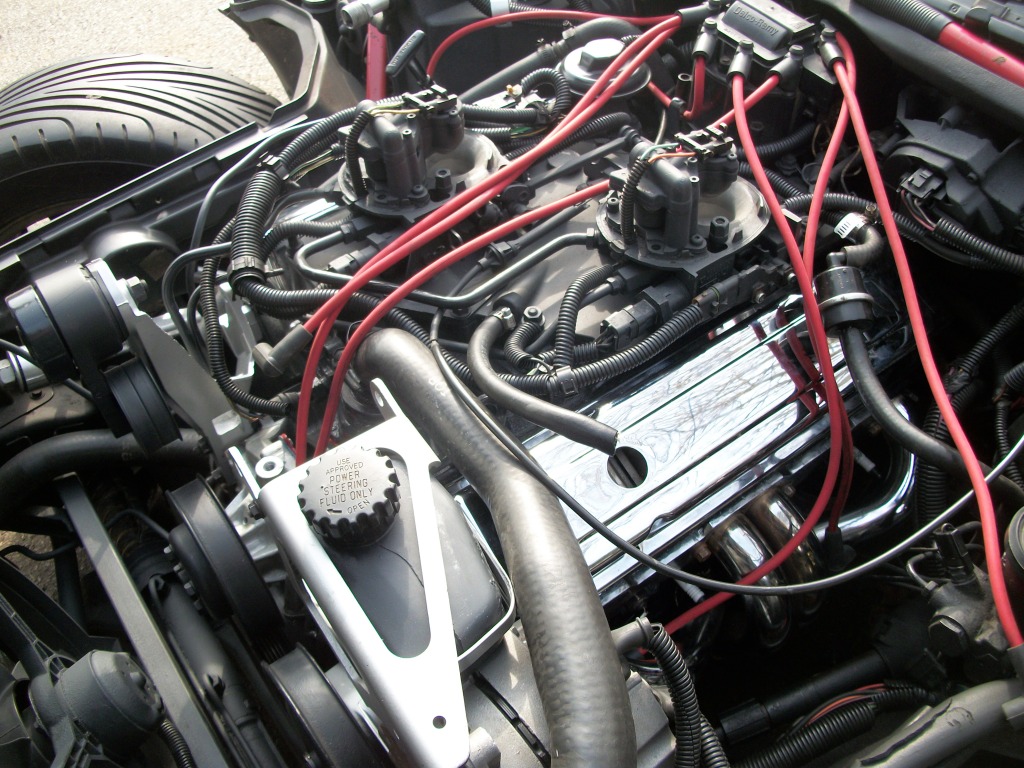

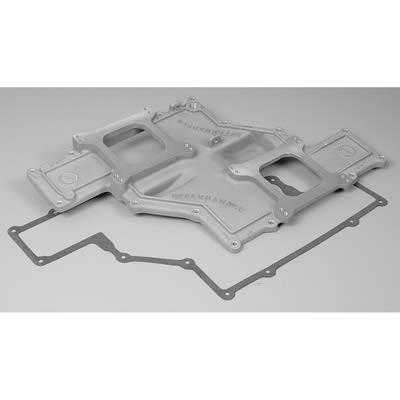

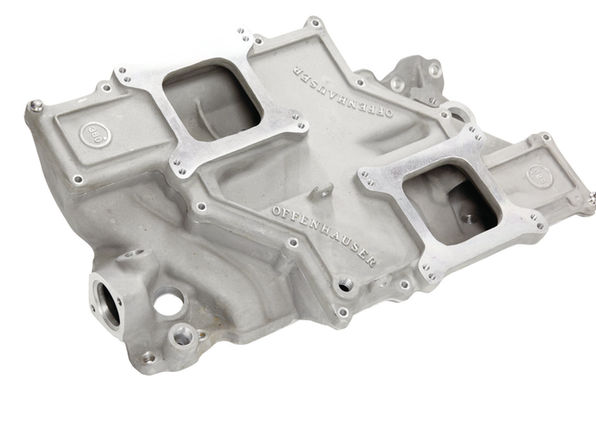

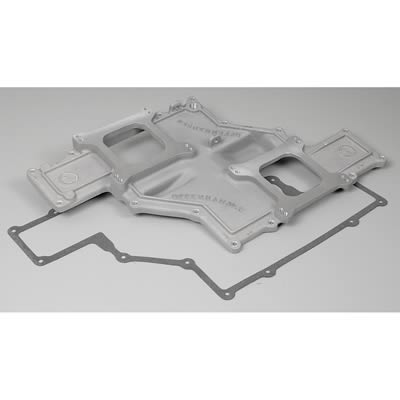

in my experience the offy can be made to fit and function well on a 383 in a c4 corvette, with two 500 cfm carbs and produces good hp

valve clearance notches in pistons generally run in the area of 5cc-7cc

below Ive posted some linked info to play with

http://www.wallaceracing.com/dynamic-cr.php

https://www.uempistons.com/index.ph...e=comp&zenid=1e826335bfac0f356463eabed4958558

https://www.uempistons.com/index.ph...=comp2&zenid=1e826335bfac0f356463eabed4958558

http://garage.grumpysperformance.com/index.php?threads/crowers-valve-timing-charts.4299/

http://garage.grumpysperformance.co...-on-building-a-383-sbc-stroker.428/#post-4987

http://garage.grumpysperformance.com/index.php?threads/redline.343/#post-1170

http://garage.grumpysperformance.com/index.php?threads/what-con-rods-would-you-buy.942/#post-1658

http://garage.grumpysperformance.com/index.php?threads/types-of-crankshaft-steel.204/

http://garage.grumpysperformance.co...ould-you-build-a-350-or-a-383-sbc-combo.8310/

http://garage.grumpysperformance.co...sfire-vette-won-t-run-right.10096/#post-39710

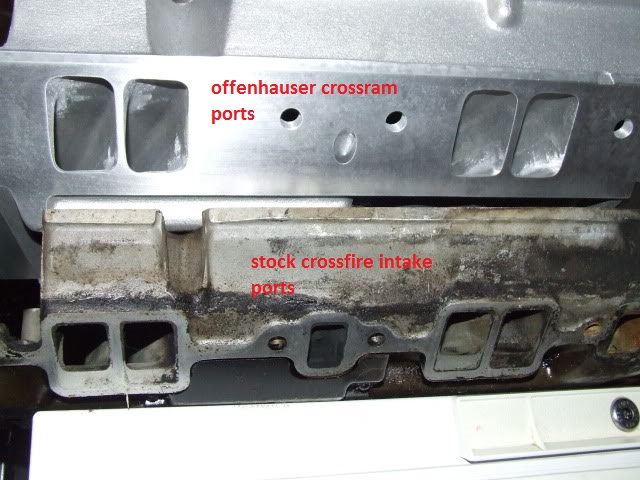

http://garage.grumpysperformance.co...ing-of-porting-an-x-fire-intake.144/#post-178

http://garage.grumpysperformance.com/index.php?threads/the-cross-ram-intake.623/#post-2154

http://garage.grumpysperformance.com/index.php?threads/a-few-cross-fire-tips.303/#post-987

http://garage.grumpysperformance.com/index.php?threads/installing-a-crossram-on-a-c4.511/#post-636

http://garage.grumpysperformance.com/index.php?threads/crossfire-sleeper.12732/page-2#post-65554

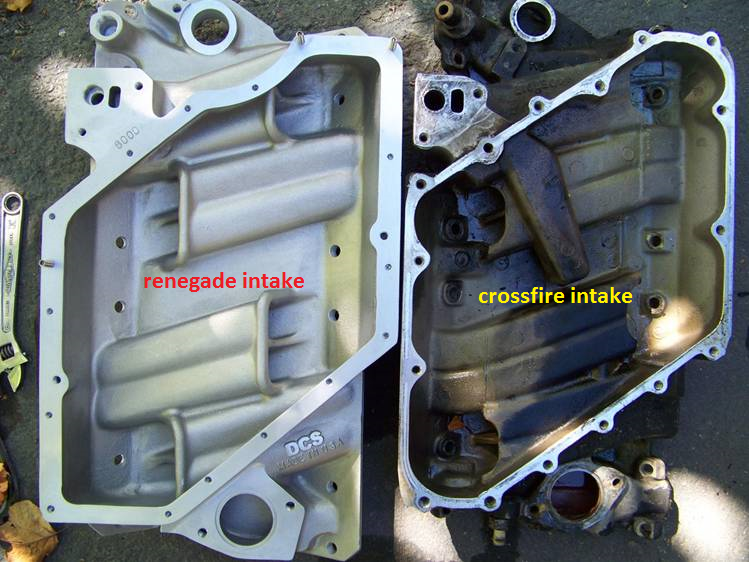

while the dual throttle body cross fire intake design is comparatively restrictive and you'll benefit noticeably,

swapping to better heads and the renegade after market intake and a cam like a crane 114132 ,

theres always been a problem with many of these dual throttle body injection system simply being improperly adjusted and tuned,

Ive found most of the 1984 corvette pick up noticeable power through simply correctly tuning and balancing the throttle bodys

the stock engines O.E.M. power is PATHETIC compared to the corvettes true potential.

theres an easy 70-80 hp or more in upgrading the cam,heads and intake

now that might not sound impressive but its easily a 45% plus power increase

the stock engine barely exceeded 205hp and 290 ft lbs

reaching in excess of 330 hp and 350 ft lbs with correctly selected parts even retaining most of the original short block 350 is do-able,

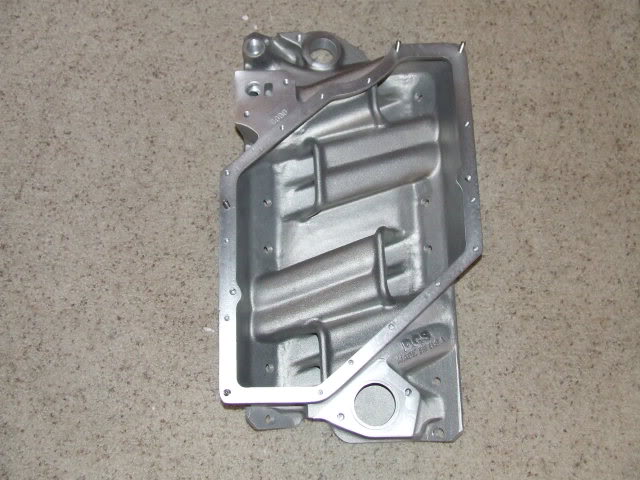

upgrade to a higher compression 383 stroker assembly and , better heads,

intake and cam, and even retaining the dual throttle body renegade of offy intake,

400 hp plus is not that difficult

https://auto.howstuffworks.com/1984-corvette3.htm

http://garage.grumpysperformance.com/index.php?threads/semi-fool-proof-cam-sellection.82/

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.co...lsa-effects-your-compression-torque-dcr.1070/

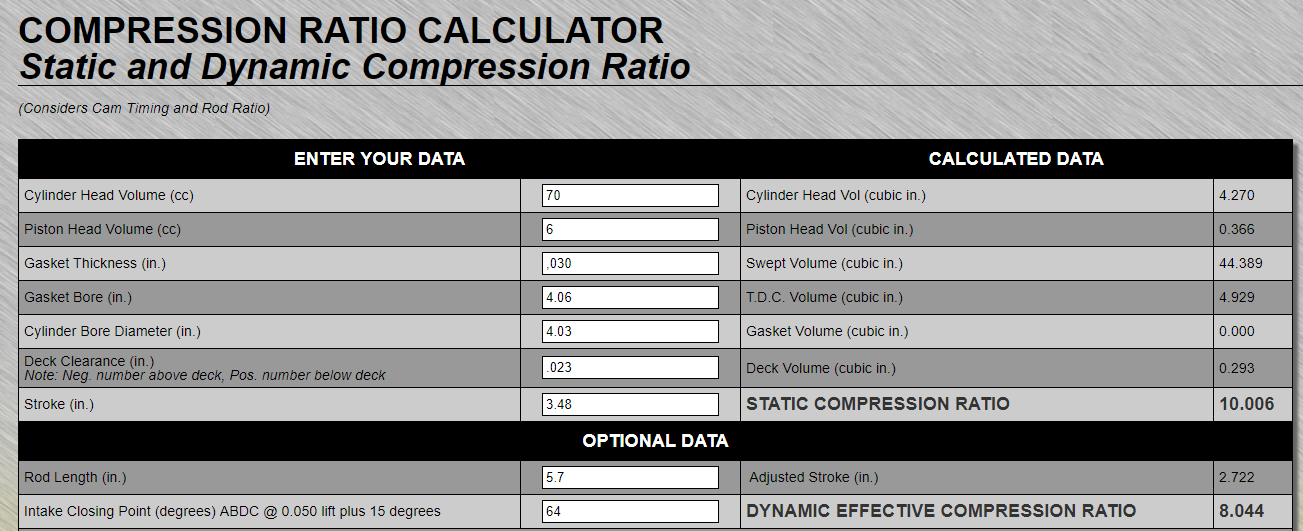

he following are different static compression ratios (SCR) with a 3.48" stroke and different camshaft intake closing points @ 0.050" tappet lift on Keith Black's dynamic compression ratio calculator. The calculator, starting at 8.25:1 SCR. The dynamic compression ratio (DCR) has been kept at just over 8.0:1, a figure that is acceptable for use with today's pump gas with a little cushion:

watch the video, and like I stated many times,

its the combo of the engines,

compression,

displacement ,

cam timing

and the exhaust scavenging ,

and the intake manifold design,

NOT the intake port cross sectional area,

that are the most critical factors, in the engines lower rpm and mid rpm torque.

but for damn sure an intake runner port can be small enough to noticeably restrict upper mid range and peak power significantly,

For 5 decades I've heard endlessly about how installing larger free flowing cylinder heads would devastate the engines ability to make any low or mid rpm torque.

especially when Id suggest using a set of smaller 300cc-320cc, aluminum,rectangle port heads on a 496 BBC, or 200 cc-210cc heads on a 406 sbc, I was asked to build

yet on every engine I've ever had built or had some guy ask me to look at, to see why it ran a great deal less impressively than he expected it too,

they brought into my shop its was very obvious (at least to me) that it was the combo of low compression, too little displacement, with too much cam duration ,

a restrictive exhaust or some guy who was trying to save money and continuing to use a stock stall speed torque converter, or retain a badly mis-matched 2.87:1-3.08:1 rear gear ratio,

with an engine that he miss matched components by slapping a large carburetor , and a single plane intake on,an engine that will rarely exceed 6000 rpm, that was the major reason.

if you want an engine combo to run your first step is to logically match the list of components you,ll use to the application,

and that requires you stop, engage the brain and think things through carefully,

and the most common way to screw up the process is to over cam a low compression engine,

have a restrictive exhaust or mis-match the drive train gearing to the engines power band.

- Static CR....Intake closing point @ 0.050"....Dynamic CR.

- 8.25........10* ABDC......8.010........................................................................................................

- 8.50........20............8.012........................................................................................................

- 8.75........27............8.022........................................................................................................

- 9.00........33............8.018........................................................................................................

- 9.25........37............8.061........................................................................................................

- 9.50........42............8.029........................................................................................................

- 9.75........46............8.016........................................................................................................

- 10.00.......49............8.038........................................................................................................

- 10.25.......52............8.043........................................................................................................

- 10.50.......55............8.029........................................................................................................

- 10.75.......57............8.069........................................................................................................

- 11.00.......60............8.022........................................................................................................

- 11.25.......62............8.038........................................................................................................

- 11.50.......64............8.042........................................................................................................

- 11.75.......66............8.035........................................................................................................

- 12.00.......68............8.017........................................................................................................