too the piston pin bore axis and piston top,surface, and how you measure it according to the manufacturer, and how did you measure both the piston and the bore and whats your ring gap supposed too be set at?

think carefully about both the initial cost and the structural strength of the engine block you select, the OEM blocks used in production car engines will RARELY accept a .030 plus over bore with out having one or more cylinders having marginally thin bore walls, this results in inadequate bore to ring sealing if its in the wrong area and promotes stress cracks. A .060 over bore in a SBC is rather commonly pushing that bore wall thickness up to or over a reasonable limit so you need to sonic and magnetically check the block for cracks and wall thickness.

you could easily dump $500-$1500 into machine work on a block that won't last more than a few months under high stress if its not carefully checked PRIOR to the machine work being done.

be sure you, measure EACH bore and EACH piston,

(CORRECTLY with the proper tools in the way the tool and piston manufacturers suggested)

and number them on an engine build sheet indicating the bore and piston diam.

from large to smallest on each and install them on each cylinder to get the most consistent piston to bore clearance's

yes the difference may only be a few ten thousands if the bores are machined correctly, but you'll get the best results , most consistent lubrication, best durability and less heat build up that might result in detonation issues that way. its the little things that add up to making a good durable engine assembly,

BTW check rod orientation, so the beveled sides don't fact the adjacent rods, and check the bearing clearances with plasti guage

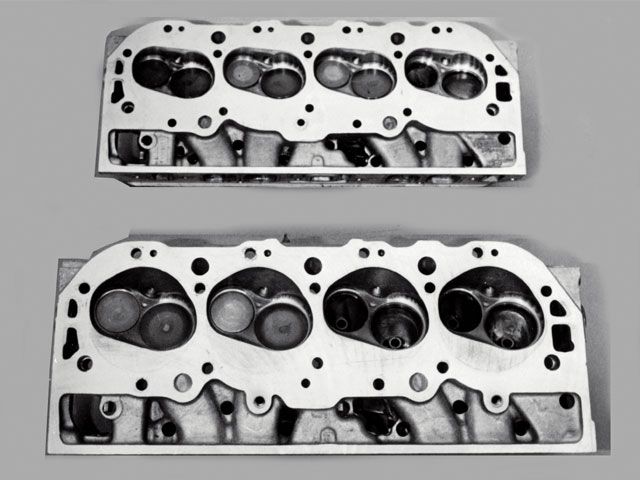

its standard practice to cc the combustion chambers, in the cylinder heads and the piston domes,(obviously check quenck and piston pin height, and clearances , mpisyton to head clearance, valve to piston cleances also,

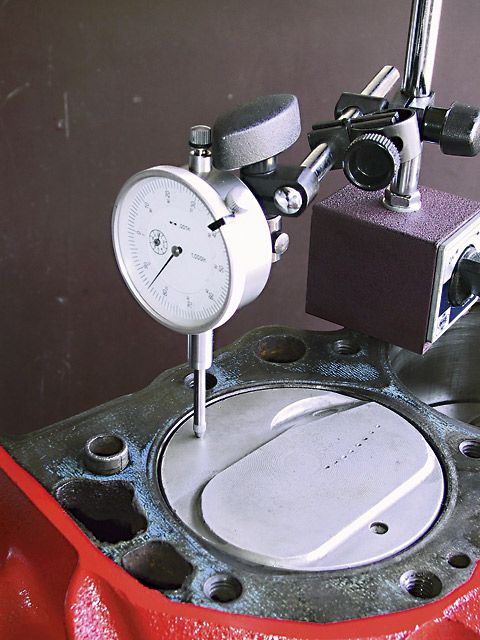

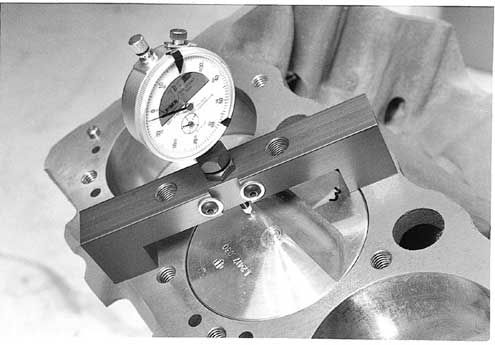

(usually the piston domes volume is generally measured with the piston deck or quench surface rotated down the bore , exactly 1 inch) use your caliper or dial indicator and piston bridge)and the rings sealed temporarily with a bith of grease or paraffin to make sure you'll be dealing with as close as possible to the exact same compression ratio, in each cylinder, mark each piston with a indulable black magic marker A,B,C,D,E,F,G,H

and the bores 1-2-3-4-5-6-7-8 so you don't get measurements on the build sheet confused between bore diam and piston diam, and you can also not confuse dme volume on each piston

ok you want to calculate your compression ratio,

be aware all BBC pistons will NOT work with ALL potential heads.

remember open and closed chamber heads on THE BBC.

youll need to verify clearance in the combustion chambers and valve to piston clearance

http://garage.grumpysperformance.com/index.php?threads/vin-casting-info.10474/#post-44012

https://www.mortec.com/bbc.htm

and you bought a short block all ready assembled from some source that has no clue what the pistons used are.

they certainly have a dome volume that will take up space in the combustion chamber and raise effective compression,

but are they 35cc-50cc, 64cc ?

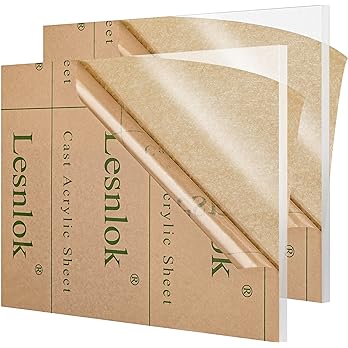

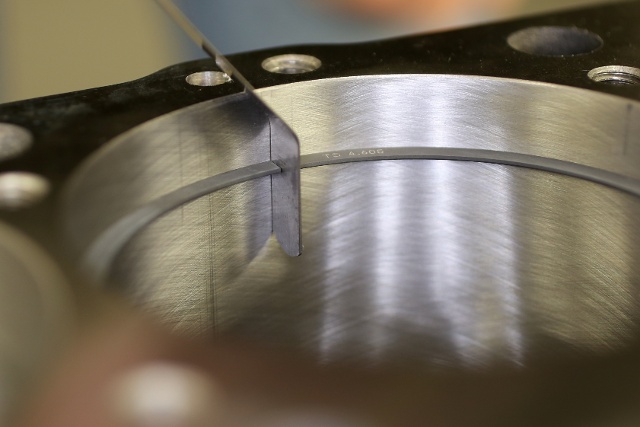

you'll need a deck bridge and dial indicator lexan plate and cc burette

,

dial indicator and ideally a lexan plate and a burret with cc measuring marks

watch the videos, the procedure is very similar to measuring combustion chamber volume

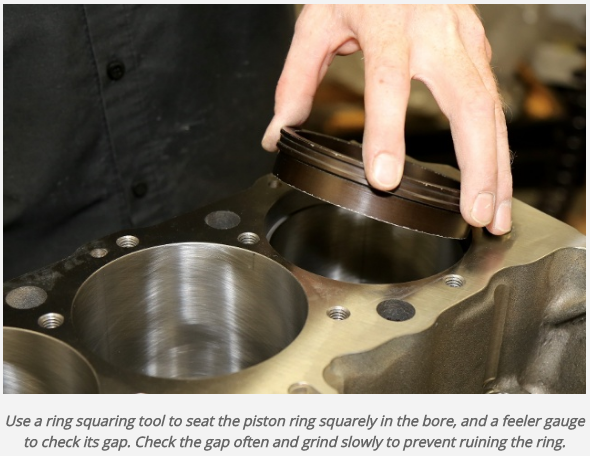

you push the piston down bore 1", using the deck bridge /dial indicator,

seal the piston to bore ring gap area with vasoline,over the rings, wipe excess away

the bore diameter must be measured accurately, a dial caliper can be used

but a bore gauge is much more accurate

owler Full Warranty Extender Dial Bore Gage Set, 52-646-400, 1.4-6" Measuring Range, 0.0005" Graduation Interval: Bore Measurement Gauges: Amazon.com: Industrial & Scientific

Fowler Full Warranty Extender Dial Bore Gage Set, 52-646-400, 1.4-6" Measuring Range, 0.0005" Graduation Interval: Bore Measurement Gauges: Amazon.com: Industrial & Scientific

www.amazon.com

6 Pcs Professional Premium Outside Micrometer Precision Machinist Tool Set 0-1"/1-2"/2-3"/3-4"/4-5"/5-6" Measuring Range Included 0.0001" Graduation: Amazon.com: Industrial & Scientific

6 Pcs Professional Premium Outside Micrometer Precision Machinist Tool Set 0-1"/1-2"/2-3"/3-4"/4-5"/5-6" Measuring Range Included 0.0001" Graduation: Amazon.com: Industrial & Scientific

www.amazon.com

Lexan Polycarbonate clear 1 sheet - 1/2" thick x 6 " x 6"

JEGS 80525: Burette and Stand Kit [100 cc x 0.2 cc Increments] - JEGS

Burette & Stand Kit

I found two 1/2" thick 6"x 6" thick lexan clear sheet on scam bay for about $22 plus shipping that will allow me to fabricate,

TWO of the 6" x 6" COMBUSTION CHAMBER CHECKING AND CCING cover plates,

a step drill helps

http://www.harborfreight.com/catalogsearch/result?q=step+drill

by simply cutting into two equal pieces and drilling a counter sunk 3/16" hole in each half.

lexans a whole lot stronger than plexi-glass, and 6" x 6" allows more sealing surface options so thats the route I took

and its extra stiffness and weight helps seal the measuring fluids

A Few Basic Precision Tools

Hey GRUMPY, I need a few basic tools to measure bearing clearances and tools for installing a cam, etc, and suggestions? (and yeah, I'm not swimming in cash, so please take that into account!) keep in mind there's a long list of more expensive tools, like mills, lathes, various types of...

garage.grumpysperformance.com

the formula for a cylinder volume is R sq times PI (3.147) times depth, 1"=25.4mm

R=1/2 the diameter of the bore.

yeah a pocket calculator may be helpful.

lets assume a 4.25" bore,and the piston 1" down bore,

4.25 bore x.5= R= 2.125 x 2.125 x 3.147=14.21067 cubic inches

theres 16.3871 ccs in a cubic inch, thus 14.21067=232.87 ccs

in this case lets say you fill the cylinder and it takes 189ccs,

you sub-track that from the potential max volume of 232.87 and see you have a 43.87 dome volume

related threads YOU'LL NEED TO READ,

don,t skip the info links it great related info

Differences In Big Block Chevy Head Gaskets

differences in big block chevy head gaskets and other related info in the links and sub-links may prove critical if you're going to build a big block chevy engine, you can in some cases, use a Gen V head on a Mark IV block (Gen IV), as long as you use the head gaskets for the Mark IV...

garage.grumpysperformance.com

big block head comparison

(below youll find several links too some of the more exotic high flow racing BBC head designs from the aftermarket ) (these are not directly interchangeable with stock components,) and will generally require selecting matching expensive aftermarket intakes, from that heads manufacturer, and...

garage.grumpysperformance.com

some basic bbc math, to get you thinking about your potential dream bbc combos.

I recently had a discussion with one of the local guys concerning what heads and rotating assembly he should buy now that he recently purchased a tall deck (10.2") big block chevy block. he has a perfectly good 427 forged crank (3.76" stroke) but hes seriously thinking of buying a (4.25" stroke)...

garage.grumpysperformance.com

unshrouding valves, and polishing combustion chambers

8 62lbs injectors good to 800 hp No airflow specs. Want at least 800 cfm. 1000-1085 cfm even bettter. 10s WOT down to floor. Part throttle response a tad bit Soggy feeling on street to be expected. After the extra 30-50-75 hp potential.

garage.grumpysperformance.com

Piston head volume and piston dome/dish volume.

Hi, Sometimes piston specs are listed with piston head volume while other times they are listed as piston dome/dish volume. I'm trying to decide on a set of pistons for 454/.030 with a pair of Edelbrock RPM Performers that Ive had sitting around for abit, but I'm not sure how to correlate...

garage.grumpysperformance.com

checking piston to valve clearances

this is an old post I got asked to repost, naturally the first step is to install and correctly degree in your cam, http://garage.grumpysperformance.com/index.php?threads/measuring-piston-dome-volume.17255/...

garage.grumpysperformance.com

ccing my heads

HELP I hope some can help me with a prob I am having. I started to cc my heads so i check all and found that they need to be ground. I have one at 64.3 so I started grinding one of them to be at 64.3 or there abouts. I ground a lot off and got a reading of 62 so I ground more off and came up...

garage.grumpysperformance.com

cc your cylinder heads, combustion chamber, or piston dome , or port volume

CC'ing a cylinder head is a process that measures the volume of the combustion chambers in the cylinder head. The term CC'ing is referring too the cubic centimeters of the pocket (combustion chamber). the purpose of cc'ing the head is to determine the size of the combustion chambers so they can...

garage.grumpysperformance.com

some basic bbc math, to get you thinking about your potential dream bbc combos.

I recently had a discussion with one of the local guys concerning what heads and rotating assembly he should buy now that he recently purchased a tall deck (10.2") big block chevy block. he has a perfectly good 427 forged crank (3.76" stroke) but hes seriously thinking of buying a (4.25" stroke)...

garage.grumpysperformance.com

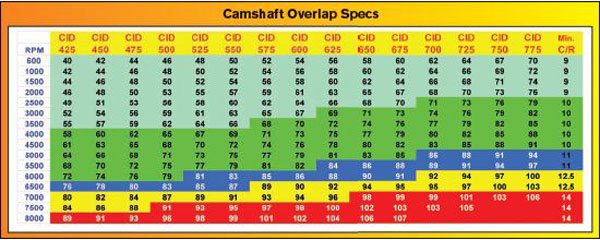

dynamic vs static compression

Blows the theory out of the water that short rods give better detonation resistance. The link article & Trigonometry show Long Rods do it instead.

garage.grumpysperformance.com

vin/casting # info

I need help decoding my motor. casting number (3932386) from left rear of motor. (19J119739) and (V0920FC) from the right front of motor. From the casting number I believe its a 1969 302,327 or 350. Valve covers are no help if its a 327. 3932386....302.....69....4...Z-28 Camaro...

garage.grumpysperformance.com

Last edited: