bud said:Grumpy I just replaced a defective battery and battery ground cable on my 1985 corvette, now the engine spins on the starter but theres no injector pulse at the injector, so where do I start looking for the source of the problem

buy a CHEVY SHOP MANUAL FOR YOUR YEAR CORVETTE!, you'll need it as its going to be a reference source you'll need as long as you own the car.

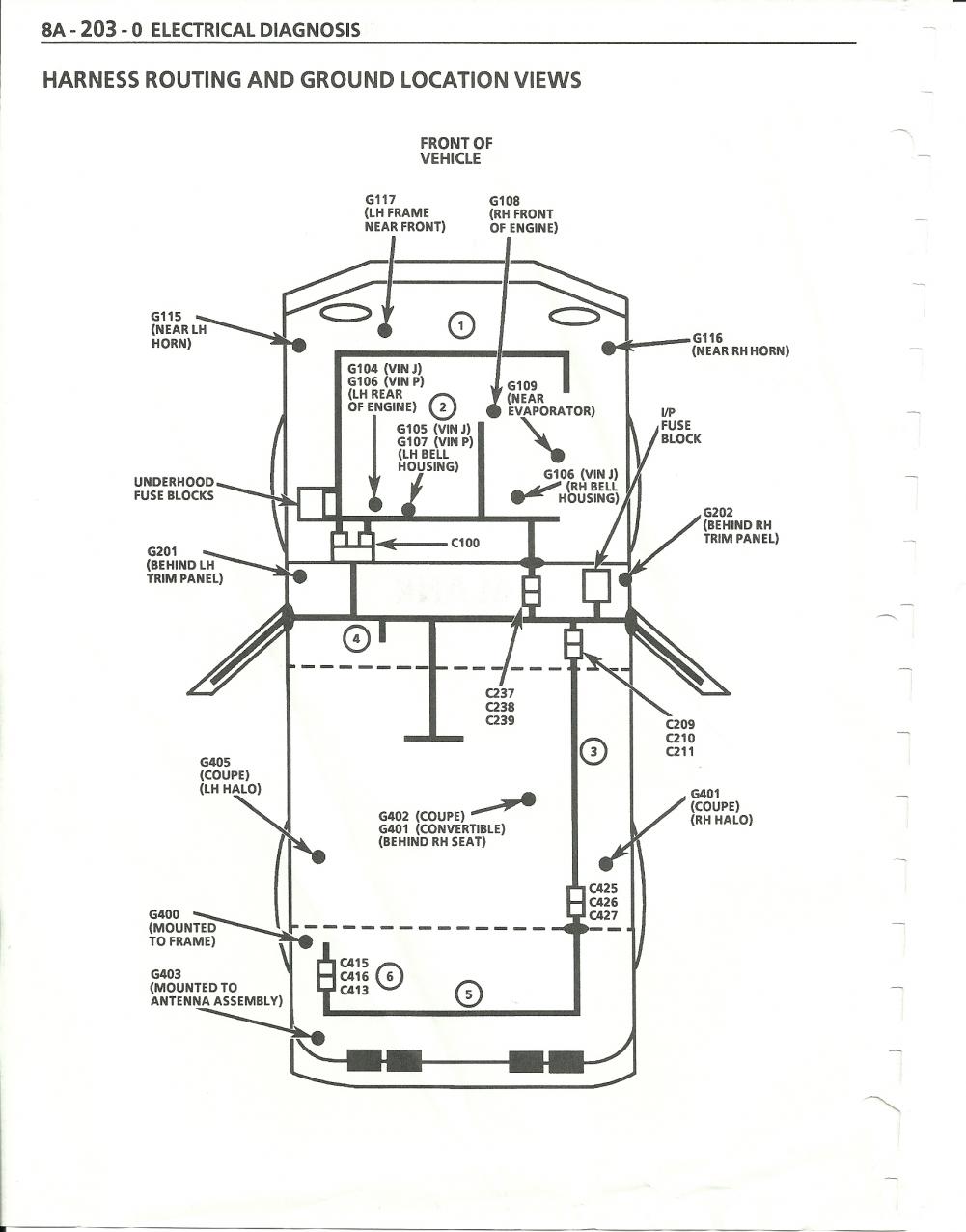

a logical step by step approach to every problem is usually the best way to find and isolate the problem and cure it. you'll usually start by pulling trouble codes,then check for vacuum leaks on the vacuum lines and on the intake,then look for loose electrical connections , get out your multi meter and verify all the sensors, chances are good a logical step by step approach will lead you to the problem, youll be amazed at what youll learn reading links. use of a shop manual and multi meter can be very helpful, since your battery failed I WOULD CHECK YOUR ALTERNATOR FUNCTION,and test your injectors,and most of the fuel supply system functioning, components, youll find links for testing both below

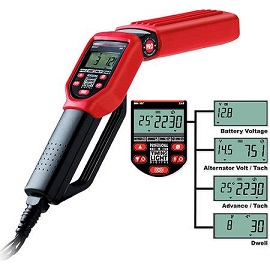

having a few basic meters,gauges etc. helps

MULTI METER

INFRARED TEMP GUN

TIMING LIGHT

COMPRESSION GAUGE

PRESSURE/VACUUM GAUGE

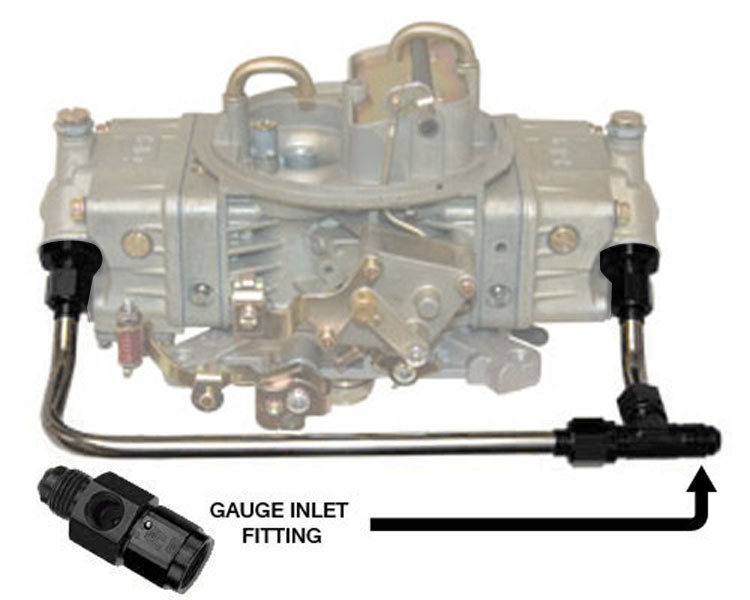

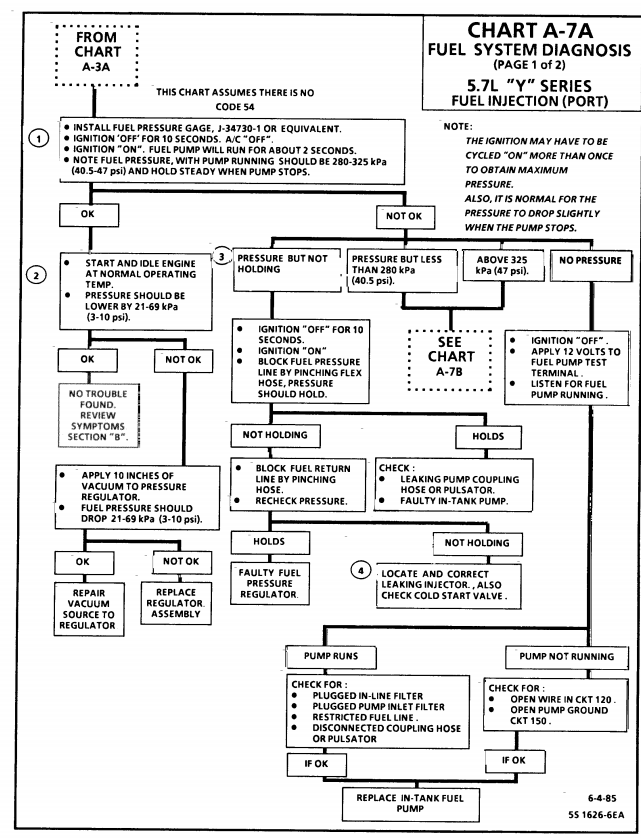

and yes, use of a small handy and accurate fuel pressure gauge, mounted on the fuel injector fuel rail (0-100 psi for FUEL INJECTION)

or carb inlet port (0-15 psi for carburetors)is almost mandatory, they generally cost under $30

every mechanic needs an ANALOG multi meter for testing capacitors with a micro farad scale, AND a DIGITAL MULTI METER

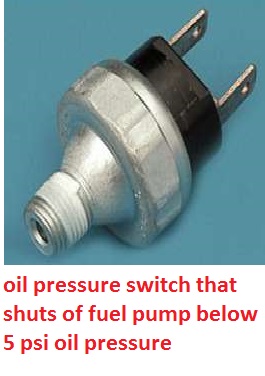

everything you need to know to track its cause and cure down is in these threads and sub links posted below,remember you need 5 psi of OIL PRESSURE or you don,t get injector pulse, so be aware that the sensor near the distributor controls that, chances are good you blew a fuse or damage a sensor during the battery exchange, but you should test the injector resistance and look for ignition ,sensor or injector wires that might have been disconnected or damaged, and don,t over look the silly stuff like you might have forgotten to check the fuel tank or oil in the engine fill levels

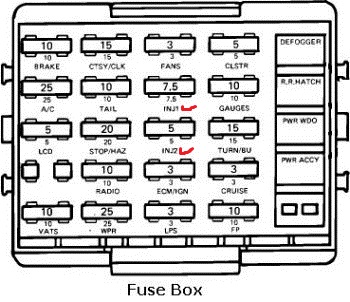

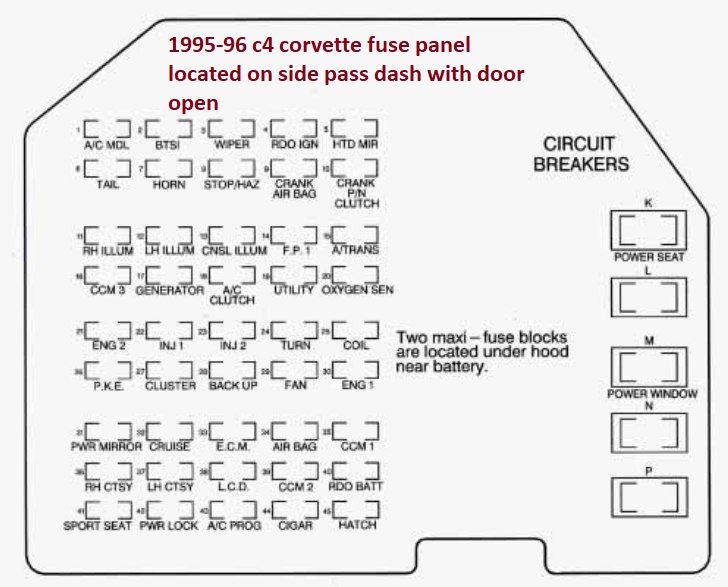

because the problem seems to have started after the batery was swaped its logical that a fuse or sensor failed due to a current /voltage surge.

check your two injector fuses, and verify you have fuel pressure at the fuel rail as a start point, read the links

reading thru a few links might be helpful

a noid test light on the injector harness

and a fuel pressure gauge on the fuel rail will be helpful

verify you have over 10 psi of oil pressure and the dip sticks says the sumps full

http://garage.grumpysperformance.co...h-flicker-on-dash-and-radio.13593/#post-70202

http://garage.grumpysperformance.com/index.php?threads/c4-corvettes-fuel-system-info.67/#post-37351

http://garage.grumpysperformance.com/index.php?threads/replacing-a-c-4-fuel-pump.33/

http://garage.grumpysperformance.co...p-after-running-out-of-fuel.11309/#post-51444

http://garage.grumpysperformance.co...-system-trouble-shooting-flow-chart-info.596/

http://forum.grumpysperformance.com/viewtopic.php?f=80&t=728&p=1915&hilit=sensors#p1915

READ THRU THESE LINKS AND YOULL NEED A MULTI METER AND FUEL PRESSURE GAUGE TO TEST WITH, and HAVING A SHOP MANUAL SURE HELPS

the sensor resistance or voltage readings youll need to test each sensor are listed in the links and sub links

http://forum.grumpysperformance.com/viewtopic.php?f=32&t=596

http://forum.grumpysperformance.com/viewtopic.php?f=32&t=33

http://members.shaw.ca/corvette86/FuelS ... gnosis.pdf

http://forum.grumpysperformance.com/viewtopic.php?f=32&t=1401

http://forum.grumpysperformance.com/viewtopic.php?f=32&t=2697

http://forum.grumpysperformance.com/viewtopic.php?f=80&t=728

viewtopic.php?f=32&t=67&p=39573&hilit=noid#p39573

viewtopic.php?f=48&t=10003&p=38749&hilit=test+alternator#p38749

viewtopic.php?f=36&t=3222&p=8575&hilit=test+alternator#p8575

Last edited by a moderator: