allen said:GRUMPY, I have a question, I purchased a crane cam #110921 to install in my chevy sb and one of my older friends strongly suggested I buy and use the Crower solid lifters with the EDM oil holes and THEN suggested I polishing lifter lower 1/2 along the side too increase oil flow? whats he talking about?

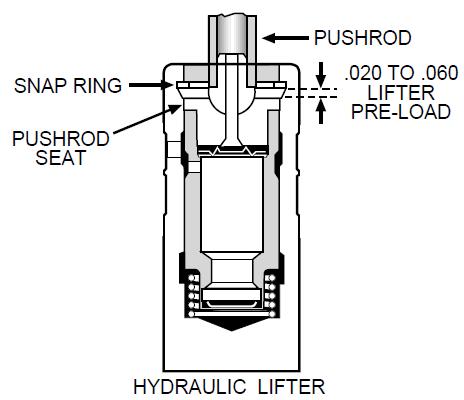

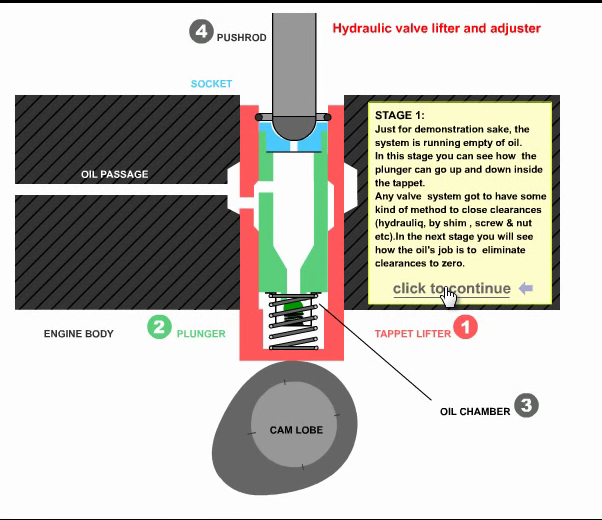

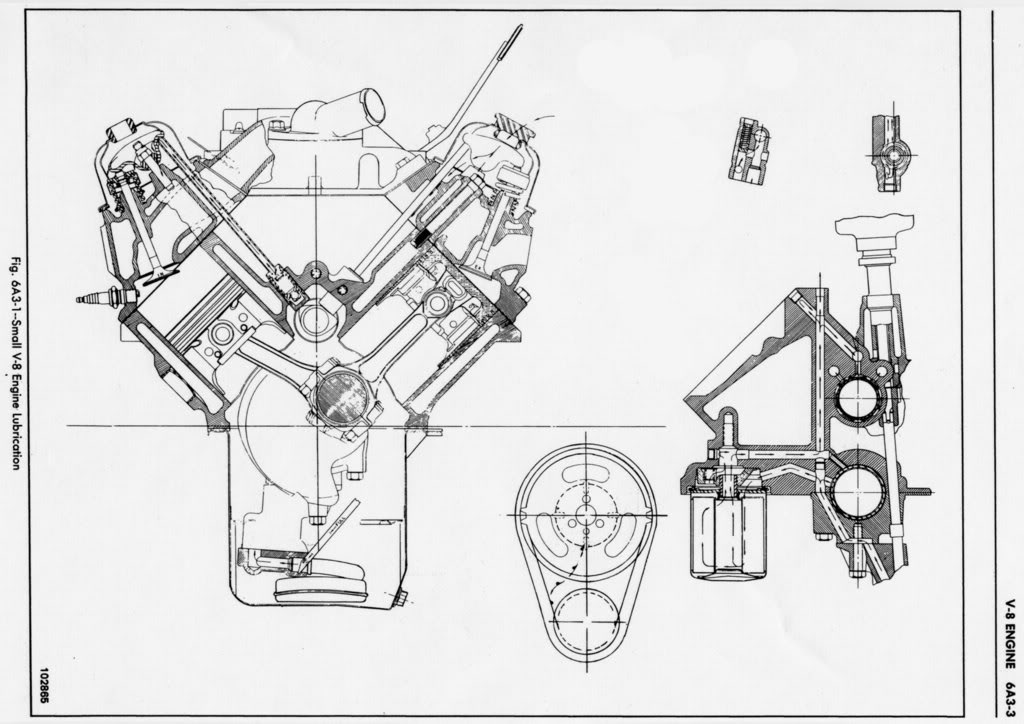

most of the GIVE or clearance or movement in a hydraulic lifter push rod seat is the result of pressurized oil flowing into and lifting the push rod seat, without the pressurized oil entering the lifter body,from the sides of the lifter body from the oil passages in the block, manually forcing the push rod seat down into the lifter body is basically a one shot deal that generally only going to compress in a minimal .060 -.08 once until oil pressure forces the seat back up.

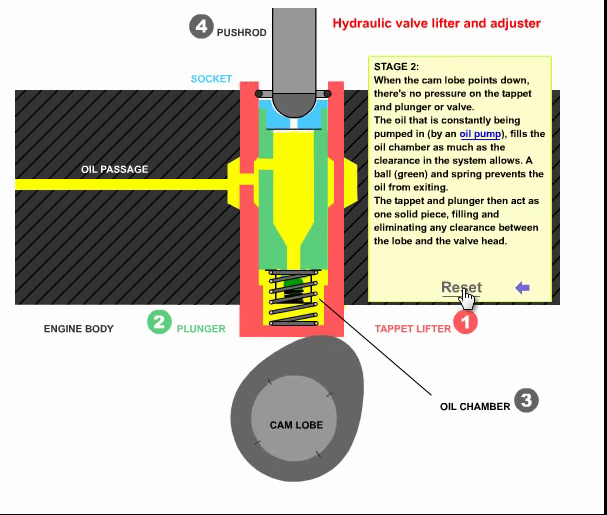

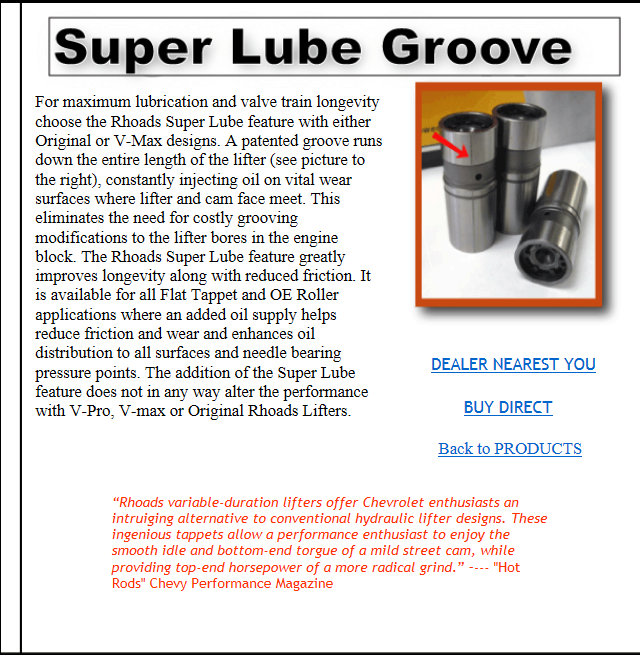

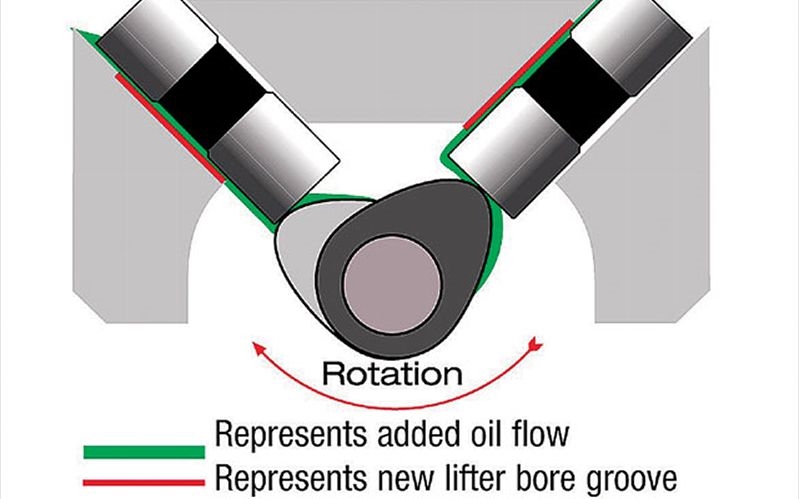

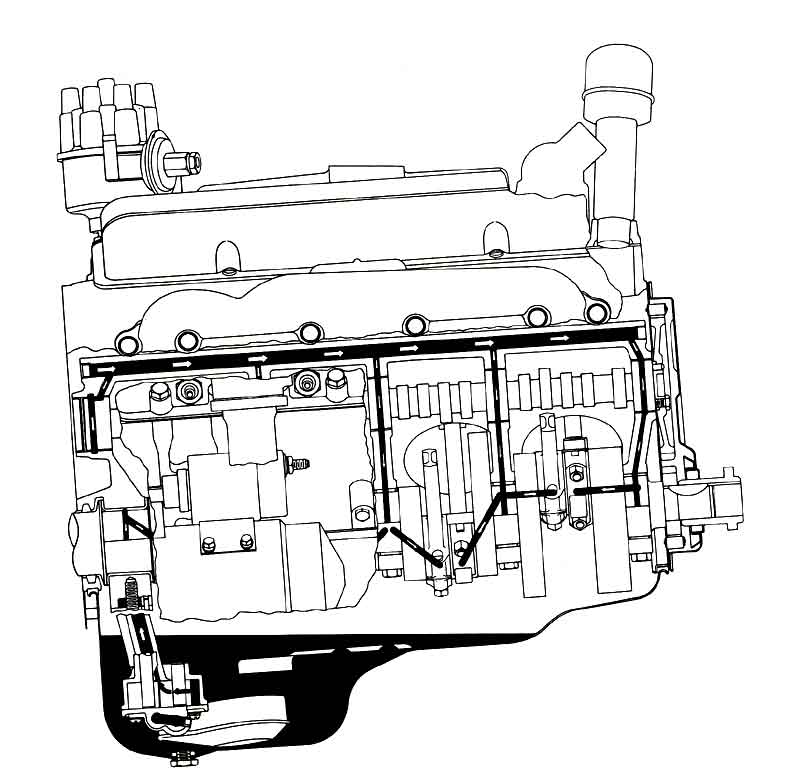

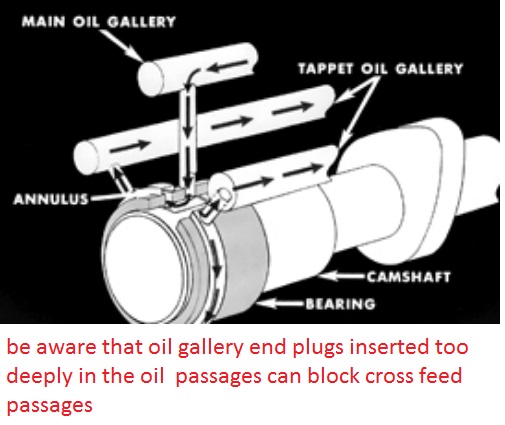

notice RHOADS LIFTERS have an OPTIONAL oil groove,feature of similar design, but due to the requirement for fast and easy manufacturing they also extend the groove upward from the oil passage band so it will squirt oil up out of the lifter bores into the lifter gallery where it does little good, rather than just to the cam & lifter interface area where it does help cool and lubricate the area under stress.

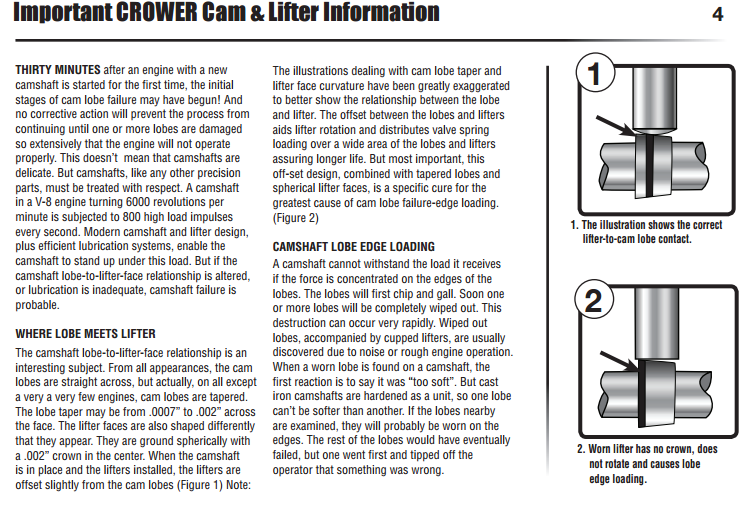

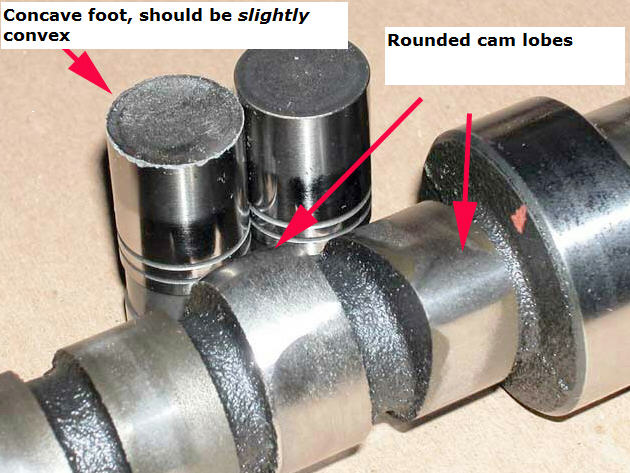

the better quality hydraulic and solid flat tappet lifters have hardened bases

btw the best deal I found lately on basic hydraulic flat tappet lifters

http://www.summitracing.com/parts/sum-ht817/overview/

read this

http://garage.grumpysperformance.com/index.php?threads/junk-hydraulic-lifters-mystery-solved.12263/

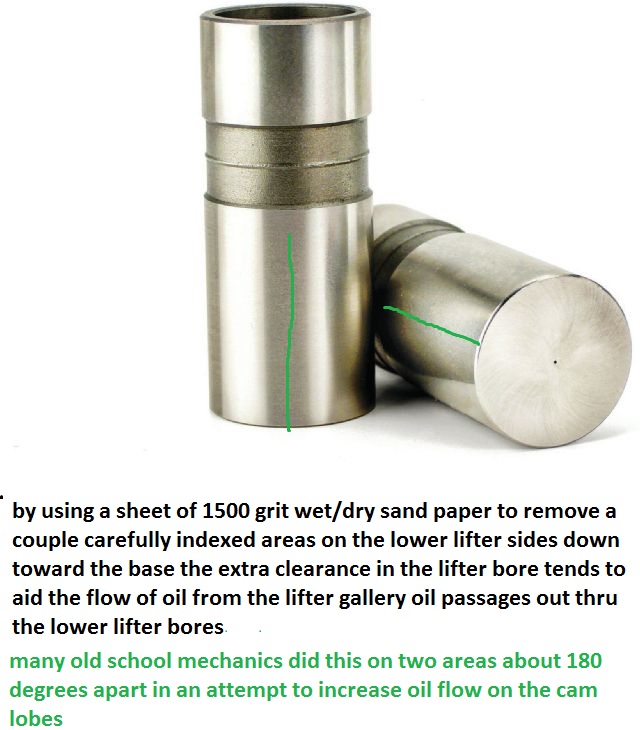

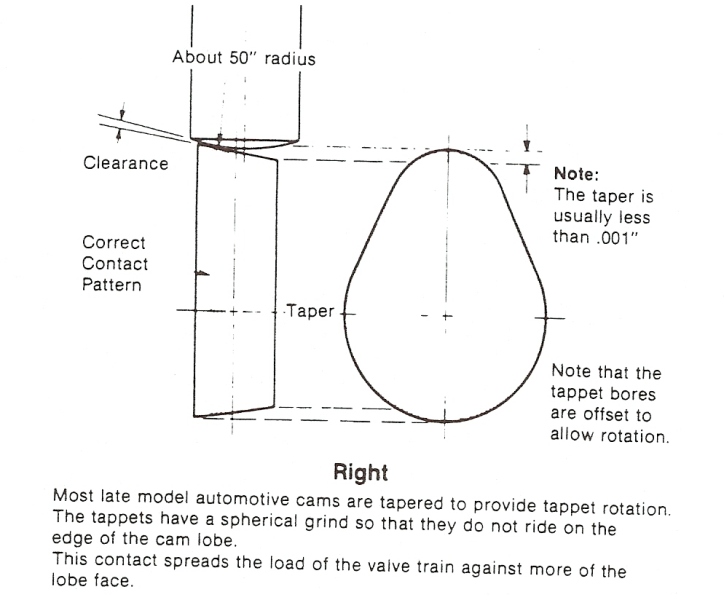

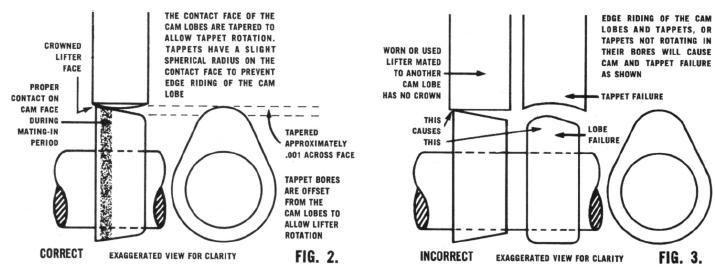

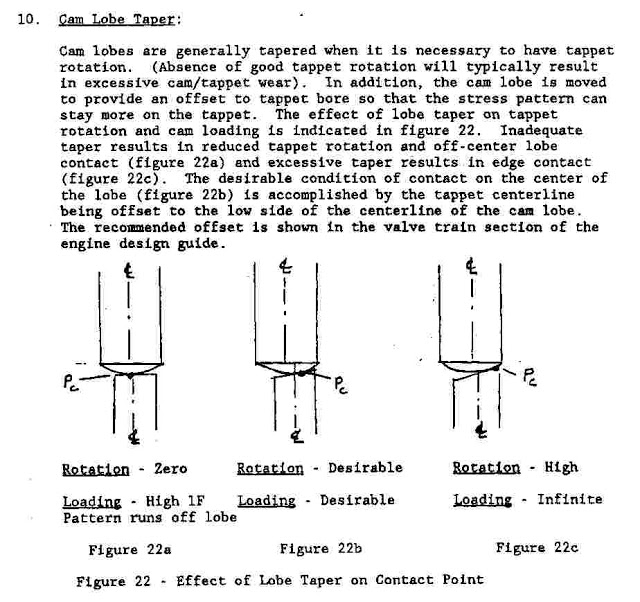

thats a very old school modification that won,t do a bit of harm, if its done carefully and can very possibly help prevent a flat tappet solid lifter cam from wearing a cam lobe, the idea is to increase the volume of oil thats spraying out around the base of the lifter in an attempt to cool and better lubricate the cam lobes.

Ive done it on dozens of engines and if you don't get carried away its a very useful modification.

you simply place a sheet of 1500 grit wet/dry sand paper on a sheet of glass and make several passes over it on two opposite sides to effectively remove a very small amount of metal thus channeling extra oil flow out of the lower lifter bore onto the cam lobes.

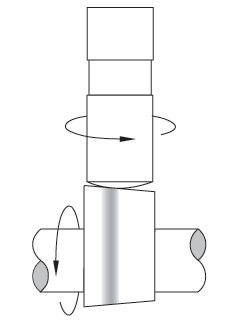

the idea is that flat tappet lifters spin rapidly in the lifter bores so sanding two 180 degree apart and slightly recessed (maybe .002 on each side and .010 wide) areas on the lifter lower base

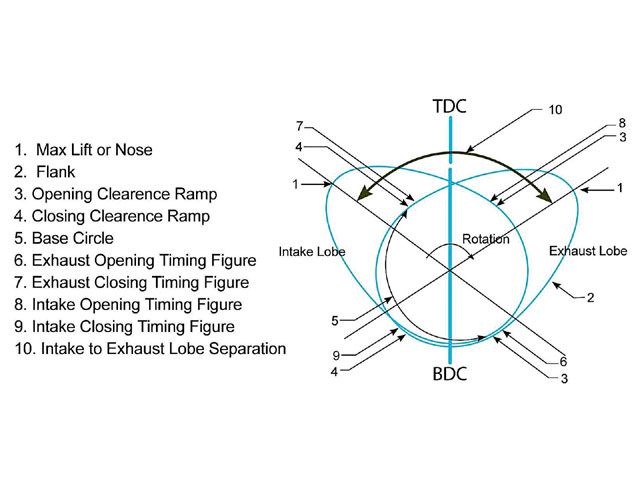

it only takes a few seconds running a new engine for an improperly installed cam , lifters and valve train, during the break-in process to generate teaspoons of metallic trash that ,once in the engine oil flow ,rapidly destroys bearings if the clearances ,spring load rates or valve train geometry is wrong

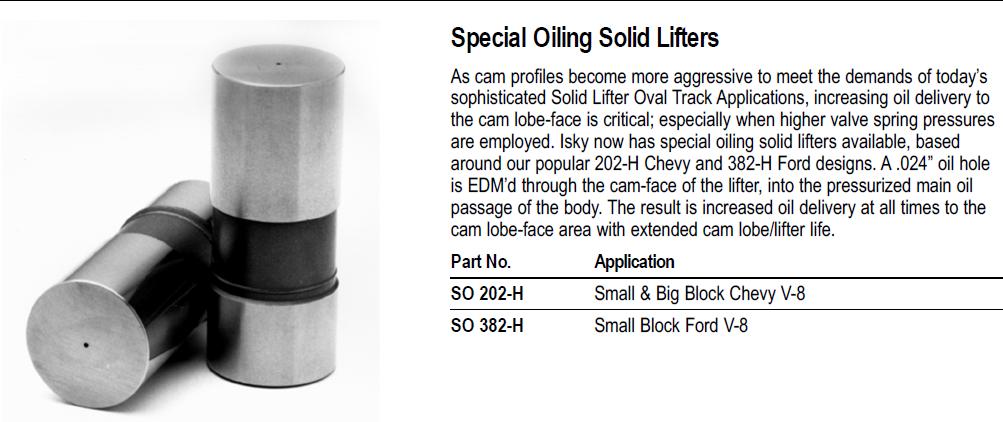

CROWER and COMP and HOWARD CAMS now sell solid flat tappet lifters with EDM drilled holes to do something similar too force oil out of the lifter base directly on the cam lobes.

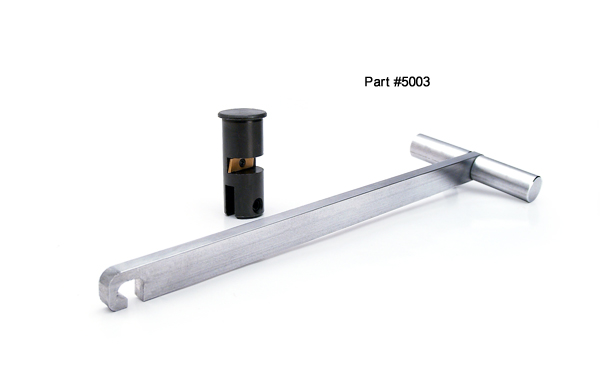

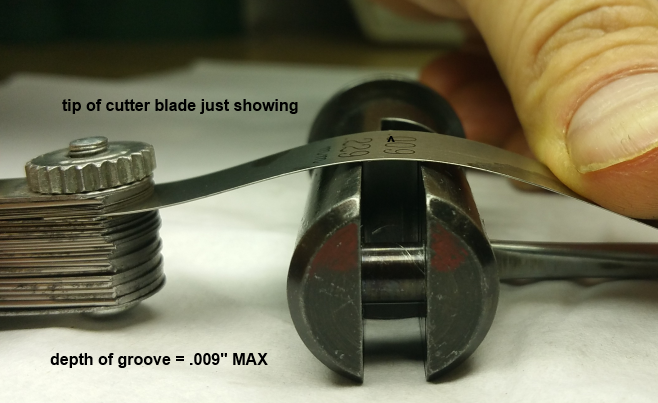

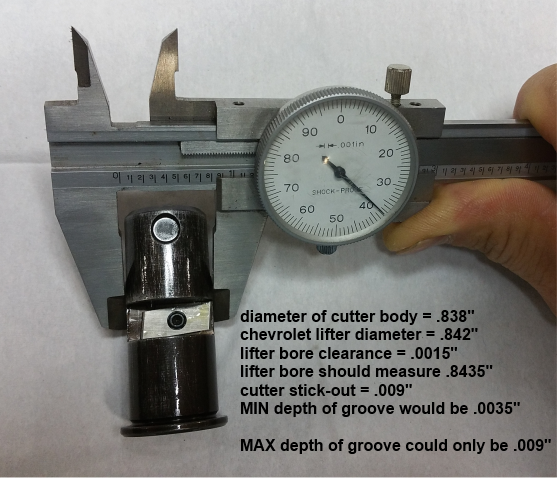

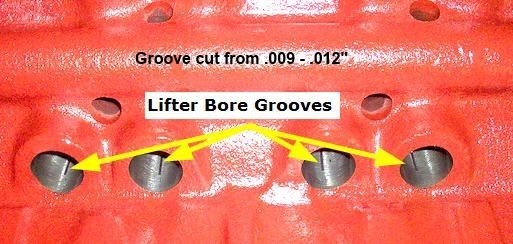

COMP SELLS A TOOL TO GROOVE LIFTER BORES

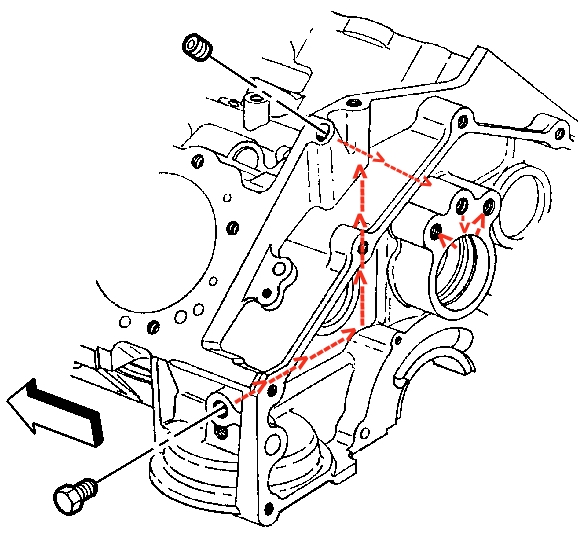

When I use the lifter bore grooves, I have always suggested a big block style oil pump be used as those grooves allow part of the oil flow to take a short cut out the lower lifter bore to keep the cam lobe/lifter contact area well lubricated, but that also means LESS oil reaching the bearings and rockers than you would have with the identical set-up without the lifter bore groove thus adding extra oil flow volume with the larger 12 tooth oil pump makes up for the lost volume

10552 high flow SBC 4 BOLT COVER OIL PUMP

http://www.summitracing.com/parts/mel-10552

High volume performance oil pump.

10% increase in volume over stock oil pump.

The 10552 is manufactured with the drive and idler shafts extended to allow for additional support in the cover eliminating dynamic shaft deflection at increased RPM levels.

The cover is doweled to the pump housing to assure alignment of the shaft bores.

Screw in plug retains relief valve spring instead of pin.

Relief hole in cover uses screw in plug instead of pressed cup plug.

All bolts are self locking socket heads, with the wrench supplied.

The housing and cover are CNC machined and phosphate coated.

Includes intermediate shaft with steel guide. Uses both 3/4” bolt on or press in screen.

The lower pressure spring is included to reduce pressure if desired.

Patent No. 5,810,571.

10778C (Anti-Cavitation)

(NOTICE ITS A 5 BOLT BIG BLOCK HIGH VOLUME OIL PUMP WITH A 3/4" pickup}

http://www.summitracing.com/parts/mel-10778

High volume performance upgrade for the 10770.

Increase in volume of 25% over stock oil pump.

The same as the 10778 except with the addition of grooves machined in the housing and cover. The grooves reduce cavitation effects in high RPM applications.

Using this oil pump will reduce pressure at idle.

Includes intermediate shaft with steel guide.

Uses 3/4” press in screen.

Racing applications only.

Patent No. 5,810,571

pre-spraying all bearing and valve train components with a moly based spray, helps embed micro moly lubricants in the metallic surface micro fissures , a good paste lube like cranes assembly lube over the spray surface helps insure a good lubricant surface coating, that is far stronger than just the ZINC and PHOSPHATES in oil

ISKY,CROWER,COMP CAMS,HOWARDS CAMS sell lifters with EDM oil feeds

lots of extra oil flow might reduce the tendency for flat tappet lifter and cam lobe wear

THERES BILLET AND TOOL STEEL CAM CORES AVAILABLE

http://www.callies.com/wp-content/uploads/2014/06/Cam-Core-Master-Price-Sheet.pdf

Callies Crankshafts Producing 8620 Billet Cam Cores

Recieved notice today, that Callies, is producing billet cam cores for the camshaft industry. This has been in the making for about 1.5 yrs. Since Crane started to have problems, the owner of Callies, took a look at the equipment, but as far as I know only purchased the gear cutting equipment. Crane used to produce the the cams for the aircraft engine mfgs that Callies, makes crankshafts for and when Crane was going down the aircraft engine mfgs notified Callies ,that production of cranks was going to end until a cam mfg was found. So they now mfg and finish cams for aircraft engines and are solving the shortage of cores elsewhere. To me it's good to know that the mfg that makes cranks for aircraft engines also mfg cranks in our market. THEY ARE NOT SUPPLING CAMS ONLY CORES FOR FINISH TO THE CAM GRINDING COMPANYS

Last edited: