I’m hoping that the experienced folks here can help me finalize my cam selection in a mild BBC build. I’m not a pro engine builder but willing to learn as much as I can. I’ve tried to research the tons of info out there - it’s been really helpful and shows me what I don’t know, so I don’t want to guess.

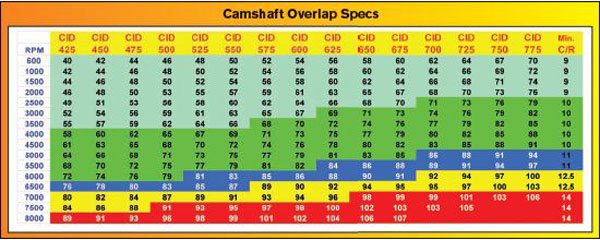

Engine is a MK IV (1979) 454 bored .030 over. It’s been in my 57 Belair with a TH400/2200 Continental converter and Ford 9 in with 3.70 gears. Relatively low miles on the engine, zero issues, but it was time for a refresh on the car and the driveline. My goal on the engine is to add a slightly more aggressive cam profile and working towards a power curve of 1400-5800 rpm.

Current cam: Erson TQ20H, .050 duration Int/Exh 214, LCA 112, lift .514, 1.7 stamped steel rockers. Induction is a Holley 4150 VS on an Edelbrock RPM intake. HEI ignition. Exhaust is 1.75 tube long tube headers to 3 in exhaust with a crossover.

Heads are 427 truck “big oval”, 2.06/1.72 open chamber, with some very mild cleanup on the ports and 116cc chambers. I’d like to continue with these heads. They will be refurbished as needed by the machine shop.

Pistons are TRW L2349 with .210 dome height. Valve clearance measured with clay at .2345. Calculated compression ratio came out right at 10:1. Factory cast crank turned .010, 2 bolt mains, new scat rods, new ARP studs on the mains and of course new rings and bearings. I plan to re-use the pistons as both the pistons and the bores measured within tolerance. This will be verified by the machine shop.

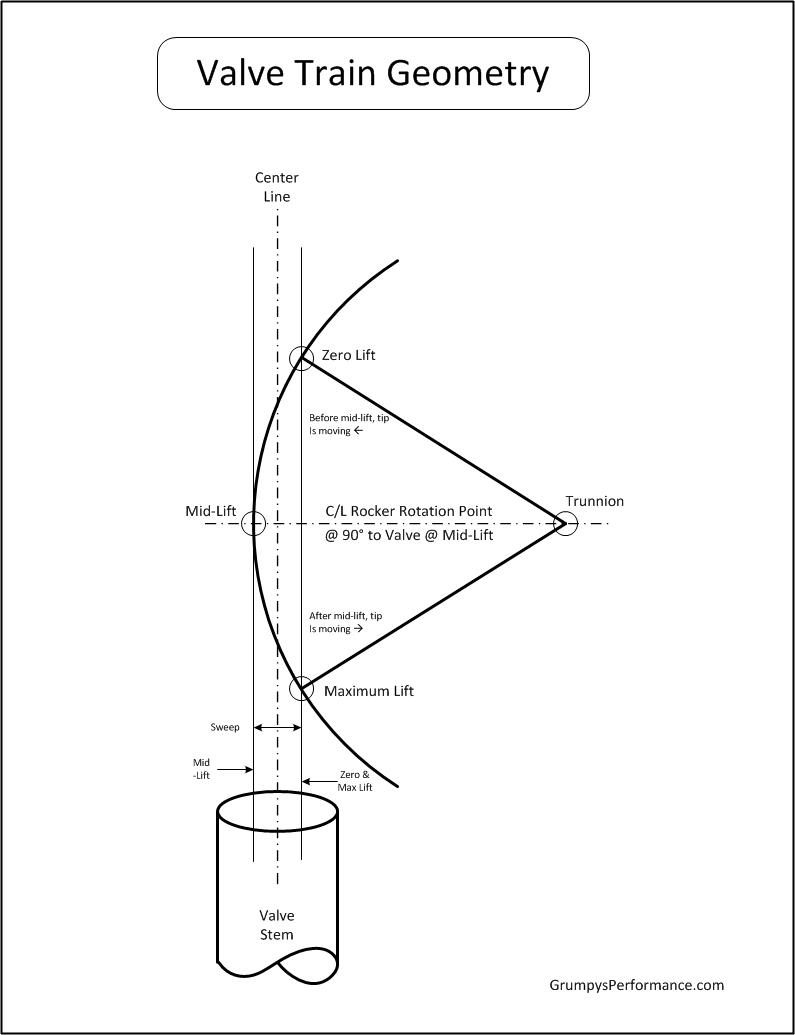

I started with about 21 cams and have narrowed it down to the ones listed below. For my budget, I want to ensure all needed machining is done but I want to use a hydraulic flat tappet cam and delphi lifters, with valve springs/retainers as recommended by the cam mfg. I also plan to use 1.7 roller rockers. I looked at the info here, including data compiled by David Vizard to try to get at least a basic understanding of what would work for my goals.

One item that bubbled up to the surface was reducing the LCA much more than I thought (108/110 vs 114) but balancing it with less duration. I tried to interpret the data into a graph for each cam that helped me to visualize the cam info. I’ve talked with several cam companies but it seems a lot of the info I received is a repeat of what I can read already.

So here’s where I’ve landed in my cam homework. As mentioned, I’m trying to learn more so any additional cam suggestions/comments are appreciated, especially if I’ve gone down the rabbit hole somewhere. The info listed here is based on installation at 0 degrees. At this point I’m leaning towards the Clay Smith 012 cam. I think for the heads that I’m using, I’m not sure I would see a benefit at lifts over .542?

Thank you for your help.

Clay Smith 02-012, 1700-5700 rpm

LCA = 108, lift = Int/Exh .542,

Dur @ .050 = Int/Exh 224

ICA = 108, 8d overlap @ .050

Crower 01295 1800-5700 rpm

LCA = 110, lift = Int .525, Exh .545

Dur @ .050 = Int 229, Exh 237

ICA = 106, 13d overlap @ .050

Comp Cams Magnum 270H, 1500-5800 rpm

LCA = 110, lift = Int/Exh .533

Dur @ .050 = Int/Exh 224

ICA = 106, 4d overlap @.050

Lunati Voodoo 10110702, 1400-5800 rpm

LCA = 112, lift = Int .530/Exh .542

Dur @ .050 = Int 219/Exh 227

ICA = 108, -1d (no overlap) at .050

Summit Racing SUM 1796

LCA = 108, lift = Int/Exh .514

Dur @ .050 = Int/Exh 226

ICA =108, 10d overlap @ .050

Howards Cams 120941-11 1500-5800 rpm

LCA = 111, lift = Int/Exh .527

Dur @ .050 = Int/Exh .225

ICA = 111, 57d overlap @ .050

Clay Smith 02-013 1700-5700 rpm

LCA = 110, lift = Int/Exh .542

Dur @ .050 = Int/Exh 224

ICA = 110, 54d overlap @ .050

Engine is a MK IV (1979) 454 bored .030 over. It’s been in my 57 Belair with a TH400/2200 Continental converter and Ford 9 in with 3.70 gears. Relatively low miles on the engine, zero issues, but it was time for a refresh on the car and the driveline. My goal on the engine is to add a slightly more aggressive cam profile and working towards a power curve of 1400-5800 rpm.

Current cam: Erson TQ20H, .050 duration Int/Exh 214, LCA 112, lift .514, 1.7 stamped steel rockers. Induction is a Holley 4150 VS on an Edelbrock RPM intake. HEI ignition. Exhaust is 1.75 tube long tube headers to 3 in exhaust with a crossover.

Heads are 427 truck “big oval”, 2.06/1.72 open chamber, with some very mild cleanup on the ports and 116cc chambers. I’d like to continue with these heads. They will be refurbished as needed by the machine shop.

Pistons are TRW L2349 with .210 dome height. Valve clearance measured with clay at .2345. Calculated compression ratio came out right at 10:1. Factory cast crank turned .010, 2 bolt mains, new scat rods, new ARP studs on the mains and of course new rings and bearings. I plan to re-use the pistons as both the pistons and the bores measured within tolerance. This will be verified by the machine shop.

I started with about 21 cams and have narrowed it down to the ones listed below. For my budget, I want to ensure all needed machining is done but I want to use a hydraulic flat tappet cam and delphi lifters, with valve springs/retainers as recommended by the cam mfg. I also plan to use 1.7 roller rockers. I looked at the info here, including data compiled by David Vizard to try to get at least a basic understanding of what would work for my goals.

One item that bubbled up to the surface was reducing the LCA much more than I thought (108/110 vs 114) but balancing it with less duration. I tried to interpret the data into a graph for each cam that helped me to visualize the cam info. I’ve talked with several cam companies but it seems a lot of the info I received is a repeat of what I can read already.

So here’s where I’ve landed in my cam homework. As mentioned, I’m trying to learn more so any additional cam suggestions/comments are appreciated, especially if I’ve gone down the rabbit hole somewhere. The info listed here is based on installation at 0 degrees. At this point I’m leaning towards the Clay Smith 012 cam. I think for the heads that I’m using, I’m not sure I would see a benefit at lifts over .542?

Thank you for your help.

Clay Smith 02-012, 1700-5700 rpm

LCA = 108, lift = Int/Exh .542,

Dur @ .050 = Int/Exh 224

ICA = 108, 8d overlap @ .050

Crower 01295 1800-5700 rpm

LCA = 110, lift = Int .525, Exh .545

Dur @ .050 = Int 229, Exh 237

ICA = 106, 13d overlap @ .050

Comp Cams Magnum 270H, 1500-5800 rpm

LCA = 110, lift = Int/Exh .533

Dur @ .050 = Int/Exh 224

ICA = 106, 4d overlap @.050

Lunati Voodoo 10110702, 1400-5800 rpm

LCA = 112, lift = Int .530/Exh .542

Dur @ .050 = Int 219/Exh 227

ICA = 108, -1d (no overlap) at .050

Summit Racing SUM 1796

LCA = 108, lift = Int/Exh .514

Dur @ .050 = Int/Exh 226

ICA =108, 10d overlap @ .050

Howards Cams 120941-11 1500-5800 rpm

LCA = 111, lift = Int/Exh .527

Dur @ .050 = Int/Exh .225

ICA = 111, 57d overlap @ .050

Clay Smith 02-013 1700-5700 rpm

LCA = 110, lift = Int/Exh .542

Dur @ .050 = Int/Exh 224

ICA = 110, 54d overlap @ .050