READ THIS THREAD AND LINKs and SUB LINKS AS ITS IMPORTANT TO UNDERSTANDING SOME FACTORS, and theres a ton of useful info in the links

read these threads and sub-links also, as they contain good info, if you fail to read thru the sub links youll miss a ton of useful info, don,t think published flow numbers or price alone are the only really useful factors to use, remember a flow bench has very little in common with a running engine

keep in mind that a properly designed exhaust system and headers goes a very long way towards increasing the efficiency of the intake manifold and head flow , and remember that the better the heads and the more effective the exhaust scavenging the less duration the cam used will require!

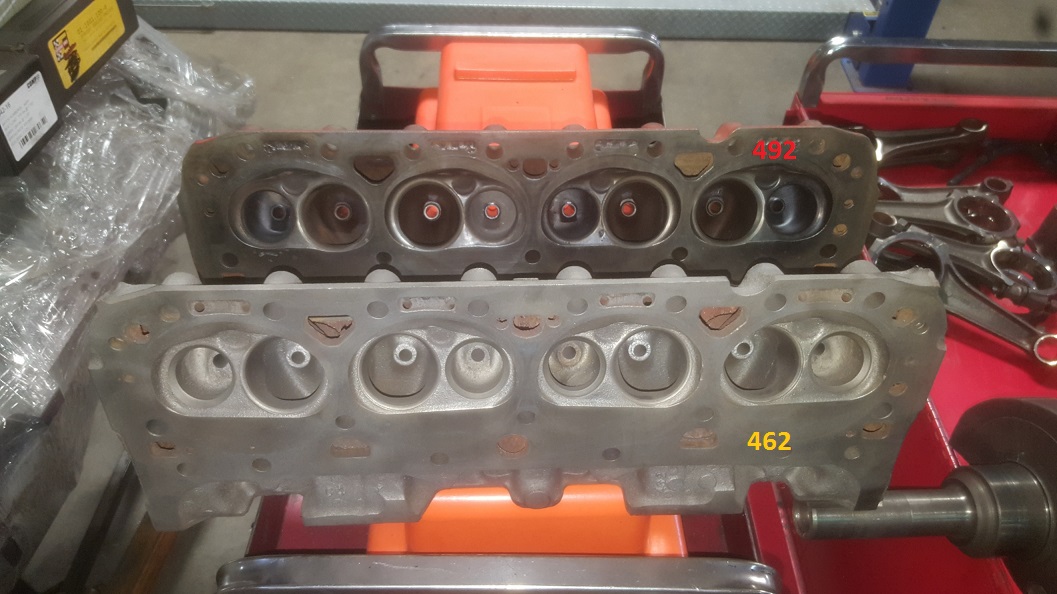

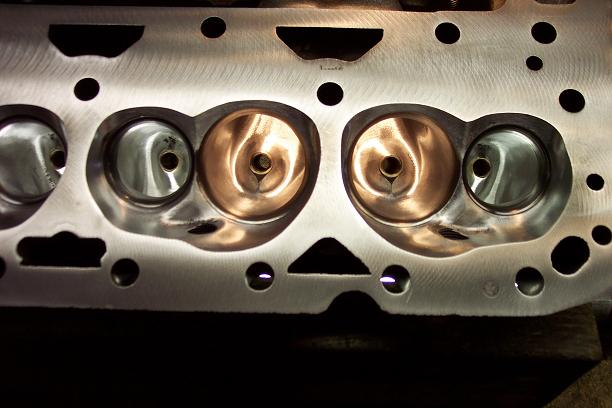

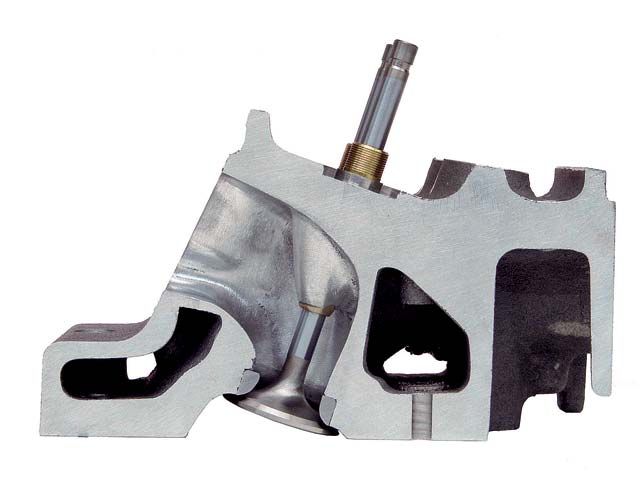

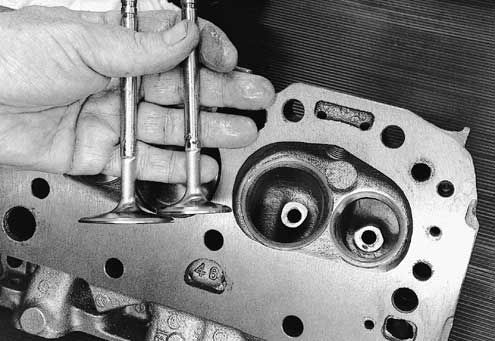

before as cast

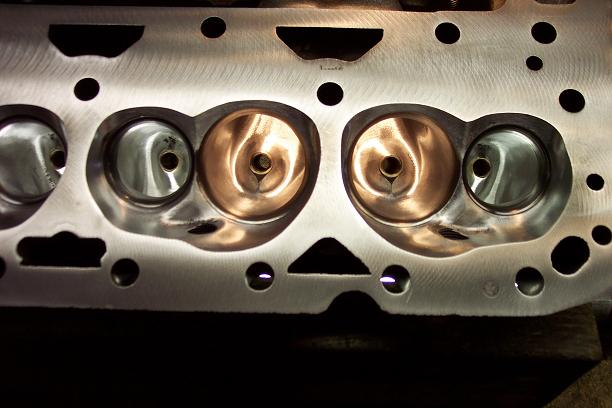

after port clean up intake

before as cast

after port clean up exhaust

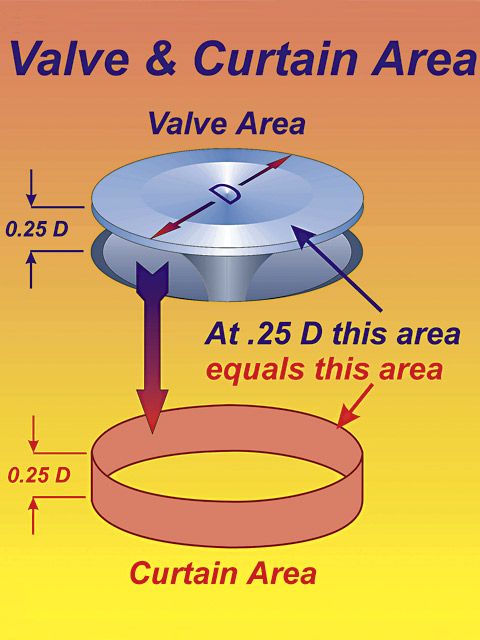

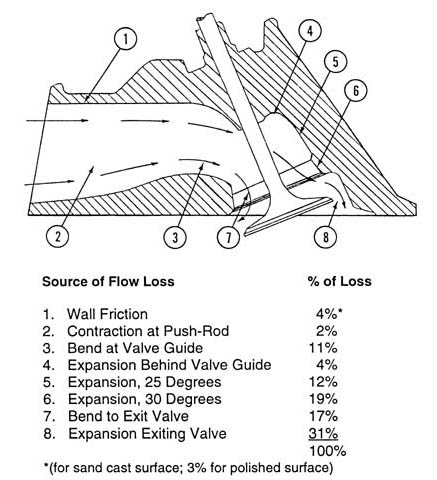

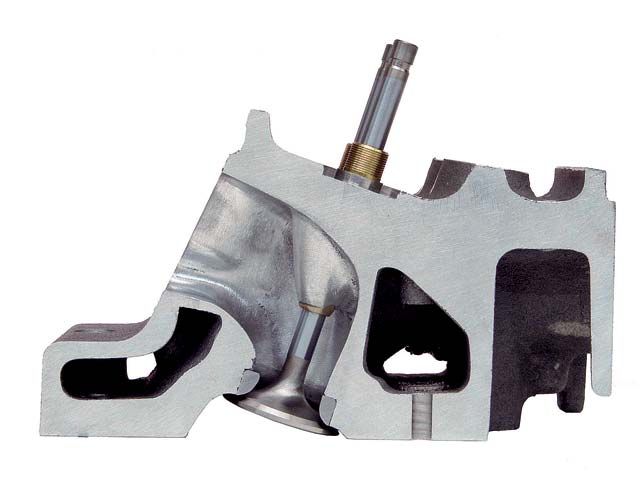

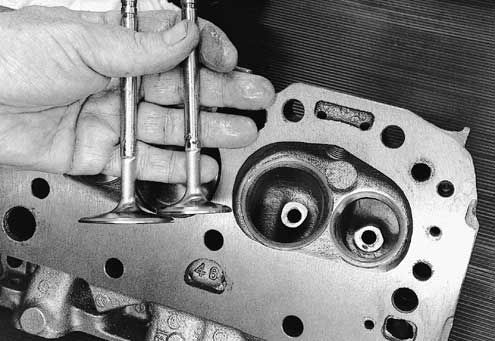

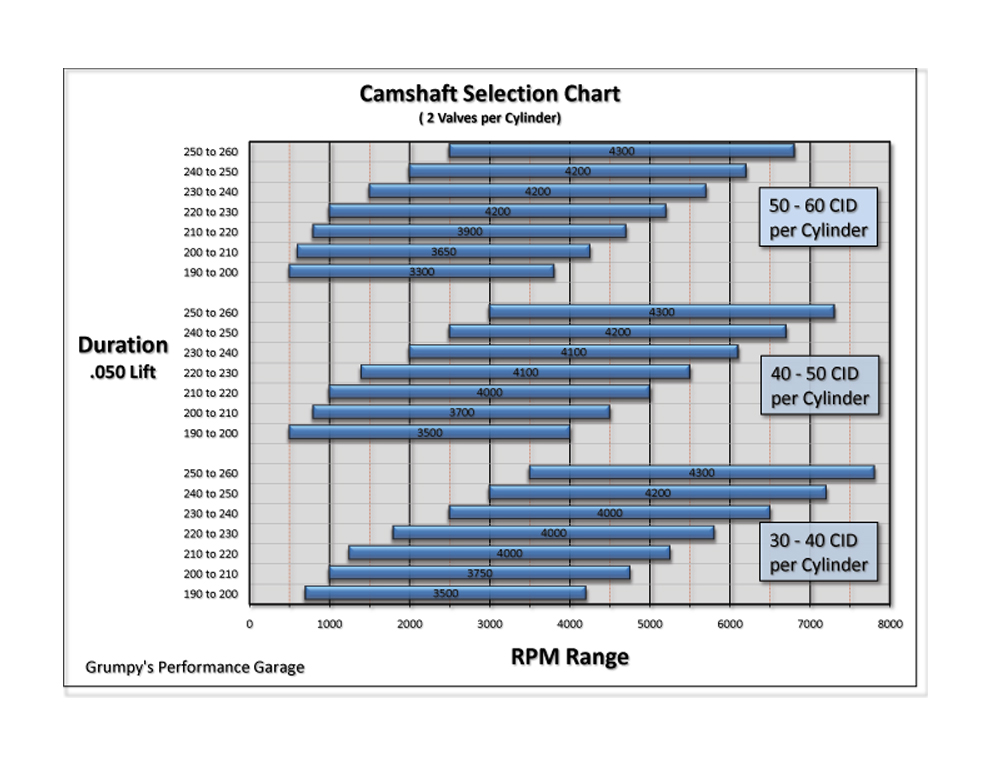

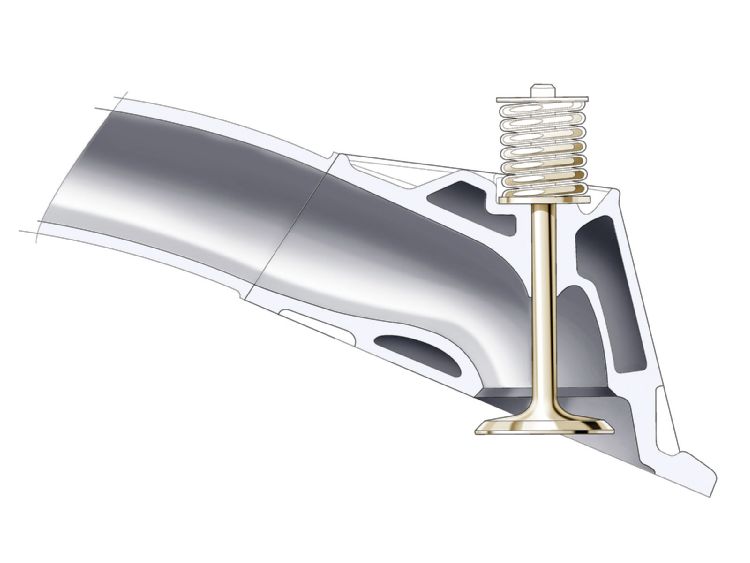

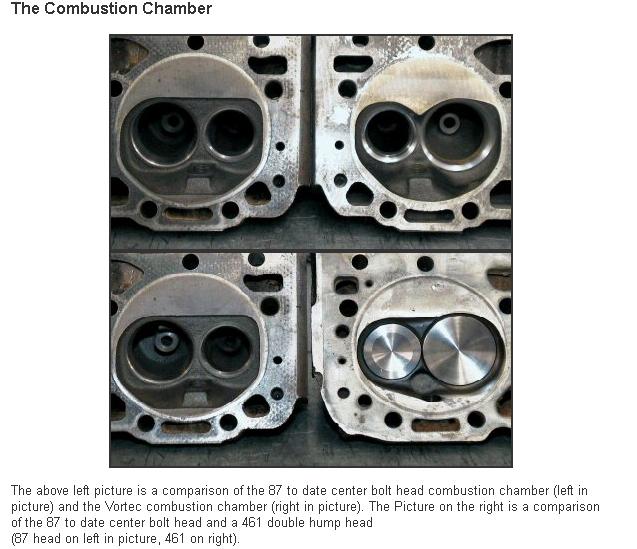

most stock and some aftermarket heads benefit from port and bowl clean up work,to smooth and increase flow rates ,port throats generally run 80%-85% of total valve diameter because you need to maintain sufficient valve seat contact area to allow sealing and cooling and some wear during operation.

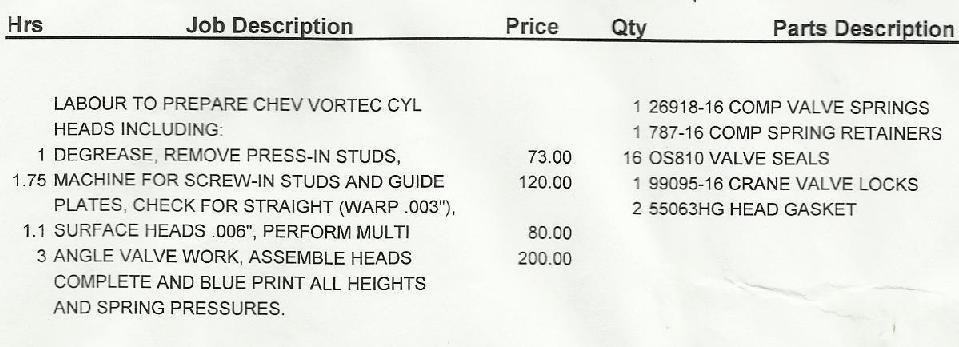

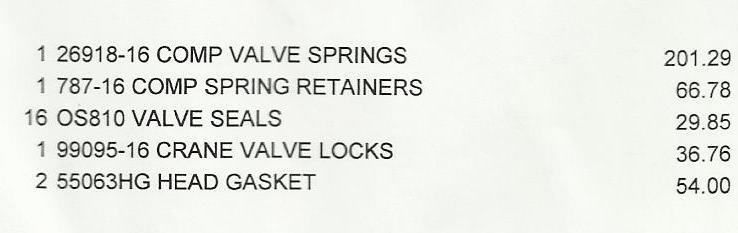

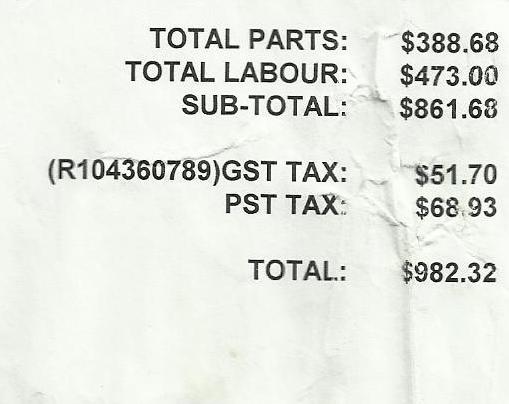

But be aware that using stock refurbished heads , can cost a good deal more than new heads will,because its very likely that by the time you hot tank or oven and shot-blast clean them

, have them dye or magnetically checked for cracks and pressure and have, a clean-up decking,pass on the milling machine,insert new valve guide inserts, select and install bigger valves , and that requires new valve seats with a good multi angle valve job, pay for and install the correct matched springs, keepers, and retainers,that came with the new cam, if you bought the matching components instead of trying to keep cost low and use the O.E.M. valve springs which are unlikely to match the application, you might be better off to buy new cylinder heads??

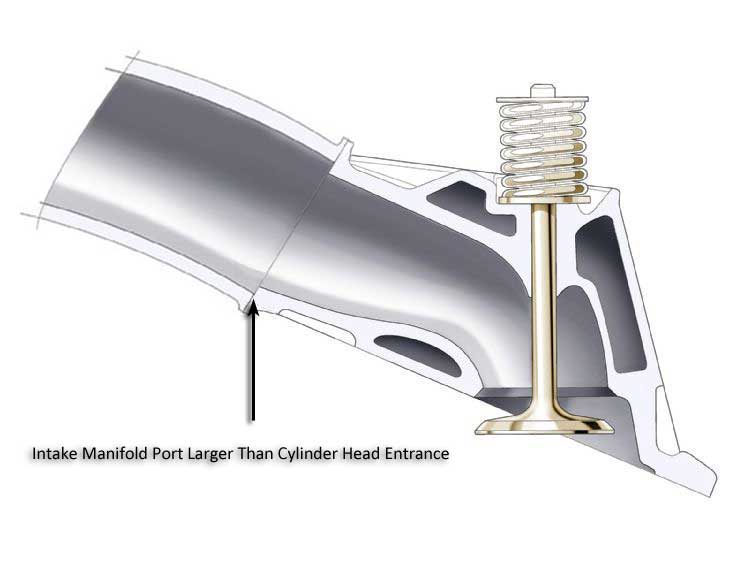

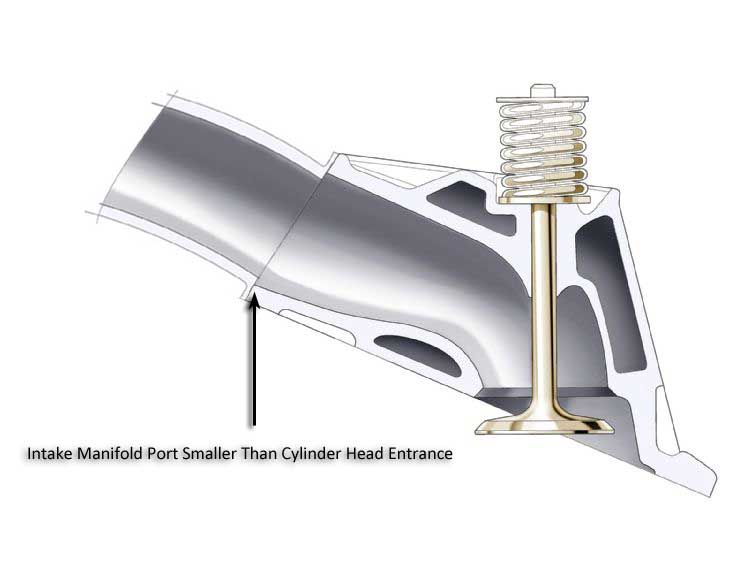

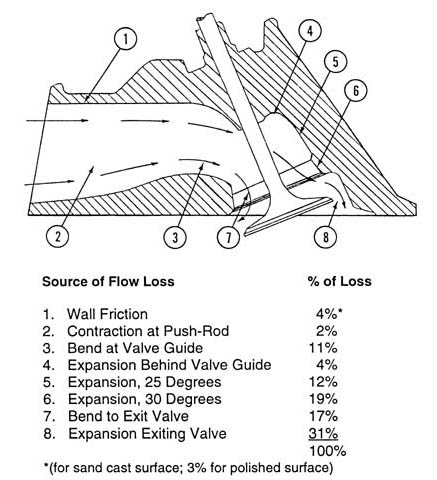

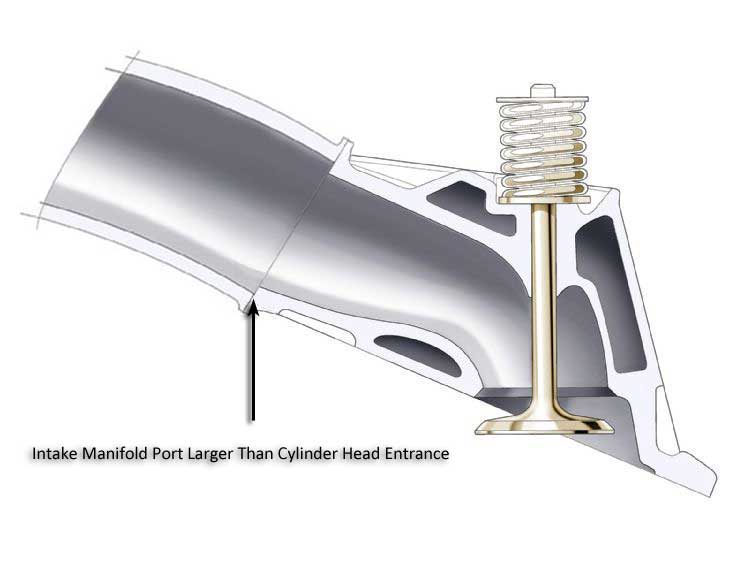

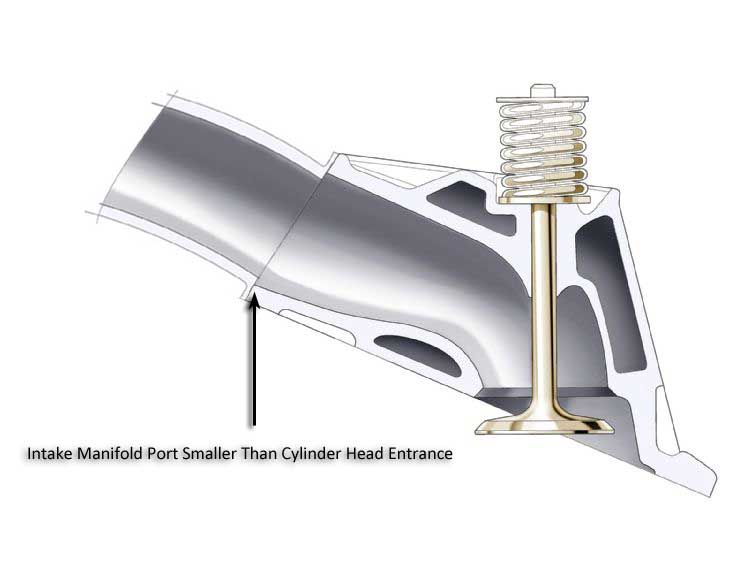

PORT MATCHING THE INTAKE RUNNER EXIT TO THE CYLINDER HEAD PORT ENTRANCE USUALLY HELPS REDUCE RESTRICTIONS TO FLOW RATES, AND REDUCES FUEL/AIR DISTRIBUTION ISSUES

a very common misconception, "that the intake runner size has the most effect on the engines torque curve,is mostly a myth" in reality ,compression ratio, cam timing and engine displacement and proper exhaust scavenging ALL have a larger effect on the engines torque that the intake runner cross sectional area.(yes getting it correct helps but your more likely to cause a problem by selecting an intake port and runner combo thats too small and restrictive than one thats too large in cross sectional area.

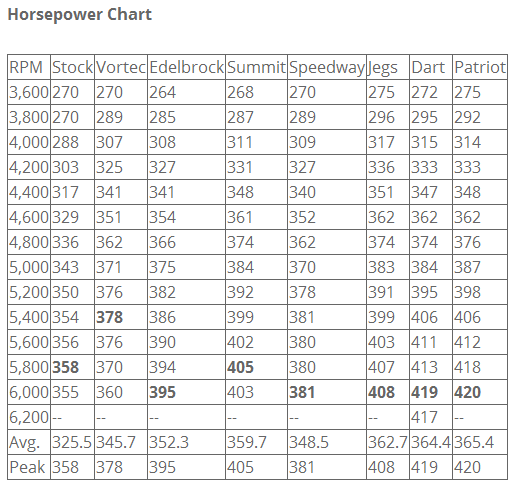

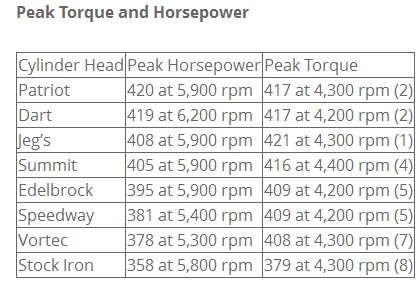

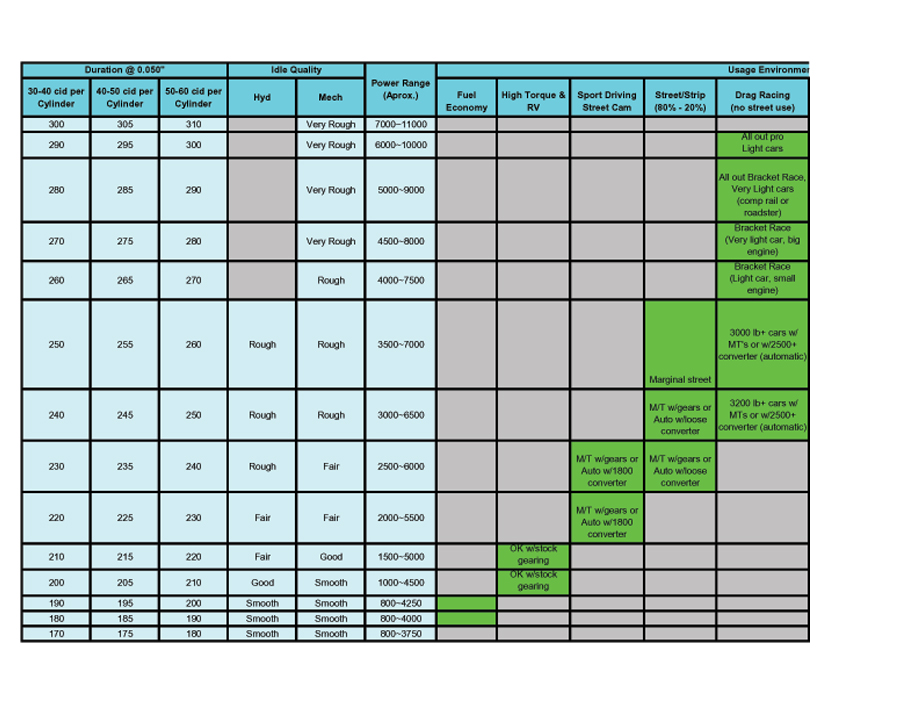

heres a chart FROM THE BOOK,HOW TO BUILD BIG-INCH CHEVY SMALL BLOCKS with some common

http://garage.grumpysperformance.com/index.php?threads/the-new-215cc-vortec-heads.266/#post-75012

FUELIE HEADS

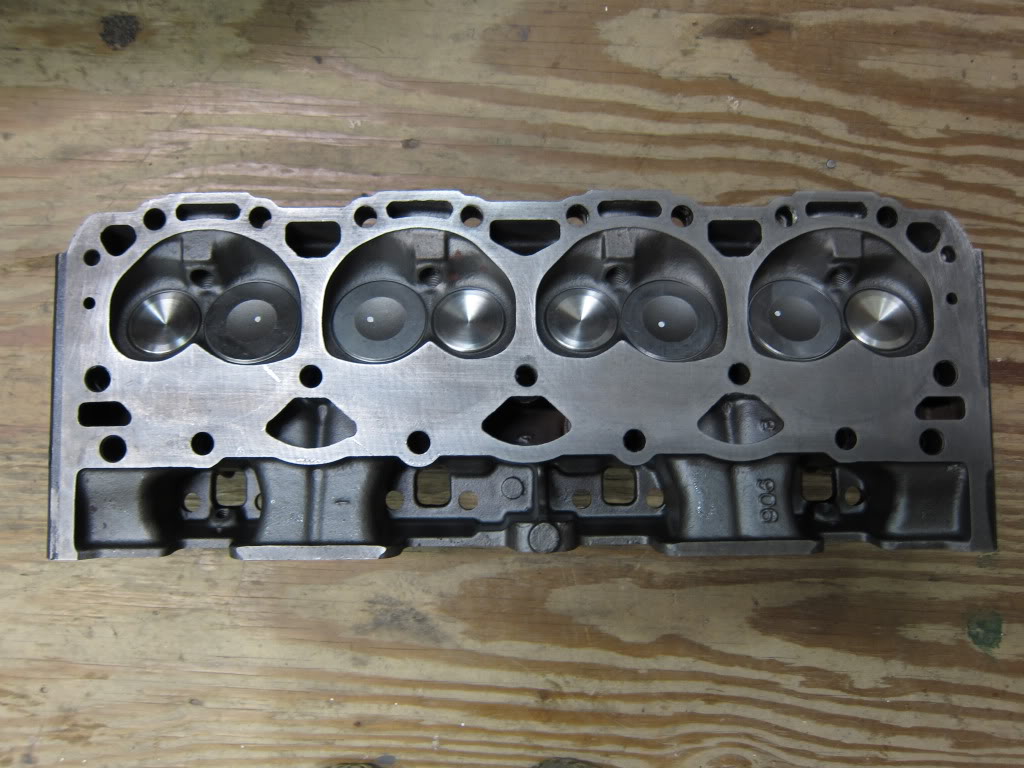

Some of the More Popular Gen I Cast Iron GM Cylinder Heads

http://www.onedirt.com/tech-stories/engine/a-guide-to-vortec-vs-oe-small-block-chevy-heads/

http://users.erols.com/srweiss/tablehdc.htm

#3767754 – Manufactured from 1959-1961 on 283 Cubic Inch engines. Called the “Power Pack” cylinder heads. 1.72˝ intake valves and 1.50˝ exhaust valves. 60cc Combustion Chambers.

#3774692 – Manufactured from 1958-1964 on 283 Cubic Inch engines. Called the “Power Pack” cylinder heads. 1.72˝ intake valves and 1.50˝ exhaust valves. 60cc Combustion Chambers.

#3795896 – Manufactured from 1963-1965 on 283 Cubic Inch engines. Called the “Power Pack” cylinder heads. 1.72˝ intake valves and 1.50˝ exhaust valves. 60cc Combustion Chambers.

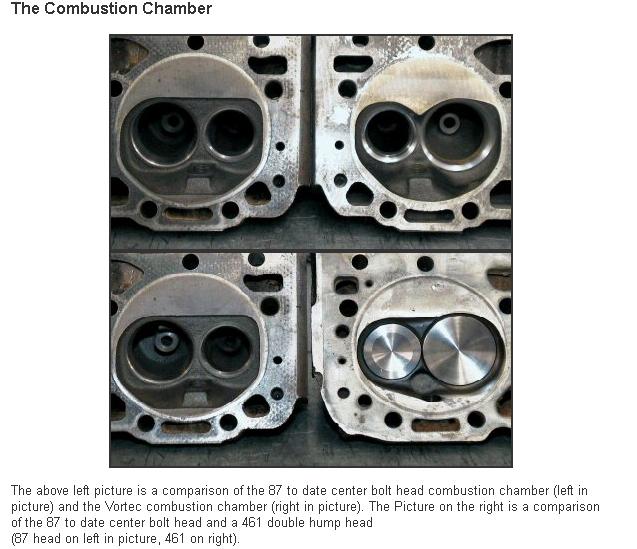

#3782461 – Manufactured from 1964-1966 on 327 Cubic Inch engines. 161/62 cc port volumes, 62cc combustion chamber. Identified by Double Camel hump symbol.

#3782461X – Manufactured from 1960-1963 on 283 and 327 Cubic Inch engines. 172/64 cc port volumes, 62cc combustion chamber. Identified by Double Camel hump symbol.

#3890462 – Manufactured from 1966-1967 on 302, 327, and 350 Cubic Inch engines. 64cc combustion chamber. Identified by Camel hump symbol. No accessory mounting holes.

#3917291 – Manufactured from 1967-1968 on 302, 327, and 350 Cubic Inch engines. 64cc combustion chamber. Identified by Camel hump symbol.

#3932441 – Manufactured from 1969-1970 on 350 Cubic Inch engines. 161-165cc intake port. 76cc combustion chamber.

#3932441X – Manufactured from 1969-1970 on 350 and 400 Cubic Inch engines. 161/65cc ports. 80cc combustion chamber. 1.94″ intake/1.5″ exhaust valves.

#333881 – Manufactured from 1974-1975 on 350 Cubic Inch engines. 76cc combustion chamber. 2.02″ intake/1.6″ Exhaust valves.

#3991492 – Manufactured from 1970 on 350 Cubic Inch engines. Available on the LT1 engine and over the counter. 64cc combustion chamber. Either straight or angled plugs.

http://www.strokerengine.com/SBCHeadsFlow.html

_______________________________________________________________

Intake Port cc & CFM @. 500" Lift

Chevrolet Production 441 Iron Head 155/201

The 882 head may have out-flowed this head but with the addition of larger 2.02-inch intake valves and some decent pocket port work these heads will out flow the 882’s. Keep in mind that with a small 155cc port volume these heads are great for making torque.

The 882 head may have out-flowed this head but with the addition of larger 2.02-inch intake valves and some decent pocket port work these heads will out flow the 882’s. Keep in mind that with a small 155cc port volume these heads are great for making torque.

_______________________________________________________________

Chevrolet Production Iron 882 Head 151/205

This head had the smallest port size of all the heads we tested. A set of 2.02/1.60-inch valves can be swapped in but be aware that without blending in the short side radius, the results usually find lost airflow.

This head had the smallest port size of all the heads we tested. A set of 2.02/1.60-inch valves can be swapped in but be aware that without blending in the short side radius, the results usually find lost airflow.

_______________________________________________________________

Chevrolet Production 462 Iron Head 156/212

This head was a small chamber head used on 327ci motors until the end of 1968. The flow can be improved a little with larger valves and port work but the additional cost of this is impractical in comparison to what you can by some other aftermarket casting for.

This head was a small chamber head used on 327ci motors until the end of 1968. The flow can be improved a little with larger valves and port work but the additional cost of this is impractical in comparison to what you can by some other aftermarket casting for.

_______________________________________________________________

Chevrolet Production Vortec Iron Head 885 170/239

This head can be seen as a sleeper when compared to other GM production heads. It outflows the LT-1 aluminum Corvette head on the intake side, plus its mid lift numbers are very impressive. This head is perfect when iron heads are required. GM designed this head and put it on trucks as well as on the later Impala SS but with a different intake bolt pattern. As for production pieces these are one of our favorites.

This head can be seen as a sleeper when compared to other GM production heads. It outflows the LT-1 aluminum Corvette head on the intake side, plus its mid lift numbers are very impressive. This head is perfect when iron heads are required. GM designed this head and put it on trucks as well as on the later Impala SS but with a different intake bolt pattern. As for production pieces these are one of our favorites.

_______________________________________________________________

Chevrolet Production L98 TPI Aluminum Head 163/196

This aluminum head was used on the Corvette TPI engines from the mid-Eighties until the LT-1 1992 motors were introduced. The 882-iron head out-flowed this head across the board. This piece is not our first choice for a performance head considering that the largest valve this head fits is a 2.00/1.55-inch combination and it has a 58cc chamber.

This aluminum head was used on the Corvette TPI engines from the mid-Eighties until the LT-1 1992 motors were introduced. The 882-iron head out-flowed this head across the board. This piece is not our first choice for a performance head considering that the largest valve this head fits is a 2.00/1.55-inch combination and it has a 58cc chamber.

_______________________________________________________________

Chevrolet Production GM LT1 372 Aluminum Head 170/214

The LT-1 head was the next generation head developed for the small blocks after the L98 head. This head uses a reverse-cooling system, which means it can not be swapped onto older blocks. The 0.400-inch airflow numbers are great and with some port work, the addition of 2.00/1.55-inch valves can really wake these heads up.

The LT-1 head was the next generation head developed for the small blocks after the L98 head. This head uses a reverse-cooling system, which means it can not be swapped onto older blocks. The 0.400-inch airflow numbers are great and with some port work, the addition of 2.00/1.55-inch valves can really wake these heads up.

_______________________________________________________________

Chevrolet Production LT4 Aluminum Head 195/250

The LT-4 is substantially different from the LT-1 casting, and the flow numbers explain why. The larger intake ports are definitely a contributing factor. For a production head these babies put up some pretty good flow numbers. Remember, like the LT-1 the LT-4 can only be used on a reverse cooling system block.

The LT-4 is substantially different from the LT-1 casting, and the flow numbers explain why. The larger intake ports are definitely a contributing factor. For a production head these babies put up some pretty good flow numbers. Remember, like the LT-1 the LT-4 can only be used on a reverse cooling system block.

_______________________________________________________________

Chevrolet LS1 Aluminum Head 204/240

GM won’t be left out of category 3 with these heads. This head has great 0.400-inch lift numbers as well as a good E/I ratio. They also feature a more flat valve angle (15 degrees) in order to promote a better combustion chamber that’s shaped like a kidney to help direct combustion and reduce possible detonation. Remember that this head will not interchange with pre-‘93 small-block heads.

GM won’t be left out of category 3 with these heads. This head has great 0.400-inch lift numbers as well as a good E/I ratio. They also feature a more flat valve angle (15 degrees) in order to promote a better combustion chamber that’s shaped like a kidney to help direct combustion and reduce possible detonation. Remember that this head will not interchange with pre-‘93 small-block heads.

_______________________________________________________________

AirFlow Research 180 Aluminum Head 181/250

This head is the smallest of AFR’s line. It is intended for engines up to 350ci. The flow numbers are especially impressive on the exhaust side of this head, leading us to believe that a single pattern cam may be the best choice here. The E/I relationship is outstanding with and 84%, almost higher than any other head in this category.

This head is the smallest of AFR’s line. It is intended for engines up to 350ci. The flow numbers are especially impressive on the exhaust side of this head, leading us to believe that a single pattern cam may be the best choice here. The E/I relationship is outstanding with and 84%, almost higher than any other head in this category.

_______________________________________________________________

AirFlow Research 190 Aluminum Head 191/262

This head has the best flow numbers of all the category 2 heads. Offering great flow throughout the entire lift range you can see this head doesn’t just put up one big number at maximum lift. If you’re looking for great flow from a mid-sized cylinder head this is definitely one of the top contenders.

This head has the best flow numbers of all the category 2 heads. Offering great flow throughout the entire lift range you can see this head doesn’t just put up one big number at maximum lift. If you’re looking for great flow from a mid-sized cylinder head this is definitely one of the top contenders.

_______________________________________________________________

AirFlow Research 210 Aluminum Head 215/271

Here is an extraordinary head. It has larger intake ports but with 240cfm at 0.400-inches of lift who cares? The E/I ratio is an incredible 75% making it hard to find anything wrong with these heads. This head may be a little much for a mouse motor but it is perfect for a big mouse somewhere in the 383 inch range up.

Here is an extraordinary head. It has larger intake ports but with 240cfm at 0.400-inches of lift who cares? The E/I ratio is an incredible 75% making it hard to find anything wrong with these heads. This head may be a little much for a mouse motor but it is perfect for a big mouse somewhere in the 383 inch range up.

_______________________________________________________________

Brodix-8 Pro Aluminum 181/254

This head features larger 2.08/1.60-inch valves combined with a 181cc-intake port. With smaller intake port this head flows outstanding at 220cfm by 0.400-inches of lift and even better by 0.500-inches. Combined with a mid-sized port this, this is an outstanding choice for a strong 350ci or 383ci motor.

This head features larger 2.08/1.60-inch valves combined with a 181cc-intake port. With smaller intake port this head flows outstanding at 220cfm by 0.400-inches of lift and even better by 0.500-inches. Combined with a mid-sized port this, this is an outstanding choice for a strong 350ci or 383ci motor.

_______________________________________________________________

Brodix Track 1 Aluminum Head 216/246

The Track 1 head may be down on the numbers at 0.400-inch lift but it’s really competitive once it sees the 0.500-inch lift point. Add some short-side radius work and wow you’ve got a killer head. If you have a set of these heads there’s definite potential.

The Track 1 head may be down on the numbers at 0.400-inch lift but it’s really competitive once it sees the 0.500-inch lift point. Add some short-side radius work and wow you’ve got a killer head. If you have a set of these heads there’s definite potential.

_______________________________________________________________

Brodix -11X 220 Aluminum Head 216/246

Brodix offers this large-port, 23-degree valve angle, small-block head as one of its largest ports in the stock valve-angle lineup. The low lift numbers are down a bit but in comparison to some of the others once the lift numbers increase you can see there is some serious airflow. These come available with minor or major port work depending on how you order them.

Brodix offers this large-port, 23-degree valve angle, small-block head as one of its largest ports in the stock valve-angle lineup. The low lift numbers are down a bit but in comparison to some of the others once the lift numbers increase you can see there is some serious airflow. These come available with minor or major port work depending on how you order them.

_______________________________________________________________

Brodix -1X Aluminum Head 223/278

The Brodix -1x heads feature a 40/60 valve spacing, meaning the centerline of each valve has been moved away from its standard location to accommodate a larger diameter valve and move both valves away from chamber walls for unshrouding. This means special offset shaft mounted rockers are needed and available from Brodix. It seems like a lot of R & D went into these bad boys and the numbers show it.

The Brodix -1x heads feature a 40/60 valve spacing, meaning the centerline of each valve has been moved away from its standard location to accommodate a larger diameter valve and move both valves away from chamber walls for unshrouding. This means special offset shaft mounted rockers are needed and available from Brodix. It seems like a lot of R & D went into these bad boys and the numbers show it.

_______________________________________________________________

Canfield Aluminum Head 195/258

Canfield only sells this head with valves. One area to pay close attention to is the excellent low and mid-lift numbers. This head actually out-flows the Category 3 heads from 0.050- through 0.400-inches of lift.

Canfield only sells this head with valves. One area to pay close attention to is the excellent low and mid-lift numbers. This head actually out-flows the Category 3 heads from 0.050- through 0.400-inches of lift.

_______________________________________________________________

Canfield 220 Aluminum Head 223/260

This race oriented small-block head requires the use of 0.150-inch offset intake rocker arm to accommodate the repositioned intake valve. The idea of spreading the valves apart is to increase valve diameter and improve flow. This head has 2.08/1.60-inch valves and probably works best on larger displacement mouse motors around 383-plus cubic inches.

This race oriented small-block head requires the use of 0.150-inch offset intake rocker arm to accommodate the repositioned intake valve. The idea of spreading the valves apart is to increase valve diameter and improve flow. This head has 2.08/1.60-inch valves and probably works best on larger displacement mouse motors around 383-plus cubic inches.

_______________________________________________________________

Dart Iron Eagle S/S 165/210

Dart offers everything from street performance heads to full race heads. This Iron Eagle piece is the smallest head at 165cc port volume but its just what you need when building a stout street motor that sees occasional strip time. Compare its flow numbers to others and you can be the judge on this one.

Dart offers everything from street performance heads to full race heads. This Iron Eagle piece is the smallest head at 165cc port volume but its just what you need when building a stout street motor that sees occasional strip time. Compare its flow numbers to others and you can be the judge on this one.

_______________________________________________________________

Dart Iron Eagle 180 174/210

This head is also a big brother but to the 165cc Dart Iron Eagle head. The 180cc head reveals a respectable intake flow curve and an outstanding exhaust port. This head comes in many different combinations. You can order the head with straight or angle plugs, a 64cc or 72cc chamber, and in iron or aluminum. You will notice this head has better mid lift intake flow figures but the same full lift numbers as the 165cc heads, however the exhaust side flows better.

This head is also a big brother but to the 165cc Dart Iron Eagle head. The 180cc head reveals a respectable intake flow curve and an outstanding exhaust port. This head comes in many different combinations. You can order the head with straight or angle plugs, a 64cc or 72cc chamber, and in iron or aluminum. You will notice this head has better mid lift intake flow figures but the same full lift numbers as the 165cc heads, however the exhaust side flows better.

_______________________________________________________________

Dart Iron Eagle 220 220/258

The Dart Iron Eagle head here offers a budget alternative to the aluminum Conquest head. With similar flow numbers the only real big difference here is iron verse aluminum and cost. This head is offered in 200 or 220cc intake ports and with 2.02 or 2.05-inch intake valves.

The Dart Iron Eagle head here offers a budget alternative to the aluminum Conquest head. With similar flow numbers the only real big difference here is iron verse aluminum and cost. This head is offered in 200 or 220cc intake ports and with 2.02 or 2.05-inch intake valves.

_______________________________________________________________

Dart Conquest Iron 220 220/252

This head really likes to flow at lifts above 0.500-inches. The E/I ratio at 0.400-inch is a very good 72% and 68% at 0.500-inches. This head comes machined for both center-bolt and perimeter-style valve covers. The Conquest can be optioned with 200 or 220cc intake ports, valves up to 2.08/1.60, and in 64 or 72cc chamber sizes.

This head really likes to flow at lifts above 0.500-inches. The E/I ratio at 0.400-inch is a very good 72% and 68% at 0.500-inches. This head comes machined for both center-bolt and perimeter-style valve covers. The Conquest can be optioned with 200 or 220cc intake ports, valves up to 2.08/1.60, and in 64 or 72cc chamber sizes.

_______________________________________________________________

Dart Pro 1 Aluminum 215 221/253

This is perhaps one of the most versatile heads out there. While the low lift numbers don’t stand out, the higher lift numbers are on par with the rest of the heads on the market. This head is definitely best on high winding motors where consistent rpm is what wins a race.

This is perhaps one of the most versatile heads out there. While the low lift numbers don’t stand out, the higher lift numbers are on par with the rest of the heads on the market. This head is definitely best on high winding motors where consistent rpm is what wins a race.

_______________________________________________________________

Dart Iron Eagle 230 229/254

This is the largest of the Dart Iron Eagle series heads. They perform best on motors above 400ci-inches and with cam lifts above 0.500-inches lift. The E/I ratio is acceptable and the castings are made of good quality. These heads flow well and do not really require too much handwork to improve airflow.

This is the largest of the Dart Iron Eagle series heads. They perform best on motors above 400ci-inches and with cam lifts above 0.500-inches lift. The E/I ratio is acceptable and the castings are made of good quality. These heads flow well and do not really require too much handwork to improve airflow.

_______________________________________________________________

Edelbrock Performer Aluminum 166/235

This head may first appear subtle in comparison to its flow numbers but don’t be fooled. The 166cc port makes for great torque and the E/I flow relationship is good. This head is perfect for a street/strip application. In our own personal experience we had a 355ci motor with 9:1 compression, a streetable Comp Cam (DEH 275), and an Edelbrock RPM manifold. With this combination we were able to achieve 420hp at 6,000rpm and 440 lb-ft of torque at 4,250 rpm.

This head may first appear subtle in comparison to its flow numbers but don’t be fooled. The 166cc port makes for great torque and the E/I flow relationship is good. This head is perfect for a street/strip application. In our own personal experience we had a 355ci motor with 9:1 compression, a streetable Comp Cam (DEH 275), and an Edelbrock RPM manifold. With this combination we were able to achieve 420hp at 6,000rpm and 440 lb-ft of torque at 4,250 rpm.

_______________________________________________________________

Edelbrock Performer RPM Aluminum 170/237

The Edelbrock RPM head is the big brother to the Performer version. It still retains a small 170cc intake port volume providing great torque down low where it’s needed. The E/I percentage is no less than 70% with much higher numbers in the low-lift areas. This head is a step up from the Performer, flowing more air, which in return will make more power on the top end.

The Edelbrock RPM head is the big brother to the Performer version. It still retains a small 170cc intake port volume providing great torque down low where it’s needed. The E/I percentage is no less than 70% with much higher numbers in the low-lift areas. This head is a step up from the Performer, flowing more air, which in return will make more power on the top end.

_______________________________________________________________

Edelbrock E-TEC 170 Vortec Aluminum 170/240

With the tremendous popularity of GM’s Vortec head, Edelbrock decided to design a head around the GM casting. This head features a 1.94/1.55-inch valve combination, and different port configuration allowing it to out perform the stock production Vortec head. However, the E-TEC heads are aluminum typically costing more than the production GM heads.

With the tremendous popularity of GM’s Vortec head, Edelbrock decided to design a head around the GM casting. This head features a 1.94/1.55-inch valve combination, and different port configuration allowing it to out perform the stock production Vortec head. However, the E-TEC heads are aluminum typically costing more than the production GM heads.

_______________________________________________________________

Edelbrock E-TEC Vortec 200/252

This head is the next step up from the smaller 170 E-TEC. It features larger valves and bigger intake ports. However, a Vortec style intake manifold must be matched with these heads. Up to 0.500-inches these heads don’t really out flow the stock Vortecs. On the other hand their exhaust ports are extremely efficient which help improve performance throughout the entire power curve. They are also aluminum, which can allow more compression with out detonation.

This head is the next step up from the smaller 170 E-TEC. It features larger valves and bigger intake ports. However, a Vortec style intake manifold must be matched with these heads. Up to 0.500-inches these heads don’t really out flow the stock Vortecs. On the other hand their exhaust ports are extremely efficient which help improve performance throughout the entire power curve. They are also aluminum, which can allow more compression with out detonation.

_______________________________________________________________

Edelbrock Victor Jr. Aluminum 219/255

This is an impressive head. It features a kidney shaped combustion chamber keeping the combustion moving, the flow is awesome from 0.400-inches all the way up to our tested 0.700-inches, and the E/I ratio is an amazing 81%. We see a head that flows some serious air and likes high lift roller cams.

This is an impressive head. It features a kidney shaped combustion chamber keeping the combustion moving, the flow is awesome from 0.400-inches all the way up to our tested 0.700-inches, and the E/I ratio is an amazing 81%. We see a head that flows some serious air and likes high lift roller cams.

_______________________________________________________________

Holley 300-570 Aluminum 172/232

This head from Holley comes with angled plugs and 69cc chambers, which are a big change from the stock 76cc smog chambers. The combustion chamber is typical of a late model design with a kidney shape that increases combustion turbulence lessening the possibility of detonation.

This head from Holley comes with angled plugs and 69cc chambers, which are a big change from the stock 76cc smog chambers. The combustion chamber is typical of a late model design with a kidney shape that increases combustion turbulence lessening the possibility of detonation.

_______________________________________________________________

Holley SysteMAX Aluminum 186/242

This head is very similar to the -8 Brodix but it appears to flow a little better on the exhaust side. Again this head looks like it offers great torque potential with its well-proportioned 186cc-intake runner

This head is very similar to the -8 Brodix but it appears to flow a little better on the exhaust side. Again this head looks like it offers great torque potential with its well-proportioned 186cc-intake runner

_______________________________________________________________

Pro Action Iron 220 225/239

These heads can be purchased in many different intake port sizes. They are available with 180, 200, 220, and 235cc intake ports. They also feature a 64cc and 72cc chamber for your desired compression levels.

These heads can be purchased in many different intake port sizes. They are available with 180, 200, 220, and 235cc intake ports. They also feature a 64cc and 72cc chamber for your desired compression levels.

_______________________________________________________________

Pro Action Iron 235 Iron 245/242

These are the largest of the Pro Action lineup. The heads are advertised as 235cc intake ports but in our testing we found them to be 245cc’s. These heads are definitely for use on big mouse motors that like to see some rpm.

These are the largest of the Pro Action lineup. The heads are advertised as 235cc intake ports but in our testing we found them to be 245cc’s. These heads are definitely for use on big mouse motors that like to see some rpm.

_______________________________________________________________

Trick Flow Specialties 195 195/250

These heads may not flow the biggest numbers but there should be little question regarding their performance that they can perform well. In CHP’s Nov. ’99 issue they were bolted on a mild 383ci motor and were able to pump up peak engine power by 15.5%. These heads offer some of the best power for the dollar on a mild small Chevy.

These heads may not flow the biggest numbers but there should be little question regarding their performance that they can perform well. In CHP’s Nov. ’99 issue they were bolted on a mild 383ci motor and were able to pump up peak engine power by 15.5%. These heads offer some of the best power for the dollar on a mild small Chevy.

_______________________________________________________________

TFS Twisted Wedge 200/254

In an attempt to be different for the better, this TSF twisted Wedge head changed the valve angles from 23 degrees to 13 degrees. The really big difference here is what the exhaust side of this head is capable of. Only one other head (AFR 210) was even close on the exhaust side. The E/I was also a very respectable 77%. This head really can wake up your engine.

In an attempt to be different for the better, this TSF twisted Wedge head changed the valve angles from 23 degrees to 13 degrees. The really big difference here is what the exhaust side of this head is capable of. Only one other head (AFR 210) was even close on the exhaust side. The E/I was also a very respectable 77%. This head really can wake up your engine.

_______________________________________________________________

World Products Iron S/R Torquer 170/225

This head is very similar to the 882 head tested earlier. The valves are larger and the flow numbers at 0.400-inch lift are almost identical. At 0.500-inch lift the flow is up 15% over the 882 head. With prices to rebuild stock heads increasing all the time these heads would probably be one of your better investments.

This head is very similar to the 882 head tested earlier. The valves are larger and the flow numbers at 0.400-inch lift are almost identical. At 0.500-inch lift the flow is up 15% over the 882 head. With prices to rebuild stock heads increasing all the time these heads would probably be one of your better investments.

DART HEADS

CHEVY 882 smogger heads

VORTEC HEADS

VORTEC HEADS

rhs heads

you might want to watch this 4 part video

http://www.summitracing.com/parts/drt-127422

one issue I see is the constant mental disconnect between the guys intended use when someone buys cylinder heads based on the posted flow numbers, and reality,

posted flow numbers and performance that results will vary significantly when you mis-match components especially when guys fail to realize the engine they are building has very few of the same components or dimensions matching the posted

“I see this problem constantly. If you read in the advertising that a certain cylinder head flows 300 cfm, on a SBC engine , very few people ask at what valve lift and what bore size and then, ask themselves if the engine they build will have much or anything in common. , if they used a 4.155 bore size to test the heads and your bore is less, like a 4.060 the resulting valve shrouding it can kill 30-50 hp because it leaves a ridge all the way around, the combustion chamber that was not there during the advertised flow test. People buy heads that were designed and tested on larger bore sizes or advertised in dyno test articles when an engine used a cam with much higher compression and a much more radical cam with a tighter LSA and more duration, and are stunned and disappointed to find they don,t get similar results using much less duration, lift and compression on a smaller displacement engine! The problem occurs because that valve size and cam lift and duration,must match the intended application, and that port is designed to flow X-amount in order to get the air speed in a certain range. So if your particular engines component list is nowhere close to the magazine articles configuration, you’ve not only killed the potential airflow, but you’ve killed the air speed and completely destroyed the advertised flow dynamics of the cylinder head you based the cylinder heads purchase on ,expecting the heads to flow as advertised.”

this works at both extremes, I see guys buy cylinder heads with much to small/restrictive ports who are convinced that a larger head will kill all the low rpm torque, only to find the heads strangle the upper rpm power,and guys that over cam an engine with too low of displacement and compression, and who fail to install effective headers and a low restriction exhaust behind the headers, who then erroneously blame the cylinder head port size for the lack of power that results.

you should read the links they contain a wealth of info

USE THE CALCULATORS to match port size to intended rpm levels... but keep in mind valve lift and port flow limitations[/color]

http://www.wallaceracing.com/runnertorquecalc.php

http://www.wallaceracing.com/ca-calc.php

http://www.wallaceracing.com/area-under-curve.php

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

http://www.profilerperformance.com/raci ... -23-degree

http://www.strokerengine.com/SBCHeadsFlow.html

http://www.superchevy.com/how-to/engines-drivetrain/sucp-0803-performance-cylinder-head-comparison/

http://www.hotrod.com/how-to/engine/ccrp-1209-eight-budget-sbc-head-shootout/

http://www.purplesagetradingpost.com/sumner/techinfo/heads1.html

http://www.enginebuildermag.com/2010/01/street-performance-cylinder-heads/

http://www.chevydiy.com/the-complete-cylinder-head-guide-for-chevy-small-block-engines/

http://www.hotrod.com/how-to/engine/ccrp-1209-eight-budget-sbc-head-shootout/

http://www.hotrod.com/how-to/engine/hrdp-0609-500hp-small-block-chevy-build/

http://www.summitracing.com/search/...Default&SortOrder=Ascending&autoview=SKU&ar=1

http://garage.grumpysperformance.co...-calculators-and-basic-math.10705/#post-46582

http://www.hotrod.com/articles/ccrp-1209-eight-budget-sbc-head-shootout/

http://www.superchevy.com/how-to/engines-drivetrain/sucp-0705-budget-chevy-cylinder-heads/

https://www.high-performance-engines.com/cylinder-heads-s/173.htm

http://users.erols.com/srweiss/tablehdc ... _Big_Block

http://www.superchevy.com/how-to/engines-drivetrain/sucp-0803-performance-cylinder-head-comparison/

http://www.superchevy.com/how-to/engines-drivetrain/sucp-0705-budget-chevy-cylinder-heads/

http://www.wallaceracing.com/area-under-curve.php

A VIDEO DART VS 882 chevy heads TO WATCH

http://www.youtube.com/watch?annotation ... v3ZkqZiMjI

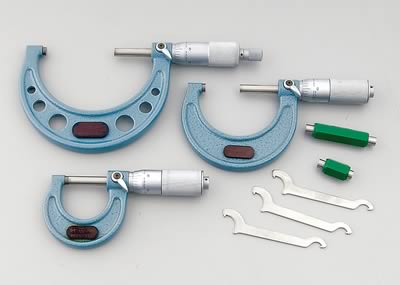

measuring throat cross sectional area

http://www.superchevy.com/how-to/project-cars/sucp-1208-big-block-heads-shootout-the-o-vs-r/

http://racingfeed.com/downloads/chevy_flow_data.pdf

http://www.profilerperformance.com/sbc-heads-176.html

http://www.airflowresearch.com/articles ... 5/A-P1.htm

http://www.airflowresearch.com/articles ... /A6-P1.htm

http://www.brodix.com/heads/compression.html

http://www.airflowresearch.com/chp_test.php

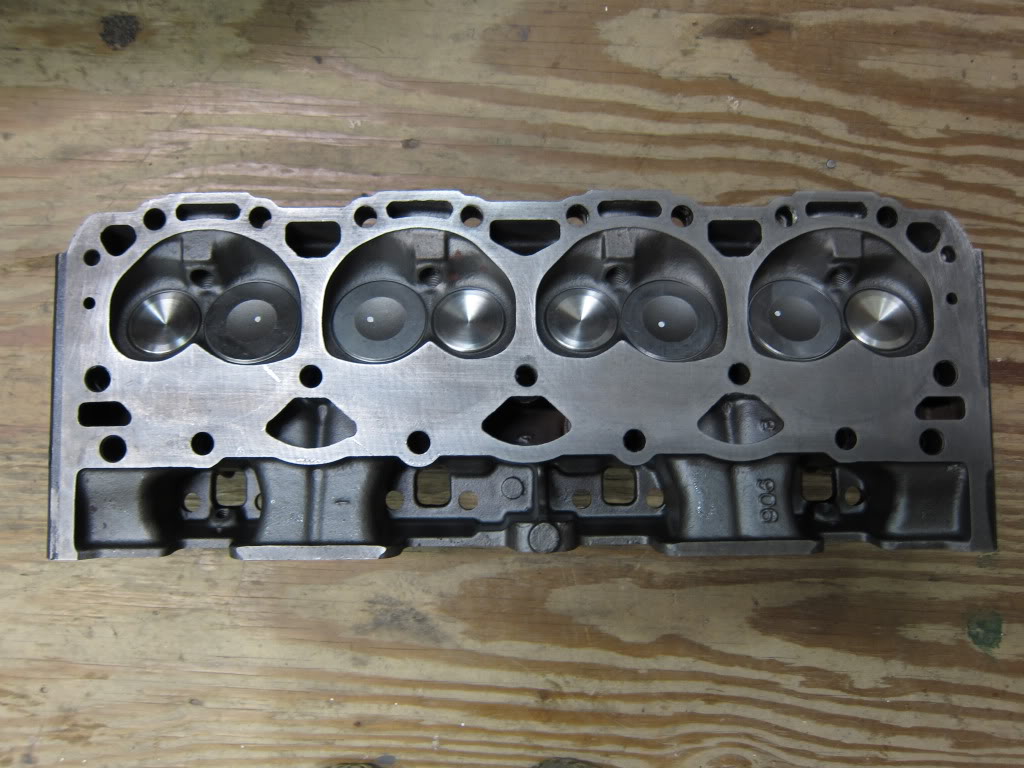

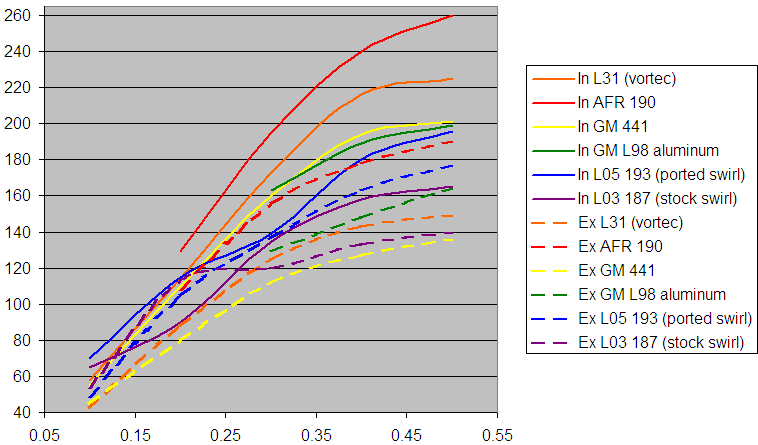

as you can see in this chart, below most of the stock heads don,t flow as well as the AFR 195cc heads and there ARE better flowing heads, but keep in mind the stock heads were never designed as race components, in most cases the engineers were more concerned with cost and low and mid range speed & torque.

A cylinder head that might be perfectly adequate for the current application may be woefully restrictive if used on a similar engine if you should choose to swap cams or swap to a well designed exhaust header, change intakes or drive train gearing, so its usually best to hedge your bet a bit on the cylinder heads selected and purchase a cylinder head that has at least some potential to flow at higher valve lifts and higher engine rpm limitations than the current combo may have.

yes we all deal with budget limitations, so you generally can,t just look for the cylinder heads with the very best flow numbers, and in most cases that would be a far from cost effective route to take. but I would suggest shopping around very carefully before spending your cash.

there's

a good deal more info posted below so its worth the time to keep reading

USE THE CALCULATORS to match port size to intended rpm levels... but keep in mind valve lift and port flow limitations[/color]

http://www.wallaceracing.com/runnertorquecalc.php

http://www.wallaceracing.com/ca-calc.php

http://www.wallaceracing.com/area-under-curve.php

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

I thought I post these flow numbers on ported vortec heads ive seen posted , just in case anyone has ever wondered or wanted to know the flow numbers a set of stock vortecs. I was also curious if any of you have any guesses on what gains I picked up on the port work.

INTAKE LIFT------- STOCK---- PORTED-- GAIN

.1---------- 59--------- 64--------- +5

.2---------- 117------- 132------- +15

.3---------- 170------- 187------- +17

.4---------- 214------- 236------- +22

.5---------- 226------- 255------- +29

.6---------- 219------- 259------- +40

EXHAUST

LIFT STOCK PORTED GAIN

.1---------- 42----------46--------- +4

.2---------- 83----------90--------- +7

.3---------- 123--------139--------+16

.4---------- 136--------161--------+25

.5---------- 143--------174--------+31

.6-----------147------- 178--------+31

http://www.circletrack.com/enginetech/c ... index.html

http://www.enginebuildermag.com/Article ... tions.aspx

http://www.trickflow.com/media/pdfs/buy ... e_2009.pdf

bbc oval ports making 697hp

http://www.popularhotrodding.com/tech/0 ... /dyno.html

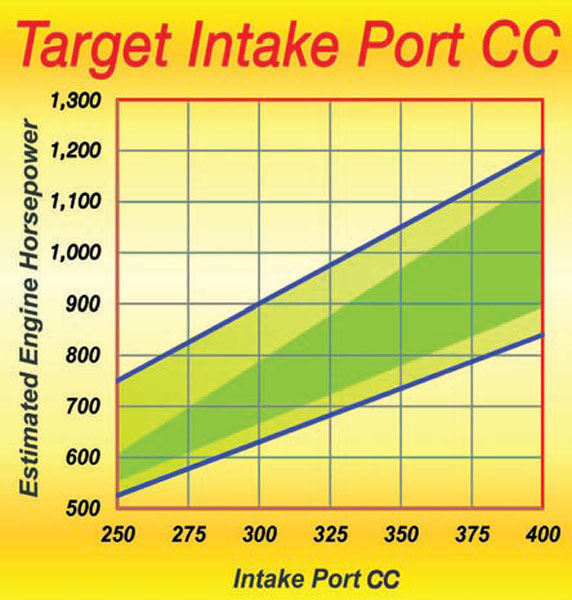

heres some guides but keep in mind its NOT the port volume or PORT CCs of total port volume your concerned with, its the port cross sectional area, at its narrow point, you cam timing, compression and displacement, combined with the cars gearing, intake design and exhaust scavenging combined that makes the port size you select work

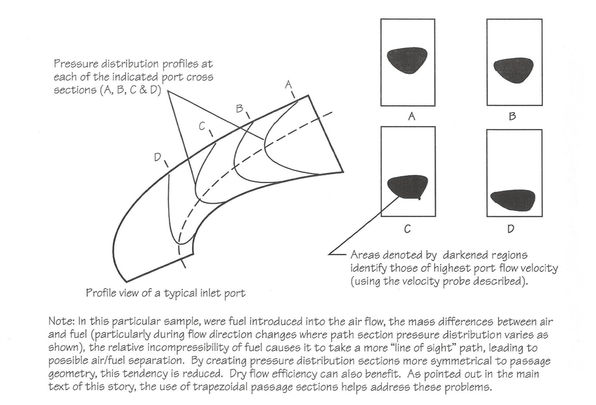

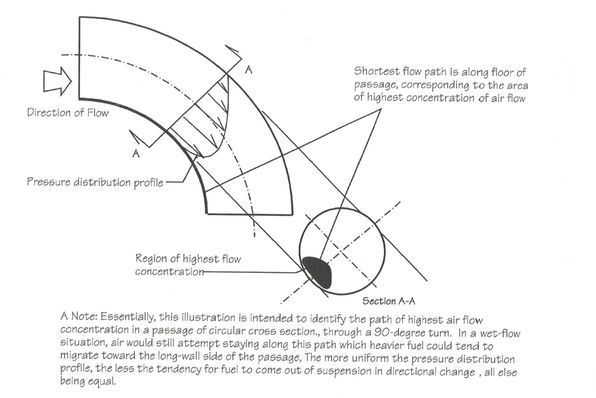

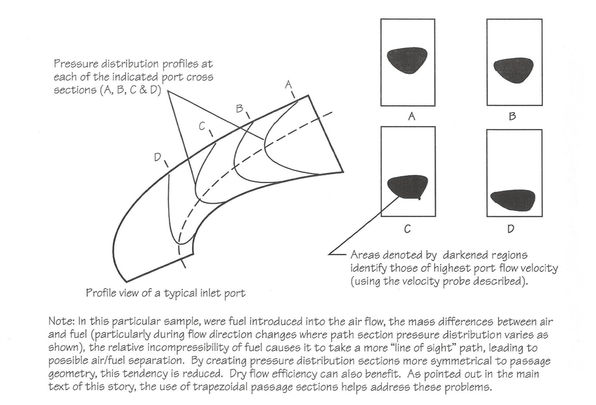

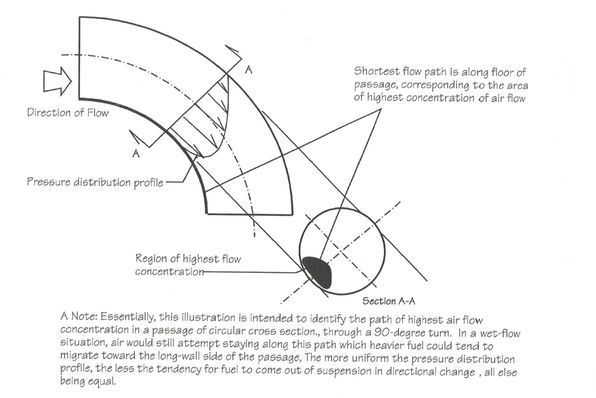

it does absolutely no good to place a cylinder head with with a port cross sectional area thats larger than the intake port that feeds it, in a combo as all the abrupt increase in port cross section does is cause increased turbulence, and a sudden loss of port air flow speed and that tends to cause fuel to drop out of the airflow or at least disrupt is even distribution

in an ideal world ports reduce cross sectional area bye about 3%-5% from entrance to the valve pocket, and the port cross section in the heads a bit smaller than the intake runner.

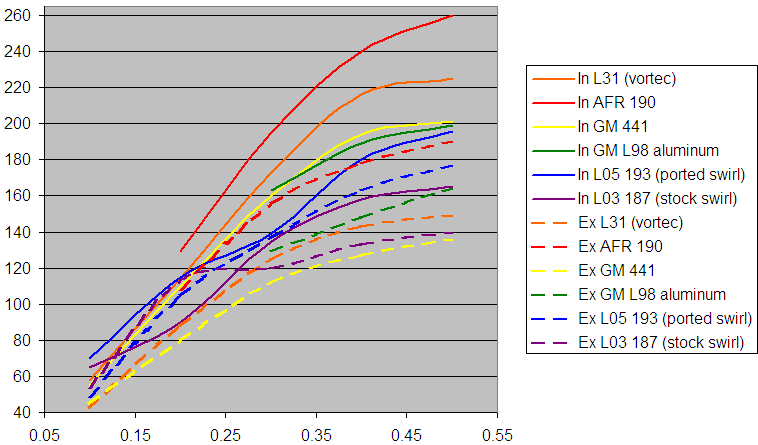

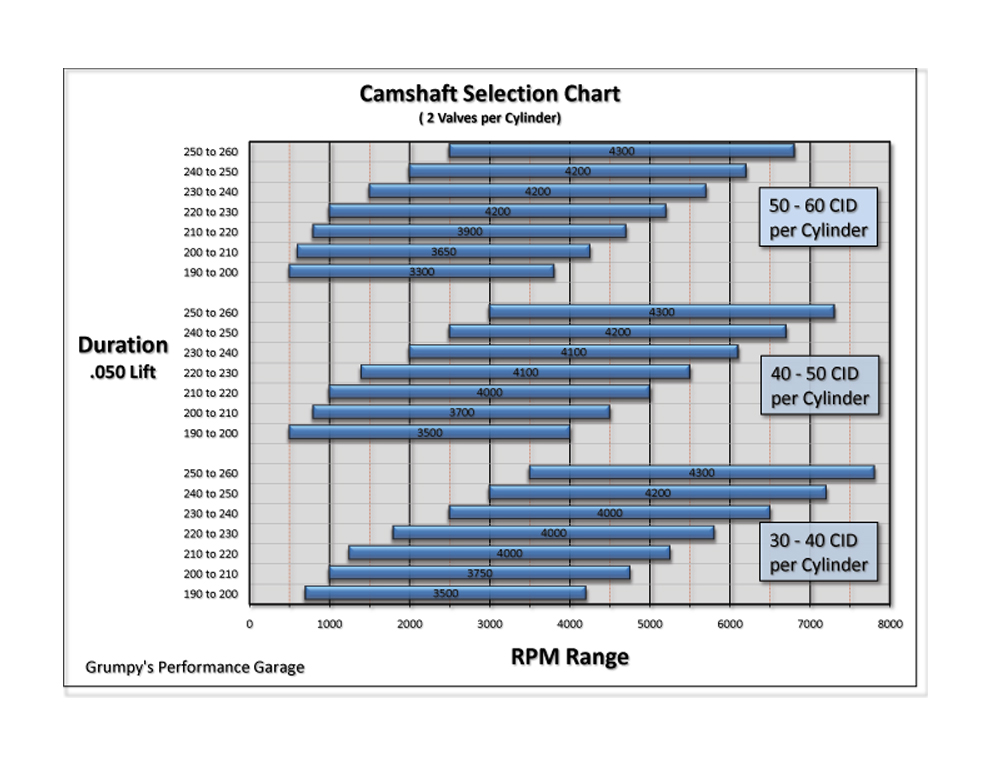

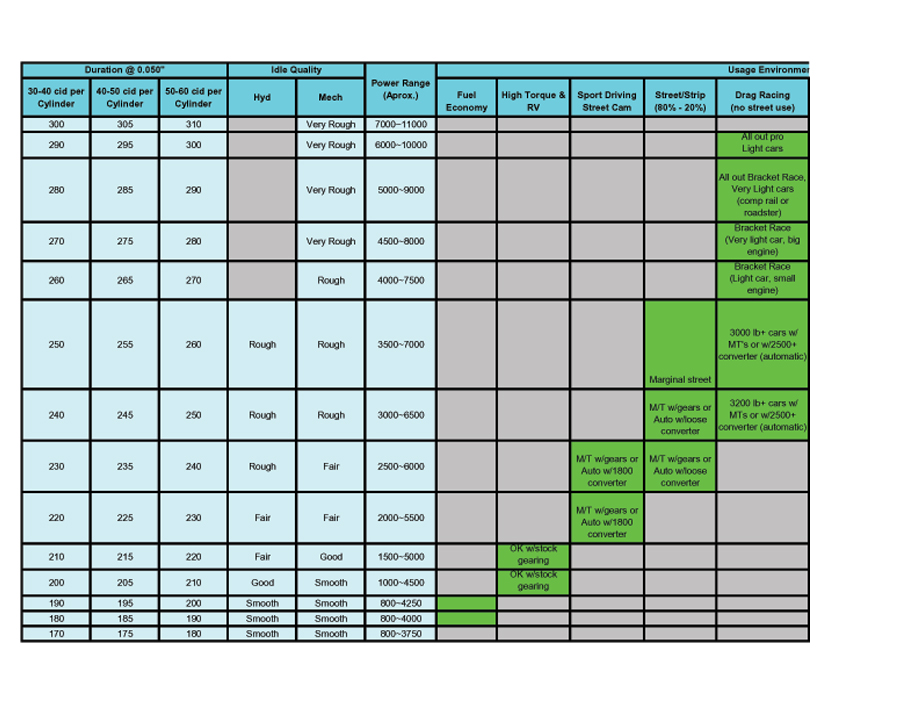

cams need to be selected with the engines intended rpm range and power band and the displacement of the engine, plus the engines compression ratio and drive train gearing taken into account, any increase in port cross sectional area above whats required to fill the cylinders in the intended power band tends to reduce efficiency.

AS your displacement per cylinder increases the effective valve size per cubic inch decreases so you need a slightly tighter LSA and these charts should help.

![[IMG] [IMG]](/proxy.php?image=https%3A%2F%2Fweb.archive.org%2Fweb%2F20151003032704%2Fhttp%3A%2F%2Fwww.grumpysperformance.com%2Frtyu1.jpg&hash=db61ac97d255ff55bbaed3c81acd7f6a)

![[IMG] [IMG]](/proxy.php?image=https%3A%2F%2Fweb.archive.org%2Fweb%2F20151003032704%2Fhttp%3A%2F%2Fwww.grumpysperformance.com%2Frtyu2.jpg&hash=4d2c8c0474643b616f25ed67c5d9071d)

so any time you want to stop guessing at the answers, or taking your Buddy,s best guess as a fact, you can use known values & calculations to arrive at valid answers and actually match components

http://garage.grumpysperformance.co...ch-quest-series-similar-350-383-sbc-info.519/

http://garage.grumpysperformance.com/index.php?threads/tbucket-engine-project-dart-shp.3814/

http://garage.grumpysperformance.com/index.php?threads/sellecting-cylinder-heads.796/

http://garage.grumpysperformance.com/index.php?threads/what-to-look-for-in-a-good-engine-combo.9930/

http://garage.grumpysperformance.com/index.php?threads/my-1st-street-383-build.6962/

http://garage.grumpysperformance.co...383-build-that-is-now-going-to-be-a-400.7804/

http://www.brodix.com/media/images/page_2.jpg

https://garage.grumpysperformance.c...t-angles-and-air-flow.8460/page-2#post-110196

http://www.corvetteflorida.com/forums/s ... hp?t=17250

http://www.rehermorrison.com/techtalk/06.htm

http://www.gmhightechperformance.com/te ... index.html

http://www.gofastnews.com/board/technic ... lumes.html

one factor that gets discussed a great deal is the difference in port size or port CCs, the sad truth is that Id bet 90% of the discussions are just guys repeating stuff they have heard with zero real idea what they are talking about.

while theres generally some relation of port cross sectional area to the listed port CCs its NOT a direct linear relationship, and its the cross sectional area,shape, length and surface finish not the port CCs that matter to the air flow., and if the exhaust system can,t effectively scavenge the cylinders or the intake can,t supply the flow, or the cam duration and lift don,t match the intended port flow rates performance will suffer

While theres no direct linear relationship between port flow and hp there is a strong relationship.So you'll generally want the highest flow numbers you can get in any port size ranges as a starting point, and yes theres other factors that go into making hp, so combustion chamber design,compression, cam timing, cylinder scavenging ETC. will effect results.you might want to keep in mind that carbs are flow rated at 1.5 inches of mercury, heads at 28" of water and that anyone who has ever watched a vacuum gauge, will tell you the readings fluctuate rapidly, under most conditions and vacuum tends to vary with the cam,used the rpms the engines running, displacement and intake design,exhaust scavenging,ETC.

in most cases there factors are at least, mostly or on occasion, partly understood well enough that theres formulas and charts that can be used to define probable results, that parts selection will result in to a reasonable degree.

you don,t build an engine combo by selecting just heads, first and then matching the other components to that head flow rates, you select a hp/torque/rpm power band as a goal and then select the necessary components to slightly exceed that hp/torque/rpm power bands requirements knowing all parts NEVER work at 100% of the potential when matched in a combo.

the ballpark formula is

.257 x port flow x 8 = potential hp

watch the video, and like I stated many times,

its the combo of the engines,

compression,

displacement ,

cam timing

and the exhaust scavenging ,

and the intake manifold design,

NOT the intake port cross sectional area,

that are the most critical factors, in the engines lower rpm and mid rpm torque.

but for damn sure an intake runner port can be small enough to noticeably restrict upper mid range and peak power significantly,

For 5 decades I've heard endlessly about how installing larger free flowing cylinder heads would devastate the engines ability to make any low or mid rpm torque.

especially when Id suggest using a set of smaller 300cc-320cc, aluminum,rectangle port heads on a 496 BBC, or 200 cc-210cc heads on a 406 sbc, I was asked to build

yet on every engine I've ever had built or had some guy ask me to look at, to see why it ran a great deal less impressively than he expected it too,

they brought into my shop its was very obvious (at least to me) that it was the combo of low compression, too little displacement, with too much cam duration ,

a restrictive exhaust or some guy who was trying to save money and continuing to use a stock stall speed torque converter, or retain a badly mis-matched 2.87:1-3.08:1 rear gear ratio,

with an engine that he miss matched components by slapping a large carburetor , and a single plane intake on,an engine that will rarely exceed 6000 rpm, that was the major reason.

if you want an engine combo to run your first step is to logically match the list of components you,ll use to the application,

and that requires you stop, engage the brain and think things through carefully,

and the most common way to screw up the process is to over cam a low compression engine,

have a restrictive exhaust or mis-match the drive train gearing to the engines power band.

EXAMPLE

if your intake port flows 250cfm

.257 x 250 x 8 = yields APPROXIMATELY a 514hp figure before your heads become the limiting factor

this ballpark formula is based on average results FROM WELL TUNED HOT ROD TYPE Engine's USING DYNO FLYWHEEL RESULTS

NOT true race only engines or street engines

also keep in mind that the results you'll get will differ and to get those numbers it requires the engine to operate in its best rpm range with a cam and compression levels that match and all other components must also match

if your heads flow 279 cfm at .700 lift but your intake only flows 240cfm and your cam has a max lift of .550 your not going to get the max potential HP results

for the ball park formula to work you must have a tuned exhaust, a cam that matches the compression ratio and all other parts must flow at least close to as well as the heads at the max figures

also keep in mind that the ports cross sectional area should keep the airflow in those ports in approximately the 200fps-300fps ranges

airflow speeds that very greatly from that 200fps-300fps will not tend to give best results, that's why huge ports that flow exceptionally well don,t work well on smaller displacement engines

port length also has a large effect on the rpm range that the ports can effectively pack the cylinders at due to harmonics in the column of air

PORT SIZE FLOW AND THE RELATION TO CAM DURATION, and your displacement and the tuned rpm that your headers operate best in for scavenging the cylinders also comes into play here!

FIRST, This will not be anything more that a brief glimpse into a subject that takes years to understand and I’m sure there are a few people on the site that can give more exact info! This is meant to apply to the 350-383 sbc engines most of us are using

My purpose is merely to give an idea as to the relationship between the factors and yes IM ignoring several minor factors to make things easier to understand

But lets look a a few concepts

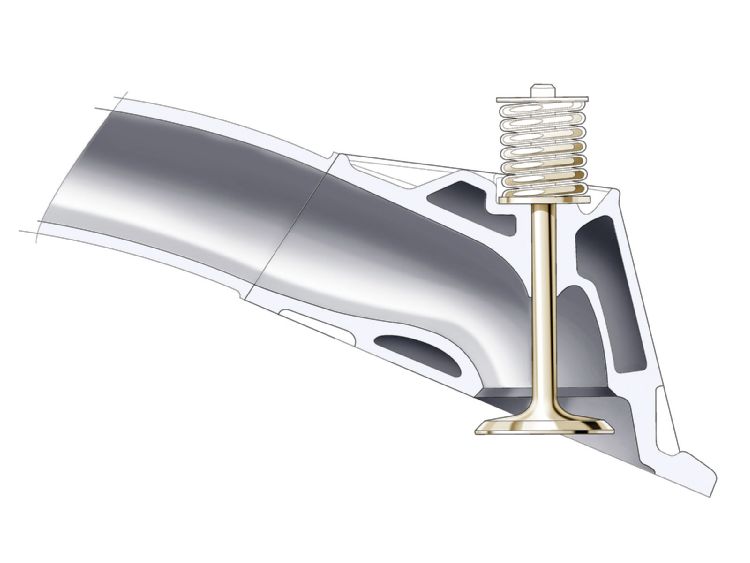

(1) There are 720 degrees in a 4 cycle engines repetitive cycle of which between about 200degrees to about 250 degrees actually allow air to pass into the cylinder, (the valves open far enough to flow meaningful air flow) and the piston has a maximum ability to draw air into that cylinder based mostly on the engines displacement and the inertia of column of air in both the intake port and the suction (or negative pressure the PROPERLY designed headers provide) this produced a max air flow thru the ports, the greater the volume of fuel/air mix effectively burn per power stroke the greater the engines potential torque production, the faster you spin an engine the greater the NUMBER OF POWER STROKES PER MINUTE, and up to the point where the cylinder filling effectiveness starts falling off due to not enough time available to fill that cylinder the torque increases, above that rpm or peak torque it’s a race between more power stokes and lower power per stroke

As air enters an engine it normally travels thru both an intake system and the cylinder heads intake port to eventually pass into the cylinder thru the valve. The valves in a normal small block corvette engine are between 1.94 and 2.08 in diameter, that’s between 2.9sq inches and 3.4 sq inches of area, but because the valves require a seat that at a minimum are about 85%-90% of that flow area we find that the intake port even with out any valve has a max flow of not more than about 90% of the flow thru a port of valve size. Or in this case 2.46 sq inches-2.9 sq inches of port area, Since you gain little if any flow having a port that’s substantially larger than the valves AT NORMAL ATMOSPHERIC pressures and since you can’t substantially increase the valve sizes for several mechanical reasons you must improve efficiency, this is done in two major ways, you can match the intake port length and cross sectional area to the engines most efficient rpm range on the intake side, to build a positive pressure behind the intake valve as it opens and match the exhaust length and diameter on the exhaust side to provide a negative pressure to help draw in more volume this will require the cam timing match that same rpm range of course. By experimentation its been found that air flow port speeds in the 200-320 cubic feet per minute range are about the best for a chevy V-8 now lets say you have a 383. 383/8=47.875 cubic inches per cylinder, the rpm range most used is 1500rpm-6000rpm so that’s where are cam and port size must match, you can do the math , (47.875 x ½ engine rpms = cubic inches, divided by your cams effective flow duration, (use 210-235) as a default for a stock cam) x 720 degrees/1728 (the number of cubic inches in a cubic foot) to get the theoretical max port flow required (I will save you the trouble its 250cfm-275cfm at max rpms and about 2.4-2.9 sq inches of port cross section, depending on where you want the torque peak, or use this handy calculator,

Intake Runner Area = Cylinder Volume X Peak Torque RPM 88200

Or this helpful info in this thread

very important calculator info

Either way you’ll find that you’ll want a port size in the 2.4sq –2.9 sq inch area

Now use this calculator to figure ideal port length, REMEMBER you'll need to add the 6†in the cylinder head to the intake runner length to get the total length and you can,t exceed the engines REDLINE RPM which with hydraulic lifters seldom is higher than 6400rpm

http://www.bgsoflex.com/intakeln.html

Ever wonder why your engines torque curve gets higher with the engines rpm level until about 4000rpm-5500rpm(DEPENDING ON YOUR COMBO) but fades above that rpm level?

well it depends on several factors, first as long as the cylinders can fill completely you get a good fuel/air burn so you get a good cylinder pressure curve against the piston each time the cylinder fires, THE ENGINES TORQUE CURVE INCREASES WITH THE NUMBER OF EFFECTIVE POWER STROKES PER SECOND, at very low speeds there’s not enough air velocity to mix the fuel correctly or produce a effective ram tuning effect but as the rpms increase the cylinders fill very efficiently until the rpms reach a point where the cylinders just don’t have the time necessary to flow

enough air through the valves to fill the cylinders , remember a 5000rpm the intake valve out of 720 degs. in each cycle opens for about 250degs of effective flow even with a hot roller cam, now that’s only about 35% of the time and there’s 41.6 intake strokes per second , that’s only 1/60th of a second for air to flow into the cylinder

Its your engines ability to fill the cylinders that increases your power and the more efficiently you do that the higher the rpm level you can accomplish that at the more power your engine makes, remember the formula for hp is (torque x rpm/ 5252=hp) so moving the torque curve higher in the rpm range increases hp but at some point the time available to fill the cylinders becomes so short that efficiency begins to drop off rapidly, the peak of efficiency is reached normally in the 4500rpm-5500rpm range, and as rpms increase its a race between more power strokes per minute trying to raise the power and the increasingly less effective percentage of cylinder filling dropping the power.

Volumetric Efficiency

The volumetric efficiency of a 4-stroke engine is the relationship between the quantity of intake air and the piston displacement. In other words, volumetric efficiency is the ratio between the charge that actually enters the cylinder and the amount that could enter under ideal conditions. Piston displacement is used since it is difficult to measure the amount of charge that would enter the cylinder under ideal conditions. An engine would have 100% volumetric efficiency if, at atmospheric pressure and normal temperature, an amount of air exactly equal to piston displacement could be drawn into the cylinder. This is not possible, except by supercharging, because the passages through which the air must flow offer a resistance, the force pushing the air into the cylinder is only atmospheric, and the air absorbs heat during the process. so, volumetric efficiency is determined by measuring (with an orifice or venturi type meter) the amount of air taken in by the engine, converting the amount to volume, and comparing this volume to the piston displacement.

this increases until the torque peak then falls as the rpms increase. Here is a rough guide to match duration to port flow at different rpm level

if you’ve been following along you’ll find that you’ll need intake ports about 2.3-2.9†sq inches in cross section, and between 12†and 21 “ long (DEPENDS ON WHERE THE ENGINE IS DESIGNED TO MAKE MAX HP) and cam timing in the 215@.050 to -240@.050 lift range, as the rpms or displacement increase either the port flow or the cams duration must increase or the engines cylinder fill efficiency rpm will drop!

Now this is important, as the port flow efficiency goes up though the use of longer and larger intake ports the cam duration could remain the same or even be lower and you get more efficient cylinder filling as the rpms increase, that’s why high efficiency port designs like on the LS1 can use lower duration cams to flow similar total air flow thru the ports than the lower efficiency ports like the old fuelie heads could but at some point all ports reach max flow and an increase in the time the valves remain open at higher rpms increases the cylinder fill efficiency and that increases the engines ability to make torque at that rpm range

http://garage.grumpysperformance.co...ers-and-yeah-thinking-it-through-helps.15137/

the basic rule is a dual plane intake will almost always be the better choice over a single plane intake if the cam duration is under about 235 degrees@.050 lift

Ive built 383,396,421 and 427 SBC combos and used both the 195cc and 210cc AFR, brodix 180,200cc , trickflow, 195, 215 and dart 200cc,-230cc heads,and Ive used the 750cfm and 850cfm carbs.

ok theres very little gained with swap between the 750/850 cfm carbs in either direction, both are almost interchangeable with the correct tuning in my opinion, but ID prefer the 750cfm about 90% of the time, as its slightly crisper in the throttle response and Id doubt youll give up 3 hp at peak with the small rated carb

the 195cc class heads produce slightly more low rpm torque, the 210-230cc slightly more peak hp,in a combo thats set up correctly to take full advantage of either heads characteristics, again the difference is more in the intake, cam, compression and exhaust tuning, but given a choice id select the 210cc heads about 75% of the time if the peak hp was the goal and the 195cc on a car used mostly on the street, as a general rule if I use a single plane intake, and a cam with about 240 plus duration,and 10.2:1 or higher compression, I tend to select the 210-230cc heads, on a dual plane intake , with a cam having under 240 duration,and 10.1:1 or lower compression, Id select the 195-200cc class heads

keep in mind its that total combo with the rear gearing, exhaust and transmission gearing, car weight, tire diam. fuel octane etc. taken into the calculations that matters not a single component

IF YOU HAVE A SET OF REALLY DEEP POCKETS

http://www.speierracingheads.com/SRH2.50.htm

read these threads and sub-links also, as they contain good info, if you fail to read thru the sub links youll miss a ton of useful info, don,t think published flow numbers or price alone are the only really useful factors to use, remember a flow bench has very little in common with a running engine

keep in mind that a properly designed exhaust system and headers goes a very long way towards increasing the efficiency of the intake manifold and head flow , and remember that the better the heads and the more effective the exhaust scavenging the less duration the cam used will require!

Cheap Good Cylinder Heads

Where do you find good and cheap cylinder heads? A set of these for $280 + valves + springs, reuse old rocker arms = $400 https://www.ebay.com/itm/393005918509 https://www.ebay.com/itm/322892146731 https://garage.grumpysperformance.com/index.php?threads/sellecting-cylinder-heads.796/page-2 Buy...

garage.grumpysperformance.com

before as cast

after port clean up intake

before as cast

after port clean up exhaust

most stock and some aftermarket heads benefit from port and bowl clean up work,to smooth and increase flow rates ,port throats generally run 80%-85% of total valve diameter because you need to maintain sufficient valve seat contact area to allow sealing and cooling and some wear during operation.

But be aware that using stock refurbished heads , can cost a good deal more than new heads will,because its very likely that by the time you hot tank or oven and shot-blast clean them

, have them dye or magnetically checked for cracks and pressure and have, a clean-up decking,pass on the milling machine,insert new valve guide inserts, select and install bigger valves , and that requires new valve seats with a good multi angle valve job, pay for and install the correct matched springs, keepers, and retainers,that came with the new cam, if you bought the matching components instead of trying to keep cost low and use the O.E.M. valve springs which are unlikely to match the application, you might be better off to buy new cylinder heads??

PORT MATCHING THE INTAKE RUNNER EXIT TO THE CYLINDER HEAD PORT ENTRANCE USUALLY HELPS REDUCE RESTRICTIONS TO FLOW RATES, AND REDUCES FUEL/AIR DISTRIBUTION ISSUES

a very common misconception, "that the intake runner size has the most effect on the engines torque curve,is mostly a myth" in reality ,compression ratio, cam timing and engine displacement and proper exhaust scavenging ALL have a larger effect on the engines torque that the intake runner cross sectional area.(yes getting it correct helps but your more likely to cause a problem by selecting an intake port and runner combo thats too small and restrictive than one thats too large in cross sectional area.

heres a chart FROM THE BOOK,HOW TO BUILD BIG-INCH CHEVY SMALL BLOCKS with some common

http://garage.grumpysperformance.com/index.php?threads/the-new-215cc-vortec-heads.266/#post-75012

FUELIE HEADS

Some of the More Popular Gen I Cast Iron GM Cylinder Heads

http://www.onedirt.com/tech-stories/engine/a-guide-to-vortec-vs-oe-small-block-chevy-heads/

http://users.erols.com/srweiss/tablehdc.htm

#3767754 – Manufactured from 1959-1961 on 283 Cubic Inch engines. Called the “Power Pack” cylinder heads. 1.72˝ intake valves and 1.50˝ exhaust valves. 60cc Combustion Chambers.

#3774692 – Manufactured from 1958-1964 on 283 Cubic Inch engines. Called the “Power Pack” cylinder heads. 1.72˝ intake valves and 1.50˝ exhaust valves. 60cc Combustion Chambers.

#3795896 – Manufactured from 1963-1965 on 283 Cubic Inch engines. Called the “Power Pack” cylinder heads. 1.72˝ intake valves and 1.50˝ exhaust valves. 60cc Combustion Chambers.

#3782461 – Manufactured from 1964-1966 on 327 Cubic Inch engines. 161/62 cc port volumes, 62cc combustion chamber. Identified by Double Camel hump symbol.

#3782461X – Manufactured from 1960-1963 on 283 and 327 Cubic Inch engines. 172/64 cc port volumes, 62cc combustion chamber. Identified by Double Camel hump symbol.

#3890462 – Manufactured from 1966-1967 on 302, 327, and 350 Cubic Inch engines. 64cc combustion chamber. Identified by Camel hump symbol. No accessory mounting holes.

#3917291 – Manufactured from 1967-1968 on 302, 327, and 350 Cubic Inch engines. 64cc combustion chamber. Identified by Camel hump symbol.

#3932441 – Manufactured from 1969-1970 on 350 Cubic Inch engines. 161-165cc intake port. 76cc combustion chamber.

#3932441X – Manufactured from 1969-1970 on 350 and 400 Cubic Inch engines. 161/65cc ports. 80cc combustion chamber. 1.94″ intake/1.5″ exhaust valves.

#333881 – Manufactured from 1974-1975 on 350 Cubic Inch engines. 76cc combustion chamber. 2.02″ intake/1.6″ Exhaust valves.

#3991492 – Manufactured from 1970 on 350 Cubic Inch engines. Available on the LT1 engine and over the counter. 64cc combustion chamber. Either straight or angled plugs.

http://www.strokerengine.com/SBCHeadsFlow.html

_______________________________________________________________

Intake Port cc & CFM @. 500" Lift

Chevrolet Production 441 Iron Head 155/201

_______________________________________________________________

Chevrolet Production Iron 882 Head 151/205

_______________________________________________________________

Chevrolet Production 462 Iron Head 156/212

_______________________________________________________________

Chevrolet Production Vortec Iron Head 885 170/239

_______________________________________________________________

Chevrolet Production L98 TPI Aluminum Head 163/196

_______________________________________________________________

Chevrolet Production GM LT1 372 Aluminum Head 170/214

_______________________________________________________________

Chevrolet Production LT4 Aluminum Head 195/250

_______________________________________________________________

Chevrolet LS1 Aluminum Head 204/240

_______________________________________________________________

AirFlow Research 180 Aluminum Head 181/250

_______________________________________________________________

AirFlow Research 190 Aluminum Head 191/262

_______________________________________________________________

AirFlow Research 210 Aluminum Head 215/271

_______________________________________________________________

Brodix-8 Pro Aluminum 181/254

_______________________________________________________________

Brodix Track 1 Aluminum Head 216/246

_______________________________________________________________

Brodix -11X 220 Aluminum Head 216/246

_______________________________________________________________

Brodix -1X Aluminum Head 223/278

_______________________________________________________________

Canfield Aluminum Head 195/258

_______________________________________________________________

Canfield 220 Aluminum Head 223/260

_______________________________________________________________

Dart Iron Eagle S/S 165/210

_______________________________________________________________

Dart Iron Eagle 180 174/210

_______________________________________________________________

Dart Iron Eagle 220 220/258

_______________________________________________________________

Dart Conquest Iron 220 220/252

_______________________________________________________________

Dart Pro 1 Aluminum 215 221/253

_______________________________________________________________

Dart Iron Eagle 230 229/254

_______________________________________________________________

Edelbrock Performer Aluminum 166/235

_______________________________________________________________

Edelbrock Performer RPM Aluminum 170/237

_______________________________________________________________

Edelbrock E-TEC 170 Vortec Aluminum 170/240

_______________________________________________________________

Edelbrock E-TEC Vortec 200/252

_______________________________________________________________

Edelbrock Victor Jr. Aluminum 219/255

_______________________________________________________________

Holley 300-570 Aluminum 172/232

_______________________________________________________________

Holley SysteMAX Aluminum 186/242

_______________________________________________________________

Pro Action Iron 220 225/239

_______________________________________________________________

Pro Action Iron 235 Iron 245/242

_______________________________________________________________

Trick Flow Specialties 195 195/250

_______________________________________________________________

TFS Twisted Wedge 200/254

_______________________________________________________________

World Products Iron S/R Torquer 170/225

DART HEADS

CHEVY 882 smogger heads

rhs heads

you might want to watch this 4 part video

http://www.summitracing.com/parts/drt-127422

one issue I see is the constant mental disconnect between the guys intended use when someone buys cylinder heads based on the posted flow numbers, and reality,

posted flow numbers and performance that results will vary significantly when you mis-match components especially when guys fail to realize the engine they are building has very few of the same components or dimensions matching the posted

“I see this problem constantly. If you read in the advertising that a certain cylinder head flows 300 cfm, on a SBC engine , very few people ask at what valve lift and what bore size and then, ask themselves if the engine they build will have much or anything in common. , if they used a 4.155 bore size to test the heads and your bore is less, like a 4.060 the resulting valve shrouding it can kill 30-50 hp because it leaves a ridge all the way around, the combustion chamber that was not there during the advertised flow test. People buy heads that were designed and tested on larger bore sizes or advertised in dyno test articles when an engine used a cam with much higher compression and a much more radical cam with a tighter LSA and more duration, and are stunned and disappointed to find they don,t get similar results using much less duration, lift and compression on a smaller displacement engine! The problem occurs because that valve size and cam lift and duration,must match the intended application, and that port is designed to flow X-amount in order to get the air speed in a certain range. So if your particular engines component list is nowhere close to the magazine articles configuration, you’ve not only killed the potential airflow, but you’ve killed the air speed and completely destroyed the advertised flow dynamics of the cylinder head you based the cylinder heads purchase on ,expecting the heads to flow as advertised.”

this works at both extremes, I see guys buy cylinder heads with much to small/restrictive ports who are convinced that a larger head will kill all the low rpm torque, only to find the heads strangle the upper rpm power,and guys that over cam an engine with too low of displacement and compression, and who fail to install effective headers and a low restriction exhaust behind the headers, who then erroneously blame the cylinder head port size for the lack of power that results.

you should read the links they contain a wealth of info

USE THE CALCULATORS to match port size to intended rpm levels... but keep in mind valve lift and port flow limitations[/color]

http://www.wallaceracing.com/runnertorquecalc.php

http://www.wallaceracing.com/ca-calc.php

http://www.wallaceracing.com/area-under-curve.php

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

http://www.profilerperformance.com/raci ... -23-degree

http://www.strokerengine.com/SBCHeadsFlow.html

http://www.superchevy.com/how-to/engines-drivetrain/sucp-0803-performance-cylinder-head-comparison/

http://www.hotrod.com/how-to/engine/ccrp-1209-eight-budget-sbc-head-shootout/

http://www.purplesagetradingpost.com/sumner/techinfo/heads1.html

http://www.enginebuildermag.com/2010/01/street-performance-cylinder-heads/

http://www.chevydiy.com/the-complete-cylinder-head-guide-for-chevy-small-block-engines/

http://www.hotrod.com/how-to/engine/ccrp-1209-eight-budget-sbc-head-shootout/

http://www.hotrod.com/how-to/engine/hrdp-0609-500hp-small-block-chevy-build/

http://www.summitracing.com/search/...Default&SortOrder=Ascending&autoview=SKU&ar=1

http://garage.grumpysperformance.co...-calculators-and-basic-math.10705/#post-46582

http://www.hotrod.com/articles/ccrp-1209-eight-budget-sbc-head-shootout/

http://www.superchevy.com/how-to/engines-drivetrain/sucp-0705-budget-chevy-cylinder-heads/

https://www.high-performance-engines.com/cylinder-heads-s/173.htm

http://users.erols.com/srweiss/tablehdc ... _Big_Block

http://www.superchevy.com/how-to/engines-drivetrain/sucp-0803-performance-cylinder-head-comparison/

http://www.superchevy.com/how-to/engines-drivetrain/sucp-0705-budget-chevy-cylinder-heads/

http://www.wallaceracing.com/area-under-curve.php

A VIDEO DART VS 882 chevy heads TO WATCH

http://www.youtube.com/watch?annotation ... v3ZkqZiMjI

measuring throat cross sectional area

http://www.superchevy.com/how-to/project-cars/sucp-1208-big-block-heads-shootout-the-o-vs-r/

http://racingfeed.com/downloads/chevy_flow_data.pdf

http://www.profilerperformance.com/sbc-heads-176.html

http://www.airflowresearch.com/articles ... 5/A-P1.htm

http://www.airflowresearch.com/articles ... /A6-P1.htm

http://www.brodix.com/heads/compression.html

http://www.airflowresearch.com/chp_test.php

as you can see in this chart, below most of the stock heads don,t flow as well as the AFR 195cc heads and there ARE better flowing heads, but keep in mind the stock heads were never designed as race components, in most cases the engineers were more concerned with cost and low and mid range speed & torque.

A cylinder head that might be perfectly adequate for the current application may be woefully restrictive if used on a similar engine if you should choose to swap cams or swap to a well designed exhaust header, change intakes or drive train gearing, so its usually best to hedge your bet a bit on the cylinder heads selected and purchase a cylinder head that has at least some potential to flow at higher valve lifts and higher engine rpm limitations than the current combo may have.

yes we all deal with budget limitations, so you generally can,t just look for the cylinder heads with the very best flow numbers, and in most cases that would be a far from cost effective route to take. but I would suggest shopping around very carefully before spending your cash.

there's

a good deal more info posted below so its worth the time to keep reading

USE THE CALCULATORS to match port size to intended rpm levels... but keep in mind valve lift and port flow limitations[/color]

http://www.wallaceracing.com/runnertorquecalc.php

http://www.wallaceracing.com/ca-calc.php

http://www.wallaceracing.com/area-under-curve.php

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

I thought I post these flow numbers on ported vortec heads ive seen posted , just in case anyone has ever wondered or wanted to know the flow numbers a set of stock vortecs. I was also curious if any of you have any guesses on what gains I picked up on the port work.

INTAKE LIFT------- STOCK---- PORTED-- GAIN

.1---------- 59--------- 64--------- +5

.2---------- 117------- 132------- +15

.3---------- 170------- 187------- +17

.4---------- 214------- 236------- +22

.5---------- 226------- 255------- +29

.6---------- 219------- 259------- +40

EXHAUST

LIFT STOCK PORTED GAIN

.1---------- 42----------46--------- +4

.2---------- 83----------90--------- +7

.3---------- 123--------139--------+16

.4---------- 136--------161--------+25

.5---------- 143--------174--------+31

.6-----------147------- 178--------+31

http://www.circletrack.com/enginetech/c ... index.html

http://www.enginebuildermag.com/Article ... tions.aspx

http://www.trickflow.com/media/pdfs/buy ... e_2009.pdf

bbc oval ports making 697hp

http://www.popularhotrodding.com/tech/0 ... /dyno.html

heres some guides but keep in mind its NOT the port volume or PORT CCs of total port volume your concerned with, its the port cross sectional area, at its narrow point, you cam timing, compression and displacement, combined with the cars gearing, intake design and exhaust scavenging combined that makes the port size you select work

it does absolutely no good to place a cylinder head with with a port cross sectional area thats larger than the intake port that feeds it, in a combo as all the abrupt increase in port cross section does is cause increased turbulence, and a sudden loss of port air flow speed and that tends to cause fuel to drop out of the airflow or at least disrupt is even distribution

in an ideal world ports reduce cross sectional area bye about 3%-5% from entrance to the valve pocket, and the port cross section in the heads a bit smaller than the intake runner.

cams need to be selected with the engines intended rpm range and power band and the displacement of the engine, plus the engines compression ratio and drive train gearing taken into account, any increase in port cross sectional area above whats required to fill the cylinders in the intended power band tends to reduce efficiency.

AS your displacement per cylinder increases the effective valve size per cubic inch decreases so you need a slightly tighter LSA and these charts should help.

![[IMG] [IMG]](/proxy.php?image=https%3A%2F%2Fweb.archive.org%2Fweb%2F20151003032704%2Fhttp%3A%2F%2Fwww.grumpysperformance.com%2Frtyu1.jpg&hash=db61ac97d255ff55bbaed3c81acd7f6a)

![[IMG] [IMG]](/proxy.php?image=https%3A%2F%2Fweb.archive.org%2Fweb%2F20151003032704%2Fhttp%3A%2F%2Fwww.grumpysperformance.com%2Frtyu2.jpg&hash=4d2c8c0474643b616f25ed67c5d9071d)

so any time you want to stop guessing at the answers, or taking your Buddy,s best guess as a fact, you can use known values & calculations to arrive at valid answers and actually match components

http://garage.grumpysperformance.co...ch-quest-series-similar-350-383-sbc-info.519/

http://garage.grumpysperformance.com/index.php?threads/tbucket-engine-project-dart-shp.3814/

http://garage.grumpysperformance.com/index.php?threads/sellecting-cylinder-heads.796/

http://garage.grumpysperformance.com/index.php?threads/what-to-look-for-in-a-good-engine-combo.9930/

http://garage.grumpysperformance.com/index.php?threads/my-1st-street-383-build.6962/

http://garage.grumpysperformance.co...383-build-that-is-now-going-to-be-a-400.7804/

http://www.brodix.com/media/images/page_2.jpg

https://garage.grumpysperformance.c...t-angles-and-air-flow.8460/page-2#post-110196

http://www.corvetteflorida.com/forums/s ... hp?t=17250

http://www.rehermorrison.com/techtalk/06.htm

http://www.gmhightechperformance.com/te ... index.html

http://www.gofastnews.com/board/technic ... lumes.html

one factor that gets discussed a great deal is the difference in port size or port CCs, the sad truth is that Id bet 90% of the discussions are just guys repeating stuff they have heard with zero real idea what they are talking about.

while theres generally some relation of port cross sectional area to the listed port CCs its NOT a direct linear relationship, and its the cross sectional area,shape, length and surface finish not the port CCs that matter to the air flow., and if the exhaust system can,t effectively scavenge the cylinders or the intake can,t supply the flow, or the cam duration and lift don,t match the intended port flow rates performance will suffer

While theres no direct linear relationship between port flow and hp there is a strong relationship.So you'll generally want the highest flow numbers you can get in any port size ranges as a starting point, and yes theres other factors that go into making hp, so combustion chamber design,compression, cam timing, cylinder scavenging ETC. will effect results.you might want to keep in mind that carbs are flow rated at 1.5 inches of mercury, heads at 28" of water and that anyone who has ever watched a vacuum gauge, will tell you the readings fluctuate rapidly, under most conditions and vacuum tends to vary with the cam,used the rpms the engines running, displacement and intake design,exhaust scavenging,ETC.

in most cases there factors are at least, mostly or on occasion, partly understood well enough that theres formulas and charts that can be used to define probable results, that parts selection will result in to a reasonable degree.

the ballpark formula is

.257 x port flow x 8 = potential hp

its the combo of the engines,

compression,

displacement ,

cam timing

and the exhaust scavenging ,

and the intake manifold design,

NOT the intake port cross sectional area,

that are the most critical factors, in the engines lower rpm and mid rpm torque.

but for damn sure an intake runner port can be small enough to noticeably restrict upper mid range and peak power significantly,

For 5 decades I've heard endlessly about how installing larger free flowing cylinder heads would devastate the engines ability to make any low or mid rpm torque.