http://www.flatlanderracing.com/jepistonpins.html

http://garage.grumpysperformance.com/index.php?threads/snap-ring-pliers.16346/

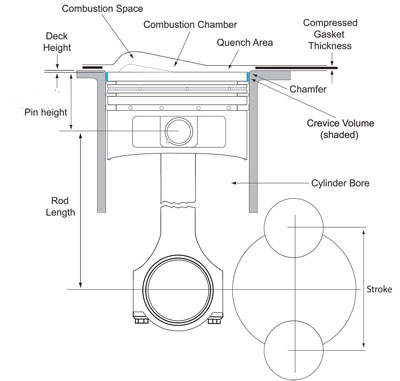

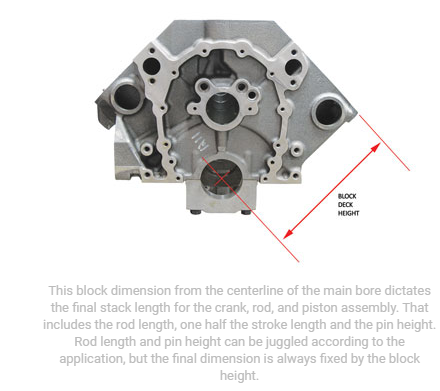

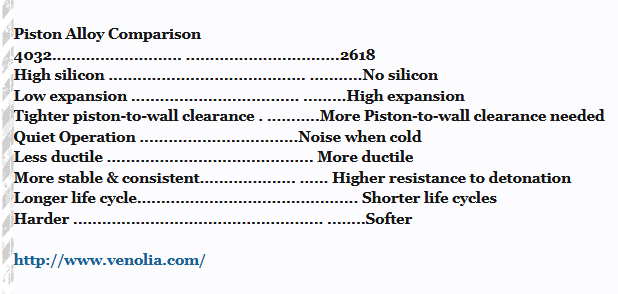

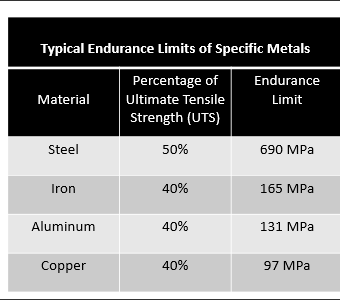

stock wrist pins and the combo of forged piston and longer connecting rods allowing a higher pin or compression height piston,of lower total weight,especially when compared too cast pistons which are rather heavy and often are over looked,as a potentially upgraded component. thinking thru the use of all the components used and what they are made of and the weight , has benefits, those, components made of stronger and lighter aftermarket forged pistons with free floating piston pins (wrist pins)made from tapered tool, or even rather exotic titanium alloy, steel wrist pins can be used to reduce significant reciprocating weight

http://www.tpub.com/content/engine/1403 ... 37_104.htm

http://www.beckracing.com/page10.htm

http://garage.grumpysperformance.co...in-height-compression-height.5064/#post-66240

http://www.enginebuildermag.com/2018/02/performance-pistons-101/

viewtopic.php?f=50&t=11029&p=48839#p48839

http://www.zoro.com/g/Snap Ring Tools/00059785/

http://www.bmeltd.com/Wristpin.htm

http://www.superchevy.com/how-to/engine ... m#cxrecs_s

http://www.kb-silvolite.com/features.ph ... ad&F_id=36

viewtopic.php?f=53&t=5064&p=14370#p14370

http://www.circletrack.com/enginetech/c ... index.html

http://www.probeindustries.com/Wrist_Pins_s/80.htm

http://www.flatlanderracing.com/ross_4340pins.html

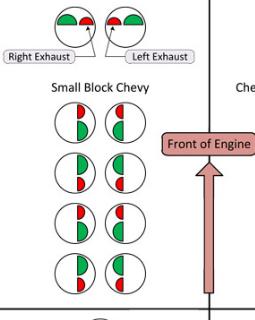

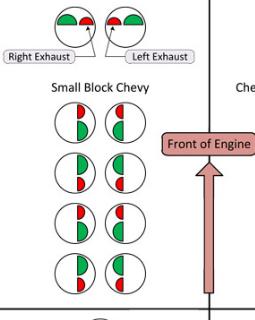

common sbc pin height info

Specs

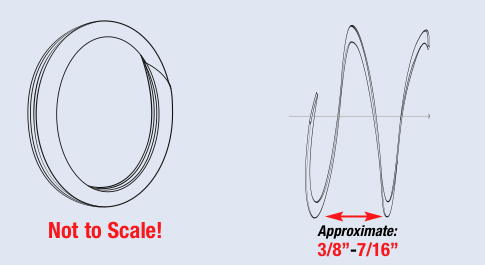

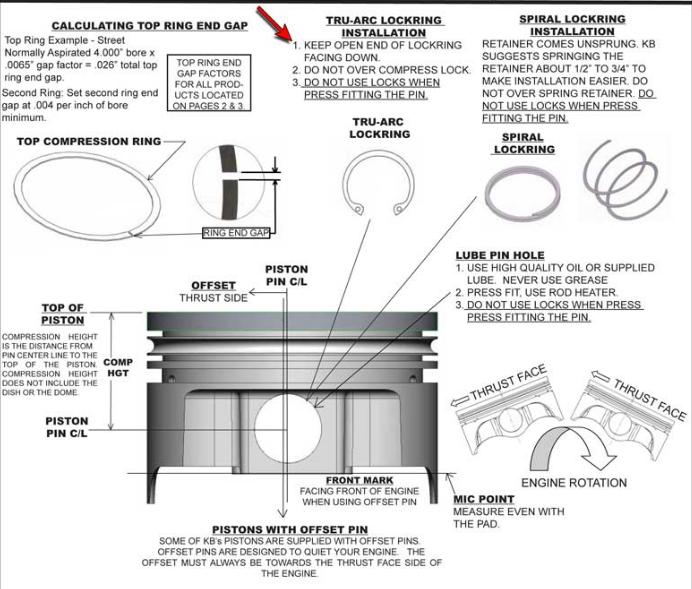

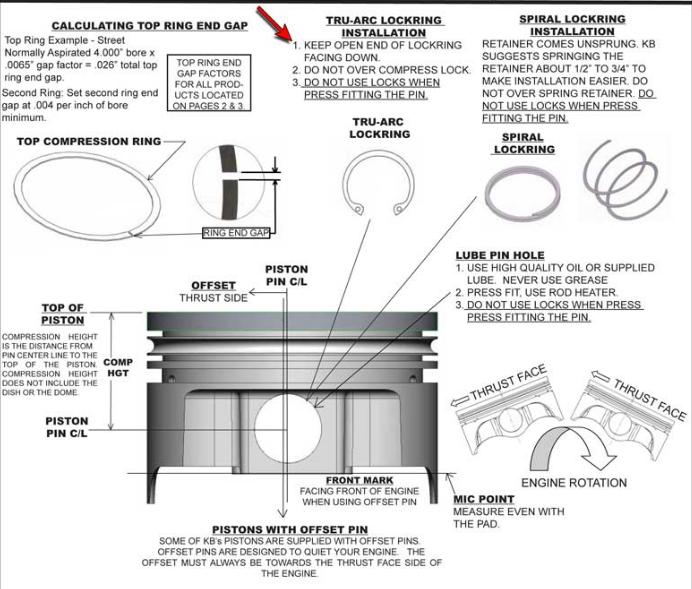

Install Tru-Arcs with the open ends pointing down only and make sure the flat side (with the sharp corners) faces out.

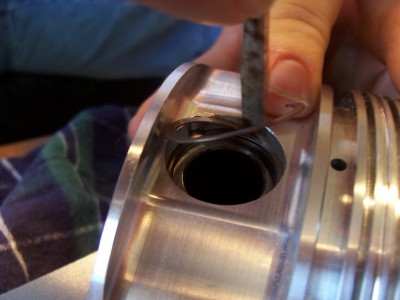

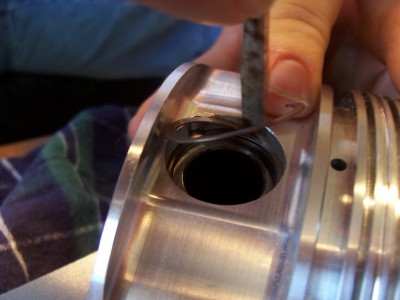

if you have free float piston pins your most likely familiar with these

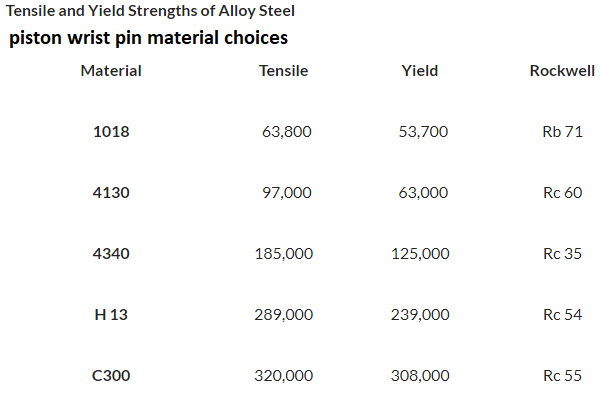

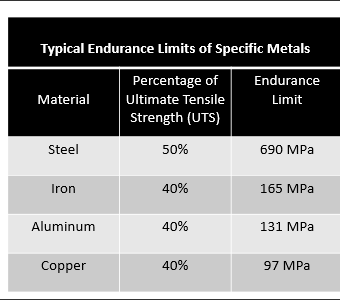

taper pins are lighter because the internal diameter is thinner towards the outer ends this reduces weight without reducing strength IF THE STEEL USED IS TOP QUALITY HEAT TREATED TOOL STEEL, BE AWARE there CHEAP SUB STANDARD CLONES that are not as well made.. quality aftermarket tool steel ,tapered tool steel piston pins usually cost $15-$30 EACH

in rod for full floating pin, to snap ring (End play 0.0 - 0.005"

the stock style piston pin is usually fairly heavy

http://kb-silvolite.com/pins.php

the aftermarket ,tapered style can be just as strong, or even stronger due to better materials and heat treating of the component, better hardening, tempering etc. and several grams lighter in weight allowing smaller crank counter weights and lower balancing costs

Most guys order a set of pistons or a rotating assembly and never think for two seconds about the wrist pins that are usually included, but that's a mistake in some cases.

yes the tapered pins cost more but they also tend to weigh less and thus put less stress on the engine at high rpms.

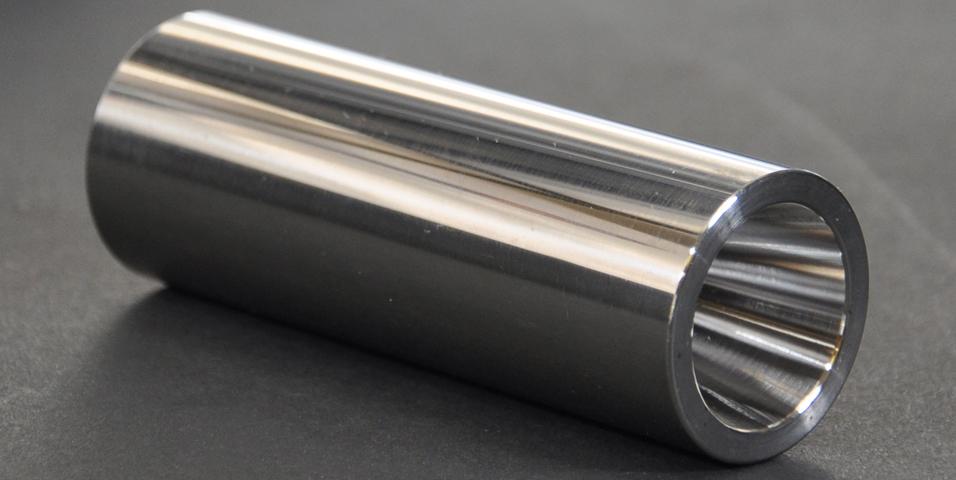

most piston wrist pins look like thick tubes with a mirror chrome finish, but theres also better quality wrist pins available made from far stronger and more expensive steel or titanium with the internal area rather hourglass shaped, where the hole thru the center tappers from a large outer end to a smaller central diam. that saves weight without sacrificing strength

one BIG ADVANTAGE to use of floating pin pistons and connecting rods it the ease of mixing and matching components and locations to minimize quench, or deck height differences during the install process

http://blog.wiseco.com/what-are-wrist-pin-buttons

https://www.musclecardiy.com/performance/how-to-build-racing-engines-piston-technology-guide/

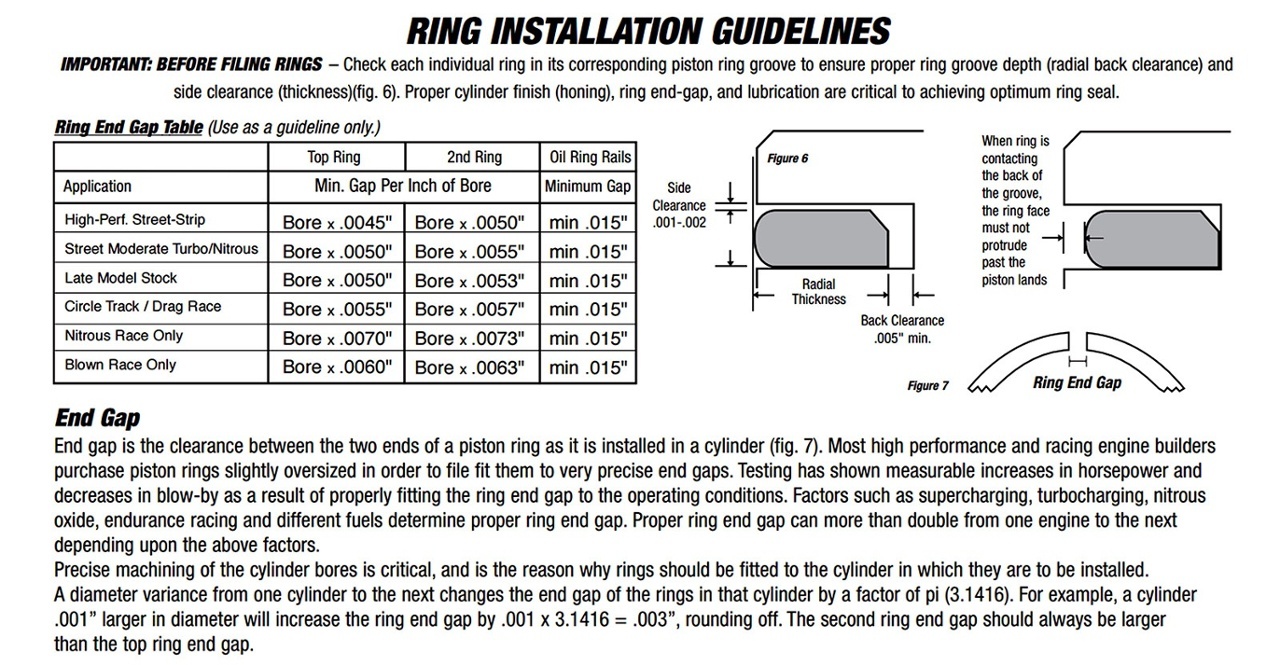

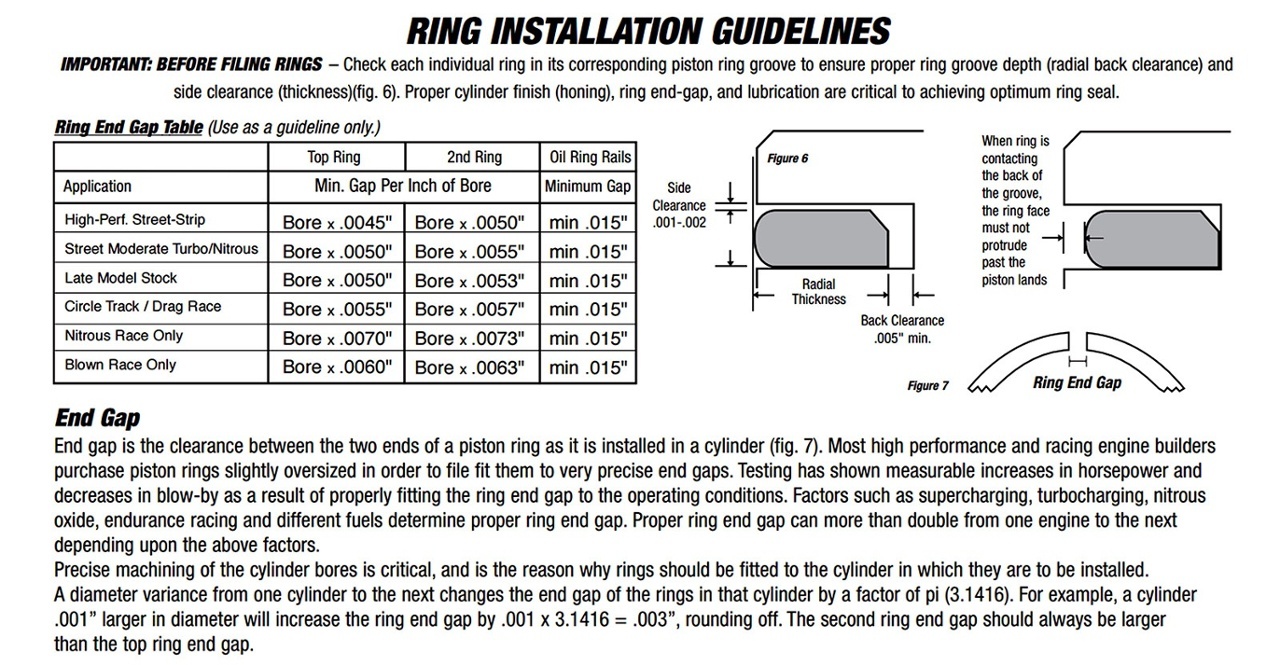

Second compression rings are really misnamed since their primary function is to assist with oil control. Most ring manufacturers hold that the second ring is about 85 percent devoted to oil control and only 10 to 15 percent to compression sealing. Its main mission is to scrape oil missed by the oil ring to that it doesn’t find its way to the combustion chamber to contaminate the fuel mixture. Since heat is not an issue with the second ring, a conventional cast-iron ring with a reverse bevel and tapered face is still employed with the primary task of scraping oil.

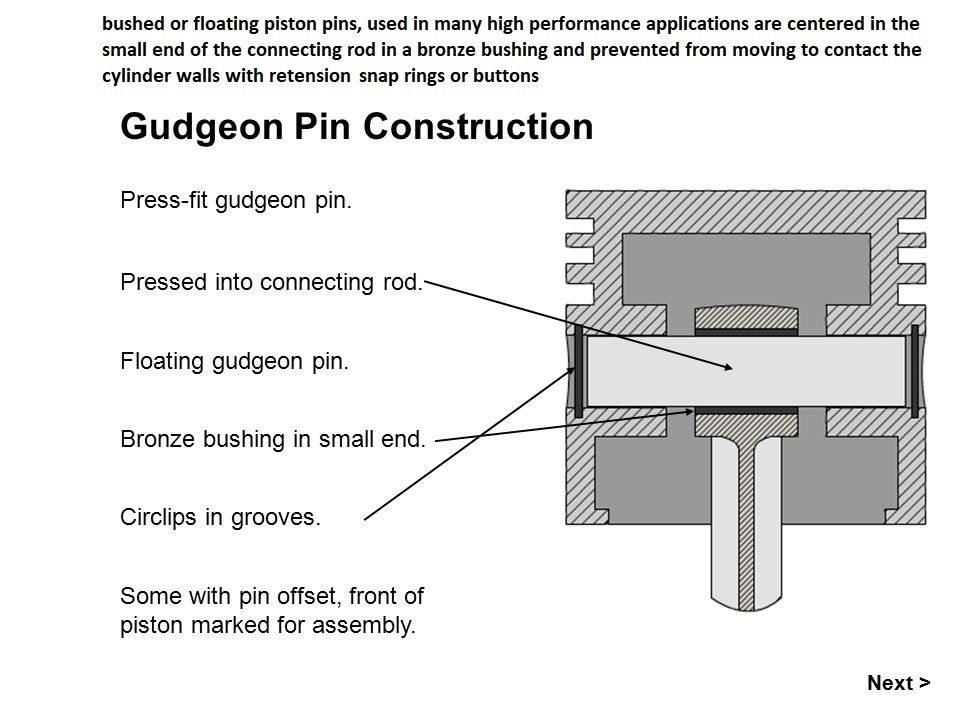

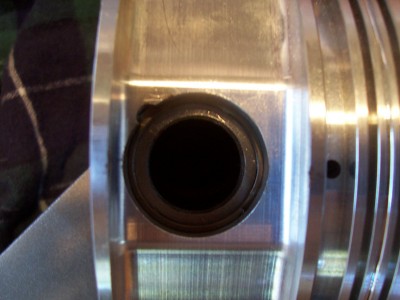

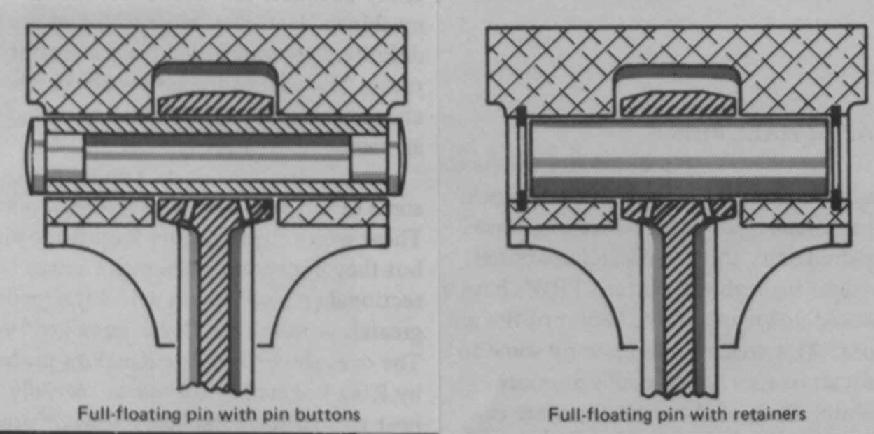

Where the pin bore encroaches on the oil ring groove, most applica¬tions use an oil ring support rail with a shorter inboard pin. The alternative is to use pin buttons with machined ring grooves that serve as oil ring supports. The buttons control pin placement and ring support, and they are much easier to assemble than the standard Spirolox or Truarc rings.

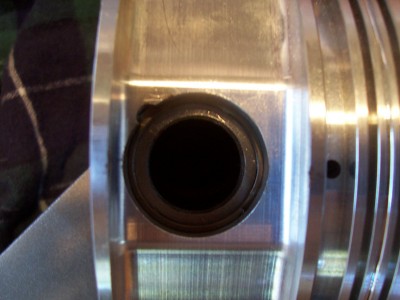

OBVIOUSLY the PIN BUTTONS upside down here to better show the ring clearance groove, it might seen that the pin retention buttons will wear the bore but in most cases the combined length of the two buttons and piston pin were several thousands less than bore diam, and in many cases the lower oil rings retain the buttons

BACK IN THE 70s pin buttons were used as they made free float piston assembly easy and in cases where the pin intersected the oil ring they helped support the oil ring

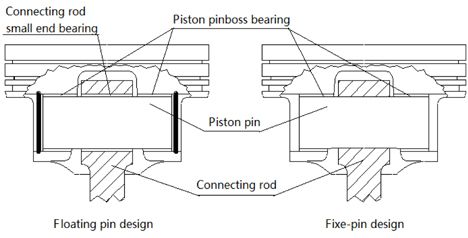

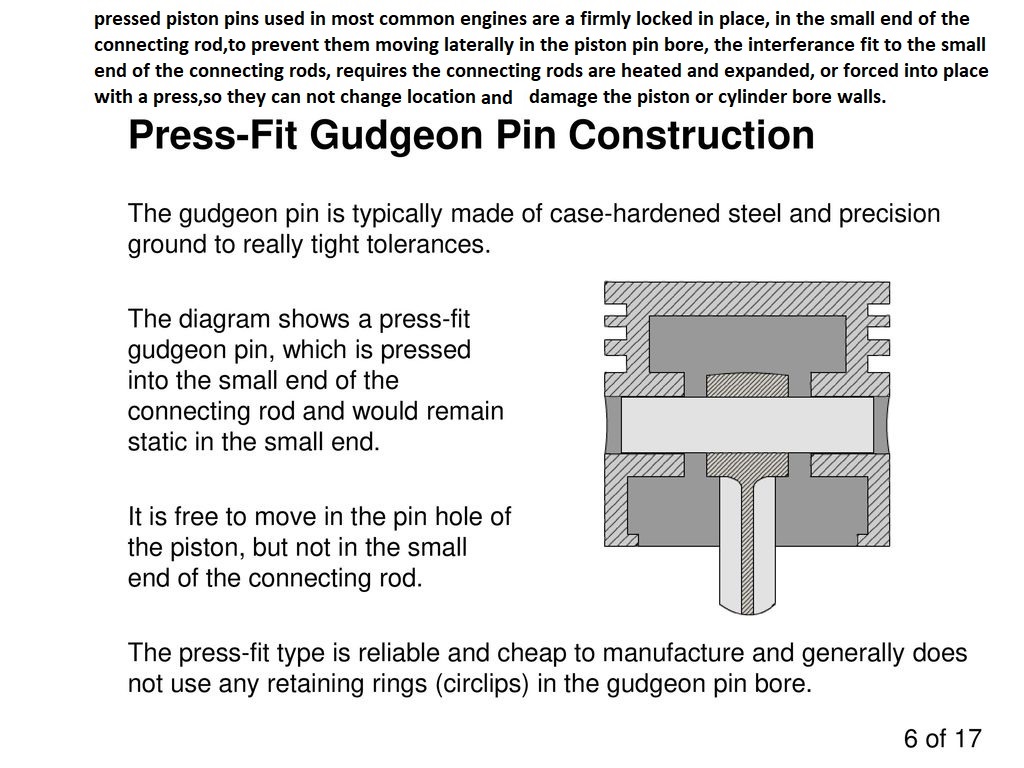

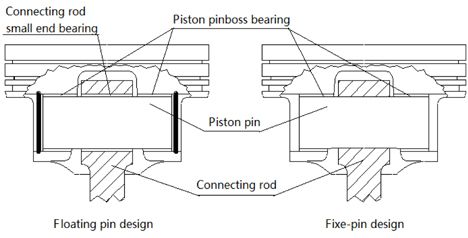

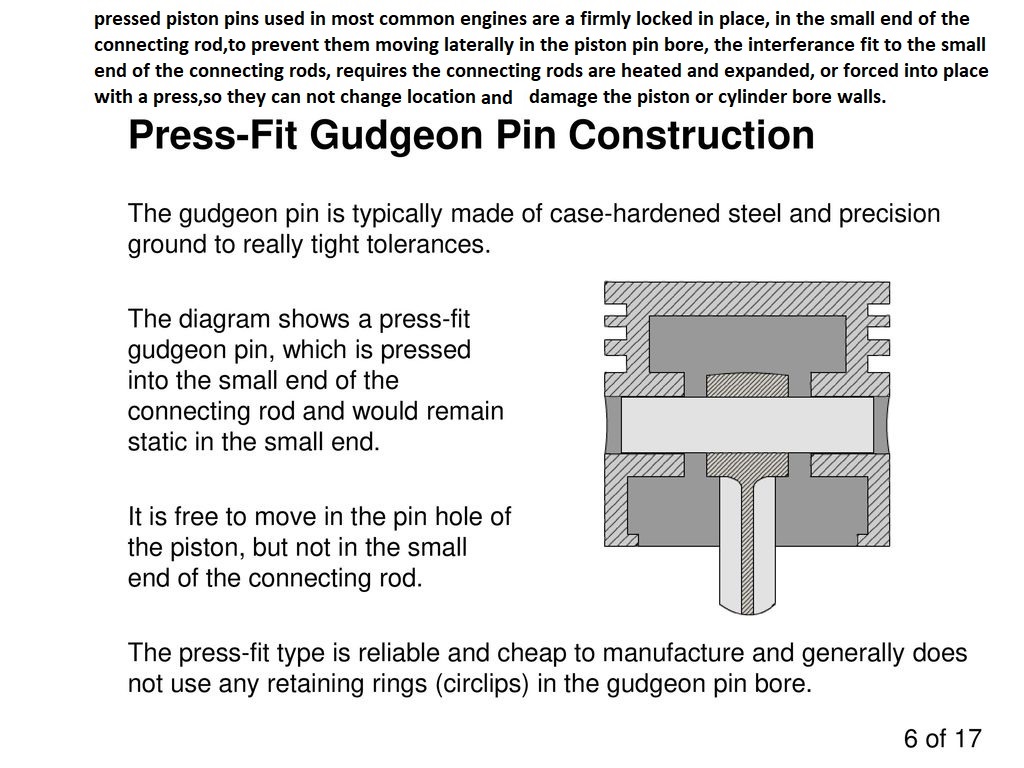

When a pressed pin is installed,into,and held in place by the small end of the connecting rod being an interference fit in a connecting rods small end, where during use its clamped firmly in place, most shops put the smaller end of the connecting rod on a connecting rod heater device that heats the piston pin end of the connecting rod to specific heat range so it expands slightly.(just enough to allow the pin to slide thru easily) With the piston sitting is a little V-block or rounded cradle, they put the rod into the piston in line with the pin bore location centerline and insert then press in the pin. The pin slides in easily since the hole in the rod has expanded, by the heat, but. Once the rod contacts the pin and piston these act like a heat sink, drawing off heat rapidly so it cools rapidly , the hole in the small end of the connecting rod tightens up as it contracts and the pin will not slide from its location. This takes only a few seconds to contract because the pin, piston and rod body draws the heat out, as soon as the heat source is removed.

WATCH THESE VIDEOS

http://www.youtube.com/watch?v=cJJI9bml ... re=related

http://www.youtube.com/watch?v=uTpRfREY ... re=related

http://www.enginebuildermag.com/2007/04/performance-connecting-rods/

To remove the pins, you don't have the ability of being able to heat just the small end of the rod up with the heater so that it alone expands and allows the pin to slide out. You have to press it out, with a hydraulic press and the pins soaked in light oil then pressed out in a jig that holds the piston assembly.

The piston body being aluminum is easy to deform and its the piston that is resisting the forces of the pin removal hydraulic pressing operation.

pistons and pins should be carefully cleaned with a solvent bath then the pin lubed before dis-assembly to prevent damage from micro crud thats likely to form in a running engine on the piston pin bores.

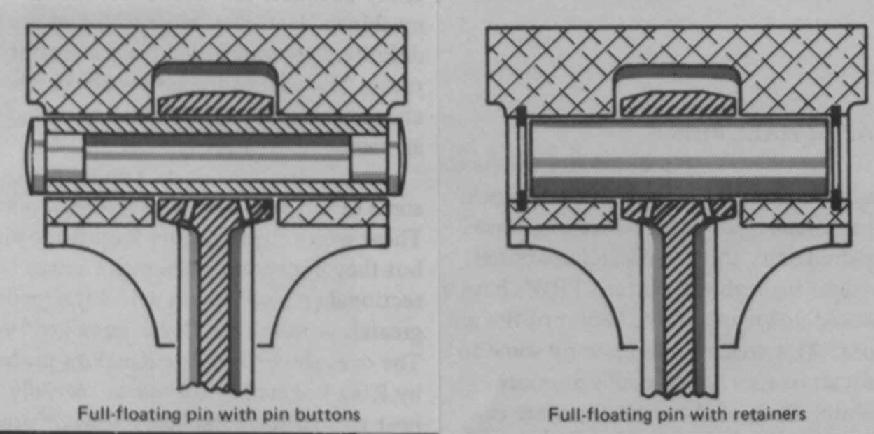

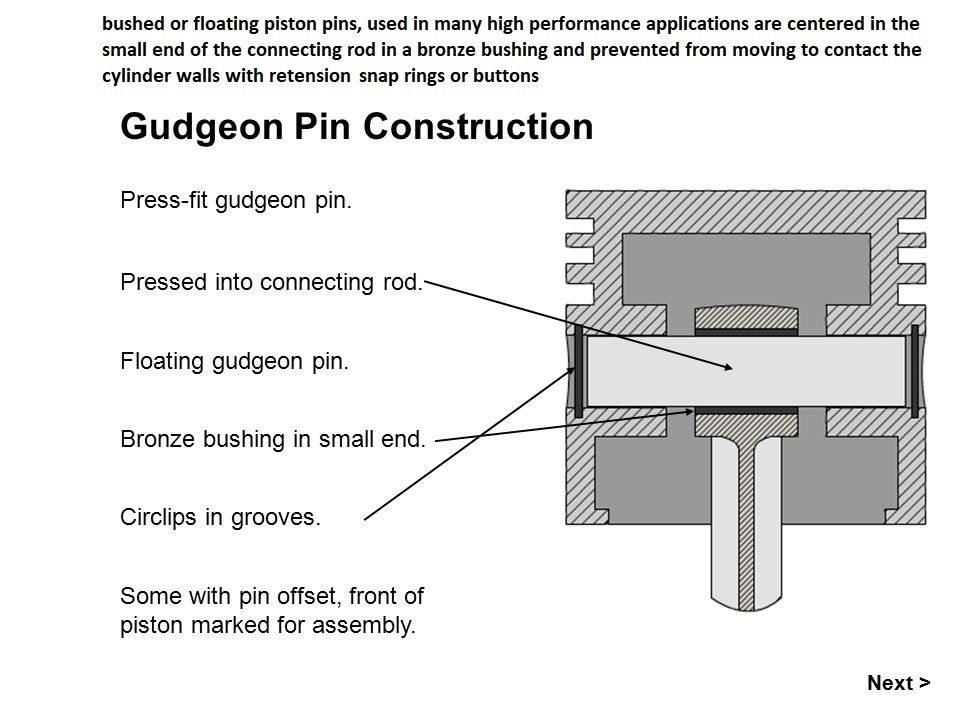

FULL FLOATING , piston pins are a slide fit in both the small end of the connecting rods and the piston pin bores and are allowed to rotate freely in both the small end of the connecting rod and the piston pin bores, this reduces friction and allows easy hand assembly, but it requires the use of locking snap rings or spiro-locks to hold the pin in its intended location in the pin bore in both the small end of the connecting rods and the piston pin bores. because the small end of the connecting rod has a pin that moves this end frequently has a bronze sleeve inserted and an oil hole drilled to increase lubrication on the piston pins

https://goodson.com/blogs/goodson-gazette/the-ins-and-outs-of-pressing-piston-pins-and-bushings

https://www.summitracing.com/search/section/connecting-rods/wrist-pin-bushing-material/bronze

https://pitstopusa.com/c-134461-eng...rod-parts-accessories-wrist-pin-bushings.html

https://goodson.com/blogs/goodson-gazette/the-ins-and-outs-of-pressing-piston-pins-and-bushings

Guys frequently ask me why I don,t refurbish stock rods or use pressed in piston pins on 90% of my engine builds, its for both economic and strength reasons,

let me say this, Ive build close to 180 engines or more MINIMUM now over 40 plus years (I lost count)and I use the local machine shop to instal pressed in pins or I talk the guys into free float piston designs and I OWN a 12 ton press and several torches, simply because its a P.I.T.A. to fix if you screw it up,and cheap to have done.

now obviously I could buy a rod heater and have the tool, but just using the far stronger aftermarket connecting rods and free float pistons makes far more sense to me, than screwing around with weaker rods and harder to assemble pistons

a good aftermarket connecting rod with 7/16" ARP rod bolts and a cap screw rod design with free float piston pins is easily 150%-200% stronger than refurbished stock connecting rods and after all the time and effort and new rod bolts , polishing, magnifluxing, resizing etc, it just makes zero sense to refurbish inferior rods or deal with press in piston pins

this is were the SPIROLOCS give you a noticeable advantage, they are basically a semi flat spring,with one flat side and one slightly micro-curved side, you pull them out to stretch them then spiral them into place (two slightly curved side BACK TO BACK) flat sides facing out, they act as mini springs taking up any residual space thus keeping the piston pin centered, and resisting any length wise travel.

related info

http://kb-silvolite.com/article.php?action=read&A_id=9

http://www.smalley.com/pdfs/spiral_reta ... emoval.pdf

http://webpages.charter.net/beckracing/page10.htm

viewtopic.php?f=53&t=978

http://www.ustream.tv/recorded/221556

http://www.angelfire.com/mech/danielspo ... rolox.html

read these threads

viewtopic.php?f=53&t=247

viewtopic.php?f=53&t=852

viewtopic.php?f=53&t=510

viewtopic.php?f=53&t=1168

viewtopic.php?f=53&t=4472

http://garage.grumpysperformance.com/index.php?threads/snap-ring-pliers.16346/

stock wrist pins and the combo of forged piston and longer connecting rods allowing a higher pin or compression height piston,of lower total weight,especially when compared too cast pistons which are rather heavy and often are over looked,as a potentially upgraded component. thinking thru the use of all the components used and what they are made of and the weight , has benefits, those, components made of stronger and lighter aftermarket forged pistons with free floating piston pins (wrist pins)made from tapered tool, or even rather exotic titanium alloy, steel wrist pins can be used to reduce significant reciprocating weight

http://www.tpub.com/content/engine/1403 ... 37_104.htm

http://www.beckracing.com/page10.htm

http://garage.grumpysperformance.co...in-height-compression-height.5064/#post-66240

http://www.enginebuildermag.com/2018/02/performance-pistons-101/

viewtopic.php?f=50&t=11029&p=48839#p48839

http://www.zoro.com/g/Snap Ring Tools/00059785/

http://www.bmeltd.com/Wristpin.htm

http://www.superchevy.com/how-to/engine ... m#cxrecs_s

http://www.kb-silvolite.com/features.ph ... ad&F_id=36

viewtopic.php?f=53&t=5064&p=14370#p14370

http://www.circletrack.com/enginetech/c ... index.html

http://www.probeindustries.com/Wrist_Pins_s/80.htm

http://www.flatlanderracing.com/ross_4340pins.html

common sbc pin height info

Specs

- Comp Height 5.565" Rod - 1.561

- Comp Height 5.7" Rod - 1.433

- Comp Height 6.0" Rod - 1.13

- Pin Diameter - 0.9272

Install Tru-Arcs with the open ends pointing down only and make sure the flat side (with the sharp corners) faces out.

if you have free float piston pins your most likely familiar with these

taper pins are lighter because the internal diameter is thinner towards the outer ends this reduces weight without reducing strength IF THE STEEL USED IS TOP QUALITY HEAT TREATED TOOL STEEL, BE AWARE there CHEAP SUB STANDARD CLONES that are not as well made.. quality aftermarket tool steel ,tapered tool steel piston pins usually cost $15-$30 EACH

in rod for full floating pin, to snap ring (End play 0.0 - 0.005"

the stock style piston pin is usually fairly heavy

http://kb-silvolite.com/pins.php

the aftermarket ,tapered style can be just as strong, or even stronger due to better materials and heat treating of the component, better hardening, tempering etc. and several grams lighter in weight allowing smaller crank counter weights and lower balancing costs

Most guys order a set of pistons or a rotating assembly and never think for two seconds about the wrist pins that are usually included, but that's a mistake in some cases.

yes the tapered pins cost more but they also tend to weigh less and thus put less stress on the engine at high rpms.

most piston wrist pins look like thick tubes with a mirror chrome finish, but theres also better quality wrist pins available made from far stronger and more expensive steel or titanium with the internal area rather hourglass shaped, where the hole thru the center tappers from a large outer end to a smaller central diam. that saves weight without sacrificing strength

one BIG ADVANTAGE to use of floating pin pistons and connecting rods it the ease of mixing and matching components and locations to minimize quench, or deck height differences during the install process

http://blog.wiseco.com/what-are-wrist-pin-buttons

https://www.musclecardiy.com/performance/how-to-build-racing-engines-piston-technology-guide/

Second compression rings are really misnamed since their primary function is to assist with oil control. Most ring manufacturers hold that the second ring is about 85 percent devoted to oil control and only 10 to 15 percent to compression sealing. Its main mission is to scrape oil missed by the oil ring to that it doesn’t find its way to the combustion chamber to contaminate the fuel mixture. Since heat is not an issue with the second ring, a conventional cast-iron ring with a reverse bevel and tapered face is still employed with the primary task of scraping oil.

Where the pin bore encroaches on the oil ring groove, most applica¬tions use an oil ring support rail with a shorter inboard pin. The alternative is to use pin buttons with machined ring grooves that serve as oil ring supports. The buttons control pin placement and ring support, and they are much easier to assemble than the standard Spirolox or Truarc rings.

OBVIOUSLY the PIN BUTTONS upside down here to better show the ring clearance groove, it might seen that the pin retention buttons will wear the bore but in most cases the combined length of the two buttons and piston pin were several thousands less than bore diam, and in many cases the lower oil rings retain the buttons

BACK IN THE 70s pin buttons were used as they made free float piston assembly easy and in cases where the pin intersected the oil ring they helped support the oil ring

When a pressed pin is installed,into,and held in place by the small end of the connecting rod being an interference fit in a connecting rods small end, where during use its clamped firmly in place, most shops put the smaller end of the connecting rod on a connecting rod heater device that heats the piston pin end of the connecting rod to specific heat range so it expands slightly.(just enough to allow the pin to slide thru easily) With the piston sitting is a little V-block or rounded cradle, they put the rod into the piston in line with the pin bore location centerline and insert then press in the pin. The pin slides in easily since the hole in the rod has expanded, by the heat, but. Once the rod contacts the pin and piston these act like a heat sink, drawing off heat rapidly so it cools rapidly , the hole in the small end of the connecting rod tightens up as it contracts and the pin will not slide from its location. This takes only a few seconds to contract because the pin, piston and rod body draws the heat out, as soon as the heat source is removed.

WATCH THESE VIDEOS

http://www.youtube.com/watch?v=cJJI9bml ... re=related

http://www.youtube.com/watch?v=uTpRfREY ... re=related

http://www.enginebuildermag.com/2007/04/performance-connecting-rods/

To remove the pins, you don't have the ability of being able to heat just the small end of the rod up with the heater so that it alone expands and allows the pin to slide out. You have to press it out, with a hydraulic press and the pins soaked in light oil then pressed out in a jig that holds the piston assembly.

The piston body being aluminum is easy to deform and its the piston that is resisting the forces of the pin removal hydraulic pressing operation.

pistons and pins should be carefully cleaned with a solvent bath then the pin lubed before dis-assembly to prevent damage from micro crud thats likely to form in a running engine on the piston pin bores.

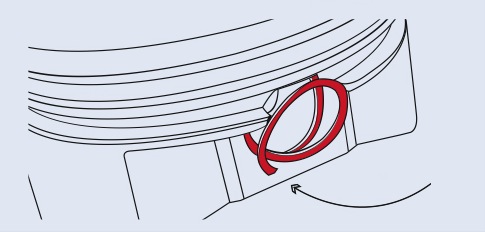

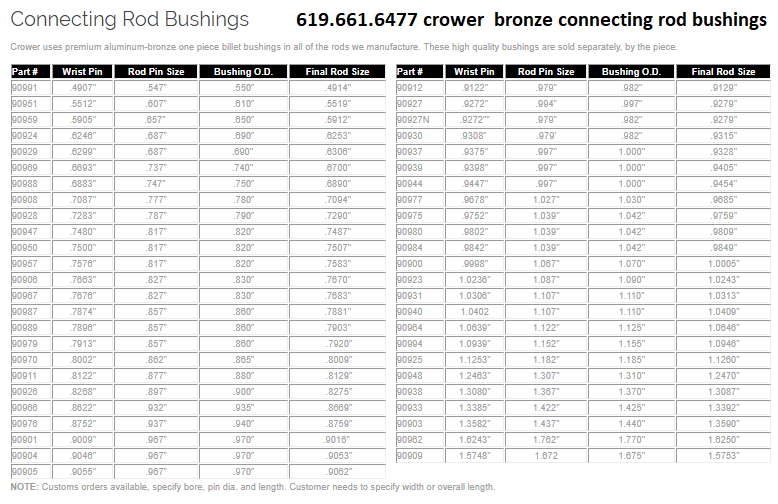

FULL FLOATING , piston pins are a slide fit in both the small end of the connecting rods and the piston pin bores and are allowed to rotate freely in both the small end of the connecting rod and the piston pin bores, this reduces friction and allows easy hand assembly, but it requires the use of locking snap rings or spiro-locks to hold the pin in its intended location in the pin bore in both the small end of the connecting rods and the piston pin bores. because the small end of the connecting rod has a pin that moves this end frequently has a bronze sleeve inserted and an oil hole drilled to increase lubrication on the piston pins

https://goodson.com/blogs/goodson-gazette/the-ins-and-outs-of-pressing-piston-pins-and-bushings

https://www.summitracing.com/search/section/connecting-rods/wrist-pin-bushing-material/bronze

https://pitstopusa.com/c-134461-eng...rod-parts-accessories-wrist-pin-bushings.html

https://goodson.com/blogs/goodson-gazette/the-ins-and-outs-of-pressing-piston-pins-and-bushings

Guys frequently ask me why I don,t refurbish stock rods or use pressed in piston pins on 90% of my engine builds, its for both economic and strength reasons,

let me say this, Ive build close to 180 engines or more MINIMUM now over 40 plus years (I lost count)and I use the local machine shop to instal pressed in pins or I talk the guys into free float piston designs and I OWN a 12 ton press and several torches, simply because its a P.I.T.A. to fix if you screw it up,and cheap to have done.

now obviously I could buy a rod heater and have the tool, but just using the far stronger aftermarket connecting rods and free float pistons makes far more sense to me, than screwing around with weaker rods and harder to assemble pistons

a good aftermarket connecting rod with 7/16" ARP rod bolts and a cap screw rod design with free float piston pins is easily 150%-200% stronger than refurbished stock connecting rods and after all the time and effort and new rod bolts , polishing, magnifluxing, resizing etc, it just makes zero sense to refurbish inferior rods or deal with press in piston pins

this is were the SPIROLOCS give you a noticeable advantage, they are basically a semi flat spring,with one flat side and one slightly micro-curved side, you pull them out to stretch them then spiral them into place (two slightly curved side BACK TO BACK) flat sides facing out, they act as mini springs taking up any residual space thus keeping the piston pin centered, and resisting any length wise travel.

related info

http://kb-silvolite.com/article.php?action=read&A_id=9

http://www.smalley.com/pdfs/spiral_reta ... emoval.pdf

http://webpages.charter.net/beckracing/page10.htm

viewtopic.php?f=53&t=978

http://www.ustream.tv/recorded/221556

http://www.angelfire.com/mech/danielspo ... rolox.html

read these threads

viewtopic.php?f=53&t=247

viewtopic.php?f=53&t=852

viewtopic.php?f=53&t=510

viewtopic.php?f=53&t=1168

viewtopic.php?f=53&t=4472

Last edited by a moderator: