I have a fairly mild SBC 383 stroker (actually 385, 4.040" x 3.750") that's in my sig. It has Summit/Dart Vortec Heads which are nothing more then Dart Iron Eagle S/S 170cc late model heads with Vortec style intake face.

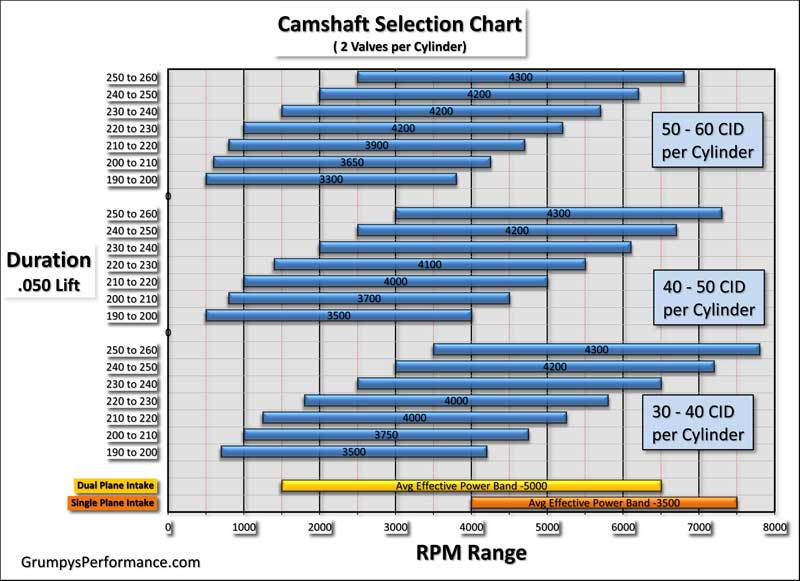

So I'd like to switch to a hydraulic roller cam and a better set of heads. I'm liking the Crower Cam pt# 00468 225°/232° dur. @.050", 277°/286° ave. dur., .535"/.550" lift, 110 LSA.

There are a ton of heads in this range. I don't necessarily need aluminum heads. Some of the heads I've been looking at-

Iron heads there are the Dart Iron Eagle 180, Chevrolet Performance Vortec Small Port Bowtie Cylinder Heads 185.

Aluminum heads are Dart SHP 180, Brodix IK 180 ($1000 for a assembled pair), Pro-Filer 185 (kind of liking these the most).

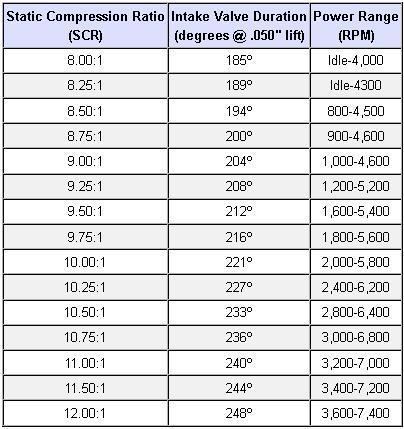

My current heads have 67cc combustion chambers. I'd go with 64cc comb. chams. on my new heads. That'll bump my compression up a tad. From 9.1:1 to maybe 9.4:1. Which should be a good thing.

Probably going to replace my Edelbrock AVS 650 with a Holley 4150, 650 w/vac. sec's, elec. choke (0-80783C). Of course the correct Edelbrock Per. RPM non-air gap intake too.

This isn't a racecar, it's driver and a fun car. Not looking to get every last bit of performance from it at the cost of drivability and fun. Opinions?

NYH1.

IT durability thats KEY in building a good engine

when ever I get into a discussion with many of the guys I build engines for, the younger guys especially seem to be captivated or primarily focused on the concept of having " a RADICAL CAM, that rumbles at idle, or the new brand X heads that some magazine is pushing in the latest engine build...

garage.grumpysperformance.com

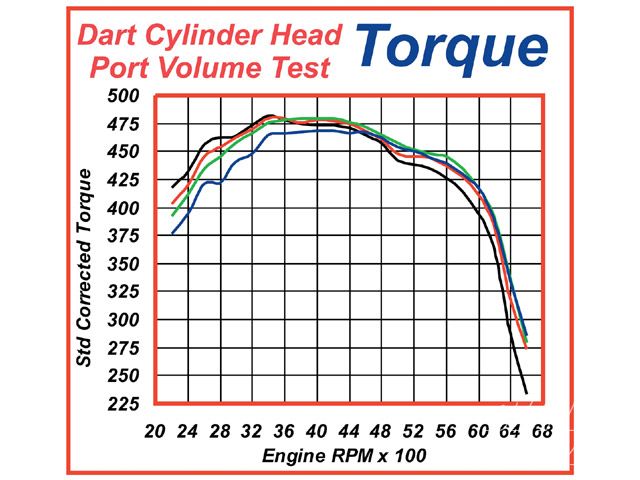

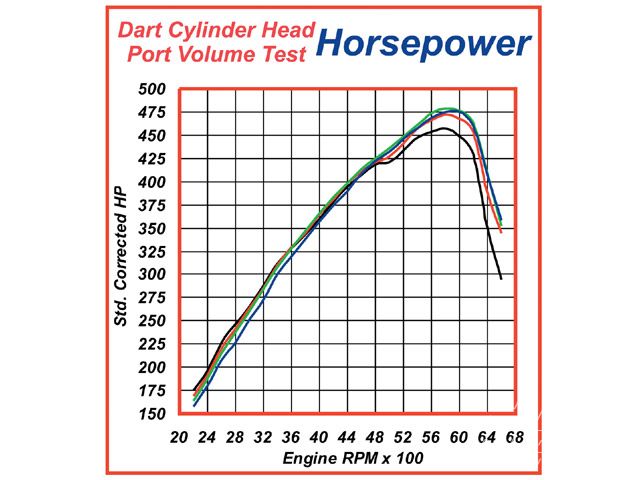

youll loose a ton of torque if the port size is slightly larger,

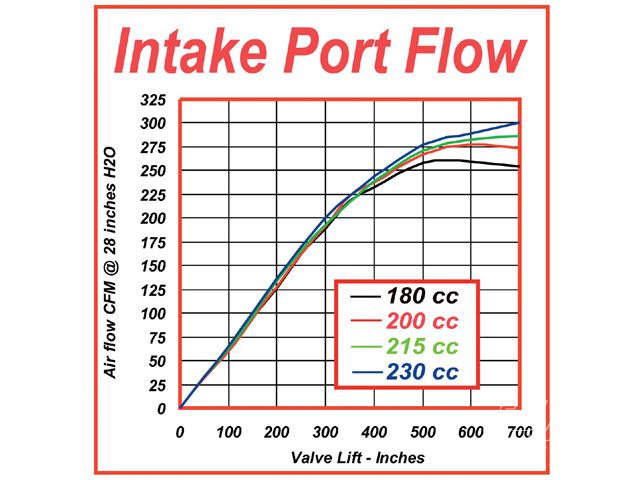

your cylinder head flow rates,

the engines dynamic compression ratio,

the intake manifold and header design,

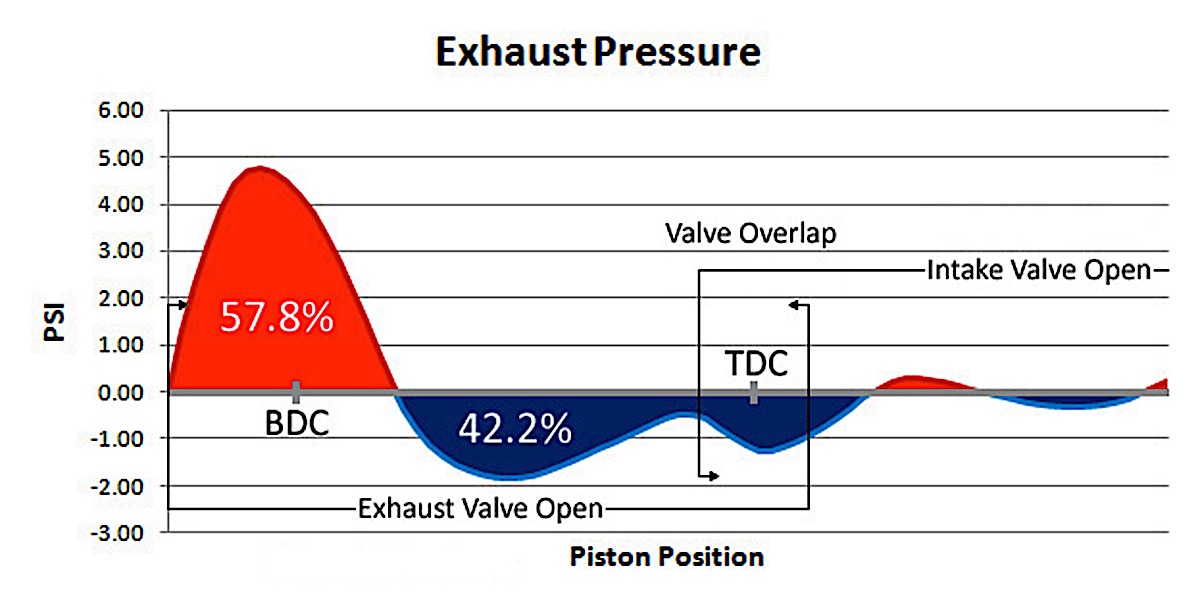

your exhaust back-pressure,

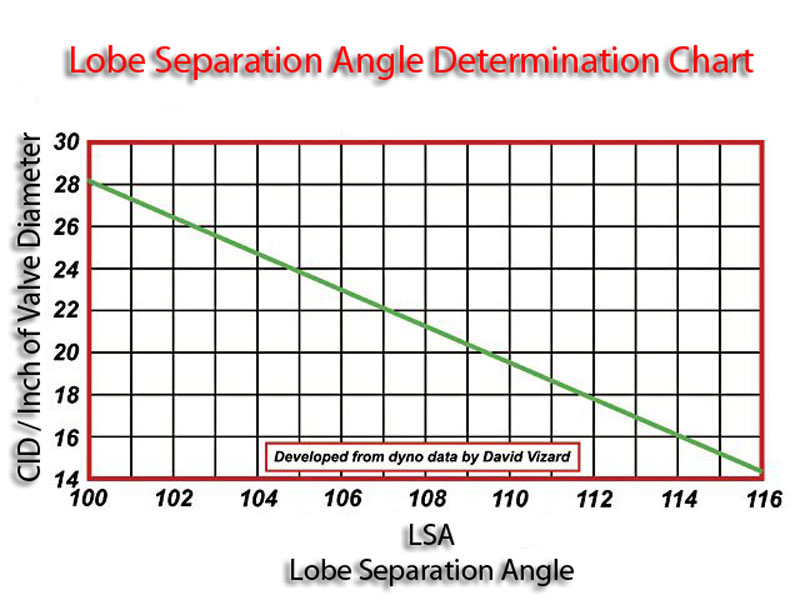

the cam timing and duration and LSA,

should be matched to maximize exhaust scavenging of the cylinders in the intended power band,

those factors FAR out weight the intake port volume as significant factors in how your engine will run

even for your non-race application on a 383 Id select a 195cc minimum port size, and on anything I was seriously looking for performance,

a set of 210cc heads would certainly be selected over the smaller port sizes,

you won,t loose anything on the low and mid rpm band but will find minimal gains above about 4500 rpm with that cam

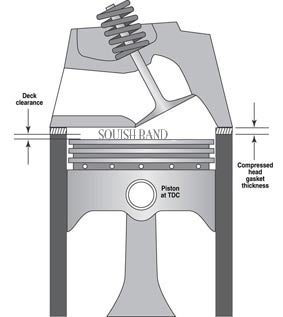

Id also suggest you carefully recalculate the engines compression ratio and dynamic compression with that cam and any heads you select,

you may find a 64-67 cc combustion chamber a bit too small on a 383 too use pump gas, generally youll want the dynamic compression near 8:1

read the links it could easily prevent you wasting money and time.

a day spent in reading linked research could save you weeks and over a $1000 is wasted cash

The Complete Cylinder Head Guide for Chevy Small Block Engines

The Complete Cylinder Head Guide for Chevy Small Block Engines- How to Build Max Performance Chevy Small Blocks on a Budget

http://garage.grumpysperformance.com/index.php?threads/tbucket-engine-project-dart-shp.3814/

http://garage.grumpysperformance.com/index.php?threads/sellecting-cylinder-heads.796/

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.com/index.php?threads/more-port-flow-related-info.322/

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/

http://garage.grumpysperformance.co...-between-shorty-and-full-length-headers.1303/

http://garage.grumpysperformance.com/index.php?threads/is-backpressure-hurting-your-combo.495/

http://garage.grumpysperformance.co...ng-combustion-chambers.2630/page-3#post-77963

http://garage.grumpysperformance.co...ding-sbc-crate-engine-heads.13041/#post-69328

http://garage.grumpysperformance.co...ing-a-383-sbc-combo-planing.12168/#post-58778

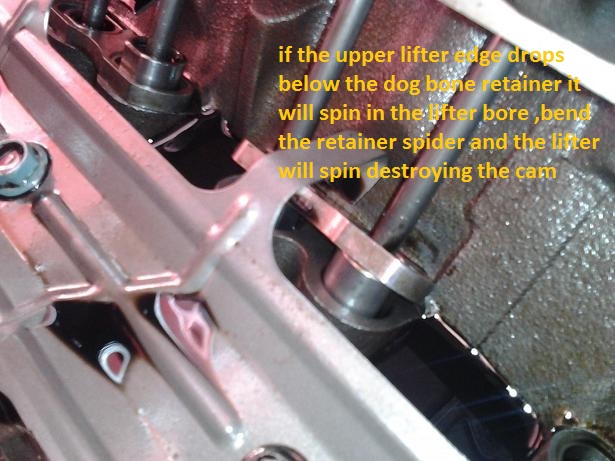

http://garage.grumpysperformance.co...train-clearances-and-problems.528/#post-57678

http://garage.grumpysperformance.com/index.php?threads/383-information-overload.11137/#post-49857

Last edited:

I try to help members AVOID all the crap I went through ,

I try to help members AVOID all the crap I went through ,