reading thru the links will provide you with a good basic understanding on torque converters, look carefully at the charts, and think through your choices carefully

the required converter stall speed, has little to do with the type of lifter your using, displacement, compression ratio, port flow, cam timing and duration, are more critical, here.

if your just racing , selecting a stall speed just maybe 1000 rpm lower than the engines torque peak ,

certainly provides much improved acceleration compared to a stock converter stall speed.

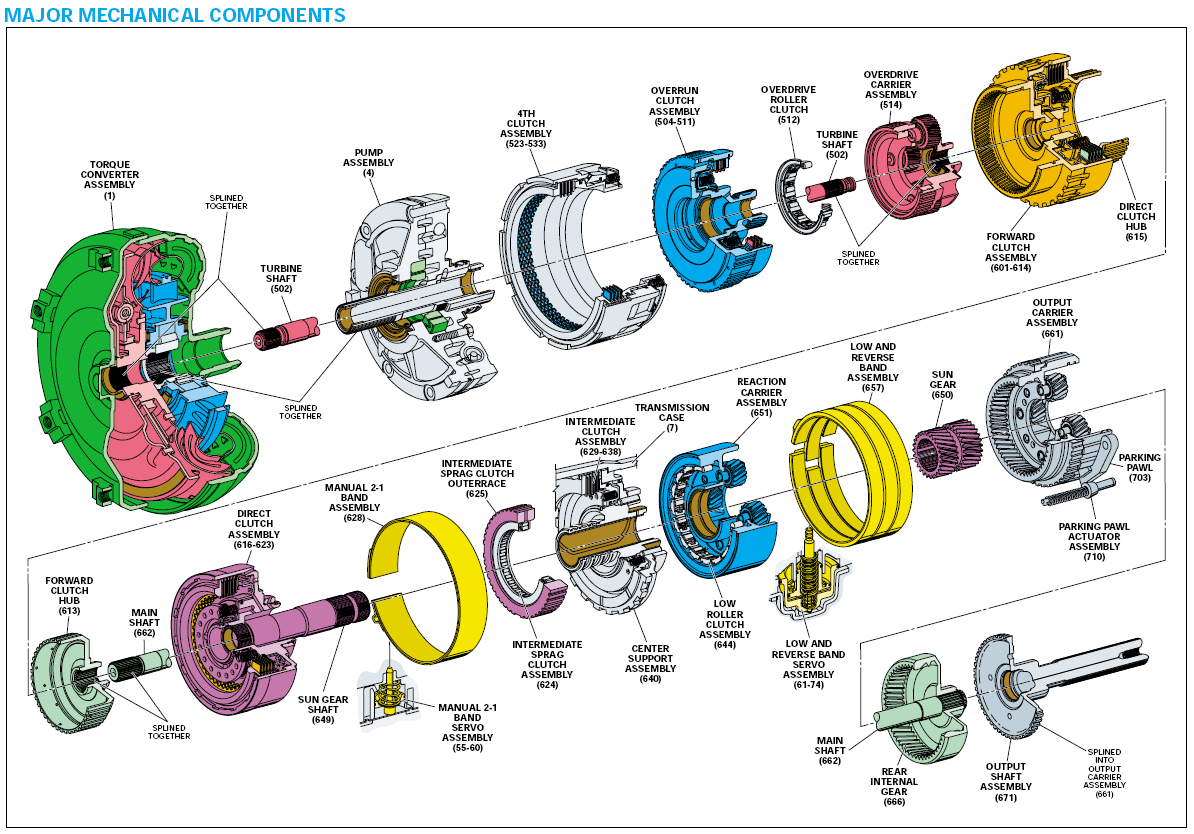

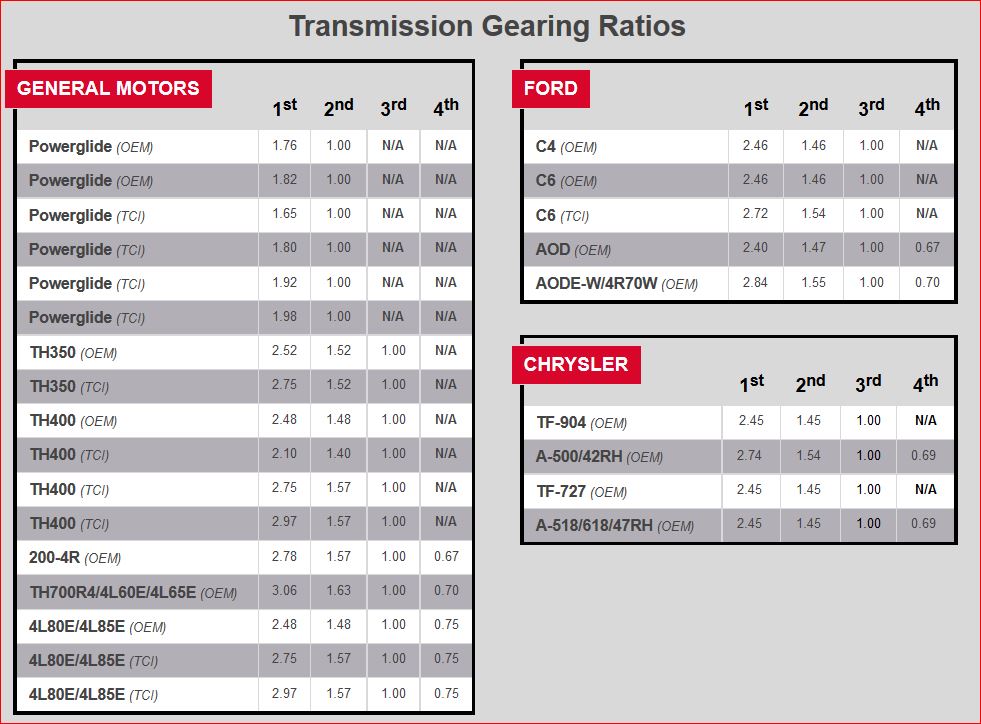

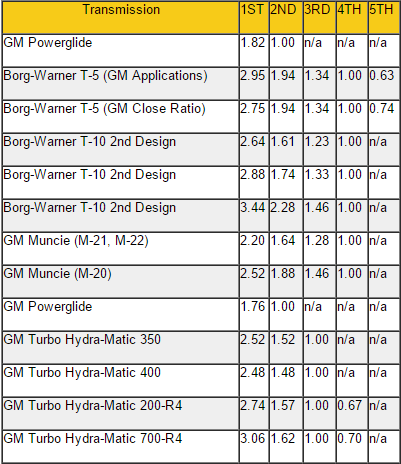

the stall speed you need, too be used, or changed is determined by the rpm range of the cam you select and your car weight, the cars automatic transmission first gear ratio, tire diameter and rear gear ratio, and most of all, the engines torque curve, that torque converter does not know if you have it installed behind a mild 307 SBC or a performance 502 BBC, the effective stall will depend a great deal on the available torque the engine produces, and yes the mild 307 SBC will stall out at a lower rpm than a performance 502 BBC,with the same torque converter.

one very good reason to talk with the torque converter manufacturers tech dept before selecting a converter and NOT just looking at the rated stall speeds listed in a catalog.

a mild roller cam would work with a stock stall converter just as a mild flat tappet lifter cam will.

the whole idea of swapping to a higher stall speed torque converter is to allow the engine UNDER LOAD to jump in rpm up into the engines most efficient power range or the most effective part of the torque curve.

the basic object of swapping to a higher stall converter speed is to allow the engine to spend a good deal more time in its most efficient power range without needing to WASTE TIME build rpms slowly up in the lower engine speed ranges where there's a good deal less usable power available, I'm always rather amused that so many guys want to get so darn confused about what is basically brutally simple, the purpose of a performance torque converter is to allow near instant access too and full use off and efficient use of the engines peak torque over most of its power band, the transmission must of course be set up to shift to the next lower gear each time the engine rpms start to exceed the ideal power range or drop back into the ideal power band if the torque available is no longer sufficient to easily move the car, to do this you simply need to know the cars drive train gearing tire size and the engines power band and red-line or upper rpm limitations, and the engines lower rpm power band effective limitations and a dyno tuning test session easily determines those factors.

of COURSE a high stall converter SLIPS a bit more than a stock converter,THATS THE WHOLE POINT OF THE DESIGN! it allows the engine rpms to nearly instantly reach the most efficient power band and almost as instantly drag the transmission gearing up into that rpm range along with it without bogging the engine or forcing it to spend wasted time at the lower rpms where the engine fights to make decent power, when you apply throttle that's,the whole IDEA! it allows the engine to rapidly increase rpms while seamlessly, transferring the engines torque to the drive train, the more force or torque you apply the higher the rpm level the converter will stall, this is why the same converter on two engines may not stall at the same rpm, but you'll find your applying the power to the rear wheels without you needing to have the engine waste time in its far less effective lower rpm power band, but you'll rarely notice that slippage, during any performance style driving, simply because the engine and transmission will rather rapidly regain similar speeds, its not like theres a noticeable time lag, between the throttle being depressed and the cars acceleration, thats nearly instant, both at part or full throttle, the difference is only in how far the engine rpms vary for an instant as the cars rear wheel speed trys to very rapidly catch up with engine rpms.

The concepts similar to a smaller engine ,manual transmission drag car letting the clutch slip for an instant as it launches so the engine rpms stays up over lets say 3500rpm,then rapidly accelerates to 6000rpm plus to prevent the car from bogging, rather than letting traction stall the engine!

IF your thinking of swapping to a higher stall converter,you should be able to answer the questions, listed below as it will be to your advantage to do so, by simply asking yourself ...those questions, but be aware your transmission gear ratios and rear gear ratio effect the correct choice in converter stall speed.one of the most common myths about high stall torque converters , is that the car won,t move under part throttle until near the rated stall speed is reached by the engine, think about that a second, then think about how your current car reacts to part throttle and realize your stock converters stall speed is probably 600-700rpm higher that the rpm that effectively moves your car at part throttle.

the first thing youll want to do is test your current converters stall speed and find out what your currently dealing with, so you have a few facts and a start point!

if YOUR NOT SURE DO YOURSELF A FAVOR AND CALL AT LEAST 5 DIFFERENT HIGH PERFORMANCE CONVERTER MANUFACTURERS AND ASK FOR RECOMMENDATIONS BASED ON YOUR COMBO, that way your bound to at least pick up some basic info and ideas.

WATCH VIDEO's CLOSELY

https://hlperformanceconverters.com/tech-notes/

http://dynamicconverters.com/converters.htm#11" Race Converters

READ THIS RELATED THREAD

READ THIS RELATED THREAD

I'll try to keep it short because it's an involved subject. Basically "stall" means when the torque converter "locks-up" under a load. With that, if you take a car with a 2,500 RPM stall converter and you hold your foot on the brake hard, and hit the gas at the same time, (as if you were going to power brake), the "general" RPM in which the tires will break loose is at "about" 2,500 RPM. If the converter was a 3,500 RPM stall, then it would be at approximately 3,500 RPM in which it forces the tires to break loose. Keep in mind, if you put that same converter behind a nasty big block, in a car that has serious traction or is quite heavy, the torque of the engine will drive the stall speed up to a higher RPM, and an engine with less power will have the opposite effect and won't be able to stall the converter out as high. It's all relative to torque, vehicle weight, traction and rear gearing. It isn't an exact science as far as an exact stall RPM goes.

Stock cars have anywhere from 1,000 to 1,400 RPM stalls from the factory. The reason a stall converter works is simple; an engine at 1,200 RPM is only making about 80 or so horsepower (on average), but at 2,500 RPM it could be making 150 to 200 HP, and obviously trying to get a car moving using 150-200 HP is going to be much easier than one trying to launch at 80 HP or so. Most performance engines don't make power until 3,000 or so RPM, hence why when you have a higher horsepower engine with a big cam, you need a higher stall speed so the engine is closer to it's "power band" when taking-off from the line, otherwise it will fall on its face and be a turd off the line.

Some people believe that "stall" means the car won't start moving until the engine reaches that particular RPM, and that isn't even close to being true. We build race cars with 6,000 RPM stall converters and when you put the car in gear and let it idle, it WILL roll along at 5 - 10 MPH, just like any other car will when put in gear and with the brake off. In fact, we usually cruise through the pits with the car simply in gear and idling, so if a 6,000 RPM converter means that the car won't start moving UNTIL that RPM, then we'd have to have the engine wound-out to 6,000 RPM to putt along through the pits at 10-15 MPH, and that simply isn't the case. Stall means when the car is on the starting line, (with say a 4,500 RPM stall converter), and the trans brake is on, (which locks the transmission in first and reverse at the same time), and you hit full throttle, the engine will wind-up to 4,500 RPM with the car just sitting there, so when you slip your finger off the trans brake button and the tranny engages out of reverse, the car instantly launches at 4,500 RPM, and a race motor at 4,500 RPM is pretty close to its peak torque curve when leaving the line, hence the big wheelies you see on some drag cars or the incredibly low 60 Ft. times when traction is good. Race engines make no power at low RPM's, and are usually shy on torque, so the nastier the engine, the higher the stall speed needs to be (in general anyway). Again, cubic inches, torque, vehicle weight and gear ratio have a big factor in this. Now, this doesn't get into the "flash" effect which is where a stall converter will "flash to" when your finger comes off the trans brake button. Typical 3,000 RPM converters can flash up to 5,000 RPM or so once you've launched the car. It's a bit more complicated and I am trying to keep this simple for you, so we'll skip that area right now.

A 6,000 RPM converter behind a stock engine might not even get to 6,000 RPM because the engine can't make enough torque (power) to spool-up to that RPM because of the load of the converter. The car will start rolling at a much lower RPM and may never be able to reach 6,000 RPM. This is also true for any converter from about 3,000 RPM on up. Most mild race cars (9-10 second quarter mile times) use anywhere from 3,500 stalls to 4,500 stall speeds on average. Faster cars usually use even higher stall speeds, especially in smaller cubic inch engines that don't make the torque of big displacement engines. Also, the higher the stall speed, the more heat the converter will make, from hydraulic (fluid) friction inside the converter. A high stall converter can easily make enough heat to fry a transmission if you hold it on the line long enough at full RPM if the stall speed is above 3,500 RPM or so, so a good tranny cooler is essential when running ANY type of high stall converter.

Most street performance cars running your typical "performance" cam should be running a stall converter in the 2,800 - 3,000 RPM area. For hotter cars (street / strip) with bigger cams, etc. then a converter in the 3,000 - 3,500 RPM is more suited. For mild performance cars with something like a 350 HP engine, a 2,200 - 2,400 stall is about right. The basic rule of thumb is; if your engine "comes alive" at say, 3,500 RPM, then you want a stall converter with about 3,500 of stall to it. Most people tend to over cam and over carbureted their cars... and those same people also tend to under stall converter their cars too, which REALLY makes it a complete turd. if they need a 3,000 RPM stall, they'll usually get something like a 2,000 RPM, which just doesn't get it off the line. You have to remember... 80% of the race is the first 100 feet. If you can't get off the line, you are going to lose the race.

BTW IF you have a dyno graph of your cars engine power curve selecting the correct matching stall speed is much easier

(1) was the current converter stall speed performing well?

(any problems or things you did not like) and at what rpm do you normally cruise in top gear?)

(2) what if anythings changed that makes you suspect a higher stall will improve things?

(if you floor the throttle from an idle in gear is there a significant time lag before your car accelerates, hard? does the car bog down if you floor the throttle at idle or does the car accelerate rapidly?)

(3) whats your current engine power curve?

(where does the engine start to really come alive, and start pulling hard, in the rpm band., at what rpm does power start to rapidly drop off?)

(4) whats your rear gear ratio?, whats your tire diameter? youll spend much less time in each transmission gear range with a 4.11:1 rear gear than a 2.87:1 rear gear so thats an important factor?

(5)are you planing mod mods that make you suspect you'll require a higher stall speed, are you planing on installing larger diameter tires? a longer duration cam?

(6) do you have an auxiliary transmission cooler installed and whats your normal trans fluid temp range?

(7) have you called at LEAST 4 different converter manufacturers and ask for their input? suggestions?

before buying any converter discuss the combo with the converters manufacturer, AND YOUR CAMS MANUFACTURER and ask for their input & suggestions

http://garage.grumpysperformance.co...w-how-to-install-a-tq-converter.386/#post-473

read the linked info below or you'll miss a good deal of useful information

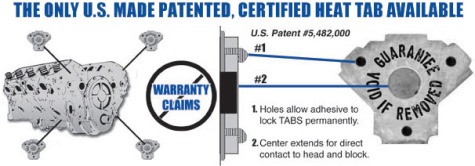

OEM flex plates are far thinner and more flexible than the SFI certified flex-plates , so they are far more likely to crack and split over time

instructions

http://www.autoshop101.com/forms/AT02.pdf

1

Examine your car's engine specifications (get the cars engine dyno tested or at leash have a good idea of the engines power curve,) or take it to a shop with a chassis dynamometer to have it measured. Note the engine's peak torque and the rpm that it occurs at youll want the stall speed to be just a bit lower on a street car to increase drive-ability and just a bit higher than peak torque on a race application to maximize useful power.

remember your converter slips a good deal more and produces a good deal more heat in the trans fluid below the stall speed, so you don,t want the engine spending a great deal of time below the stall speed in its intended application.

consult with at least three different converter manufacturers, about the best converter stall speed for your particular application, before making a choice and ask LOTS OF questions

2

Add about 15 percent to your engine's peak torque figure if you used a chassis dyno instead of factory horsepower ratings, and your looking at a race application,. The engine, transmission and wheel require a certain amount of horsepower to turn, meaning that such "wheel horsepower" will register lower than the flywheel horsepower you need.

keep in mind your car will be able to drive and move well below the cars stall speed with a high stall converter but your converter slips a good deal more and produces a good deal more heat in the trans fluid below the stall speed, so you don,t want the engine spending a great deal of time driving the car below the stall speed in its intended application, and adding a trans cooler with a higher stall converter is just about mandatory

http://garage.grumpysperformance.co...gine-to-match-the-cam-specs.11764/#post-55651

http://www.zealautowerks.com/transcalc.php

3

Order a torque converter that matches your engine's peak torque output and peak torque rpm as closely as possible. If you can't find one that matches it precisely, error on the side of caution by choosing one with a slightly lower stall or higher torque rating . You'll lose a little performance with a stall that's too low, but you'll lose performance, fuel economy and drive-ability with one that's too high.

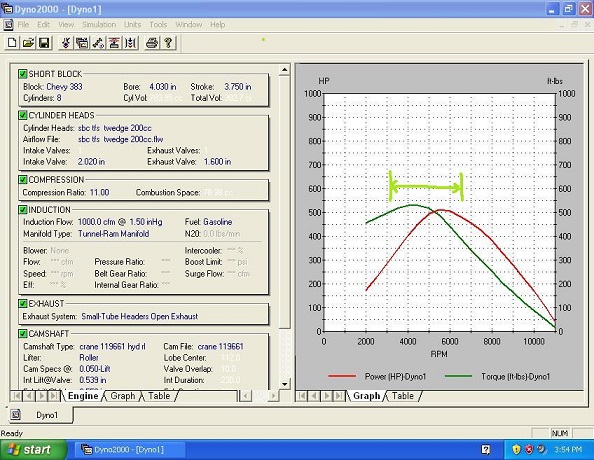

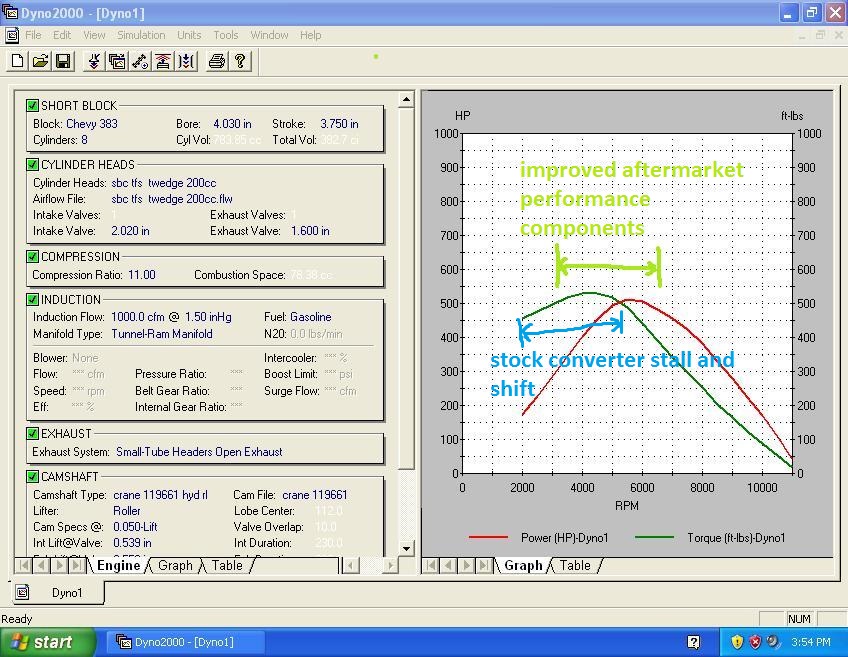

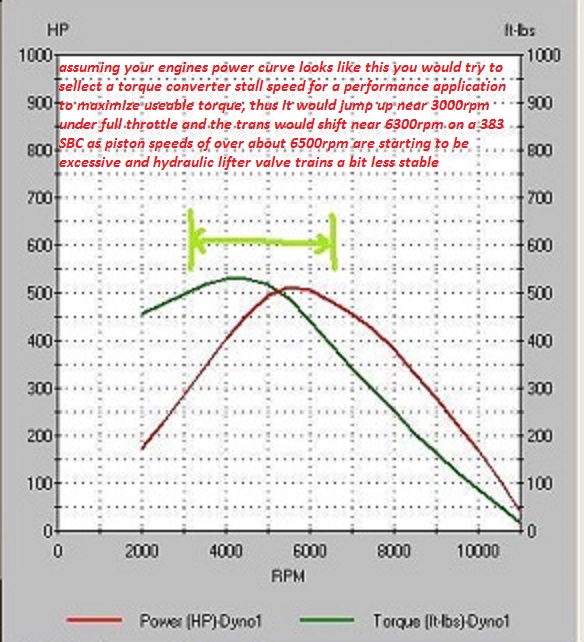

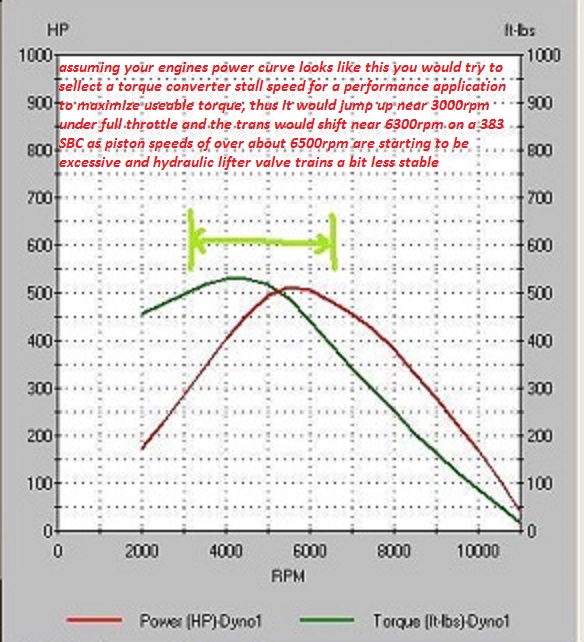

EXAMPLE, HERES MY CORVETTES POWER CURVE

it should be obvious why a 3000 rpm-3200 stall converter stall speed was selected to maximize the power curves and why the ignition rev limiter is set at 6300 rpm

yes I have to admit that when I personally swapped from a stock stall speed converter

,in my 383 sbc corvette and a 3200 rpm stall speed converter the difference in performance was amazingly better.

swap too a 3.73:1 rear gear and you've noticeably further enhanced that seat of the pants and slam in the back acceleration.

people tend to not fully appreciate the fact that the performance cars drive train gearing, power to weight ratio and the converter stall

(in the case of automatic transmission) must match the engine torque curve if the car is to perform to anything close to its best potential

http://www.highperformancepontiac.c...vigilante_torque_converter_install/index.html

READ THE SUB LINKS, they contain a wealth of additional info

http://www.superchevy.com/how-to/transm ... selection/

http://www.carcraft.com/techarticles/se ... index.html

http://www.chevyhiperformance.com/techa ... index.html

http://www.chevyhiperformance.com/tech/ ... index.html

http://www.protorque.com/FAQ.html#6

http://www.protorque.com/techi/ti_faq.htm

"

STALL SPEED

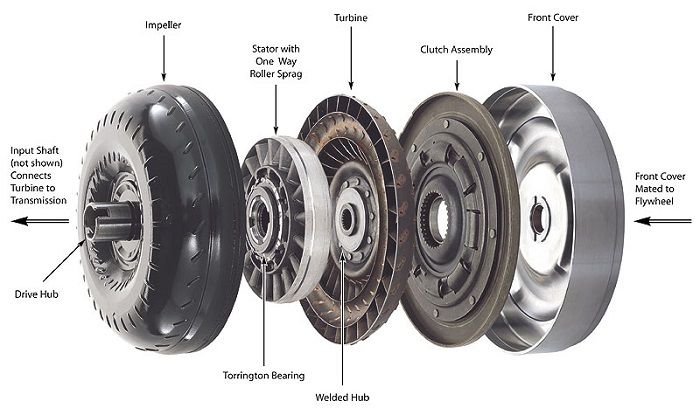

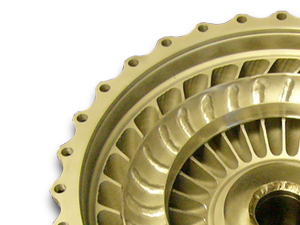

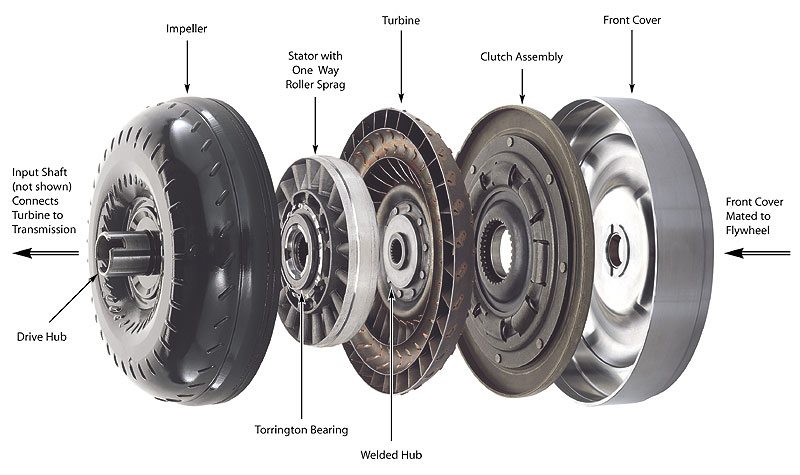

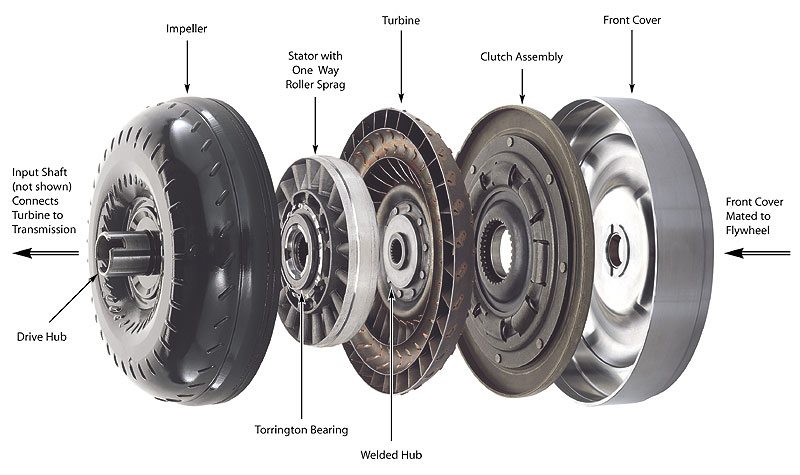

Torque converter stall is a commonly used term and is commonly misunderstood. Stall is the speed at which the converter will hold the engine speed and not allow further gain (i.e., the engine "stalls"). The key word here is engine. The speed at which stall occurs with a given converter is a function of engine peak torque. It is clear that the stall speed on a given converter will not be the same coupled to a tame small block engine when compared to a big block with all of the muscle features added. When comparing stall speeds it is important to account for the engine that drives it. True converter stall can best be determined when a Transbrake is used. Testing for stall value by locking the wheel brakes generally does not produce a true stall value because the engine power can often cause wheel turn by overpowering the brakes. Stall speed determined by this method should be identified as such when discussing stall speed determination. Flash stall is determined by launching at full throttle and observing the peak speed attained at launch. Selection of the right stall speed for your vehicle should be matched to the engine peak torque, engine torque curve shape and vehicle weight. In general, the stall speed selected for your converter would be 500 to 700 rpm below the peak torque. This speed allows the margin for application of the torque reserve on takeoff. When selecting stall speed without having prior experience to go by, it is better to conservatively estimate the engine torque than it is to over estimate it. If you over estimate the torque output you will have a converter with a stall speed too low, making your car slow off the line and have slow ET. A properly selected stall speed will give you better launch and better ET. You can see why it is important to consult with professionals prior to making a stall speed selection. Within the converter, stall speed is balanced off against inefficiency after launch. Getting desired stall at the expense of performance after launch is just as costly as improper stall speed to begin. The optimum converter has careful selection and design of changes to the impeller, turbine and stator.

"HOW CAN I DETERMINE THE STALL SPEED OF MY CONVERTER?

Stall speed is very difficult to determine unless your car is equipped with a Transbrake to lock your drive train. Testing stall speed by holding the wheel brakes and running the engine against the locked brakes will usually result in wheel rotation before true stall speed is reached. The engine simply overpowers the ability of the brakes to hold the car. When rotation starts you are no longer at stall. For this reason people talk about brake stall which is not a true stall at all. An alternative method of measurement is to launch at wide open throttle and observe engine RPM reached at launch. This is flash stall.

"

For most hot street cars, that weight between about 3300lbs and 3700lbs (WHICH IS MOST MUSCLE CARS) with a reasonable street/strip compromise cam in the 225-235 duration range designed to run on pump gas and having a 3.73-4.11 rear gear with tires in the 25"-28" range,a 3000-3200rpm rpm stall should be fine in a combo like you describe, I'm running a 3000stall converter in my car, theres a common mis-understanding that installing a 3000rpm stall converter means the car won,t move until you hit 3000rpm, that's a fallacy, theres a bit more slippage but it drives just fine at lower rpms at part throttle if your just cruising, but the slippage make HEAT so don,t forget to add a decent trans cooler

as an example on this 500hp 350sbc above,designed for the drag strip, a 4500 stall would be almost ideal.

on this 400hp 350 designed for the street a 3000rpm stalls fine, but if you installed a 5000rpm stall you'll be loosing a great deal of the engines power curve

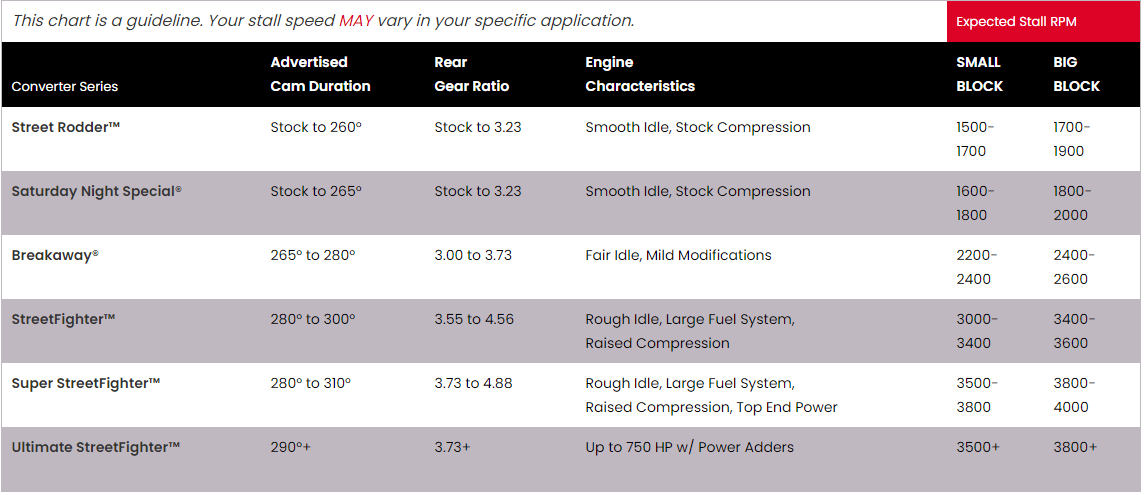

Advertized stall speed is "indicative" or only an average result usually based on a common stock engine displacement and torque level such as with a 350hp 350 sbc

The more torque your engine produces ,the higher rpm a torque converter will stall at.

A converter will stall higher on a hot 383 or 427 sbc than on a stock 350 despite what it's rated stall speed is.

The better manufacturers have a chart telling what speed a certain converter will stall at with what torque level but even then its just an educated guess, as each converter will be a bit different from its clones.

and remember you get what you pay for,if you find a new converter costs significantly less than similar advertised converters theres a REASON

and you can bet that they left out some feature you need like anti ballooning plates of brazing the internal fins, or they used thinner/weaker components

Example

a 9" converter stall is advertized as a 3000 stall

but gives your approximately

3000rpm @ 400 ft/lb

3185rpm @ 450 ft/lb

3300rpm @ 550 ft/lb

https://robrobinette.com/et.htm

http://www.cprparts.com/HPcalculator.html

https://www.gregraven.org/hotwater/calculators/qm-from-wt-hp.html

https://www.tciauto.com/racing-calculators

https://teamcsr.net/Racing Calculator.htm

https://racingcalcs.com/horsepower-hp-required-for-elapsed-time-et-goal-calculator/

calculators like those linked above assume you have close to ideal,

traction

(suspension, tires, weight transfer)

and gearing

( transmission gearing, stall speed and shift between gears effectively in the ideal power band)

to maximize the cars acceleration potential

the required converter stall speed, has little to do with the type of lifter your using, displacement, compression ratio, port flow, cam timing and duration, are more critical, here.

if your just racing , selecting a stall speed just maybe 1000 rpm lower than the engines torque peak ,

certainly provides much improved acceleration compared to a stock converter stall speed.

the stall speed you need, too be used, or changed is determined by the rpm range of the cam you select and your car weight, the cars automatic transmission first gear ratio, tire diameter and rear gear ratio, and most of all, the engines torque curve, that torque converter does not know if you have it installed behind a mild 307 SBC or a performance 502 BBC, the effective stall will depend a great deal on the available torque the engine produces, and yes the mild 307 SBC will stall out at a lower rpm than a performance 502 BBC,with the same torque converter.

one very good reason to talk with the torque converter manufacturers tech dept before selecting a converter and NOT just looking at the rated stall speeds listed in a catalog.

a mild roller cam would work with a stock stall converter just as a mild flat tappet lifter cam will.

the whole idea of swapping to a higher stall speed torque converter is to allow the engine UNDER LOAD to jump in rpm up into the engines most efficient power range or the most effective part of the torque curve.

the basic object of swapping to a higher stall converter speed is to allow the engine to spend a good deal more time in its most efficient power range without needing to WASTE TIME build rpms slowly up in the lower engine speed ranges where there's a good deal less usable power available, I'm always rather amused that so many guys want to get so darn confused about what is basically brutally simple, the purpose of a performance torque converter is to allow near instant access too and full use off and efficient use of the engines peak torque over most of its power band, the transmission must of course be set up to shift to the next lower gear each time the engine rpms start to exceed the ideal power range or drop back into the ideal power band if the torque available is no longer sufficient to easily move the car, to do this you simply need to know the cars drive train gearing tire size and the engines power band and red-line or upper rpm limitations, and the engines lower rpm power band effective limitations and a dyno tuning test session easily determines those factors.

of COURSE a high stall converter SLIPS a bit more than a stock converter,THATS THE WHOLE POINT OF THE DESIGN! it allows the engine rpms to nearly instantly reach the most efficient power band and almost as instantly drag the transmission gearing up into that rpm range along with it without bogging the engine or forcing it to spend wasted time at the lower rpms where the engine fights to make decent power, when you apply throttle that's,the whole IDEA! it allows the engine to rapidly increase rpms while seamlessly, transferring the engines torque to the drive train, the more force or torque you apply the higher the rpm level the converter will stall, this is why the same converter on two engines may not stall at the same rpm, but you'll find your applying the power to the rear wheels without you needing to have the engine waste time in its far less effective lower rpm power band, but you'll rarely notice that slippage, during any performance style driving, simply because the engine and transmission will rather rapidly regain similar speeds, its not like theres a noticeable time lag, between the throttle being depressed and the cars acceleration, thats nearly instant, both at part or full throttle, the difference is only in how far the engine rpms vary for an instant as the cars rear wheel speed trys to very rapidly catch up with engine rpms.

The concepts similar to a smaller engine ,manual transmission drag car letting the clutch slip for an instant as it launches so the engine rpms stays up over lets say 3500rpm,then rapidly accelerates to 6000rpm plus to prevent the car from bogging, rather than letting traction stall the engine!

IF your thinking of swapping to a higher stall converter,you should be able to answer the questions, listed below as it will be to your advantage to do so, by simply asking yourself ...those questions, but be aware your transmission gear ratios and rear gear ratio effect the correct choice in converter stall speed.one of the most common myths about high stall torque converters , is that the car won,t move under part throttle until near the rated stall speed is reached by the engine, think about that a second, then think about how your current car reacts to part throttle and realize your stock converters stall speed is probably 600-700rpm higher that the rpm that effectively moves your car at part throttle.

the first thing youll want to do is test your current converters stall speed and find out what your currently dealing with, so you have a few facts and a start point!

if YOUR NOT SURE DO YOURSELF A FAVOR AND CALL AT LEAST 5 DIFFERENT HIGH PERFORMANCE CONVERTER MANUFACTURERS AND ASK FOR RECOMMENDATIONS BASED ON YOUR COMBO, that way your bound to at least pick up some basic info and ideas.

WATCH VIDEO's CLOSELY

https://hlperformanceconverters.com/tech-notes/

http://dynamicconverters.com/converters.htm#11" Race Converters

Help in installing a bone dry rebuild transmission

Installing a rebuilt 4L80 transmission: Do I pour a QT of ATF into the bone dry Torque convertor?? How much does a bone dry 4L80 get?? Should I run synthetic ATF?? And I am under the impression I put a few QTs of ATF into the transmission, and then before starting it check to see if my dip...

garage.grumpysperformance.com

What does a high stall converter do?

Bad-Ass Racing Engines specializes in building some of the baddest street and race engines around!

www.badasscars.com

What does a high stall converter do?

I'll try to keep it short because it's an involved subject. Basically "stall" means when the torque converter "locks-up" under a load. With that, if you take a car with a 2,500 RPM stall converter and you hold your foot on the brake hard, and hit the gas at the same time, (as if you were going to power brake), the "general" RPM in which the tires will break loose is at "about" 2,500 RPM. If the converter was a 3,500 RPM stall, then it would be at approximately 3,500 RPM in which it forces the tires to break loose. Keep in mind, if you put that same converter behind a nasty big block, in a car that has serious traction or is quite heavy, the torque of the engine will drive the stall speed up to a higher RPM, and an engine with less power will have the opposite effect and won't be able to stall the converter out as high. It's all relative to torque, vehicle weight, traction and rear gearing. It isn't an exact science as far as an exact stall RPM goes.

Stock cars have anywhere from 1,000 to 1,400 RPM stalls from the factory. The reason a stall converter works is simple; an engine at 1,200 RPM is only making about 80 or so horsepower (on average), but at 2,500 RPM it could be making 150 to 200 HP, and obviously trying to get a car moving using 150-200 HP is going to be much easier than one trying to launch at 80 HP or so. Most performance engines don't make power until 3,000 or so RPM, hence why when you have a higher horsepower engine with a big cam, you need a higher stall speed so the engine is closer to it's "power band" when taking-off from the line, otherwise it will fall on its face and be a turd off the line.

Some people believe that "stall" means the car won't start moving until the engine reaches that particular RPM, and that isn't even close to being true. We build race cars with 6,000 RPM stall converters and when you put the car in gear and let it idle, it WILL roll along at 5 - 10 MPH, just like any other car will when put in gear and with the brake off. In fact, we usually cruise through the pits with the car simply in gear and idling, so if a 6,000 RPM converter means that the car won't start moving UNTIL that RPM, then we'd have to have the engine wound-out to 6,000 RPM to putt along through the pits at 10-15 MPH, and that simply isn't the case. Stall means when the car is on the starting line, (with say a 4,500 RPM stall converter), and the trans brake is on, (which locks the transmission in first and reverse at the same time), and you hit full throttle, the engine will wind-up to 4,500 RPM with the car just sitting there, so when you slip your finger off the trans brake button and the tranny engages out of reverse, the car instantly launches at 4,500 RPM, and a race motor at 4,500 RPM is pretty close to its peak torque curve when leaving the line, hence the big wheelies you see on some drag cars or the incredibly low 60 Ft. times when traction is good. Race engines make no power at low RPM's, and are usually shy on torque, so the nastier the engine, the higher the stall speed needs to be (in general anyway). Again, cubic inches, torque, vehicle weight and gear ratio have a big factor in this. Now, this doesn't get into the "flash" effect which is where a stall converter will "flash to" when your finger comes off the trans brake button. Typical 3,000 RPM converters can flash up to 5,000 RPM or so once you've launched the car. It's a bit more complicated and I am trying to keep this simple for you, so we'll skip that area right now.

A 6,000 RPM converter behind a stock engine might not even get to 6,000 RPM because the engine can't make enough torque (power) to spool-up to that RPM because of the load of the converter. The car will start rolling at a much lower RPM and may never be able to reach 6,000 RPM. This is also true for any converter from about 3,000 RPM on up. Most mild race cars (9-10 second quarter mile times) use anywhere from 3,500 stalls to 4,500 stall speeds on average. Faster cars usually use even higher stall speeds, especially in smaller cubic inch engines that don't make the torque of big displacement engines. Also, the higher the stall speed, the more heat the converter will make, from hydraulic (fluid) friction inside the converter. A high stall converter can easily make enough heat to fry a transmission if you hold it on the line long enough at full RPM if the stall speed is above 3,500 RPM or so, so a good tranny cooler is essential when running ANY type of high stall converter.

Most street performance cars running your typical "performance" cam should be running a stall converter in the 2,800 - 3,000 RPM area. For hotter cars (street / strip) with bigger cams, etc. then a converter in the 3,000 - 3,500 RPM is more suited. For mild performance cars with something like a 350 HP engine, a 2,200 - 2,400 stall is about right. The basic rule of thumb is; if your engine "comes alive" at say, 3,500 RPM, then you want a stall converter with about 3,500 of stall to it. Most people tend to over cam and over carbureted their cars... and those same people also tend to under stall converter their cars too, which REALLY makes it a complete turd. if they need a 3,000 RPM stall, they'll usually get something like a 2,000 RPM, which just doesn't get it off the line. You have to remember... 80% of the race is the first 100 feet. If you can't get off the line, you are going to lose the race.

BTW IF you have a dyno graph of your cars engine power curve selecting the correct matching stall speed is much easier

(1) was the current converter stall speed performing well?

(any problems or things you did not like) and at what rpm do you normally cruise in top gear?)

(2) what if anythings changed that makes you suspect a higher stall will improve things?

(if you floor the throttle from an idle in gear is there a significant time lag before your car accelerates, hard? does the car bog down if you floor the throttle at idle or does the car accelerate rapidly?)

(3) whats your current engine power curve?

(where does the engine start to really come alive, and start pulling hard, in the rpm band., at what rpm does power start to rapidly drop off?)

(4) whats your rear gear ratio?, whats your tire diameter? youll spend much less time in each transmission gear range with a 4.11:1 rear gear than a 2.87:1 rear gear so thats an important factor?

(5)are you planing mod mods that make you suspect you'll require a higher stall speed, are you planing on installing larger diameter tires? a longer duration cam?

(6) do you have an auxiliary transmission cooler installed and whats your normal trans fluid temp range?

(7) have you called at LEAST 4 different converter manufacturers and ask for their input? suggestions?

before buying any converter discuss the combo with the converters manufacturer, AND YOUR CAMS MANUFACTURER and ask for their input & suggestions

http://garage.grumpysperformance.co...w-how-to-install-a-tq-converter.386/#post-473

Precision Industries said:The formula for STR is EXACT OUTPUT TORQUE ÷ EXACT INPUT TORQUE = STR.

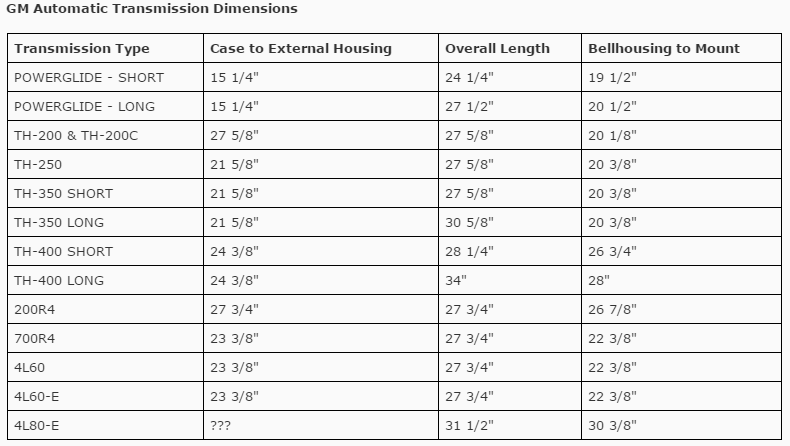

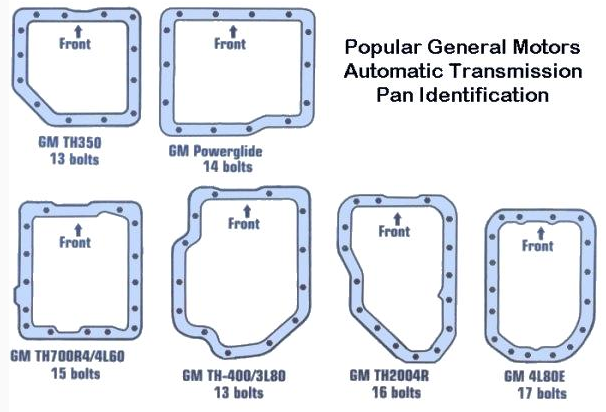

while a manual transmission like a muncie has traditionally been used in performance muscle cars , the current technology with a higher than stock stall speed converter and a decently strong auto transmission like a properly built TH400 or $l80E makes the rather common 450-500 hp 383 small block a much more reasonable combo, with decent durability.

Ive built dozens of 383-406 SBC engines and properly configured and assembled 383-406 SBC engines are fully able to shred a stock 700r4/700r style auto transmission, over time as both transmissions were designed to operate with engines providing no more than 400 ft lbs of torque.

This requires a known power source and a data recovery system. STR is just what the name implies. The ratio of torque multiplication at stall. As soon as the turbine rotates (car moves) the ratio starts dropping rapidly until enough RPM has been reached for the ratio to drop to 1:1. The RPM that the ratio reaches 1:1 varies depending on other factors in and out of the torque converter such as impeller exit angle, stator design, impeller to turbine clearance, input torque (engine), etc.the stock torque converter you took out of your car has a STR of 1.9-1.94. In our tests we have never seen an STR over 2.55.

http://converter.com/truth.htm

read the linked info below or you'll miss a good deal of useful information

OEM flex plates are far thinner and more flexible than the SFI certified flex-plates , so they are far more likely to crack and split over time

instructions

http://www.autoshop101.com/forms/AT02.pdf

1

Examine your car's engine specifications (get the cars engine dyno tested or at leash have a good idea of the engines power curve,) or take it to a shop with a chassis dynamometer to have it measured. Note the engine's peak torque and the rpm that it occurs at youll want the stall speed to be just a bit lower on a street car to increase drive-ability and just a bit higher than peak torque on a race application to maximize useful power.

remember your converter slips a good deal more and produces a good deal more heat in the trans fluid below the stall speed, so you don,t want the engine spending a great deal of time below the stall speed in its intended application.

consult with at least three different converter manufacturers, about the best converter stall speed for your particular application, before making a choice and ask LOTS OF questions

2

Add about 15 percent to your engine's peak torque figure if you used a chassis dyno instead of factory horsepower ratings, and your looking at a race application,. The engine, transmission and wheel require a certain amount of horsepower to turn, meaning that such "wheel horsepower" will register lower than the flywheel horsepower you need.

keep in mind your car will be able to drive and move well below the cars stall speed with a high stall converter but your converter slips a good deal more and produces a good deal more heat in the trans fluid below the stall speed, so you don,t want the engine spending a great deal of time driving the car below the stall speed in its intended application, and adding a trans cooler with a higher stall converter is just about mandatory

http://garage.grumpysperformance.co...gine-to-match-the-cam-specs.11764/#post-55651

http://www.zealautowerks.com/transcalc.php

3

Order a torque converter that matches your engine's peak torque output and peak torque rpm as closely as possible. If you can't find one that matches it precisely, error on the side of caution by choosing one with a slightly lower stall or higher torque rating . You'll lose a little performance with a stall that's too low, but you'll lose performance, fuel economy and drive-ability with one that's too high.

EXAMPLE, HERES MY CORVETTES POWER CURVE

it should be obvious why a 3000 rpm-3200 stall converter stall speed was selected to maximize the power curves and why the ignition rev limiter is set at 6300 rpm

yes I have to admit that when I personally swapped from a stock stall speed converter

,in my 383 sbc corvette and a 3200 rpm stall speed converter the difference in performance was amazingly better.

swap too a 3.73:1 rear gear and you've noticeably further enhanced that seat of the pants and slam in the back acceleration.

people tend to not fully appreciate the fact that the performance cars drive train gearing, power to weight ratio and the converter stall

(in the case of automatic transmission) must match the engine torque curve if the car is to perform to anything close to its best potential

http://www.highperformancepontiac.c...vigilante_torque_converter_install/index.html

READ THE SUB LINKS, they contain a wealth of additional info

http://www.superchevy.com/how-to/transm ... selection/

http://www.carcraft.com/techarticles/se ... index.html

http://www.chevyhiperformance.com/techa ... index.html

http://www.chevyhiperformance.com/tech/ ... index.html

http://www.protorque.com/FAQ.html#6

http://www.protorque.com/techi/ti_faq.htm

"

STALL SPEED

Torque converter stall is a commonly used term and is commonly misunderstood. Stall is the speed at which the converter will hold the engine speed and not allow further gain (i.e., the engine "stalls"). The key word here is engine. The speed at which stall occurs with a given converter is a function of engine peak torque. It is clear that the stall speed on a given converter will not be the same coupled to a tame small block engine when compared to a big block with all of the muscle features added. When comparing stall speeds it is important to account for the engine that drives it. True converter stall can best be determined when a Transbrake is used. Testing for stall value by locking the wheel brakes generally does not produce a true stall value because the engine power can often cause wheel turn by overpowering the brakes. Stall speed determined by this method should be identified as such when discussing stall speed determination. Flash stall is determined by launching at full throttle and observing the peak speed attained at launch. Selection of the right stall speed for your vehicle should be matched to the engine peak torque, engine torque curve shape and vehicle weight. In general, the stall speed selected for your converter would be 500 to 700 rpm below the peak torque. This speed allows the margin for application of the torque reserve on takeoff. When selecting stall speed without having prior experience to go by, it is better to conservatively estimate the engine torque than it is to over estimate it. If you over estimate the torque output you will have a converter with a stall speed too low, making your car slow off the line and have slow ET. A properly selected stall speed will give you better launch and better ET. You can see why it is important to consult with professionals prior to making a stall speed selection. Within the converter, stall speed is balanced off against inefficiency after launch. Getting desired stall at the expense of performance after launch is just as costly as improper stall speed to begin. The optimum converter has careful selection and design of changes to the impeller, turbine and stator.

"HOW CAN I DETERMINE THE STALL SPEED OF MY CONVERTER?

Stall speed is very difficult to determine unless your car is equipped with a Transbrake to lock your drive train. Testing stall speed by holding the wheel brakes and running the engine against the locked brakes will usually result in wheel rotation before true stall speed is reached. The engine simply overpowers the ability of the brakes to hold the car. When rotation starts you are no longer at stall. For this reason people talk about brake stall which is not a true stall at all. An alternative method of measurement is to launch at wide open throttle and observe engine RPM reached at launch. This is flash stall.

"

For most hot street cars, that weight between about 3300lbs and 3700lbs (WHICH IS MOST MUSCLE CARS) with a reasonable street/strip compromise cam in the 225-235 duration range designed to run on pump gas and having a 3.73-4.11 rear gear with tires in the 25"-28" range,a 3000-3200rpm rpm stall should be fine in a combo like you describe, I'm running a 3000stall converter in my car, theres a common mis-understanding that installing a 3000rpm stall converter means the car won,t move until you hit 3000rpm, that's a fallacy, theres a bit more slippage but it drives just fine at lower rpms at part throttle if your just cruising, but the slippage make HEAT so don,t forget to add a decent trans cooler

as an example on this 500hp 350sbc above,designed for the drag strip, a 4500 stall would be almost ideal.

on this 400hp 350 designed for the street a 3000rpm stalls fine, but if you installed a 5000rpm stall you'll be loosing a great deal of the engines power curve

Advertized stall speed is "indicative" or only an average result usually based on a common stock engine displacement and torque level such as with a 350hp 350 sbc

The more torque your engine produces ,the higher rpm a torque converter will stall at.

A converter will stall higher on a hot 383 or 427 sbc than on a stock 350 despite what it's rated stall speed is.

The better manufacturers have a chart telling what speed a certain converter will stall at with what torque level but even then its just an educated guess, as each converter will be a bit different from its clones.

and remember you get what you pay for,if you find a new converter costs significantly less than similar advertised converters theres a REASON

and you can bet that they left out some feature you need like anti ballooning plates of brazing the internal fins, or they used thinner/weaker components

Example

a 9" converter stall is advertized as a 3000 stall

but gives your approximately

3000rpm @ 400 ft/lb

3185rpm @ 450 ft/lb

3300rpm @ 550 ft/lb

https://robrobinette.com/et.htm

http://www.cprparts.com/HPcalculator.html

https://www.gregraven.org/hotwater/calculators/qm-from-wt-hp.html

https://www.tciauto.com/racing-calculators

https://teamcsr.net/Racing Calculator.htm

https://racingcalcs.com/horsepower-hp-required-for-elapsed-time-et-goal-calculator/

calculators like those linked above assume you have close to ideal,

traction

(suspension, tires, weight transfer)

and gearing

( transmission gearing, stall speed and shift between gears effectively in the ideal power band)

to maximize the cars acceleration potential

Last edited by a moderator: