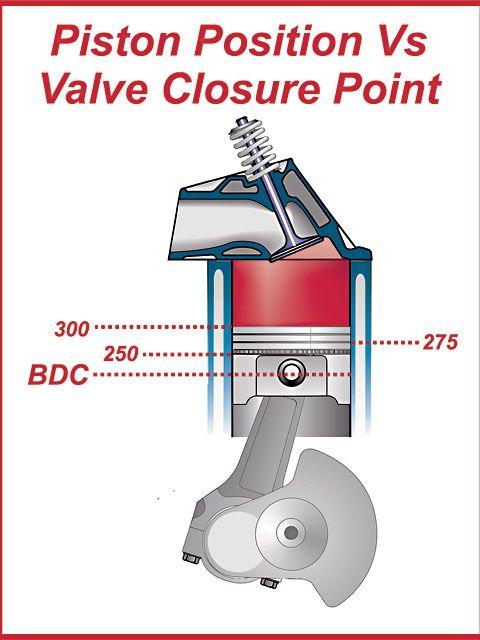

read this, BUT keep in mind it does little good to have killer head flow numbers if the intake manifold flows less or if the exhaust is restricting flow, and heads that flow killer numbers at .700 lift, and are designed to feed a 427 displacement at 7500rpm, DON,T do you much good if the CAM you sellected has a .520 lift AND ONLY SPIN THE ENGINE TO 6000RPM

http://www.tmossporting.com/tabid/1805/Default.aspx

http://www.airflowresearch.com/super-chevy-apr-2010-210cc-sbc.php

you might want too look thru this link also

http://www.weldtech.com/productsframe.html

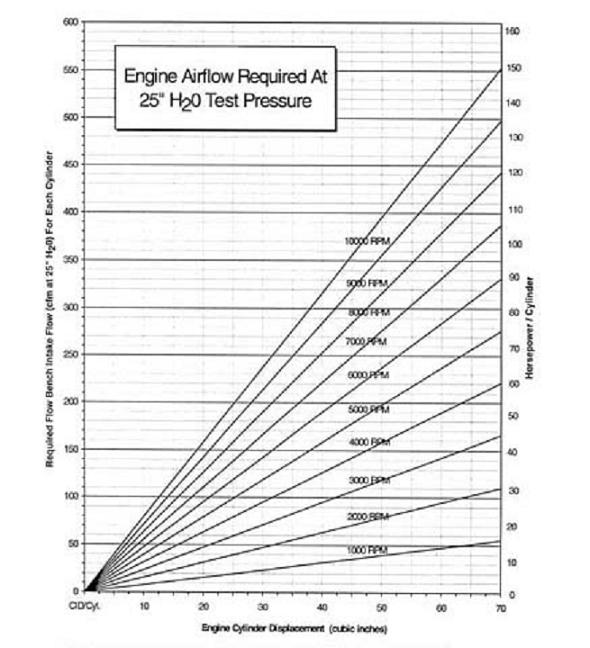

USE THE CALCULATORS to match port size to intended rpm levels... but keep in mind valve lift and port flow limitations[/color]

http://www.wallaceracing.com/runnertorquecalc.php

http://www.wallaceracing.com/ca-calc.php

http://www.wallaceracing.com/area-under-curve.php

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

BTW.

ITS A COMMON MISCONCEPTION,THAT YOU MEASURE PORT CROSS SECTION AT THE PORT ENTRANCE,BUT ITS NOT the port area at the entrance , you need to use in the calcs, ITS the MINIMAL port cross section at the SMALLEST point in the port, usually near the push-rod area.

LIKE a funnel, its not the largest part of the opening but the smallest thats the restriction to flow

SO HOW do you MEASURE THEN??

http://www.harborfreight.com/cpi/ctaf/d ... umber=5649

http://store.summitracing.com/partdetai ... toview=sku

USE THIS

http://www.rbracing-rsr.com/runnertorquecalc.html

on the better 23 degree SMALL BLOCK AFTERMARKET HEADS THERE'S ABOUT 5.5 INCHES OF INTAKE PORT LENGTH ON AVERAGE FROM INTAKE GASKET TO THE BACK OF THE INTAKE VALVE AT THE FAR EDGE

http://users.erols.com/srweiss/tablehdc.htm

http://www.malcams.com/legacy/misc/headflow.htm

here,s a chart FROM THE BOOK,HOW TO BUILD BIG-INCH CHEVY SMALL BLOCKS with some common cross sectional port sizes

(measured at the smallest part of the ports)

...........................sq inches........port cc

edelbrock performer rpm ....1.43.............170

vortec......................1.66.............170

tfs195......................1.93.............195

afr 180.....................1.93.............180

afr 195.....................1.98.............195

afr 210.....................2.05.............210

dart pro 200................2.06.............200

dart pro 215................2.14.............215

brodix track 1 .............2.30.............221

dart pro 1 230..............2.40.............230

edelbrock 23 high port .....2.53.............238

edelbrock 18 deg............2.71.............266

tfs 18 deg..................2.80.............250

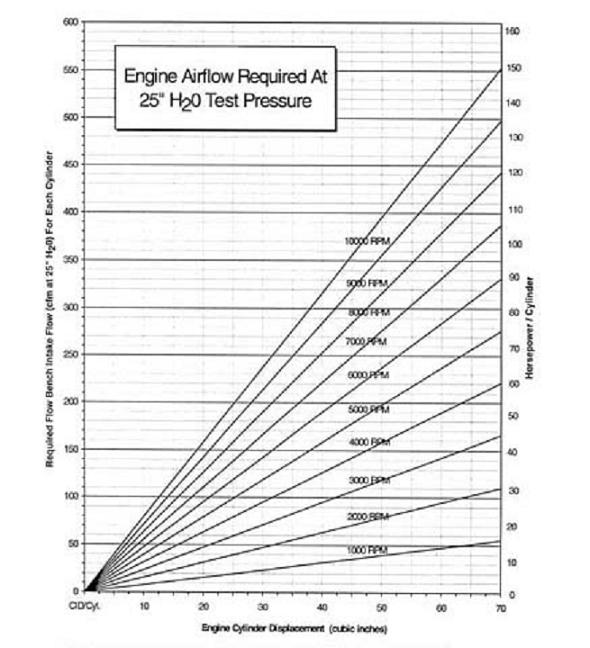

Potential HP based on Airflow (Hot Rod, Jun '99, p74):

Airflow at 28" of water x 0.257 x number of cylinders = potential HP

or required airflow based on HP:

HP / 0.257 / cylinders = required airflow

I know from experience not one guy in a hundred will take the effort to actually measure so I figured I,d try to keep the idea, I was posting about, rather easy to grasp, keep the math minimal ,and hope the point gets thru.

THINK OF COMPONENT SELECTION AS A PROCESS OF ELIMINATING THE WEAK LINK IN A CHAIN!

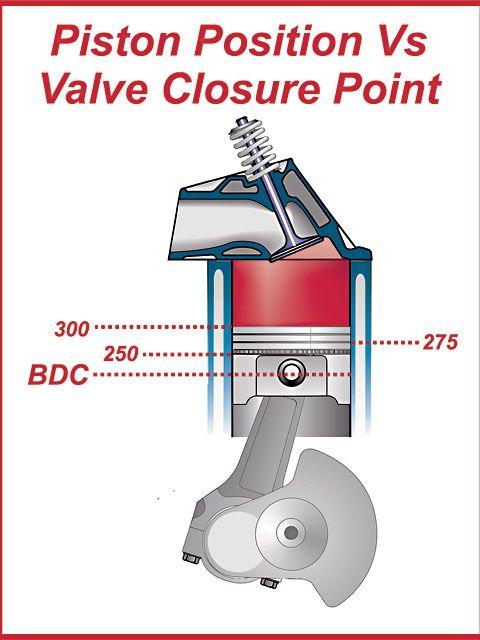

keep in mind it does you little good to have a SBC cylinder head that flows 310cfm at .700 lift, if you install a cam with .550 max lift,or UNDER ABOUT 245 DURATION at .050 lift or matched to an intake that flows 270cfm , or an exhaust pipe thats restrictive to exhaust flow at peak rpms

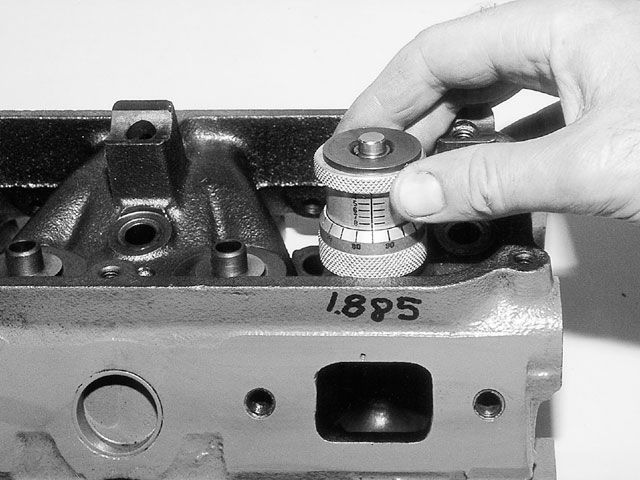

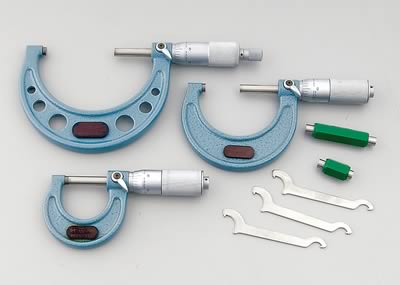

I can,t begin to tell you the number of times Ive grabbed snap gauges and a dial caliper and got questioned about what I was measuring when checking port throat restrictions or runner cross sections.

and in case some guys still don,t grasp it the point is that your dealing with a rather complex system with several potential restrictions and simply throwing a good flowing intake on an engine or increasing the rocker ratio may or may not provide an increase in flow potential, the result depends on how the rest of the components flow and react to the component being changed or the mods you've done, there's always several components that act like weak links in the chain, so locating those and improving those gets the best results, but of course once they are radically improved other components can become the new weak link or restriction.

so your trying to maintain a balance that potentially allows you to reach and exceed the power goals while hopefully not going bankrupt

400 cu in (6.6 L) SBC (1970-1981)150–265 hp (112–198 kW) 155cc-165cc intake port size

396 and 402 BBC 255 cc intake port size

The 396-cubic-inch (6.5 L) V8 was introduced in the 1965 Corvette as the L78 option and in the Z16 Chevelle as the L37 option. It had a bore of 4.094 in (104.0 mm) and a stroke of 3.760 in (95.5 mm),[8][9] and produced 375 hp (280 kW) and 410 lb⋅ft (560 N⋅m). The solid lifter version was capable of being operated in the upper 6000 rpm range, and when installed in the 1965 Corvette, was factory-rated at 425 horsepower.

Introduced in 1970, the 402-cubic-inch (6.6 L) was a 396-cubic-inch bored out by 0.030 in (0.76 mm). Despite the fact that it was 6 cubic inches (98 cc) larger, Chevrolet continued marketing it under the popular "396" label in the smaller cars while at the same time labeling it "Turbo-Jet 400" in the full-size cars. Power rating(s) by year:

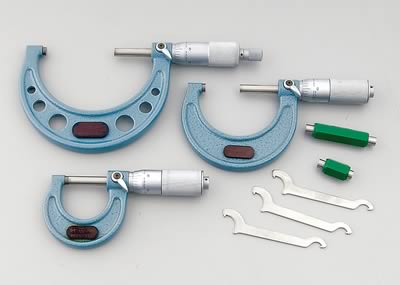

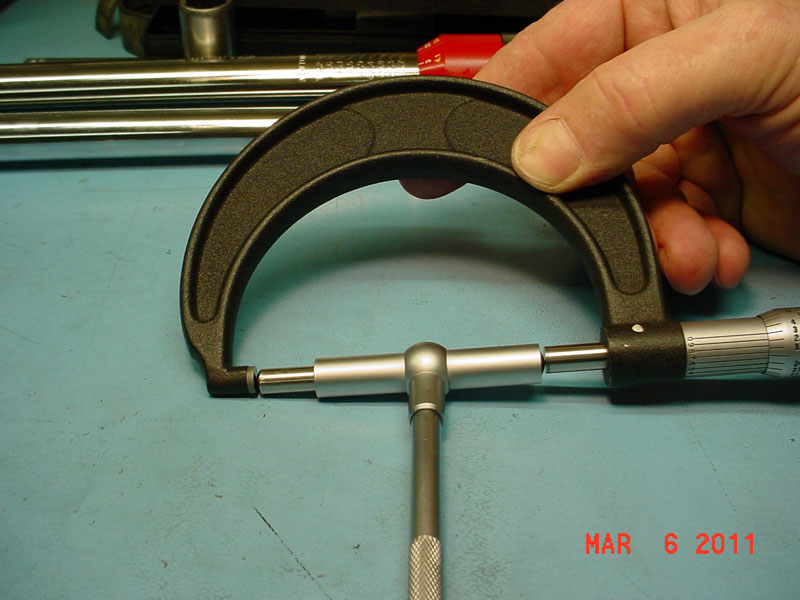

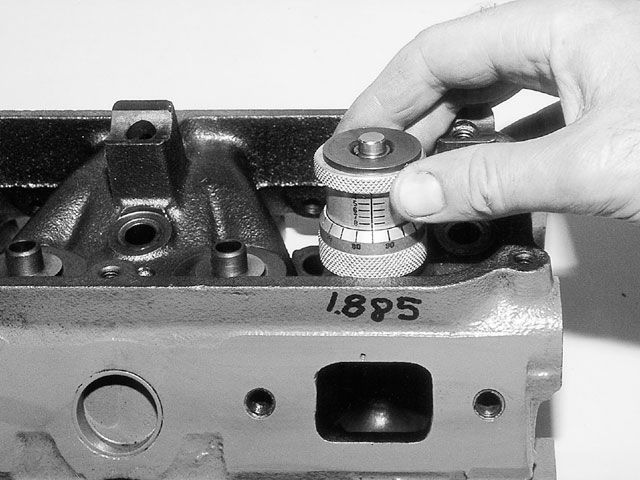

having a valve spring micrometer of the correct size and knowing how to use it helps a great deal

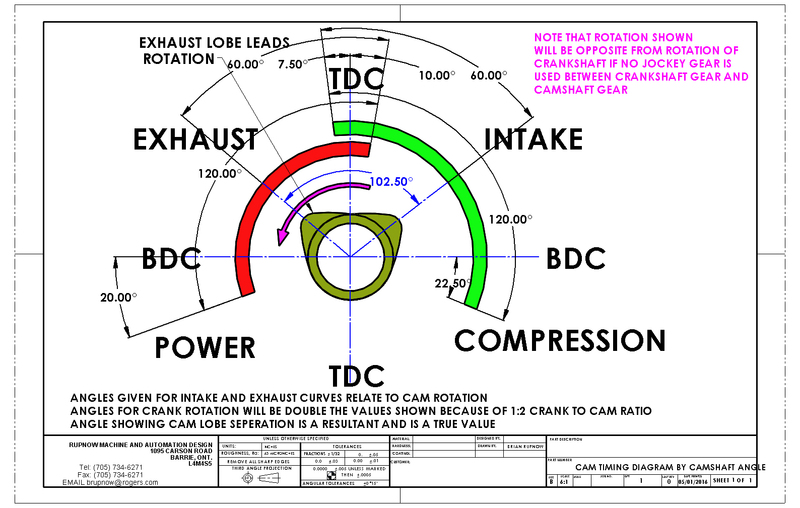

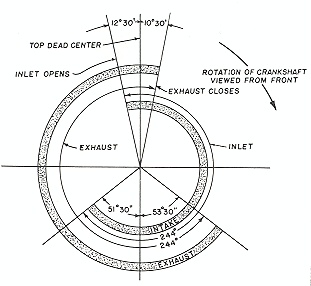

a good deal of the results you see on the EXHAUST side AND THE INTAKE SIDE are greatly effected by the scavenging design rpm range of the headers and the restriction to flow beyond the collectors.

YOU CAN,T CRAM MORE IN TILL THE OLD F/A CHARGE VOLUME IS REMOVED, and with a properly designed low restriction exhaust , the fast moving exhaust mass in the headers helps to drag in the next intake charge into the cylinders.

generally you can get a bit of useful info with a pressure gauge, if the exhaust have greater than about 1 PSI you've generally got a restriction thats hurting the power,and that restriction to flow DOES effect the engine tuning results and the cam timing you-ll want to use.

now Ive generally found that the collector lengths on commercial headers are too short and in many cases designed wrong to maximize the cylinder scavenging.

it does little good to stick a decent set of headers on a car and then hook the collectors up to a restrictive 2" or 2.5" exhaust either.

if your car runs noticeably better with open headers at the track, you can bet your street exhaust is restrictive.

viewtopic.php?f=56&t=1730&p=5392&hilit=horse+power+from+flow#p5392

there ARE aftermarket header merge collectors and things you can do to reduce the restriction to flow, (THE (H) and (X) pipes that split or share the exhaust between both sides, and a custom 3" exhaust and low restriction mufflers comes instantly too mind here)

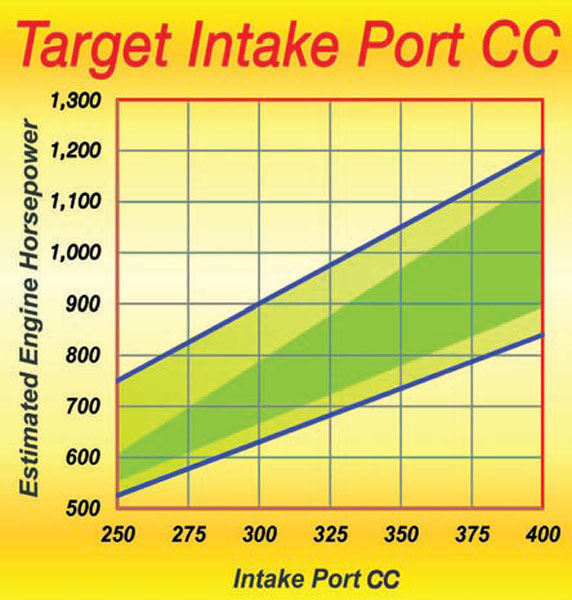

every component selected is a compromise in some area, stock Chevy small block intake ports run 145cc-170cc in most cases they are generally designed to maximize the 1000rpm-4500rpm power band , the aftermarket "smaller" 180cc ports keep the port velocity and torque high in lower rpms and provide a very noticeable improvement over the stock heads and are a better match to stock rear gears and mild cams

yes you can jump to the 195cc-200cc port size but you tend to loose some low rpm response and torque, swapping to a 3.73:1 rear gear and a 3000rpm stall converter allows you to make more high rpm power with a larger duration cam and bigger heads and still have a good low rpm power potential because your able to jump up into a higher average part of the power band on demand, and not be required to slowly work up to the required rpms , its generally the 2500-2800rpm and below where the larger heads cause the response to be a bit soggy , being able to skip that at wide open throttle helps, but keep in mind the, engine displacement, compression ratio, headers, intake, cam, and other factors also effect your results

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=5078&p=14840#p14840

http://forum.grumpysperformance.com/viewtopic.php?f=44&t=38

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=5364

viewtopic.php?f=50&t=1266

viewtopic.php?f=52&t=975&p=1700&hilit=210cc#p1700

http://users.erols.com/srweiss/tablehdc.htm

viewtopic.php?f=52&t=4532&p=12045&hilit=bushing+timing#p12045

viewtopic.php?f=32&t=5521

http://www.j-performance.com/index.php? ... view&id=48

viewtopic.php?f=52&t=1070&p=2054#p2054

http://www.tmossporting.com/tabid/1805/Default.aspx

http://www.airflowresearch.com/super-chevy-apr-2010-210cc-sbc.php

you might want too look thru this link also

http://www.weldtech.com/productsframe.html

USE THE CALCULATORS to match port size to intended rpm levels... but keep in mind valve lift and port flow limitations[/color]

http://www.wallaceracing.com/runnertorquecalc.php

http://www.wallaceracing.com/ca-calc.php

http://www.wallaceracing.com/area-under-curve.php

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

BTW.

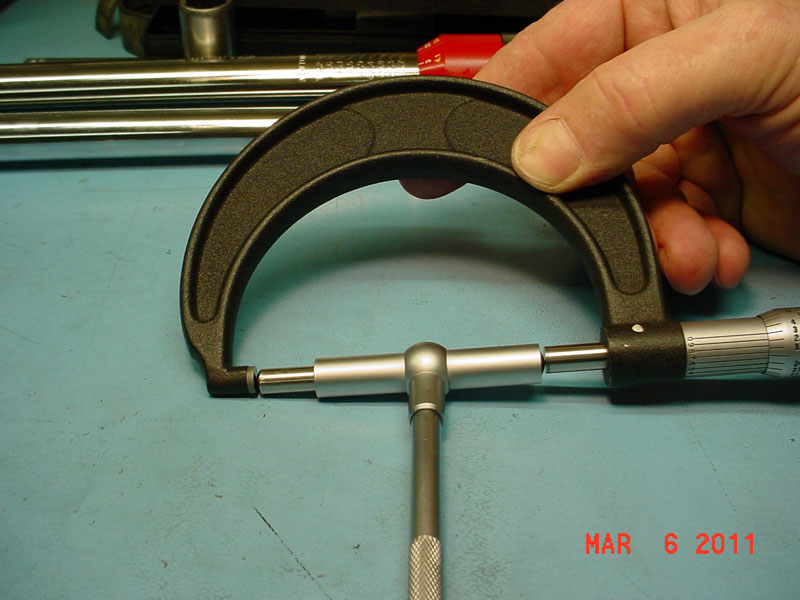

ITS A COMMON MISCONCEPTION,THAT YOU MEASURE PORT CROSS SECTION AT THE PORT ENTRANCE,BUT ITS NOT the port area at the entrance , you need to use in the calcs, ITS the MINIMAL port cross section at the SMALLEST point in the port, usually near the push-rod area.

LIKE a funnel, its not the largest part of the opening but the smallest thats the restriction to flow

SO HOW do you MEASURE THEN??

http://www.harborfreight.com/cpi/ctaf/d ... umber=5649

http://store.summitracing.com/partdetai ... toview=sku

USE THIS

http://www.rbracing-rsr.com/runnertorquecalc.html

on the better 23 degree SMALL BLOCK AFTERMARKET HEADS THERE'S ABOUT 5.5 INCHES OF INTAKE PORT LENGTH ON AVERAGE FROM INTAKE GASKET TO THE BACK OF THE INTAKE VALVE AT THE FAR EDGE

http://users.erols.com/srweiss/tablehdc.htm

http://www.malcams.com/legacy/misc/headflow.htm

here,s a chart FROM THE BOOK,HOW TO BUILD BIG-INCH CHEVY SMALL BLOCKS with some common cross sectional port sizes

(measured at the smallest part of the ports)

...........................sq inches........port cc

edelbrock performer rpm ....1.43.............170

vortec......................1.66.............170

tfs195......................1.93.............195

afr 180.....................1.93.............180

afr 195.....................1.98.............195

afr 210.....................2.05.............210

dart pro 200................2.06.............200

dart pro 215................2.14.............215

brodix track 1 .............2.30.............221

dart pro 1 230..............2.40.............230

edelbrock 23 high port .....2.53.............238

edelbrock 18 deg............2.71.............266

tfs 18 deg..................2.80.............250

Potential HP based on Airflow (Hot Rod, Jun '99, p74):

Airflow at 28" of water x 0.257 x number of cylinders = potential HP

or required airflow based on HP:

HP / 0.257 / cylinders = required airflow

I know from experience not one guy in a hundred will take the effort to actually measure so I figured I,d try to keep the idea, I was posting about, rather easy to grasp, keep the math minimal ,and hope the point gets thru.

THINK OF COMPONENT SELECTION AS A PROCESS OF ELIMINATING THE WEAK LINK IN A CHAIN!

keep in mind it does you little good to have a SBC cylinder head that flows 310cfm at .700 lift, if you install a cam with .550 max lift,or UNDER ABOUT 245 DURATION at .050 lift or matched to an intake that flows 270cfm , or an exhaust pipe thats restrictive to exhaust flow at peak rpms

I can,t begin to tell you the number of times Ive grabbed snap gauges and a dial caliper and got questioned about what I was measuring when checking port throat restrictions or runner cross sections.

and in case some guys still don,t grasp it the point is that your dealing with a rather complex system with several potential restrictions and simply throwing a good flowing intake on an engine or increasing the rocker ratio may or may not provide an increase in flow potential, the result depends on how the rest of the components flow and react to the component being changed or the mods you've done, there's always several components that act like weak links in the chain, so locating those and improving those gets the best results, but of course once they are radically improved other components can become the new weak link or restriction.

so your trying to maintain a balance that potentially allows you to reach and exceed the power goals while hopefully not going bankrupt

400 cu in (6.6 L) SBC (1970-1981)150–265 hp (112–198 kW) 155cc-165cc intake port size

396 and 402 BBC 255 cc intake port size

The 396-cubic-inch (6.5 L) V8 was introduced in the 1965 Corvette as the L78 option and in the Z16 Chevelle as the L37 option. It had a bore of 4.094 in (104.0 mm) and a stroke of 3.760 in (95.5 mm),[8][9] and produced 375 hp (280 kW) and 410 lb⋅ft (560 N⋅m). The solid lifter version was capable of being operated in the upper 6000 rpm range, and when installed in the 1965 Corvette, was factory-rated at 425 horsepower.

Introduced in 1970, the 402-cubic-inch (6.6 L) was a 396-cubic-inch bored out by 0.030 in (0.76 mm). Despite the fact that it was 6 cubic inches (98 cc) larger, Chevrolet continued marketing it under the popular "396" label in the smaller cars while at the same time labeling it "Turbo-Jet 400" in the full-size cars. Power rating(s) by year:

- 1966: 325 hp (242 kW)/350 hp (260 kW)/360 hp (270 kW)/375 hp (280 kW)

- 1967: 325 hp (242 kW)/350 hp (260 kW)/375 hp (280 kW)

- 1968: 325 hp (242 kW)/350 hp (260 kW)/375 hp (280 kW)

- 1969: 265 hp (198 kW)(2bbl)/325 hp (242 kW)/350 hp (260 kW)/375 hp (280 kW)

- 1970: 330 hp (250 kW)/350 hp (260 kW)/375 hp (280 kW)

- 1971: 300 hp (220 kW) SAE gross; SAE net hp was 260 for dual exhaust and 206 for single exhaust

- 1972: 240 hp (180 kW) SAE net for dual exhaust and 210 hp SAE net for single exhaust

having a valve spring micrometer of the correct size and knowing how to use it helps a great deal

a good deal of the results you see on the EXHAUST side AND THE INTAKE SIDE are greatly effected by the scavenging design rpm range of the headers and the restriction to flow beyond the collectors.

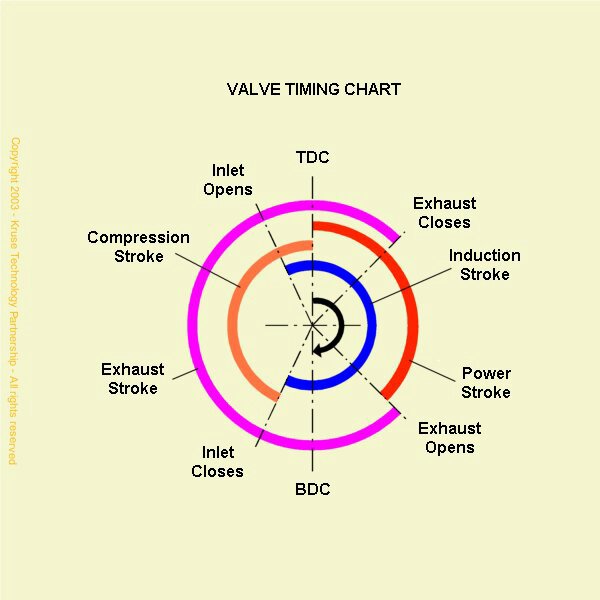

YOU CAN,T CRAM MORE IN TILL THE OLD F/A CHARGE VOLUME IS REMOVED, and with a properly designed low restriction exhaust , the fast moving exhaust mass in the headers helps to drag in the next intake charge into the cylinders.

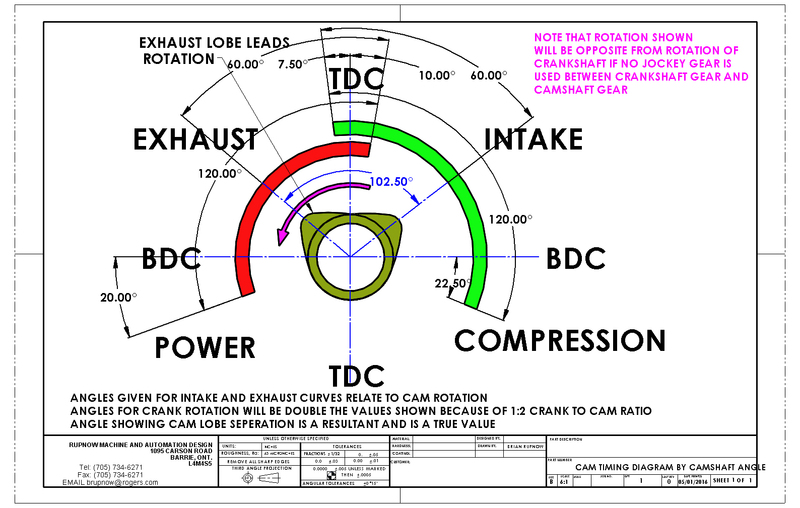

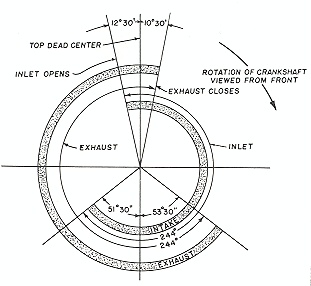

generally you can get a bit of useful info with a pressure gauge, if the exhaust have greater than about 1 PSI you've generally got a restriction thats hurting the power,and that restriction to flow DOES effect the engine tuning results and the cam timing you-ll want to use.

now Ive generally found that the collector lengths on commercial headers are too short and in many cases designed wrong to maximize the cylinder scavenging.

it does little good to stick a decent set of headers on a car and then hook the collectors up to a restrictive 2" or 2.5" exhaust either.

if your car runs noticeably better with open headers at the track, you can bet your street exhaust is restrictive.

viewtopic.php?f=56&t=1730&p=5392&hilit=horse+power+from+flow#p5392

there ARE aftermarket header merge collectors and things you can do to reduce the restriction to flow, (THE (H) and (X) pipes that split or share the exhaust between both sides, and a custom 3" exhaust and low restriction mufflers comes instantly too mind here)

every component selected is a compromise in some area, stock Chevy small block intake ports run 145cc-170cc in most cases they are generally designed to maximize the 1000rpm-4500rpm power band , the aftermarket "smaller" 180cc ports keep the port velocity and torque high in lower rpms and provide a very noticeable improvement over the stock heads and are a better match to stock rear gears and mild cams

yes you can jump to the 195cc-200cc port size but you tend to loose some low rpm response and torque, swapping to a 3.73:1 rear gear and a 3000rpm stall converter allows you to make more high rpm power with a larger duration cam and bigger heads and still have a good low rpm power potential because your able to jump up into a higher average part of the power band on demand, and not be required to slowly work up to the required rpms , its generally the 2500-2800rpm and below where the larger heads cause the response to be a bit soggy , being able to skip that at wide open throttle helps, but keep in mind the, engine displacement, compression ratio, headers, intake, cam, and other factors also effect your results

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=5078&p=14840#p14840

http://forum.grumpysperformance.com/viewtopic.php?f=44&t=38

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=5364

viewtopic.php?f=50&t=1266

viewtopic.php?f=52&t=975&p=1700&hilit=210cc#p1700

http://users.erols.com/srweiss/tablehdc.htm

viewtopic.php?f=52&t=4532&p=12045&hilit=bushing+timing#p12045

viewtopic.php?f=32&t=5521

http://www.j-performance.com/index.php? ... view&id=48

viewtopic.php?f=52&t=1070&p=2054#p2054

Last edited by a moderator: