What is the best procedure for reinstalling the transmission oil pan on a Th400 in regards to the gasket and the use of some type of sealant. Do you just use the gasket or combine with the use of some type of sealant material? Same question for the rear differential.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sealing the trans pan

- Thread starter chromebumpers

- Start date

I ask only because I've seen it done different ways and I don't want any leaking. I hope this isn't such a dumb question and somebody please let me know. Thanks.

the last time I did a trans pan gasket , install.I simply sprayed the gasket on both sides of the pan gasket, with copper coat spray, and installed it wet and clamped it down evenly

BTW I have on several occasions seen guys who complain about various oil leaks on valve covers and rear seals ETC.

Used, engine parts will have oil embedded deeply into the micro surfaces.

almost all replacement parts will have a wax or grease preservative coating to prevent corrosion during shipping!

IF YOU simply wipe off oil soaked surfaces with a paper towel, who then smear on the sealant of there choice and proceed to install gaskets,

YOU WILL OCCASIONALLY HAVE LEAKS!

and then they wonder or maybe be in shock when you find the seeping oil leak has returned in a few weeks time!

metal surfaces may look smooth as glass but under a microscope they look like the surface of the moon , with lots of jagged surface cracks, so you really need to wash out the micro lubricants trapped in those cracks with a thin fast evaporating grease solvent and a lint free rag , followed by a second repeat of the process and in many cases a few minutes with a heat gun to dry and evaporate the solvent in the micro cracks ,

STOP AND READ THE SEALANT PACKAGE DIRECTIONS!

you'll generally find some rather amazing , bits of info such as temperature requirements, temperature limitations, what solvents work best to remove the cement or sealant, only after reading the directions, do you then smear the gasket sealant on both mating surfaces before bonding the two gasket & metal surfaces.(and in many cases you use a brush as dirt or oil on fingers prevents a good seal!)

pontiac

http://www.boxwrench.net/specs/pont_265-455.htm

chevy sb

http://www.boxwrench.net/specs/chevy_sb.htm

chevy BB

http://www.boxwrench.net/specs/chevy_bb.htm

426hemi

http://www.boxwrench.net/specs/hemi_426.htm

383-440 mopar

http://www.boxwrench.net/specs/bchrys_B.htm

318-340-360 mopar

http://www.boxwrench.net/specs/schrys_A.htm

ford 429-460

http://www.boxwrench.net/specs/ford_429-514.htm

302-351 windsor ford

http://www.boxwrench.net/specs/ford_302_351W.htm

351 cleveland ford

http://www.boxwrench.net/specs/ford_351C.htm

352-428 ford

http://www.boxwrench.net/specs/ford_352-428.htm

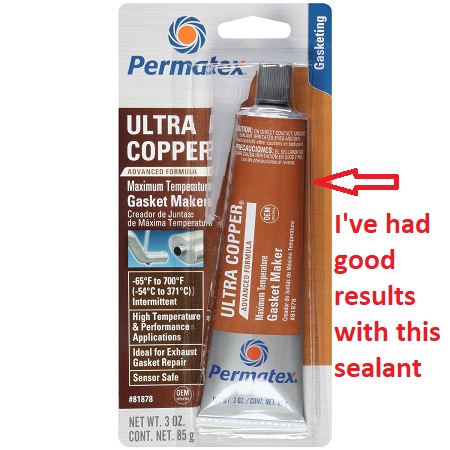

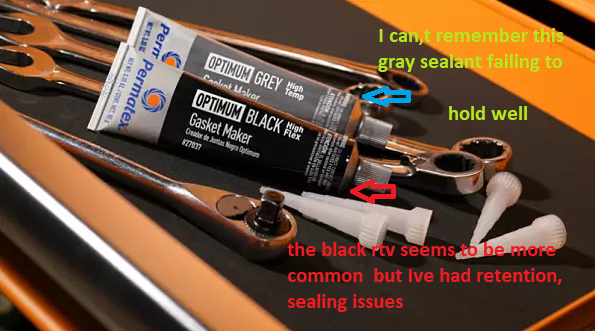

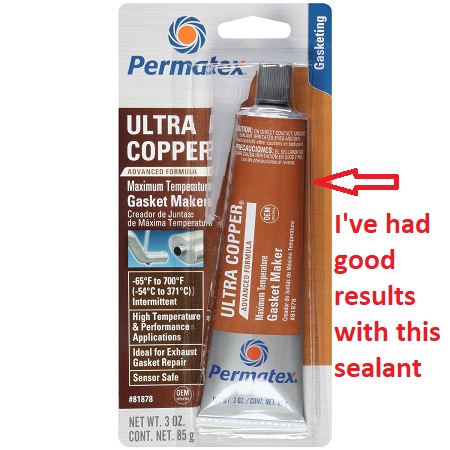

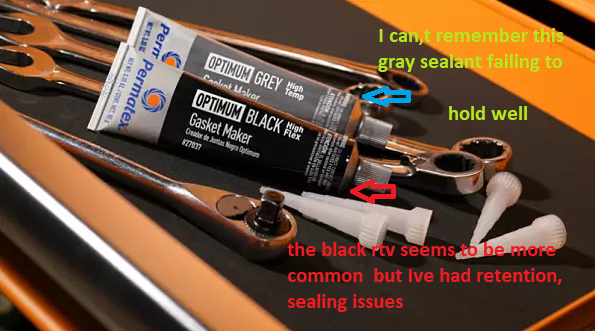

youll occasionally find uses for a high temp rated silicone sealant

like ultra-copper that has about twice the temp tolerance of the common black RTV

In my experience, the black rtv works ok,

but the high heat gray or copper gasket sealant has always worked a bit better

I prefer this for most of the jobs where silicone type gasket sealants get used like intake gaskets and valve cover gaskets

http://garage.grumpysperformance.com/index.php?threads/sealants-and-threads.805/#post-71928

BTW I have on several occasions seen guys who complain about various oil leaks on valve covers and rear seals ETC.

Used, engine parts will have oil embedded deeply into the micro surfaces.

almost all replacement parts will have a wax or grease preservative coating to prevent corrosion during shipping!

IF YOU simply wipe off oil soaked surfaces with a paper towel, who then smear on the sealant of there choice and proceed to install gaskets,

YOU WILL OCCASIONALLY HAVE LEAKS!

and then they wonder or maybe be in shock when you find the seeping oil leak has returned in a few weeks time!

metal surfaces may look smooth as glass but under a microscope they look like the surface of the moon , with lots of jagged surface cracks, so you really need to wash out the micro lubricants trapped in those cracks with a thin fast evaporating grease solvent and a lint free rag , followed by a second repeat of the process and in many cases a few minutes with a heat gun to dry and evaporate the solvent in the micro cracks ,

STOP AND READ THE SEALANT PACKAGE DIRECTIONS!

you'll generally find some rather amazing , bits of info such as temperature requirements, temperature limitations, what solvents work best to remove the cement or sealant, only after reading the directions, do you then smear the gasket sealant on both mating surfaces before bonding the two gasket & metal surfaces.(and in many cases you use a brush as dirt or oil on fingers prevents a good seal!)

pontiac

http://www.boxwrench.net/specs/pont_265-455.htm

chevy sb

http://www.boxwrench.net/specs/chevy_sb.htm

chevy BB

http://www.boxwrench.net/specs/chevy_bb.htm

426hemi

http://www.boxwrench.net/specs/hemi_426.htm

383-440 mopar

http://www.boxwrench.net/specs/bchrys_B.htm

318-340-360 mopar

http://www.boxwrench.net/specs/schrys_A.htm

ford 429-460

http://www.boxwrench.net/specs/ford_429-514.htm

302-351 windsor ford

http://www.boxwrench.net/specs/ford_302_351W.htm

351 cleveland ford

http://www.boxwrench.net/specs/ford_351C.htm

352-428 ford

http://www.boxwrench.net/specs/ford_352-428.htm

youll occasionally find uses for a high temp rated silicone sealant

like ultra-copper that has about twice the temp tolerance of the common black RTV

In my experience, the black rtv works ok,

but the high heat gray or copper gasket sealant has always worked a bit better

I prefer this for most of the jobs where silicone type gasket sealants get used like intake gaskets and valve cover gaskets

http://garage.grumpysperformance.com/index.php?threads/sealants-and-threads.805/#post-71928

Last edited by a moderator: